Flow Rate Optimization in a Flat-Panel Photobioreactor for the Cultivation of Microalgae for Mitigating Waste Gas

Abstract

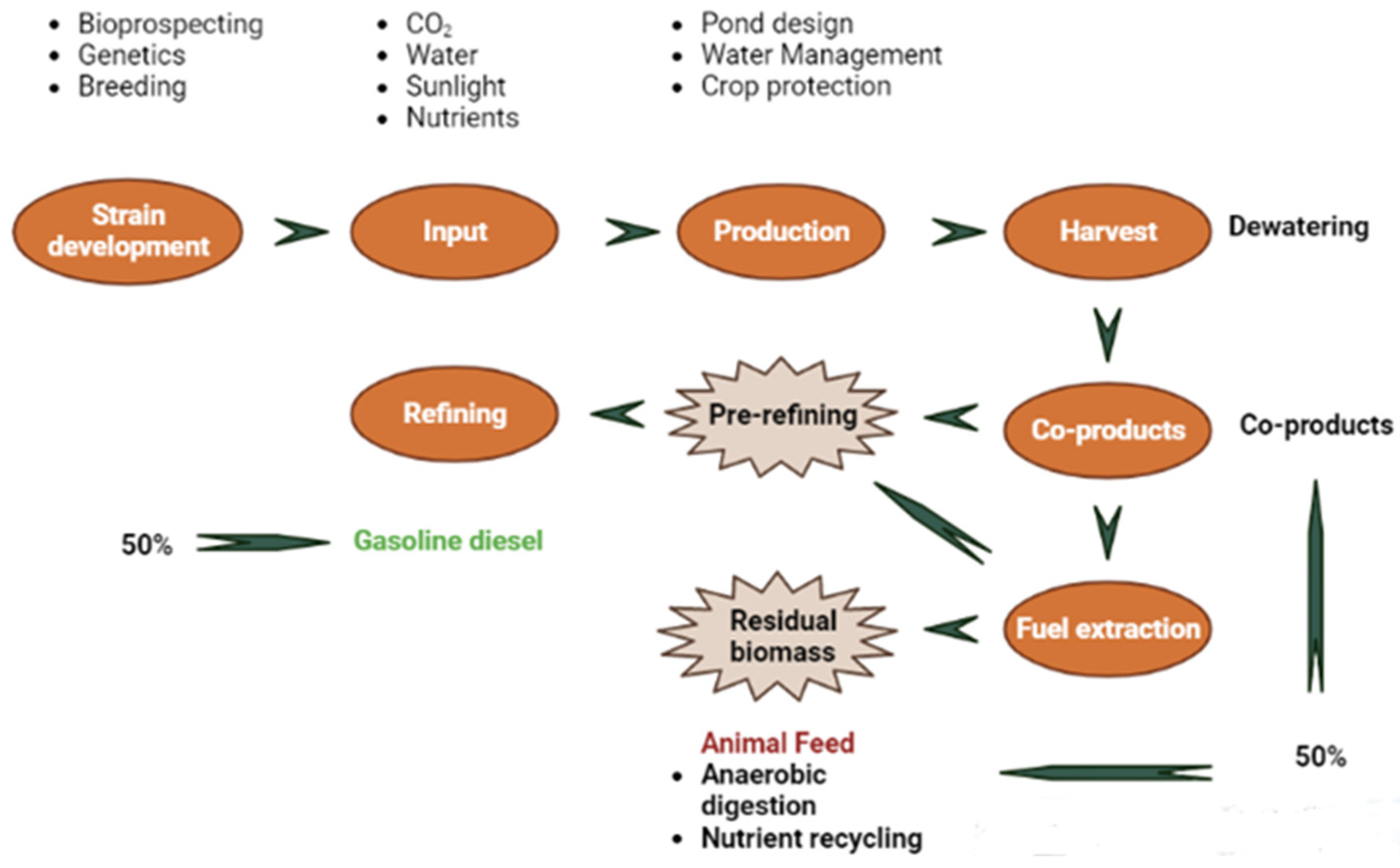

:1. Introduction

2. Materials and Methods

2.1. Microalgae and Culture Medium

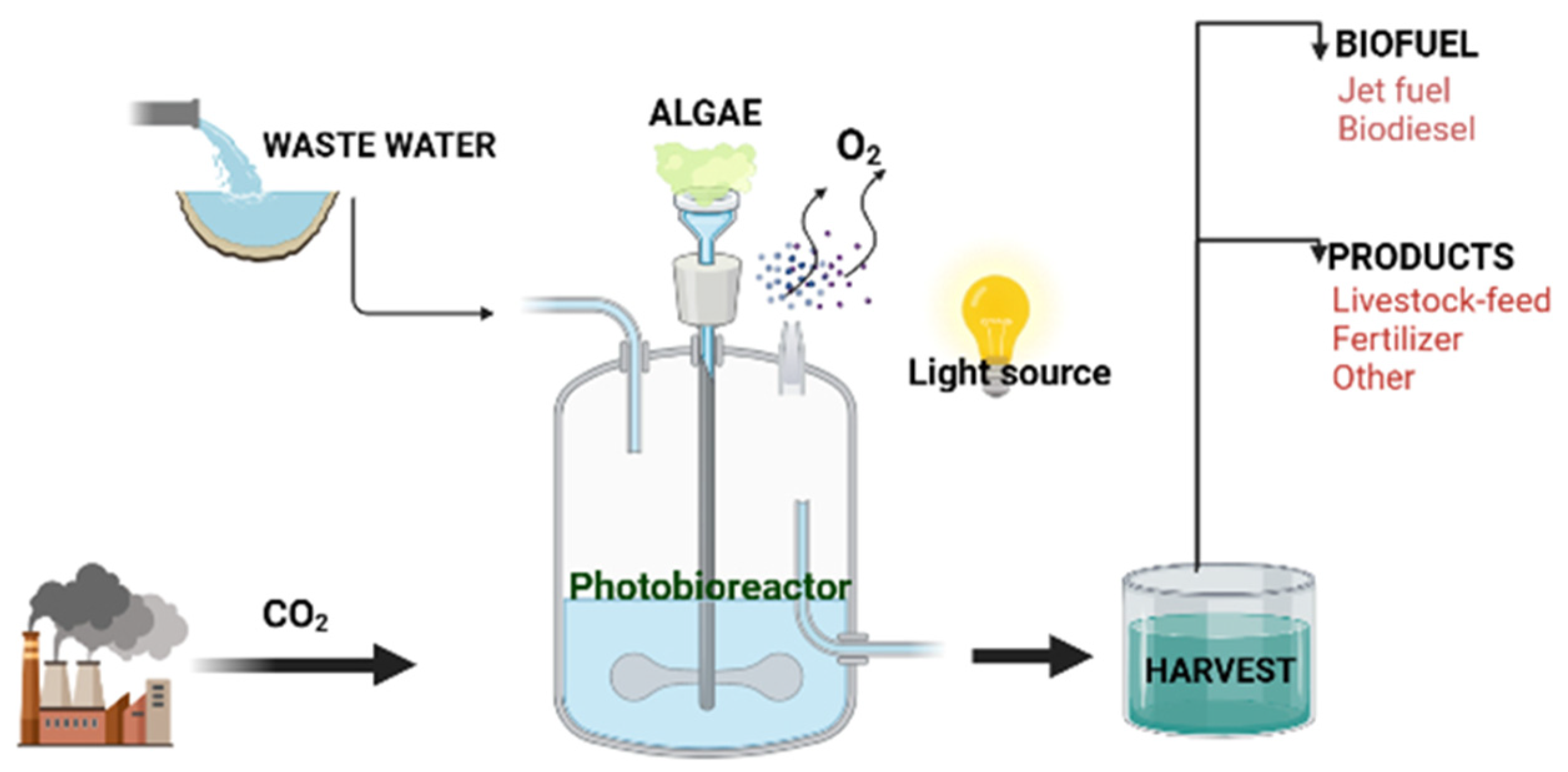

2.2. Photobioreactor (P.B.R.)

2.3. Lipid Estimation

2.4. Biodiesel Characterization

2.5. Computational Model

3. Results

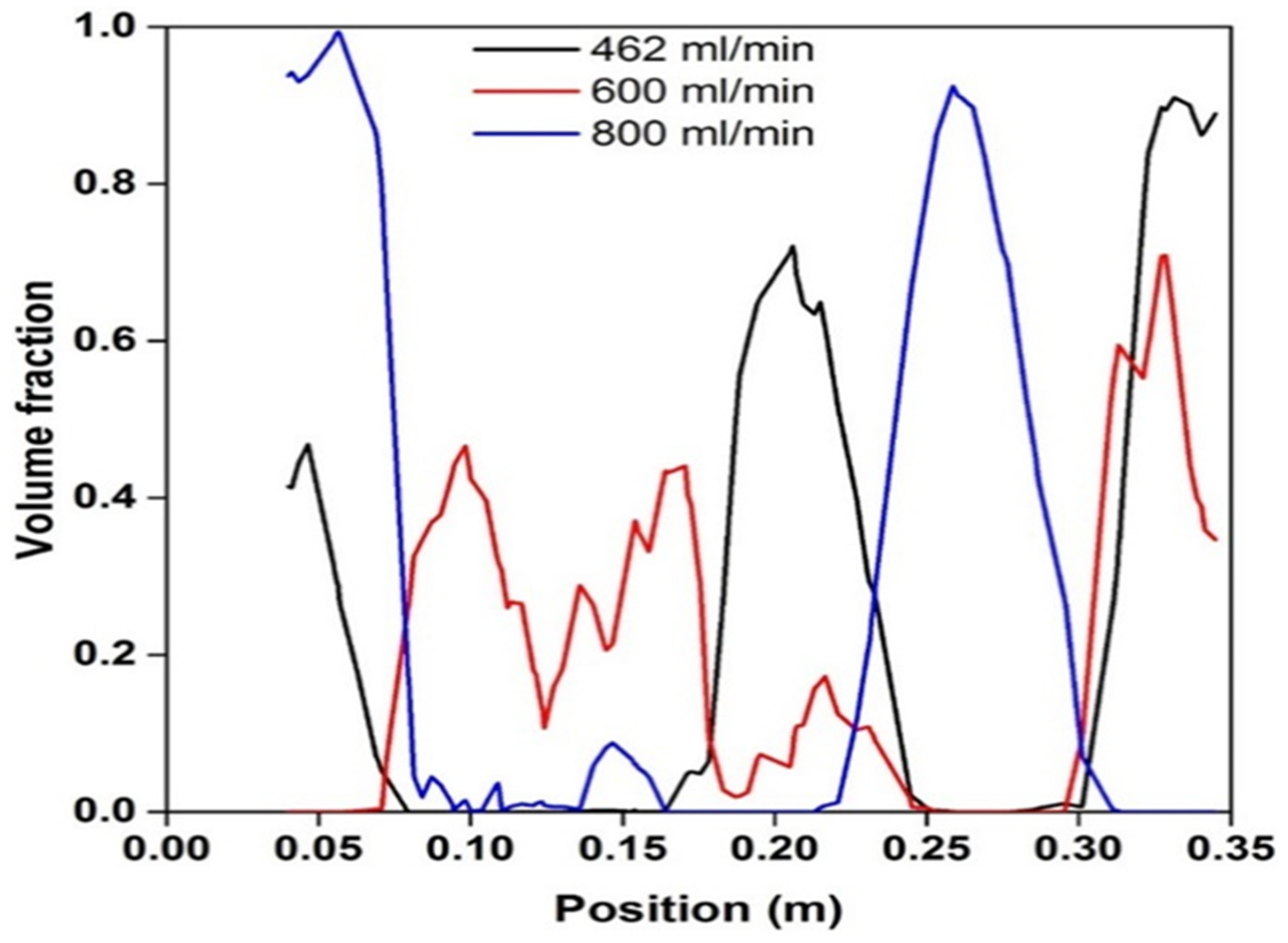

Gas Distribution for Appropriate Mixing State Determination inside the P.B.R. (C.F.D. Simulation)

4. Discussion

5. Conclusions and Future Studies

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahuja, D.; Tatsutani, M. Sustainable energy for developing countries. SAPIENS Surv. Perspect. Integr. Environ. Soc. 2009. [Google Scholar]

- Kumar, J.C.R.; Majid, M.A. Renewable Energy for Sustainable Development in India: Current Status, Future Prospects, Challenges, Employment, and Investment Opportunities. Energy Sustain. Soc. 2020, 10, 2. [Google Scholar] [CrossRef]

- Ogunkunle, O.; Ahmed, N.A. Overview of Biodiesel Combustion in Mitigating the Adverse Impacts of Engine Emissions on the Sustainable Human–Environment Scenario. Sustainability 2021, 13, 5465. [Google Scholar] [CrossRef]

- Udayan, A.; Pandey, A.K.; Sirohi, R.; Sreekumar, N.; Sang, B.-I.; Sim, S.J.; Kim, S.H.; Pandey, A. Production of Microalgae with High Lipid Content and Their Potential as Sources of Nutraceuticals. Phytochem. Rev. 2022, 1–28. [Google Scholar] [CrossRef]

- Cheah, W.Y.; Show, P.L.; Yap, Y.J.; Mohd Zaid, H.F.; Lam, M.K.; Lim, J.W.; Ho, Y.-C.; Tao, Y. Enhancing Microalga Chlorella Sorokiniana CY-1 Biomass and Lipid Production in Palm Oil Mill Effluent (POME) Using Novel-Designed Photobioreactor. Bioengineered 2019, 11, 61–69. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saad, M.G.; Dosoky, N.S.; Zoromba, M.S.; Shafik, H.M. Algal Biofuels: Current Status and Key Challenges. Energies 2019, 12, 1920. [Google Scholar] [CrossRef] [Green Version]

- Zabochnicka, M.; Krzywonos, M.; Romanowska-Duda, Z.; Szufa, S.; Darkalt, A.; Mubashar, M. Algal Biomass Utilization toward Circular Economy. Life 2022, 12, 1480. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Chilvers, A.; Azapagic, A. Environmental Sustainability of Biofuels: A Review. Proc. Math. Phys. Eng. Sci. 2020, 476, 20200351. [Google Scholar] [CrossRef]

- Ganesan, R.; Manigandan, S.; Samuel, M.S.; Shanmuganathan, R.; Brindhadevi, K.; Lan Chi, N.T.; Duc, P.A.; Pugazhendhi, A. A Review on Prospective Production of Biofuel from Microalgae. Biotechnol. Rep. 2020, 27, e00509. [Google Scholar] [CrossRef]

- Ali, S.; Mastropetros, S.G.; Schagerl, M.; Sakarika, M.; Elsamahy, T.; El-Sheekh, M.; Sun, J.; Kornaros, M. Recent Advances in Wastewater Microalgae-Based Biofuels Production: A State-of-the-Art Review. Energy Rep. 2022, 8, 13253–13280. [Google Scholar] [CrossRef]

- Kiran, B.R.; Venkata Mohan, S. Microalgal Cell Biofactory—Therapeutic, Nutraceutical and Functional Food Applications. Plants 2021, 10, 836. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.Y.; Sankaran, R.; Chew, K.W.; Tan, C.H.; Krishnamoorthy, R.; Chu, D.-T.; Show, P.-L. Waste to Bioenergy: A Review on the Recent Conversion Technologies. BMC Energy 2019, 1, 4. [Google Scholar] [CrossRef]

- Torres-León, C.; Ramírez-Guzman, N.; Londoño-Hernandez, L.; Martinez-Medina, G.A.; Díaz-Herrera, R.; Navarro-Macias, V.; Alvarez-Pérez, O.B.; Picazo, B.; Villarreal-Vázquez, M.; Ascacio-Valdes, J.; et al. Food Waste and Byproducts: An Opportunity to Minimize Malnutrition and Hunger in Developing Countries. Front. Sustain. Food Syst. 2018, 2, 52. [Google Scholar] [CrossRef]

- Khanna, M.; Crago, C.L.; Black, M. Can Biofuels Be a Solution to Climate Change? The Implications of Land Use Change-Related Emissions for Policy. Interface Focus 2011, 1, 233. [Google Scholar] [CrossRef] [Green Version]

- Masum, B.M.; Masjuki, H.H.; Kalam, M.A.; Palash, S.M.; Habibullah, M. Effect of Alcohol–Gasoline Blends Optimization on Fuel Properties, Performance and Emissions of a S.I. Engine. J. Clean. Prod. 2015, 86, 230–237. [Google Scholar] [CrossRef] [Green Version]

- Chai, S.; Shi, J.; Huang, T.; Guo, Y.; Wei, J.; Guo, M.; Li, L.; Dou, S.; Liu, L.; Liu, G. Characterization of Chlorella sorokiniana growth properties in monosaccharide-supplemented batch culture. PLoS ONE 2018, 13, e0199873. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ziganshina, E.E.; Bulynina, S.S.; Ziganshin, A.M. Comparison of the photoautotrophic growth regimens of Chlorella sorokiniana in a photobioreactor for enhanced biomass productivity. Biology 2020, 9, 169. [Google Scholar] [CrossRef] [PubMed]

- Lizzul, A.M.; Lekuona-Amundarain, A.; Purton, S.; Campos, L.C. Characterization of Chlorella sorokiniana, UTEX 1230. Biology 2018, 7, 25. [Google Scholar] [CrossRef] [Green Version]

- Loomba, V.; von Lieres, E.; Huber, G. How do operational and design parameters affect biomass productivity in a flat-panel photobioreactor? A computational analysis. Processes 2021, 9, 1387. [Google Scholar] [CrossRef]

- Xu, J.; Cheng, J.; Lai, X.; Zhang, X.; Yang, W.; Park, J.Y.; Xu, L. Enhancing microalgal biomass productivity with an optimized flow field generated by double paddlewheels in a flat plate photoreactor with CO2 aeration based on numerical simulation. Bioresour. Technol. 2020, 314, 123762. [Google Scholar] [CrossRef]

- Acién Fernández, F.G.; Fernández Sevilla, J.M.; Molina Grima, E. Photobioreactors for the production of microalgae. Rev. Environ. Sci. Bio/Technol. 2013, 12, 131–151. [Google Scholar] [CrossRef]

- Pirasaci, T.; Manisali, A.Y.; Dogaris, I.; Philippidis, G.; Sunol, A.K. Hydrodynamic design of an enclosed Horizontal bioreactor (H.B.R.) for algae cultivation. Algal Res. 2017, 28, 57–65. [Google Scholar] [CrossRef]

- Huang, J.; Ying, J.; Fan, F.; Yang, Q.; Wang, J.; Li, Y. Development of a novel multi-column airlift photobioreactor with easy scalability by means of computational fluid dynamics simulations and experiments. Bioresour. Technol. 2016, 222, 399–407. [Google Scholar] [CrossRef] [PubMed]

- dos Santos, C.; Dionisio, R.; Cerqueira, H.; Sousa-Aguiar, E.; Mori, M.; d´Avila, M. Three-Dimensional Gas-Liquid C.F.D. Simulations in Cylindrical Bubble Columns. Int. J. Chem. React. Eng. 2007, 5. [Google Scholar] [CrossRef]

- Mobin Siddique, M.B.; Khairuddin, N.; Ali, N.A.; Hassan, M.A.; Ahmed, J.; Kasem, S.; Tabassum, M.; Afrouzi, H.N. A Comprehensive Review on the Application of Bioethanol/Biodiesel in Direct Injection Engines and Consequential Environmental Impact. Clean. Eng. Technol. 2021, 3, 100092. [Google Scholar] [CrossRef]

- Kumar, K.; Banerjee, D.; Das, D. Carbon dioxide sequestration from industrial flue gas by Chlorella sorokiniana. Bioresour. Technol. 2014, 152, 225–233. [Google Scholar] [CrossRef]

- Therien, J.B.; Zadvornyy, O.A.; Posewitz, M.C.; Bryant, D.A.; Peters, J.W. Growth of Chlamydomonas reinhardtii in Acetate-Free Medium When Co-Cultured with Alginate-Encapsulated, Acetate-Producing Strains of Synechococcus Sp. PCC 7002. Biotechnol. Biofuels 2014, 7, 154. [Google Scholar] [CrossRef] [Green Version]

- Breil, C.; Abert Vian, M.; Zemb, T.; Kunz, W.; Chemat, F. “Bligh and Dyer” and Folch Methods for Solid–Liquid–Liquid Extraction of Lipids from Microorganisms. Comprehension of Solvatation Mechanisms and towards Substitution with Alternative Solvents. Int. J. Mol. Sci. 2017, 18, 708. [Google Scholar] [CrossRef] [Green Version]

- Ichihara, K.; Kobayashi, Y. Preparation of Fatty Acid Methyl Esters for Gas-Liquid Chromatography. J. Lipid Res. 2010, 51, 635–640. [Google Scholar] [CrossRef] [Green Version]

- Jabbari, M.; Bulatova, R.; Hattel, J.H.; Bahl, C.R.H. An Evaluation of Interface Capturing Methods in a VOF-Based Model for Multiphase Flow of a Non-Newtonian Ceramic in Tape Casting. Appl. Math. Model. 2014, 38, 3222–3232. [Google Scholar] [CrossRef]

| The Organism Has Grown on | Max Biomass (g L−1) | Biomass Productivity (g L−1 d−1) | Total Lipid Content (%w w−1) | Total Protein Content (%w w−1) | Total Carbohydrate Content (%w w−1) | Total Chlorophyll Content (μg mg−1) |

|---|---|---|---|---|---|---|

| Chlorella sorokiniana | 1.892 ± 0.05 | 0.52 ± 0.03 | 19 ± 0.05 | 36 ± 0.03 | 27 ± 0.05 | 0.022 ± 0.01 |

| Fatty Acids | Algal Biomass is Grown in 5% CO2 (Relative Perent of Fatty Acid) |

|---|---|

| Capric acid (C10:0) | 4.6 ± 0.18 |

| Lauric (C12:0) | 16.23 ± 0.48 |

| Myristic (C14:0) | 19.53 ± 0.39 |

| 10-Pentadecenoic (C15:1) | 2.21 ± 0.11 |

| Palmitic (C16:0) | 16.42 ± 0.72 |

| Palmitoleic acid (C16:1) | 3.67 ± 0.18 |

| Margaric (C17:0) | - |

| Stearic (C18:0) | 16.41 ± 0.67 |

| Oleic (C18:1) | 2.12 ± 0.11 |

| Linoleic acid (C18:2) | - |

| α Linolenic acid (C18:3) | 1.82 ± 0.1 |

| Arachidic (C20:0) | 6.2 ± 0.2 |

| Eicosenoic acid (C20:1) | 1.72 ± 0.08 |

| Eicosapentaenoic acid (C20:5) | - |

| Erucic acid (C22:1) | 3.1 ± 0.15 |

| Tricosanoic acid (C23:0) | 1.0 ± 0.1 |

| Other unknown fatty acids | 5.0 ± 0.4 |

| MUFA | 12.81 ± 0.63 |

| PUFA | 1.82 ± 0.1 |

| Saturated fatty acids (S.F.A.) | 80.39 ± 2.26 |

| Medium-chain fatty acids (C10-C15) | 42.57 ± 1.16 |

| Long-chain fatty acids (C16-C18) | 40.44 ± 1.78 |

| Very long-chain fatty acids (≥C20) | 12.03 ± 0.53 |

| Properties | ASTM (Standard) | Diesel | Biodiesel from Chlorella sorokiniana |

|---|---|---|---|

| Kinematic viscosity at 40 °C (mm2 s−1) | 5.2 | 4.1 | 5 |

| Density (kg m−3) | 825 | 900 | |

| Cetane number | 47 | 59 | 63 |

| Flow Rate (mL min−1) | Cg |

|---|---|

| 462 | 0.11 |

| 600 | 0.07 |

| 800 | 0.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banerjee, S.; Dasgupta, S.; Atta, A.; Das, D.; Dayal, D.; Malik, S.; Kumar, H.; Kishore, S.; Rustagi, S.; Almutary, A.G. Flow Rate Optimization in a Flat-Panel Photobioreactor for the Cultivation of Microalgae for Mitigating Waste Gas. Water 2023, 15, 2824. https://doi.org/10.3390/w15152824

Banerjee S, Dasgupta S, Atta A, Das D, Dayal D, Malik S, Kumar H, Kishore S, Rustagi S, Almutary AG. Flow Rate Optimization in a Flat-Panel Photobioreactor for the Cultivation of Microalgae for Mitigating Waste Gas. Water. 2023; 15(15):2824. https://doi.org/10.3390/w15152824

Chicago/Turabian StyleBanerjee, Srijoni, Soumendu Dasgupta, Arnab Atta, Debabrata Das, Deen Dayal, Sumira Malik, Harshavardhan Kumar, Shristi Kishore, Sarvesh Rustagi, and Abdulmajeed G. Almutary. 2023. "Flow Rate Optimization in a Flat-Panel Photobioreactor for the Cultivation of Microalgae for Mitigating Waste Gas" Water 15, no. 15: 2824. https://doi.org/10.3390/w15152824

APA StyleBanerjee, S., Dasgupta, S., Atta, A., Das, D., Dayal, D., Malik, S., Kumar, H., Kishore, S., Rustagi, S., & Almutary, A. G. (2023). Flow Rate Optimization in a Flat-Panel Photobioreactor for the Cultivation of Microalgae for Mitigating Waste Gas. Water, 15(15), 2824. https://doi.org/10.3390/w15152824