Experimental Study of Roughness Reduction of Large Aqueducts in the Middle Route of the South-to-North Water Diversion Project

Abstract

:1. Introduction

2. Materials and Methods

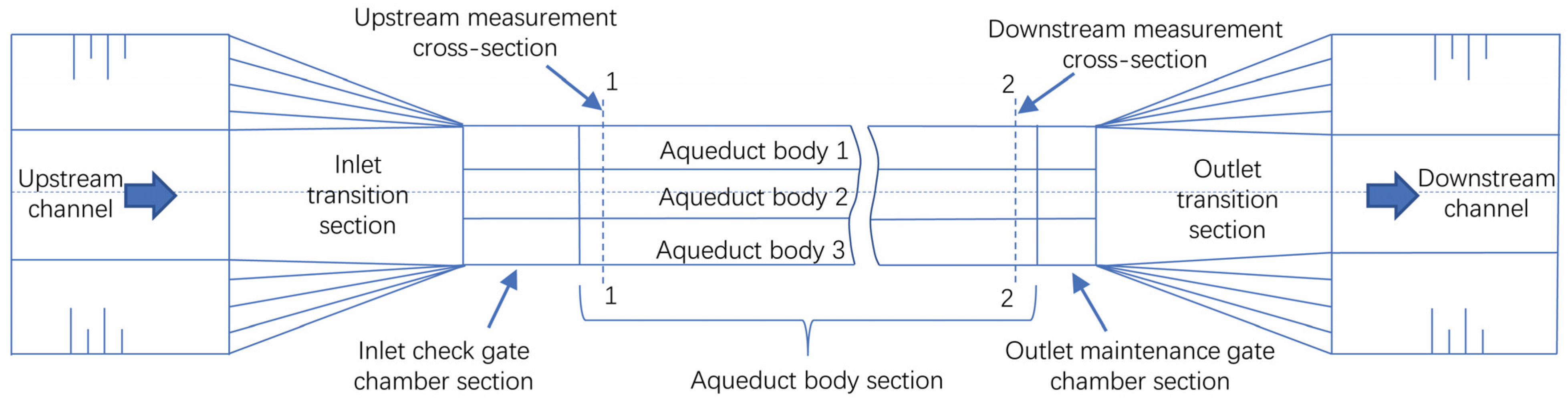

2.1. Overview of the Fangshui River Aqueduct

2.2. Application of Drag-Reduction Coating

2.3. Calculation of Roughness and Error Analysis

2.4. Field Observation Schemes

2.4.1. Field Observation in 2021

- Scheduling scheme

- 2.

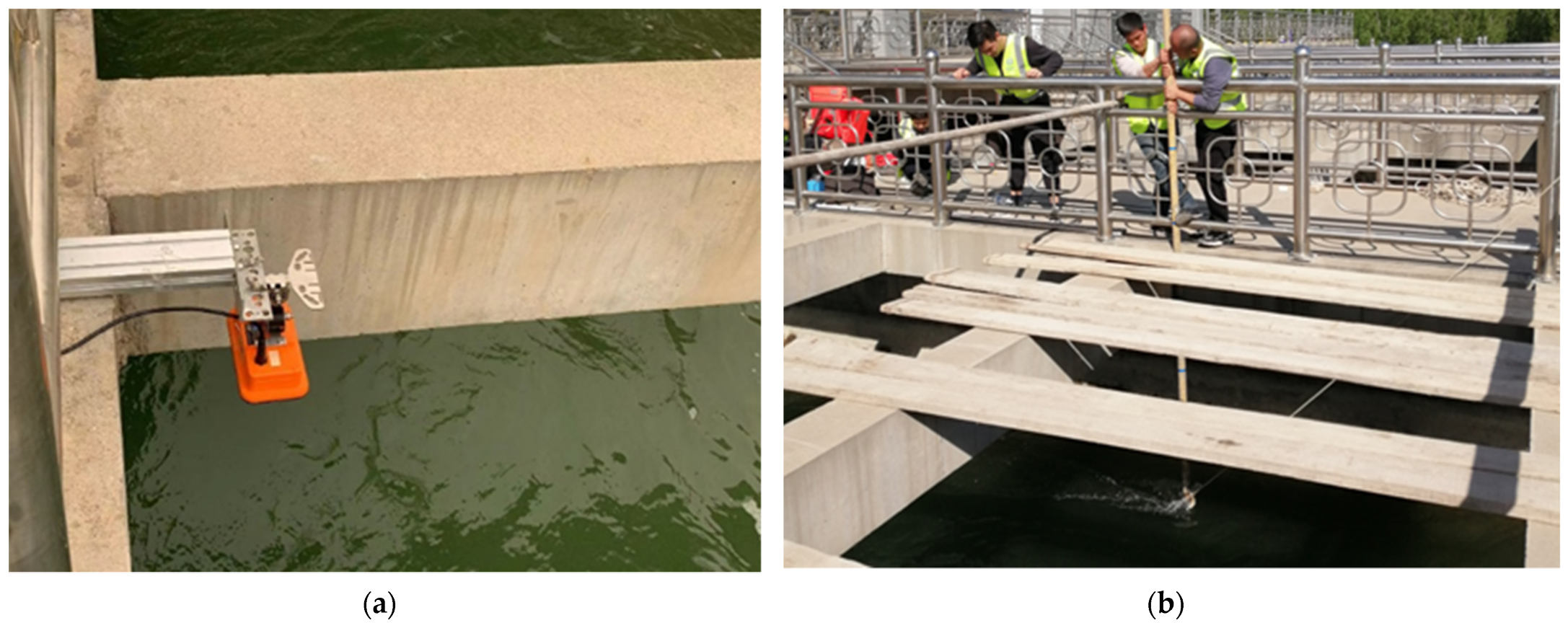

- Observation scheme

2.4.2. Field Observation in 2023

- 1.

- Scheduling scheme

- 2.

- Observation scheme

3. Field Observation Results

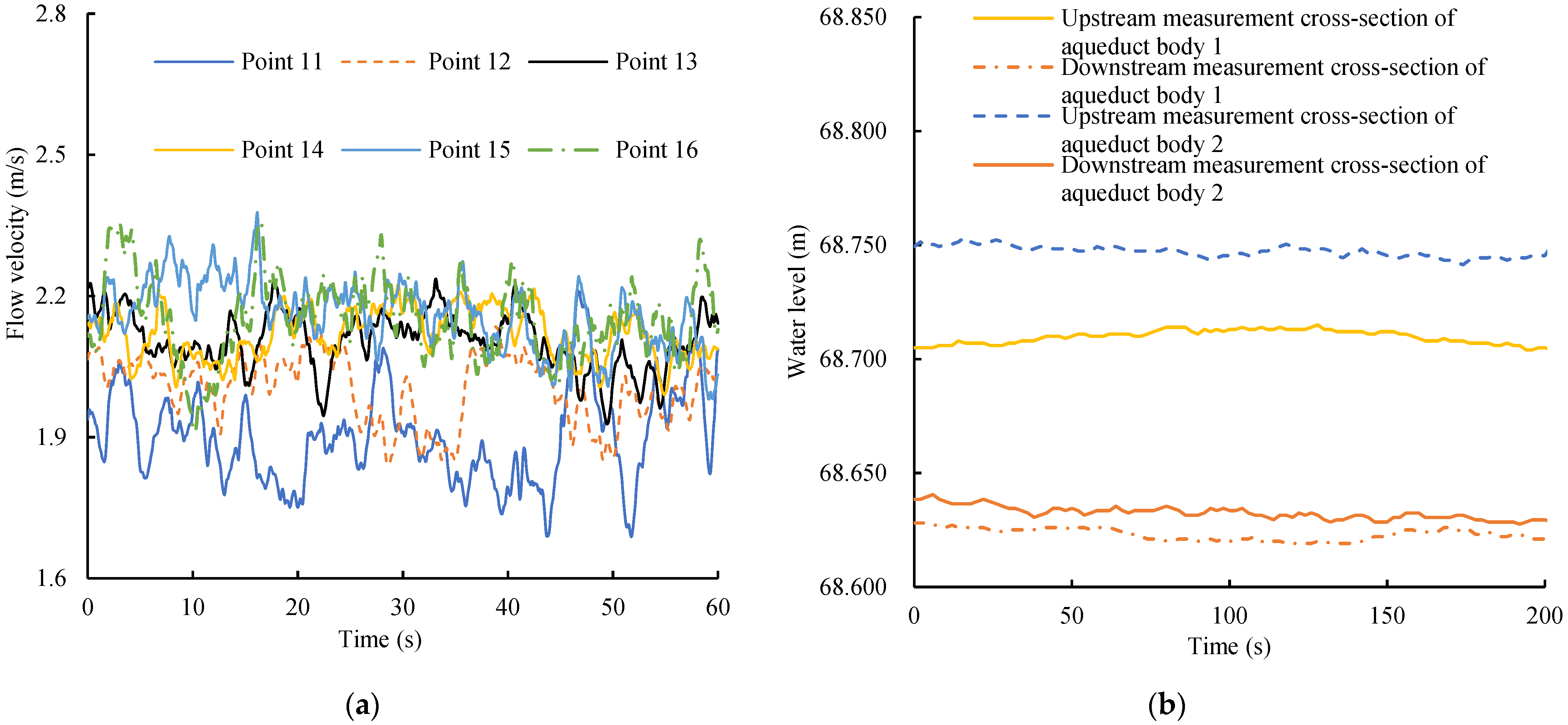

3.1. Results and Errors for 2021

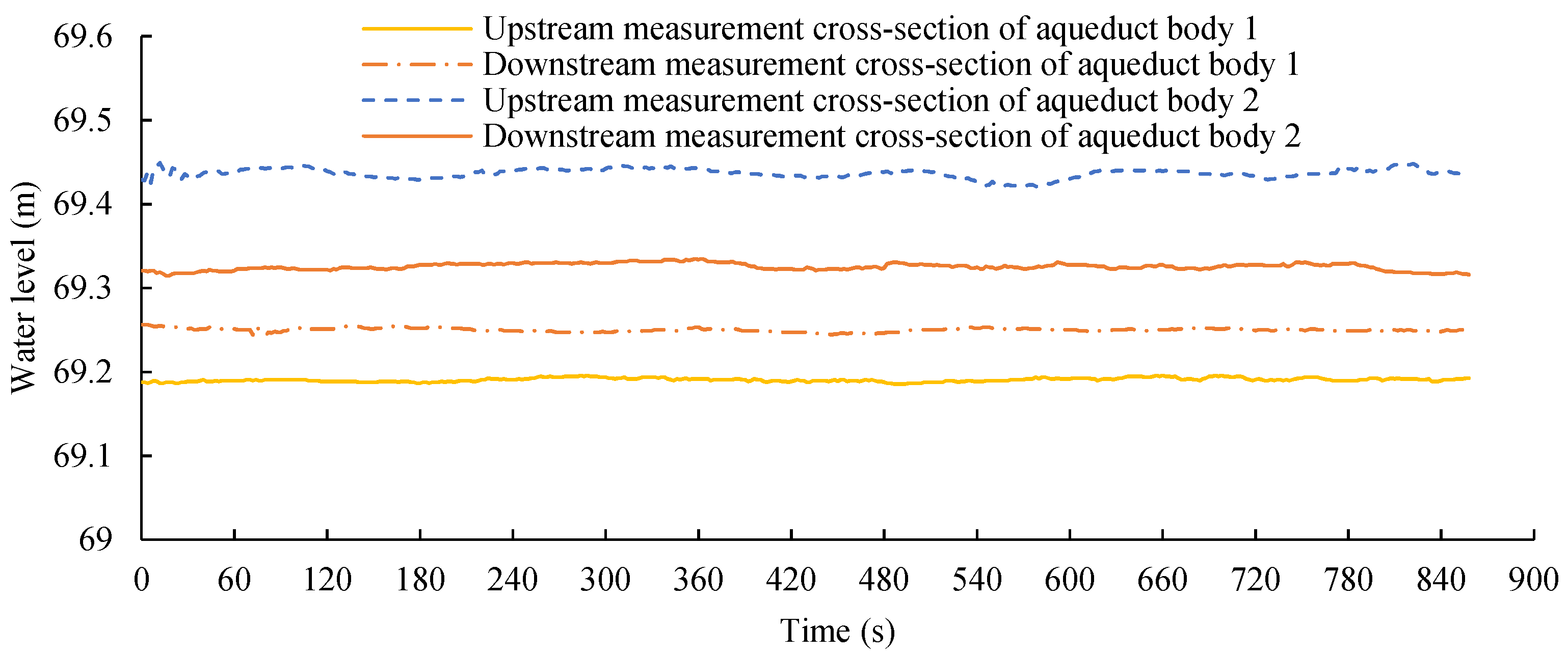

3.2. Results and Errors for 2023

4. Discussion

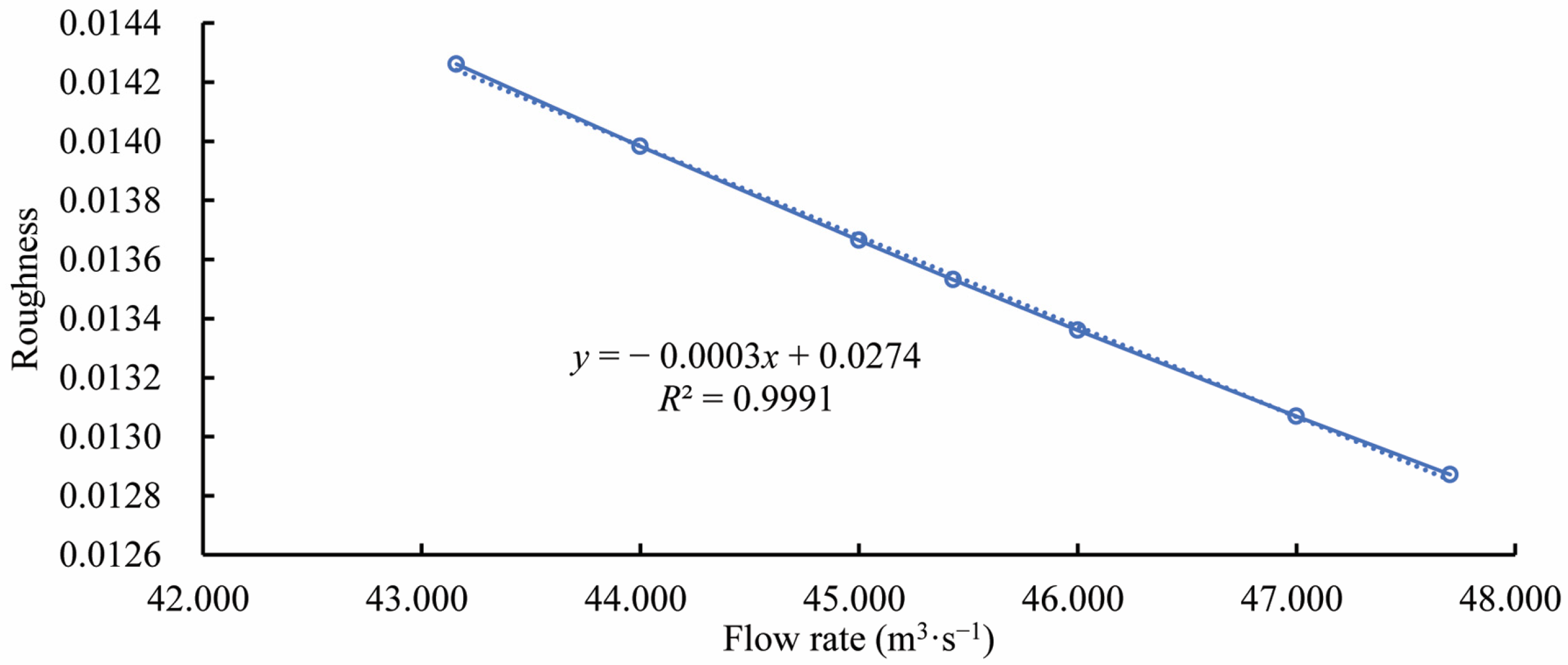

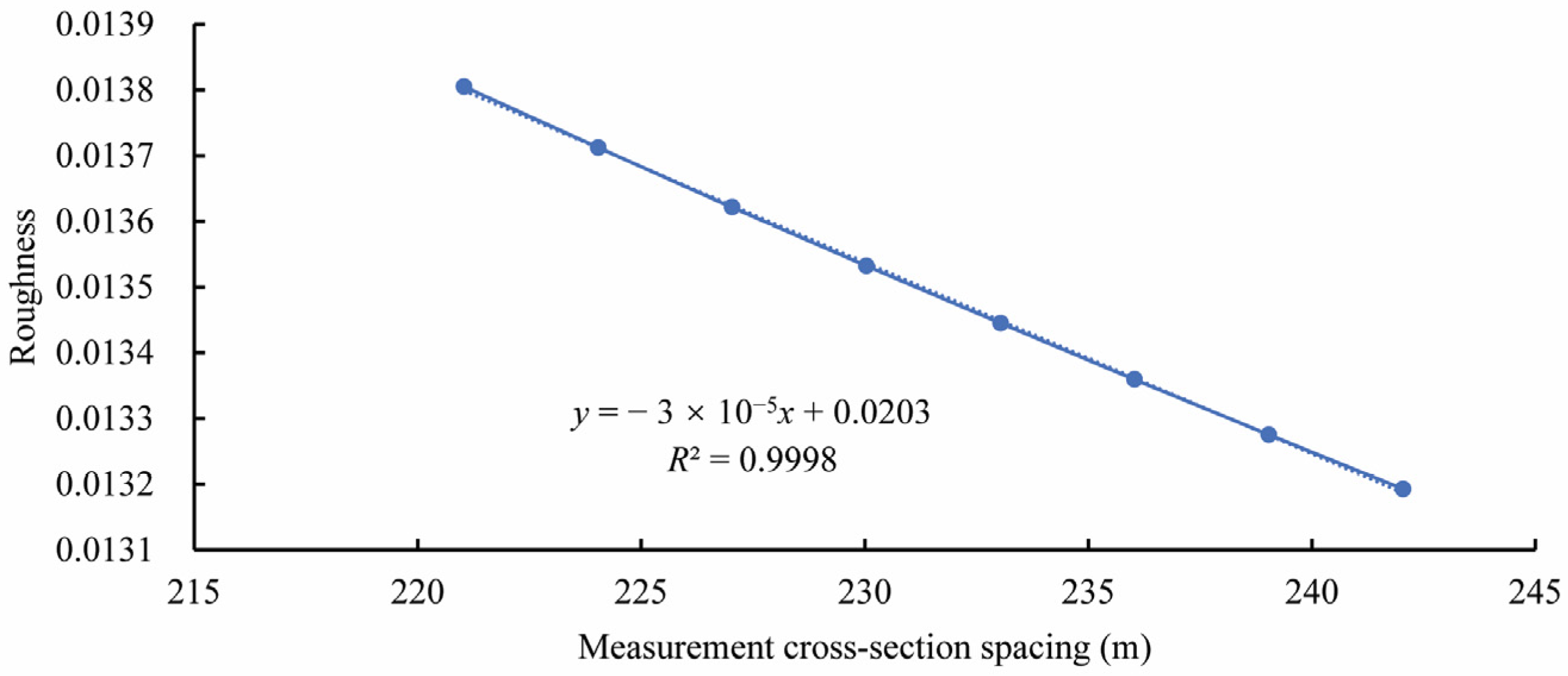

4.1. Error Sensitivity Analysis

4.2. Comparison of Results from Field Observations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Niu, X.Q. The First Stage of the Middle-Line South-to-North Water-Transfer Project. Engineering 2022, 16, 21–28. [Google Scholar] [CrossRef]

- Li, W.; Xu, X.P. Hydraulics, 3rd ed.; Press of Wuhan University of Hydraulic and Electric Engineering: Wuhan, China, 2002; pp. 152–165. [Google Scholar]

- Erhan, A.; Halil, B.U.; Bekir, S.K.; Musa, A.; Serafettin, A. Evaluation of Irrigation Canal Maintenance According to Roughness and Active Canal Capacity Values. J. Irrig. Drain. Eng. 2008, 134, 60–66. [Google Scholar] [CrossRef]

- Cui, W.; Chen, W.; Mu, X.; Xiong, Q.; Lu, M. Calculation of Head Losses and Analysis of Influencing Factors of Crossing Water-Conveyance Structures of Main Canal of Middle Route of South-to-North Water Diversion Project. Water 2023, 15, 871. [Google Scholar] [CrossRef]

- Asghar, Z.; Shah, R.A.; Shatanawi, W.; Ali, N. A Theoretical Approach to Mathematical Modeling of Sperm Swimming in Viscoelastic Ellis Fluid in a Passive Canal. Arch. Appl. Mech. 2023, 93, 1525–1534. [Google Scholar] [CrossRef]

- Asghar, Z.; Khan, M.W.S.; Shatanawi, W.; Gondal, M.A.; Ghaffari, A. An IFDM Analysis of Low Reynolds Number Flow Generated in a Complex Wavy Curved Passage Formed by Artificial Beating Cilia. Int. J. Mod. Phys. B 2023, 37, 2350187. [Google Scholar] [CrossRef]

- Kada, B.; Pasha, A.A.; Asghar, Z.; Khan, M.W.S.; Aris, I.B.; Shaikh, M.S. Carreau–Yasuda Fluid Flow Generated via Metachronal Waves of Cilia in a Micro-channel. Phys. Fluids 2023, 35, 013110. [Google Scholar] [CrossRef]

- Asghar, Z.; Elmoasry, A.; Shatanawi, W.; Gondal, M.A. An Exact Solution for Directional Cell Movement over Jeffrey Slime Layer with Surface Roughness Effects. Phys. Fluids 2023, 35, 041901. [Google Scholar] [CrossRef]

- Asghar, Z.; Shah, R.A.; Ali, N. A Numerical Framework for Modeling the Dynamics of Micro-organism Movement on Carreau-Yasuda layer. Soft. Comput. 2023, 27, 8525–8539. [Google Scholar] [CrossRef]

- Asghar, Z. Enhancing Motility of Micro-swimmers via Electric and Dynamical Interaction Effects. Eur. Phys. J. Plus 2023, 138, 357. [Google Scholar] [CrossRef]

- Lu, S. Fabrication and Drag Reduction Mechanism of Super-Hydrophobic Surfaces with Micro-Nano Structures. Master’s Thesis, Tsinghua University, Beijing, China, 2012. [Google Scholar]

- Falk, C.; Maribu, J.; Eide, L.O. Commissioning the Zeepipe System Sets New Standards. Pipeline Gas J. 1994, 221, 24. [Google Scholar]

- Folga, S.M. Natural Gas Pipeline Technology Overview; Argonne National Lab. (ANL): Argonne, IL, USA, 2007. [Google Scholar] [CrossRef] [Green Version]

- Qu, D.J. The Engineering Defects and Technologies for Danger Elimination and Reinforcement of Jiangjunshan Aqueduct. J. China Inst. Water Resour. Hydropower Res. 2016, 14, 73–78. [Google Scholar] [CrossRef]

- Gu, J.C.; Lu, L.G.; Wang, Y.P.; Zhu, J.; Wu, H.F. Application and Effect Analysis of SCL Impermeable Film in Reducing Roughness of Aqueduct. China Rural Water Hydropower 2020, 9, 71–74. [Google Scholar]

- Zhu, J.; Gu, J.C.; Lu, L.G. Application of SK Polyurea in Reducing Roughness and Increasing Flow of Yazhugou Aqueduct in Hongsipu, Ningxia. China Rural Water Hydropower 2020, 10, 181–183+188. [Google Scholar]

- Q/HRYSY 001-2020; Nano Modified Silicate Water Solution Permeable Crystal Type Material. Beijing Yisheng Yuan Environmental Protection Engineering Co., Ltd.: Beijing, China, 2020.

- Wu, B.; Zhang, K.Y.; Li, X. Application of Nano-rubber in the Reinforcement and Repair Project of Xiangyang Sluice. Water Sci. Eng. Technol. 2021, 6, 66–68. [Google Scholar] [CrossRef]

- Zuo, F.S.; Zhao, L.; Wu, H.G. Durability Repairing and Protection Technology of Nano-inorganic Water Permeable Crystalline Concrete and Application Thereof in Hydraulic Concrete. China Water Power Electrif. 2021, 9, 19–23. [Google Scholar] [CrossRef]

- Chen, X.C.; Chen, Z.; Liu, B. Application of Nano⁃rubber Concrete Protection Technology in Water Conservancy Projects. Water Conserv. Constr. Manag. 2020, 8, 61–65. [Google Scholar]

- Chen, W.X.; Cui, W.; He, S.N.; Mu, X.P. Study on Method of Roughness Calibration for Water Conveyance System. Water Resour. Hydropower Eng. 2019, 50, 116–121. [Google Scholar] [CrossRef]

- Abbas, S.A.; Al-Aboodi, A.H.; Ibrahim, H.T. Identification of Manning’s Coefficient Using HEC-RAS Model: Upstream Al-Amarah Barrage. J. Eng. 2020, 2020, 6450825. [Google Scholar] [CrossRef] [Green Version]

- Hu, P.N. Prototype Observation of Roughness and Overflow Capacity in Pandaoling Tunnel. J. Yangtze River Sci. Res. Inst. 2019, 36, 67–70+76. [Google Scholar] [CrossRef]

- Cui, W.; Liu, L.; Dai, D.C.; Mu, X.P.; Chen, W.X. Uncertainty Analysis of Roughness Measurements for a Large-Scale Canal. In Proceedings of the 38th IAHR World Congress, Panama City, Panama, 1–6 September 2019. [Google Scholar] [CrossRef]

- Despax, A.; Perret, C.; Garçon, R.; Hauet, A.; Belleville, A. Considering Sampling Strategy and Cross Section Complexity for Estimating the Uncertainty of Discharge Measurements Using the Velocity-area Method. J. Hydrol. 2016, 533, 128–140. [Google Scholar] [CrossRef] [Green Version]

- Yang, K.L.; Wang, Y.S. Error Analysis of Roughness Coefficient Calibration for Channels. J. Hydraul. Eng. 2012, 43, 639–644. [Google Scholar] [CrossRef]

- He, Z.; Zheng, Q.; Cai, X.H. Water Characteristics between Nanoparticles of Calcium Silicate Hydrate. J. Hydraul. Eng. 2014, 45, 205–212. [Google Scholar] [CrossRef]

- Li, L.Q.; Chen, X.N.; Chen, W.X. A Probe into the Surface Roughness Reduction and Protection of Typical Water Conveyance Structures in the South-to-North Water Diversion Middle Route project. China Rural Water Hydropower 2022, 10, 143–147+153. [Google Scholar] [CrossRef]

- GBT 21303-2017; Specifications for Water Measurement of Irrigation Canal System. State General Administration of the People’s Republic of China for Quality Supervision and Inspection and Quarantine. Standardization Administration of the People’s Republic of China: Beijing, China, 2017.

- SL 337-2006; Code for Discharge Measurement of Acoustic Doppler Current. Ministry of Water Resources of the People’s Republic of China: Beijing, China, 2006.

| No. | Type | Model or Specification | Main Performance Indicators | Measurements | Year of Observation |

|---|---|---|---|---|---|

| 1 | Radar water level gauge | HZ-RLS-26L-50 | Range: 0.25–15 m; Range hole: 0.25 m; Range accuracy: ±2 mm | Water level | 2021/2023 |

| 2 | ADCP | SonTek RiverSurveyor | Velocity measurement range: ±10 m/s; Resolution: 0.001 m/s; Accuracy: ±1% | Discharge | 2023 |

| 3 | Remotely controlled, unmanned ship system | Nortek USV | Scope of application: rivers or channels with a velocity of 0–5 m/s | / | 2023 |

| 4 | Electronic level | Leica SPRINTER 100/100M | Elevation measurement accuracy: 2.0 mm; Distance measurement accuracy: standard deviation = 1‰ of the measured value; Distance measurement range: 2–80 m | Elevation | 2021/2023 |

| 5 | Rangefinder | Leica D5 | Measuring range: 0.05–200 m; Measuring accuracy: ±1.0 mm | Distance | 2021/2023 |

| 6 | Electromagnetic flowmeter | ACM2-RS | Measuring range: ±2.50 m/s; Measuring accuracy: ±0.005 m/s or ±2% (0–±1 m/s); Resolution: 0.001 m/s; | Flow velocity | 2021 |

| Working Condition | Aqueduct Body | Water Depth at the Upstream Measurement Cross-Section (m) | Water Depth at the Downstream Measurement Cross-Section (m) | Cross-Sectional Average Flow Velocity (m/s) | Flow Rate (m3/s) | Roughness |

|---|---|---|---|---|---|---|

| #1_2021_Before | #1 | 3.519 | 3.470 | 2.217 | 53.216 | 0.0130 |

| #1_2021_After | #1 | 3.462 | 3.441 | 2.305 | 54.859 | 0.0105 |

| #2_2021_Before | #2 | 3.476 | 3.438 | 2.079 | 49.530 | 0.0132 |

| #2_2021_After | #2 | 3.468 | 3.443 | 2.110 | 50.342 | 0.0120 |

| Working Condition | Aqueduct Body #1 | Aqueduct Body #2 | Aqueduct Body #3 | Aqueduct Outlet |

|---|---|---|---|---|

| #1_2023_After | 45.431 | 0.000 | 42.748 | 87.794 |

| #2_2023_After | 10.907 | / | 10.376 | 86.933 |

| Working Condition | Aqueduct Body | Water Depth at the Upstream Measurement Cross-Section (m) | Water Depth at the Downstream Measurement Cross-Section (m) | Cross-Sectional Average Flow Velocity (m/s) | Flow Rate (m3/s) | Roughness |

|---|---|---|---|---|---|---|

| #1_2023_After | #1 | 4.015 | 4.012 | 1.631 | 45.431 | 0.0135 |

| #2_2023_After | #2 | 4.202 | 4.135 | 2.269 | 65.650 | 0.0147 |

| Item | 2021 | 2023 | Notes | |

|---|---|---|---|---|

| Before Reduction | Immediately after Reduction | Two Years after Reduction | ||

| Roughness of aqueduct body 1 | 0.0130 | 0.0105 | 0.0135 | Cleaning and coating |

| Roughness of aqueduct body 2 | 0.0132 | 0.0120 | 0.0147 | Cleaning |

| Difference in the roughnesses of aqueduct bodies 1 and 2 | 0.0002 | 0.0015 | 0.0012 | Including the difference in background roughness |

| 0 | 0.0013 | 0.0010 | Excluding the difference in background roughness | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, W.; Chen, W.; Mu, X.; Xiong, Q.; Li, J.; Li, X.; Liu, Z.; Zhang, Z. Experimental Study of Roughness Reduction of Large Aqueducts in the Middle Route of the South-to-North Water Diversion Project. Water 2023, 15, 2640. https://doi.org/10.3390/w15142640

Cui W, Chen W, Mu X, Xiong Q, Li J, Li X, Liu Z, Zhang Z. Experimental Study of Roughness Reduction of Large Aqueducts in the Middle Route of the South-to-North Water Diversion Project. Water. 2023; 15(14):2640. https://doi.org/10.3390/w15142640

Chicago/Turabian StyleCui, Wei, Wenxue Chen, Xiangpeng Mu, Qilin Xiong, Junqiang Li, Xiaochen Li, Zhe Liu, and Zheqi Zhang. 2023. "Experimental Study of Roughness Reduction of Large Aqueducts in the Middle Route of the South-to-North Water Diversion Project" Water 15, no. 14: 2640. https://doi.org/10.3390/w15142640