Alternatives for Fresh Water in Cement-Based Materials: A Review

Abstract

1. Introduction

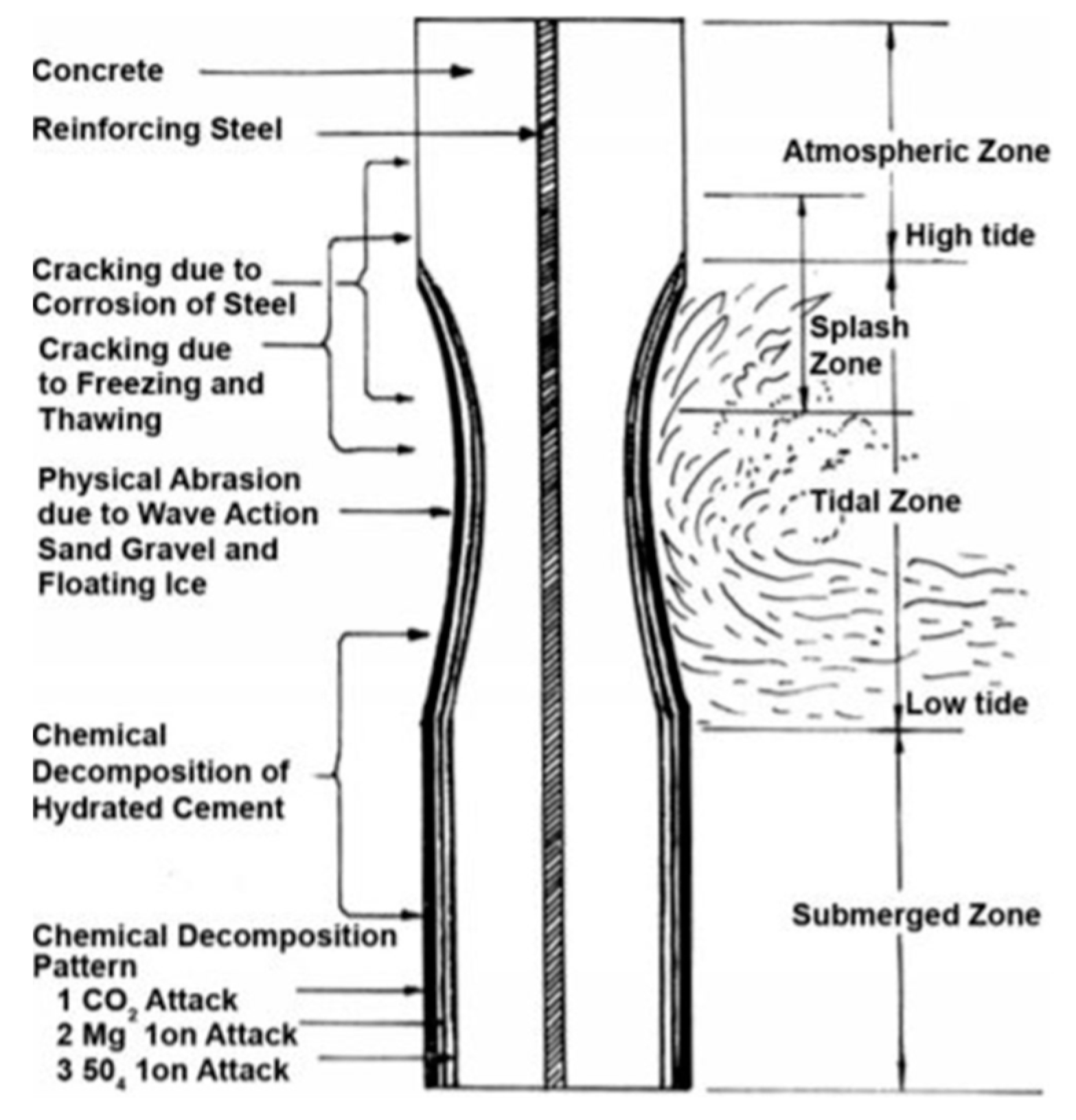

2. Using Seawater in CBMs

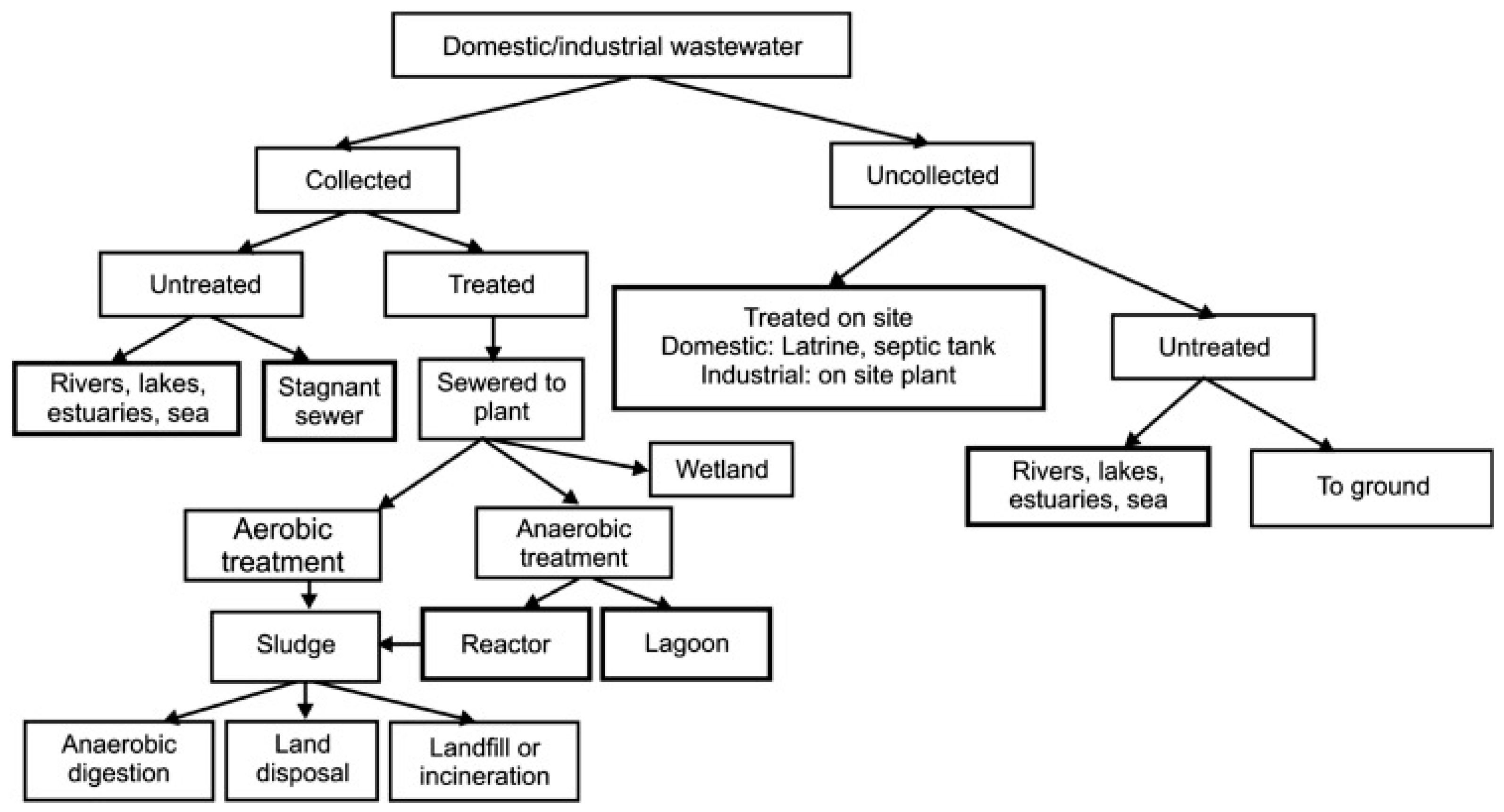

3. Using Treated Industrial Wastewater in CBMs

4. Using Treated Sewage Wastewater in CBMs

5. Using Carwash Service Station Wastewater in CBMs

6. Using Wastewater from Ready-Mix Concrete Plants in CBMs

7. Using Wastewater from the Stone-Cutting Industry in CBMs

8. Conclusions

- Seawater does not considerably affect the air content, density, chloride ingression, pore structure, permeability, and carbonation of CBMs; however, it reduces the setting time.

- Industrial wastewater can be used (up to 100%) as a replacement for normal water in CBMs after treatment. However, the compressive and tensile strengths can be decreased by up to 15 and 7% by using it as a full replacement for normal water, respectively, and by postponing the setting time. Industrial wastewater decreases workability but has a negligible effect on the air content of fresh concrete.

- The secondary-treated domestic sewerage wastewater is suitable for producing cement mortars and concretes in accordance with the allowable limits of mixing water for concrete compared with primary-treated domestic sewerage wastewater.

- The use of carwash service wastewater in CBMs may have adverse effects on their mechanical and durability properties, such as compressive strength, corrosion, chloride penetration, acid attack, sulphate attack, and water absorption, because they may contain many pollutants. Carwash service wastewater should be used partially as a replacement for potable water in CBMs for its safe usage.

- The use of raw waste wash water from a ready-mix concrete plant reduces the compressive strength of concrete by about 10%, and the use of recycled ready-mixed concrete wastewater for mortars and concrete does not have harmful effects on their properties. However, it reduces the setting times.

- Wastewater from the stone-cutting industry used in concrete production reduces the slump value by about 58% and increases its compressive and flexural strengths by 21 and 18% at 28 days, respectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Aïtcin, P.C. 5—Water and its role on concrete performance. In Science and Technology of Concrete Admixtures; Aïtcin, P.-C., Flatt, R.J., Eds.; Woodhead Publishing: Sawston, CA, USA, 2016; pp. 75–86. [Google Scholar]

- Powers, T.C. The Nature of Concrete; Mielenz, R., Bloem, D., Gregg, L., Gregg, L., Kesler, C., Price, W., Eds.; ASTM International: West Conshohocken, PA, USA, 1966; pp. 61–72. [Google Scholar]

- More, A.; Ghodake, R.; Nimbalkar, H.; Chandake, P.; Maniyar, S.; Narute, Y. Reuse of treated domestic wastewater in concrete—A sustainable approach. Indian J. Appl. Res. 2014, 4, 182–184. [Google Scholar] [CrossRef]

- Miller, S.A.; Horvath, A.; Monteiro, P.J.M. Impacts of booming concrete production on water resources worldwide. Nat. Sustain. 2018, 1, 69–76. [Google Scholar] [CrossRef]

- Asadollahfardi, G.; Mahdavi, A.R. The feasibility of using treated industrial wastewater to produce concrete. Struct. Concr. 2019, 20, 123–132. [Google Scholar] [CrossRef]

- Nikbin, I.M.; Beygi, M.H.A.; Kazemi, M.T.; Vaseghi Amiri, J.; Rabbanifar, S.; Rahmani, E.; Rahimi, S. A comprehensive investigation into the effect of water to cement ratio and powder content on mechanical properties of self-compacting concrete. Constr. Build. Mater. 2014, 57, 69–80. [Google Scholar] [CrossRef]

- Zhang, J.; Fan, T.; Ma, H.; Li, Z. Monitoring setting and hardening of concrete by active acoustic method: Effects of water-to-cement ratio and pozzolanic materials. Constr. Build. Mater. 2015, 88, 118–125. [Google Scholar] [CrossRef]

- Bertuzzi, G.; Ghisi, E. Potential for Potable Water Savings Due to Rainwater Use in a Precast Concrete Factory. Water 2021, 13, 448. [Google Scholar] [CrossRef]

- El-Nawawy, O.A.; Ahmad, S. Use of treated effluent in concrete mixing in an arid climate. Cem. Concr. Compos. 1991, 13, 137–141. [Google Scholar] [CrossRef]

- Reddy Babu, G.; Madhusudana Reddy, B.; Venkata Ramana, N. Quality of mixing water in cement concrete “A review”. Mater. Today Proc. 2018, 5, 1313–1320. [Google Scholar] [CrossRef]

- Saravanakumar, P.; Dhinakaran, G. Effect of Acidic Water on Strength, Durability and Corrosion of Concrete. J. Civ. Eng. Res. Pract. 2010, 7, 1–10. [Google Scholar] [CrossRef]

- Ramana Reddy, I.; Prasad Reddy, N.; Reddy Babu, G.; Kotaiah, B.; Chiranjeevi, P. Effect of biological contaminated water on cement mortar properties. Indian Concr. J. 2006, 80, 13–19. [Google Scholar]

- Al-Saleh, S.A. Analysis of total chloride content in concrete. Case Stud. Constr. Mater. 2015, 3, 78–82. [Google Scholar] [CrossRef]

- BS 3148-1980; Method for test for water for making concrete. British Standard Institution: Loughborough, UK, 1980.

- Kucche, K.; Jamkar, S.; Sadgir, P. Quality of water for making concrete: A review of literature. Int. J. Sci. Res. Publ. 2015, 5, 1–10. [Google Scholar]

- McCoy, W.J. Chapter 43—Mixing and Curing Water for Concrete; Best, C.H., Ed.; ASTM International: West Conshohocken, PA, USA, 1978; pp. 765–773. [Google Scholar]

- Rashid, K.; Yazdanbakhsh, A.; Rehman, M.U. Sustainable selection of the concrete incorporating recycled tire aggregate to be used as medium to low strength material. J. Clean. Prod. 2019, 224, 396–410. [Google Scholar] [CrossRef]

- Mangi, S.A.; Ibrahim, M.H.W.; Jamaluddin, N.; Arshad, M.F.; Memon, F.A.; Jaya, R.P.; Shahidan, S. A review on potential use of coal bottom ash as a supplementary cementing material in sustainable concrete construction. Int. J. Integr. Eng. 2018, 10. [Google Scholar] [CrossRef]

- Lenzen, M.; Moran, D.; Bhaduri, A.; Kanemoto, K.; Bekchanov, M.; Geschke, A.; Foran, B. International trade of scarce water. Ecol. Econ. 2013, 94, 78–85. [Google Scholar] [CrossRef]

- Okello, C.; Tomasello, B.; Greggio, N.; Wambiji, N.; Antonellini, M. Impact of population growth and climate change on the freshwater resources of Lamu Island, Kenya. Water 2015, 7, 1264–1290. [Google Scholar] [CrossRef]

- Zabarenko, D. Water use rising faster than world population. Reuters Green Business News, 25 October 2011. [Google Scholar]

- Swain, A. Water wars: Fact or fiction? Futures 2001, 33, 769–781. [Google Scholar] [CrossRef]

- Tundisi, J.G. Water resources in the future: Problems and solutions. Estud. Av. 2008, 22, 7–16. [Google Scholar] [CrossRef]

- Mangi, S.A.; Makhija, A.; Raza, M.S.; Khahro, S.H.; Jhatial, A.A. A Comprehensive Review on Effects of Seawater on Engineering Properties of Concrete. Silicon 2020, 13, 4519–4526. [Google Scholar] [CrossRef]

- Hassani, M.S.; Asadollahfardi, G.; Saghravani, S.F.; Jafari, S.; Peighambarzadeh, F.S. The difference in chloride ion diffusion coefficient of concrete made with drinking water and wastewater. Constr. Build. Mater. 2020, 231, 117182. [Google Scholar] [CrossRef]

- McCarthy, L.M. Analysis of Alternative Water Sources for Use in the Manufacture of Concrete. Master’s Thesis, Queensland University of Technology, Brisbane City, Australia, 2010. [Google Scholar]

- Islam, M.M.; Islam, M.S.; Mondal, B.C.; Islam, M.R. Strength behavior of concrete using slag with cement in sea water environment. J. Civ. Eng. 2010, 38, 129–140. [Google Scholar]

- Islam, M.; Islam, M.; Mondal, B. Effect of freeze-thaw action on physical and mechanical behavior of marine concrete. J. Inst. Eng. Malays. 2010, 77, 53–64. [Google Scholar]

- Ahn, N. Effects of C3A and Mineral Admixtures on the Sulfate Attack Using ASTM C 1012. J. ASTM Int. 2005, 2, 1–20. [Google Scholar]

- Abalaka, A.; Babalaga, A. Effects of sodium chloride solutions on compressive strength development of concrete containing rice husk ash. ATBU J. Environ. Technol. 2011, 4, 33–40. [Google Scholar]

- Mangi, S.A.; Wan Ibrahim, M.H.; Jamaluddin, N.; Arshad, M.F.; Shahidan, S. Performances of concrete containing coal bottom ash with different fineness as a supplementary cementitious material exposed to seawater. Eng. Sci. Technol. Int. Journal 2019, 22, 929–938. [Google Scholar] [CrossRef]

- Xiao, J.; Qiang, C.; Nanni, A.; Zhang, K. Use of sea-sand and seawater in concrete construction: Current status and future opportunities. Constr. Build. Mater. 2017, 155, 1101–1111. [Google Scholar] [CrossRef]

- Younis, A.; Ebead, U.; Suraneni, P.; Nanni, A. Fresh and hardened properties of seawater-mixed concrete. Constr. Build. Mater. 2018, 190, 276–286. [Google Scholar] [CrossRef]

- Olutoge, F.A.; Amusan, G.M. The effect of sea water on compressive strength of concrete. Int. J. Eng. Sci. Invent. 2014, 3, 23–31. [Google Scholar]

- Osuji, S.; Nwankwo, E. Marine water effect on compressive strength of concrete: A case study of Escravos Area of Nigerian delta. Niger. J. Technol. 2015, 34, 240–244. [Google Scholar] [CrossRef]

- Abdel-Magid, T.I.; Osman, O.M.; Ibrahim, O.H.; Mohammed, R.T.; Hassan, S.O.; Bakkab, A.A.H. Influence of seawater in strengths of concrete mix design when used in mixing and curing. In Key Engineering Materials; Trans Tech Publications: Stafa-Zurich, Switzerland, 2016; pp. 382–389. [Google Scholar]

- Mohammed, T.U.; Hamada, H.; Yamaji, T. Performance of seawater-mixed concrete in the tidal environment. Cem. Concr. Res. 2004, 34, 593–601. [Google Scholar] [CrossRef]

- Guo, Q.; Chen, L.; Zhao, H.; Admilson, J.; Zhang, W. The effect of mixing and curing sea water on concrete strength at different ages. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018; p. 2004. [Google Scholar]

- Susilorini, R.; Dewi, W.; Retno, K.; Wibowo, T. The performance of early-age concrete with seawater curing. J. Coast. Dev. 2004, 8, 89–95. [Google Scholar]

- Tiwari, P.; Chandak, R.; Yadav, R. Effect of salt water on compressive strength of concrete. Int. J. Eng. Res. Appl. 2014, 4, 38–42. [Google Scholar]

- Wegian, F.M. Effect of seawater for mixing and curing on structural concrete. IES J. Part A Civ. Struct. Eng. 2010, 3, 235–243. [Google Scholar] [CrossRef]

- Park, S.S.; Kwon, S.-J.; Song, H.-W. Analysis technique for restrained shrinkage of concrete containing chlorides. Mater. Struct. 2011, 44, 475–486. [Google Scholar] [CrossRef]

- O’Neill Iqbal, P.; Ishida, T. Modeling of chloride transport coupled with enhanced moisture conductivity in concrete exposed to marine environment. Cem. Concr. Res. 2009, 39, 329–339. [Google Scholar] [CrossRef]

- Chen, Z.; Mo, L.; Song, C.; Zhang, Y. Investigation on compression properties of seawater-sea sand concrete. Adv. Concr. Constr. 2021, 12, 93–103. [Google Scholar]

- Chalee, W.; Jaturapitakkul, C.; Chindaprasirt, P. Predicting the chloride penetration of fly ash concrete in seawater. Mar. Struct. 2009, 22, 341–353. [Google Scholar] [CrossRef]

- Emmanuel, A.O.; Oladipo, F.A.; Olabode, O. Investigation of salinity effect on compressive strength of reinforced concrete. J. Sustain. Dev. 2012, 5, 74–82. [Google Scholar] [CrossRef]

- Nishida, T.; Otsuki, N.; Ohara, H.; Garba-Say, Z.M.; Nagata, T. Some considerations for applicability of seawater as mixing water in concrete. J. Mater. Civ. Eng. 2015, 27, B4014004. [Google Scholar] [CrossRef]

- Zheng, X.; Ji, T.; Easa, S.M.; Ye, Y. Evaluating feasibility of using sea water curing for green artificial reef concrete. Constr. Build. Mater. 2018, 187, 545–552. [Google Scholar] [CrossRef]

- Muralikrishna, I.V.; Manickam, V. Industrial wastewater treatment technologies, recycling, and reuse. Environ. Manag. 2017, 295–336. [Google Scholar]

- Raza, A.; Shah, S.A.R.; Kazmi, S.N.H.; Ali, R.Q.; Akhtar, H.; Fakhar, S.; Khan, F.N.; Mahmood, A. Performance evaluation of concrete developed using various types of wastewater: A step towards sustainability. Constr. Build. Mater. 2020, 262, 120608. [Google Scholar] [CrossRef]

- Meena, K.; Luhar, S. Effect of wastewater on properties of concrete. J. Build. Eng. 2019, 21, 106–112. [Google Scholar] [CrossRef]

- Al-Jabri, K.S.; Al-Saidy, A.H.; Taha, R.; Al-Kemyani, A.J. Effect of using Wastewater on the Properties of High Strength Concrete. Procedia Eng. 2011, 14, 370–376. [Google Scholar] [CrossRef]

- Varshney, H.; Khan, R.A.; Khan, I.K. Sustainable use of different wastewater in concrete construction: A review. J. Build. Eng. 2021, 41, 102411. [Google Scholar] [CrossRef]

- Demirbas, A.; Edris, G.; Alalayah, W.M. Sludge production from municipal wastewater treatment in sewage treatment plant. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 999–1006. [Google Scholar] [CrossRef]

- Crini, G.; Lichtfouse, E. Advantages and disadvantages of techniques used for wastewater treatment. Environ. Chem. Lett. 2019, 17, 145–155. [Google Scholar] [CrossRef]

- Al-Ghusain, I.; Terro, M. Use of treated wastewater for concrete mixing in Kuwait. Kuwait J. Sci. Eng. 2003, 30, 213–228. [Google Scholar]

- Cebeci, Z.; Saatci, A. Domestic sewage as mixing water in concrete. Mater. J. 1989, 86, 503–506. [Google Scholar]

- Ramkar, A.; Ansari, U. Effect of treated waste water on strength of concrete. J. Mech. Civ. Eng. 2016, 13, 41–45. [Google Scholar]

- Ghrair, A.M.; Al-Mashaqbeh, O. Domestic Wastewater Reuse in Concrete Using Bench-Scale Testing and Full-Scale Implementation. Water 2016, 8, 366. [Google Scholar] [CrossRef]

- Asadollahfardi, G.; Delnavaz, M.; Rashnoiee, V.; Ghonabadi, N. Use of treated domestic wastewater before chlorination to produce and cure concrete. Constr. Build. Mater. 2016, 105, 253–261. [Google Scholar] [CrossRef]

- Saxena, S.; Tembhurkar, A.R. Impact of use of steel slag as coarse aggregate and wastewater on fresh and hardened properties of concrete. Constr. Build. Mater. 2018, 165, 126–137. [Google Scholar] [CrossRef]

- Rao, P.R.M.; Moinuddin, S.; Jagadeesh, P. Effect of treated waste water on the properties of hardened concrete. Int. J. Chem. Sci. 2014, 12, 155–162. [Google Scholar]

- Al-Odwani, A.; Ahmed, M.; Bou-Hamad, S. Carwash water reclamation in Kuwait. Desalination 2007, 206, 17–28. [Google Scholar] [CrossRef]

- Kwach, B.; Lalah, J. High concentrations of polycyclic aromatic hydrocarbons found in water and sediments of car wash and kisat areas of Winam Gulf, Lake Victoria-Kenya. Bull. Environ. Contam. Toxicol. 2009, 83, 727. [Google Scholar] [CrossRef]

- Nadzirah, Z.; Nor Haslina, H.; Rafidah, H. Removal of important parameter from car wash wastewater-a review. In Applied Mechanics and Materials; Trans Tech Publications: Stafa-Zurich, Switzerland, 2015; pp. 1153–1157. [Google Scholar]

- Shahidan, S.; Kadir, A.A.; Yee, L.H.; Ramzi, N.I.R.; Sheikh, F. Utilizing Slurry and Carwash Wastewater as Fresh Water Replacement in Concrete Properties. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2017; p. 1020. [Google Scholar]

- Mehta, P.K. Greening of the concrete industry for sustainable development. Concr. Int. 2002, 24, 23–28. [Google Scholar]

- Ghrair, A.M.; Heath, A.; Paine, K.; Al Kronz, M. Waste Wash-Water Recycling in Ready Mix Concrete Plants. Environments 2020, 7, 108. [Google Scholar] [CrossRef]

- Semerjian, L.; Ayoub, G.M. High-pH–magnesium coagulation–flocculation in wastewater treatment. Adv. Environ. Res. 2003, 7, 389–403. [Google Scholar] [CrossRef]

- Ghrair, A.M.; Al-Mashaqbeh, O.A.; Sarireh, M.K.; Al-Kouz, N.; Farfoura, M.; Megdal, S.B. Influence of grey water on physical and mechanical properties of mortar and concrete mixes. Ain Shams Eng. J. 2018, 9, 1519–1525. [Google Scholar] [CrossRef]

- Seo, M.; Lee, S.-Y.; Lee, C.; Cho, S.-S. Recycling of cement kiln dust as a raw material for cement. Environments 2019, 6, 113. [Google Scholar] [CrossRef]

- Chatveera, B.; Lertwattanaruk, P. Use of ready-mixed concrete plant sludge water in concrete containing an additive or admixture. J. Environ. Manag. 2009, 90, 1901–1908. [Google Scholar] [CrossRef] [PubMed]

- Chatveera, B.; Lertwattanaruk, P.; Makul, N. Effect of sludge water from ready-mixed concrete plant on properties and durability of concrete. Cem. Concr. Compos. 2006, 28, 441–450. [Google Scholar] [CrossRef]

- Klus, L.; Václavík, V.; Dvorský, T.; Svoboda, J.; Papesch, R. The utilization of waste water from a concrete plant in the production of cement composites. Buildings 2017, 7, 120. [Google Scholar] [CrossRef]

- Chini, A.; Muszynski, L.; Bergin, M.; Ellis, B. Reuse of wastewater generated at concrete plants in Florida in the production of fresh concrete. Mag. Concr. Res. 2001, 53, 311–319. [Google Scholar] [CrossRef]

- Ekolu, S.O.; Dawneerangen, A. Evaluation of recycled water recovered from a ready-mix concrete plant for reuse in concrete. J. South Afr. Inst. Civ. Eng. 2010, 52, 77–82. [Google Scholar]

- Alzboon, K.K.; Mahasneh, K.N. Effect of using stone cutting waste on the compression strength and slump characteristics of concrete. Int. J. Environ. Sci. Eng. 2009, 1, 167–172. [Google Scholar]

- Nagaraj, H.; Anand, K.; Devaraj, N. Utilization of granite sludge in the preparation of durable compressed stabilized earth blocks. MOJ Civ. Eng. 2018, 2, 237–243. [Google Scholar]

- Joulani, N.; Awad, R.A.-K. The Effect of Using Wastewater from Stone Industry in Replacement of Fresh Water on the Properties of Concrete. J. Environ. Prot. 2019, 10, 276. [Google Scholar] [CrossRef]

| S. No. | Main Findings | References |

|---|---|---|

| Fresh properties of CBMs | ||

| 1 | The workability of concrete containing supplementary cementitious materials (SCMs) and seawater decreased compared to plain concrete. | [30,31] |

| 2 | The workability of concrete mixed with seawater was unaffected compared with plain concrete prepared with tap water. | [32] |

| 3 | The workability of concrete mixes can vary using seawater and sea sand from various regions. | [32] |

| 4 | The workability of concrete reduces by using seawater in its mixing. | [33] |

| Physical properties of CBMs | ||

| 1 | The setting time of the cement paste was unaffected by using seawater. | [34] |

| 2 | The initial and final setting times of cement decreased with the increase in the concentration of seawater. | [32,35] |

| 3 | Setting time of cement paste with seawater decreased by about 30% compared to that with normal potable water due to the fast hydration process of cement. | [33] |

| 4 | The weight of the concrete with seawater increased by around 2% after 28 days. It can be controlled by using SCMs, such as coal bottom ash because it decays the penetration of harmful salts and reduces the setting time of CBMs. | [31] |

| 5 | Concrete mixed and cured with seawater had a minimum water penetration depth of 25 mm due to the crystallisation of salts. | [36] |

| 6 | The density and modulus of the elasticity of concrete mixed and cured with seawater were unaffected compared with normal concrete. | [36] |

| 7 | Seawater does not affect the air content and density of CBMs because the density of seawater is 2%–3% higher than that of fresh tap water. | [33] |

| 8 | Concrete specimens (1.7% volume) exposed to the freeze–thaw action in the marine environment decreased by the effect of seawater, and their colours changed from dark grey to light grey. | [28] |

| Strength properties of CBMs | ||

| 1 | The early strength-gaining rate of concrete made and cured with seawater increased rapidly at 7 days due to chlorides in the seawater that accelerated the setting of cement and improved the strength. | [30,37] |

| 2 | The strength-gaining rate was observed to be reduced at 14, 28, and 90 days due to leaching out of soft hydration products or sulphates in seawater that retarded the setting of cement. | [38,39,40] |

| 3 | The strength of concrete containing seawater was observed to be reduced by around 15% compared to similar concrete specimens made and cured with fresh water at 90 days. | [38,41] |

| 4 | Concrete mixed and cured in seawater had higher compressive, tensile, flexural, and bond strengths than concrete mixed and cured in fresh water at the early ages of 7 and 14 days. The strengths after 28 and 90 days for concrete mixes mixed and cured in fresh water increased slowly. | [24,42] |

| 5 | The tensile properties of concrete were weakened by the sulphate salts present in the seawater. | [43] |

| 6 | The seawater and sea sand concretes were slightly more brittle than ordinary concrete. | [44] |

| 7 | Seawater had an enhanced effect on the early strength development of sea sand concrete. | [44] |

| Durability properties of CBMs | ||

| 1 | The usage of fly ash with a low w/c ratio made the concrete more chloride-resistant against seawater. | [45] |

| 2 | Chloride salts in the seawater caused the deterioration of concrete due to the chloride-induced corrosion of steel. | [43] |

| 3 | No effect was observed on the stress–strain performance of seawater-cured concrete compared with the freshwater-cured concrete. | [28] |

| 4 | Seawater was responsible for the corrosion of concrete reinforcement. | [46] |

| 5 | The usage of corrosion inhibitors, such as fibre-reinforced polymers, was suggested to overcome the negative effects of seawater. | [47] |

| 6 | A negligible effect of seawater was observed on the carbonation process of concrete. | [32] |

| 7 | Concretes with seawater had more resistance against drying shrinkage and less against the freeze–thaw action due to the presence of chlorides. | [32] |

| 8 | The permeability of concrete produced through seawater mixing was not influenced. | [33] |

| 9 | Shrinkage was recorded to be 5% more than the conventional concrete produced through normal water mixing. | [33] |

| 10 | Chloride ingression resistance was unaffected by seawater. A rapid chloride permeability test was performed on freshwater and seawater concretes, and the results were approximately the same for the two concretes. | [33] |

| 11 | The same pore structure was found for freshwater-cured concrete and seawater-cured concrete. | [48] |

| 12 | The use of SCMs improved the serviceability and life of concrete exposed to the marine environment. | [31] |

| S. No. | Main Findings | References |

|---|---|---|

| Fresh properties of CBMs | ||

| 1 | The use of treated industrial wastewater has a minimal effect on the air content of freshly mixed concrete. | [5] |

| 2 | The workability of concrete decreased by using tertiary and secondary-treated wastewaters; however, it can be improved by adding plasticisers. | [51] |

| Physical properties of CBMs | ||

| 1 | The use of treated industrial wastewater has a minimal effect on the normal consistency of hydraulic cement and the density of concrete. | [5] |

| 2 | The use of treated industrial wastewater in the cement paste postponed the final setting time to 17 min. | [5] |

| 3 | Concrete with treated industrial wastewater has regular and well-formed crystals compared with concrete that has drinking water in accordance with the scanning electron microscopy images. | [5] |

| Strength properties of CBMs | ||

| 1 | Textile factory wastewater presented higher compressive and split tensile strengths than concrete with potable water. | [50] |

| 2 | The compressive strengths of concrete samples made with 100%drinking water were higher than concrete samples mixed withwater containing 25 to 100% of treated wastewater. | [52] |

| 3 | The compressive strength of concrete with treated industrial wastewater decreased by an average of 6.9% than the compressive strength of cement mortar with drinking water. | [5] |

| 4 | The use of treated industrial wastewater in concrete production decreased the tensile strength of concrete by 11.8% at 90 days. | [5] |

| 5 | The compressive strengths of concrete ranged from 85% to 94% ofnormal concrete by replacing 100% tap water with tertiary-treated wastewater and curing in tap water with tertiary wastewater. | [51] |

| 6 | The use of industrial wastewater had a minor effect on the strength properties of concrete. | [53] |

| Durability properties of CBMs | ||

| 1 | Amongst the five various types of wastewaters separately used for the mixing of concrete (textile factory wastewater, fertiliserfactory wastewater, domestic sewerage wastewater, service station wastewater, and sugar factory wastewater), fertiliser factory wastewater showed the highest mass loss and chloride penetration. | [50] |

| 2 | An increase of about 7.7% was observed in the electrical resistivity of concrete with treated industrial wastewater than using drinking water in concrete production. | [5] |

| 3 | The carbonation resistance of concrete decreased by using tertiary-treated water as a replacement for tap water. | [51] |

| 4 | The use of tertiary wastewater with tap water for curing or only tertiary wastewater for the curing of concrete increased the abrasion resistance. | [51] |

| S. No. | Main Findings | References |

|---|---|---|

| Fresh properties of CBMs | ||

| 1 | The slump of concrete was unaffected by the type of mixing water, such as preliminary-, secondary-, and tertiary-treated sewage wastewaters. | [56] |

| 2 | For primary, secondary, and domestic wastewaters and potable water, the slump value of concrete changed between 90 and 100 mm. | [58] |

| 3 | The initial and final setting times of cement paste were the same for potable water and secondary-treated wastewater, whereas they decreased for primary-treated wastewater. | [58] |

| 4 | A reduction in concrete workability was observed using domestic primary-treated wastewater. | [59] |

| 5 | The use of treated domestic wastewater increased the setting time of cement related to using drinking water in concrete. | [60] |

| 6 | The use of domestic wastewater in concrete did not cause any remarkable deterioration in its fresh and hardened properties. | [61] |

| 7 | The use of wastewaters from small-scale water treatment plants in residential buildings did not affect the initial setting time of OPC; however, a considerable change was observed in its final setting time. | [10] |

| Physical properties of CBMs | ||

| 1 | The density of concrete was unaffected by the type of mixing water, such as preliminary, secondary, and tertiary-treated sewage wastewaters. | [56] |

| 2 | Initial and final setting times of concrete were found to increase with deteriorating water quality. Preliminary and secondary-treated wastewaters had more effects on retarding the setting times. | [56] |

| 3 | A considerable increase in the initial setting time of up to 16.7% was observed in the concrete using domestic primary-treated wastewater compared with potable wastewater. | [59] |

| 4 | No considerable effect was observed on the use of domestic primary- or secondary-treated wastewater on the soundness value of mortar. | [59] |

| Strength properties of CBMs | ||

| 1 | Concrete with domestic sewerage wastewater showed a reduction of about 50% in compressive strength due to the water absorption property of mixed organic waste than that of the compressive strength of concrete made by using potable water. | [50] |

| 2 | Concrete mixes with domestic sewerage wastewater showed a maximum split tensile strength of 92.3% compared with that of concrete having potable water. | [50] |

| 3 | Concrete with preliminary and secondary sewage-treated wastewaters showed lower strengths for ages of up to 1 year than concrete made with potable water. | [56] |

| 4 | The compressive strength of mortar and concrete improved at 28 and 60 days by mixing secondary-treated wastewater, respectively. However, no improvement was observed in the tensile and flexural strengths of mortar and concrete by mixing secondary-treated wastewater compared with potable water. | [58] |

| 5 | No negative effect was observed on the compressive strength of mortar made with domestic secondary-treated wastewater at a curing age of 200 days. However, a reduction of about 16.2% was found in the compressive strength of mortar using domestic primary-treated wastewater. | [59] |

| 6 | The type of mixing water, such as domestic primary- and secondary-treated wastewater, distilled water, and fresh water did not affect the continuous increase in the concrete and mortar’s compressive strength. However, the compressive strength growth rate is dependent on the type of mixing water. | [59] |

| 7 | Concrete cast with treated sewage wastewater obtained higher compressive strength compared with concrete treated with potable water for up to 28 days. | [62] |

| 8 | The compressive strength of concrete under rapid freezing and thawing decreased by about 10% by using treated domestic wastewater in place of using drinking water. | [60] |

| 9 | The use of secondary-treated sewage wastewater had a negligible effect on the strength properties of concrete. | [53] |

| 10 | The compressive and flexural strengths of OPC pastes made with wastewaters from small-scale water treatment plants in residential buildings were less than the samples made with distilled water. However, they were within the limits as per code IS: 456-2000 and BS: 3148-1980. | [10] |

| Durability properties of CBMs | ||

| 1 | Water absorption of the concrete with domestic sewerage wastewater was about 114.05% at 28 days and 120.65% at 90 days than that of concrete with potable water. | [50] |

| 2 | Concrete with domestic sewerage wastewater showed the highest mass loss of about 103.3% due to the acid attack at the testing age of 120 days compared with that of the concrete with potable water. | [50] |

| 3 | Concrete with domestic sewerage wastewater showed a maximum chloride penetration of 101.7% compared with that of concrete having potable water at 120 days. | [50] |

| 4 | The possibility of steel corrosion increased by using sewage-treated wastewater. | [56] |

| 5 | The effects of domestic primary- and secondary-treated wastewater on concrete water absorption and durability were insignificant. | [59] |

| 6 | Concrete samples produced and cured with treated domestic wastewater did not have remarkable effects on water absorption and surface electrical resistivity compared to concrete samples using drinking water. | [60] |

| 7 | Chloride permeability was high for sewage-treated wastewater concrete compared to potable water concrete at 14 and 28 days. | [62] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yousuf, S.; Shafigh, P.; Muda, Z.C.; Katman, H.Y.B.; Latif, A. Alternatives for Fresh Water in Cement-Based Materials: A Review. Water 2023, 15, 2828. https://doi.org/10.3390/w15152828

Yousuf S, Shafigh P, Muda ZC, Katman HYB, Latif A. Alternatives for Fresh Water in Cement-Based Materials: A Review. Water. 2023; 15(15):2828. https://doi.org/10.3390/w15152828

Chicago/Turabian StyleYousuf, Sumra, Payam Shafigh, Zakaria Che Muda, Herda Yati Binti Katman, and Abid Latif. 2023. "Alternatives for Fresh Water in Cement-Based Materials: A Review" Water 15, no. 15: 2828. https://doi.org/10.3390/w15152828

APA StyleYousuf, S., Shafigh, P., Muda, Z. C., Katman, H. Y. B., & Latif, A. (2023). Alternatives for Fresh Water in Cement-Based Materials: A Review. Water, 15(15), 2828. https://doi.org/10.3390/w15152828