Experimental and Numerical Analysis of Forced Convection in a Horizontal Tube Partially Filled with a Porous Medium under Local Thermal Equilibrium Conditions

Abstract

:1. Introduction

2. Materials and Methods

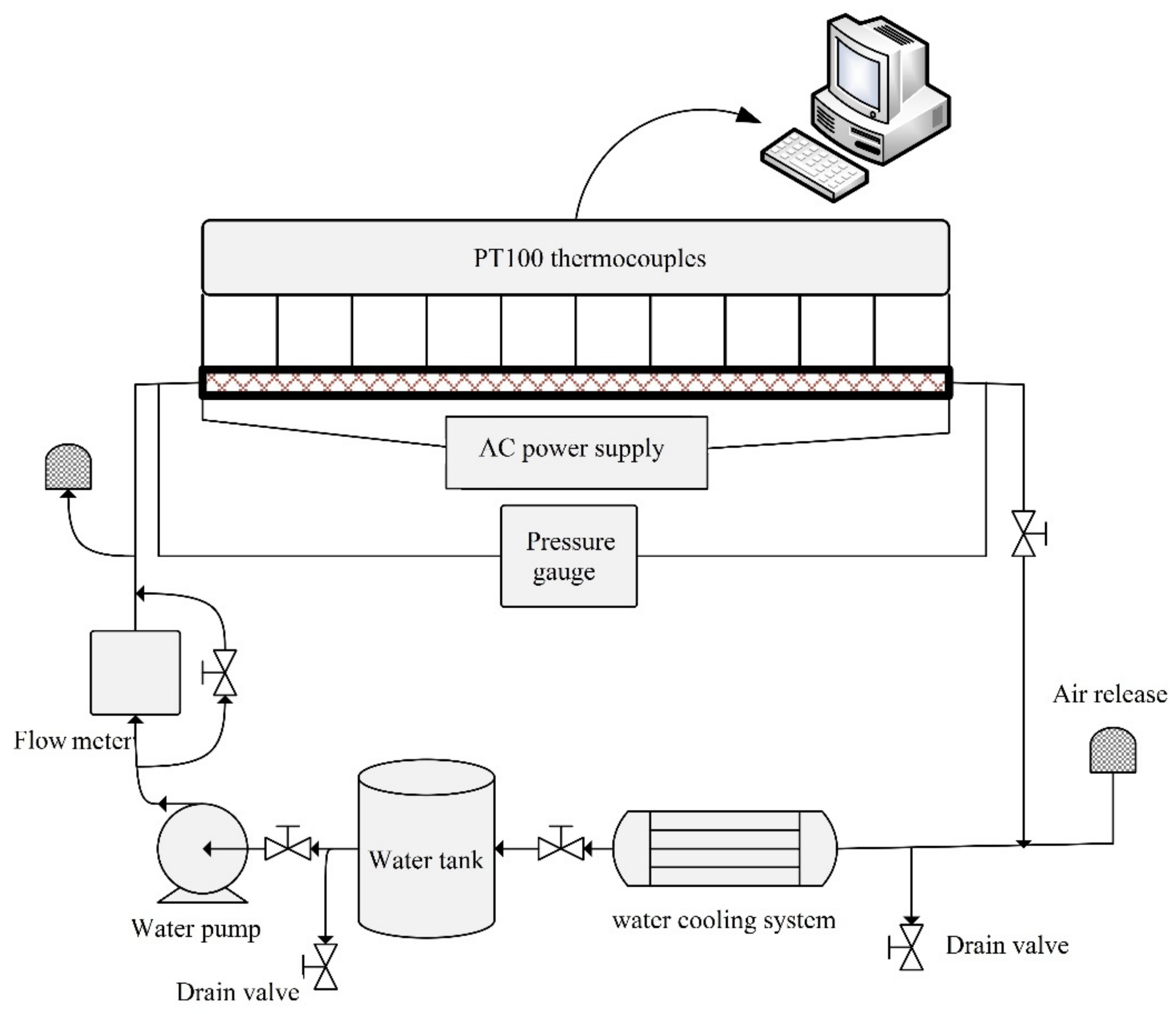

2.1. Experimental Setup

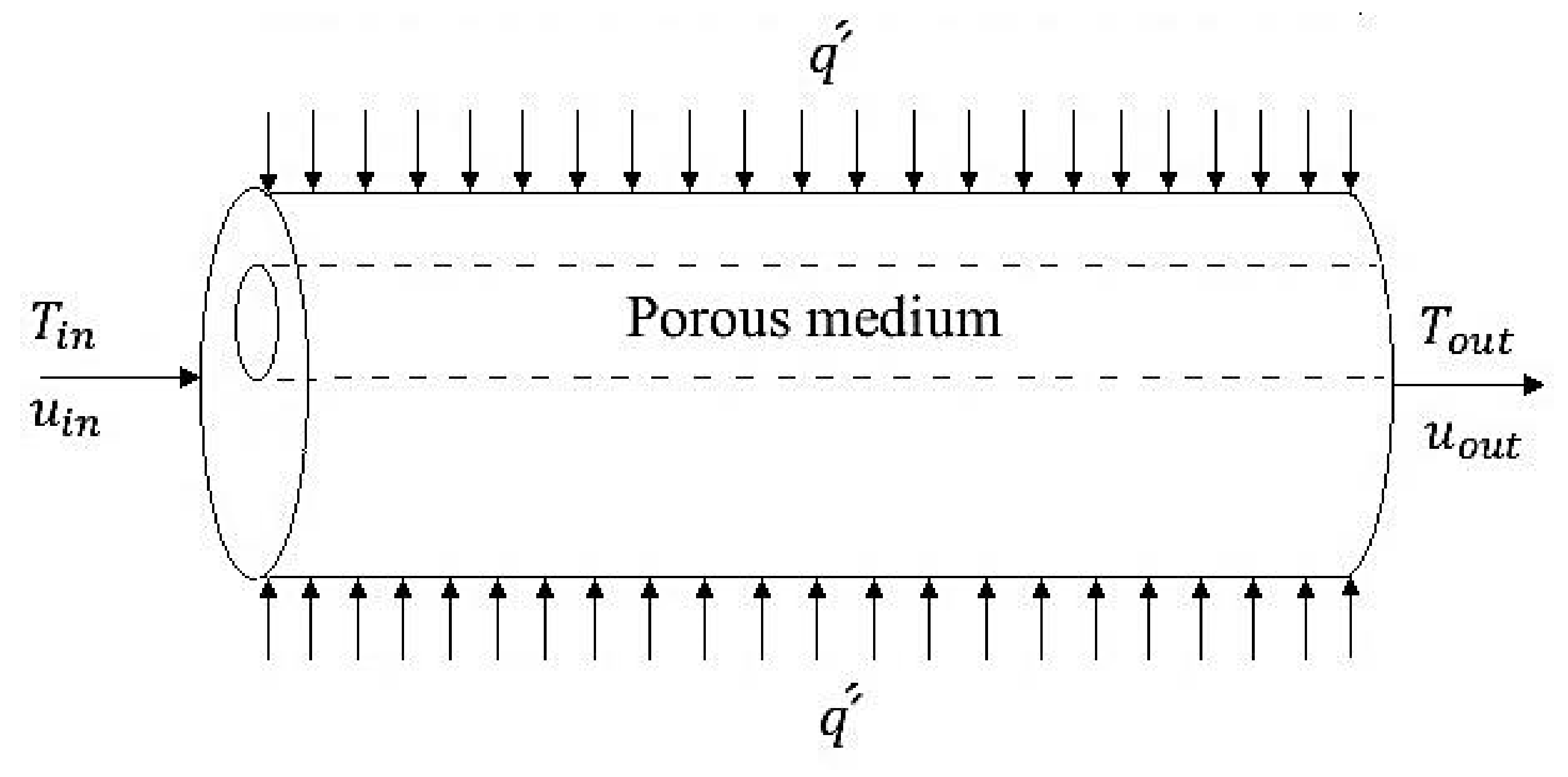

2.2. Governing Equations

- Inlet: uniform profile; Z = 0, W = 1, U = V = 0, and T* = 0.

- Outlet: hydrodynamically and thermally fully development.

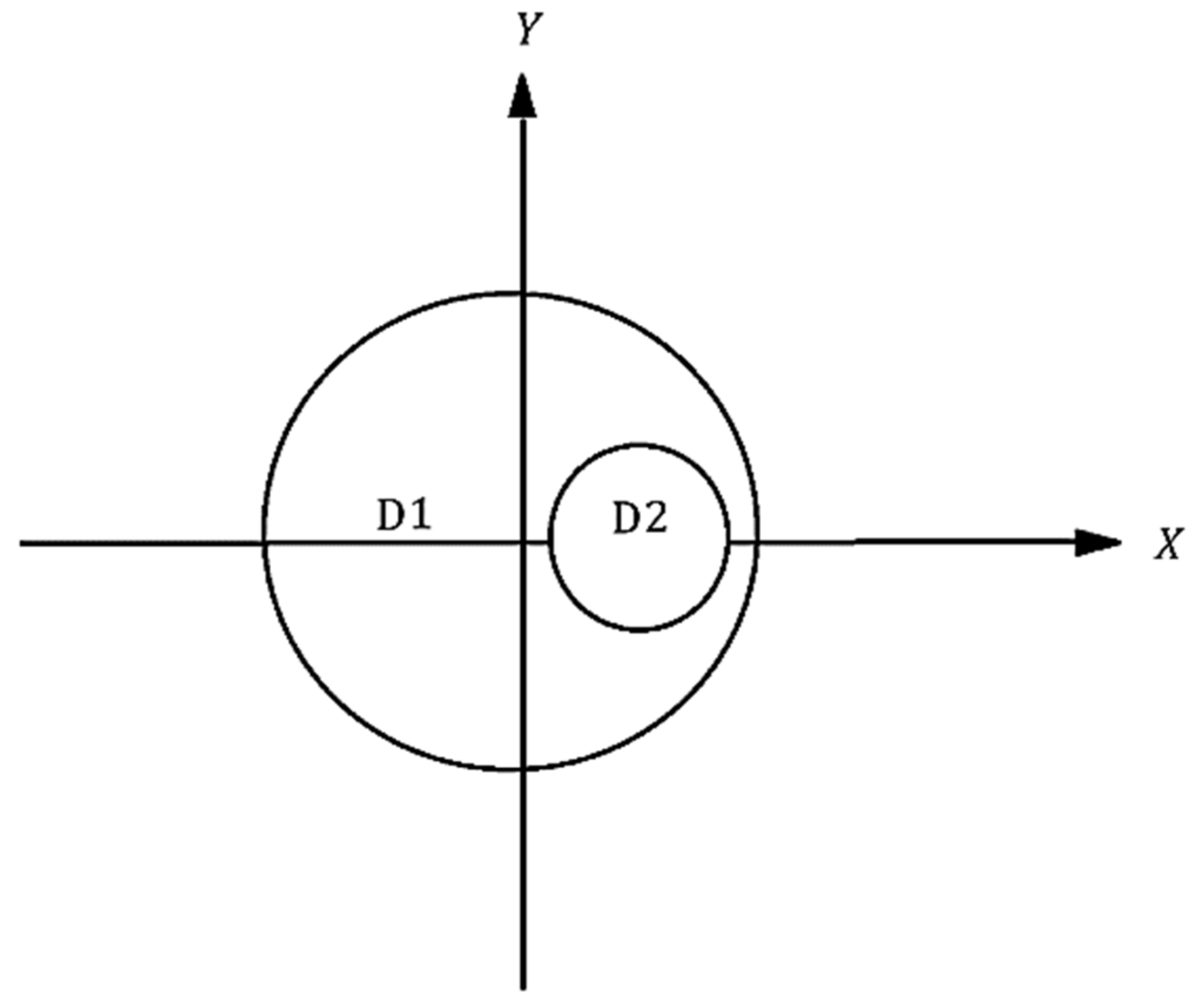

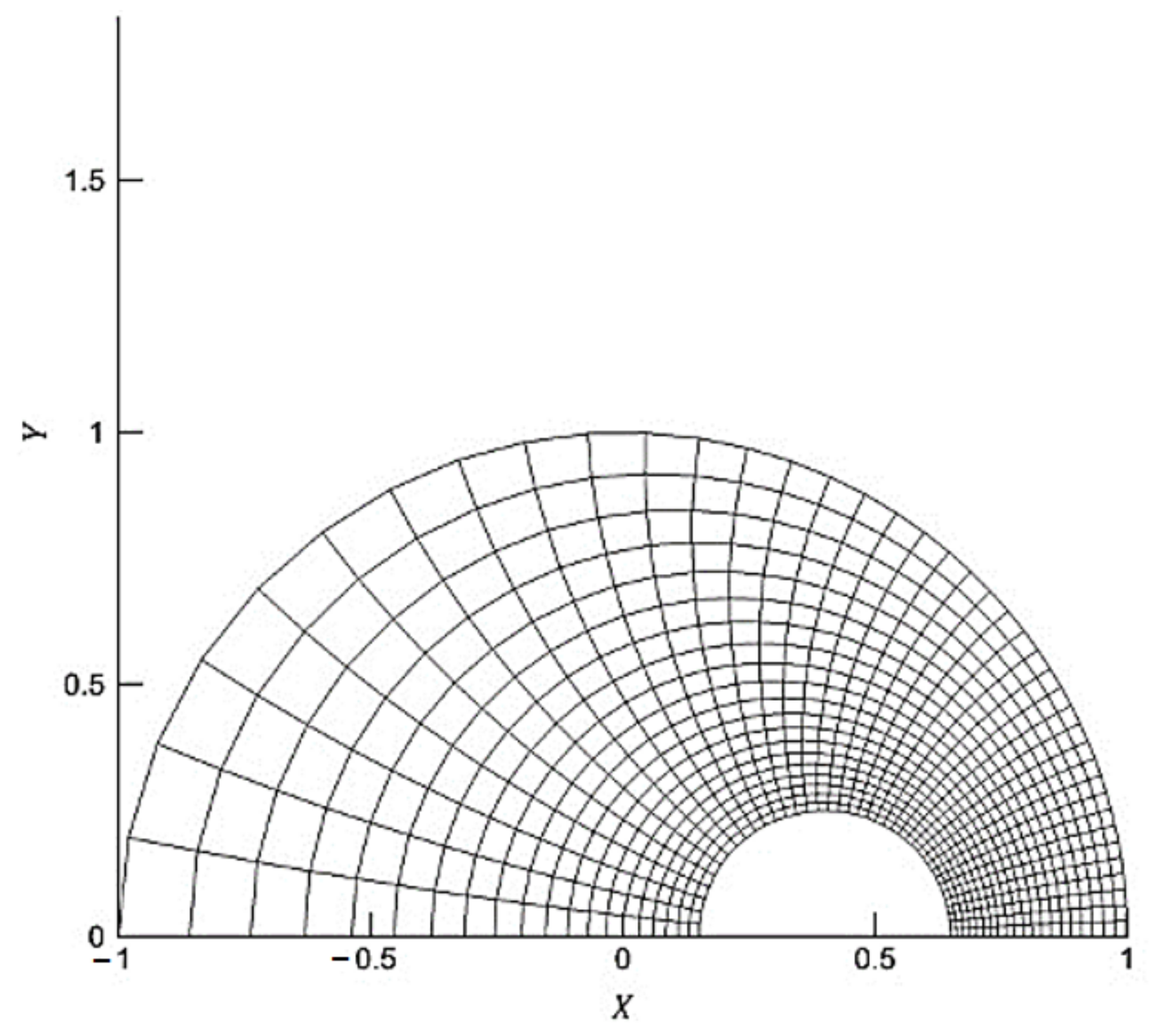

2.2.1. Using Conformal Mapping in Numerical Analysis

2.2.2. Numerical Solution Details

2.2.3. Mesh Domain 1 in Computational Space

2.2.4. Mesh Domain 1 in Physical Space

2.2.5. Mesh Domain 2

2.2.6. Solution Methodology

3. Results and Discussion

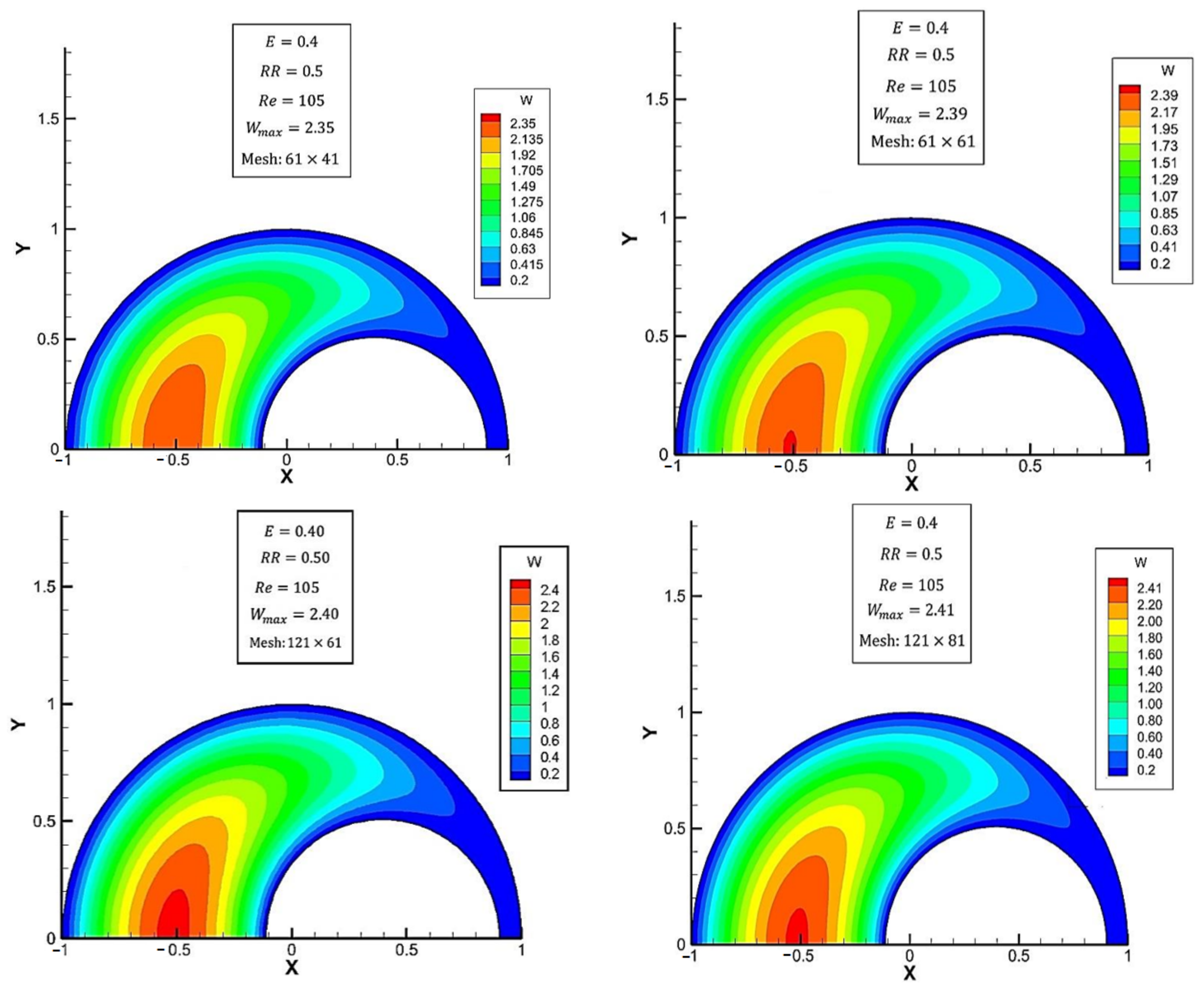

3.1. Grid Independency Analysis

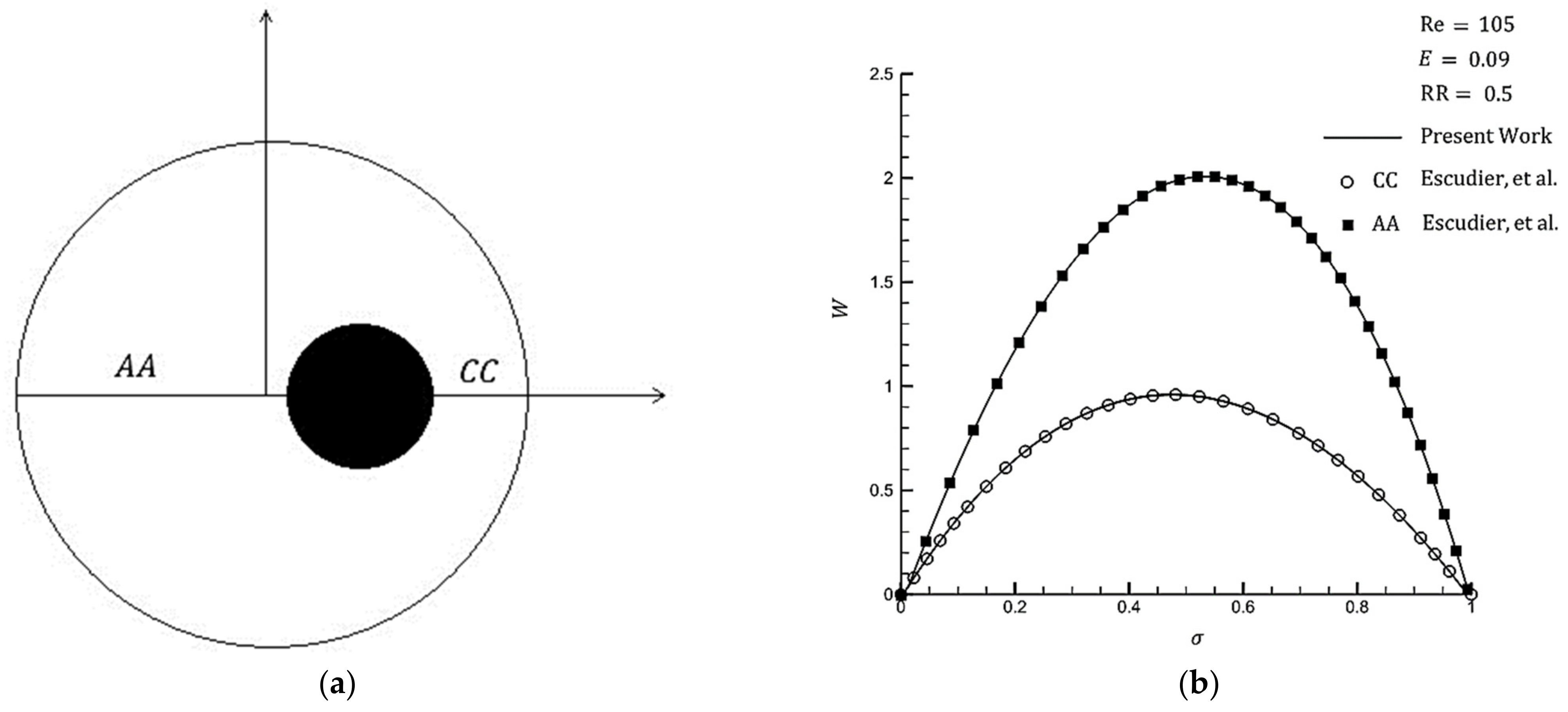

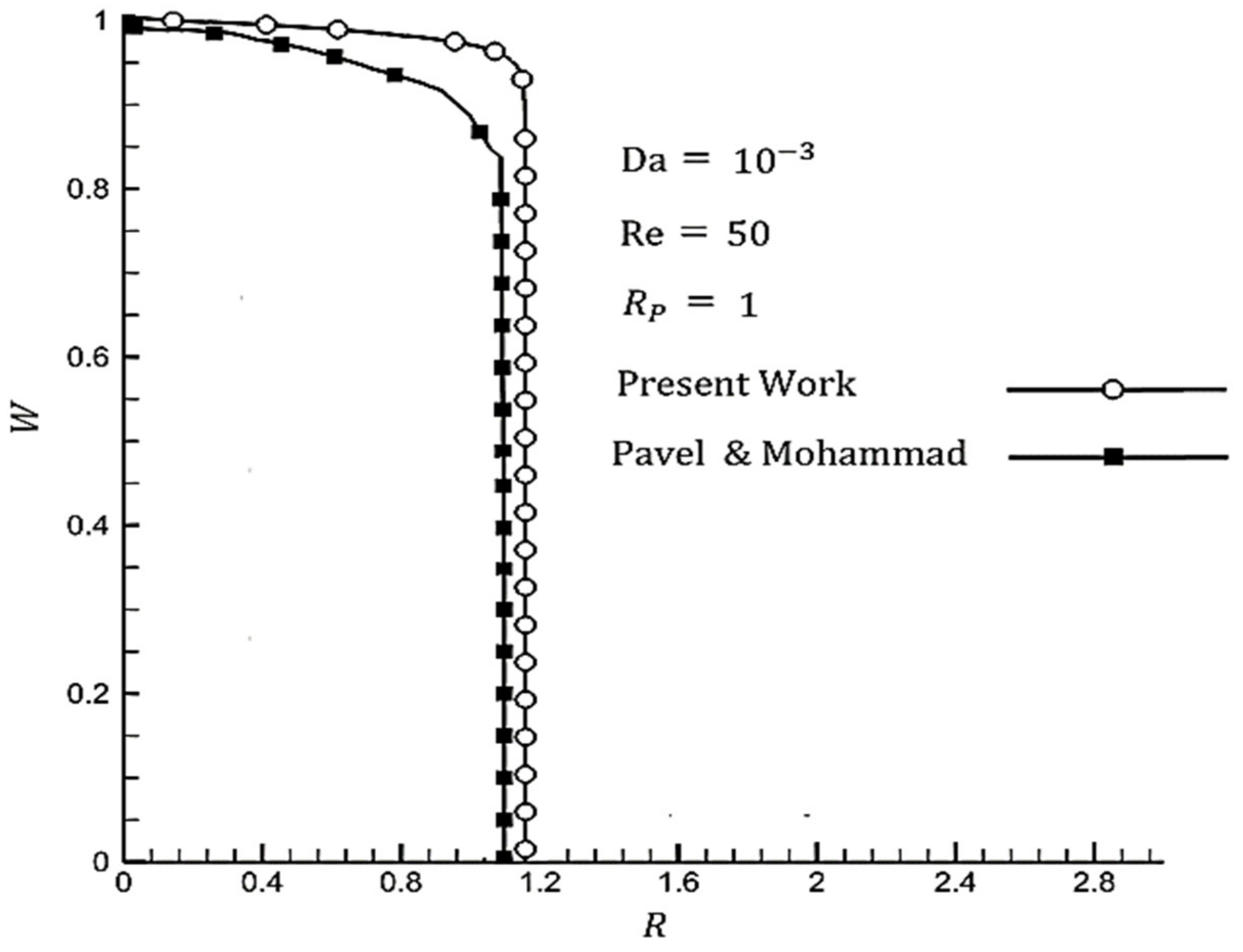

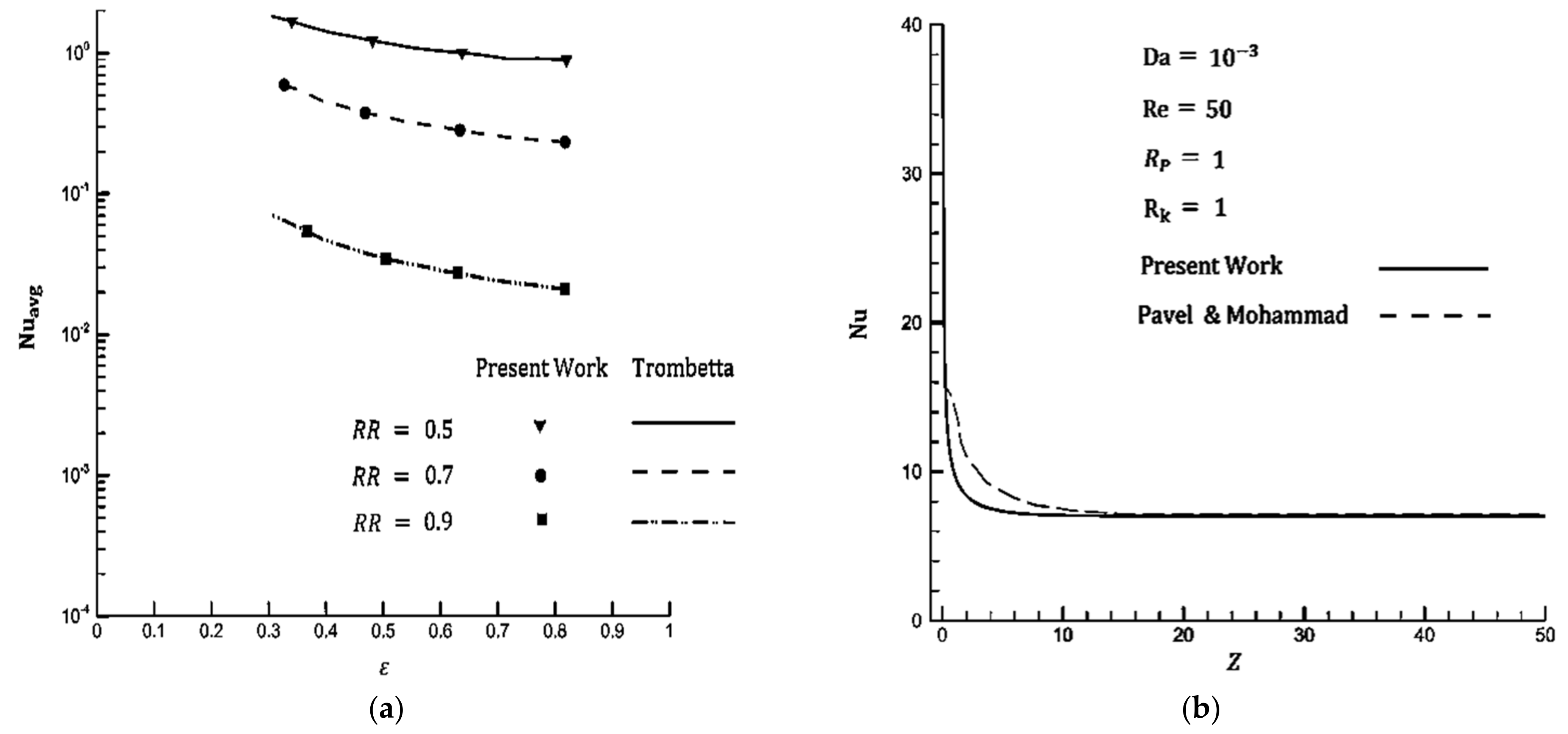

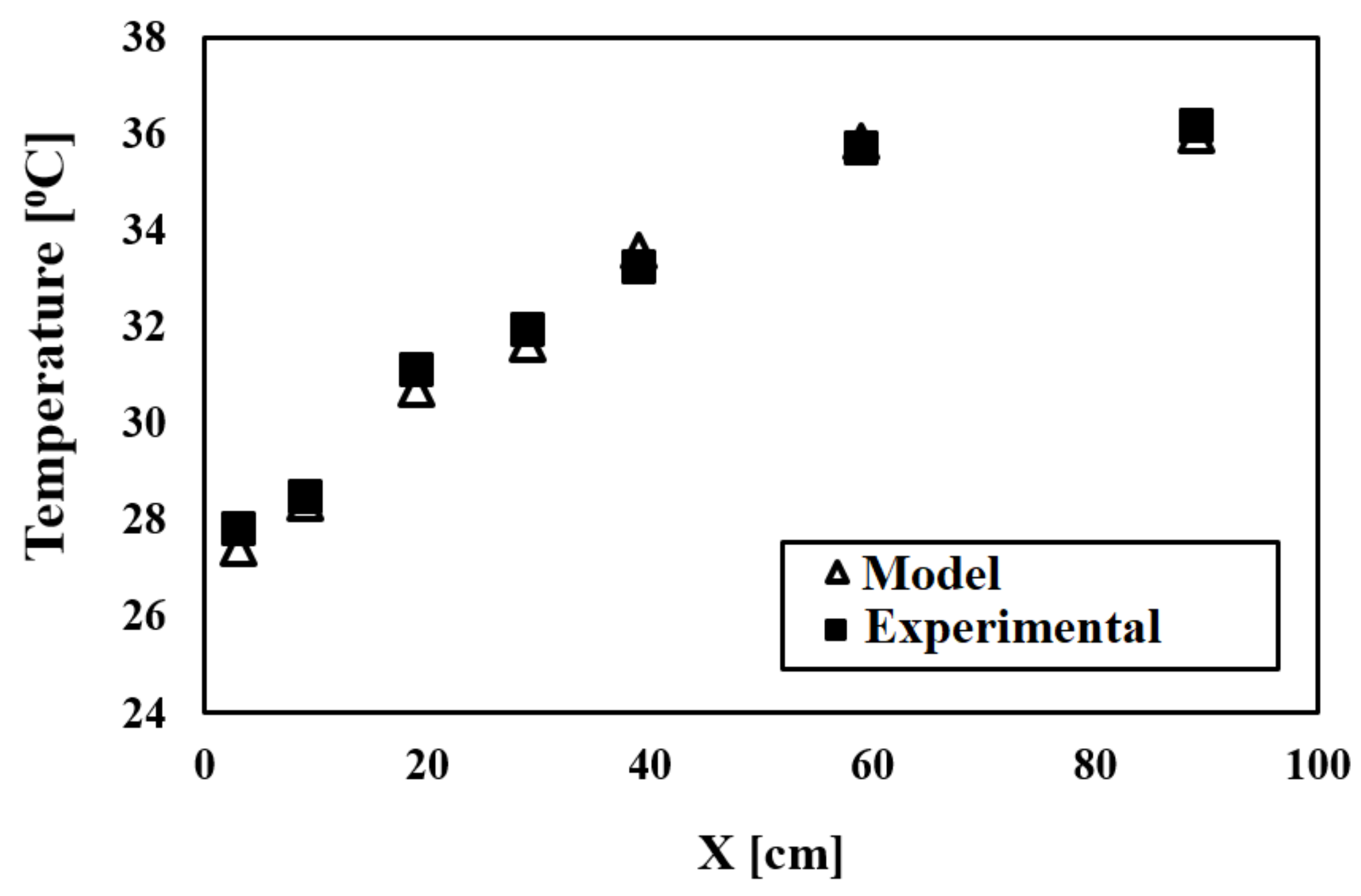

3.2. Validation of Present Study

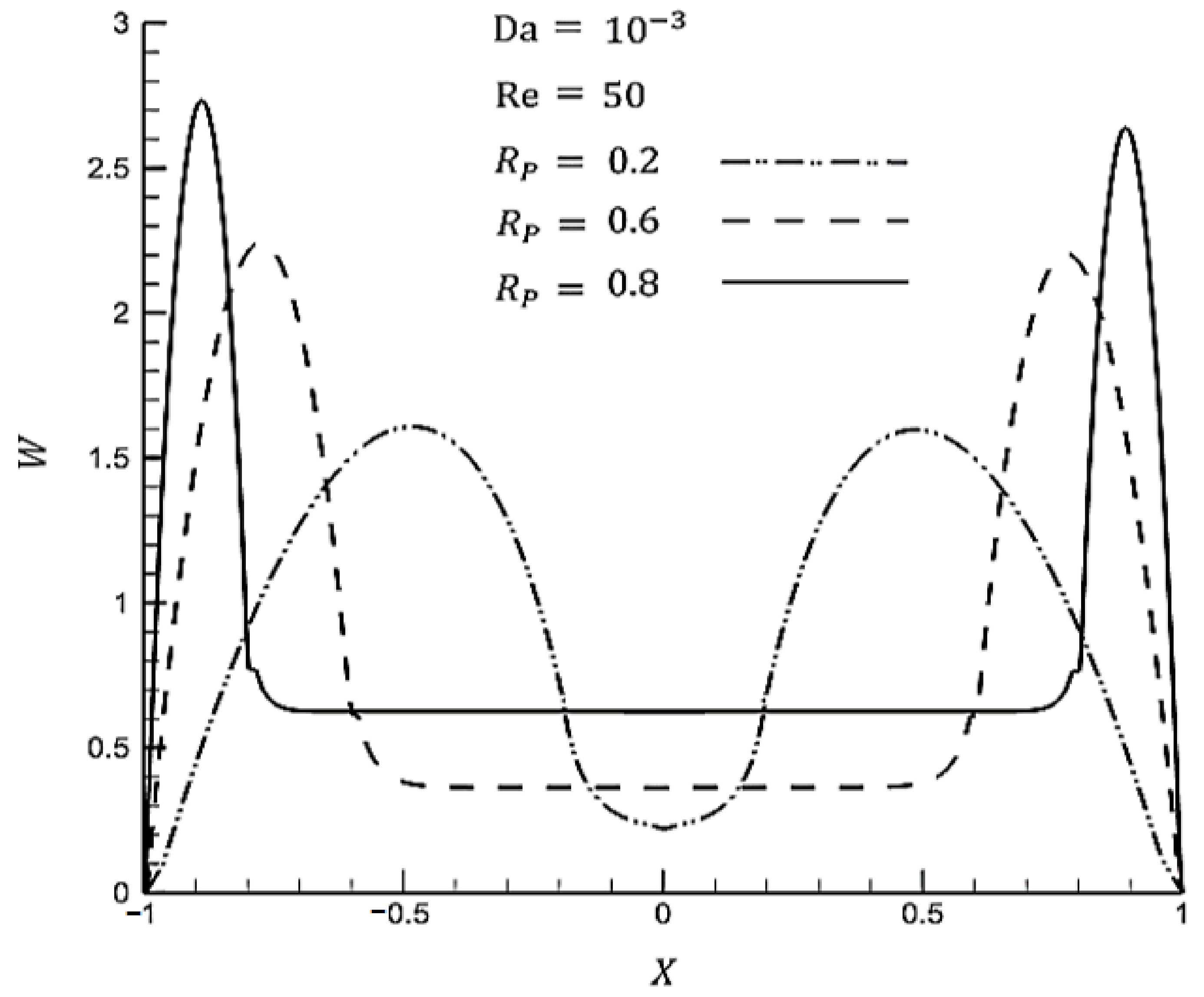

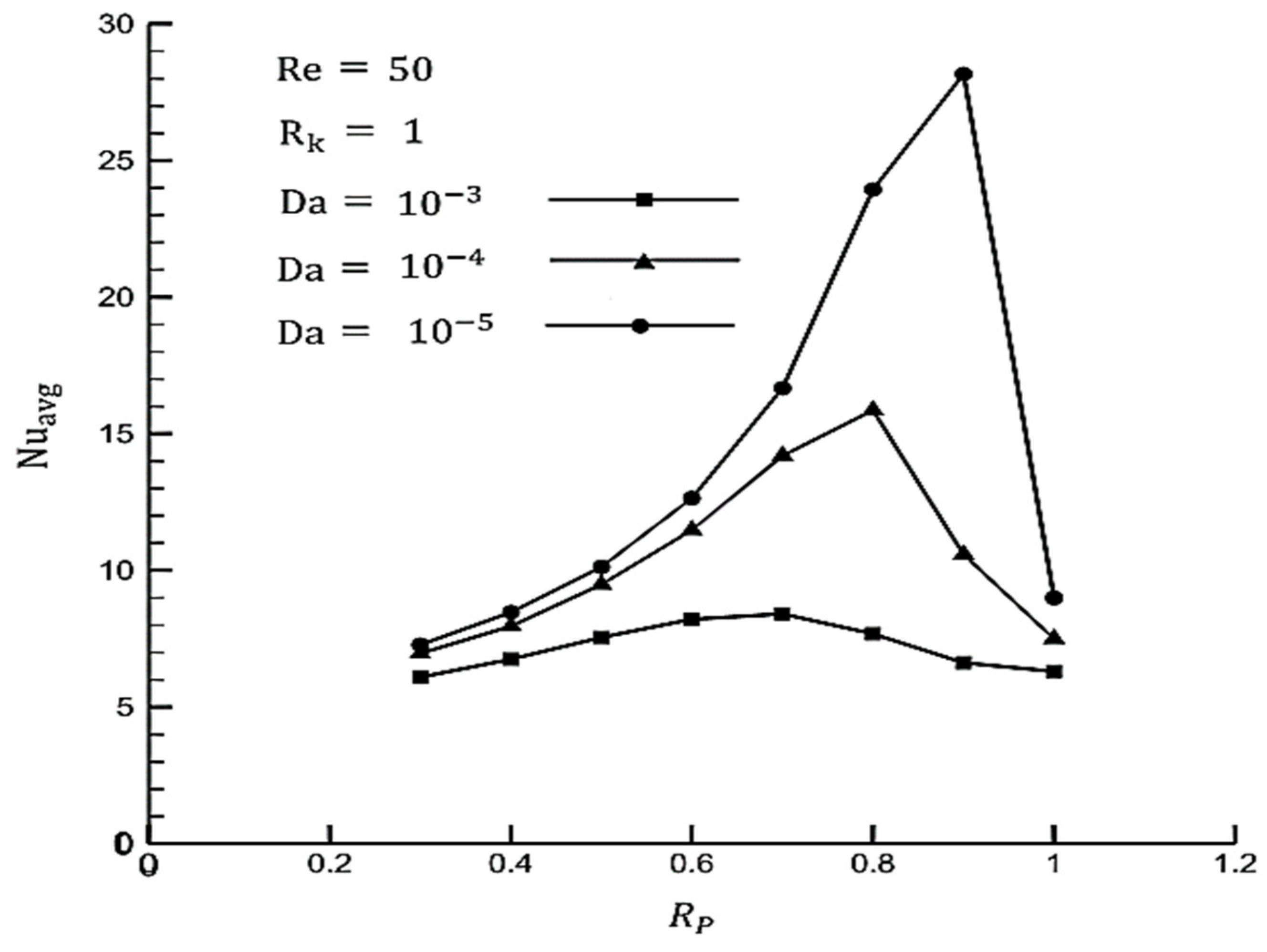

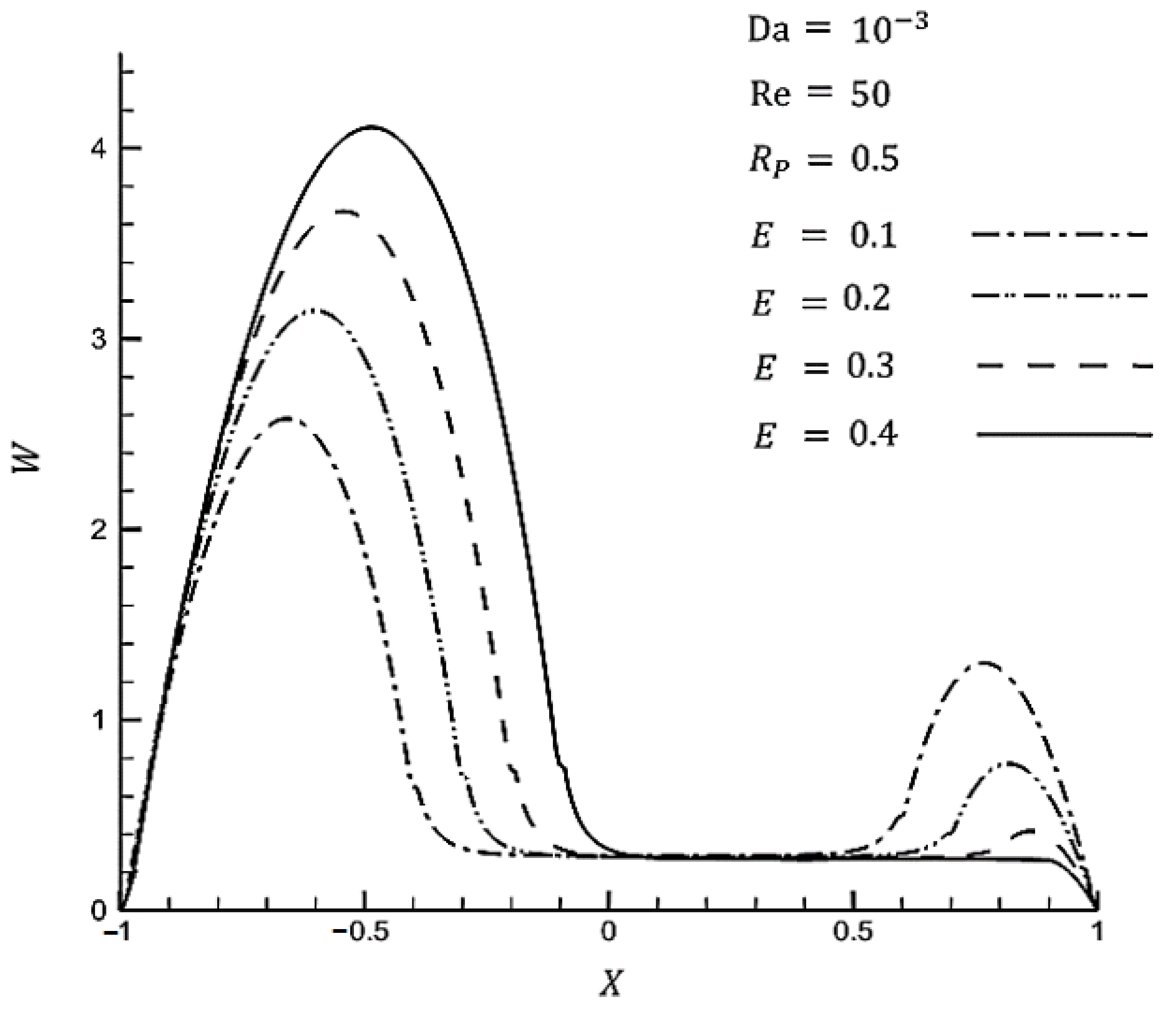

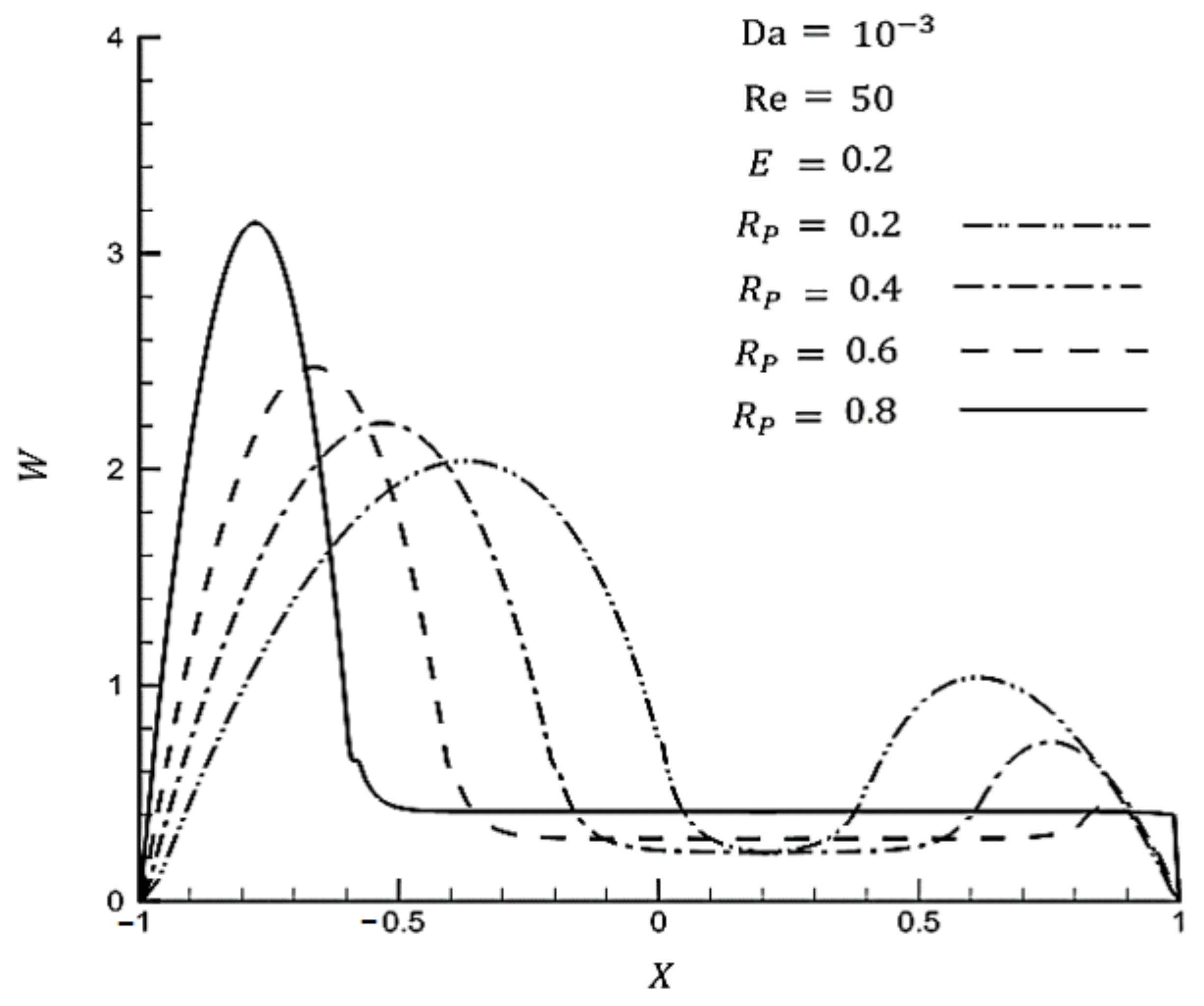

3.3. Impact of Various Parameters on the Hydrothermal Behavior of Fluid Flow

4. Conclusions

- In the present work, force convection flow in a tube partially filled with a porous medium at eccentric posture is investigated numerically. In addition, the effects of various parameters, including eccentricity, thickness and permeability of the porous media, are studied and the following conclusions are obtained.

- A smaller Darcy number leads to a higher heat transfer rate in the concentric position. In addition, the highest average Nusselt number can be achieved at a specific thickness, which is considered to be the optimum thickness for a given Darcy number. Optimum thicknesses in the range of 0.7–0.9 increase with a decreasing Darcy number.

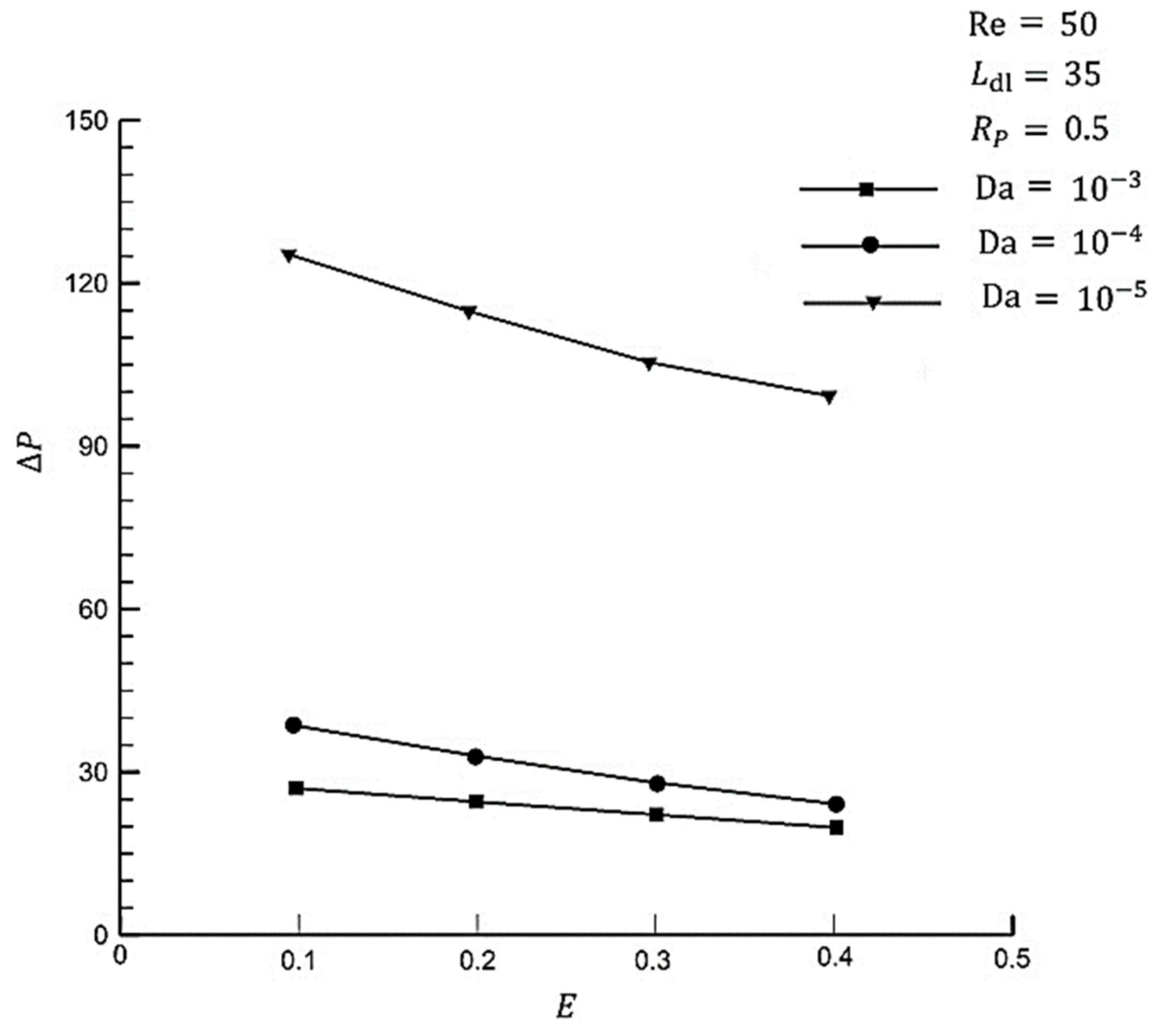

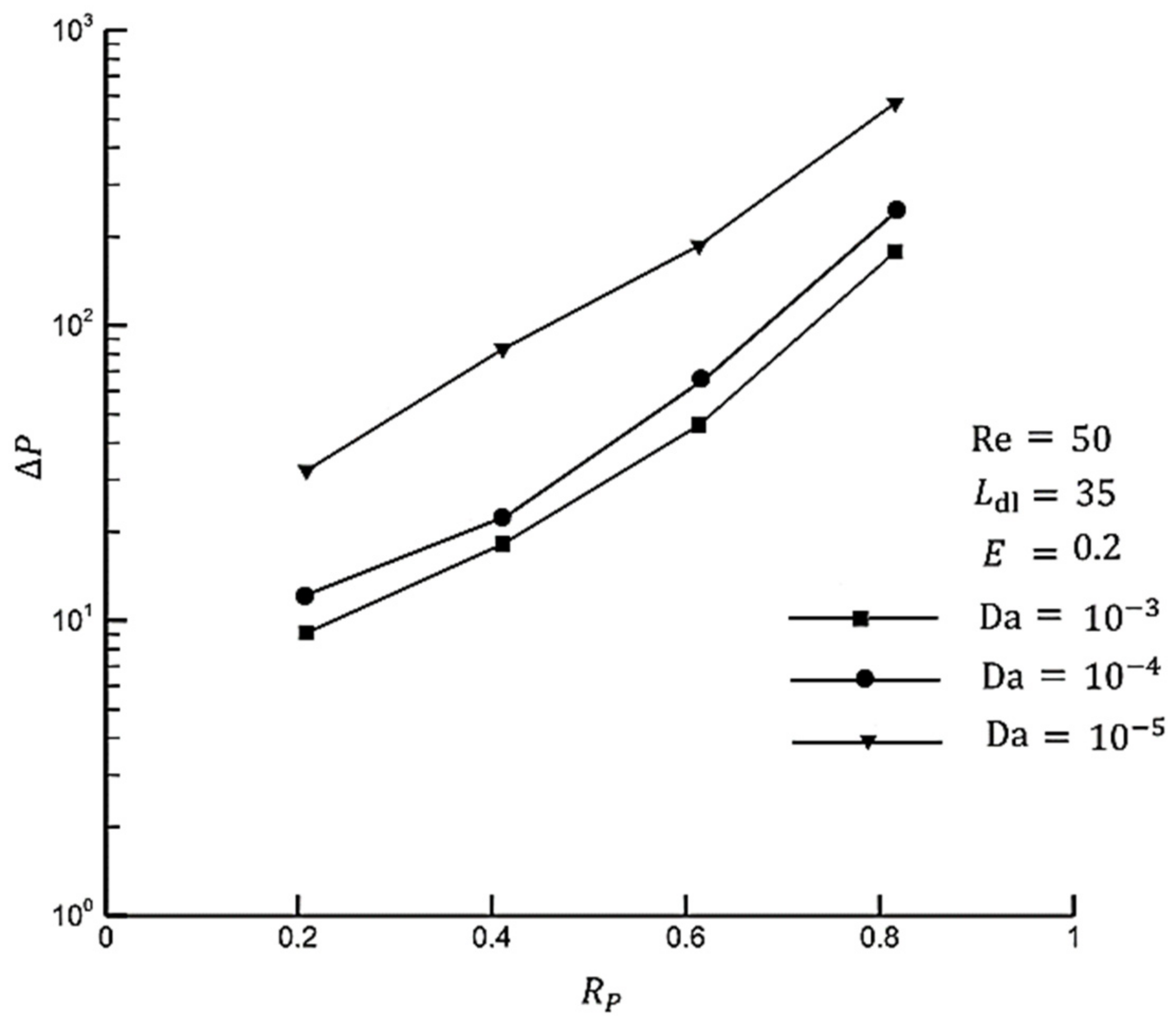

- A decreasing Darcy number gives rise to a pressure drop. This is due to a smaller Darcy number leading to a decline in permeability. On the other hand, rising eccentricity results in a decreasing pressure drop. In addition, the reduction rate grows while the Darcy number decreases. Pressure drop falls at the fastest rate to about at and . Applying eccentricity can be considered as a solution to reduce the pressure drop in porous media.

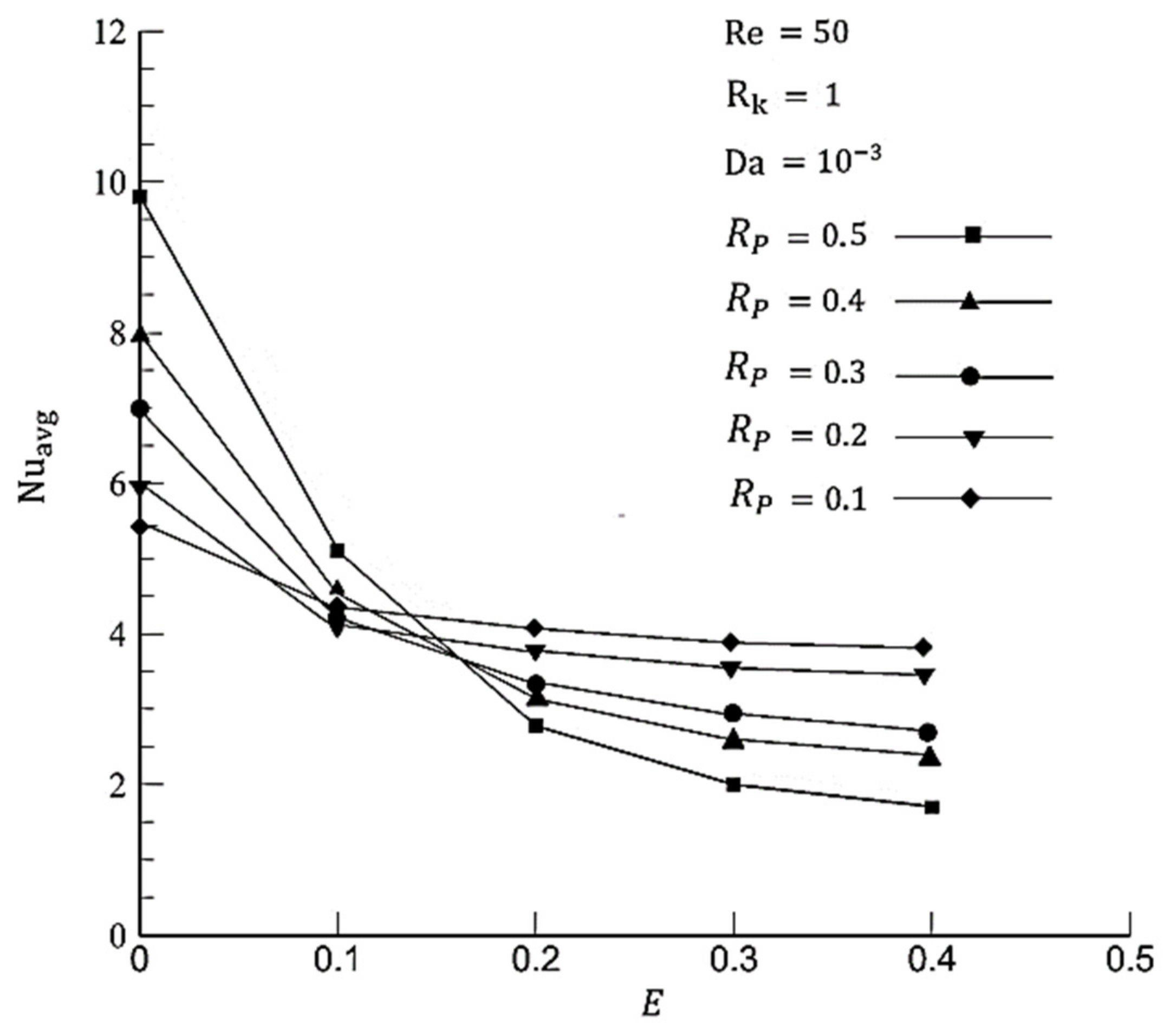

- The average Nusselt number decreases sharply with increasing eccentricity at a high radius ratio. By way of illustration, by increasing eccentricity from 0.1 to 0.4, the Nusselt number reduces by and at respectively. Although there is a smaller reduction at a larger eccentricity, it is not effective to apply eccentric porous media inside at a high radius ratio.

- The average Nusselt number decreases slower in small values of thickness. As there is a slower decreasing rate for the average Nusselt number and a small pressure drop, using eccentricity is beneficial for a small range of thicknesses.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Brinkman number () [nd] | Greek Symbols | ||

| Forchheimer coefficient [1/m] | Dimensionless group [nd] | ||

| Specific heat | Eccentricity [nd] | ||

| Darcy number | Vertical coordinate in calculation domain | ||

| Non-dimensional eccentric of porous media | Angle [degree] | ||

| Dependent parameter in governing equation | Dynamic viscosity [] | ||

| Convective heat transfer coefficient | Horizontal coordinate in calculation domain | ||

| Conductive coefficient | Density [] | ||

| Permeability [] | Heat capacity ratio [nd] | ||

| Length of heated section [m] | Fluid density [] | ||

| Prandtl number () [nd] | Subscripts | ||

| Wall heat flux | Fluid | ||

| Reynolds number (Re=(v.d)/ν) [nd] | Effective | ||

| Pipe radius [] | - | Fluid domain in the interface of fluid-porous | |

| Cylindrical porous media radius [m] | + | Porous domain in the interface of fluid-porous | |

| Heat conduction ratio | Abbreviation | ||

| Heat source term | LTE | Local Thermal Equilibrium | |

| Dimensionless temperature [nd] | LTNE | Local Thermal Non-Equilibrium | |

| Surface temperature [K] | |||

| Velocity vector | |||

References

- Ajarostaghi, S.S.M.; Javadi, H.; Mousavi, S.S.; Poncet, S.; Pourfallah, M. Thermal performance of a single U-tube ground heat exchanger: A parametric study. J. Cent. South Univ. 2021, 28, 3580–3598. [Google Scholar] [CrossRef]

- Hashemi-Valikboni, S.Z.; Ajarostaghi, S.S.M.; Delavar, M.A.; Sedighi, K. Numerical prediction of humidification process in planar porous membrane humidifier of a PEM fuel cell system to evaluate the effects of operating and geometrical parameters. J. Therm. Anal. Calorim. 2020, 141, 1687–1701. [Google Scholar] [CrossRef]

- Ajarostaghi, S.S.M.; Delavar, M.A.; Poncet, S. Thermal mixing, cooling and entropy generation in a micromixer with a porous zone by the lattice Boltzmann method. J. Therm. Anal. Calorim. 2020, 140, 1321–1339. [Google Scholar] [CrossRef]

- Ajarostaghi, S.S.M.; Poncet, S. Thermal mixing in T-shaped micromixers with a porous block by the lattice Boltzmann method: Influence of the mixing channel configuration. Front. Therm. Eng. 2022, 15, 961083. [Google Scholar] [CrossRef]

- Mahdavi, M.; Saffar-Avval, M.; Tiari, S.; Mansoori, Z. Entropy generation and heat transfer numerical analysis in pipes partially filled with porous medium. Int. J. Heat Mass Transf. 2014, 79, 496–506. [Google Scholar] [CrossRef]

- Baragh, S.; Shokouhmand, H.; Ajarostaghi, S.S.M.; Nikian, M. An experimental investigation on forced convection heat transfer of single-phase flow in a channel with different arrangements of porous media. Int. J. Therm. Sci. 2018, 134, 370–379. [Google Scholar] [CrossRef]

- Baragh, S.; Shokouhmand, H.; Ajarostaghi, S.S.M. Experiments on mist flow and heat transfer in a tube fitted with porous media. Int. J. Therm. Sci. 2019, 137, 388–398. [Google Scholar] [CrossRef]

- Afsharpanah, F.; Izadi, M.; Hamedani, F.A.; Ajarostaghi, S.S.M.; Yaïci, W. Solidification of nano-enhanced PCM-porous composites in a cylindrical cold thermal energy storage enclosure. Case Stud. Therm. Eng. 2022, 39, 102421. [Google Scholar] [CrossRef]

- Ajarostaghi, S.S.M.; Zaboli, M.; Javadi, H.; Badenes, B.; Urchueguia, J.F. A review of recent passive heat transfer enhancement methods. Energies 2022, 15, 986. [Google Scholar] [CrossRef]

- Teggar, M.; Ajarostaghi, S.S.; Yıldız, Ç.; Arıcı, M.; Ismail, K.A.; Niyas, H.; Khalid, M. Performance enhancement of latent heat storage systems by using extended surfaces and porous materials: A state-of-the-art review. J. Energy Storage 2021, 44, 103340. [Google Scholar] [CrossRef]

- Mohamad, A.A. Heat transfer enhancements in heat exchangers fitted with porous media Part I: Constant wall temperature. Int. J. Therm. Sci. 2003, 42, 385–395. [Google Scholar] [CrossRef]

- Pavel, B.I.; Mohamad, A.A. An experimental and numerical study on heat transfer enhancement for gas heat exchangers fitted with porous media. Int. J. Heat Mass Transf. 2004, 47, 4939–4952. [Google Scholar] [CrossRef]

- Huang, Z.F.; Nakayama, A.; Yang, K.; Yang, C.; Liu, W. Enhancing heat transfer in the core flow by using porous medium insert in a tube. Int. J. Heat Mass Transf. 2010, 53, 1164–1174. [Google Scholar] [CrossRef]

- Nimvari, M.E.; Jouybari, N.F. Investigation of turbulence effects within porous layer on the thermal performance of a partially filled pipe. Int. J. Therm. Sci. 2017, 118, 374–385. [Google Scholar] [CrossRef]

- Mahmoudi, Y.; Karimi, N.; Mazaheri, K. Analytical investigation of heat transfer enhancement in a channel partially filled with a porous material under local thermal non-equilibrium condition: Effects of different thermal boundary conditions at the porous-fluid interface. Int. J. Heat Mass Transf. 2014, 70, 875–891. [Google Scholar] [CrossRef] [Green Version]

- Lin, W.; Xie, G.; Yuan, J.; Sundén, B. Comparison and Analysis of Heat Transfer in Aluminum Foam Using Local Thermal Equilibrium or Nonequilibrium Model. Heat Transf. Eng. 2016, 37, 314–322. [Google Scholar] [CrossRef]

- Lu, W.; Zhang, T.; Yang, M. Analytical solution of forced convective heat transfer in parallel-plate channel partially filled with metallic foams. Int. J. Heat Mass Transf. 2016, 100, 718–727. [Google Scholar] [CrossRef]

- Buonomo, B.; Diana, A.; Manca, O.; Nardini, S. Local Thermal Non-Equilibrium Investigation on Natural Convection in Horizontal Channel Heated from Above and Partially Filled with Aluminum Foam. Energy Procedia 2017, 126, 42–49. [Google Scholar] [CrossRef]

- Mahmoudi, Y.; Karimi, N. Numerical investigation of heat transfer enhancement in a pipe partially filled with a porous material under local thermal non-equilibrium condition. Int. J. Heat Mass Transf. 2014, 68, 161–173. [Google Scholar] [CrossRef] [Green Version]

- Torabi, M.; Zhang, K.; Yang, G.; Wang, J.; Wu, P. Heat transfer and entropy generation analyses in a channel partially filled with porous media using local thermal non-equilibrium model. Energy 2015, 82, 922–938. [Google Scholar] [CrossRef]

- Shokouhmand, H.; Jam, F.; Salimpour, M.R. Simulation of laminar flow and convective heat transfer in conduits filled with porous media using Lattice Boltzmann Method. Int. Commun. Heat Mass Transf. 2009, 36, 378–384. [Google Scholar] [CrossRef]

- Alkam, M.K.; Al-Nimr, M.A. Transient non-Darcian forced convection flow in a pipe partially filled with a porous material. Int. J. Heat Mass Transf. 1998, 41, 347–356. [Google Scholar] [CrossRef]

- Minkowycz, W.J.; Haji-Sheikh, A. Heat transfer in parallel plates and circular porous passages with axial conduction. Int. J. Heat Mass Transf. 2006, 49, 2381–2390. [Google Scholar] [CrossRef]

- Zhao, T.S.; Song, Y.J. Forced convection in a porous medium heated by a permeable wall perpendicular to flow direction: Analyses and measurements. Int. J. Heat Mass Transf. 2001, 44, 1031–1037. [Google Scholar] [CrossRef]

- Alazmi, B.; Vafai, K. Analysis of fluid flow and heat transfer interfacial conditions between a porous medium and a fluid layer. Int. J. Heat Mass Transf. 2001, 44, 1735–1749. [Google Scholar] [CrossRef]

- Shokouhmand, H.; Jam, F.; Salimpour, M.R. The effect of porous insert position on the enhanced heat transfer in partially filled channels. Int. Commun. Heat Mass Transf. 2011, 38, 1162–1167. [Google Scholar] [CrossRef]

- Haji-Sheikh, A.; Vafai, K. Analysis of flow and heat transfer in porous media imbedded inside various-shaped ducts. Int. J. Heat Mass Transf. 2004, 47, 1889–1905. [Google Scholar] [CrossRef]

- Sheikhnejad, Y.; Hosseini, R.; Avval, M.S. Experimental study on heat transfer enhancement of laminar ferrofluid flow in horizontal tube partially filled porous media under fixed parallel magnet bars. J. Magn. Magn. Mater. 2017, 424, 16–25. [Google Scholar] [CrossRef]

- Sheikhnejad, Y.; Hosseini, M.M.; Shahpari, A.; Teixeira, A.; Hosseini, R.; Avval, M.S. Experimental investigation and three dimensional numerical analysis of ferroconvection through horizontal tube under magnetic field of fixed parallel magnet bars. ASME J. Heat Transf. 2017, 139, 101703–101713. [Google Scholar] [CrossRef]

- Sheikhnejad, Y.; Ansari, A.B.; Ferreira, J.; Martins, N. Effects of parallel magnet bars and partially filled porous media on magneto-thermo-hydro-dynamic characteristics of pipe ferroconvection. Int. J. Heat Mass Transf. 2019, 136, 1273–1281. [Google Scholar] [CrossRef]

- Nield, D.A.; Bejan, A. Mechanics of fluid flow through a porous medium. In Convection in Porous Media; Springer: New York, NY, USA, 2013; pp. 1–29. [Google Scholar]

- Nejad, Y.S.; Nassab, S.G. Three-dimensional numerical analysis of hydrodynamic characteristics of axial groove journal bearings running with ferrofluids under magnetic field. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2010, 224, 609–619. [Google Scholar] [CrossRef]

- Trombetta, M.L. Laminar forced convection in eccentric annuli. Int. J. Heat Mass Transf. 1971, 14, 1161–1173. [Google Scholar] [CrossRef]

- Escudier, M.P.; Gouldson, I.W.; Oliveira, P.J.; Pinho, F.T. Effects of inner cylinder rotation on laminar flow of a Newtonian fluid through an eccentric annulus. Int. J. Heat Fluid Flow 2000, 21, 92–103. [Google Scholar] [CrossRef]

| Instrumentation | Specifications | Sensed Parameter | Accuracy |

|---|---|---|---|

| Type-K, thermocouple | Testo, flexible | Tw | ±1.0 ℃ |

| PT100 | Testo, highly accurate immersion | Tin, Tout | ±0.03 ℃ |

| PT100 Data logger | Testo 454 | - | - |

| Differential Pressure (dP) Gauge | Model: 3051C, Rosemount, USA, Range: ±6.21 kPa | Differential pressure, ΔP | ±0.015% Range = 1.8 Pa |

| Scaled decanter | 2 Lit, 100 cc scaled | Volume | - |

| Type-K Data acquisition | USB 4718, Advantech | - | - |

| Ultrasonic Flowmeter | Flownetix, 100 series (0.5–25 L/min) | Flow rate, Q | 3% (reading value) |

| Equations | |||

|---|---|---|---|

| Continuity | |||

| Momentum indirection | |||

| Momentum indirection | |||

| Momentum indirection | |||

| Energy |

| Grid Dimension | ||||

|---|---|---|---|---|

| 2.50 | 2.39 | 2.37 | 2.37 |

| Grid Dimension | ||

|---|---|---|

| 8.19 | 8.20 |

| Grid Number in z Direction | 100 | 130 | 160 | 190 |

|---|---|---|---|---|

| 12.61 | 12.10 | 12.08 | 12.08 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amoli, B.S.; Ajarostaghi, S.S.M.; Saffar-Avval, M.; Abardeh, R.H.; Akkurt, N. Experimental and Numerical Analysis of Forced Convection in a Horizontal Tube Partially Filled with a Porous Medium under Local Thermal Equilibrium Conditions. Water 2022, 14, 3832. https://doi.org/10.3390/w14233832

Amoli BS, Ajarostaghi SSM, Saffar-Avval M, Abardeh RH, Akkurt N. Experimental and Numerical Analysis of Forced Convection in a Horizontal Tube Partially Filled with a Porous Medium under Local Thermal Equilibrium Conditions. Water. 2022; 14(23):3832. https://doi.org/10.3390/w14233832

Chicago/Turabian StyleAmoli, Behzad Siavash, Seyed Soheil Mousavi Ajarostaghi, Majid Saffar-Avval, Reza Hosseini Abardeh, and Nevzat Akkurt. 2022. "Experimental and Numerical Analysis of Forced Convection in a Horizontal Tube Partially Filled with a Porous Medium under Local Thermal Equilibrium Conditions" Water 14, no. 23: 3832. https://doi.org/10.3390/w14233832

APA StyleAmoli, B. S., Ajarostaghi, S. S. M., Saffar-Avval, M., Abardeh, R. H., & Akkurt, N. (2022). Experimental and Numerical Analysis of Forced Convection in a Horizontal Tube Partially Filled with a Porous Medium under Local Thermal Equilibrium Conditions. Water, 14(23), 3832. https://doi.org/10.3390/w14233832