Sludge Treatment Wetland for Treating Microalgae Digestate Grown in Agricultural Runoff: A Technical, Economic, and Environmental Assessment

Abstract

1. Introduction

2. Materials and Methods

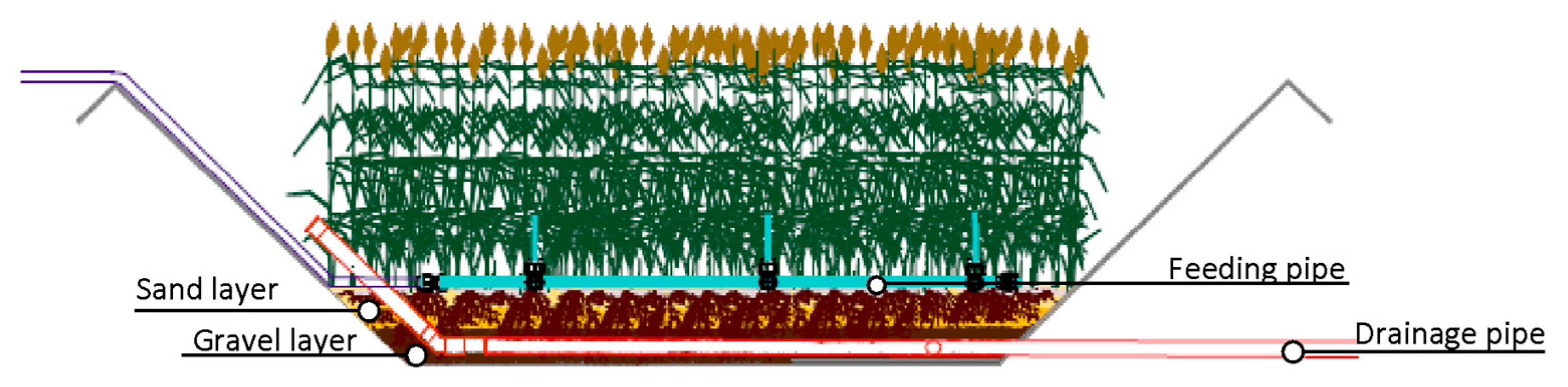

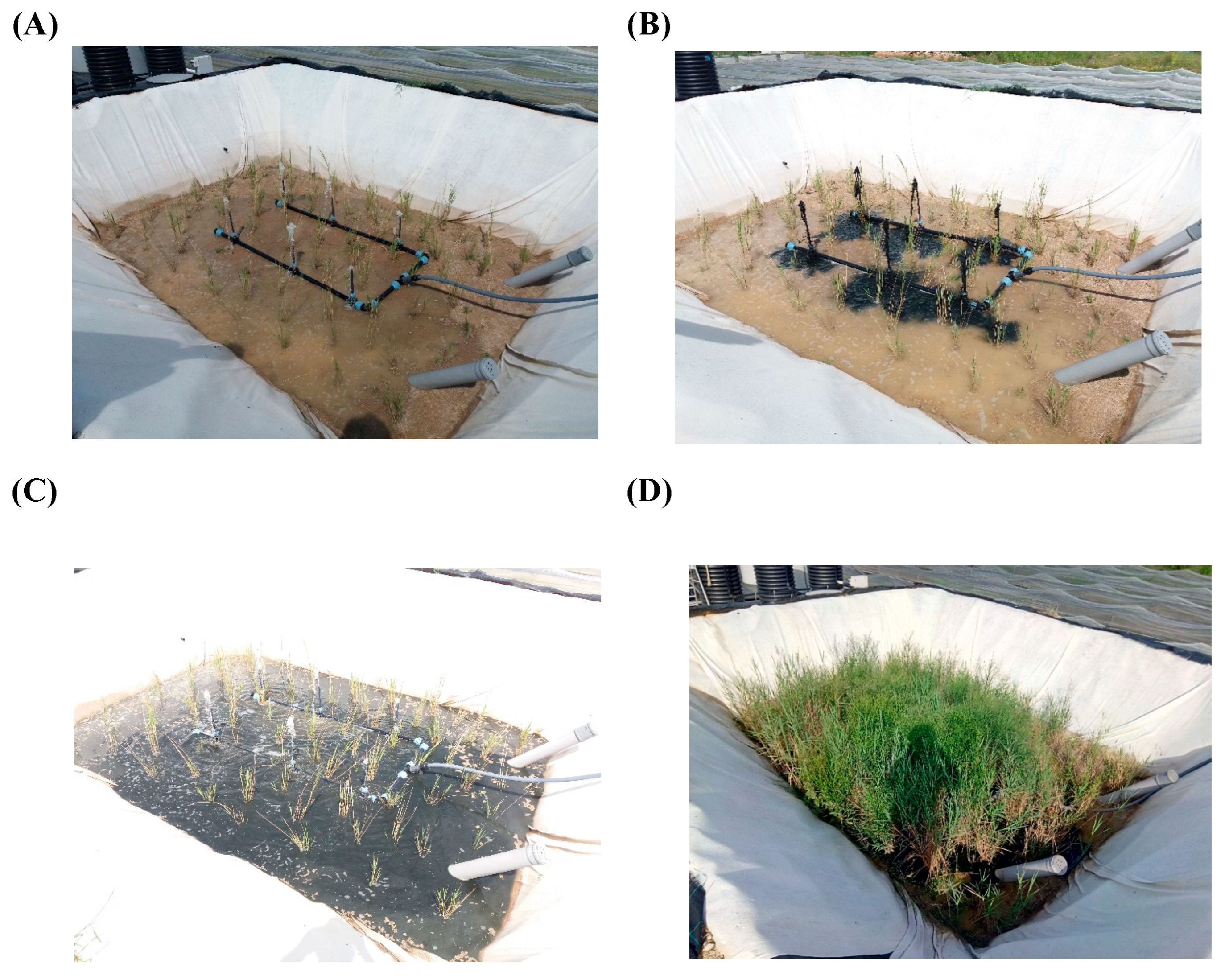

2.1. Experimental Setup

2.2. Sample Collection and Characterization

2.3. Sustainability Assessment

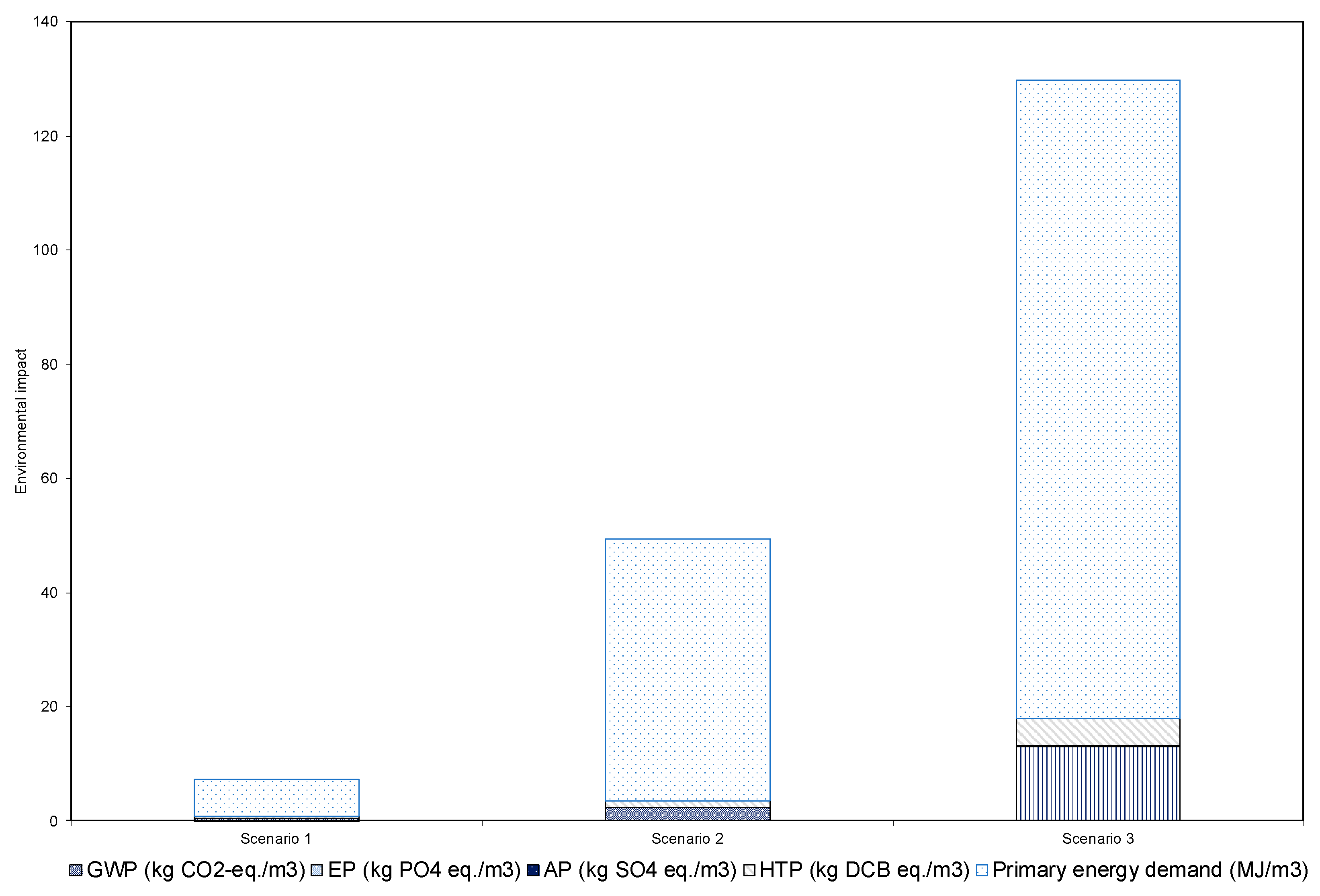

- The first scenario contains the STW and field application of the dried digestate (30% of dry matter (DM)) with transport.

- The second scenario comprised dewatering with a centrifuge and field application of the dewatered digestate. The dry matter content of digestate after dewatering reached 30% as well.

- The third scenario consists of the centrifuge dewatering step that is followed by digestate incineration and, finally, land application of ash.

3. Results

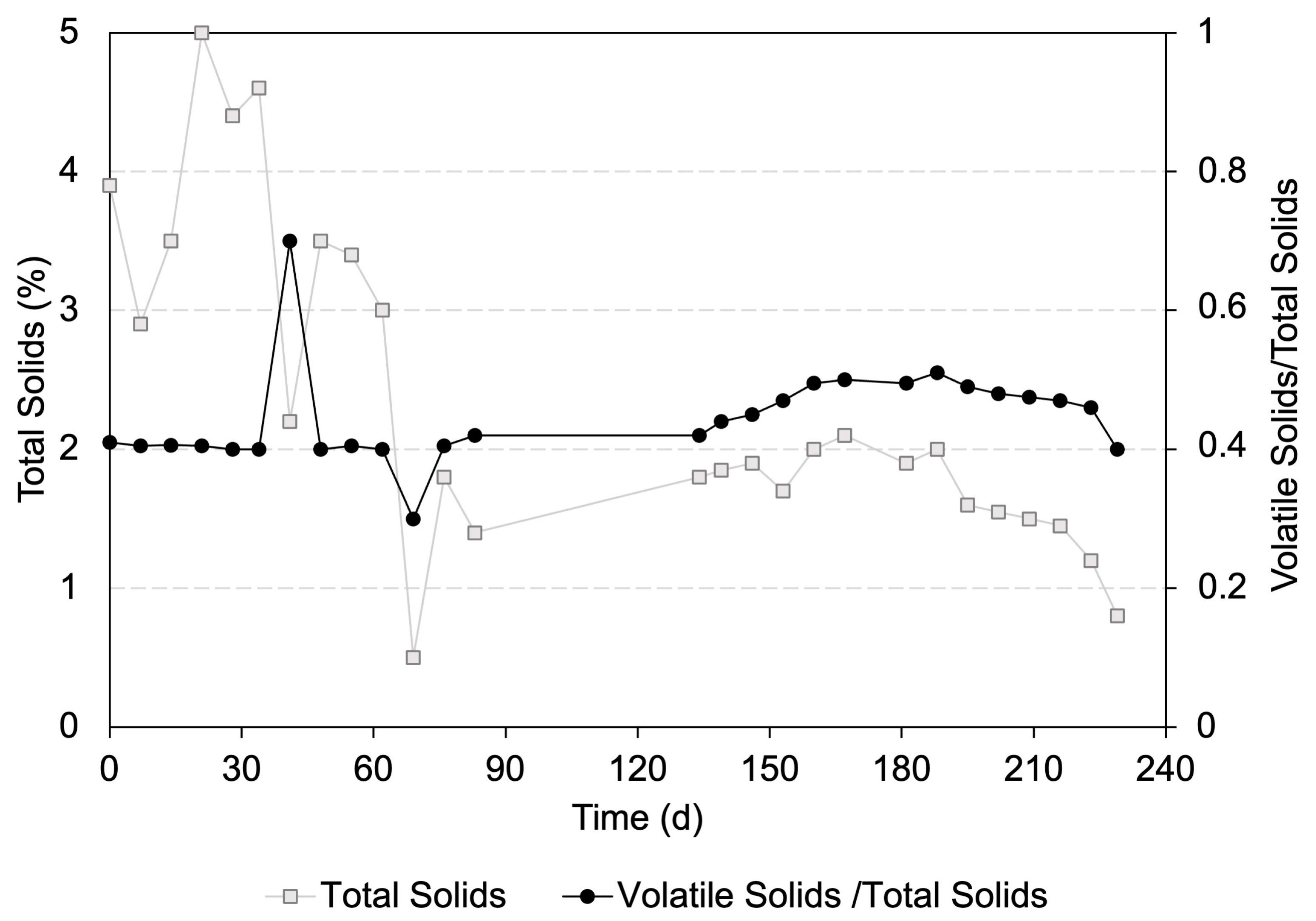

3.1. STW Performance Characterization

3.2. Environmental Impact LCA

3.3. Economic Impact LCC

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbol and Abbreviations | Description |

| AC | acidification potential |

| LCA | life cycle assessment |

| Cd | cadmium |

| CAPEX | capital expenditures |

| Cr | chromium |

| Cu | copper |

| DM | dry matter |

| DW | dry weight |

| EC | European Commission |

| EU | European Union |

| EP | eutrophication potential |

| FU | functional unit |

| GWP | global warming potential |

| HTP | human toxicity potential |

| Fe | iron |

| Pb | lead |

| LCC | life-cycle costing |

| Mn | mangesium |

| Ni | niquel |

| OPEX | operational expenditures |

| PE | primary energy use |

| STW | Sludge Treatment Wetlands |

| TC | total carbon |

| TN | total nitrogen |

| TS | total solids |

| UPC | unit production costs |

| VS | volatile solids |

| Zn | zinc |

References

- United Nations Environment. The United Nations world water development report, 2017: Wastewater: The untapped resource. J. Chem. Inf. Model. UNESCO 2017, 689–1699. Available online: https://unesdoc.unesco.org/ark:/48223/pf0000247153 (accessed on 20 February 2023).

- Tarantini, M.; Buttol, P.; Maiorino, L. An environmental LCA of alternative scenarios of urban sewage sludge treatment and disposal. Therm. Sci. 2007, 11, 153–164. [Google Scholar] [CrossRef]

- Uggetti, E.; Ferrer, I.; Molist, J.; García, J. Technical, economic and environmental assessment of sludge treatment wetlands. Water Res. 2011, 45, 573–582. [Google Scholar] [CrossRef]

- Uggetti, E.; Ferrer, I.; Llorens, E.; García, J. Sludge treatment wetlands: A review on the state of the art. Bioresour. Technol. 2010, 101, 2905–2912. [Google Scholar] [CrossRef]

- Brix, H. Sludge Dewatering and Mineralization in Sludge Treatment Reed Beds. Water 2017, 9, 160. [Google Scholar] [CrossRef]

- Nielsen, S. Sludge reed bed facilities: Operation and problems. Water Sci. Technol. 2005, 51, 99–107. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, S. Sludge treatment reed bed facilities—Organic load and operation problems. Water Sci. Technol. 2011, 63, 941–947. [Google Scholar] [CrossRef]

- Luo, H.; Duan, M.; He, L.; Yang, S.; Zou, Y.; Tang, X. A New Organic-Inorganic Compound Fertilizer for Improving Growth, Yield, and 2-Acetyl-1-Pyrroline Biosynthesis of Fragrant Rice. Agriculture 2021, 11, 1121. [Google Scholar] [CrossRef]

- Dharminder; Singh, R.K.; Kumar, V.; Pramanick, B.; Alsanie, W.F.; Gaber, A.; Hossain, A. The use of municipal solid waste compost in combination with proper irrigation scheduling influences the productivity, microbial activity and water use efficiency of direct seeded rice. Agriculture 2021, 11, 941. [Google Scholar] [CrossRef]

- Frišták, V.; Pipíška, M.; Koperová, D.; Jagerhofer, R.; Soja, G.; Bell, S.M. Utilization of Sewage Sludge-Derived Pyrogenic Material as a Promising Soil Amendment. Agriculture 2022, 12, 360. [Google Scholar] [CrossRef]

- Mahapatra, D.M.; Satapathy, K.C.; Panda, B. Biofertilizers and nanofertilizers for sustainable agriculture: Phycoprospects and challenges. Sci. Total Environ. 2022, 803, 149990. [Google Scholar] [CrossRef] [PubMed]

- Pajura, R.; Masłoń, A.; Czarnota, J. The Use of Waste to Produce Liquid Fertilizers in Terms of Sustainable Development and Energy Consumption in the Fertilizer Industry—A Case Study from Poland. Energies 2023, 16, 1747. [Google Scholar] [CrossRef]

- Bora, R.R.; Richardson, R.E.; You, F. Resource recovery and waste-to-energy from wastewater sludge via thermochemical conversion technologies in support of circular economy: A comprehensive review. BMC Chem. Eng. 2020, 2, 8. [Google Scholar] [CrossRef]

- García, J.; Ortiz, A.; Álvarez, E.; Belohlav, V.; García-Galán, M.J.; Díez-Montero, R.; Álvarez, J.A.; Uggetti, E. Nutrient removal from agricultural run-off in demonstrative full scale tubular photobioreactors for microalgae growth. Ecol. Eng. 2018, 120, 513–521. [Google Scholar] [CrossRef]

- Council Directive 86/278/EEC of 12 June 1986 on the Protection of the Environment, and in Particular of the Soil, when Sewage Sludge is Used in Agriculture. Available online: https://www.legislation.gov.uk/eudr/1986/278/contents (accessed on 20 February 2023).

- EC 2000 Water Framework Directive 2000/60/EC of the European Parliament and of the Council Establishing a Framework for the Community Action in the Field of Water Policy. Available online: https://eur-lex.europa.eu/eli/dir/2000/60/oj (accessed on 20 February 2023).

- Uggetti, E.; García, J.; Álvarez, J.A.; García-Galán, M.J. Start-up of a microalgae-based treatment system within the biorefinery concept: From wastewater to bioproducts. Water Sci. Technol. 2018, 78, 114–124. [Google Scholar] [CrossRef]

- Díez-Montero, R.; Vassalle, L.; Passos, F.; Ortiz, A.; García-Galán, M.J.; García, J.; Ferrer, I. Scaling-Up the Anaerobic Digestion of Pretreated Microalgal Biomass within a Water Resource Recovery Facility. Energies 2020, 13, 5484. [Google Scholar] [CrossRef]

- Ortiz, A.; García-Galán, M.J.; García, J.; Díez-Montero, R. Optimization and operation of a demonstrative full scale microalgae harvesting unit based on coagulation, flocculation and sedimentation. Sep. Purif. Technol. 2021, 259, 118171. [Google Scholar] [CrossRef]

- Ortiz, A.; García, J.; Uggetti, E.; Díez-Montero, R. Optimization of multi-stage thickening of biomass in a demonstrative full–scale microalgae-based wastewater treatment system. Sep. Purif. Technol. 2022, 281, 119830. [Google Scholar] [CrossRef]

- APHA; AWWA; WPCF. Standard Methods for the Examination of Water and Wastewater, 20th ed.; APHA, AWWA, WPCF: Washington, DC, USA, 2001. [Google Scholar]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Gargalo, C.L.; Cheali, P.; Posada, J.A.; Carvalho, A.; Gernaey, K.V.; Sin, G. Assessing the environmental sustainability of early stage design for bioprocesses under uncertainties: An analysis of glycerol bioconversion. J. Clean. Prod. 2016, 139, 1245–1260. [Google Scholar] [CrossRef]

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life Cycle Assessment: Past, Present, and Future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef] [PubMed]

- Roskosch, A.; Heidecke, P. Klärschlammentsorgung in der Bundesrepublik Deutschland; Umweltbundesamt: Dessau-Roßlau, Germany, 2018. [Google Scholar]

- Wiechmann, B.; Dienemann, C.; Kabbe, C.; Brandt, S.; Vogel, I.; Roskosch, A. Klärschlammentsorgung in der Bundesrepublik Deutschland, Stand: 01.01.2012. Ed.; Umweltbundesamt: Dessau-Roßlau, Germany, 2012. [Google Scholar]

- Becker, E.W. Micro-algae as a source of protein. Biotechnol. Adv. 2007, 25, 207–210. [Google Scholar] [CrossRef] [PubMed]

- Marschner, P. Marschner’s Mineral Nutrition of Higher Plants, 3rd ed.; Academic Press: Cambridge, MA, USA, 2011; 651p. [Google Scholar] [CrossRef]

- Taiz, L.; Zeiger, E. Plant physiology. 3rd edn. Ann. Bot. 2003, 91, 750. [Google Scholar] [CrossRef]

- White, P.J.; Brown, P.H. Plant nutrition for sustainable development and global health. Ann. Bot. 2010, 105, 1073–1080. [Google Scholar] [CrossRef]

- Saeed, M.; Hassan, A. Magnesium and sodium in sludge stabilized with chemical and biological agents for reuse in agriculture. J. Environ. Sci. Health Part A Toxic/Hazard. Subst. Environ. Eng. 2008, 43, 1918–1923. [Google Scholar]

- Gondek, K.; Filiper-Mazur, B. Yielding and the contents of Calcium, Magnesium and Sodium in maize fertilized with organic materials. Ecol. Chem. Eng. A 2009, 16, 1284–1292. [Google Scholar]

- Oehme, S.; Fuchinoue, Y.; Van Leeuwen, E. Application of Sewage Sludge to Agricultural Land: Nutrient Contents and Fate of Heavy Metals and Pollutants. In Hazardous Waste Management; IntechOpen: London, UK, 2012; pp. 1–7. [Google Scholar] [CrossRef]

| Material or Energy Flow | Amount | |

|---|---|---|

| Infrastructure | Excavation, m3 | 50.08 |

| Steel, kg | 1.57 | |

| PE tube, kg | 34.76 | |

| PE liner, kg | 113.98 | |

| PP tube, kg | 5.85 | |

| PP geotextile, kg | 36.00 | |

| Rubber, kg | 0.20 | |

| Bitumen, kg | 0.30 | |

| Pump, kg | 82.00 | |

| Sand, kg | 7680.00 | |

| Gravel, kg | 43,200.00 | |

| Earth, kg | 72,115.20 | |

| Land occupation, m2 | 2000.00 | |

| Operation | Transport, km | 2557.73 |

| Electricity, MJ | 953.33 | |

| Credits | Superphosphate equivalent, kg | 2840.7 |

| Potassium chloride, kg | 1412.5 | |

| Material or Energy Flow | Amount | |

|---|---|---|

| Dewatering | Excavation, m3 | 18.278 |

| Transport, km | 2335.72 | |

| Gravel, kg | 20246.4 | |

| Concrete, kg | 22,496 | |

| Concrete working, kg | 22,496 | |

| Glass fibre reinforced plastic, kg | 637.71 | |

| Steel, kg | 1462.63 | |

| Pump, kg | 111.75 | |

| PAM, kg | 58,788.756 | |

| Polymer dosing unit, PEHD, kg | 320 | |

| Polymer dosing unit, PVC, kg | 200 | |

| Polymer dosing unit, steel, kg | 80 | |

| Agitator TIMSA, steel, kg | 120 | |

| Agitator TIMSA, motor, kg | 40 | |

| Land occupation, m2 | 2000 | |

| Electricity, MJ | 2,035,123.2 | |

| Centrifugal decanter | Steel, kg | 800 |

| Steelworking, kg | 800 | |

| Electric motor, kg | 200 | |

| Electricity, MJ | 2,312,640 | |

| Incineration | Unit process for municipal sludge, kg | 22,445,455.4 |

| Transport, km | 1,468,799.1 | |

| Spreading of ash | Unit process, kg | 3,022,200 |

| Transport, km | 151,110 | |

| Crediting ash | Superphosphate | 163,932.17 |

| KCl | 81,111.111 | |

| Ammonium nitrate | 35,713.781 | |

| Spreading of dewatered sludge | Unit process, kg | 22,445,455.42 |

| Transport, km | 1,122,272.771 | |

| Crediting sludge | Superphosphate | 163,932.172 |

| KCl | 81,111.111 | |

| Ammonium nitrate | 35,713.781 | |

| Cu | Zn | Fe | Mn | Ni | Cd | Cr | Pb | |

|---|---|---|---|---|---|---|---|---|

| Council Directive 86/278/EEC limits (mg/kg) | 1000–1750 | 4000 | - | - | 300–400 | 20–40 | - | 750–1200 |

| STW (mg/kg DW) | 50 ± 0 | 291.5 ± 0.70 | 7873 ± 144 | 290 ± 2.82 | 31 ± 1.41 | 0.7 ± 0 | 26 ± 1.27 | 11.85 ± 0.35 |

| CAPEX EUR | OPEX (EUR/Year) | LCC, Discounted Total Costs (EUR/Lifetime) | Unit Production Cost (EUR/m3) | |

|---|---|---|---|---|

| STW | 4296.69 | 126.16 | 9852.86 | 1.74 |

| Dewatering | 122,947.25 | 8565.61 | 444,423.22 | 1.52 |

| STW and field application | n.a. | n.a. | 20,973.30 | 3.71 |

| Dewatering and field application | n.a. | n.a. | 1,018,923 | 3.49 |

| Dewatering, incineration, and field application | n.a. | n.a. | 1,653,159 | 5.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gonzalez-Flo, E.; Ortiz, A.; A. Arias, C.; Díez-Montero, R.; Kohlheb, N.; Schauser, U.-H.; García, J.; Gregersen, P.K.S. Sludge Treatment Wetland for Treating Microalgae Digestate Grown in Agricultural Runoff: A Technical, Economic, and Environmental Assessment. Water 2023, 15, 2159. https://doi.org/10.3390/w15122159

Gonzalez-Flo E, Ortiz A, A. Arias C, Díez-Montero R, Kohlheb N, Schauser U-H, García J, Gregersen PKS. Sludge Treatment Wetland for Treating Microalgae Digestate Grown in Agricultural Runoff: A Technical, Economic, and Environmental Assessment. Water. 2023; 15(12):2159. https://doi.org/10.3390/w15122159

Chicago/Turabian StyleGonzalez-Flo, Eva, Antonio Ortiz, Carlos A. Arias, Rubén Díez-Montero, Norbert Kohlheb, Ulf-Henning Schauser, Joan García, and Peder K. S. Gregersen. 2023. "Sludge Treatment Wetland for Treating Microalgae Digestate Grown in Agricultural Runoff: A Technical, Economic, and Environmental Assessment" Water 15, no. 12: 2159. https://doi.org/10.3390/w15122159

APA StyleGonzalez-Flo, E., Ortiz, A., A. Arias, C., Díez-Montero, R., Kohlheb, N., Schauser, U.-H., García, J., & Gregersen, P. K. S. (2023). Sludge Treatment Wetland for Treating Microalgae Digestate Grown in Agricultural Runoff: A Technical, Economic, and Environmental Assessment. Water, 15(12), 2159. https://doi.org/10.3390/w15122159