Concentrations and Retention Efficiency of Tire Wear Particles from Road Runoff in Bioretention Cells

Abstract

:1. Introduction

2. Materials and Methods

2.1. Case Study

2.1.1. Sampling Site and Sample Collection

2.1.2. Size Fractionation

2.2. Column Experiment

2.2.1. Engineered Soil and Column Dimensions

2.2.2. Influent Water and Hydraulic Load

2.2.3. Retention Efficiency of the Columns

2.2.4. TWP Concentrations in Top and Bottom Soil

2.3. STA-FTIR Analysis and Data Modeling

3. Results and Discussion

3.1. Case Study

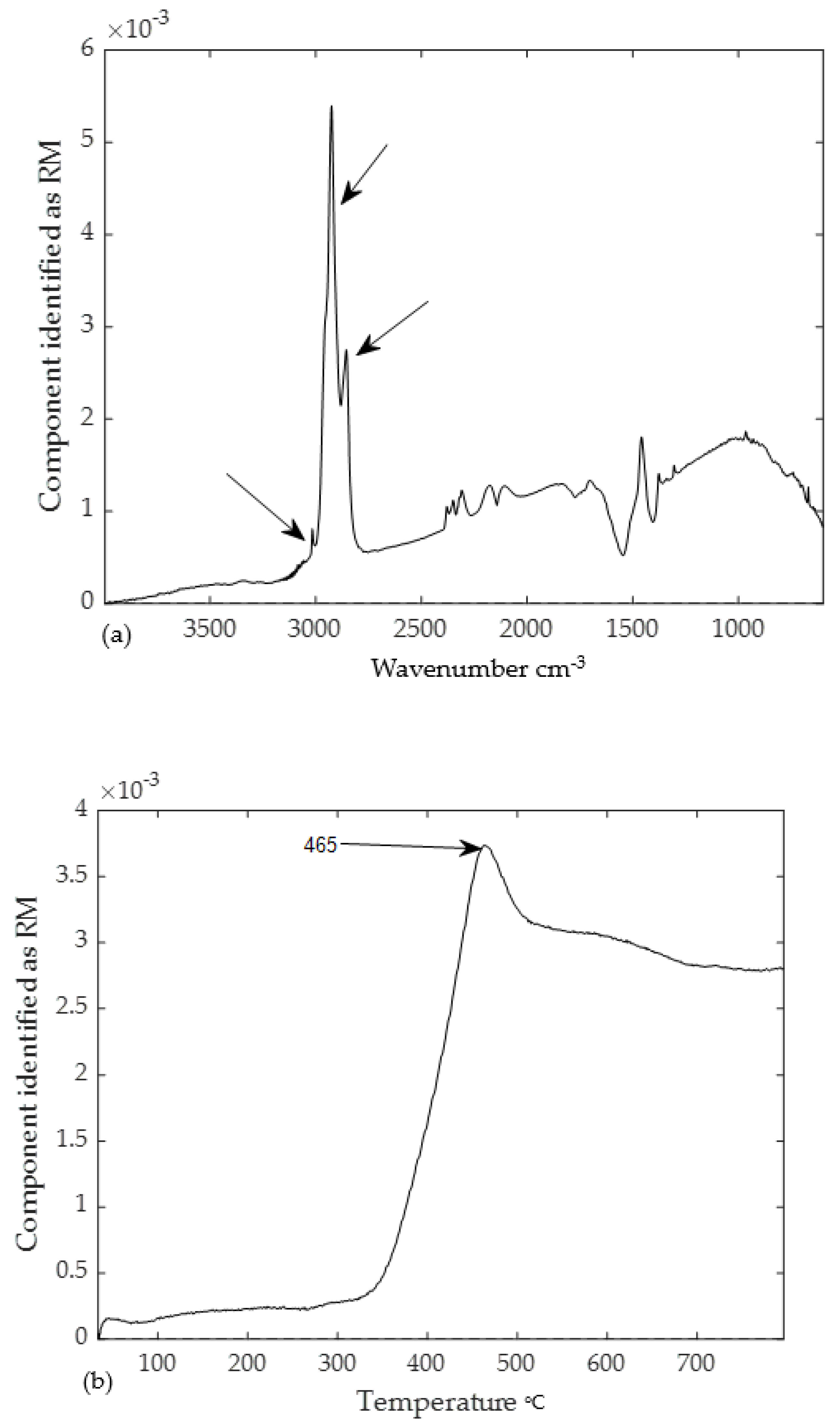

3.1.1. Detection of TWP in the Soil of Bioretention Cells

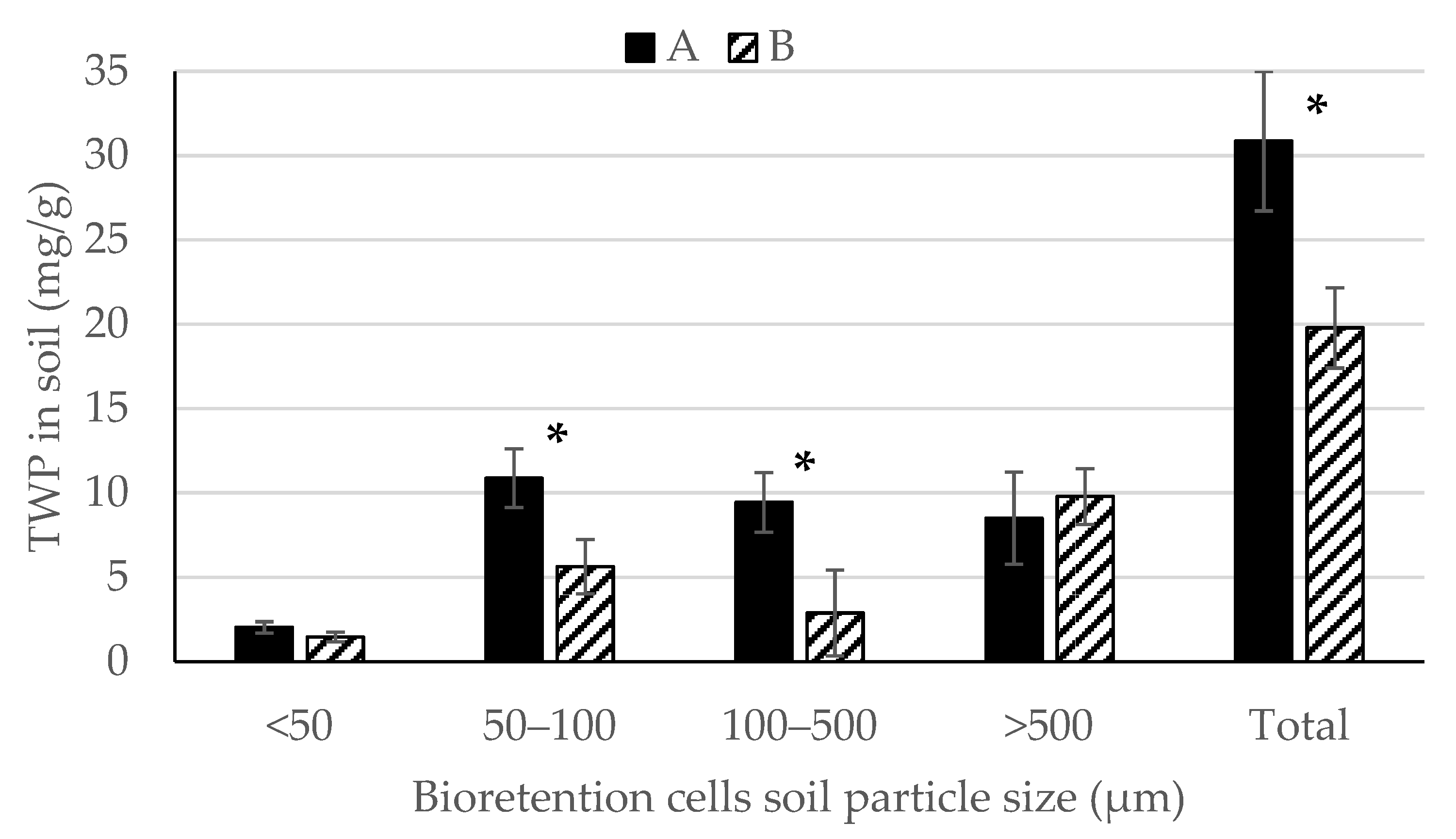

3.1.2. TWP Concentrations in Soil Size Fractions Close to and Further away from the Inlet

3.2. Column Infiltration Experiment

3.2.1. Retention Efficiency of the Engineered Soil

3.2.2. Vertical Distribution of TWP in the Columns

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ding, B.; Rezanezhad, F.; Gharedaghloo, B.; Van Cappellen, P.; Passeport, E. Science of the Total Environment Bioretention cells under cold climate conditions: Effects of freezing and thawing on water in fi ltration, soil structure, and nutrient removal. Sci. Total Environ. 2019, 649, 749–759. [Google Scholar] [CrossRef]

- Paus, K.H.; Morgan, J.; Gulliver, J.S.; Leiknes, T.; Hozalski, R.M. Assessment of the Hydraulic and Toxic Metal Removal Capacities of Bioretention Cells After 2 to 8 Years of Service. Water Air Pollut. 2014, 225, 1803. [Google Scholar] [CrossRef]

- Kratky, H.; Li, Z.; Chen, Y.; Wang, C.; Li, X.; Yu, T. A critical literature review of bioretention research for stormwater management in cold climate and future research recommendations. Front. Environ. Sci. Eng. 2017, 11, 16. [Google Scholar] [CrossRef]

- Khan, U.T.; Valeo, C.; Chu, A.; Van Duin, B. Bioretention cell efficacy in cold climates: Part 2—Water quality performance. Can. J. Civ. Eng. 2013, 39, 1222–1233. [Google Scholar] [CrossRef]

- Kim, H.; Seagren, E.A.; Davis, A.P. Engineered Bioretention for Removal of Nitrate from Stormwater Runoff. Water Environ. Res. 2003, 75, 355–367. [Google Scholar] [CrossRef]

- LeFevre, G.H.; Paus, K.H.; Natarajan, P.; Gulliver, J.S.; Novak, P.J.; Hozalski, R.M. Review of Dissolved Pollutants in Urban Storm Water and Their Removal and Fate in Bioretention Cells. J. Environ. Eng. 2015, 141, 04014050. [Google Scholar] [CrossRef]

- Paus, K.H.; Muthanna, T.M.; Braskerud, B.C. The hydrological performance of bioretention cells in regions with cold climates: Seasonal variation and implications for design. Hydrol. Res. 2016, 47, 291–304. [Google Scholar] [CrossRef]

- Paus, K.H.; Braskerud, B.C. Forslag til dimensjonering og utforming av regnbed for norske forhold. Vann. 2013, 1, 54–67. [Google Scholar]

- Gilbreath, A.; Mckee, L.; Shimabuku, I.; Lin, D. Multiyear Water Quality Performance and Mass Accumulation of PCBs, Mercury, Methylmercury, Copper, and Microplastics in a Bioretention Rain Garden. J. Sustain. Water Built Environ. 2019, 5, 1–10. [Google Scholar] [CrossRef]

- Lefevre, G.H.; Novak, P.J.; Hozalski, R.M. Fate of naphthalene in laboratory-scale bioretention cells: Implications for sustainable stormwater management. Environ. Sci. Technol. 2012, 46, 995–1002. [Google Scholar] [CrossRef] [PubMed]

- LeFevre, G.H.; Hozalski, R.M.; Novak, P.J. The role of biodegradation in limiting the accumulation of petroleum hydrocarbons in raingarden soils. Water Res. 2012, 46, 6753–6762. [Google Scholar] [CrossRef]

- Roy-poirier, A.; Champagne, P.; Filion, Y. Bioretention processes for phosphorus pollution control. Environ. Rev. 2010, 18, 159–173. [Google Scholar] [CrossRef]

- Brown, R.A.; Hunt, W.F. Improving bioretention/biofiltration performance with restorative maintenance. Water Sci. Technol. 2012, 65, 361–367. [Google Scholar] [CrossRef] [Green Version]

- Roy-poirier, A.; Champagne, P.; Filion, Y. Review of bioretention system research and design: Past, present, and future. J. Environ. Eng. 2010, 136, 878–889. [Google Scholar] [CrossRef]

- Kole, J.P.; Löhr, A.J.; Van Belleghem, F.G.A.J.; Ragas, A.M.J. Wear and tear of tyres: A stealthy source of microplastics in the environment. Int. J. Environ. Res. Public Health 2017, 14, 1265. [Google Scholar] [CrossRef]

- Vogelsang, C.; Lusher, A.L.; Dadkhah, M.E.; Sundvor, I.; Umar, M.; Ranneklev, S.B.; Eidsvoll, D.; Meland, S. Microplastics in Road Dust—Characteristics, Pathways and Measures; Norwegian Institute for Water Research: Oslo, Norway, 2018; 173p. [Google Scholar]

- European Commission Directorate-General for Research and Innovation. Environmental and Health Risks of Microplastic Pollution; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar] [CrossRef]

- Kreider, M.L.; Sweet, L.I.; Panko, J.M.; McAtee, B.L.; Finley, B.L. Physical and chemical characterization of tire-related particles: Comparison of particles generated using different methodologies. Sci. Total Environ. 2009, 408, 652–659. [Google Scholar] [CrossRef]

- Adachi, K.; Tainosho, Y. Characterization of heavy metal particles embedded in tire dust. Environ. Int. 2004, 30, 1009–1017. [Google Scholar] [CrossRef] [PubMed]

- Cadle, S.H.; Williams, R.L. Gas and particle emissions from automobile tires in laboratory and field studies. J. Air Pollut. Control Assoc. 1978, 28, 502–507. [Google Scholar] [CrossRef]

- Wagner, S.; Hüffer, T.; Klöckner, P.; Wehrhahn, M.; Hofmann, T.; Reemtsma, T. Tire wear particles in the aquatic environment—A review on generation, analysis, occurrence, fate and effects. Water Res. 2018, 139, 83–100. [Google Scholar] [CrossRef] [PubMed]

- Andersson-Sköld, Y.; Johanesson, M.; Gustafsson, M.; Järlskog, I.; Lithner, D.; Polukarova, M.; Strömvall, A.-M. Microplastics from Tyre and Road Wear—A Literature Review; Swedish National Road and Transport Research Institute: Linköping, Sweden, 2020. [Google Scholar] [CrossRef]

- Smyth, K.; Drake, J.; Li, Y.; Rochman, C.; Van Seters, T.; Passeport, E. Bioretention cells remove microplastics from urban stormwater. Water Res. 2021, 191, 116785. [Google Scholar] [CrossRef]

- Klöckner, P.; Seiwert, B.; Weyrauch, S.; Escher, B.I.; Reemtsma, T.; Wagner, S. Comprehensive characterization of tire and road wear particles in highway tunnel road dust by use of size and density fractionation. Chemosphere 2021, 279, 130530. [Google Scholar] [CrossRef]

- Lange, K.; Magnusson, K.; Viklander, M.; Blecken, G.T. Removal of rubber, bitumen and other microplastic particles from stormwater by a gross pollutant trap—Bioretention treatment train. Water Res. 2021, 202, 117457. [Google Scholar] [CrossRef] [PubMed]

- Lange, K.; Österlund, H.; Viklander, M.; Blecken, G.T. Occurrence and concentration of 20–100 μm sized microplastic in highway runoff and its removal in a gross pollutant trap—Bioretention and sand filter stormwater treatment train. Sci. Total Environ. 2022, 809, 151151. [Google Scholar] [CrossRef] [PubMed]

- Haraldsen, T.K.; Gamborg, M.; Vike, E. Utvikling av Jordblandinger til regnbed i Drammen Potteforsøk med Periodevis Vannmetning og Uttørking; Norwegian Institute of Bioeconomy Research (NIBIO): Ås, Norway, 2019; Volume 5. [Google Scholar]

- Statens Vegvesen. Vegkart. 2020. Available online: https://vegkart-2019.atlas.vegvesen.no/#kartlag:geodata/hva:(~(farge:’0_0,id:643))/hvor:(kommune:(~602))/@243508,6627176,8/vegobjekt:1007532883:40a744:643 (accessed on 21 March 2021).

- Prosesskode 1: Standard Beskrivelse for Vegkontrakter; Statens Vegvesen: Oslo, Norway, 2018.

- Nilsen, V.; Christensen, E.; Myrmel, M.; Heistad, A. Spatio-temporal dynamics of virus and bacteria removal in dual-media contact-filtration for drinking water. Water Res. 2019, 156, 9–22. [Google Scholar] [CrossRef]

- Mengistu, D.; Heistad, A.; Coutris, C. Tire wear particles concentrations in gully pot sediments. Sci. Total Environ. 2021, 769, 144785. [Google Scholar] [CrossRef]

- Paus, K.H. Forslag til dimensjonerende verdier for trinn 1 i Norsk Vann sin tre-trinns strategi for håndtering av overvann. Vannforeningen 2018, 1, 66–77. [Google Scholar]

- Unice, K.M.; Weeber, M.P.; Abramson, M.M.; Reid, R.C.D.; van Gils, J.A.G.; Markus, A.A.; Vethaak, A.D.; Panko, J.M. Characterizing export of land-based microplastics to the estuary—Part II: Sensitivity analysis of an integrated geospatial microplastic transport modeling assessment of tire and road wear particles. Sci. Total Environ. 2019, 646, 1650–1659. [Google Scholar] [CrossRef]

- Mengistu, D.; Nilsen, V.; Heistad, A.; Kvaal, K. Detection and Quantification of Tire Particles in Sediments Using a Combination of Simultaneous Thermal Analysis, Fourier Transform Infra-Red, and Parallel Factor Analysis. Int. J. Environ. Res. Public Health 2019, 16, 3444. [Google Scholar] [CrossRef] [Green Version]

- Baum, A.; Hansen, P.W.; Nørgaard, L.; Sørensen, J.; Mikkelsen, J.D. Rapid quantification of casein in skim milk using Fourier transform infrared spectroscopy, enzymatic perturbation, and multiway partial least squares regression: Monitoring chymosin at work. J. Dairy Sci. 2016, 99, 6071–6079. [Google Scholar] [CrossRef] [PubMed]

- Thorpe, A.; Harrison, R.M. Sources and properties of non-exhaust particulate matter from road traffic: A review. Sci. Total Environ. 2008, 400, 270–282. [Google Scholar] [CrossRef]

- Fernández-Berridi, M.J.; González, N.; Mugica, A.; Bernicot, C. Pyrolysis-FTIR and TGA techniques as tools in the characterization of blends of natural rubber and SBR. Thermochim. Acta 2006, 444, 65–70. [Google Scholar] [CrossRef]

- Jusli, E.; Nor, H.M.; Jaya, R.P.; Zaiton, H. Chemical Properties of Waste Tyre Rubber Granules. Adv. Mater. Res. 2014, 911, 77–81. [Google Scholar] [CrossRef]

- Ragn-Sells Gummigranulat. 2018. Available online: https://www.ragnsells.no/globalassets/norge/dokumenter/dekkgjenvinning/rs_pb_granulat_fin_v5-2018-01-16.pdf (accessed on 2 August 2020).

- Panko, J.M.; Chu, J.; Kreider, M.L.; Unice, K.M. Measurement of airborne concentrations of tire and road wear particles in urban and rural areas of France, Japan, and the United States. Atmos. Environ. 2013, 72, 192–199. [Google Scholar] [CrossRef]

- Unice, K.M.; Kreider, M.L.; Panko, J.M. Comparison of tire and road wear particle concentrations in sediment for watersheds in France, Japan, and the United States by quantitative pyrolysis GC/MS analysis. Environ. Sci. Technol. 2013, 47, 8138–8147. [Google Scholar] [CrossRef] [PubMed]

- Sommer, F.; Dietze, V.; Baum, A.; Sauer, J.; Gilge, S.; Maschowski, C.; Gieré, R. Tire abrasion as a major source of microplastics in the environment. Aerosol Air Qual. Res. 2018, 18, 2014–2028. [Google Scholar] [CrossRef]

- Murphy, K.R.; Stedmon, C.A.; Graeber, D.; Bro, R. Fluorescence spectroscopy and multi-way techniques. PARAFAC. Anal. Methods 2013, 5, 6557–6566. [Google Scholar] [CrossRef] [Green Version]

- Bro, R.; Kiers, H.A.L. A new efficient method for determining the number of components in PARAFAC models. J. Chemom. 2003, 17, 274–286. [Google Scholar] [CrossRef]

- Besseling, E.; Quik, J.T.K.; Sun, M.; Koelmans, A.A. Fate of nano- and microplastic in freshwater systems: A modeling study. Environ. Pollut. 2017, 220, 540–548. [Google Scholar] [CrossRef]

- Klöckner, P.; Seiwert, B.; Eisentraut, P.; Braun, U.; Reemtsma, T.; Wagner, S. Characterization of tire and road wear particles from road runoff indicates highly dynamic particle properties. Water Res. 2020, 185, 116262. [Google Scholar] [CrossRef]

- Eisentraut, P.; Dümichen, E.; Ruhl, A.S.; Jekel, M.; Albrecht, M.; Gehde, M.; Braun, U. Two Birds with One Stone—Fast and Simultaneous Analysis of Microplastics: Microparticles Derived from Thermoplastics and Tire Wear. Environ. Sci. Technol. Lett. 2018, 5, 608–613. [Google Scholar] [CrossRef]

- Baensch-Baltruschat, B.; Kocher, B.; Stock, F.; Reifferscheid, G. Tyre and road wear particles (TRWP)—A review of generation, properties, emissions, human health risk, ecotoxicity, and fate in the environment. Sci. Total Environ. 2020, 733, 137823. [Google Scholar] [CrossRef] [PubMed]

- Hallberg, M.; Renman, G. Suspended solids concentration in highway runoff during summer conditions. Polish J. Environ. Stud. 2008, 17, 237–241. [Google Scholar]

- Thomson, N.; McBean, E.; Mostrenko, I.B.; Snodgrass, W. Characterization of Stormwater Runoff from Highways. J. Water Manag. Model. 1994, 6062, 141–158. [Google Scholar] [CrossRef] [Green Version]

- Alem, A.; Elkawafi, A.; Ahfir, N.D.; Wang, H.Q. Filtration of kaolinite particles in a saturated porous medium: Hydrodynamic effects. Hydrogeol. J. 2013, 21, 573–586. [Google Scholar] [CrossRef]

- Conley, G.; Beck, N.; Riihimaki, C.A.; Tanner, M. Quantifying clogging patterns of infiltration systems to improve urban stormwater pollution reduction estimates. Water Res. X 2020, 7, 100049. [Google Scholar] [CrossRef]

- Hanvey, J.S.; Lewis, P.J.; Lavers, J.L.; Crosbie, N.D.; Pozo, K.; Clarke, B.O. A review of analytical techniques for quantifying microplastics in sediments. Anal. Methods 2017, 9, 1369–1383. [Google Scholar] [CrossRef]

- Imhof, H.K.; Schmid, J.; Niessner, R.; Ivleva, N.P.; Laforsch, C.; Imhof, H.K.; Schmid, J.; Laforsch, C.; Ivleva, N.P. A novel, highly efficient method for the separation and quantification of plastic particles in sediments of aquatic environments. Limnol. Oceanogr. Methods 2016, 10, 524–537. [Google Scholar] [CrossRef]

- Karlsson, T.M.; Ekstrand, E.; Threapleton, M.; Mattsson, K.; Nordberg, K.; Hassellöv, M. Undersökning av mikroskräp längs bohuslänska stränder och i Sediment; University of Gothenburg: Kristineberg, Sweden, 2019. [Google Scholar]

| Proportion in Bulk Soil (%) | ||

|---|---|---|

| Soil Size Fraction (µm) | A | B |

| <50 | 3.8 | 3.3 |

| 50–100 | 24.6 | 22.6 |

| 100–500 | 35.6 | 39.0 |

| >500 | 36.0 | 35.1 |

| Sample | Column | Water (L) | Total Solid Particles >25 µm (mg/L) | TWP Concentration mg/L | Removal Efficiency (%) | ||

|---|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | ||||

| Influent | 366.7 | 79.9 | 4.9 | ||||

| Effluent | C1 | 13.8 | 40.6 | 0.1 | 0.1 | 99.9 | 0.1 |

| C2 | 10.3 | 117.3 | 0.8 | 0.2 | 99.0 | 0.2 | |

| C3 | 14.2 | 12.5 | 0.1 | 0.0 | 99.9 | 0.0 | |

| Column | Top 5 cm | Bottom 5 cm | ||

|---|---|---|---|---|

| Mean | SD | Mean | SD | |

| C3* | 5.0 | 1.4 | 0.0 | 0.0 |

| C3** | 1.0 | 1.7 | N/A | N/A |

| C1 | 0.9 | 1.0 | 0.4 | 0.5 |

| C2 | 0.8 | 0.3 | 0.9 | 0.5 |

| C3 | 0.6 | 0.7 | 0.4 | 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mengistu, D.; Coutris, C.; Paus, K.A.H.; Heistad, A. Concentrations and Retention Efficiency of Tire Wear Particles from Road Runoff in Bioretention Cells. Water 2022, 14, 3233. https://doi.org/10.3390/w14203233

Mengistu D, Coutris C, Paus KAH, Heistad A. Concentrations and Retention Efficiency of Tire Wear Particles from Road Runoff in Bioretention Cells. Water. 2022; 14(20):3233. https://doi.org/10.3390/w14203233

Chicago/Turabian StyleMengistu, Demmelash, Claire Coutris, Kim Aleksander Haukeland Paus, and Arve Heistad. 2022. "Concentrations and Retention Efficiency of Tire Wear Particles from Road Runoff in Bioretention Cells" Water 14, no. 20: 3233. https://doi.org/10.3390/w14203233