Experimental Investigation on Reinforcement Application of Newly Permeable Polymers in Dam Engineering with Fine Sand Layers

Abstract

:1. Introduction

2. Test Content and Scheme

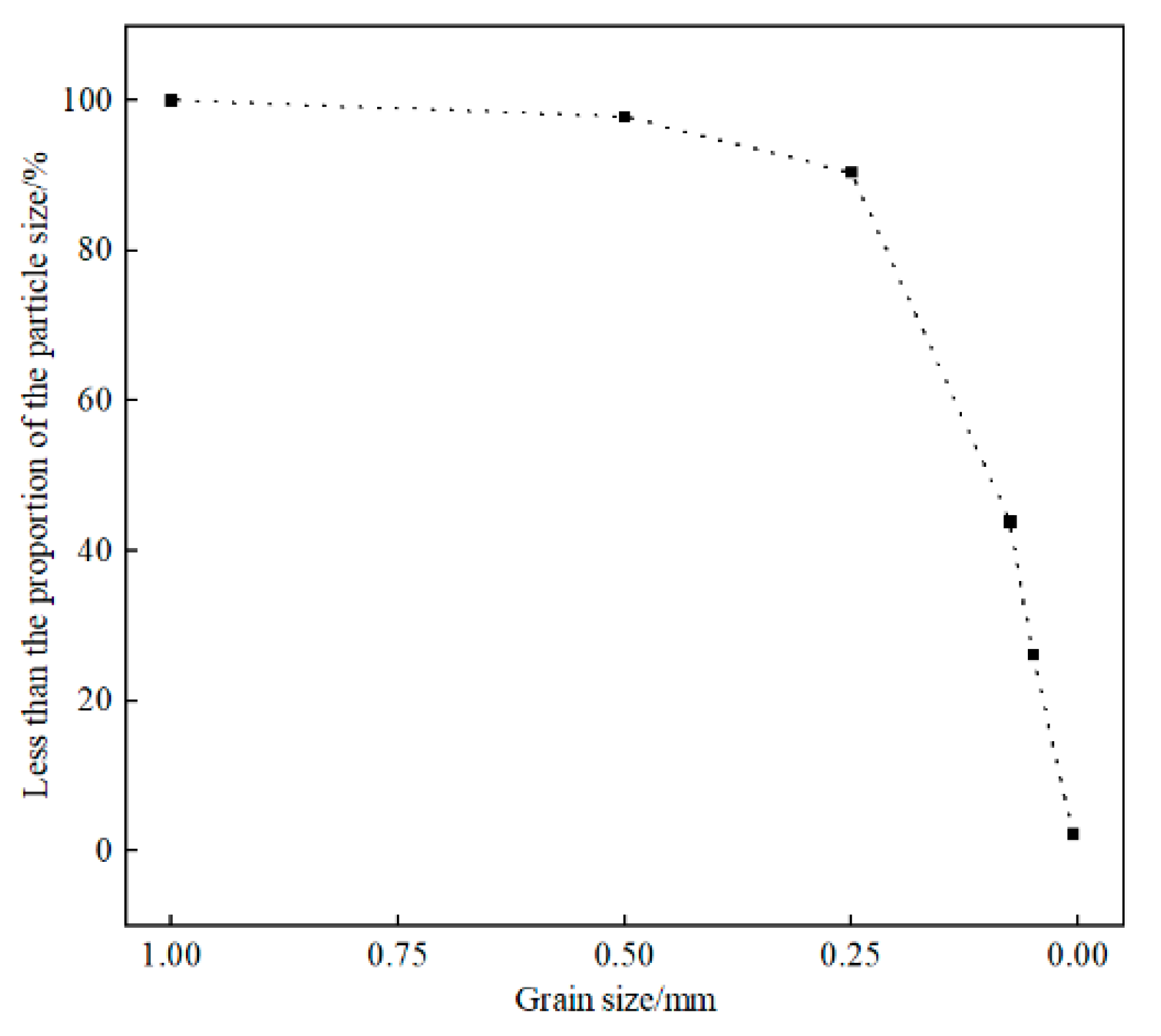

2.1. Test Materials

2.2. Test Equipment

2.3. Test Scheme

3. Interfacial Strength of Polymers and Concrete under Different Conditions

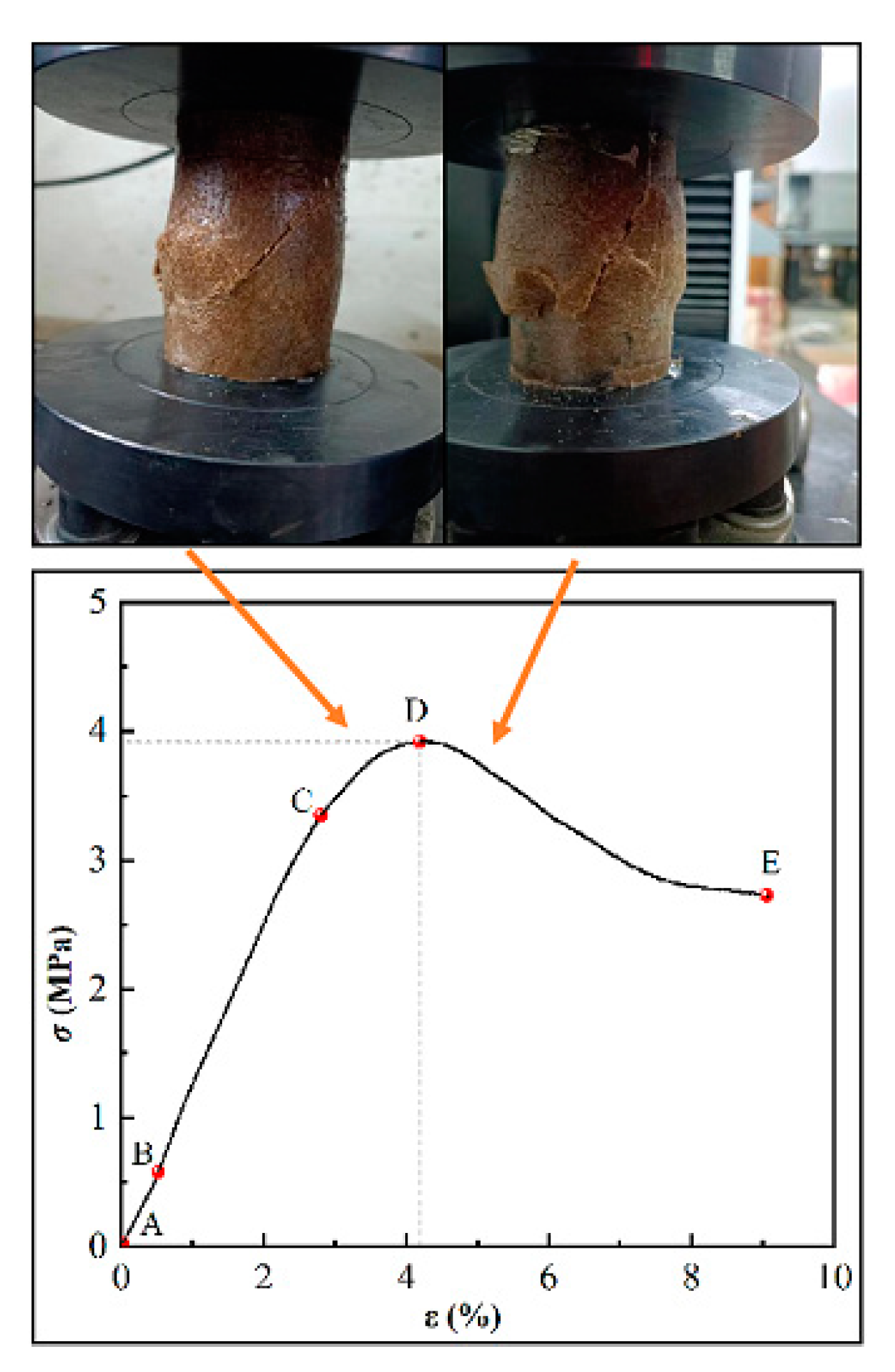

3.1. Failure Forms of Grouting Stones

- (1)

- The failure mode of grouting stones

- (2)

- Stress–strain curve

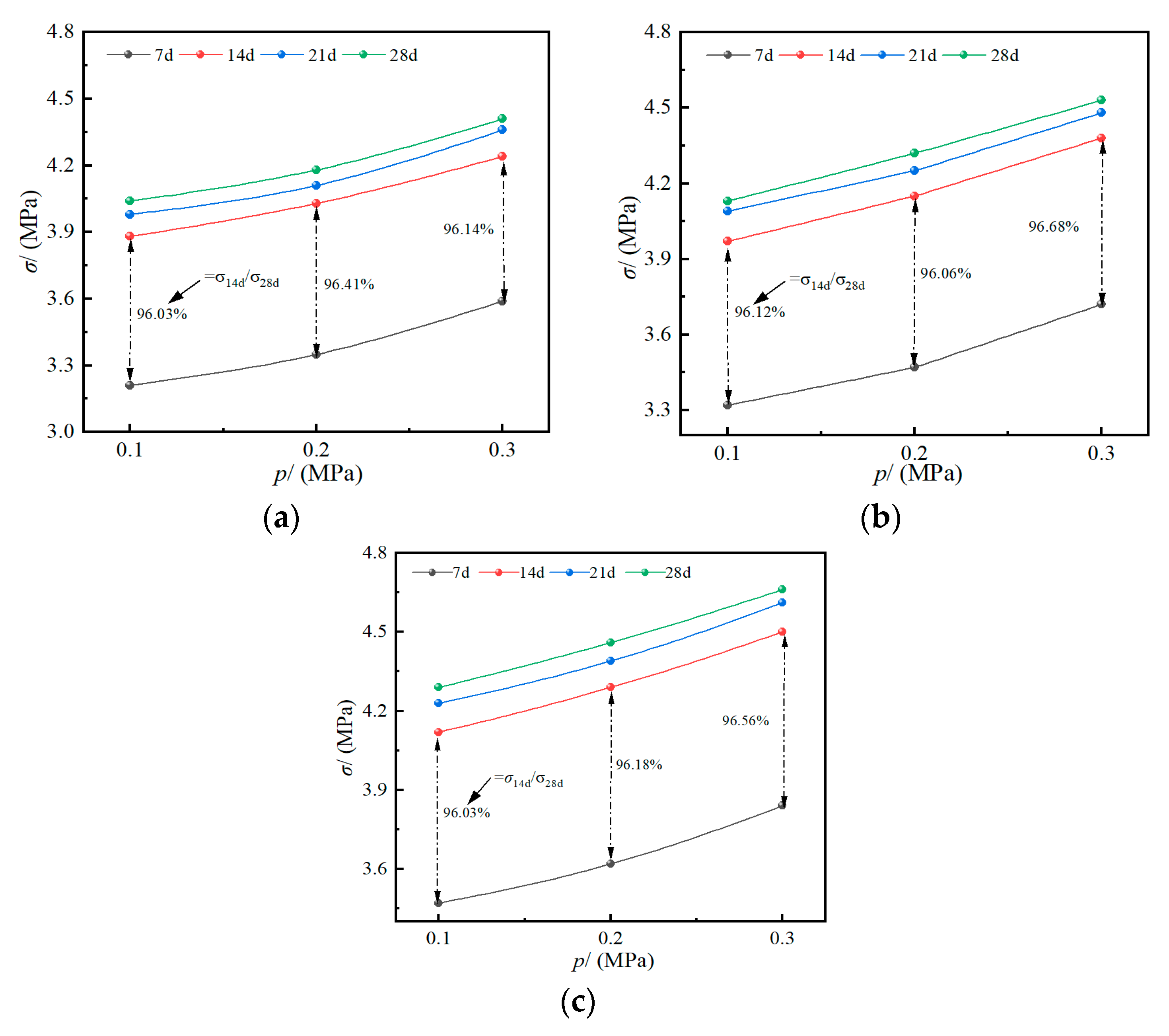

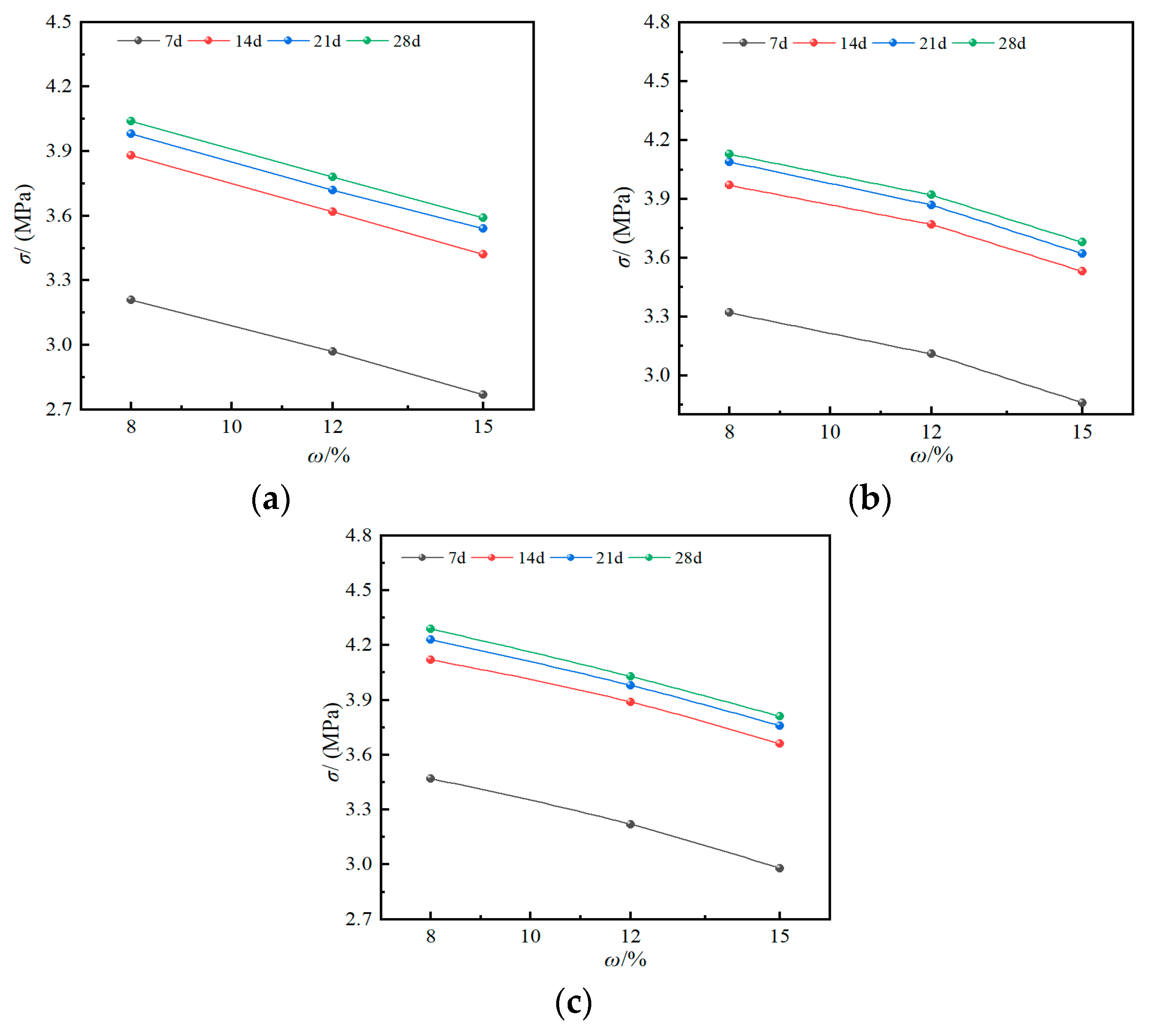

3.2. Influence of Grouting Pressures and Curing Days on Compressive Strength

3.3. Influence of Porosity on Compressive Strength

3.4. Influence of Moisture Content on Compressive Strength

4. Linear Regression Analysis of Compressive Strength of Grouting Stones

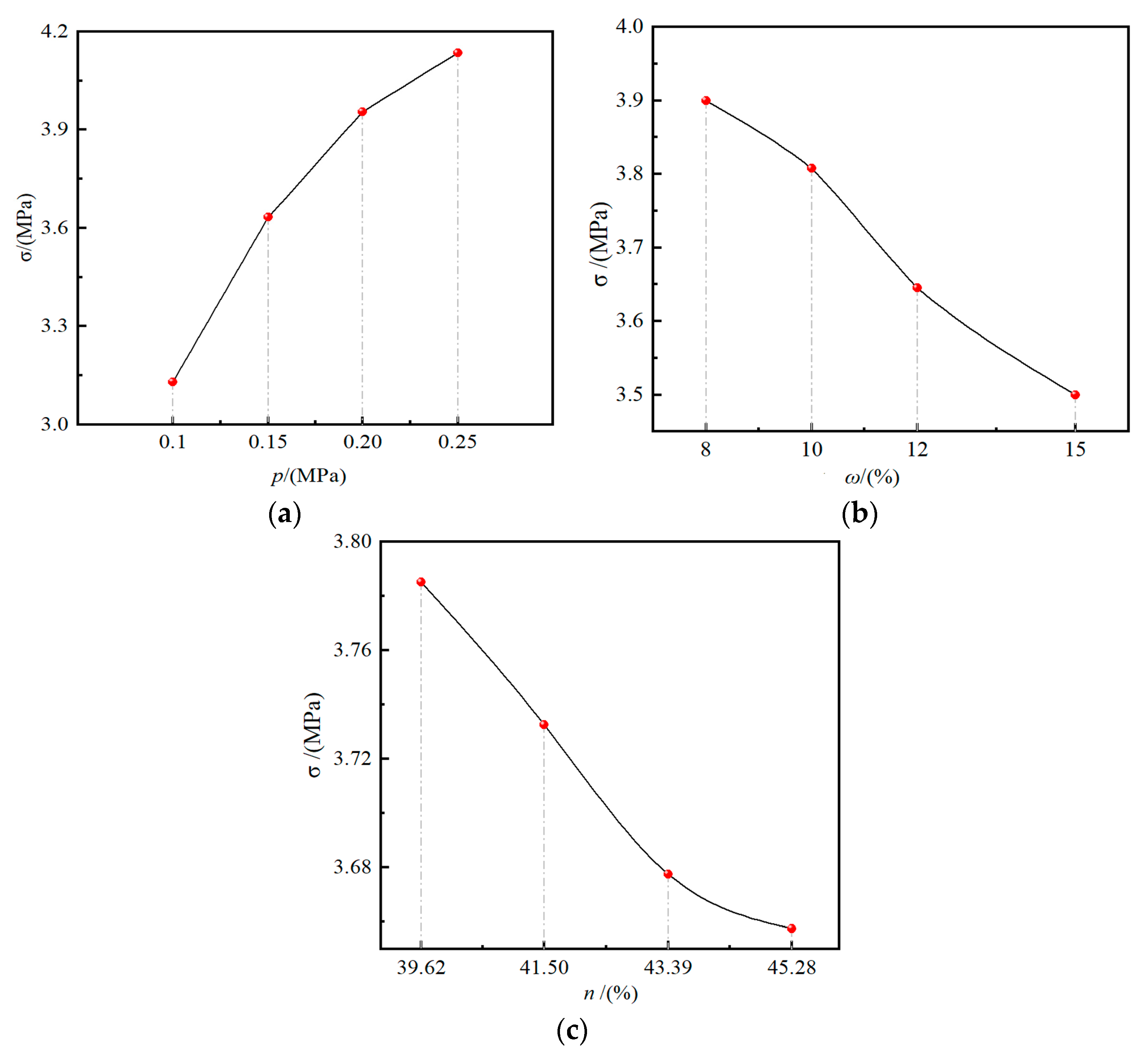

4.1. Sensitivity of Strength to Different Factors

4.2. Establishment and Verification of Theoretical Model

5. Microscopic Characteristics of Grouting Stones

5.1. Microscopic Morphology of Grouting Stones

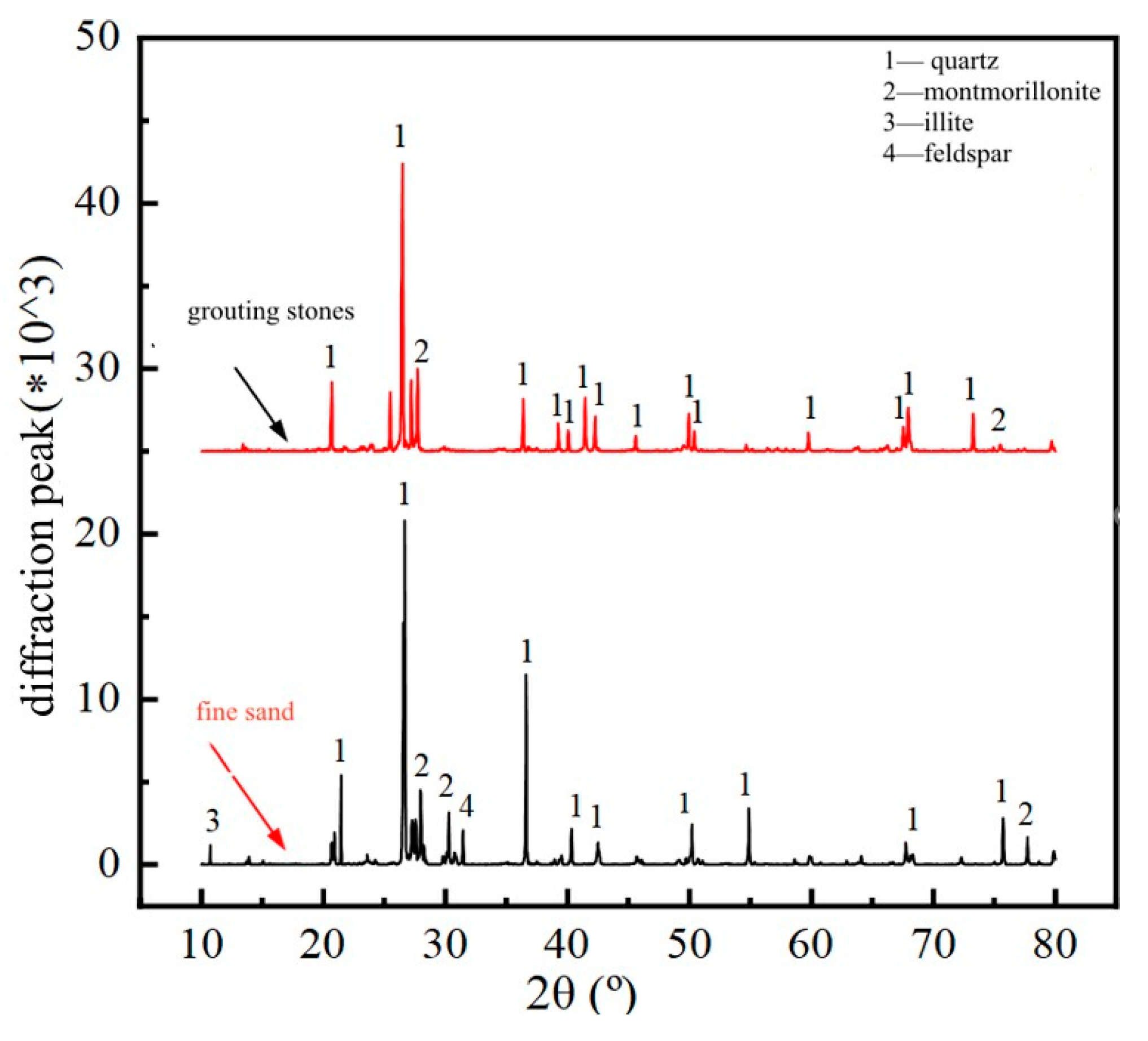

5.2. X-ray Powder Diffractometer

6. Conclusions

- (1)

- With the increasing grouting pressure and curing time, the compressive strength of the fine sand reinforced by permeable polymer increases. The pore structure of fine sand is filled with slurry as the grouting pressure increases. The grouting stone becomes denser before it fully solidifies. The compressive strength of grouting stones shows a rapid growth trend from 7 to 14 days, reaching about 96% of the maximum strength;

- (2)

- With the increasing grouting pressure and curing time, the compressive strength of the fine sand reinforced by permeable polymer decreases. The slurry becomes more permeable as the porosity increases. The poor bonding effect of the pore framework between the slurry and fine sand is caused by the dispersion of the pore structure;

- (3)

- The compressive strength of fine sand reinforced by permeable polymers is inversely proportional to the moisture content of fine sand. As the moisture content of fine sand increases, more water will react with permeable polymers. The reduction in the strength of the permeable polymer and the weakening of the bonding effect of the fine sand particles are both caused by the participation of excess water;

- (4)

- The influence of grouting pressure on compressive strength is greater than that of moisture content and porosity. The influence of porosity on compressive strength is minimal;

- (5)

- Permeable polymers effectively reduce the porosity of fine sand and increase the bonding force between soil particles through chemical bonding and physical filling. No new material was produced after grouting.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Faramarzi, L.; Rasti, A.; Abtahi, S.M. An experimental study of the effect of cement and chemical grouting on the improvement of the mechanical and hydraulic properties of alluvial formations. Constr. Build. Mater. 2016, 126, 32–43. [Google Scholar] [CrossRef]

- Li, Z.; Liu, H.; Dun, Z.; Ren, L.; Fang, J. Grouting effect on rock fracture using shear and seepage assessment. Constr. Build. Mater. 2020, 242, 118131. [Google Scholar] [CrossRef]

- Shamsuddoha, M.; Hüsken, G.; Schmidt, W.; Kühne, H.-C.; Baeßler, M. Ternary mix design of grout material for structural repair using statistical tools. Constr. Build. Mater. 2018, 189, 170–180. [Google Scholar] [CrossRef]

- Guo, S.Y.; Luo, H.H.; Tan, Z.; Chen, J.Z.; Zhang, L.; Ren, J. Impermeability and interfacial bonding strength of TiO2-graphene modified epoxy resin coated OPC concrete. Prog. Org. Coat. 2021, 151, 106029. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, Y.; Cao, C. Experimental Study on Flow Water Diffusion of Cement-Sodium Silicate Grouting in Rough Fracture Model. KSCE J. Civ. Eng. 2023, 27, 1955–1965. [Google Scholar] [CrossRef]

- Li, X.; Zhou, S.; Di, H. Observed Ground Pressure Acting on the Lining of a Large-Diameter Shield Tunnel in Sandy Stratum under High Water Pressure. Adv. Civ. Eng. 2020, 2020, 3091528. [Google Scholar] [CrossRef]

- Zhang, J.; Liang, Y.; Feng, T. Investigation of the cause of shield-driven tunnel instability in soil with a soft upper layer and hard lower layer. Eng. Fail. Anal. 2020, 118, 104832. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, X. Investigation and Calculation Method for the Mechanical Properties of Filament Wound Profiles for Deformed Shield Tunnel Reinforcement. Materials 2023, 16, 1645. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, P.; Zhang, Y. Investigation of Frost-Heaving Characteristics of Horizontal-Cup-Shape Frozen Ground Surface for Reinforced End Soil Mass in Shield Tunnel Construction. Period. Polytech. Civ. Eng. 2017, 61, 541–547. [Google Scholar] [CrossRef]

- Han, L.; He, Y. Experimental Study on Mechanical Characteristics of Cracked Rock Mass Reinforced by Bolting and Grouting. J. China Univ. Min. Technol. 2005, 15, 177–182. [Google Scholar]

- Barton, N. Shear strength criteria for rock, rock joints, rockfill and rock masses: Problems and some solutions. J. Rock Mech. Geotech. Eng. 2013, 5, 249–261. [Google Scholar] [CrossRef]

- Bhasin, R.; Høeg, K. Numerical modelling of block size effects and influence of joint properties in multiply jointed rock. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 1998, 13, 181–188. [Google Scholar] [CrossRef]

- Kulatilake PH, S.W.; Panda, B.B. Effect of Block Size and Joint Geometry on Jointed Rock Hydraulics and REV. J. Eng. Mech. 2000, 126, 850–858. [Google Scholar] [CrossRef]

- Nakhatakyan, F.G. Numerical determination of the elastic compliance of roller bearings using the hertz theory. J. Mach. Manuf. Reliab. 2011, 40, 23–26. [Google Scholar] [CrossRef]

- Maghous, S.; Dormieux, L.; Barthélémy, J.F. Micromechanical approach to the strength properties of frictional geomaterials. Eur. J. Mech. A Solids 2008, 28, 179–188. [Google Scholar] [CrossRef]

- Maghous, S.; Saada, Z.; Dormieux, L.; Canou, J.; Dupla, J.C. A model for in situ grouting with account for particle filtration. Comput. Geotech. 2006, 34, 164–174. [Google Scholar] [CrossRef]

- Eklundl, D.; Stille, H. Penetrability due to filtration tendency of cement-based grouts. Tunn. Undergr. Space Technol. 2008, 23, 389–398. [Google Scholar] [CrossRef]

- Kim, J.; Lee, I.; Jang, J. Groutability of cement-based grout with consideration of viscosity and filtration phenomenon. Int. J. Numer. Anal. Methods Geomech. 2009, 33, 1771–1797. [Google Scholar] [CrossRef]

- Wang, Y.; Wan, Y.; Guo, C.; Zeng, C.; Shao, J.; Wang, F. Experimental investigation on the monotonic, cyclic and post cyclic interfacial behavior of non-water reacted polymer and concrete. Constr. Build. Mater. 2021, 292, 123323. [Google Scholar] [CrossRef]

- Huang, Y.; Wen, Z.; Wang, L.; Zhu, C. Centrifuge testing of liquefaction mitigation effectiveness on sand foundations treated with nanoparticles. Eng. Geol. 2019, 249, 249–256. [Google Scholar] [CrossRef]

- Salvatore, E.; Modoni, G.; Mascolo, M.C.; Grassi, D.; Spagnoli, G. Experimental Evidence of the Effectiveness and Applicability of Colloidal Nanosilica Grouting for Liquefaction Mitigation. J. Geotech. Geoenviron. Eng. 2020, 146, 04020108. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, L. Reply to the discussion by Ochoa-Cornejo et al. on “Laboratory investigation of liquefaction mitigation in silty sand using nanoparticles” [Eng.Geol.204:23–32]. Eng. Geol. 2017, 221, 202. [Google Scholar] [CrossRef]

- Wang, Y.; Han, M.; Li, B.; Wan, Y. Stability evaluation of earth-rock dam reinforcement with new permeable polymer based on reliability method. Constr. Build. Mater. 2022, 320, 126294. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, B.; Wan, Y. Experimental Investigation and Numerical Verification on Diffusion of Permeable Polymers in Sandy Soils with Considering Grouting Parameters. Int. J. Civ. Eng. 2022, 21, 617–632. [Google Scholar] [CrossRef]

- Guo, C.; Hu, D.; Wang, F. Diffusion Behavior of Polymer Grouting Materials in Sand and Gravel. Soil Mech. Found. Eng. 2021, 57, 440–444. [Google Scholar] [CrossRef]

- Guo, C.; Sun, B.; Hu, D.; Wang, F.; Shi, M. A Field Experimental Study on the Diffusion Behavior of Expanding Polymer Grouting Material in Soil. Soil Mech. Found. Eng. 2019, 56, 171–177. [Google Scholar] [CrossRef]

- Wang, C.; Guo, C.; Du, X.; Shi, M.; Liu, Q.; Xia, Y. Reinforcement of silty soil with permeable polyurethane by penetration injection. Constr. Build. Mater. 2021, 310, 124829. [Google Scholar] [CrossRef]

- Mu, J.; Zhuang, J.; Kong, J.; Wang, S.; Wang, J.; Zheng, J.; Fu, Y.; Du, C. Study on Improving Loess Properties with Permeable Polymer Materials. Polymers 2022, 14, 2862. [Google Scholar] [CrossRef]

- Zhao, W.; Guo, C.; Wang, C.; Wang, Y.; Wang, L. Study on Mechanical Properties of Permeable Polymer Treated Loess. Materials 2022, 15, 6647. [Google Scholar] [CrossRef]

| Parameters | Gs | ρdmax (g/cm3) | ρdmin (g/cm3) | emax | emin | Cu | Cc |

|---|---|---|---|---|---|---|---|

| Fine sand | 2.65 | 1.61 | 1.41 | 0.88 | 0.64 | 2.77 | 1.0 |

| Test Code | Grouting Pressure p (MPa) | Moisture Content (ω/%) | Porosity (n/%) | 7 d σ/(MPa) | 14 d σ/(MPa) | 21 d σ/(MPa) | 28 d σ/(MPa) |

|---|---|---|---|---|---|---|---|

| 1 | 0.1 | 45.28 | 8.0 | 3.21 | 3.88 | 3.98 | 4.04 |

| 2 | 0.2 | 45.28 | 8.0 | 3.35 | 4.03 | 4.11 | 4.18 |

| 3 | 0.3 | 45.28 | 8.0 | 3.59 | 4.24 | 4.36 | 4.41 |

| 4 | 0.1 | 43.39 | 8.0 | 3.32 | 3.97 | 4.09 | 4.13 |

| 5 | 0.2 | 43.39 | 8.0 | 3.47 | 4.15 | 4.25 | 4.32 |

| 6 | 0.3 | 43.39 | 8.0 | 3.72 | 4.38 | 4.48 | 4.53 |

| 7 | 0.1 | 39.62 | 8.0 | 3.47 | 4.12 | 4.23 | 4.29 |

| 8 | 0.2 | 39.62 | 8.0 | 3.62 | 4.29 | 4.39 | 4.46 |

| 9 | 0.3 | 39.62 | 8.0 | 3.84 | 4.50 | 4.61 | 4.66 |

| 10 | 0.1 | 45.28 | 12.0 | 2.97 | 3.62 | 3.72 | 3.78 |

| 11 | 0.2 | 45.28 | 12.0 | 3.12 | 3.79 | 3.89 | 3.93 |

| 12 | 0.3 | 45.28 | 12.0 | 3.27 | 3.93 | 4.04 | 4.08 |

| 13 | 0.1 | 43.39 | 12.0 | 3.11 | 3.77 | 3.87 | 3.92 |

| 14 | 0.2 | 43.39 | 12.0 | 3.22 | 3.88 | 3.98 | 4.04 |

| 15 | 0.3 | 43.39 | 12.0 | 3.39 | 4.04 | 4.15 | 4.20 |

| 16 | 0.1 | 39.62 | 12.0 | 3.22 | 3.89 | 3.98 | 4.03 |

| 17 | 0.2 | 39.62 | 12.0 | 3.30 | 3.96 | 4.05 | 4.11 |

| 18 | 0.3 | 39.62 | 12.0 | 3.47 | 4.13 | 4.23 | 4.29 |

| 19 | 0.1 | 45.28 | 15.0 | 2.77 | 3.42 | 3.54 | 3.59 |

| 20 | 0.2 | 45.28 | 15.0 | 2.91 | 3.58 | 3.67 | 3.73 |

| 21 | 0.3 | 45.28 | 15.0 | 3.06 | 3.72 | 3.84 | 3.89 |

| 22 | 0.1 | 43.39 | 15.0 | 2.86 | 3.53 | 3.62 | 3.68 |

| 23 | 0.2 | 43.39 | 15.0 | 3.03 | 3.69 | 3.81 | 3.86 |

| 24 | 0.3 | 43.39 | 15.0 | 3.23 | 3.90 | 4.01 | 4.06 |

| 25 | 0.1 | 39.62 | 15.0 | 2.98 | 3.66 | 3.76 | 3.81 |

| 26 | 0.2 | 39.62 | 15.0 | 3.12 | 3.77 | 3.89 | 3.95 |

| 27 | 0.3 | 39.62 | 15.0 | 3.30 | 3.95 | 4.09 | 4.13 |

| Test Code | Grouting Pressure (p/MPa) | Moisture Content (ω/%) | Porosity (n/%) | Curing Time (d) | Compressive Strength (σ/MPa) |

|---|---|---|---|---|---|

| 1 | 0.1 | 0.08 | 39.62 | 28 | 3.48 |

| 2 | 0.1 | 0.1 | 41.5 | 28 | 3.22 |

| 3 | 0.1 | 0.12 | 43.39 | 28 | 3.04 |

| 4 | 0.1 | 0.15 | 45.28 | 28 | 2.78 |

| 5 | 0.15 | 0.08 | 41.5 | 28 | 3.85 |

| 6 | 0.15 | 0.1 | 39.62 | 28 | 3.72 |

| 7 | 0.15 | 0.12 | 45.28 | 28 | 3.51 |

| 8 | 0.15 | 0.15 | 43.39 | 28 | 3.45 |

| 9 | 0.2 | 0.08 | 43.39 | 28 | 3.91 |

| 10 | 0.2 | 0.1 | 45.28 | 28 | 3.98 |

| 11 | 0.2 | 0.12 | 39.62 | 28 | 4.05 |

| 12 | 0.2 | 0.15 | 41.5 | 28 | 3.88 |

| 13 | 0.25 | 0.08 | 45.28 | 28 | 4.36 |

| 14 | 0.25 | 0.1 | 43.39 | 28 | 4.31 |

| 15 | 0.25 | 0.12 | 41.5 | 28 | 3.98 |

| 16 | 0.25 | 0.15 | 39.62 | 28 | 3.89 |

| Grouting Pressure (p/MPa) | Porosity (n/%) | Moisture Content (ω/%) | |

|---|---|---|---|

| K1 | 3.13 | 3.785 | 3.9 |

| K2 | 3.6325 | 3.7325 | 3.8075 |

| K3 | 3.955 | 3.6775 | 3.645 |

| K4 | 4.135 | 3.6575 | 3.5 |

| R | 1.005 | 0.1275 | 0.4 |

| Order of influencing factors | Grouting pressure > Moisture content > Porosity | ||

| Regression Coefficient | a | b1 | c1 | d1 |

|---|---|---|---|---|

| Value | 3.246 | 0.3021 | −0.3216 | −0.1792 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Shi, Z.; Li, Z.; Wang, Y. Experimental Investigation on Reinforcement Application of Newly Permeable Polymers in Dam Engineering with Fine Sand Layers. Water 2023, 15, 3761. https://doi.org/10.3390/w15213761

Liu H, Shi Z, Li Z, Wang Y. Experimental Investigation on Reinforcement Application of Newly Permeable Polymers in Dam Engineering with Fine Sand Layers. Water. 2023; 15(21):3761. https://doi.org/10.3390/w15213761

Chicago/Turabian StyleLiu, Heng, Zixian Shi, Zhenyu Li, and Yuke Wang. 2023. "Experimental Investigation on Reinforcement Application of Newly Permeable Polymers in Dam Engineering with Fine Sand Layers" Water 15, no. 21: 3761. https://doi.org/10.3390/w15213761

APA StyleLiu, H., Shi, Z., Li, Z., & Wang, Y. (2023). Experimental Investigation on Reinforcement Application of Newly Permeable Polymers in Dam Engineering with Fine Sand Layers. Water, 15(21), 3761. https://doi.org/10.3390/w15213761