Water Disappearance and Manure Production at Growing–Finishing Commercial Pig Farms in Brazil—A Simplified Model Approach

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Design

2.2. Water Disappearance and Manure Production

2.3. Simplified Mathematic Model Approach

2.4. Statistical Analyses

3. Results and Discussion

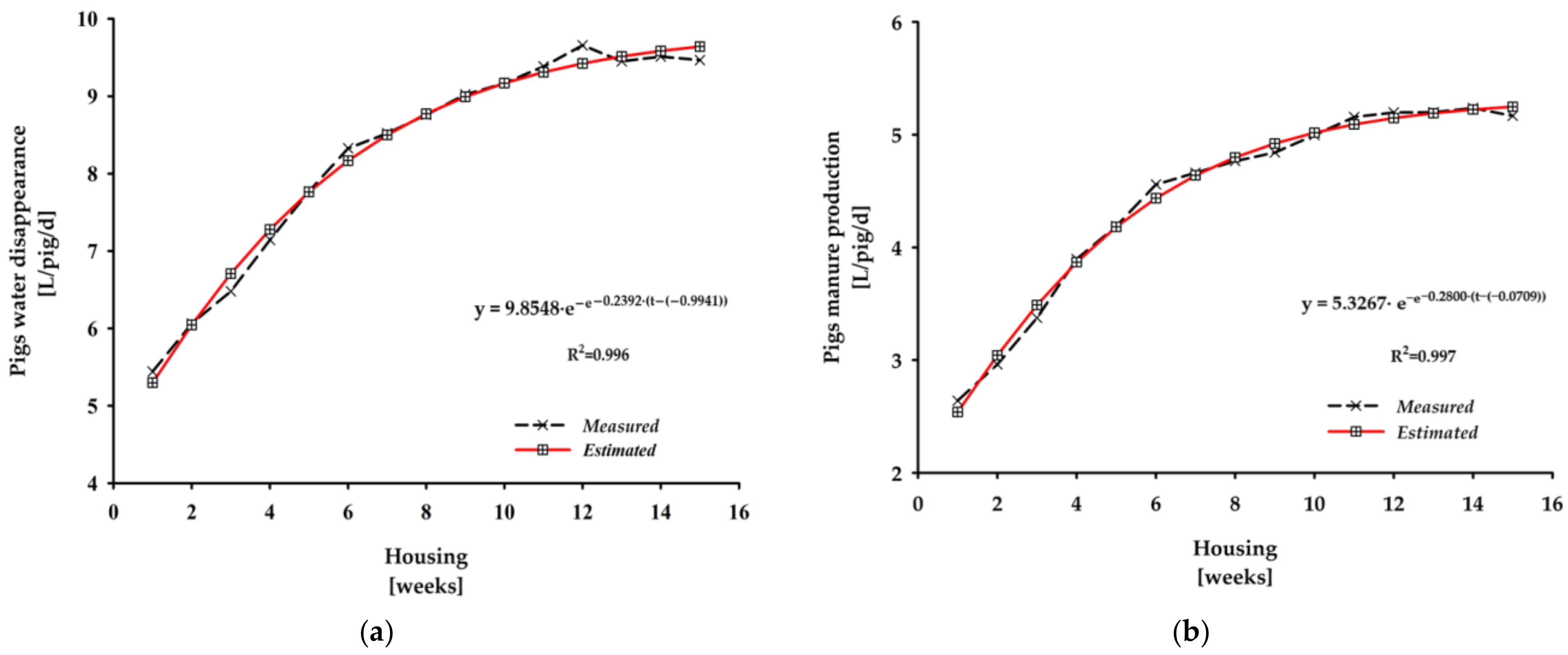

3.1. Gompertz Non-Linear Model Adjusted to the Weekly Means of Water Disappearance and Manure Production, as a Function of the pigs’ Housing Period

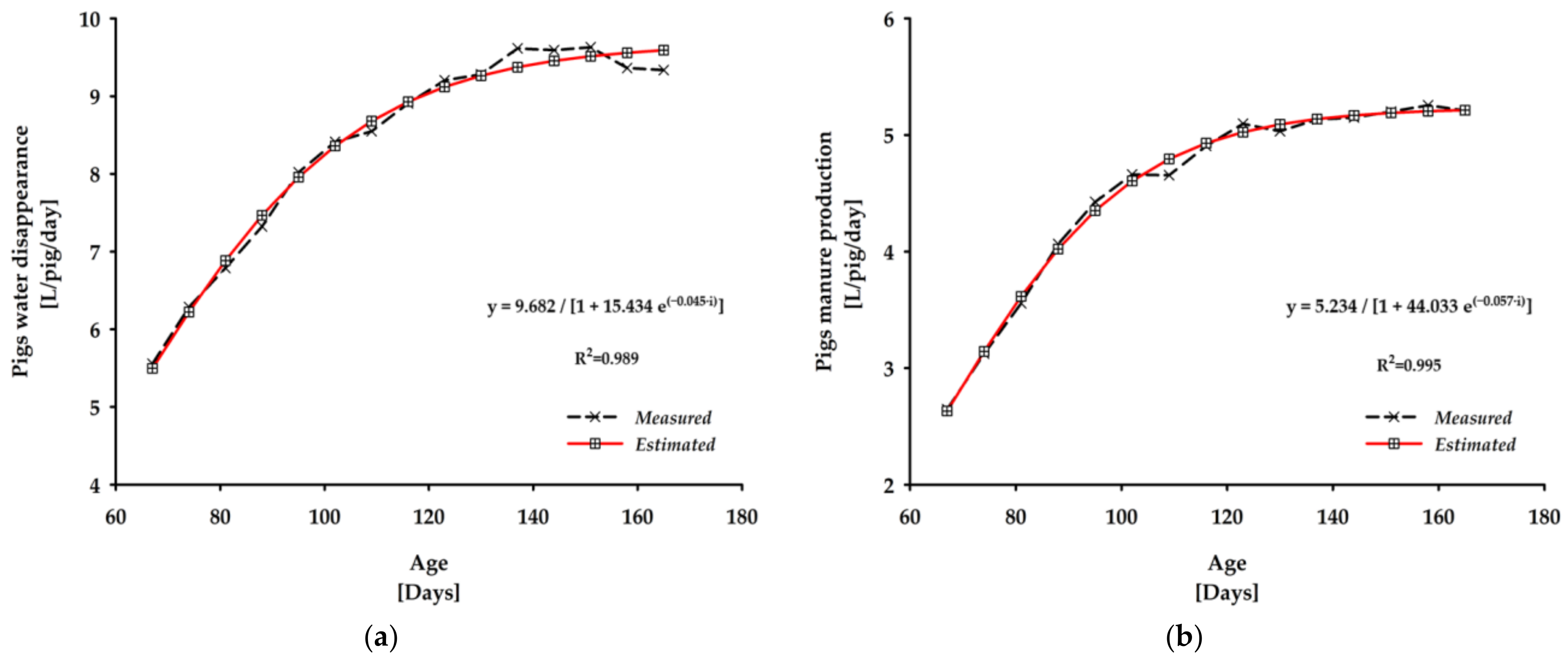

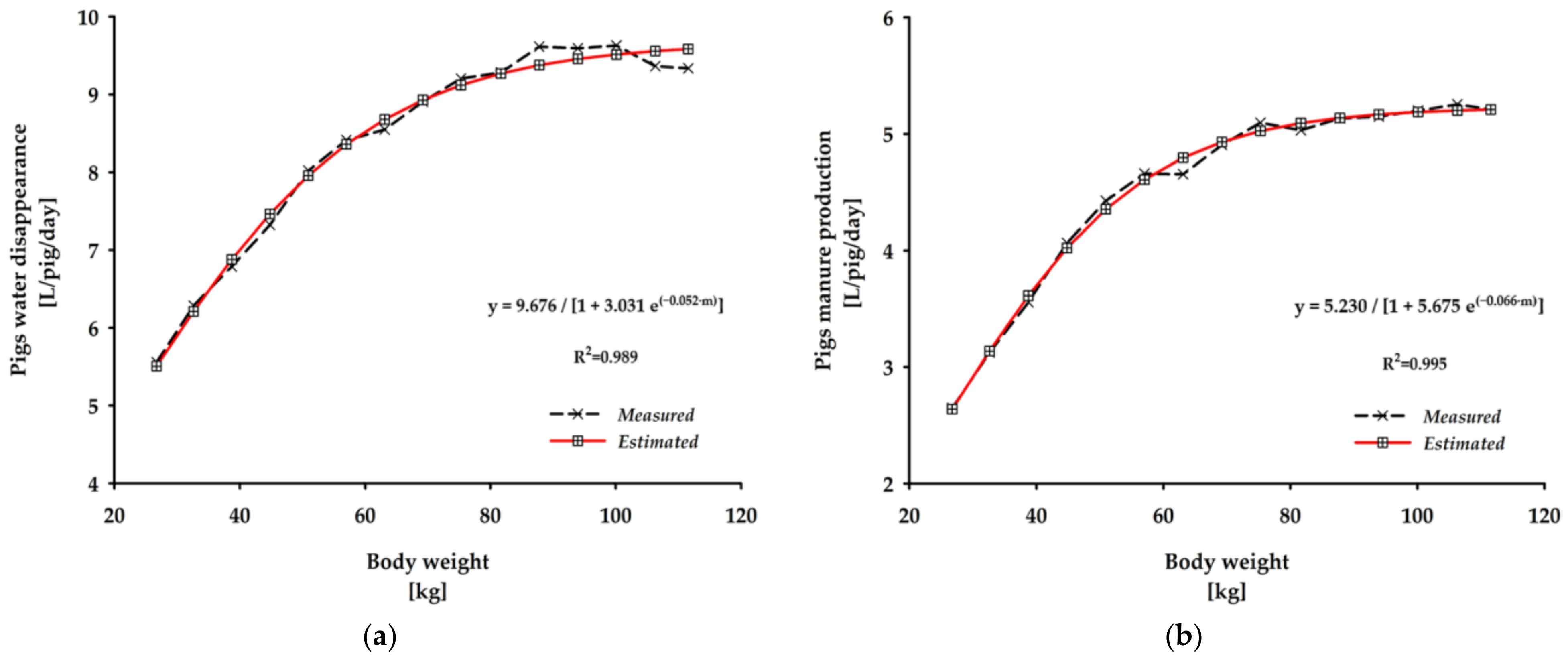

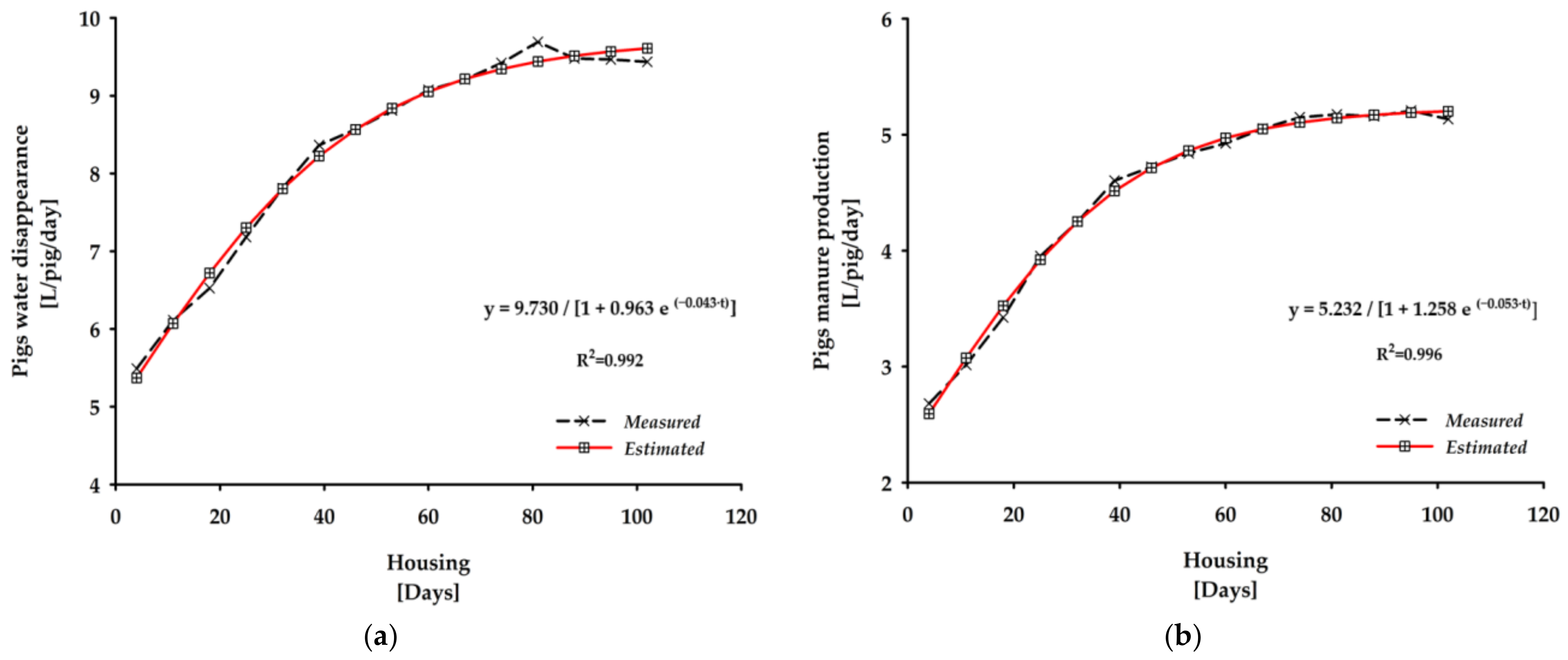

3.2. Different Non-Linear Models Adjusted to the Weekly Means of Water Disappearance and Manure Production in Commercial Pig Farms According to Pigs’ Age

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tavares, J.M.R. Modelagem do Consumo de Água, Produção de Chorumes e Emissão de Gases de Efeito Estufa e Amônia na Suinocultura (in English: Modeling of Water Disappearance, Manure Production, Greenhouse Gases Emissions and Ammonia in Pig Farms). Ph.D. Thesis, Federal University of Santa Catarina, Florianópolis, Brazil, 2016. Available online: https://repositorio.ufsc.br/xmlui/bitstream/handle/123456789/175847/345551.pdf (accessed on 30 November 2022).

- Bjørndal, T.; Herrero, I.; Newman, A.; Romero, C.; Weintraub, A. Operations research in the natural resource industry. Int. Trans. Oper. Res. 2012, 19, 39–62. [Google Scholar] [CrossRef]

- Mellaku, M.T.; Sebsibe, A.S. Potential of mathematical model-based decision making to promote sustainable performance of agriculture in developing countries: A review article. Heliyon 2022, 8, e08968. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Z.; Martínez, J.F.; Beltran, V.; Martínez, N.L. Decision support systems for agriculture 4.0: Survey and challenges. Comput. Electron Agric. 2020, 170, 105256. [Google Scholar] [CrossRef]

- Dumas, A.; Dijkstra, J.; France, J. Mathematical modelling in animal nutrition: A centenary review. J. Agr. Sci. 2008, 146, 123–142. [Google Scholar] [CrossRef] [Green Version]

- Van Milgen, J.; Valancogne, A.; Dubois, S.; Dourmad, J.-V.; Sève, B.; Noblet, J. InraPorc: A model and decision support tool for the nutrition of growing pigs. Anim. Feed Sci. Tech. 2008, 143, 387–405. [Google Scholar] [CrossRef]

- Pineiro, C.; Morales, J.; Rodriguez, M.; Aparicio, M.; Manzanilla, E.G.; Koketsu, Y. Big (pig) data and the internet of the swine things: A new paradigm in the industry. Anim. Front. 2019, 9, 6–15. [Google Scholar] [CrossRef]

- Revilla, M.; Guillaume, L.; Loic, F.-G.; Rafael, M.-T.; Friggens, N.C. Quantifying growth perturbations over the fattening period in swine via mathematical modelling. Peer Community J. 2020, 2, 16. [Google Scholar] [CrossRef]

- Whittemore, C.; Tullis, B.J.; Emmans, G. Protein growth in pigs. Anim. Prod. 1998, 46, 437–445. [Google Scholar] [CrossRef]

- Mischan, M.M.; Pinho, S.Z. Modelos Não Lineares: Funções Assintóticas de Crescimento (in english: Nonlinear Models: Asymptotic Growth Functions), 1st ed.; Cultura Acadêmica: São Paulo, Brazil, 2015. [Google Scholar]

- Fitzhugh, H.A., Jr. Analysis of growth curves and strategies for altering their shape. J. Anim. Sci. 1976, 42, 1036–1051. [Google Scholar] [CrossRef] [Green Version]

- Paro de Paz, C.C.; Packer, I.U.; Freitas, A.R.; Tambasco-Talhari, D.; Reginato, L.C.A.; Alencar, M.M.; Cruz, G.M. Ajuste de modelos não lineares em estudos de associação entre polimorfismos genéticos e crescimento em bovinos de corte (in English: Adjustment of nonlinear models in study of association between genetic polymorphisms and growth in beef cattle). Rev. Bras. Zootecn. 2004, 33, 1416–1425. [Google Scholar] [CrossRef]

- Oliveira, H.N.; Lôbo, R.B.; Pereira, C.S. Comparação de modelos não lineares para descrever o crescimento de fêmeas da raça Guzerá (in English: Comparison of non-linear models for describing growth of Guzerat beef cattle females). Pesqui Agropecu Bras. 2000, 35, 1843–1851. [Google Scholar] [CrossRef] [Green Version]

- Tavares, J.M.R.; Belli Filho, P.; Coldebella, A.; Oliveira, P.A.V. The water disappearance and manure production at commercial growing-finishing pig farms. Livest Sci. 2014, 169, 146–154. [Google Scholar] [CrossRef]

- Brody, S. Bioenergetics and Growth, 1st ed.; Reinhold Publishing Corporation: New York, NY, USA, 1945. [Google Scholar]

- Laird, A.K. Dynamics of relative growth. Growth 1965, 29, 249–263. [Google Scholar]

- Nelder, J.A. The fitting of a generalization of the logistic curve. Biometrics 1961, 17, 89–110. [Google Scholar] [CrossRef]

- Richards, F.J. A flexible growth function for empirical use. J. Exp. Bot. 1959, 10, 290–300. [Google Scholar] [CrossRef]

- Von Bertalanffy, L. Quantitative laws in metabolism and growth. Q. Rev. Biol. 1975, 32, 217–230. Available online: https://www.jstor.org/stable/2815257 (accessed on 30 November 2022). [CrossRef]

- National Research Council (NRC). Nutrient Requirements of Swine, 10th ed.; National Academy Press: Washington, DC, USA, 1998. [Google Scholar]

- Rostagno, H.S.; Albino, L.F.T.; Donzele, J.L.; Gomes, P.C.; Oliveira, R.F.; Lopes, D.C.; Ferreira, A.S.; Barreto, S.L.T.; Euclides, R.F. Tabelas Brasileiras Para Aves e Suínos: Composição de Alimentos e Exigências Nutricionais (In English: Brazilian Tables for Poultry and Swine: Feed Composition and Nutritional Requirements), 3rd ed.; Federal University of Viçosa: Viçosa, Brazil, 2011. [Google Scholar]

- Brumm, M.C.; Dahlquist, J.M.; Heemstra, J.M. Impact of feeders and drinker devices on pig performance, water use and manure volume. Swine Health Prod. 2000, 8, 51–57. [Google Scholar]

- Li, Y.Z.; Chénard, L.; Lemay, S.; Gonyou, H. Water intake and wastage at nipple drinkers by growing-finishing pigs. J. Anim. Sci. 2005, 83, 1413–1422. [Google Scholar] [CrossRef] [Green Version]

- Sas Institute Inc. System for Microsoft Windows, Release 9.4 M7; Sas Institute Inc.: Cary, NC, USA, 2020.

- Zhuang, X.; Bi, M.; Guo, J.; Wu, S.; Zhang, T. Development of an early warning algorithm to detect sick broilers. Comput. Electron Agri. 2018, 144, 102–113. [Google Scholar] [CrossRef]

- Oczak, M.; Ismayilova, G.; Costa, A.; Viazzi, S.; Sonoda, L.T.; Fels, M.; Bahr, C.; Hartung, J.; Guarino, M.; Berckmans, D.; et al. Analysis of aggressive behaviours of pigs by automatic video recordings. Comput. Electron. Agri. 2013, 99, 209–217. [Google Scholar] [CrossRef]

- Brown-Brandl, T.; Rohrer, G.; Eigenberg, R. Analysis of feeding behavior of group housed growing-finishing pigs. Comput. Electron Agri. 2013, 96, 246–252. [Google Scholar] [CrossRef]

| Non-Linear Models † | Parameters | AIC | R2 | Error ‡ | ||

|---|---|---|---|---|---|---|

| a | b | c | ||||

| 1 | 9.871 | 3.487 | 0.031 | −4.33 | 0.984 | 0.13 |

| 2 | 9.756 | 0.038 | 52.599 | −7.41 | 0.987 | 0.12 |

| 3 | 9.682 | 15.434 | 0.045 | −10.00 | 0.989 | 0.11 |

| 4 | 9.759 | 0.007 | 0.038 | −7.40 | 0.987 | 0.12 |

| 5 | 9.792 | 1.888 | 0.035 | −6.42 | 0.986 | 0.13 |

| Non-Linear Models † | Parameters | AIC | R2 | Error ‡ | ||

|---|---|---|---|---|---|---|

| a | b | c | ||||

| 1 | 9.860 | 1.158 | 0.035 | −4.87 | 0.985 | 0.13 |

| 2 | 9.751 | 0.044 | 14.181 | −7.88 | 0.988 | 0.12 |

| 3 | 9.676 | 3.031 | 0.052 | −10.38 | 0.989 | 0.11 |

| 4 | 9.751 | 0.002 | 0.044 | −7.88 | 0.988 | 0.12 |

| 5 | 9.782 | 0.527 | 0.041 | −6.92 | 0.987 | 0.12 |

| Non-Linear Models † | Parameters | AIC | R2 | Error ‡ | ||

|---|---|---|---|---|---|---|

| a | b | c | ||||

| 1 | 9.988 | 0.524 | 0.028 | −6.04 | 0.987 | 0.12 |

| 2 | 9.834 | 0.035 | −10.01 | −10.24 | 0.990 | 0.10 |

| 3 | 9.730 | 0.963 | 0.043 | −14.16 | 0.992 | 0.09 |

| 4 | 9.834 | 0.001 | 0.035 | −10.24 | 0.813 | 0.52 |

| 5 | 9.878 | 0.212 | 0.033 | −8.86 | 0.989 | 0.11 |

| Non-Linear Models † | Parameters | AIC | R2 | Error ‡ | ||

|---|---|---|---|---|---|---|

| a | b | c | ||||

| 1 | 5.339 | 6.115 | 0.037 | −30.54 | 0.993 | 0.05 |

| 2 | 5.276 | 0.047 | 59.611 | −35.26 | 0.995 | 0.05 |

| 3 | 5.234 | 44.033 | 0.057 | −36.35 | 0.995 | 0.04 |

| 4 | 5.276 | 0.016 | 0.047 | −35.26 | 0.995 | 0.05 |

| 5 | 5.294 | 3.860 | 0.043 | −34.03 | 0.994 | 0.05 |

| Non-Linear Models † | Parameters | AIC | R2 | Error ‡ | ||

|---|---|---|---|---|---|---|

| a | b | c | ||||

| 1 | 5.332 | 1.626 | 0.043 | −31.40 | 0.993 | 0.05 |

| 2 | 5.271 | 0.054 | 20,279 | −35.81 | 0.995 | 0.04 |

| 3 | 5.230 | 5.675 | 0.066 | −36.44 | 0.995 | 0.04 |

| 4 | 5.271 | 0.003 | 0.054 | −35.81 | 0.995 | 0,04 |

| 5 | 5.288 | 0.810 | 0.050 | −34.71 | 0.995 | 0.05 |

| Non-Linear Models † | Parameters | AIC | R2 | Error ‡ | ||

|---|---|---|---|---|---|---|

| a | b | c | ||||

| 1 | 5.361 | 0.602 | 0.033 | −24.36 | 0.990 | 0.06 |

| 2 | 5.283 | 0.043 | −3.526 | −31.53 | 0.994 | 0.05 |

| 3 | 5.232 | 1.258 | 0.053 | −37.83 | 0.996 | 0.04 |

| 4 | 5.283 | 0.001 | 0.043 | −31.52 | 0.994 | 0.05 |

| 5 | 5.305 | 0.254 | 0.040 | −29.15 | 0.993 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tavares, J.M.R.; Lopes, J.d.C.; Belli Filho, P.; Coldebella, A.; Oliveira, P.A.V.d. Water Disappearance and Manure Production at Growing–Finishing Commercial Pig Farms in Brazil—A Simplified Model Approach. Water 2023, 15, 278. https://doi.org/10.3390/w15020278

Tavares JMR, Lopes JdC, Belli Filho P, Coldebella A, Oliveira PAVd. Water Disappearance and Manure Production at Growing–Finishing Commercial Pig Farms in Brazil—A Simplified Model Approach. Water. 2023; 15(2):278. https://doi.org/10.3390/w15020278

Chicago/Turabian StyleTavares, Jorge Manuel Rodrigues, Janice da Conceição Lopes, Paulo Belli Filho, Arlei Coldebella, and Paulo Armando Victória de Oliveira. 2023. "Water Disappearance and Manure Production at Growing–Finishing Commercial Pig Farms in Brazil—A Simplified Model Approach" Water 15, no. 2: 278. https://doi.org/10.3390/w15020278