Energy Consumption and Carbon Footprint of Greek Wastewater Treatment Plants

Abstract

:1. Introduction

2. Materials and Methods

- CO2 production from biomass decay;

- CO2 production from BOD removal and biomass production;

- CO2 consumption from nitrification;

- CO2 production from denitrification;

- Ν2O (in equivalent CO2) production from nitrification and denitrification processes;

- CO2 production from biogas use for heating and electricity production;

- CO2 production from biogas leakage to the atmosphere. A biogas leakage of 1% was assumed in this study;

- CO2 production from chemicals used in the WWTP;

- Off-site GHG emissions considered in this study were:

- Net power consumption;

- Sludge disposal;

- Discharge to the effluent.

3. Results and Discussion

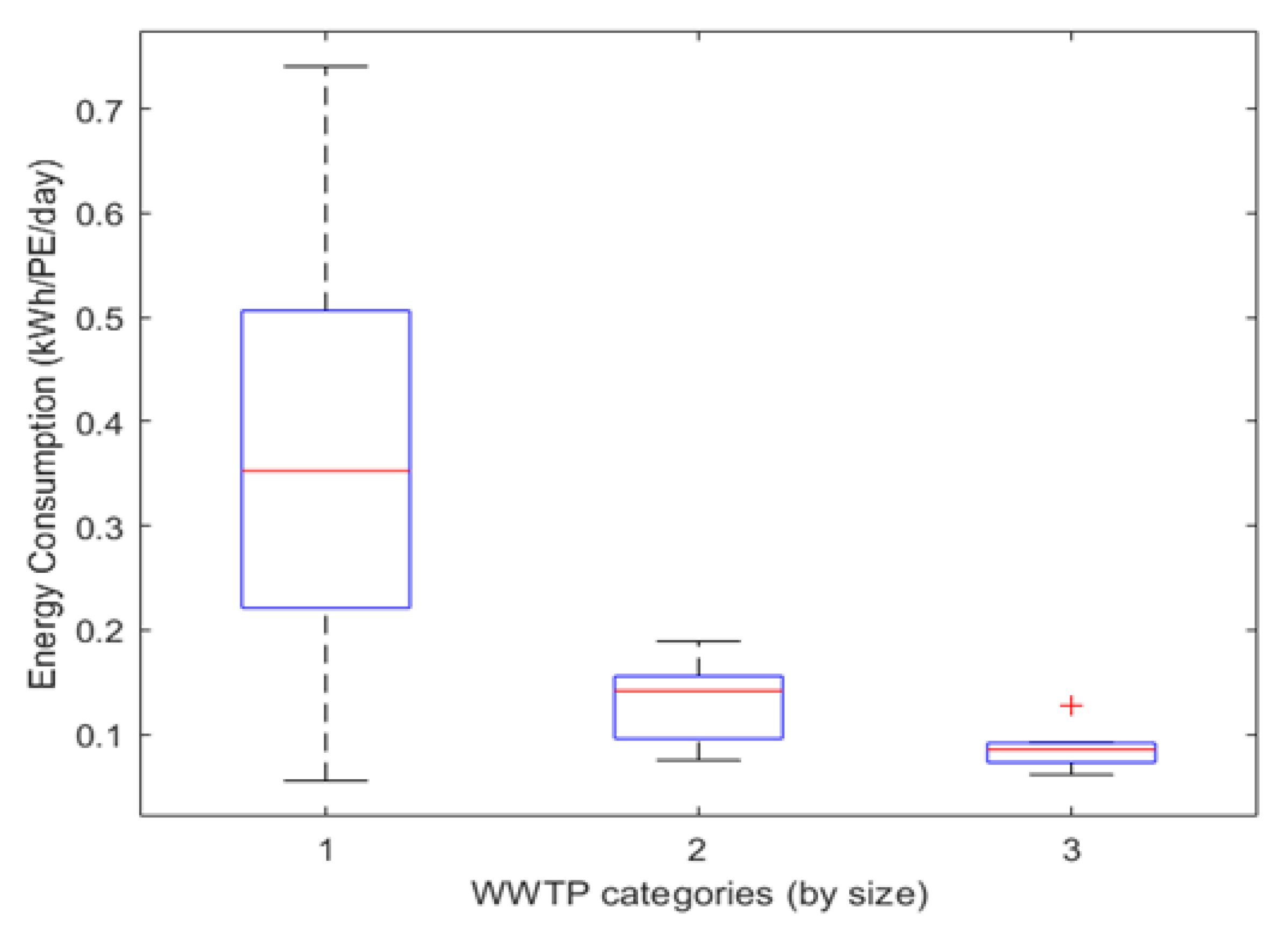

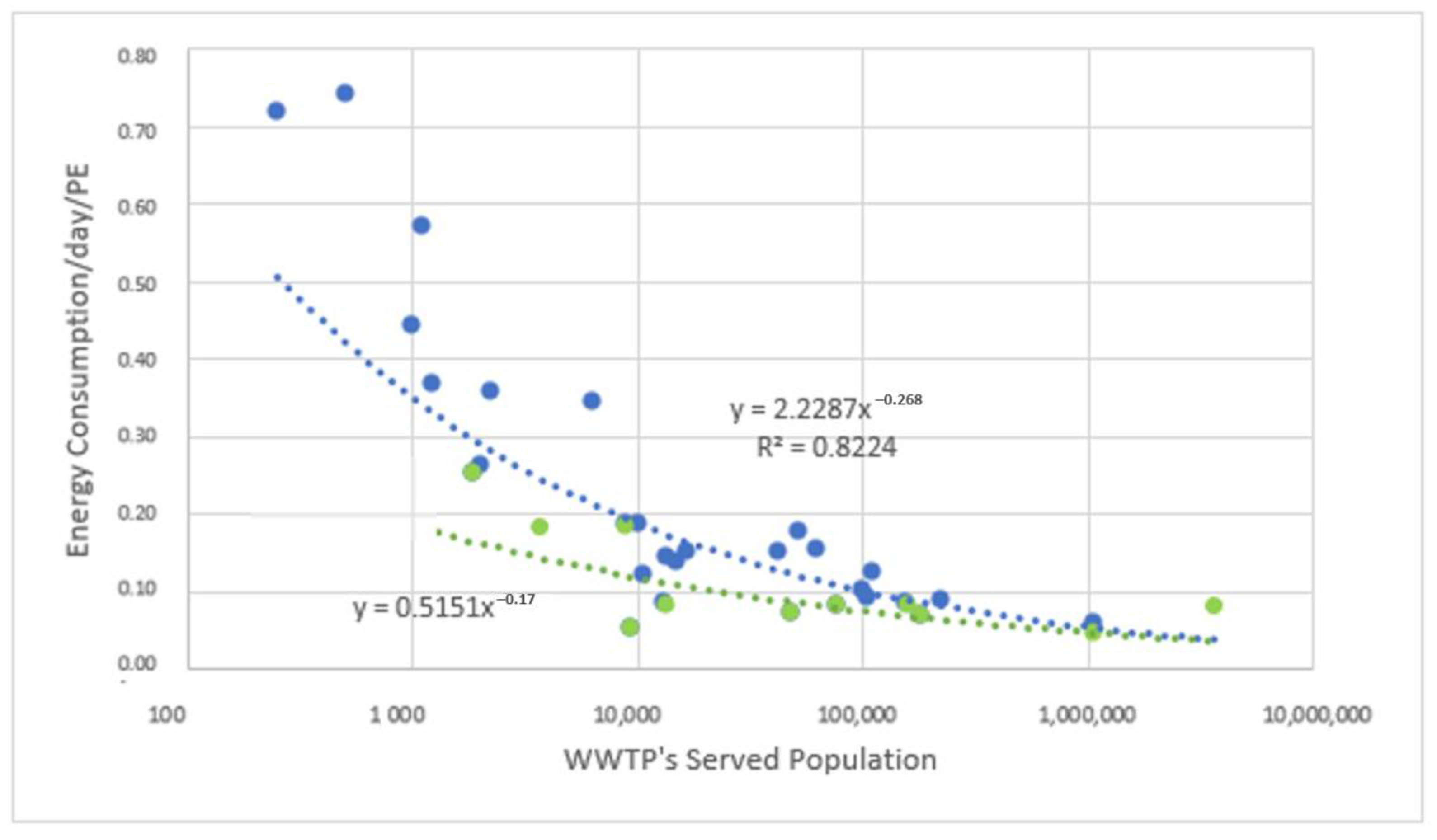

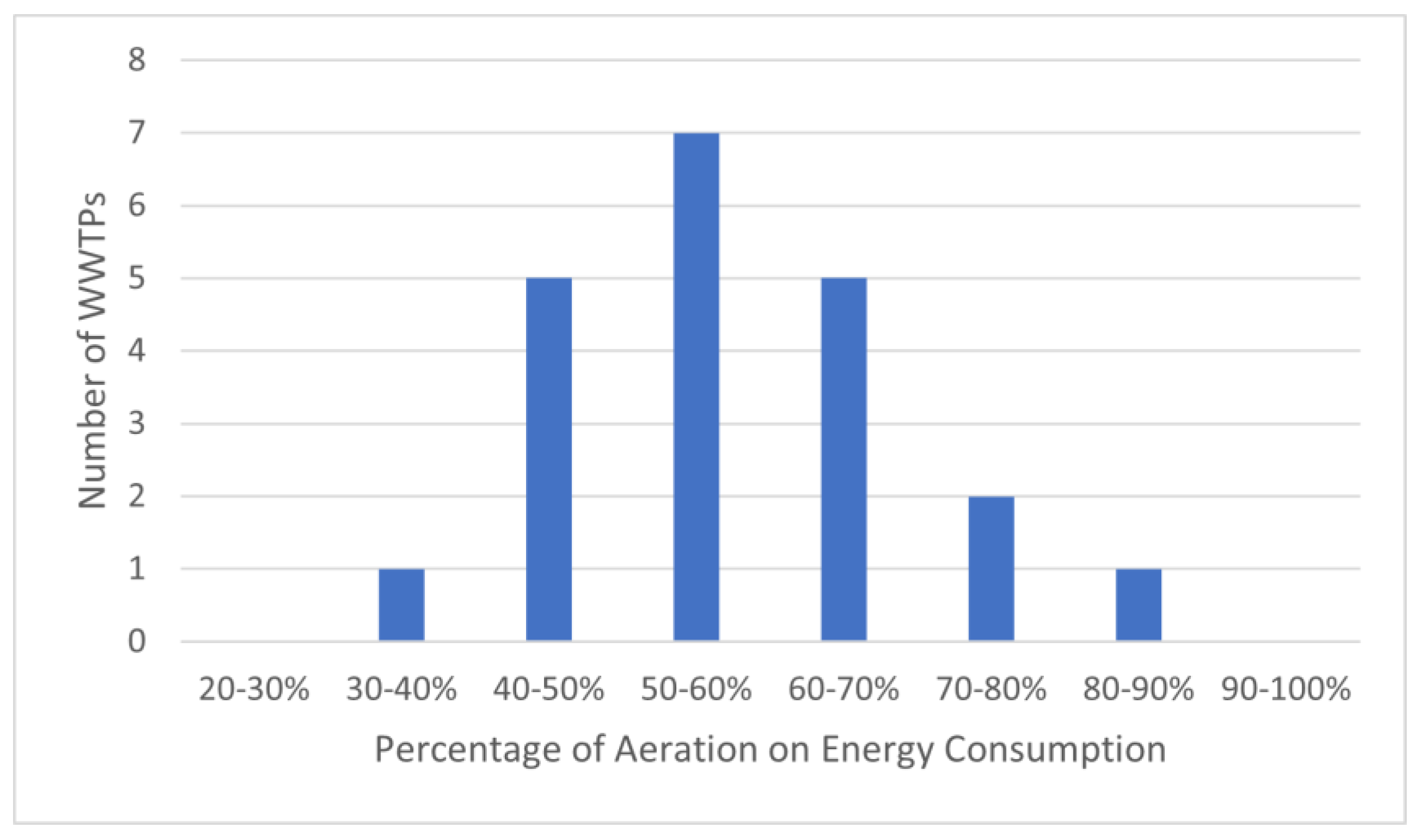

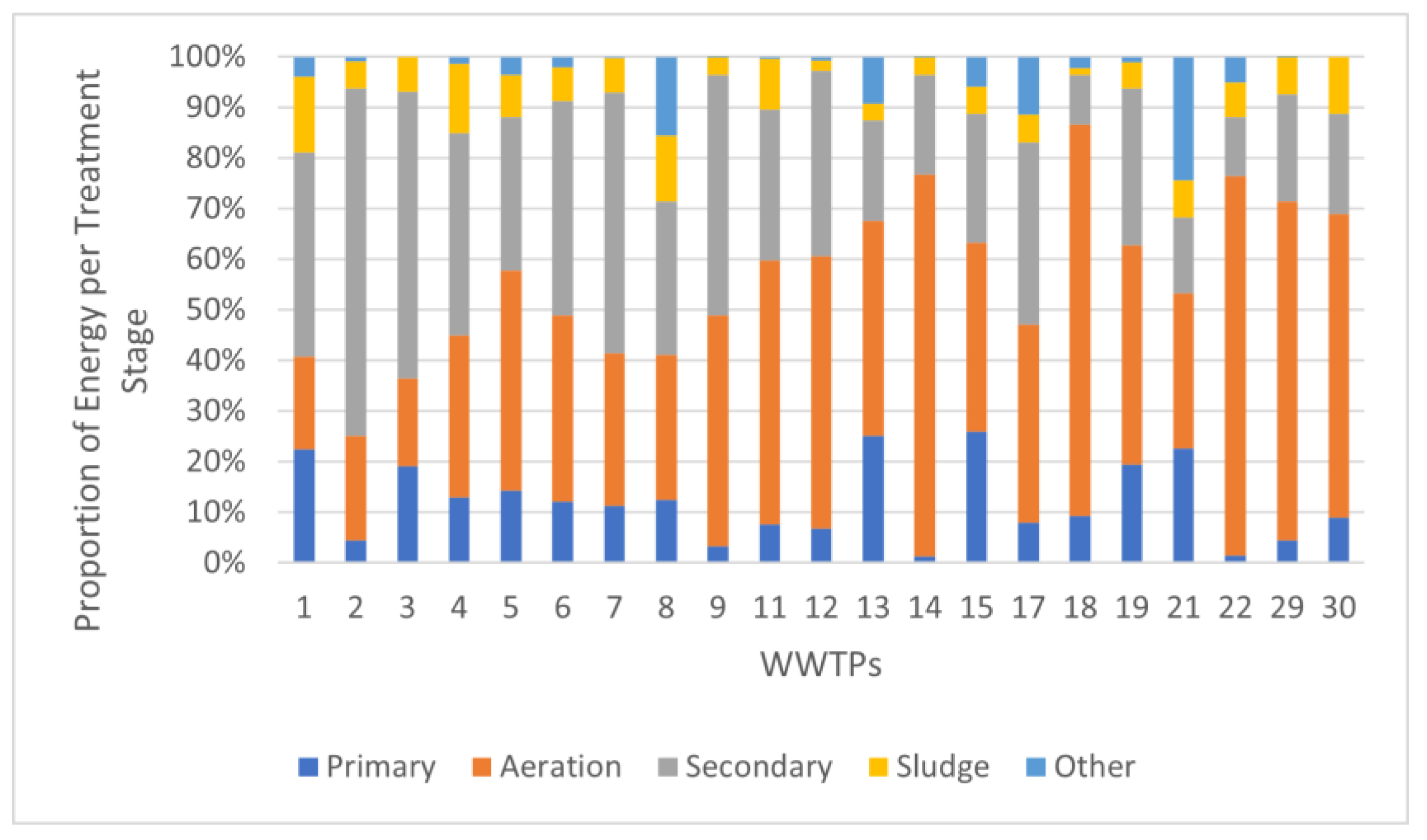

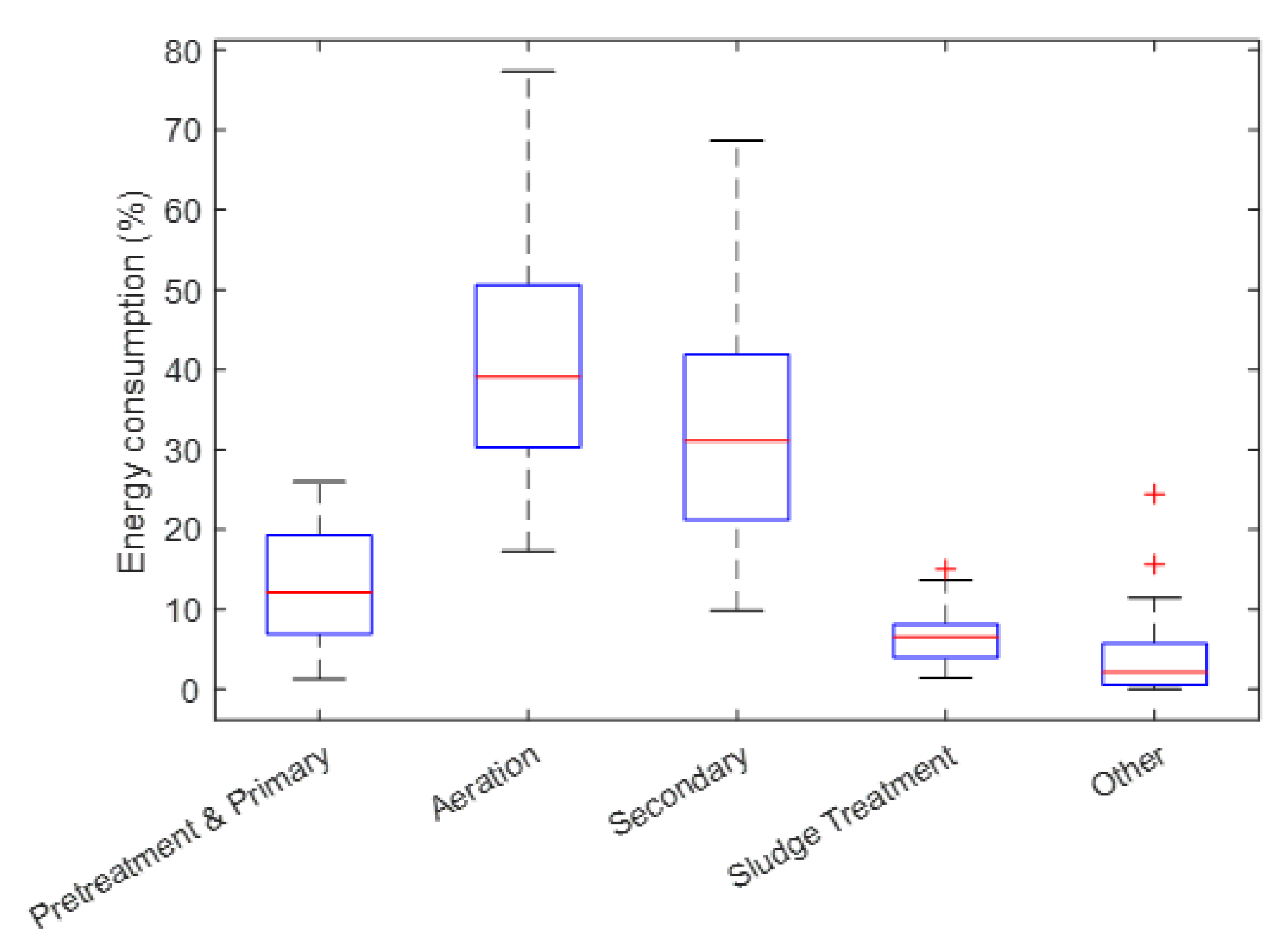

3.1. Energy Consumption

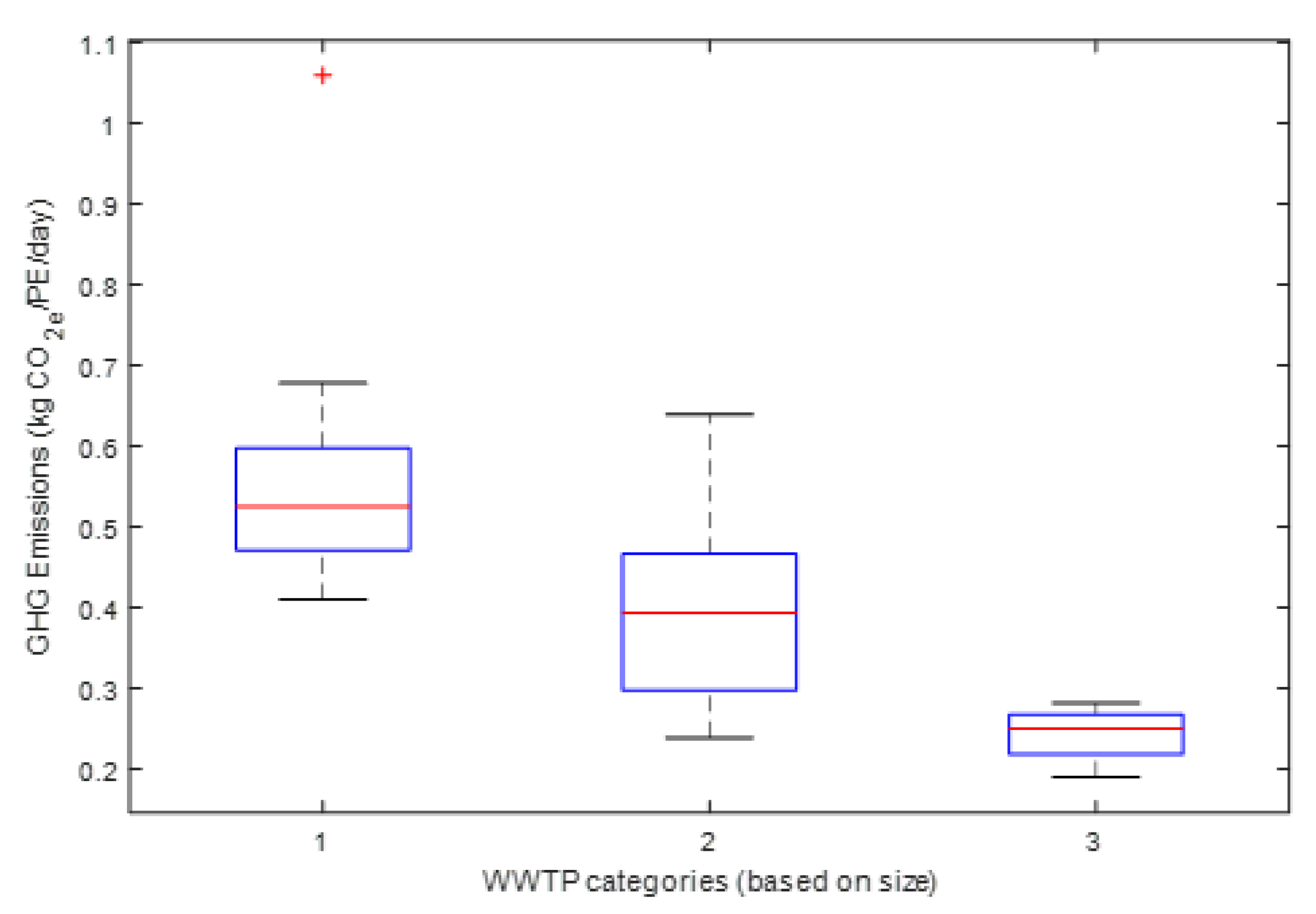

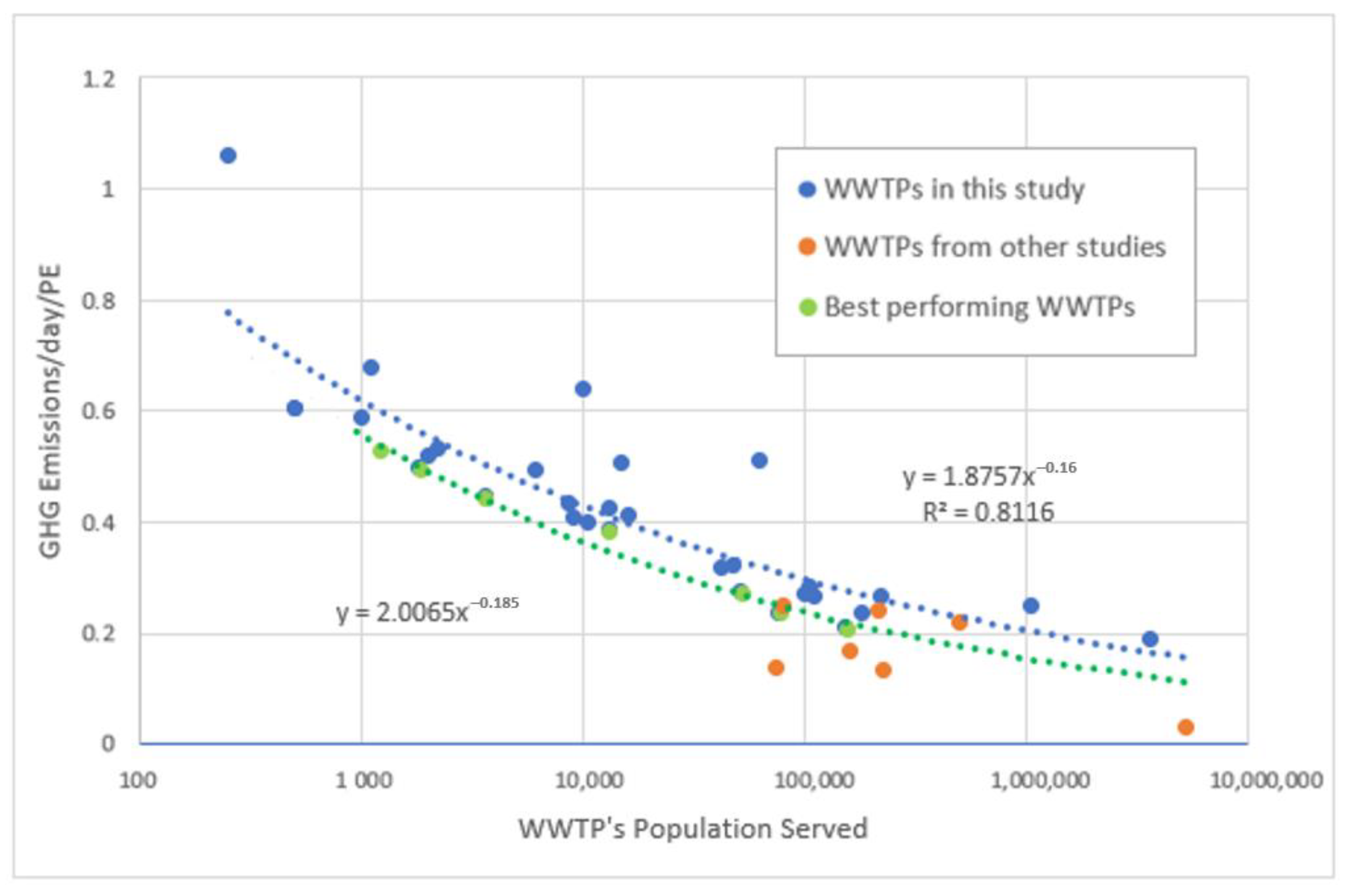

3.2. GHG Emissions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gu, Y.; Li, Y.; Li, X.; Luo, P.; Wang, H.; Wang, X.; Wu, J.; Li, F. Energy self-sufficient wastewater treatment plants: Feasibilities and challenges. Energy Procedia 2017, 105, 3741–3751. [Google Scholar] [CrossRef]

- Tolkou, A.K.; Zouboulis, A.I. Effect of climate change in WWTPs with a focus on MBR infrastructure. Desalination Water Treat. 2016, 57, 2344–2354. [Google Scholar] [CrossRef]

- Dickin, S.; Bayoumi, M.; Giné, R.; Andersson, K.; Jiménez, A. Sustainable Sanitation and gaps in global climate policy and financing. Npj Clean Water 2020, 3, 24. [Google Scholar] [CrossRef]

- Daw, J.; Hallett, K.; DeWolfe, J.; Venner, I. Energy Efficiency Strategies for Municipal Wastewater Treatment Facilities; Technical Report NREL/TP-7A30-53341; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2012.

- Simon-Várhelyi, M.; Cristea, V.M.; Luca, A.V. Reducing energy costs of the wastewater treatment plant by improved scheduling of the periodic influent load. J. Environ. Manag. 2020, 262, 110294. [Google Scholar] [CrossRef] [PubMed]

- Vergara-Araya, M.; Hilgenfeldt, V.; Peng, D.; Steinmetz, H.; Wiese, J. Modelling to lower energy consumption in a large wwtp in china while optimising nitrogen removal. Energies 2021, 14, 5826. [Google Scholar] [CrossRef]

- Stillwell, A.; Hoppock, D.; Webber, M. Energy recovery from wastewater treatment plants in the United States: A case study of the energy-water nexus. Sustainability 2010, 2, 945–962. [Google Scholar] [CrossRef] [Green Version]

- Jonasson, M. Energy Benchmark for Wastewater Treatment Processes—A Comparison between Sweden and Austria; Department of Industrial Electrical Engineering and Automation, Lund University: Lund, Sweden, 2007. [Google Scholar]

- Balmer, P. Operation costs and consumption of resources at nordic nutrient removal plants. Water Sci. Technol. 2000, 41, 273–279. [Google Scholar] [CrossRef]

- Krampe, J. Energy benchmarking of South Australian WWTPs. Water Sci. Technol. 2013, 67, 2059–2066. [Google Scholar] [CrossRef]

- Mamais, D.; Noutsopoulos, C.; Dimopoulou, A.; Stasinakis, A.; Lekkas, T.D. Wastewater treatment process impact on energy savings and greenhouse gas emissions. Water Sci. Technol. 2015, 71, 303–308. [Google Scholar] [CrossRef]

- O’Conner, K.; Cantwell, J.; Wilson, M.; Bolles, S.; Schmidt, A.; Burgess, J. Evaluation of Energy Conservation Measures for Wastewater Treatment Facilities; EPA: Washington, DC, USA, 2010.

- EPA Estimate of Global Greenhouse Gas Emissions from Industrial and Domestic Wastewater Treatment; EPA: Washington, DC, USA, 1997.

- Zib, L.; Byrne, D.M.; Marston, L.T.; Chini, C.M. Operational carbon footprint of the U.S. water and wastewater sector’s energy consumption. J. Clean. Prod. 2021, 321, 128815. [Google Scholar] [CrossRef]

- Gustavsson, D.J.I.; Tumlin, S. Carbon footprints of scandinavian wastewater treatment plants. Water Sci. Technol. 2013, 68, 887–893. [Google Scholar] [CrossRef] [PubMed]

- Wendland, A. Operation Costs of Wastewater Treatment Plants; Employee of Hamburg Public Sewage Company: Ahrensburg, Germany, 2005; Available online: https://cgi.tu-harburg.de/~awwweb/wbt/emwater/documents/slides_c2.pdf (accessed on 22 December 2021).

- European Commission 2030 Climate Target Plan. Available online: https://ec.europa.eu/clima/eu-action/european-green-deal/2030-climate-target-plan_el (accessed on 8 November 2021).

- Parravicini, V.; Svardal, K.; Krampe, J. Greenhouse Gas Emissions from Wastewater Treatment Plants. Energy Procedia 2016, 97, 246–253. [Google Scholar] [CrossRef] [Green Version]

- Khalkhali, M.; Mo, W. The energy implication of climate change on urban wastewater systems. J. Clean. Prod. 2020, 267, 121905. [Google Scholar] [CrossRef]

- Qadir, M.; Drechsel, P.; Jiménez Cisneros, B.; Kim, Y.; Pramanik, A.; Mehta, P.; Olaniyan, O. Global and regional potential of wastewater as a water, nutrient and energy source. Nat. Resour. Forum 2020, 44, 40–51. [Google Scholar] [CrossRef] [Green Version]

- Howard, G.; Calow, R.; Macdonald, A.; Bartram, J. Climate change and water and sanitation: Likely impacts and emerging trends for action. Annu. Rev. Environ. Resour. 2016, 41, 253–276. [Google Scholar] [CrossRef] [Green Version]

- Campana, P.E.; Mainardis, M.; Moretti, A.; Cottes, M. 100% renewable wastewater treatment plants: Techno-economic assessment using a modelling and optimization approach. Energy Convers. Manag. 2021, 239, 114214. [Google Scholar] [CrossRef]

- Kollmann, R.; Neugebauer, G.; Kretschmer, F.; Truger, B.; Kindermann, H.; Stoeglehner, G.; Ertl, T.; Narodoslawsky, M. Renewable energy from wastewater—Practical aspects of integrating a wastewater treatment plant into local energy supply concepts. J. Clean. Prod. 2017, 155, 119–129. [Google Scholar] [CrossRef]

- Mi, Z.; Guan, D.; Liu, Z.; Liu, J.; Viguié, V.; Fromer, N.; Wang, Y. Cities: The core of climate change mitigation. J. Clean. Prod. 2019, 207, 582–589. [Google Scholar] [CrossRef]

- EPA Energy Efficiency in Water and Wastewater Facilities; EPA: Washington, DC, USA, 2013.

- Cooper, R.N.; Houghton, J.T.; McCarthy, J.J.; Metz, B. Climate change 2001: The scientific basis. Foreign Aff. 2002, 81. [Google Scholar] [CrossRef]

- Bridle, T.; Shaw, A.; Cooper, S.; Yap, K.; Third, K.; Domurad, M. Estimation of greenhouse emissions from wastewater treatment plants. In Proceedings of the IWA World Water Congress, Vienna, Austria, 7–12 September 2008. [Google Scholar]

- Snip, L. Quantifying the Greenhouse Emissions of Wastewater Plants. 2010. Available online: https://edepot.wur.nl/138115 (accessed on 22 December 2021).

- PPC What Is the Energy Mix in Your Bill? Available online: https://www.dei.gr/el/oikiakoi-pelates/xrisimes-plirofories-gia-to-logariasmo-sas/logariasmos-kai-xrewseis/ti-einai-to-energeiako-migma-sto-logariasmo (accessed on 2 December 2021).

- Johansson, J. Risk and Vulnerability Analysis of Interdependent Technical Infrastructures: Addressing Socio-Technical Systems; Lund University, Department of Measurement Technology and Industrial Electric Engineering: Lund, Sweden, 2010. [Google Scholar]

- State of New South Wales and Office of Environment and Heritage Energy Efficiency Opportunities in Wastewater Treatment Facilities; 2019. Available online: https://www.environment.nsw.gov.au/resources/business/wastewater-treatment-facilities-energy-efficiency-opportunities-190114.pdf (accessed on 22 December 2021).

- Kirchem, D.; Lynch, M.; Bertsch, V.; Casey, E. Modelling demand response with process models and energy systems models: Potential applications for wastewater treatment within the energy-water nexus. Appl. Energy 2020, 260, 114321. [Google Scholar] [CrossRef]

- Cottes, M.; Mainardis, M.; Goi, D.; Simeoni, P. Demand-response application in wastewater treatment plants using compressed air storage system: A modelling approach. Energies 2020, 13, 4780. [Google Scholar] [CrossRef]

- Flores-Alsina, X.; Corominas, L.; Snip, L.; Vanrolleghem, P.A. Including greenhouse gas emissions during benchmarking of wastewater treatment plant control strategies. Water Res. 2011, 45, 4700–4710. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Yang, Y.; Keller, A.A.; Li, X.; Feng, S.; Dong, Y.N.; Li, F. Comparative analysis of energy intensity and carbon emissions in wastewater treatment in USA, Germany, China and South Africa. Appl. Energy 2016, 184, 873–881. [Google Scholar] [CrossRef] [Green Version]

- Singh, V.; Phuleria, H.C.; Chandel, M.K. Estimation of greenhouse gas emissions from municipal wastewater treatment systems in India. Water Environ. J. 2017, 31, 537–544. [Google Scholar] [CrossRef]

- Negi, R.; Chandel, M.K. Analysing water-energy-ghg nexus in a wastewater treatment plant of Mumbai metropolitan region, India. Environ. Res. 2021, 196, 110931. [Google Scholar] [CrossRef] [PubMed]

- Wolf, S.; Teitge, J.; Mielke, J.; Schütze, F.; Jaeger, C. The European green deal—More Than climate neutrality. Intereconomics 2021, 56, 99–107. [Google Scholar] [CrossRef]

- Yoshida, H.; Mønster, J.; Scheutz, C. Plant-integrated measurement of greenhouse gas emissions from a municipal wastewater treatment plant. Water Res. 2014, 61, 108–118. [Google Scholar] [CrossRef]

- Nguyen, T.K.L.; Ngo, H.H.; Guo, W.S.; Chang, S.W.; Nguyen, D.D.; Nghiem, L.D.; Nguyen, T.V. A critical review on life cycle assessment and plant-wide models towards emission control strategies for greenhouse gas from wastewater treatment plants. J. Environ. Manag. 2020, 264, 110440. [Google Scholar] [CrossRef]

- Ganora, D.; Hospido, A.; Husemann, J.; Krampe, J.; Loderer, C.; Longo, S.; Moragas Bouyat, L.; Obermaier, N.; Piraccini, E.; Stanev, S.; et al. Opportunities to improve energy use in urban wastewater treatment: A European-scale analysis. Environ. Res. Lett. 2019, 14, 044028. [Google Scholar] [CrossRef]

- Yang, X.; Wei, J.; Ye, G.; Zhao, Y.; Li, Z.; Qiu, G.; Li, F.; Wei, C. The correlations among wastewater internal energy, energy consumption and energy recovery/production potentials in wastewater treatment plant: An assessment of the energy balance. Sci. Total Environ. 2020, 714, 136655. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y.; Wang, H.; Wu, J.; Wang, X.; Li, F. Exploring the feasibility of energy self-sufficient wastewater treatment plants: A case study in eastern China. Energy Procedia 2017, 142, 3055–3061. [Google Scholar] [CrossRef]

- Jenicek, P.; Kutil, J.; Benes, O.; Todt, V.; Zabranska, J.; Dohanyos, M. Energy self-sufficient sewage wastewater treatment plants: Is optimized anaerobic sludge digestion the key? Water Sci. Technol. 2013, 68, 1739–1744. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Gu, J.; Zhang, M. A-B Processes: Towards Energy Self-Sufficient Municipal Wastewater Treatment; IWA Publishing: London, UK, 2020. [Google Scholar]

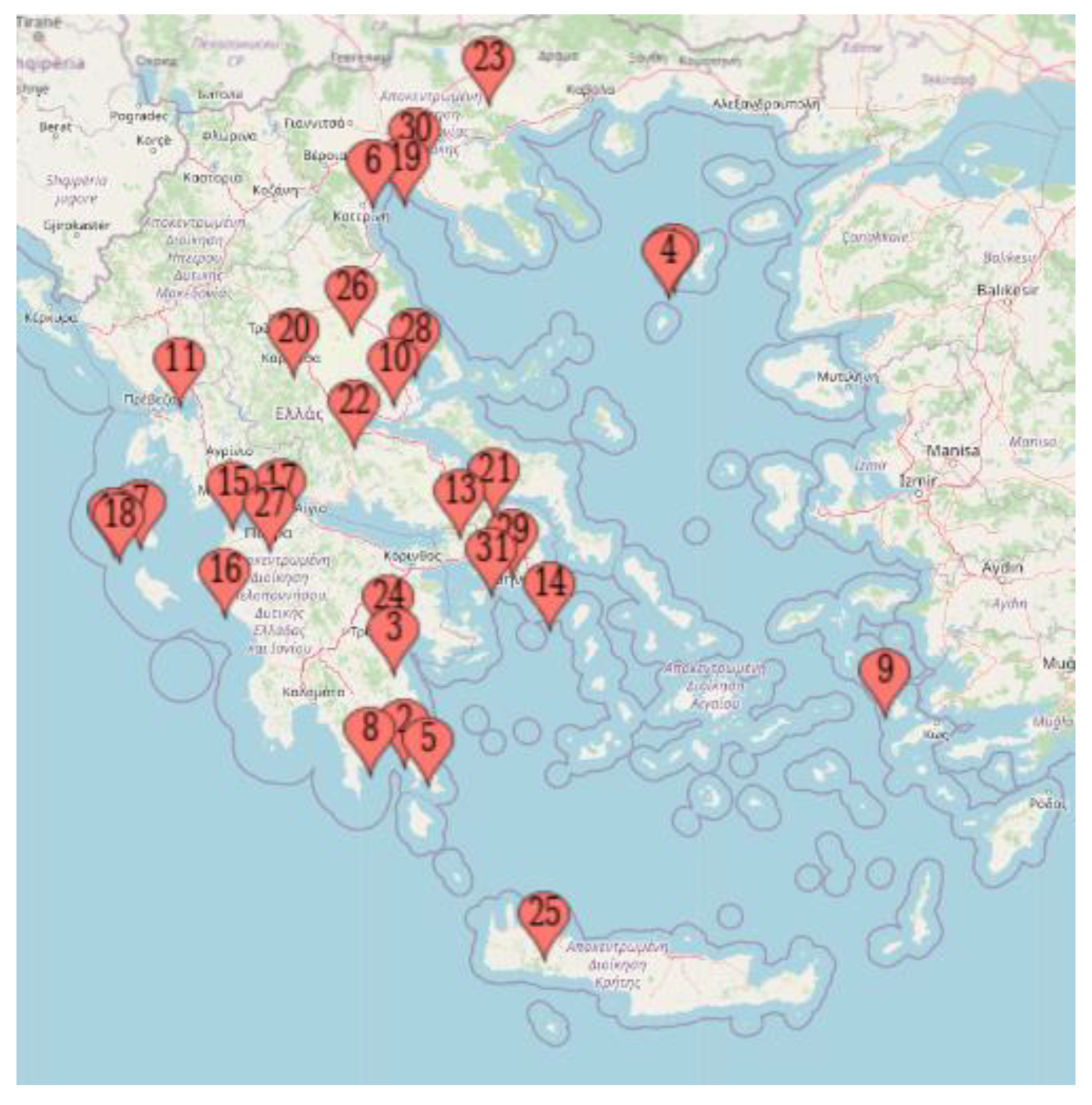

| Groups | A/a | Population Served | Treatment Method | Nutrient Removal |

|---|---|---|---|---|

| Small | 1 | 250 | Type 1 | N |

| 2 | 500 | Type 1 | N | |

| 3 | 1000 | Type 1 | N & P | |

| 4 | 1101 | Type 1 | N | |

| 5 | 1230 | Type 1 | N | |

| 6 | 1850 | Type 1 | N & P | |

| 7 | 2000 | Type 1 | N | |

| 8 | 2209 | Type 1 | N & P | |

| 9 | 3620 | Type 1 | - | |

| 10 | 6215 | Type 1 | N & P | |

| 11 | 8704 | Type 1 | - | |

| 12 | 9123 | Type 1 | N | |

| Medium | 13 | 10,033 | Type 1 | N & P |

| 14 | 10,494 | Type 1 | N | |

| 15 | 13,125 | Type 1 | N & P | |

| 16 | 13,268 | Type 1 | N & P | |

| 17 | 15,000 | Type 1 | N | |

| 18 | 16,243 | Type 1 | - | |

| 19 | 42,672 | Type 2 | N & P | |

| 20 | 47,475 | Type 1 | N | |

| 21 | 52,003 | Type 2 | N | |

| 22 | 63,167 | Type 1 | N & P | |

| 23 | 77,278 | Type 1 | N & P | |

| 24 | 99,760 | Type 1 | N | |

| Large | 25 | 105,421 | Type 2 | N |

| 26 | 109,814 | Type 2 | N | |

| 27 | 155,080 | Type 2 | N & P | |

| 28 | 180,997 | Type 2 | N | |

| 29 | 224,517 | Type 2 | N | |

| 30 | 1,050,874 | Type 3 | N | |

| 31 | 3,646,388 | Type 3 | N |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goliopoulos, N.; Mamais, D.; Noutsopoulos, C.; Dimopoulou, A.; Kounadis, C. Energy Consumption and Carbon Footprint of Greek Wastewater Treatment Plants. Water 2022, 14, 320. https://doi.org/10.3390/w14030320

Goliopoulos N, Mamais D, Noutsopoulos C, Dimopoulou A, Kounadis C. Energy Consumption and Carbon Footprint of Greek Wastewater Treatment Plants. Water. 2022; 14(3):320. https://doi.org/10.3390/w14030320

Chicago/Turabian StyleGoliopoulos, Nikos, Daniel Mamais, Constantinos Noutsopoulos, Argyri Dimopoulou, and Christos Kounadis. 2022. "Energy Consumption and Carbon Footprint of Greek Wastewater Treatment Plants" Water 14, no. 3: 320. https://doi.org/10.3390/w14030320

APA StyleGoliopoulos, N., Mamais, D., Noutsopoulos, C., Dimopoulou, A., & Kounadis, C. (2022). Energy Consumption and Carbon Footprint of Greek Wastewater Treatment Plants. Water, 14(3), 320. https://doi.org/10.3390/w14030320