Recent Advancements in the Treatment of Petroleum Refinery Wastewater

Abstract

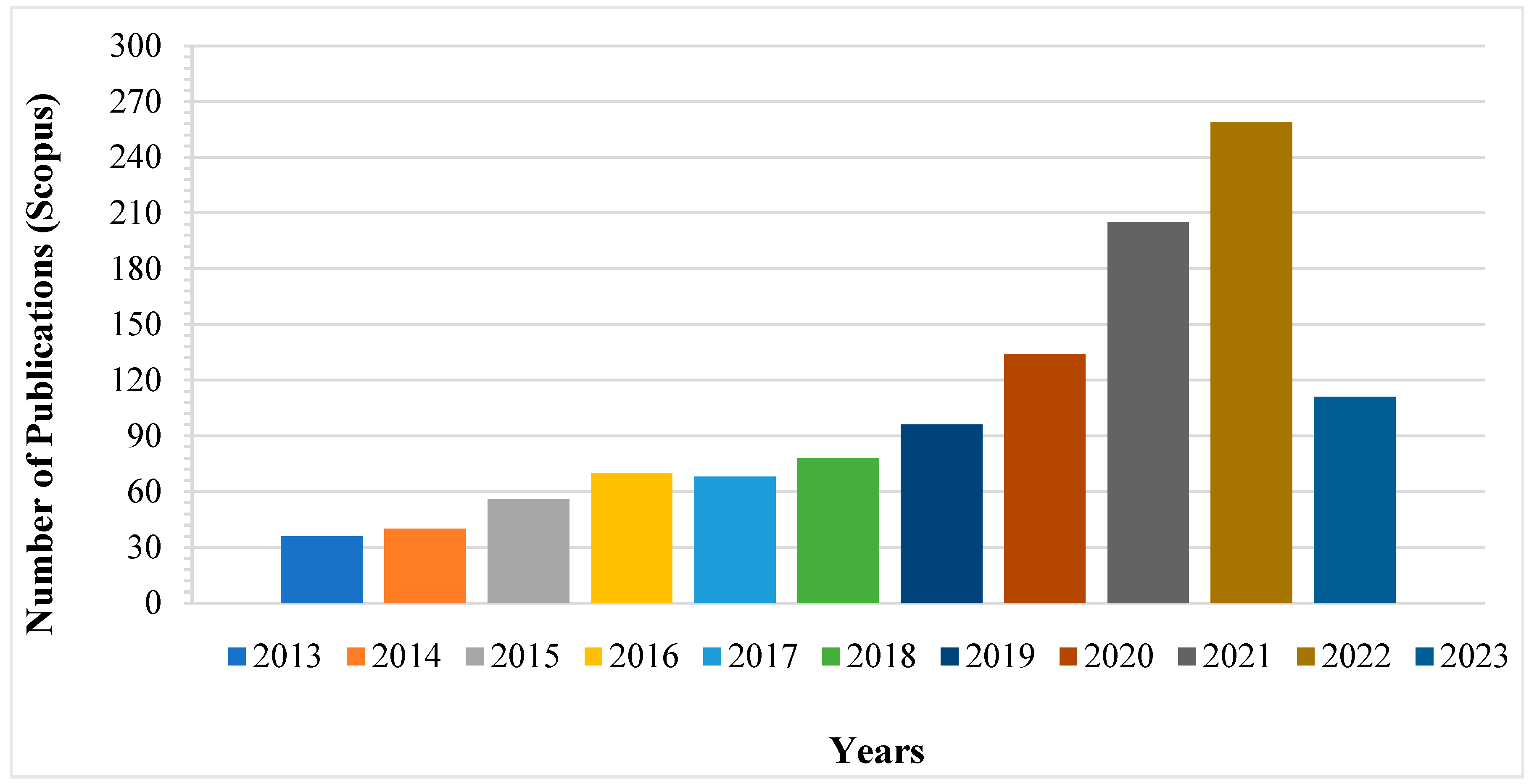

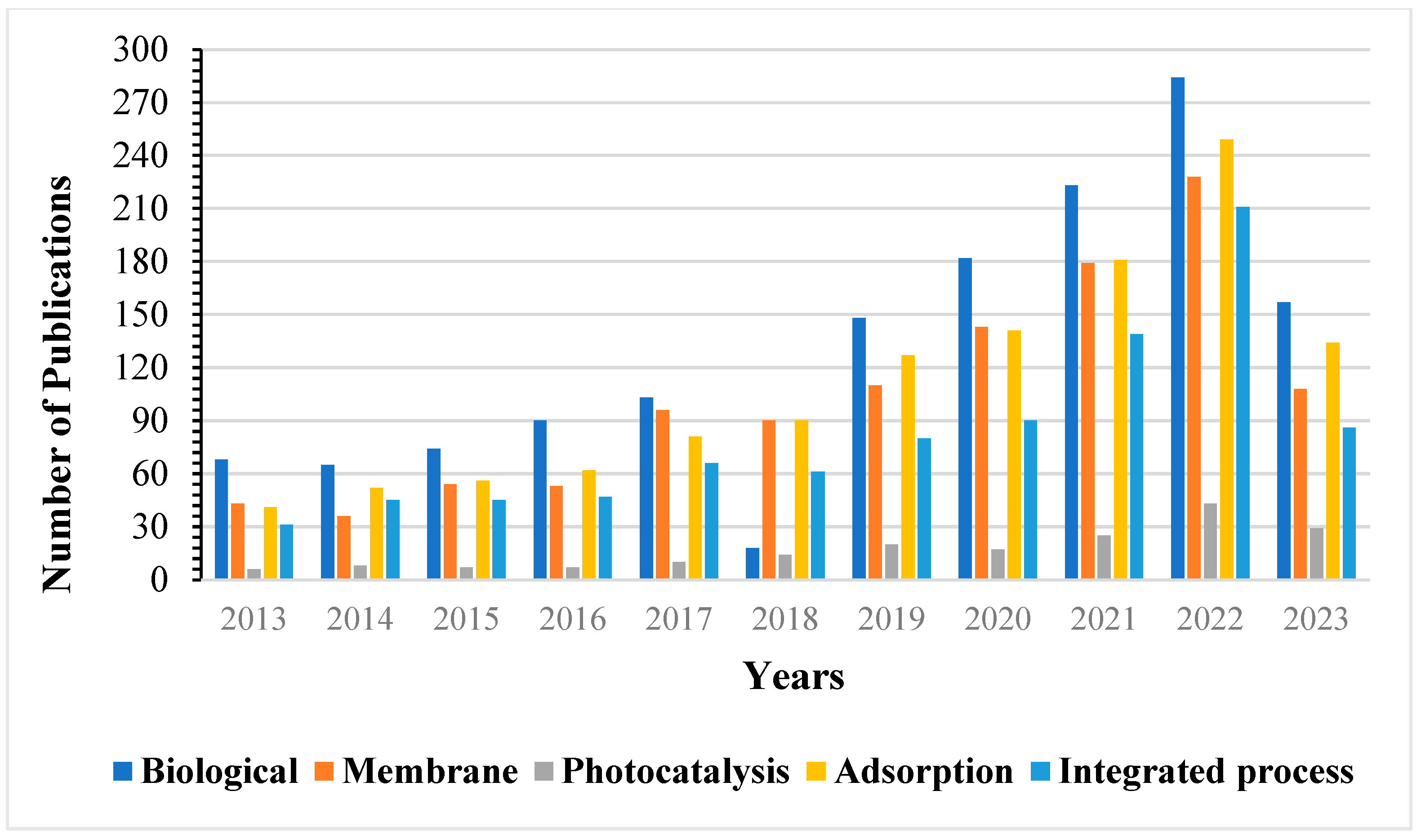

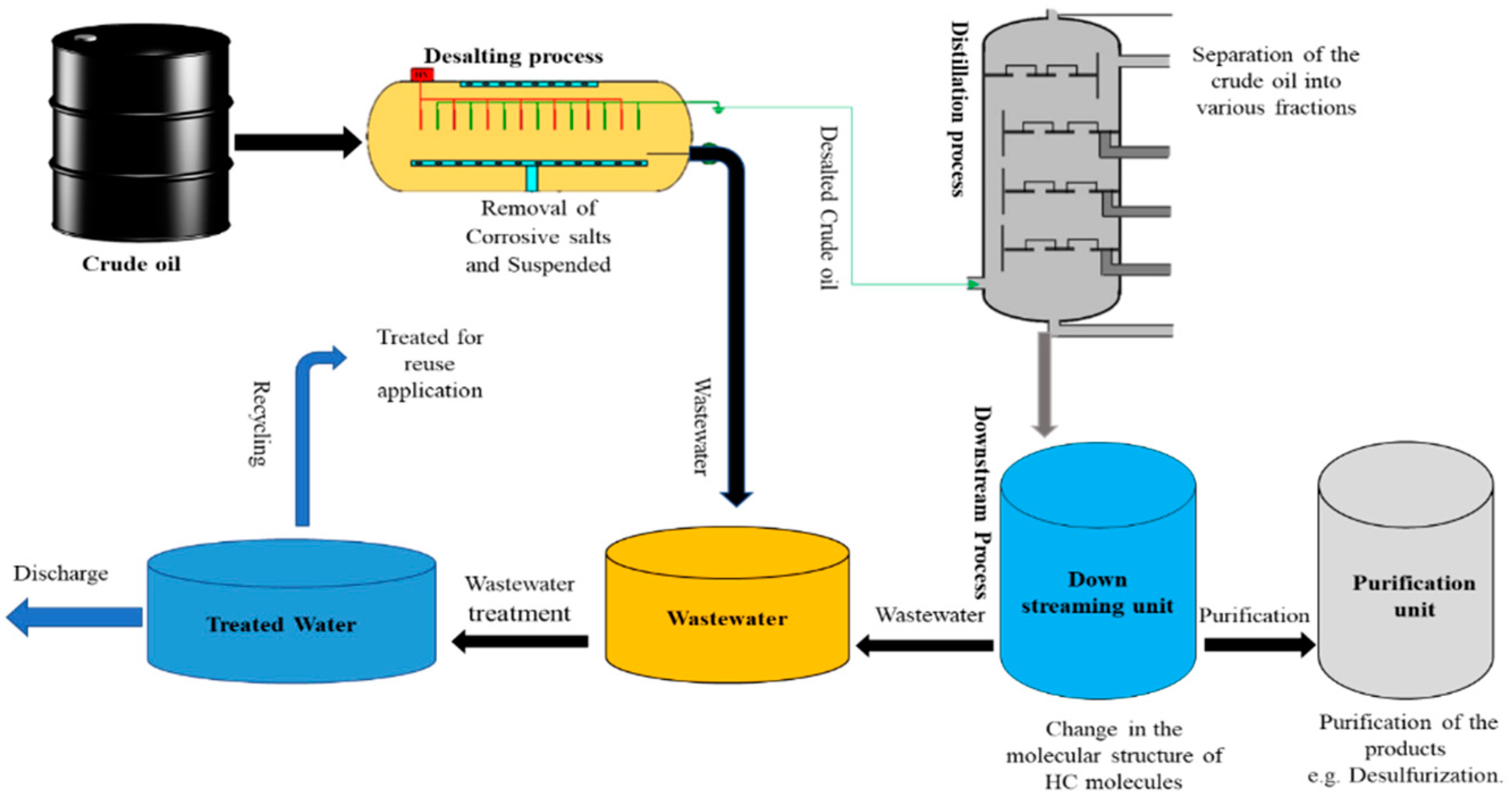

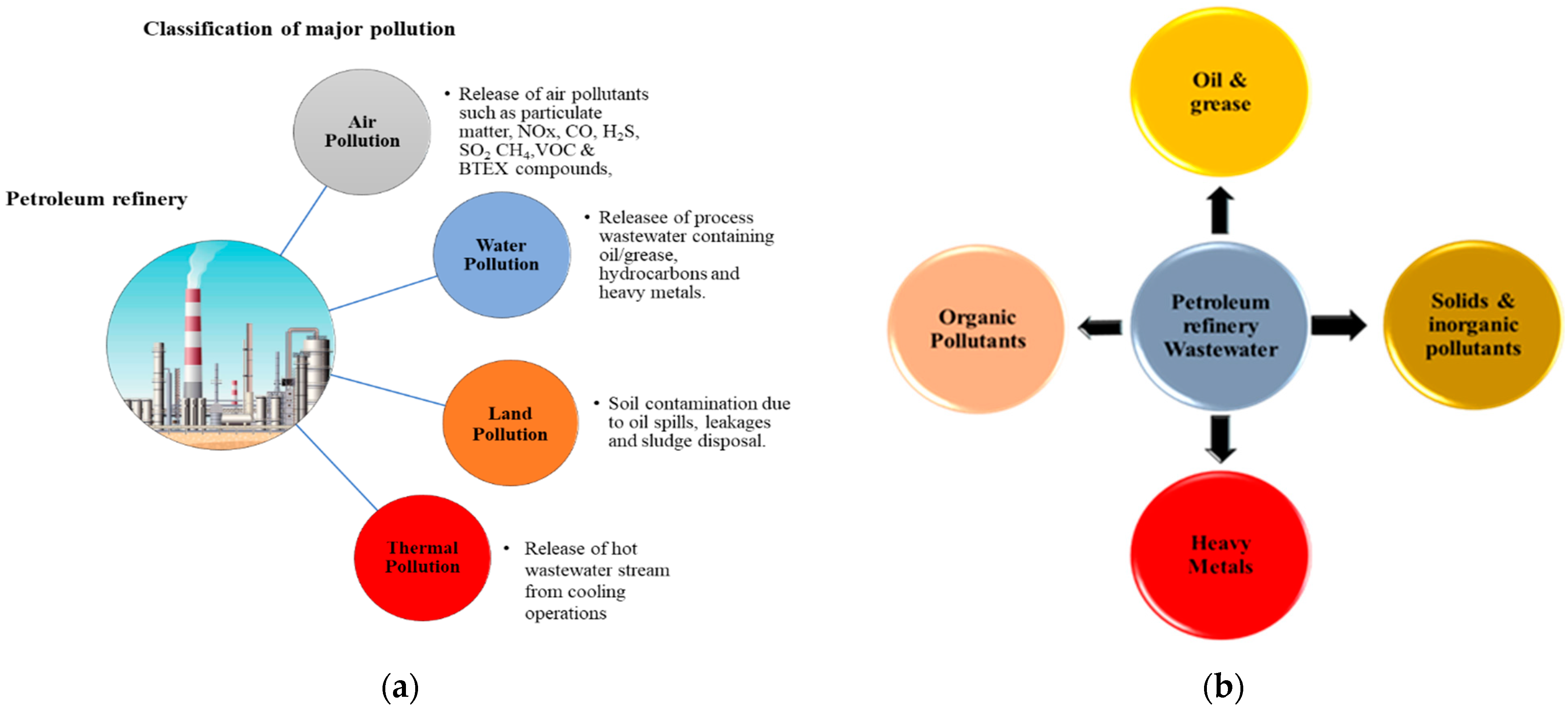

:1. Introduction

2. Characterization of Petroleum Refinery Wastewater

| Parameters | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| pH | BOD (mg/L) | COD (mg/L) | TSS (mg/L) | TDS (mg/L) | TOC (mg/L) | NH3 (mg/L) | Phenols (mg/L) | Sulfides (mg/L) | Oil and Grease (mg/L) | Reference |

| 7.74 | 155 | 485 | 600 | 800 | - | 13.7 | 3.5 | - | 17.36 | [32] |

| - | 1198 | 2554 | - | - | 610.93 | 81.2 | - | - | - | [33] |

| 6.7 | 174 | 450 | 150 | - | 119 | - | - | - | 870 | [34] |

| 8.3–8.9 | - | 3600–5300 | 30–40 | 3.8–6.2 | - | 11–14 | - | - | [25] | |

| 9.2 | - | 970 | 42.3 | 1220 | - | - | - | [35] | ||

| 7.2 | 107.3 | 232.7 | 86.2 | 276 | - | 0.7 | 0.17 | - | 2.9 | [36] |

| 8.0 | 718 | 1494 | 75 | - | -- | - | 70 | 142 | - | [37] |

| 8.0 | 195 | 480 | 315 | - | - | - | 13.8 | 16.8 | 94 | [38] |

| 8.3–8.7 | - | 3970–4745 | 30–40 | 3800–6200 | 8–10 | - | - | [39] | ||

| 7.82 | - | 310 | - | 1910 | -- | -- | - | - | - | [40] |

| 8.2 | 23 | - | 31 | - | - | 0.81 | 20.7 | - | - | [24] |

| 7.8 | 44,300 | 74,800 | 2010 | 41,600 | 5490 | - | - | - | - | [31] |

| 7.3 | - | 330 | 253.3 | -- | 391 | 9.5 | - | - | - | [41] |

| 7.2 | - | 1179 | - | 74 | -- | - | 257 | 0.18 | 217 | [42] |

| 8.0 | 138 | 350 | 60 | 2100 | - | - | 7.35 | - | 14.75 | [43] |

| 8.0 | 8.6 | 112 | 930 | - | 0.7 | - | - | [44] | ||

| Heavy Metals | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cadmium | Chromium | Copper | Lead | Manganese | Iron | Zinc | Arsenic | Mercury | Nickel | Reference |

| <0.005–0.2 | 0.02–1.1 | <0.002–1.5 | <0.004–175 | – | <0.1–100 | 0.01–35 | 0.01–35 | <0.001–0.002 | – | [5] |

| – | <0.01 | <0.01 | 0.04 | 0.58 | 5.14 | 0.75 | <0.4 | <0.15 | 0.02 | [40] |

| 0.045 | 0.022 | – | 0.03 | – | – | – | – | – | 0.176 | [45] |

| ND | – | – | 0.0135 | – | 0.253 | 0.33 | – | – | – | [46] |

| – | 1.225 | 0.005 | 0.47 | – | – | 0.45 | – | – | – | [47] |

| <0.001 | 0.06 | – | – | 0.149 | 2.535 | 1.133 | – | – | – | [48] |

| 0.031 | 2.33 | 0.86 | 2.06 | – | 2.28 | 7.56 | 1.03 | [41] | ||

| 0.054 | 0.025 | 0.031 | – | 0.775 | 0.75 | – | – | 0.188 | [49] | |

| 0.026 | 0.04 | 0.03 | 0.01 | – | 0.88 | 0.03 | – | – | [50] | |

| 5.93 | – | – | – | – | – | – | 2.78 | 1.05264 | – | [51] |

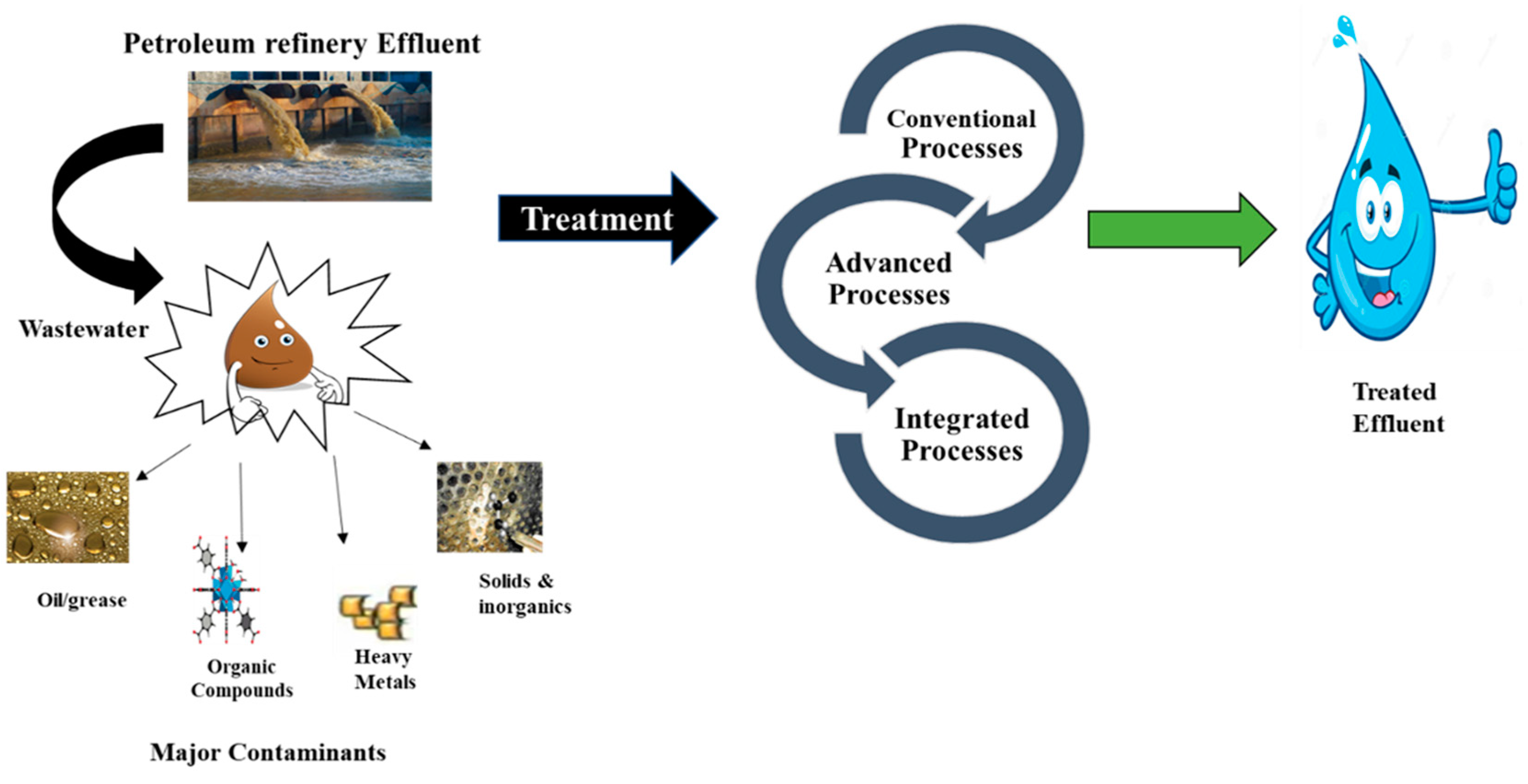

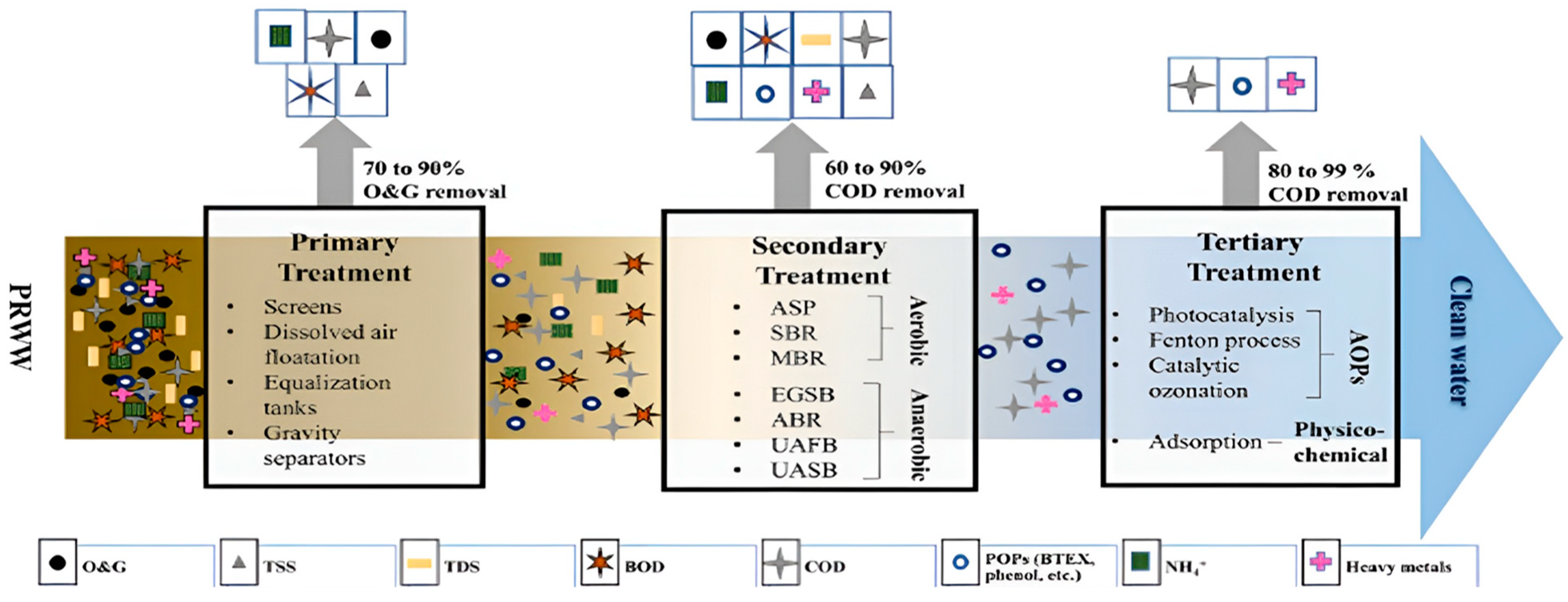

3. Treatment of Petroleum Refinery Wastewater

3.1. Conventional Treatment Techniques

3.1.1. Physicochemical Processes

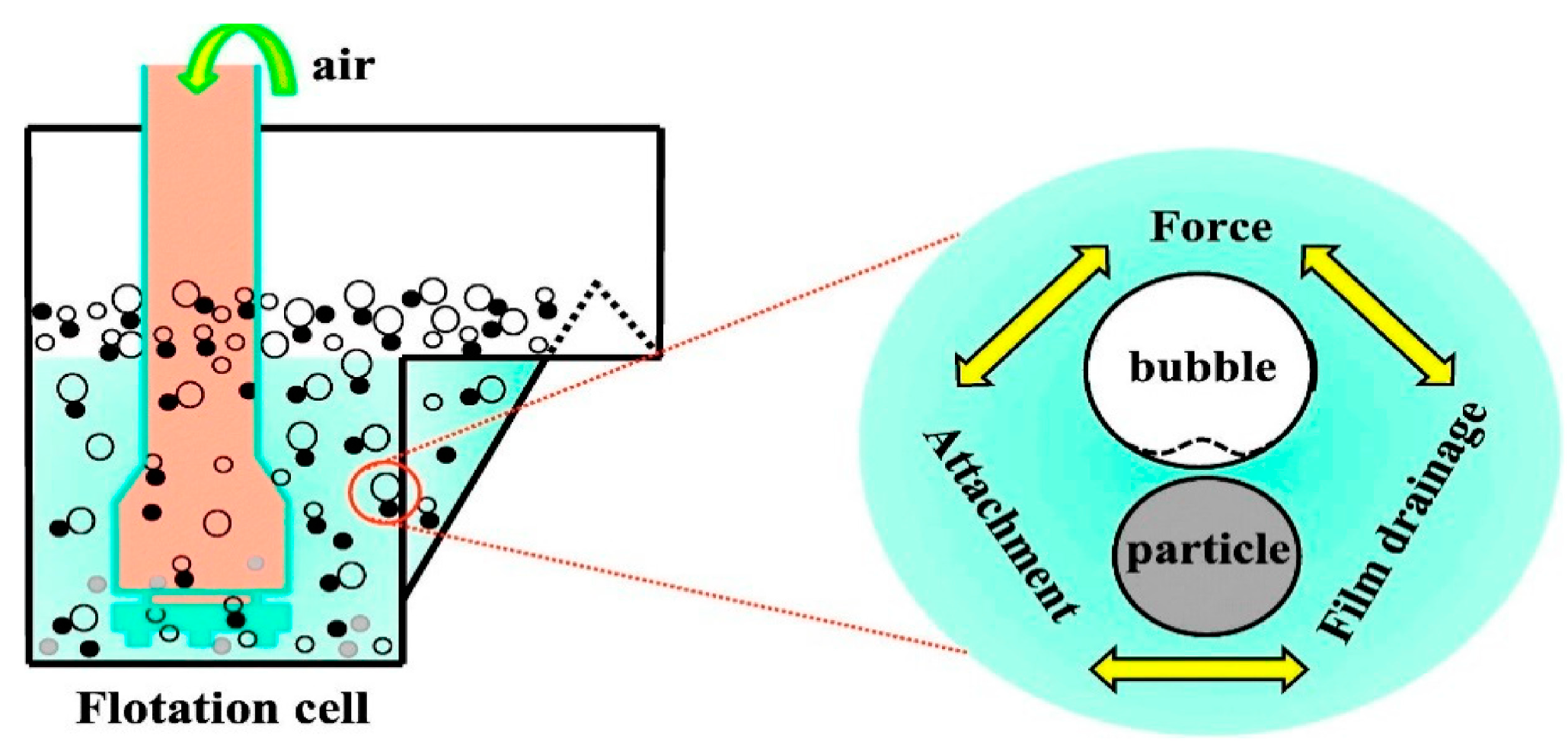

Flotation and Sedimentation Processes

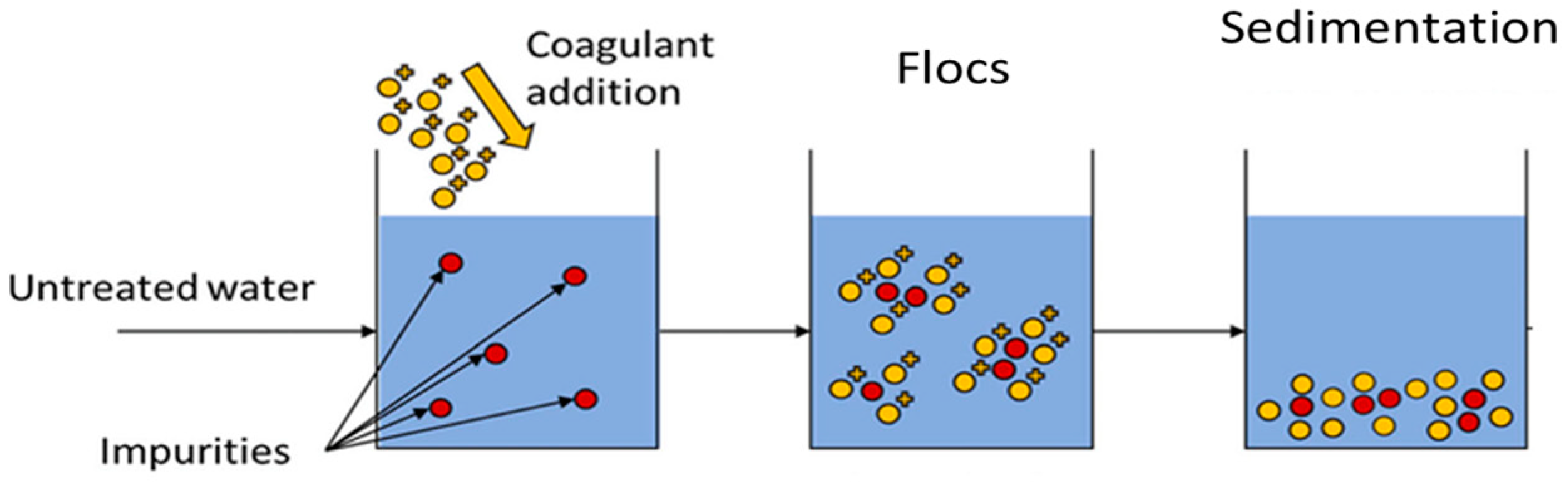

Coagulation/Flocculation

| Experimental Conditions | ||||||||

|---|---|---|---|---|---|---|---|---|

| S/No. | Adsorbent | pH | Dosage | Temp. (°C) | Time (Min) | Pollutants Removed | Removal Efficiency (%) | Reference |

| 1 | Activated carbon (AC), natural clay (NC) and sawdust (SD) | 7 | NC 18.96 mg/g, AC 16.25 mg/g & SD 14.11 mg/g. | NR | 100 | Colour | 83.1 | [83] |

| COD | 67.2 | |||||||

| 2 | Activated carbon fixed-bed column | 5.7 | 80% Parking | 25 ± 2 | 73 | COD | 96.7 | [84] |

| 3 | Synthesized nanorods ZnO/SiO2 via the sol-gel | Pb2+ | 85.06 | [85] | ||||

| Cd2+ | 84.12 | |||||||

| 4 | Functionalized mesoporous material with amine groups (NH2-MCM-41) | 7 | 0.4 g/L | 50 | PAHs | 85.7 | [86] | |

| 5 | ZnO/Fe3O4 nanocomposite | NR | 0.08 g | 30 | 900 | Cu2+ | 92.99 | [87] |

| Cr6+ | 77.60 | |||||||

| 6 | Date pit-activated carbon (DPAC) | COD | 95.0 | [87] | ||||

| Wooden activated carbon | 8–9 | 2 g/L | BOD | 95.00 | [88] | |||

| TOC | 88.00 | |||||||

| COD | 68.67 | |||||||

| 7 | Graphene oxide nanocomposites with Cadmium oxide (CdO) | 5 | 1.3 g/L | Cr6+ | 98 | [89] | ||

Adsorption Using Conventional Adsorbents

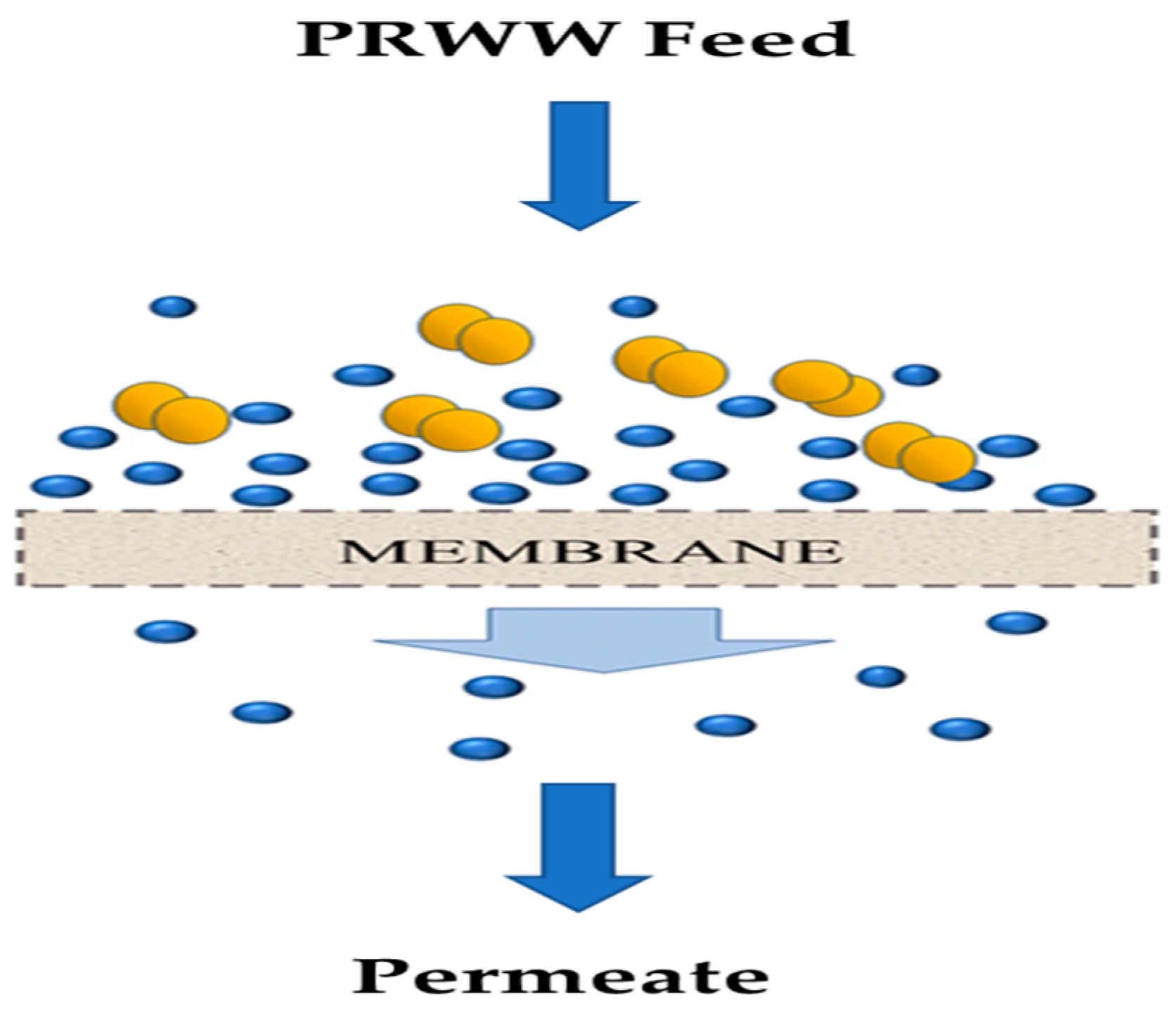

Membrane Processes

3.2. Chemical Processes

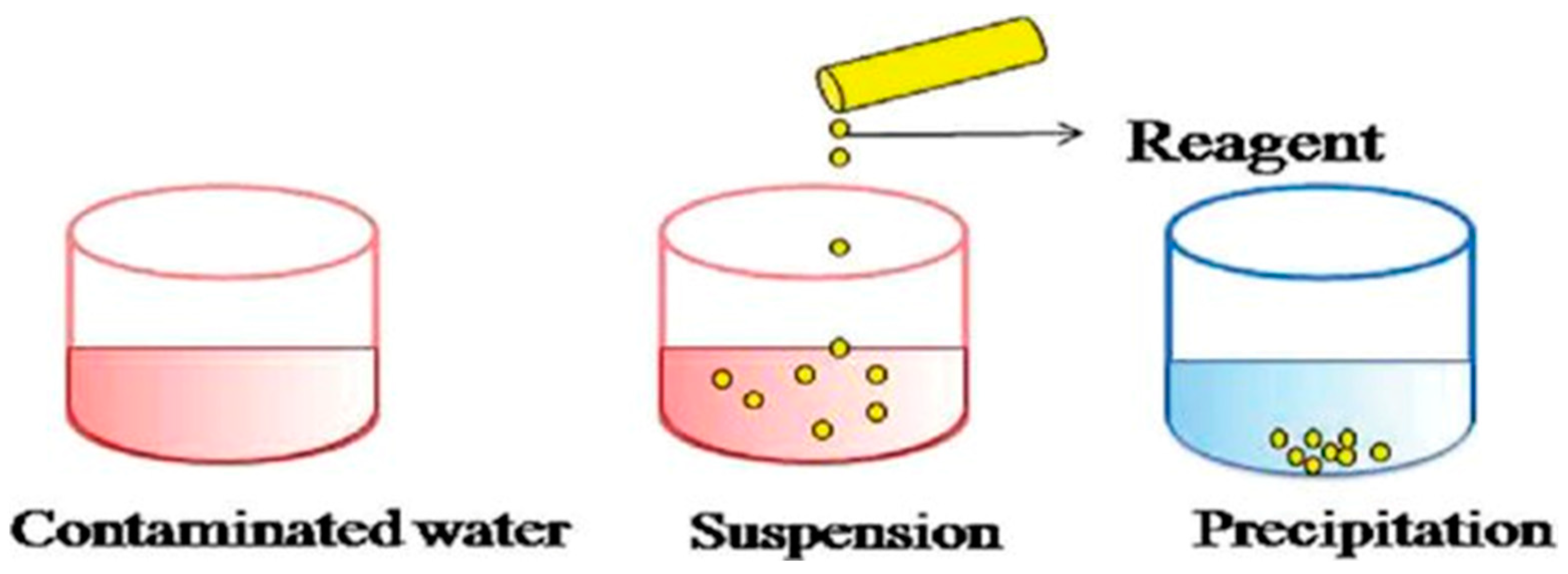

Chemical Precipitation and Ion Exchange

3.3. Biological Processes

3.3.1. Bioremediation Using Constructed Wetlands

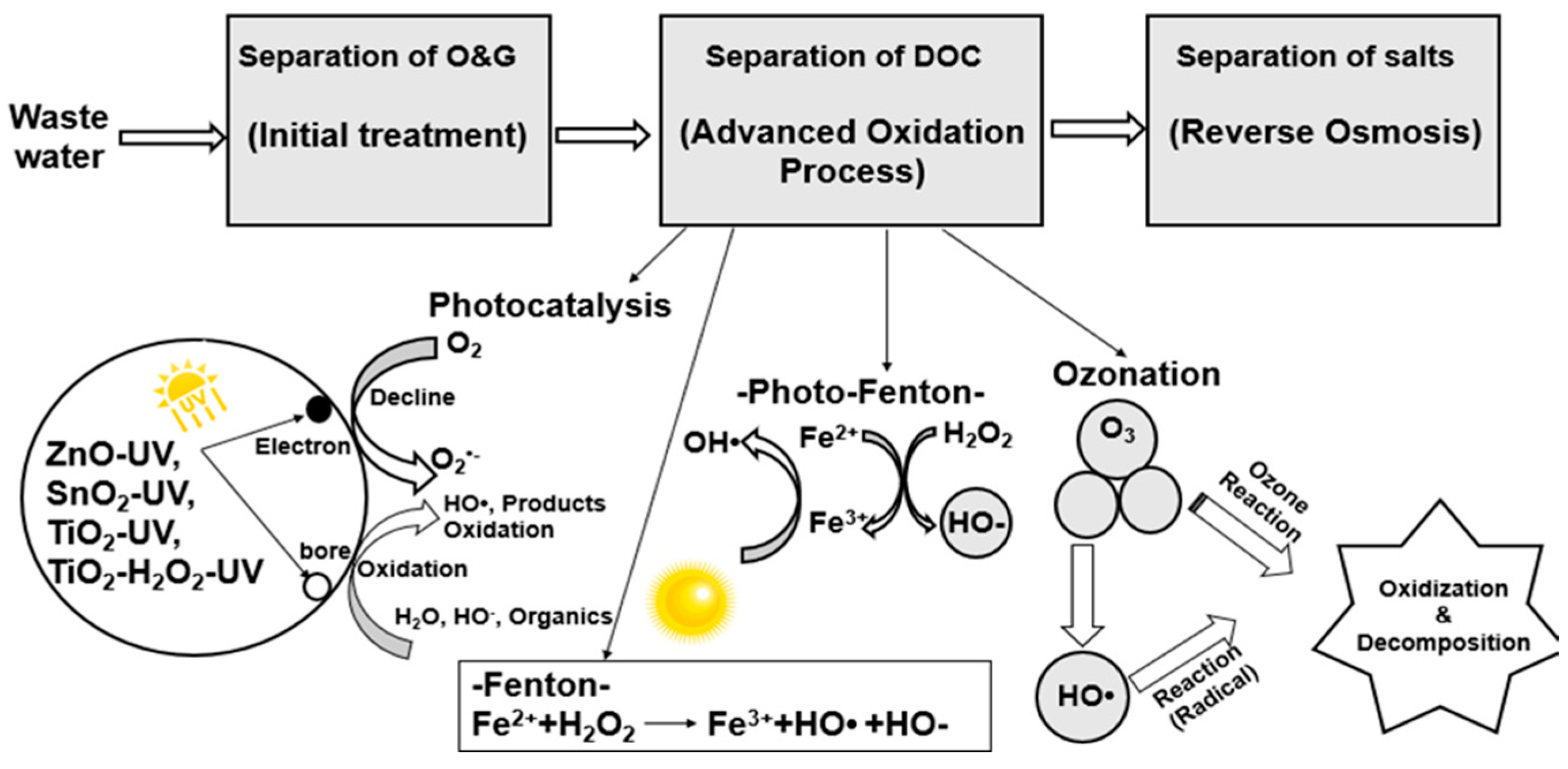

3.4. Advanced Treatment Processes

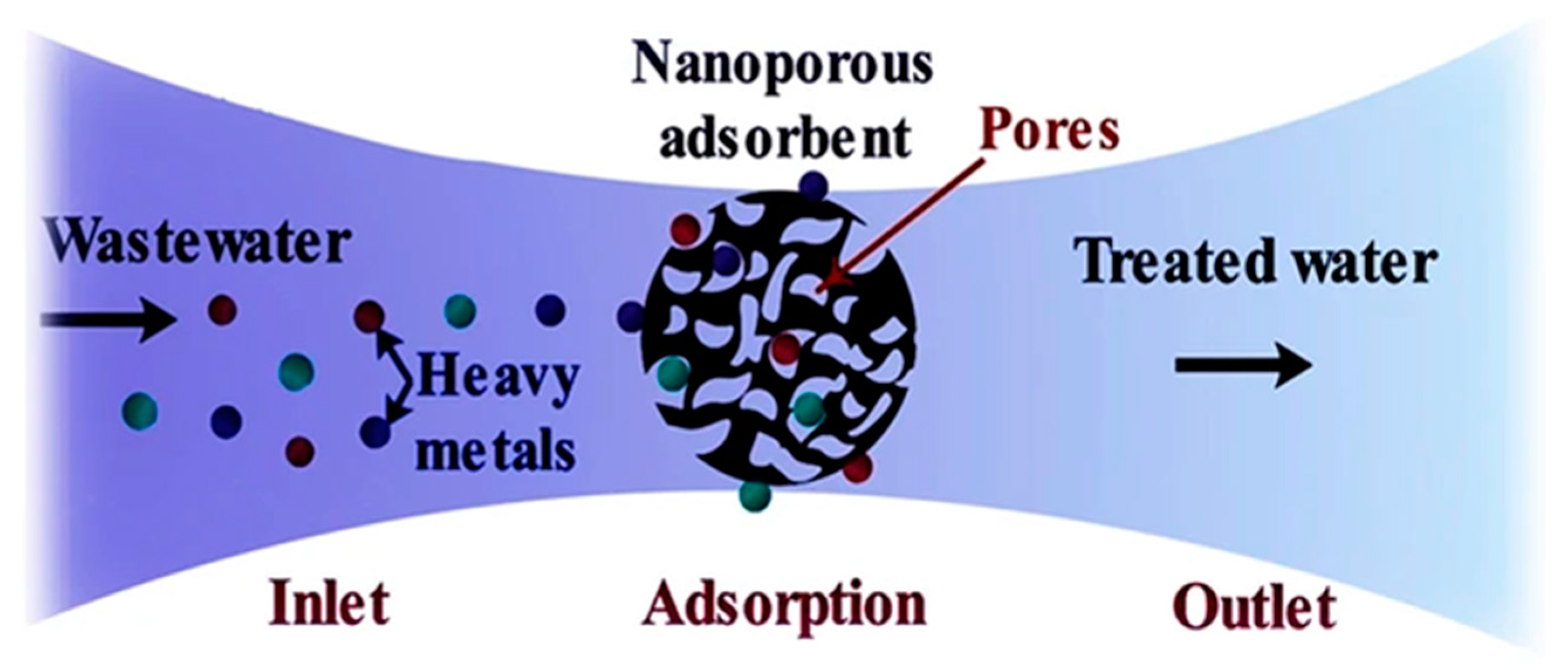

3.4.1. Adsorption Using Modified Adsorbents

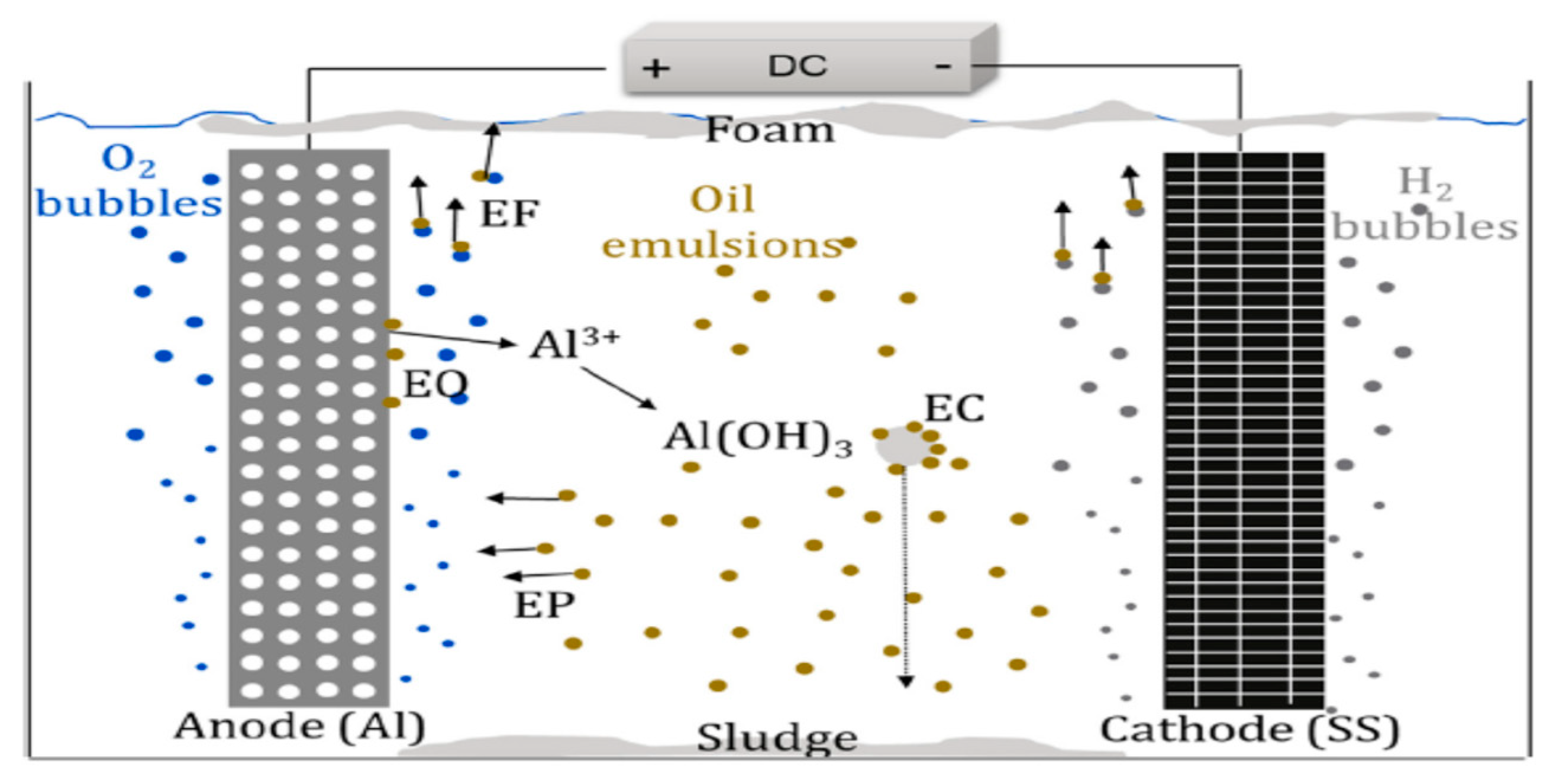

3.4.2. Electrochemical Techniques

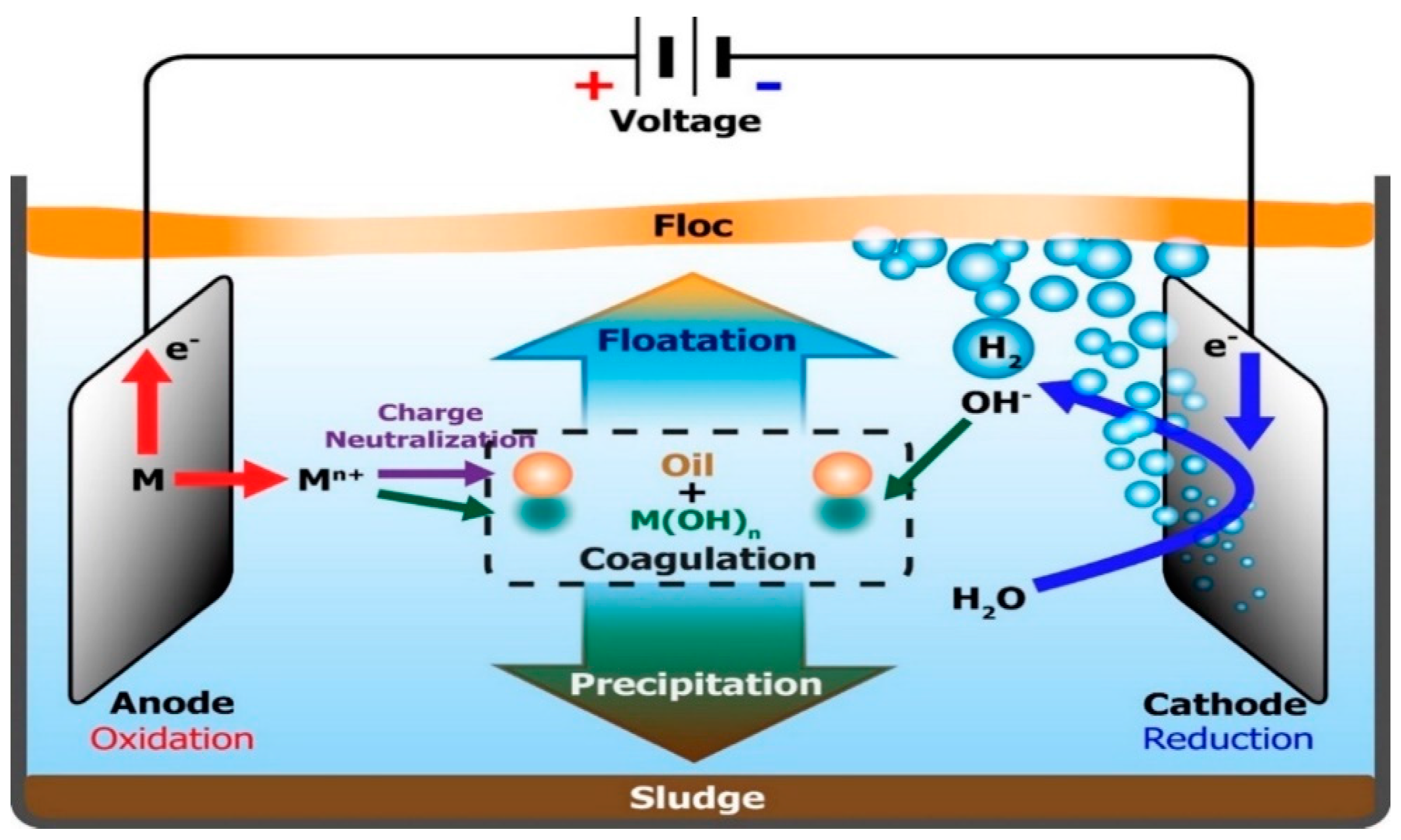

Electro Floatation (EF)

Electrocoagulation (EC)

Electrooxidation (EO)

3.4.3. Advanced Oxidation Processes

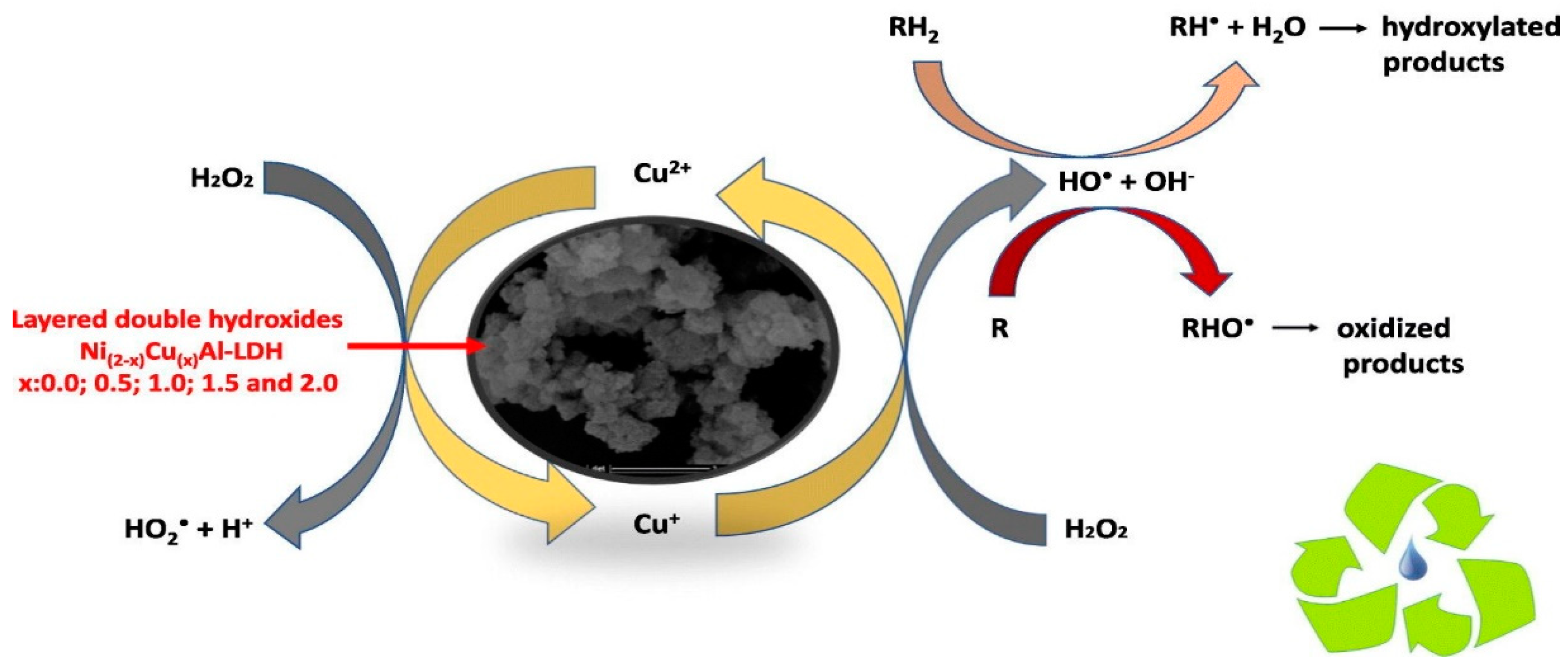

Fenton-Oxidation

Electro-Fenton Process

Photocatalysis

Properties of the Photocatalysts

Metal Doping and Hybridization of Photocatalysts

Treatment of PRWW Using Photocatalysis

3.4.4. Combined H2O2/UV Advanced Oxidation Processes

| Kin | Experimental Conditions | Efficiency (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Photocatalyst | Light | pH | Dosage | Temp. (°C) | Time (Min) | COD | Phenols | Oil | Reference |

| TiO2/Fe-ZSM-5 | UV | 4 | 2.1 g/L | 45 | 240 | 80 | - | - | [191] |

| TiO2 | UV | 3 | 100 mg/L | 30 °C | 90 | 93.1 | 98.8 | - | [34] |

| TiO2/ZnO | Solar | 6.8 | 0.5 g/L | NR | 170 | 76 | - | - | [193] |

| TiO2 with synergistic effects of O3, H2O2 and O3/H2O2 | UV | NR | 280 | 38 | - | - | [194] | ||

| TiO2/Ag | Solar/UV | 4.5 | NR | NR | NR | 51.8/76.3 | -- | - | [195] |

| Zeolite and TiO2. | UV | NR | 0.5–1.5 g/L | 92/91 | -- | [196] | |||

| ZnO | Solar | 10 | 3 g/L | NR | NR | -- | 75 | [197] | |

| TiO2 Degussa P25 (80% anatase and 20% rutile) | UV | NR | 8 g/L | 76 | - | [199] | |||

| TiO2 | UV | NR | 0.2 g/L | NR | 300 | 100 | - | - | [200] |

| TiO2/ZnO | UV | 7 | 54 g/L and 50 g/L | 74 | - | - | [201] | ||

| ZnO nanorods (NRs) | UV | NR | NR | NR | 600 | 90 | - | [204] | |

3.5. Integrated Treatment Processes (ITP)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Qiu, B.; Tao, X.; Wang, H.; Li, W.; Ding, X.; Chu, H. Biochar as a low-cost adsorbent for aqueous heavy metal removal: A review. J. Anal. Appl. Pyrolysis 2021, 155, 105081. [Google Scholar] [CrossRef]

- Salem, F.; Thiemann, T. Produced Water from Oil and Gas Exploration—Problems, Solutions and Opportunities. J. Water Resour. Prot. 2022, 14, 142–185. [Google Scholar] [CrossRef]

- Al-Khalid, T.; El-Naas, M.H. Organic contaminants in refinery wastewater: Characterization and novel approaches for biotreatment. In Recent Insights in Petroleum Science and Engineering; InTechOpen: London, UK, 2018. [Google Scholar] [CrossRef]

- Yu, L.; Han, M.; He, F. A review of treating oily wastewater. Arab. J. Chem. 2013, 10, S1913–S1922. [Google Scholar] [CrossRef]

- Elmobarak, W.F.; Hameed, B.H.; Almomani, F.; Abdullah, A.Z. A review on the treatment of petroleum refinery wastewater using advanced oxidation processes. Catalysts 2021, 11, 782. [Google Scholar] [CrossRef]

- Kulkarni, S.J.; Goswami, A.K. A review on wastewater treatment for petroleum industries and refineries. Int. J. Innov. Res. Sci. Eng. Technol. 2015, 1, 280–283. [Google Scholar]

- Aljuboury, D.A.D.A.; Palaniandy, P.; Abdul Aziz, H.B.; Feroz, S. Treatment of petroleum wastewater by conventional and new technologies—A review. Glob. Nest J. 2017, 19, 439–452. [Google Scholar]

- Jain, M.; Majumder, A.; Ghosal, P.S.; Gupta, A.K. A review on treatment of petroleum refinery and petrochemical plant wastewater: A special emphasis on constructed wetlands. J. Environ. Manag. 2020, 272, 111057. [Google Scholar] [CrossRef] [PubMed]

- Adetunji, A.I.; Olaniran, A.O. Treatment of industrial oily wastewater by advanced technologies: A review. Appl. Water Sci. 2021, 11, 98. [Google Scholar] [CrossRef]

- Rahi, M.N.; Jaeel, A.J.; Abbas, A.J. Treatment of petroleum refinery effluents and wastewater in Iraq: A mini review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1058, 012072. [Google Scholar] [CrossRef]

- Kalair, A.; Abas, N.; Saleem, M.S.; Kalair, A.R.; Khan, N. Role of energy storage systems in energy transition from fossil fuels to renewables. Energy Storage 2020, 3, e135. [Google Scholar] [CrossRef]

- Pinzón-Espinosa, A. Unravelling the Chemistry behind the Toxicity of Oil Refining Effluents: From Characterisation to Treatment. Doctoral Dissertation, Brunel University: London, UK, 2018. [Google Scholar]

- IPIECA. Petroleum Refining Water/Wastewater Use and Management; IPIECA Operations Best Practice Series; IPIECA: London, UK, 2010. [Google Scholar]

- Ezugbe, E.O.; Rathilal, S. Membrane technologies in wastewater treatment: A review. Membranes 2020, 10, 89. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.M.; Abu-Hassan, M.A.; Ibrahim, R.R.; Zaini, M.A.; Abdulkarim, B.I.; Hussein, A.S.; Su, S.M.; Halim, M.A.I.M. Characterization of petroleum sludge from refinery industry biological wastewater treatment unit. Preprints 2017. [Google Scholar] [CrossRef]

- Pal, S.; Banat, F.; Almansoori, A.; Haija, M.A. Review of technologies for biotreatment of refinery wastewaters: Progress, challenges and future opportunities. Environ. Technol. Rev. 2017, 5, 12–38. [Google Scholar] [CrossRef]

- Polvara, E.; Roveda, L.; Invernizzi, M.; Capelli, L.; Sironi, S. Estimation of Emission Factors for Hazardous Air Pollutants from Petroleum Refineries. Atmosphere 2021, 12, 1531. [Google Scholar] [CrossRef]

- Islam, B. Petroleum sludge, its treatment and disposal: A review. Int. J. Chem. Sci. 2015, 13, 1584–1602. [Google Scholar]

- Lattanzio, R.K. An Overview of Air Quality Issues in Natural Gas Systems; Congressional Research Service, the Library of Congress: Washington, DC, USA, 2016. [Google Scholar]

- Diya’uddeen, B.H.; Daud, W.M.A.W.; Aziz, A.A. Treatment technologies for petroleum refinery effluents: A review. Process Saf. Environ. Prot. 2011, 89, 95–105. [Google Scholar] [CrossRef]

- Whale, G.; Hjort, M.; Di Paolo, C.; Redman, A.; Postma, J.; Legradi, J.; Leonards, P. Assessment of oil refinery wastewater and effluent integrating bioassays, mechanistic modelling and bioavailability evaluation. Chemosphere 2022, 287, 132146. [Google Scholar] [CrossRef]

- Bayona, J.M.; Domínguez, C.; Albaigés, J. Analytical developments for oil spill fingerprinting. Trends Environ. Anal. Chem. 2015, 5, 26–34. [Google Scholar] [CrossRef]

- Tang, X.; Eke, P.E.; Scholz, M.; Huang, S. Processes impacting on benzene removal in vertical-flow constructed wetlands. Bioresour. Technol. 2009, 100, 227–234. [Google Scholar] [CrossRef]

- Aziz, N.M.; Sabbar, A.A. Physiochemical Properties of Basrah oil refinery discharges and its potential effects on Shatt Al-Basrah Canal. Marsh Bull. 2013, 8, 39–57. [Google Scholar]

- El-Naas, M.H.; Abu Alhaija, M.; Al-Zuhair, S. Evaluation of a three-step process for the treatment of petroleum refinery wastewater. J. Environ. Chem. Eng. 2014, 2, 56–62. [Google Scholar] [CrossRef]

- Pinzón-Espinosa, A.; Kanda, R. Naphthenic acids are key contributors to toxicity of heavy oil refining effluents. Sci. Total. Environ. 2020, 729, 138119. [Google Scholar] [CrossRef] [PubMed]

- Tetteh, E.K.; Rathilal, S. Evaluation of different polymeric coagulants for the treatment of oil refinery wastewater. Cogent Eng. 2020, 7, 1785756. [Google Scholar] [CrossRef]

- Aljuboury, D.D.A.; Senthilkumar, R. Phenol degradation of industrial wastewater by photocatalysis. J. Innov. Eng. 2014, 2, 1–10. [Google Scholar]

- Radelyuk, I.; Tussupova, K.; Zhapargazinova, K.; Yelubay, M.; Persson, M. Pitfalls of wastewater treatment in oil refinery enterprises in kazakhstan—A system approach. Sustainability 2019, 11, 1618. [Google Scholar] [CrossRef]

- Qaderi, F.; Abdolalian, S. Treatment of petroleum wastewater using solar power-based photocatalysis. In Petroleum Industry Wastewater: Advanced and Sustainable Treatment Methods; Elsevier: Amsterdam, The Netherlands, 2022; pp. 161–170. [Google Scholar] [CrossRef]

- Eldos, H.I.; Khan, M.; Zouari, N.; Saeed, S.; Al-Ghouti, M.A. Characterization and assessment of process water from oil and gas production: A case study of process wastewater in Qatar. Case Stud. Chem. Environ. Eng. 2022, 6, 100210. [Google Scholar] [CrossRef]

- Aziz, S.Q.; Fakhrey, E.S.A. The effect of kawergosk oil refinery wastewater on surrounding water resources. ZANCO J. Pure Appl. Sci. 2016, 28, 656–667. [Google Scholar]

- Dai, X.; Chen, C.; Chen, Y.; Guo, S. Comprehensive Evaluation of a Full-Scale Combined Biological Process for the Treatment of Petroleum Refinery Wastewater using GC-MS and PCR-DGGE Techniques. Int. J. Electrochem. Sci. 2020, 15, 2013–2026. [Google Scholar] [CrossRef]

- Saber, A.; Hasheminejad, H.; Taebi, A.; Ghaffari, G. Optimization of Fenton-based treatment of petroleum refinery wastewater with scrap iron using response surface methodology. Appl. Water Sci. 2013, 4, 283–290. [Google Scholar] [CrossRef]

- Ul Haq, I.U.; Ahmad, W.; Ahmad, I.; Yaseen, M. Photocatalytic oxidative degradation of hydrocarbon pollutants in refinery wastewater using TiO2 as catalyst. Water Environ. Res. 2020, 92, 2086–2094. [Google Scholar] [CrossRef]

- Mustapha, H.I. Treatment of Petroleum Refinery Wastewater with Constructed Wetlands; CRC Press: London, UK, 2018. [Google Scholar]

- Jafarinejad, S. Activated sludge combined with powdered activated carbon (PACT process) for the petroleum industry wastewater treatment: A review. Chem. Int. 2017, 3, 368. [Google Scholar]

- Ibrahim, D.S.; Devi, P.S.; Balasubramanian, N. Electrochemical oxidation treatment of petroleum refinery effluent. Int. J. Sci. Eng. Res. 2013, 4, 1–5. [Google Scholar]

- El-Naas, M.H.; Surkatti, R.; Al-Zuhair, S. Petroleum refinery wastewater treatment: A pilot scale study. J. Water Process Eng. 2016, 14, 71–76. [Google Scholar] [CrossRef]

- Khatoon, K.; Malik, A. Cyto-genotoxic potential of petroleum refinery wastewater mixed with domestic sewage used for irrigation of food crops in the vicinity of an oil refinery. Heliyon 2021, 7, e08116. [Google Scholar] [CrossRef] [PubMed]

- Ghezali, K.; Bentahar, N.; Barsan, N.; Nedeff, V.; Moșneguțu, E. Potential of Canna indica in Vertical Flow Constructed Wetlands for Heavy Metals and Nitrogen Removal from Algiers Refinery Wastewater. Sustainability 2022, 14, 4394. [Google Scholar] [CrossRef]

- Bastos, P.D.A.; Santos, M.A.; Carvalho, P.J.; Velizarov, S.; Crespo, J.G. Pilot scale reverse osmosis refinery wastewater treatment—A techno-economical and sustainability assessment. Environ. Sci. Water Res. Technol. 2021, 7, 549–561. [Google Scholar] [CrossRef]

- Nkwocha, A.C.; Ekeke, I.C.; Kamen, F.L.; Oghome, P.I. Performance Evaluation of Petroleum Refinery Wastewater Treatment Plant. Int. J. Sci. Eng. Investig. 2013, 2, 17. [Google Scholar]

- Daflon, S.; Guerra, I.; Reynier, M.; Botta, C.; Campos, J. Toxicity identification and evaluation of a refinery wastewater from Brazil (Phase I). Ecotoxicol. Environ. Contam. 2015, 10, 41. [Google Scholar] [CrossRef]

- Hashemi, F.; Hashemi, H.; Dehghani, M.; Hoseini, M. Removal of heavy metals from oil refinery effluent by micellar-enhanced ultrafiltration (MEUF). J. Health Sci. Surveill. Syst. 2018, 6, 123–129. [Google Scholar]

- Wokoma, O.A.F.; Edori, O.S. Heavy metals content of an oily wastewater effluent from an oil firm at the point of discharge. Int. J. Chem. Pharm. Technol. 2018, 2, 154–161. [Google Scholar]

- Olayebi, O.O.; Adebayo, A.T. Removal of Heavy Metals from Petroleum Refinery Effluent Using Coconut Shell Effluent Using Coconut Shell-Based Activated Based Activated Carbon. CARD Int. J. Eng. Emerg. Sci. Discov. 2017, 2, 102–117. [Google Scholar]

- Igbagara, P.W.; Ntekim, J. Determination of heavy metals concentration in waste water of Warri Refining and Petrochemicals Company (WRPC). Trop. J. Sci. Technol. 2021, 2, 29–37. [Google Scholar]

- Ho, S.; Cm, I.; Cn, S. Bioremoval of heavy metals from effluent of port harcourt refinery using pluerotus ostreatus. J. Pet. Environ. Biotechnol. 2017, 8, 1000324. [Google Scholar] [CrossRef]

- Ghezali, K.; Tahar, N.B.; Otmanine, G.; Guettaf, N. Environmental assessment and compliance of wastewater from arzew oil refinery for future development and reuse. J. Environ. Treat. Technol. 2022, 10, 18–23. [Google Scholar]

- Ugboma, C.; Sampson, T.; Mbonu, N. Bioremediation of heavy metals from artisanal crude oil refinery (Kpo-Fire) impacted soil using Bacillus flexus and Pseudomonas aeruginosa in Ngie Community, Degema Local Government Area, Rivers State, Nigeria. J. Appl. Sci. Environ. Manag. 2021, 24, 2049–2054. [Google Scholar] [CrossRef]

- Petrowiki. Produced Oilfield Water. 2018. Available online: https://petrowiki.org/Produced_oilfield_water (accessed on 15 July 2019).

- Amakiri, K.T.; Canon, A.R.; Molinari, M.; Angelis-Dimakis, A. Review of Petroleum oilfield produced water treatment technologies. Chemosphere 2022, 298, 134064. [Google Scholar] [CrossRef]

- Tong, K.; Zhang, Y.; Liu, G.; Ye, Z.; Chu, P.K. Treatment of heavy oil wastewater by a conventional activated sludge process coupled with an immobilized biological filter. Int. Biodeterior. Biodegrad. 2013, 84, 65–71. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Q.; Li, M.; Yang, Y.; He, W.; Yan, G.; Guo, S. An alternative anaerobic treatment process for treatment of heavy oil refinery wastewater containing polar organics. Biochem. Eng. J. 2015, 105, 44–51. [Google Scholar] [CrossRef]

- Vendramel, S.; Bassin, J.P.; Dezotti, M.; Sant’Anna, G.L., Jr. Treatment of petroleum refinery wastewater containing heavily polluting substances in an aerobic submerged fixed-bed reactor. Environ. Technol. 2015, 36, 2052–2059. [Google Scholar] [CrossRef]

- Wang, C.; Chen, Z.; Li, Y.; Feng, K.; Peng, Z.; Zhu, Y.; Yang, X. Refinery wastewater treatment via a multistage enhanced biochemical process. Sci. Rep. 2021, 11, 10282. [Google Scholar] [CrossRef]

- Dehghani, M.; Alizadeh, M.H. The effects of the natural coagulant Moringa oleifera and alum in wastewater treatment at the Bandar Abbas Oil Refinery. Environ. Health Eng. Manag. 2016, 3, 225–230. [Google Scholar] [CrossRef]

- Singh, B.; Kumar, P. Pre-treatment of petroleum refinery wastewater by coagulation and flocculation using mixed coagulant: Optimization of process parameters using response surface methodology (RSM). J. Water Process Eng. 2020, 36, 101317. [Google Scholar] [CrossRef]

- Zueva, S.; Corradini, V.; Ruduka, E.; Veglio, F. Treatment of petroleum refinery wastewater by physicochemical methods. E3S Web Conf. 2020, 161, 01042. [Google Scholar] [CrossRef]

- Ratman, I.; Kusworo, T.D.; Utomo, D.P.; Azizah, D.A.; Ayodyasena, W.A. Petroleum refinery wastewater treatment using three steps modified nanohybrid membrane coupled with ozonation as integrated pre-treatment. J. Environ. Chem. Eng. 2020, 8, 103978. [Google Scholar] [CrossRef]

- Estrada-Arriaga, E.B.; Zepeda-Aviles, J.A.; García-Sánchez, L. Post-treatment of real oil refinery effluent with high concentrations of phenols using photo-ferrioxalate and Fenton’s reactions with membrane process step. Chem. Eng. J. 2016, 285, 508–516. [Google Scholar] [CrossRef]

- Razavi, S.M.R.; Miri, T. A real petroleum refinery wastewater treatment using hollow fiber membrane bioreactor (HF-MBR). J. Water Process Eng. 2015, 8, 136–141. [Google Scholar] [CrossRef]

- Nogueira, A.A.; Bassin, J.P.; Cerqueira, A.C.; Dezotti, M. Integration of biofiltration and advanced oxidation processes for tertiary treatment of an oil refinery wastewater aiming at water reuse. Environ. Sci. Pollut. Res. 2016, 23, 9730–9741. [Google Scholar] [CrossRef]

- Coelho, A.; Castro, A.V.; Dezotti, M.; Sant’Anna, G.L., Jr. Treatment of petroleum refinery sourwater by advanced oxidation processes. J. Hazard. Mater. 2016, 137, 178–184. [Google Scholar] [CrossRef]

- Chen, C.; Yoza, B.A.; Wang, Y.; Wang, P.; Li, Q.X.; Guo, S.; Yan, G. Catalytic ozonation of petroleum refinery wastewater utilizing Mn-Fe-Cu/Al2O3 catalyst. Environ. Sci. Pollut. Res. 2015, 22, 5552–5562. [Google Scholar] [CrossRef]

- Ebrahiem, E.E.; Al-Maghrabi, M.N.; Mobarki, A.R. Removal of organic pollutants from industrial wastewater by applying photo-Fenton oxidation technology. Arab. J. Chem. 2013, 10, S1674–S1679. [Google Scholar] [CrossRef]

- Zhang, Y.; Quan, X.; Chen, S.; Zhao, Y.; Yang, F. Microwave assisted catalytic wet air oxidation of H-acid in aqueous solution under the atmospheric pressure using activated carbon as catalyst. J. Hazard. Mater. 2006, 137, 534–540. [Google Scholar] [CrossRef] [PubMed]

- Abuhasel, K.; Kchaou, M.; Alquraish, M.; Munusamy, Y.; Jeng, Y.T. Oily Wastewater Treatment: Overview of Conventional and Modern Methods, Challenges, and Future Opportunities. Water 2021, 13, 980. [Google Scholar] [CrossRef]

- Varjani, S.; Joshi, R.; Srivastava, V.K.; Ngo, H.H.; Guo, W. Treatment of Wastewater from Petroleum Industry: Current Practices and Perspectives. Environ. Sci. Pollut. Res. 2019, 27, 27172–27180. [Google Scholar] [CrossRef]

- Shuokr, Q.A.; Sazan, M.A. Characteristics, treatment techniques, and operational limitations for refinery wastewater: Review. Reciklaza I Odrziv. Razvoj 2021, 14, 19–30. [Google Scholar] [CrossRef]

- Renault, F.; Sancey, B.; Badot, P.-M.; Crini, G. Chitosan for coagulation/flocculation processes—An eco-friendly approach. Eur. Polym. J. 2009, 45, 1337–1348. [Google Scholar] [CrossRef]

- Van Le, T.; Imai, T.; Higuchi, T.; Yamamoto, K.; Sekine, M.; Doi, R.; Vo, H.T.; Wei, J. Performance of tiny microbubbles enhanced with “normal cyclone bubbles” in separation of fine oil-in-water emulsions. Chem. Eng. Sci. 2013, 94, 1–6. [Google Scholar] [CrossRef]

- Li, M.; Liu, H.; Liu, J.; Pei, Y.; Zheng, X.; Tang, K.; Wang, F. Hydrophobic and self-recoverable cellulose nanofibrils/N-alkylated chitosan/poly(vinyl alcohol) sponge for selective and versatile oil/water separation. Int. J. Biol. Macromol. 2021, 192, 169–179. [Google Scholar] [CrossRef]

- Wang, B.; Wan, Y.; Gao, Y.; Zheng, G.; Yang, M.; Wu, S.; Hu, J. Occurrences and behaviors of Naphthenic Acids in a petroleum refinery wastewater treatment plant. Environ. Sci. Technol. 2015, 49, 5796–5804. [Google Scholar] [CrossRef]

- Iwuozor, K.O. Prospects and challenges of using coagulation-flocculation method in the treatment of effluents. Adv. J. Chem. A 2019, 2, 105–127. [Google Scholar] [CrossRef]

- Hassan, A.K.; Hassan, M.M.A.; Hasan, A.F. Treatment of Iraqi Petroleum Refinery Wastewater by Advanced Oxidation Processes. J. Phys. Conf. Ser. 2020, 1660, 012071. [Google Scholar] [CrossRef]

- Sukmana, H.; Bellahsen, N.; Pantoja, F.; Hodur, C. Adsorption and coagulation in wastewater treatment—Review. Prog. Agric. Eng. Sci. 2021, 17, 49–68. [Google Scholar] [CrossRef]

- Lal, K.; Garg, A. Effectiveness of synthesized aluminum and iron based inorganic polymer coagulants for pulping wastewater treatment. J. Environ. Chem. Eng. 2019, 7, 103204. [Google Scholar] [CrossRef]

- Ayhan, N.N.; Aldemir, A.; Özgüven, A. Treatment of petroleum refinery wastewater by chemical coagulation method: Determination of optimum removal conditions using experimental design. Braz. J. Chem. Eng. 2023, 1–17. [Google Scholar] [CrossRef]

- Kareem, B.Y.; Tameemi, H.M.A. The performance of potassium ferrate for COD removal in AL-SAMAWAH refinery wastewataer. Am. Inst. Phys. 2022, 2386, 080023. [Google Scholar] [CrossRef]

- Hassan, A.A.; Naeem, H.T.; Hadi, R.T. A comparative study of chemical material additives on polyacrylamide to the treatment of wastewater in refineries. IOP Conf. Ser. Mater. Sci. Eng. 2019, 518, 062003. [Google Scholar] [CrossRef]

- Fadali, O.A.; Ebrahiem, E.E.; Farrag, T.E.; Mahmoud, M.S.; El-Gamil, A. Treatment of Oily Wastewater Produced from Refinery Processes Using Adsorption Technique. Minia J. Eng. Technol. 2013, 32, 88–101. [Google Scholar]

- Kassob, A.N.; Abbar, A.H. Treatment of petroleum refinery wastewater by adsorption using activated carbon fixed bed column with batch recirculation mode. Al-Qadisiyah J. Eng. Sci. 2022, 15, 102–112. [Google Scholar] [CrossRef]

- Shaba, E.Y.; Tijani, J.O.; Jacob, J.O.; Suleiman, M.A.T. Simultaneous removal of Cu (II) and Cr (VI) ions from petroleum refinery wastewater using ZnO/Fe3O4 nanocomposite. J. Environ. Sci. Health Part A 2022, 57, 1146–1167. [Google Scholar] [CrossRef]

- Kalash, K.R.; Albayati, T.M. Remediation of oil refinery wastewater implementing functionalized mesoporous materials MCM-41 in batch and continuous adsorption process. Desalination Water Treat. 2021, 220, 130–141. [Google Scholar] [CrossRef]

- Sakhile, K.; Sarkar, J.P.; Gupta, P.; Shaik, F. Removal of major pollutants from petroleum wastewater by adsorption with activated carbon derived from date seed in an inverse fluidized bed. Arab. J. Sci. Eng. 2022, 48, 8557–8569. [Google Scholar] [CrossRef]

- Wang, B.; Shui, Y.; Ren, H.; He, M. Research of combined adsorption-coagulation process in treating petroleum refinery effluent. Environ. Technol. 2016, 38, 456–466. [Google Scholar] [CrossRef] [PubMed]

- Bukhari, A.; Ijaz, I.; Zain, H.; Mehmood, U.; Iqbal, M.M.; Gilani, E.; Nazir, A. Introduction of CdO nanoparticles into graphene and graphene oxide nanosheets for increasing adsorption capacity of Cr from wastewater collected from petroleum refinery. Arab. J. Chem. 2023, 16, 104445. [Google Scholar] [CrossRef]

- Turner, T.; Wheeler, R.; Stone, A.; Oliver, I. Potential alternative reuse pathways for water treatment residuals: Remaining barriers and questions—A review. Water Air Soil Pollut. 2019, 230, 227. [Google Scholar] [CrossRef]

- Cai, L.; Zhang, Y.; Zhou, Y.; Zhang, X.; Ji, L.; Song, W.; Zhang, H.; Liu, J. Effective adsorption of diesel oil by crab-shell-derived biochar nanomaterials. Materials 2019, 12, 236. [Google Scholar] [CrossRef]

- Gkika, D.A.; Mitropoulos, A.C.; Kyzas, G.Z. Why reuse spent adsorbents? The latest challenges and limitations. Sci. Total. Environ. 2022, 822, 153612. [Google Scholar] [CrossRef]

- Afroze, S.; Sen, T.K.; Ang, H.M. Adsorption removal of zinc (II) from the aqueous phase by raw and base modified Eucalyptus sheathiana bark: Kinetics, mechanism and equilibrium study. Process Saf. Environ. Prot. 2016, 102, 336–352. [Google Scholar] [CrossRef]

- Ballav, N.; Das, R.; Giri, S.; Muliwa, A.M.; Pillay, K.; Maity, A. l-cysteine doped polypyrrole (PPy@L-Cyst): A super adsorbent for the rapid removal of Hg+2 and efficient catalytic activity of the spent adsorbent for reuse. Chem. Eng. J. 2018, 345, 621–630. [Google Scholar] [CrossRef]

- Crini, G.; Lichtfouse, E.; Wilson, L.D.; Morin-Crini, N. Conventional and non-conventional adsorbents for wastewater treatment. Environ. Chem. Lett. 2018, 17, 195–213. [Google Scholar] [CrossRef]

- Barakat, M. New trends in removing heavy metals from industrial wastewater. Arab. J. Chem. 2011, 4, 361–377. [Google Scholar] [CrossRef]

- Charmas, B.; Zięzio, M.; Jedynak, K. Assessment of the Porous Structure and Surface Chemistry of Activated Biocarbons Used for Methylene Blue Adsorption. Molecules 2023, 28, 4922. [Google Scholar] [CrossRef]

- Qasem, N.A.A.; Mohammed, R.H.; Lawal, D.U. Removal of heavy metal ions from wastewater: A comprehensive and critical review. npj Clean Water 2021, 4, 36. [Google Scholar] [CrossRef]

- Shenvi, S.S.; Isloor, A.M.; Ismail, A. A review on RO membrane technology: Developments and challenges. Desalination 2015, 368, 10–26. [Google Scholar] [CrossRef]

- Moslehyani, A.; Ismail, F.; Othman, M.H.D.; Matsuura, T. Design and performance study of hybrid photocatalytic reactor-PVDF/MWCNT nanocomposite membrane system for treatment of petroleum refinery wastewater. Desalination 2015, 363, 99–111. [Google Scholar] [CrossRef]

- Rashid, R.; Shafiq, I.; Akhter, P.; Iqbal, M.J.; Hussain, M. A state-of-the-art review on wastewater treatment techniques: The effectiveness of adsorption method. Environ. Sci. Pollut. Res. 2021, 28, 9050–9066. [Google Scholar] [CrossRef] [PubMed]

- Chun, Y.; Mulcahy, D.; Zou, L.; Kim, I.S. A short review of membrane fouling in forward osmosis processes. Membranes 2017, 7, 30. [Google Scholar] [CrossRef] [PubMed]

- Madaeni, S.S.; Gheshlaghi, A.; Rekabdar, F. Membrane treatment of oily wastewater from refinery processes: Membrane Treatment of Oily Wastewater. Asia-Pac. J. Chem. Eng. 2012, 8, 45–53. [Google Scholar] [CrossRef]

- Lebron, Y.A.R.; Moser, P.B.; Moreira, V.R.; Silva, G.R.d.A.; Soalheiro, A.; de Souza, B.P.; de Paula, E.C.; Amaral, M.C.S. Osmotic membrane bioreactor (OMBR) in refinery wastewater treatment: The impact of a draw solute with lower diffusivity in the process performance. Chem. Eng. J. 2021, 406, 127074. [Google Scholar] [CrossRef]

- Asatekin, A.; Mayes, A.M. Oil industry wastewater treatment with fouling resistant membranes containing amphiphilic comb copolymers. Environ. Sci. Technol. 2009, 43, 4487–4492. [Google Scholar] [CrossRef]

- Kusworo, T.D.; Kumoro, A.C.; Nabilah, Y.; Rasendriya, A.; Utomo, D.P.; Hasbullah, H. Advanced method for clean water recovery from batik wastewater via sequential adsorption, ozonation and photocatalytic membrane PVDF-TiO2/rGO processes. J. Environ. Chem. Eng. 2022, 10, 108708. [Google Scholar] [CrossRef]

- Salahi, A.; Noshadi, I.; Badrnezhad, R.; Kanjilal, B.; Mohammadi, T. Nano-porous membrane process for oily wastewater treatment: Optimization using response surface methodology. J. Environ. Chem. Eng. 2013, 1, 218–225. [Google Scholar] [CrossRef]

- Ratman, I.; Kusworo, T.D.; Utomo, D.P. Petroleum Refinery Wastewater Treatment Using a Polysulfone-Nano TiO2 Hybrid Membrane Coupled with an Ozonation Process as a Pre-Treatment. J. Membr. Sci. Res. 2021, 7, 141–151. [Google Scholar]

- Alnakeeb, A.; Rasheed, R.M. Chemical Precipitation method for Sulphate Removal from Treated Wastewater of Al-Doura Refinery. Eng. Technol. J. 2021, 39, 338–354. [Google Scholar] [CrossRef]

- Altaş, L.; Büyükgüngör, H. Sulfide removal in petroleum refinery wastewater by chemical precipitation. J. Hazard. Mater. 2008, 153, 462–469. [Google Scholar] [CrossRef] [PubMed]

- Habte, L.; Shiferaw, N.; Thriveni, T.; Mulatu, D.; Lee, M.-H.; Jung, S.-H.; Ahn, J.W. Removal of Cd(II) and Pb(II) from wastewater via carbonation of aqueous Ca(OH)2 derived from eggshell. Process Saf. Environ. Prot. 2020, 141, 278–287. [Google Scholar] [CrossRef]

- Park, J.H.; Choi, G.J.; Kim, S.H. Effects of pH and slow mixing conditions on heavy metal hydroxide precipitation. J. Korea Org. Resour. Recycl. ISLAM 2014, 22, 50–56. [Google Scholar]

- Stec, M.; Jagustyn, B.; Słowik, K.; Ściążko, M.; Iluk, T. Influence of high chloride concentration on ph control in hydroxide precipitation of heavy metals. J. Sustain. Met. 2020, 6, 239–249. [Google Scholar] [CrossRef]

- Fu, F.; Wang, Q. Removal of heavy metal ions from wastewaters: A review. J. Environ. Manag. 2011, 92, 407–418. [Google Scholar] [CrossRef]

- Sillanpää, M.; Shestakova, M. Emerging and combined electrochemical methods. In Electrochemical Water Treatment Methods: Fundamentals, Methods and Full-Scale Applications; Elsevier: Amsterdam, The Netherlands, 2017; pp. 131–225. [Google Scholar]

- Chakraborty, R.; Asthana, A.; Singh, A.K.; Jain, B.; Susan, A.B.H. Adsorption of heavy metal ions by various low-cost adsorbents: A review. Int. J. Environ. Anal. Chem. 2020, 102, 342–379. [Google Scholar] [CrossRef]

- Ghimire, N.; Wang, S. Biological treatment of petrochemical wastewater. In Petroleum Chemicals: Recent Insight; IntechOpen: London, UK, 2018; pp. 55–74. [Google Scholar]

- Wu, C.; Zhou, Y.; Sun, Q.; Fu, L.; Xi, H.; Yu, Y.; Yu, R. Appling hydrolysis acidification-anoxic–oxic process in the treatment of petrochemical wastewater: From bench scale reactor to full scale wastewater treatment plant. J. Hazard. Mater. 2016, 309, 185–191. [Google Scholar] [CrossRef]

- Rasheed, Q.J.; Muthukumar, K. Treatment of Petrochemical Wastewater using Sequencing Batch Reactor. In Proceedings of the Recent Trends in Engineering & Education (RTEE), NITTTR, Kolkata, Inda, 28–29 January 2010. [Google Scholar]

- Liang, J.; Mai, W.; Tang, J.; Wei, Y. Highly effective treatment of petrochemical wastewater by a super-sized industrial scale plant with expanded granular sludge bed bioreactor and aerobic activated sludge. Chem. Eng. J. 2018, 360, 15–23. [Google Scholar] [CrossRef]

- Cao, C.-Y.; Zhao, Y.-H. The comparison of MBBR and ASP for treatment on petrochemical wastewater. Pet. Sci. Technol. 2012, 30, 1461–1467. [Google Scholar] [CrossRef]

- Zou, X.-L. Treatment of heavy oil wastewater by UASB–BAFs using the combination of yeast and bacteria. Environ. Technol. 2015, 36, 2381–2389. [Google Scholar] [CrossRef] [PubMed]

- Mohanakrishna, G.; Abu-Reesh, I.M.; Pant, D. Enhanced bioelectrochemical treatment of petroleum refinery wastewater with Labaneh whey as co-substrate. Sci. Rep. 2020, 10, 19665. [Google Scholar] [CrossRef] [PubMed]

- Hayder, G.; Ramli, M.; Malek, M.; Khamis, A.; Hilmin, N. Prediction model development for petroleum refinery wastewater treatment. J. Water Process Eng. 2014, 4, 1–5. [Google Scholar] [CrossRef]

- Khondabia, V.G.; Fazlalia, A.; Arjomandzadeganb, M. Biological treatment of phenol from petroleum refinery wastewater using mixed indigenous cultures in a rotating biological contactor: Experimental and statistical studies. Desalination Water Treat. 2019, 1, 1–9. [Google Scholar]

- Stefanakis, A.I.; Thullner, M. Fate of phenolic compounds in constructed wetlands treating contaminated water. In Phytoremediation; Springer: Cham, Switzerland, 2016; pp. 311–325. [Google Scholar] [CrossRef]

- Vikrant, K.; Kim, K.-H. Nanomaterials for the adsorptive treatment of Hg (II) ions from water. Chem. Eng. J. 2018, 358, 264–282. [Google Scholar] [CrossRef]

- Sabir, S. Approach of cost-effective adsorbents for oil removal from oily water. Crit. Rev. Environ. Sci. Technol. 2015, 45, 1916–1945. [Google Scholar] [CrossRef]

- Abdeen, Z.; Moustafa, Y.M.M. Treatment of oily wastewater by using porous PVA hydrogels as oil adsorbent. J. Dispers. Sci. Technol. 2015, 37, 799–805. [Google Scholar] [CrossRef]

- Li, F.; Miao, G.; Gao, Z.; Xu, T.; Zhu, X.; Miao, X.; Song, Y.; Ren, G.; Li, X. A versatile hydrogel platform for oil/water separation, dye adsorption, and wastewater purification. Cellulose 2022, 29, 4427–4438. [Google Scholar] [CrossRef]

- Xue, Z.; Xing, X.; Zhu, S.; Zhang, W.; Luan, L.; Niu, Y.; Bai, L.; Chen, H.; Tao, Q. Underwater superoleophobic porous hydrogel film prepared by soluble salt-template method for oil/water separation in complex environments. Desalination Water Treat. 2019, 164, 151–161. [Google Scholar] [CrossRef]

- Zheng, R.; Wang, B.; Shi, K.; Sha, D.; Ji, X. Polyvinyl alcohol formaldehyde three-dimensional composite sponges with hierarchical pore structure for W/O emulsion separation. Appl. Surf. Sci. 2023, 611, 155754. [Google Scholar] [CrossRef]

- Tai, M.H.; Mohan, B.C.; Yao, Z.; Wang, C.-H. Superhydrophobic leached carbon Black/Poly(vinyl) alcohol aerogel for selective removal of oils and organic compounds from water. Chemosphere 2022, 286, 131520. [Google Scholar] [CrossRef] [PubMed]

- Zhang, E.; Li, W.; Gao, Y.; Lei, C.; Huang, H.-Y.; Yang, J.; Zhang, H.; Li, D. High-capacity reusable chitosan absorbent with a hydrogel-coated/aerogel-core structure and superhydrophilicity under oil for water removal from oil. ACS Appl. Bio Mater. 2020, 3, 5872–5879. [Google Scholar] [CrossRef] [PubMed]

- Sha, D.; Zheng, R.; Wang, B.; Shi, K.; Yang, X.; Liu, X.; Liu, Z.; Ji, X. Three-dimensional superhydrophilic polyvinyl alcohol–formaldehyde composite sponges with suitable pore sizes for high efficiency emulsion separation. New J. Chem. 2021, 45, 17816–17826. [Google Scholar] [CrossRef]

- Treviño-Reséndez, J.d.J.; Medel, A.; Meas, Y. Electrochemical technologies for treating petroleum industry wastewater. Curr. Opin. Electrochem. 2021, 27, 100690. [Google Scholar] [CrossRef]

- Khalifa, O.; Banat, F.; Hasan, S.W. Electrochemical treatment of petroleum wastewater: Standalone and integrated processes. In Petroleum Industry Wastewater: Advanced and Sustainable Treatment Methods; Elsevier: Amsterdam, The Netherlands, 2022; pp. 171–183. [Google Scholar] [CrossRef]

- Ibrahim, M.H.; Banerjee, A.; El-Naas, M.H. Treatment of petroleum industry wastewater: Current practices and perspectives. In Petroleum Industry Wastewater: Advanced and Sustainable Treatment Methods; Elsevier: Amsterdam, The Netherlands, 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Mickova, I.L. Advanced electrochemical technologies in wastewater treatment. Part II: Electro-flocculation and electro-flotation. Am. Acad. Sci. Res. J. Eng. Technol. Sci. 2015, 14, 273–294. [Google Scholar]

- Mohtashami, R.; Shang, J.Q. Electroflotation for treatment of industrial wastewaters: A focused review. Environ. Process. 2019, 6, 325–353. [Google Scholar] [CrossRef]

- Alam, R.; Shang, J.Q. Removal of bitumen from mature oil sands tailings slurries by electro-flotation. J. Water Process Eng. 2017, 15, 116–123. [Google Scholar] [CrossRef]

- Merma, A.G.; Santos, B.F.; Rego, A.S.; Hacha, R.R.; Torem, M.L. Treatment of oily wastewater from mining industry using electrocoagulation: Fundamentals and process optimization. J. Mater. Res. Technol. 2020, 9, 15164–15176. [Google Scholar] [CrossRef]

- Akkaya, G.K. Treatment of petroleum wastewater by electrocoagulation using scrap perforated (Fe-anode) and plate (Al and Fe-cathode) metals: Optimization of operating parameters by RSM. Chem. Eng. Res. Des. 2022, 187, 261–275. [Google Scholar] [CrossRef]

- El-Ashtoukhy, E.S.Z.; El-Taweel, Y.A.; Abdelwahab, O.; Nassef, E.M. Treatment of petrochemical wastewater con taining phenolic compounds by electrocoagulation using a fixed bed electrochemical reactor. Int. J. Electrochem. Sci. 2013, 8, 1534–1550. [Google Scholar] [CrossRef]

- Gousmi, N.; Sahmi, A.; Li, H.; Poncin, S.; Djebbar, R.; Bensadok, K. Purification and detoxification of petroleum refinery wastewater by electrocoagulation process. Environ. Technol. 2016, 37, 2348–2357. [Google Scholar] [CrossRef] [PubMed]

- An, C.; Huang, G.; Yao, Y.; Zhao, S. Emerging usage of electrocoagulation technology for oil removal from wastewater: A review. Sci. Total. Environ. 2017, 579, 537–556. [Google Scholar] [CrossRef] [PubMed]

- Gargouri, B.; Gargouri, O.D.; Gargouri, B.; Trabelsi, S.K.; Abdelhedi, R.; Bouaziz, M. Application of electrochemical technology for removing petroleum hydrocarbons from produced water using lead dioxide and boron-doped diamond electrodes. Chemosphere 2014, 117, 309–315. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, H.; Wang, F.; Xiong, X.; Tian, K.; Sun, Y.; Yu, T. Application of heterogeneous catalytic ozonation for refractory organics in wastewater. Catalysts 2019, 9, 241. [Google Scholar] [CrossRef]

- Azizah, A.N.; Widiasa, I.N. Advanced oxidation processes (AOPs) for refinery wastewater treatment contains high phenol concentration. MATEC Web Conf. 2018, 156, 03012. [Google Scholar] [CrossRef]

- de Oliveira, C.P.M.; Viana, M.M.; Amaral, M.C.S. Coupling photocatalytic degradation using a green TiO2 catalyst to membrane bioreactor for petroleum refinery wastewater reclamation. J. Water Process Eng. 2019, 34, 101093. [Google Scholar] [CrossRef]

- Fahim, A.S.; Abbar, A.H. Treatment of petroleum refinery wastewater by electro-Fenton process using porous graphite electrodes. Egypt. J. Chem. 2020. [Google Scholar] [CrossRef]

- Palaniandy, P.; Feroz, S. Advanced Oxidation Processes (AOPs) to Treat the Petroleum Wastewater. In Advanced Oxidation Processes (AOPs) in Water and Wastewater Treatment; IGI Global: Hershey, PA, USA, 2019; pp. 99–122. [Google Scholar]

- Nidheesh, P.V.; Gandhimathi, R. Textile Wastewater Treatment by Electro-Fenton Process in Batch and Continuous Modes. J. Hazard. Toxic Radioact. Waste 2015, 19, 04014038. [Google Scholar] [CrossRef]

- Quang, H.H.P.; Dinh, N.T.; Thi, T.N.T.; Bao, L.T.N.; Yuvakkumar, R.; Nguyen, V.-H. Fe2+, Fe3+, Co2+ as highly efficient cocatalysts in the homogeneous electro-Fenton process for enhanced treatment of real pharmaceutical wastewater. J. Water Process Eng. 2022, 46, 102635. [Google Scholar] [CrossRef]

- Giwa, A.-R.A.; Bello, I.A.; Olabintan, A.B.; Bello, O.S.; Saleh, T.A. Kinetic and thermodynamic studies of fenton oxidative decolorization of methylene blue. Heliyon 2020, 6, e04454. [Google Scholar] [CrossRef] [PubMed]

- Shokri, A.; Bayat, A.; Mahanpoor, K. Employing Fenton-like process for the remediation of petrochemical wastewater through Box–Behnken design method. Desalination Water Treat. 2019, 166, 135–143. [Google Scholar] [CrossRef]

- Tony, M.A.; Purcell, P.J.; Zhao, Y. Oil refinery wastewater treatment using physicochemical, Fenton and Photo-Fenton oxidation processes. J. Environ. Sci. Health Part A 2012, 47, 435–440. [Google Scholar] [CrossRef] [PubMed]

- Radji, G.; Bettahar, N.; Bahmani, A.; Boukhetache, I.; Contreras, S. Heterogeneous Fenton-like degradation of organic pollutants in petroleum refinery wastewater by copper-type layered double hydroxides. J. Water Process Eng. 2022, 50, 103305. [Google Scholar] [CrossRef]

- Divyapriya, G.; Nidheesh, P.V. Importance of graphene in the electro-fenton process. ACS Omega 2020, 5, 4725–4732. [Google Scholar] [CrossRef]

- Atiyah, A.S.; Al-Samawi, A.A.A.; Hassan, A.A. Photovoltaic cell electro-Fenton oxidation for treatment oily wastewater. Am. Inst. Phys. 2020, 2235, 020009. [Google Scholar] [CrossRef]

- Procházka, P.; Tutter, Š.; Ditl, P. Electrochemically Enhanced Fenton’s Reaction. Chem. Eng. 2019, 74, 1315–1320. [Google Scholar]

- Rashid, J.; Barakat, M.A.; Ruzmanova, Y.; Chianese, A. Fe3O4/SiO2/TiO2 nanoparticles for photocatalytic degradation of 2-chlorophenol in simulated wastewater. Environ. Sci. Pollut. Res. 2015, 22, 3149–3157. [Google Scholar] [CrossRef]

- Yang, X.; Wang, D. Photocatalysis: From fundamental principles to materials and applications. ACS Appl. Energy Mater. 2018, 1, 6657–6693. [Google Scholar] [CrossRef]

- Candish, L.; Collins, K.D.; Cook, G.C.; Douglas, J.J.; Gómez-Suárez, A.; Jolit, A.; Keess, S. Photocatalysis in the Life Science Industry. Chem. Rev. 2021, 122, 2907–2980. [Google Scholar] [CrossRef]

- Khan, M.M. Nanostructured Materials for Visible Light Photocatalysis; Micro and Nano Technologies; Elsevier: Amsterdam, The Netherlands, 2022; pp. 185–195. [Google Scholar]

- Sakka, S. Chapter 11.1.2. Sol–Gel Process and Applications. In Handbook of Advanced Ceramics; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Lau, W.-J.; Ismail, A.F.; Isloor, A.; Al-Ahmed, A. Advanced Nanomaterials for Membrane Synthesis and Its Applications; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Abeish, A.B.M.S. Enhanced Photocatalytic Degradation of Biorefractory Pollutants in Petroleum Refinery Wastewater. Doctoral Dissertation, Curtin University, Bentley, Australia, 2015. [Google Scholar]

- Park, S.J.; Yang, J.H.; Joo, M.H.; Sohn, Y. Current status, research gaps, and future scope for nanomaterials toward visible light photocatalysis. In Nanostructured Materials for Visible Light Photocatalysis; Elsevier: Amsterdam, The Netherlands, 2022; pp. 569–608. [Google Scholar] [CrossRef]

- Pardeshi, S.; Patil, A. A simple route for photocatalytic degradation of phenol in aqueous zinc oxide suspension using solar energy. Sol. Energy 2008, 82, 700–705. [Google Scholar] [CrossRef]

- Ren, G.; Han, H.; Wang, Y.; Liu, S.; Zhao, J.; Meng, X.; Li, Z. Recent advances of photocatalytic application in water treatment: A review. Nanomaterials 2021, 11, 1804. [Google Scholar] [CrossRef] [PubMed]

- Sushma; Yadav, A. Biological and physicochemical combination processes. In Nanomaterials for Air Remediation; Elsevier: Amsterdam, The Netherlands, 2020; pp. 361–372. [Google Scholar] [CrossRef]

- Al-Mamun, M.R.; Kader, S.; Islam, M.S.; Khan, M.Z.H. Photocatalytic activity improvement and application of UV-TiO2 photocatalysis in textile wastewater treatment: A review. J. Environ. Chem. Eng. 2019, 7, 103248. [Google Scholar] [CrossRef]

- Anucha, C.B.; Altin, I.; Bacaksiz, E.; Stathopoulos, V.N. Titanium Dioxide (TiO2)-Based Photocatalyst Materials Activity Enhancement for Contaminants of Emerging Concern (CECs) Degradation: In the Light of Modification Strategies. Chem. Eng. J. Adv. 2022, 10, 100262. [Google Scholar] [CrossRef]

- Stasinakis, A.S. Use of selected advanced oxidation processes (AOPs) for wastewater treatment—A mini review. Glob. NEST J. 2008, 10, 376–385. [Google Scholar]

- Dang, T.T.T.; Le, S.T.T.; Channei, D.; Khanitchaidecha, W.; Nakaruk, A. Photodegradation mechanisms of phenol in the photocatalytic process. Res. Chem. Intermed. 2016, 42, 5961–5974. [Google Scholar] [CrossRef]

- Nasr, M.; Eid, C.; Habchi, R.; Miele, P.; Bechelany, M. Recent progress on titanium dioxide nanomaterials for photocatalytic applications. ChemSusChem 2018, 11, 3023–3047. [Google Scholar] [CrossRef]

- Kane, A.; Assadi, A.A.; El Jery, A.; Badawi, A.K.; Kenfoud, H.; Baaloudj, O.; Assadi, A.A. Advanced photocatalytic treatment of wastewater using immobilized titanium dioxide as a photocatalyst in a pilot-scale reactor: Process intensification. Materials 2022, 15, 4547. [Google Scholar] [CrossRef]

- Baradaran, M.; Ghodsi, F.E. Investigation of the properties of oxide-based multilayer thin films and their use in the photocatalytic applications. In Chemical Solution Synthesis for Materials Design and Thin Film Device Applications; Elsevier: Amsterdam, The Netherlands, 2021; pp. 697–715. [Google Scholar] [CrossRef]

- Tahir, M.B.; Sohaib, M.; Sagir, M.; Rafique, M.D. Role of nanotechnology in photocatalysis. Encycl. Smart Mater. 2020, 2, 578–589. [Google Scholar]

- Das, S.; Dhara, S. Chemical Solution Synthesis for Materials Design and Thin Film Device Applications; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Estrada-Flores, S.; Martínez-Luévanos, A.; Perez-Berumen, C.M.; García-Cerda, L.A.; Flores-Guia, T.E. Relationship between morphology, porosity, and the photocatalytic activity of TiO2 obtained by sol–gel method assisted with ionic and nonionic surfactants. Boletín De La Soc. Española De Cerámica Y Vidr. 2020, 59, 209–218. [Google Scholar] [CrossRef]

- Shymanovska, V.; Khalyavka, T.; Manuilov, E.; Gavrilko, T.; Aho, A.; Naumov, V.; Shcherban, N. Effect of surface doping of TiO2 powders with Fe ions on the structural, optical and photocatalytic properties of anatase and rutile. J. Phys. Chem. Solids 2021, 160, 110308. [Google Scholar] [CrossRef]

- Xu, J.-C.; Shi, Y.-L.; Huang, J.-E.; Wang, B.; Li, H.-L. Doping metal ions only onto the catalyst surface. J. Mol. Catal. A Chem. 2004, 219, 351–355. [Google Scholar] [CrossRef]

- Sahoo, C.; Gupta, A.K.; Pillai, I.M.S. Photocatalytic degradation of methylene blue dye from aqueous solution using silver ion-doped TiO2 and its application to the degradation of real textile wastewater. J. Environ. Sci. Health Part A 2012, 47, 1428–1438. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Song, X.; Jiang, S.; Wei, C. Enhanced photocatalytic activity of Pt-doped TiO2 for NOx oxidation both under UV and visible light irradiation: A synergistic effect of lattice Pt4+ and surface PtO. Chem. Eng. J. 2015, 274, 102–112. [Google Scholar] [CrossRef]

- Zhao, Y.; Nakamura, R.; Kamiya, K.; Nakanishi, S.; Hashimoto, K. Nitrogen-doped carbon nanomaterials as non-metal electrocatalysts for water oxidation. Nat. Commun. 2013, 4, 2390. [Google Scholar] [CrossRef]

- Saleh, T.A. Polymer Hybrid Materials and Nanocomposites: Fundamentals and Applications; William Andrew: Oxford, UK, 2021. [Google Scholar]

- Hamal, D.B.; Klabunde, K.J. Synthesis, characterization, and visible light activity of new nanoparticle photocatalysts based on silver, carbon, and sulfur-doped TiO2. J. Colloid Interface Sci. 2007, 311, 514–522. [Google Scholar] [CrossRef]

- Barakat, M.; Tseng, J.; Huang, C. Hydrogen peroxide-assisted photocatalytic oxidation of phenolic compounds. Appl. Catal. B Environ. 2005, 59, 99–104. [Google Scholar] [CrossRef]

- Ghasemi, Z.; Younesi, H.; Zinatizadeh, A.A. Preparation, characterization and photocatalytic application of TiO2/Fe-ZSM-5 nanocomposite for the treatment of petroleum refinery wastewater: Optimization of process parameters by response surface methodology. Chemosphere 2016, 159, 552–564. [Google Scholar] [CrossRef]

- Widayat, W.; Annisa, A.N. Synthesis and characterization of ZSM-5 catalyst at different temperatures. IOP Conf. Ser. Mater. Sci. Eng. 2017, 214, 012032. [Google Scholar] [CrossRef]

- Aljuboury, D.A.D.A.; Palaniandy, P.; Abdul Aziz, H.B.; Feroz, S.; Abu Amr, S.S. Evaluating photo-degradation of COD and TOC in petroleum refinery wastewater by using TiO2/ZnO photo-catalyst. Water Sci. Technol. 2016, 74, 1312–1325. [Google Scholar] [CrossRef]

- Fernandes, A.; Makoś, P.; Wang, Z.; Boczkaj, G. Synergistic effect of TiO2 photocatalytic advanced oxidation processes in the treatment of refinery effluents. Chem. Eng. J. 2019, 391, 123488. [Google Scholar] [CrossRef]

- Delnavaz, M.; Bos’hagh, M.A. Photocatalytic treatment of real oil refinery wastewater using TiO2/Ag-doped nanoparticles. Sharif J. Civ. Eng. 2021, 37, 121–129. [Google Scholar]

- Tetteh, E.K.; Obotey Ezugbe, E.; Rathilal, S.; Asante-Sackey, D. Removal of COD and SO42− from oil refinery wastewater using a photo-catalytic system—Comparing TiO2 and zeolite efficiencies. Water 2020, 12, 214. [Google Scholar] [CrossRef]

- Mohammed, S.A.; Al-Azawiey, S.S.; Ali, A.H. Treatment of Organic Compounds Resulting from Oil Refineries under Solar Light and Reuse it for Industrial Purpose. Muthanna J. Eng. Technol. 2021, 9, 20–24. [Google Scholar] [CrossRef]

- Daher, E.; Francis, E.; Hamd, W. Photocatalytic degradation of phenolic effluents in petroleum refineries. Int. J. E-Learn. Educ. Technol. Digit. Media. 2019, 5, 22–29. [Google Scholar] [CrossRef]

- Tetteh, E.K.; Rathilal, S.; Naidoo, D.B. Photocatalytic degradation of oily waste and phenol from a local South Africa oil refinery wastewater using response methodology. Sci. Rep. 2020, 10, 8850. [Google Scholar] [CrossRef]

- Ramachandran, B.; Sushma, G.; Rani, P.Y. Phenol Waste Water Treatment Using Solar Photo Catalytic Treatment in Industry. Turk. J. Comput. Math. Educ. 2021, 12, 826–834. [Google Scholar]

- Aljuboury, D.A.D.A.; Shaik, F. Optimization of the petroleum wastewater treatment process using TiO2/Zn photocatalyst. S. Afr. J. Chem. Eng. 2021, 38, 61–69. [Google Scholar] [CrossRef]

- Huang, Y.; Kong, M.; Coffin, S.; Cochran, K.H.; Westerman, D.C.; Schlenk, D.; Richardson, S.D.; Lei, L.; Dionysiou, D.D. Degradation of contaminants of emerging concern by UV/H2O2 for water reuse: Kinetics, mechanisms, and cytotoxicity analysis. Water Res. 2020, 174, 115587. [Google Scholar] [CrossRef]

- Dhivakar, V.; Rajan, T. BTEX compounds removal from waste water by using UV&UV/H2O2 process. Int. J. Recent Eng. Sci. 2018, 5, 22–25. [Google Scholar]

- Jafarinejad, S.; Jiang, S.C. Current technologies and future directions for treating petroleum refineries and petrochemical plants (PRPP) wastewaters. J. Environ. Chem. Eng. 2019, 7, 103326. [Google Scholar] [CrossRef]

- Oller, I.; Malato, S.; Sánchez Pérez, J.A. Combination of advanced oxidation processes and biological treatments for wastewater decontamination—A review. Sci. Total Environ. 2011, 409, 4141–4166. [Google Scholar] [CrossRef] [PubMed]

- Obuebite, A.A.; Okwonna, O.O. Refinery effluent water treatment: An integrated approach. World J. Adv. Res. Rev. 2023, 18, 57–62. [Google Scholar] [CrossRef]

- Keramati, M.; Ayati, B. Petroleum wastewater treatment using a combination of electrocoagulation and photocatalytic process with immobilized ZnO nanoparticles on concrete surface. Process Saf. Environ. Prot. 2019, 126, 356–365. [Google Scholar] [CrossRef]

- Mokhtari, H.A.; Mirbagheri, S.A.; Dehkordi, N.R. Performance, evaluation, and modelling of an integrated petroleum refinery wastewater treatment system using multi-layer perceptron neural networks. Desalination Water Treat. 2021, 212, 31–42. [Google Scholar] [CrossRef]

| Experimental Conditions | ||||||||

|---|---|---|---|---|---|---|---|---|

| S/No. | Adsorbent | pH | Dosage | Temp. (°C) | Time (Min) | Pollutants Removed | Removal Efficiency (%) | Reference |

| 1 | Activated carbon (AC), natural clay (NC) and sawdust (SD) | 7 | NC 18.96 mg/g, AC 16.25 mg/g and SD 14.11 mg/g | NR | 100 | Colour | 83.1 | [83] |

| - | - | COD | 67.2 | |||||

| 2 | Activated carbon fixed-bed column | 5.7 | 80% Packing | 25 ± 2 | 73 | COD | 96.7 | [84] |

| 3 | Synthesized nanorods ZnO/SiO2 via sol-gel | - | - | Pb2+ | 85.06 | [85] | ||

| - | - | Cd2+ | 84.12 | |||||

| 4 | Functionalized mesoporous material with amine groups (NH2-MCM-41) | 7 | 0.4 g/L | - | 50 | PAHs | 85.7 | [86] |

| 5 | ZnO/Fe3O4 nanocomposite | NR | 0.08 g | 30 | 900 | Cu2+ | 92.99 | [87] |

| - | - | Cr6+ | 77.60 | |||||

| 6 | Date pit-activated carbon (DPAC) | - | - | COD | 95.0 | [89] | ||

| 8 | Wooden activated carbon | 8–9 | 2 g/L | - | - | BOD | 95.00 | [88] |

| - | - | TOC | 88.00 | |||||

| - | - | COD | 68.67 | |||||

| 9 | Graphene oxide nanocomposites with Cadmium oxide (CdO) | 5 | 1.3 g/L | - | - | Cr6+ | 98 | [89] |

| S/No. | Membrane | Pollutants Removed | Removal Efficiency (%) | Reference |

|---|---|---|---|---|

| 1 | Polyether sulfone (PES) membrane consisting of zinc oxide (ZnO) nanoparticles | TDS | 18.6 | [61] |

| COD | 16.7 | |||

| Ammonia | 87.1 | |||

| 2 | Micellar-enhanced ultrafiltration (MEUF) | Nickel | 96 | [45] |

| Lead | 95 | |||

| Cadmium | 92 | |||

| Chromium | 86 | |||

| 3 | Polysulfone zinc oxide (ZnO) nanoparticles to PSf membrane | TDS | 70.21 | [64] |

| COD | 74.68 | |||

| 4 | Polysulfone-nano TiO2 hybrid membrane | TDS | 77% | [108] |

| COD | 77.2 | |||

| Phenols | 78.5 | |||

| 5 | HF-MBR | COD | 82 | [63] |

| BOD | 89 | |||

| TSS | 99 | |||

| 6 | MF GRM and UF GRM polymeric membranes | DOC | 99 | [104] |

| 7 | Polyvinyl chloride–titanium oxide (PVC–TiO2-NPs) membranes | COD | 79.6 | |

| 8 | Polyacrylonitrile-graft-poly (ethylene oxide) UF membranes | COD | 96% | [107] |

| 9 | A sheet nano-porous membrane (PAN) | TSS | 100 | [106] |

| TDS | 44.4 | |||

| Oil/grease | 99.9 | |||

| COD | 80.3 | |||

| BOD | 76.9 |

| Experimental Conditions | ||||||||

|---|---|---|---|---|---|---|---|---|

| S/No. | Precipitant | pH | Dosage | Temp. (°C) | Time (Min) | Pollutants Removed | Removal Efficiency (%) | Reference |

| 1 | BaCl2 and Al (OH)3 | 7 | 0.36 g/L | NR | 15 | Sulfate ion | [109] | |

| 2 | Ca(OH)2 and Fe2+ ions | 5 | 40 mg/L | NR | NR | Sulfide | 97.5 | [110] |

| COD | 65 | |||||||

| 3 | Ca(OH)2 derived from eggshell | NR | 3 g/L | NR | NR | Cd2+ | 99.99 | [111] |

| Pb2+ | 99.63 | |||||||

| S/No. | Biological Process/Reactor | COD (%) | TOC (%) | Phenols (%) | TSS (%) | Reference |

|---|---|---|---|---|---|---|

| 1 | Aerobic biological treatment | 78 | 94 | [72] | ||

| 3 | Granular sludge bed bioreactor and aerobic-activated sludge treatment (GSB-BR) | 85.6 | NR | NR | NR | [120] |

| 4 | Spouted bed bioreactor (SBBR) | 96 | NR | 100 | NR | [39] |

| 5 | Aerobic submerged fixed-bed reactor (ASFBR) | 91 | NR | 92 | [56] | |

| 6 | Membrane bioreactor (MBBR) | 80 | NR | NR | NR | [121] |

| 7 | Up-flow anaerobic sludge blanket (UASB) reactor biological aerated filter (BAF) | 90.2 | NR | NR | NR | [122] |

| 8 | Microbial fuel cells (MFCs) | 63.1 | NR | NR | NR | [123] |

| 9 | Multi-stage biological reactors (MSBR) | 98% | NR | NR | NR | [124] |

| 10 | Rotating Biological Contactor (RBC) | 87 | 55 | 99 | 85 | [125] |

| Removal Efficiency | |||||

|---|---|---|---|---|---|

| Electrodes/Reactor | Process | COD (%) | Phenols (%) | Oil (%) | Reference |

| Porous graphite electrodes. | EFen | 95.9 | - | [133] | |

| Electrochemical reactor with Ti-IrO2 mesh anode | EF | - | - | 90 | [141] |

| Aluminum and iron cathode electrodes from scrap metals | EC | 91.18 | 91.46 | - | [143] |

| Fixed-bed electrochemical reactor | EC | - | 100 | - | [144] |

| Aluminium electrodes in an electrolytic reactor | EC | 83.5 | - | - | [145] |

| Ruthenium oxide-coated titanium and stainless steel | EO | 92 | - | - | [38] |

| Lead oxide reinforced on tantalum (Ta/PbO2) and boron-doped diamond (BDD) anodes | EO | 96 | - | - | [147] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lawan, M.S.; Kumar, R.; Rashid, J.; Barakat, M.A.E.-F. Recent Advancements in the Treatment of Petroleum Refinery Wastewater. Water 2023, 15, 3676. https://doi.org/10.3390/w15203676

Lawan MS, Kumar R, Rashid J, Barakat MAE-F. Recent Advancements in the Treatment of Petroleum Refinery Wastewater. Water. 2023; 15(20):3676. https://doi.org/10.3390/w15203676

Chicago/Turabian StyleLawan, Muhammad Shettima, Rajeev Kumar, Jamshaid Rashid, and Mohamed Abou El-Fetouh Barakat. 2023. "Recent Advancements in the Treatment of Petroleum Refinery Wastewater" Water 15, no. 20: 3676. https://doi.org/10.3390/w15203676

APA StyleLawan, M. S., Kumar, R., Rashid, J., & Barakat, M. A. E.-F. (2023). Recent Advancements in the Treatment of Petroleum Refinery Wastewater. Water, 15(20), 3676. https://doi.org/10.3390/w15203676