Impact of Piping Erosion Process on the Temporal–Spatial Mechanisms of Soil

Abstract

:1. Introduction

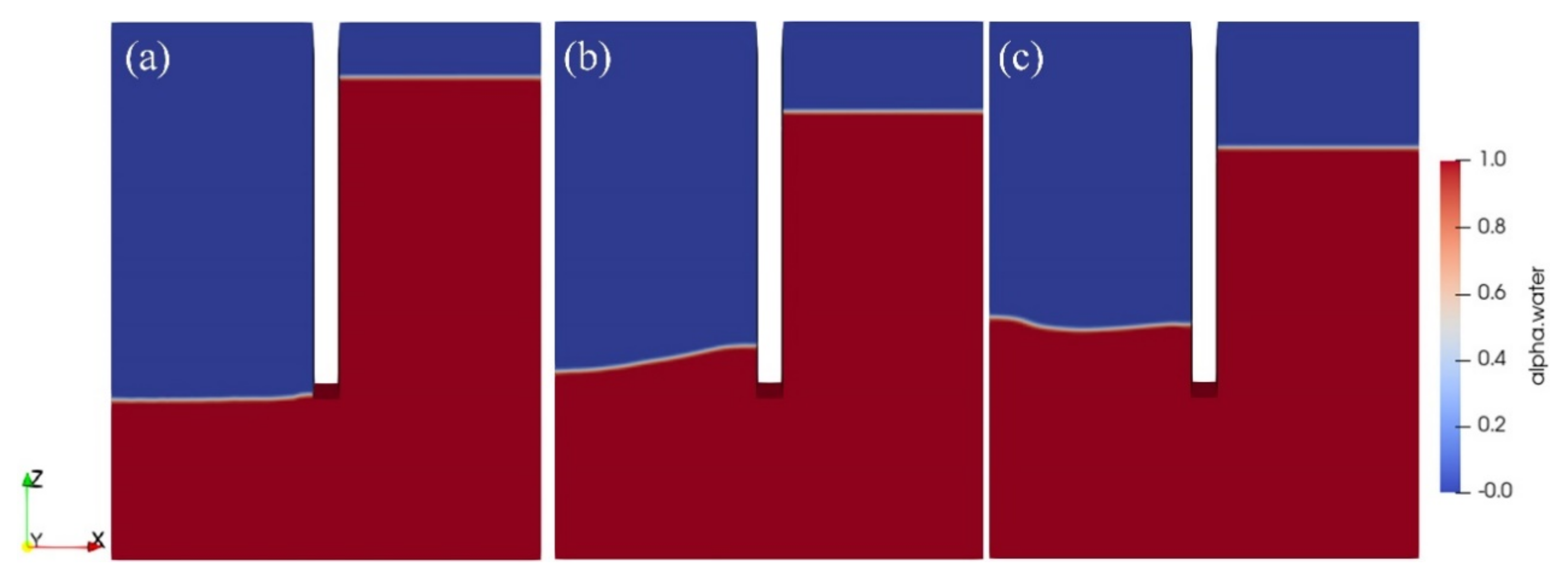

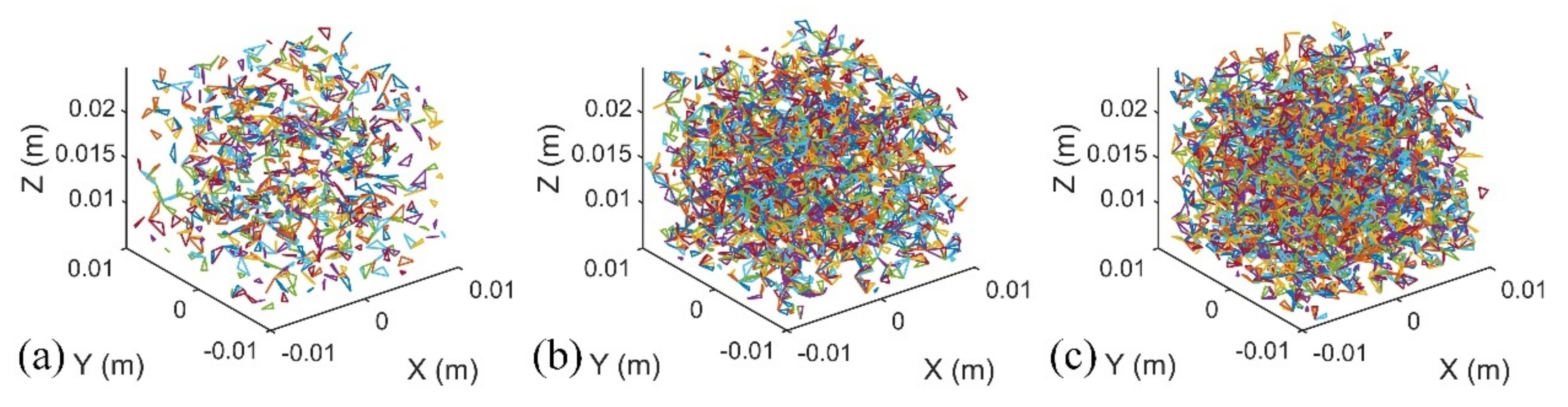

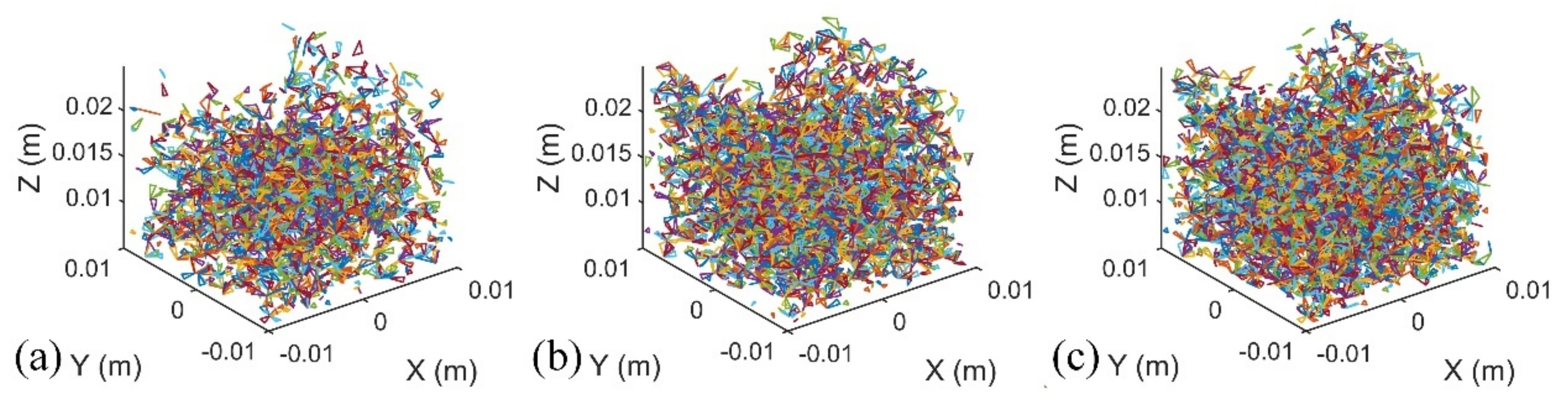

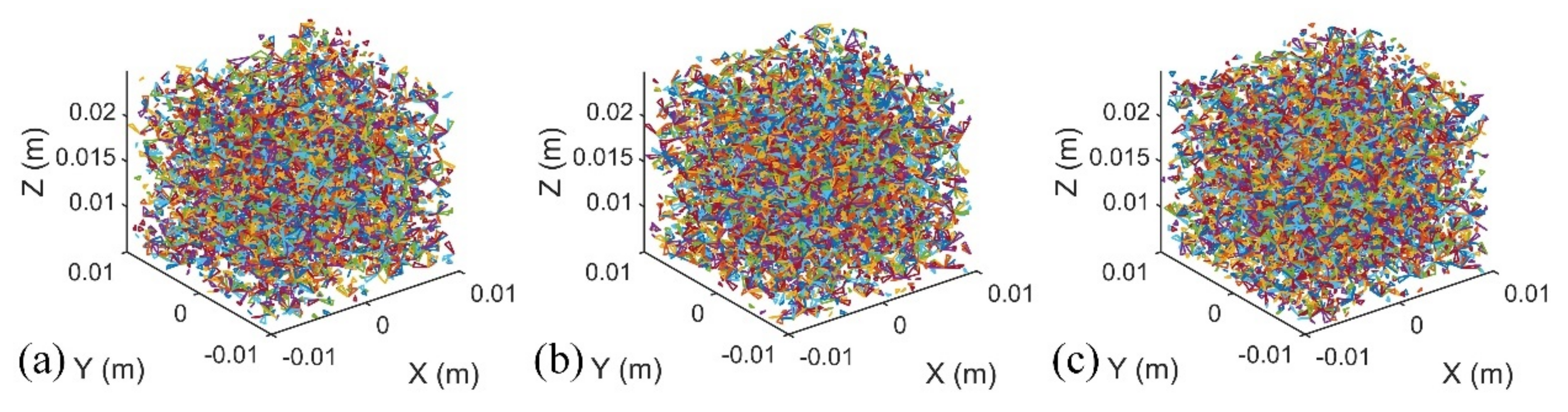

2. Methodology

3. Observations of Seepage Erosion

3.1. Material Properties

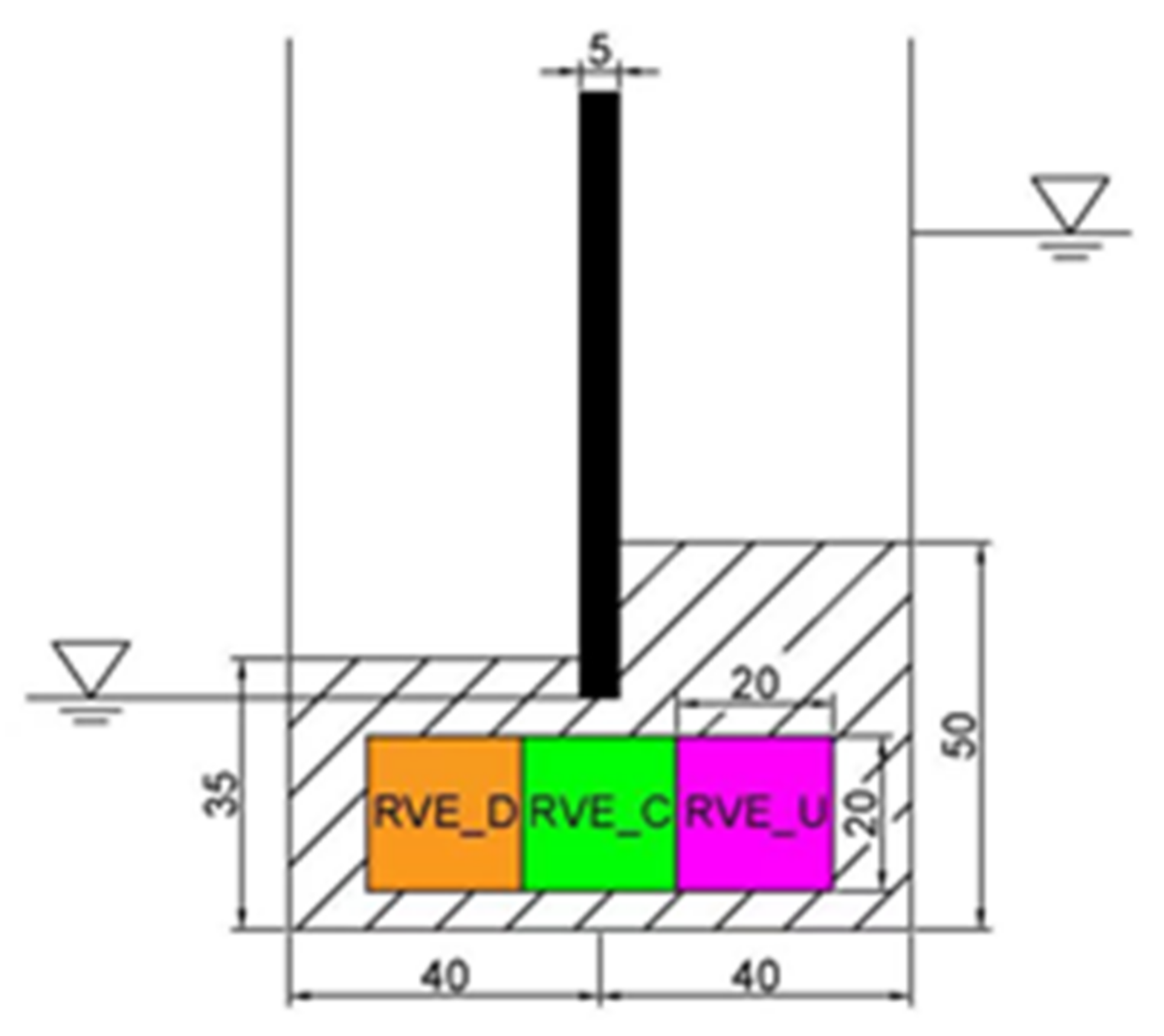

3.2. Numerical Model Set-Up

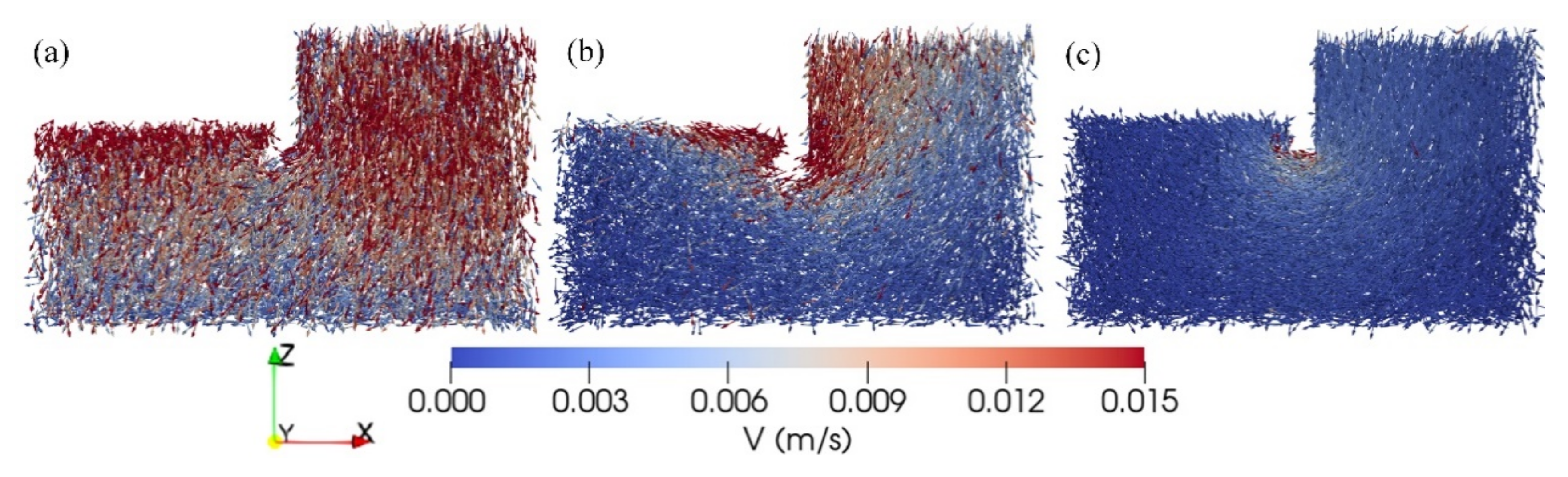

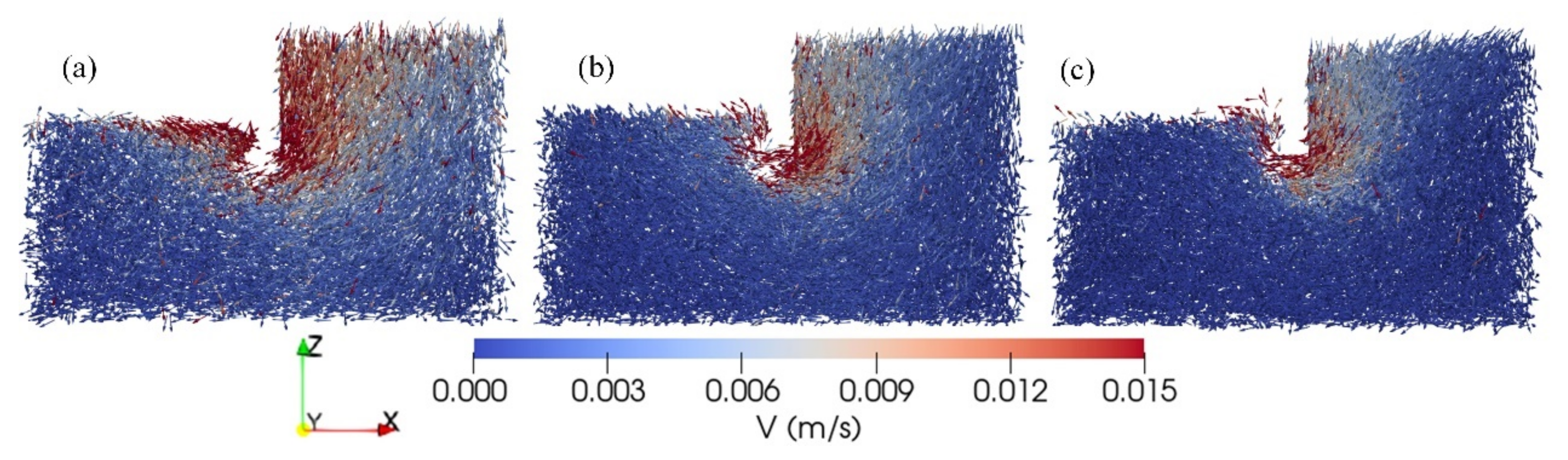

3.3. Particle Velocity

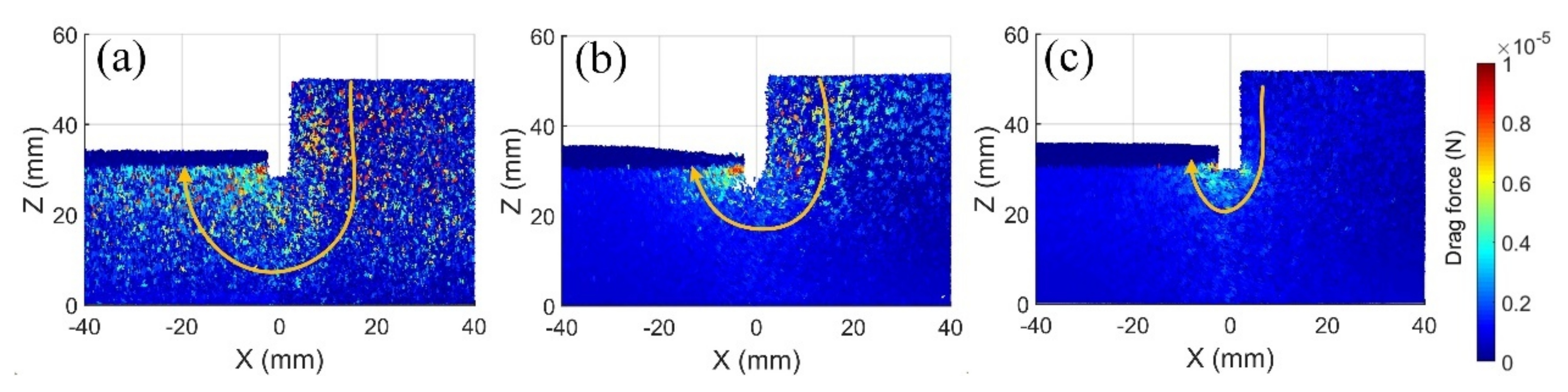

3.4. Drag Force

3.5. Local Observations of Piping Erosion

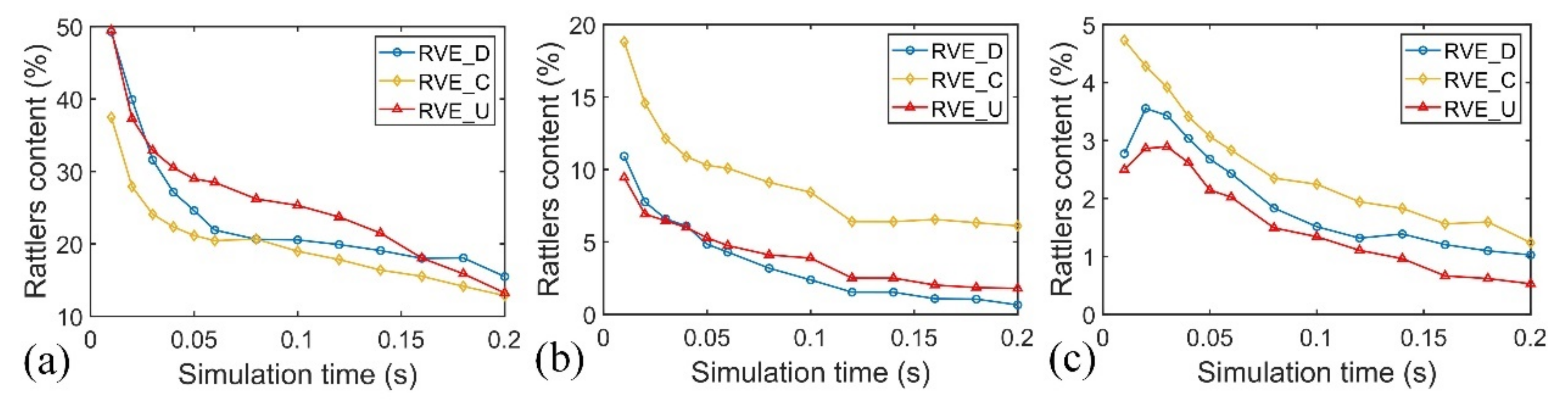

3.5.1. Rattler Contents

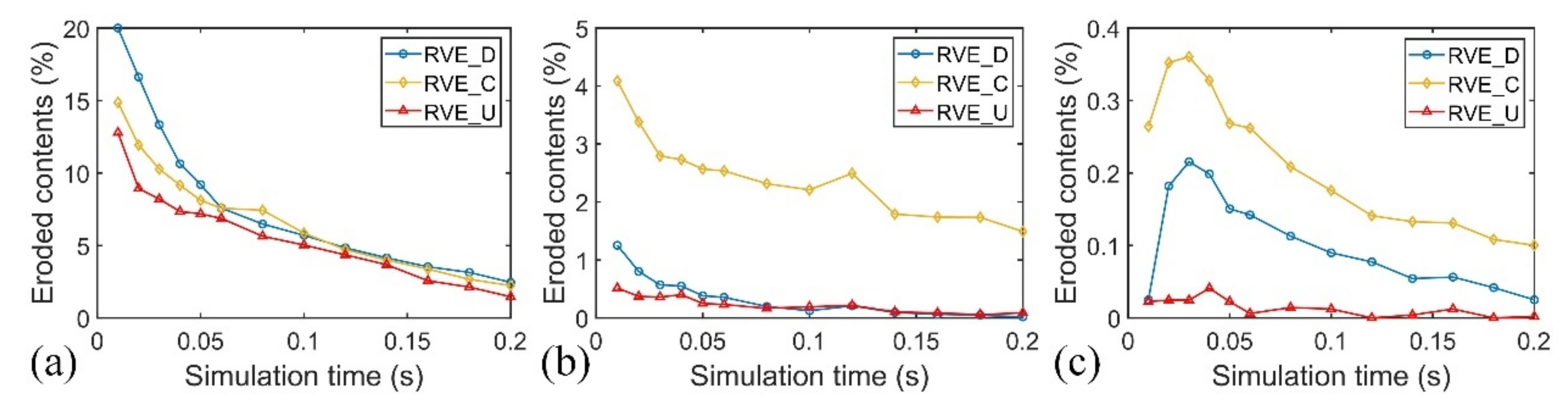

3.5.2. Erodible Particles

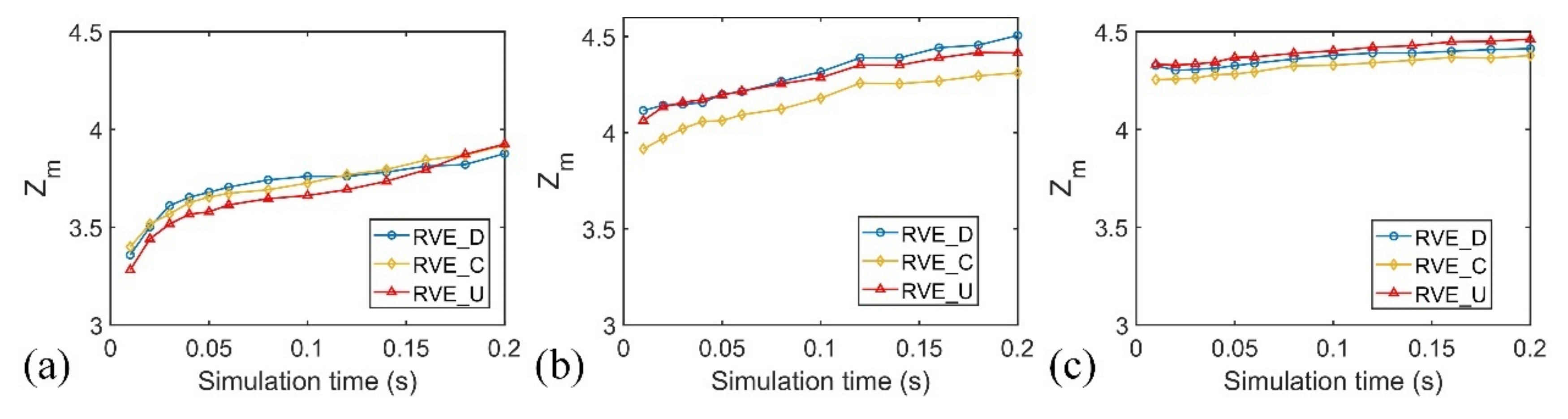

3.5.3. Coordination Number

3.5.4. Geometry

4. Constitutive Material Behavior and Discussion

4.1. Numerical Model Set-Up

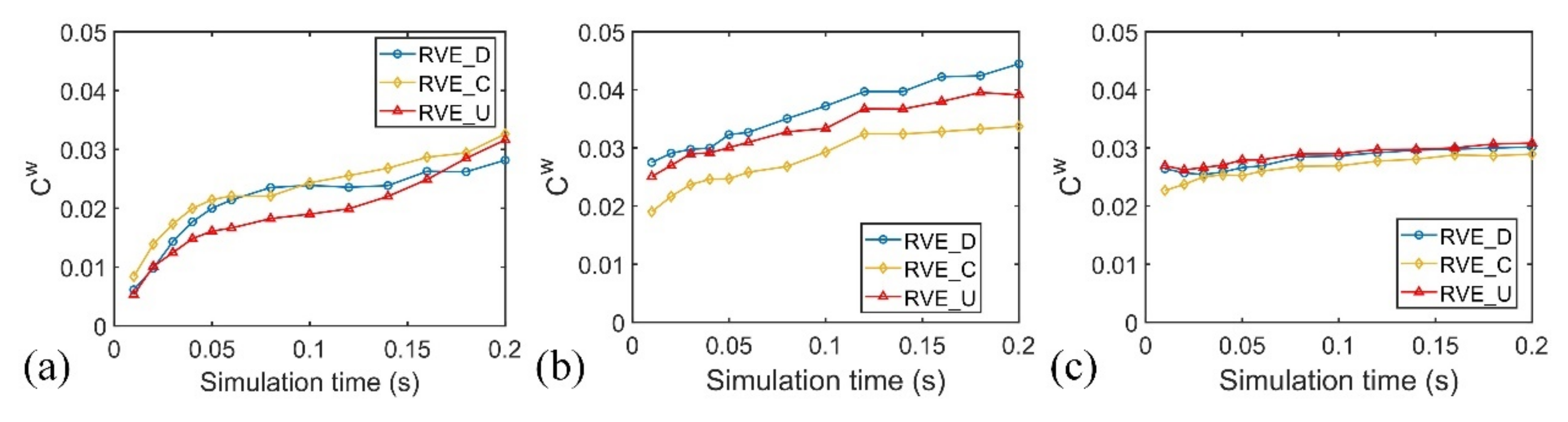

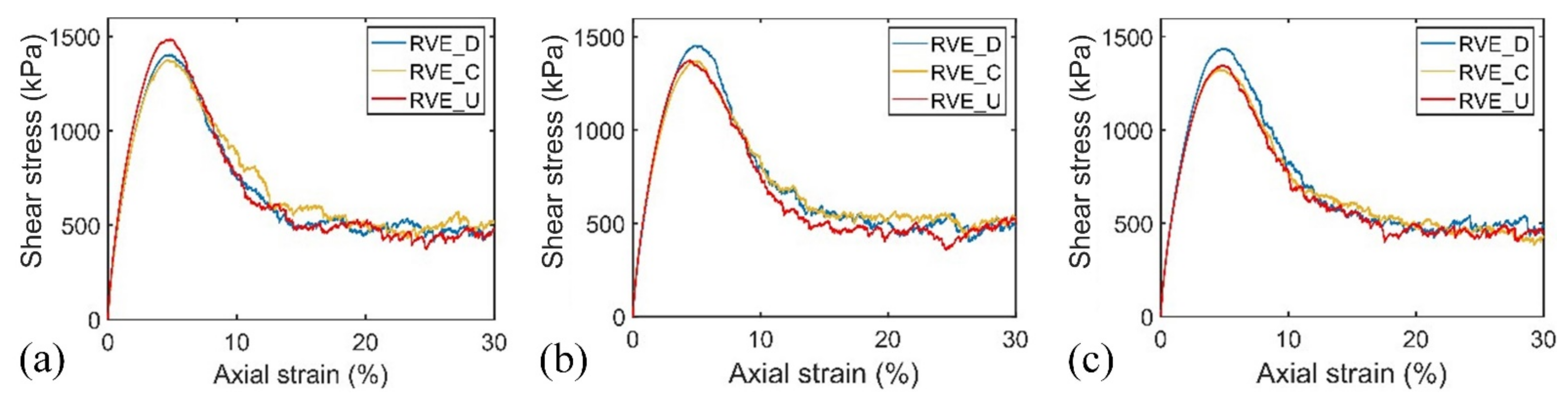

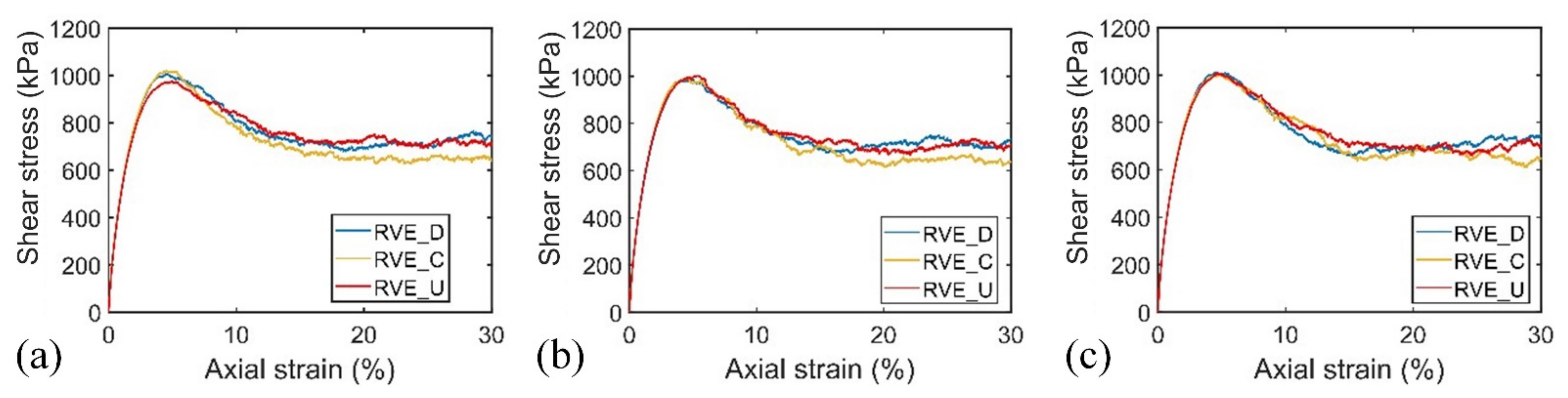

4.2. Material Behavior

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Sterpi, D. Effects of the erosion and transport of fine particles due to seepage flow. Int. J. Geomech. 2003, 3, 111–122. [Google Scholar] [CrossRef]

- Foster, M.; Fell, R.; Spannagle, M. The statistics of embankment dam failures and accidents. Can. Geotech. J. 2000, 37, 1000–1024. [Google Scholar] [CrossRef]

- Terzaghi, K. Der Grundbruch an Stauwerken und seine Verhutung. In From Theory to Practice in Soil Mechanics; John Wiley & Sons (in German): New York, NY, USA, 1960; pp. 445–449. [Google Scholar]

- Terzaghi, K. Theoretical Soil Mechanics; Wiley: Hoboken, NJ, USA, 1943. [Google Scholar]

- Kenney, T.C.; Lau, D. Internal stability of granular filters. Can. Geotech. J. 1985, 22, 215–225. [Google Scholar] [CrossRef]

- Wan, C.F.; Fell, R. Investigation of rate of erosion of soils in embankment dams. J. Geotech. Geoenviron. Eng. 2004, 130, 373–380. [Google Scholar] [CrossRef]

- Chang, D.S.; Zhang, L.M. Critical Hydraulic Gradients of Internal Erosion under Complex Stress States. J. Geotech. Geoenviron. Eng. 2013, 139, 1454–1467. [Google Scholar] [CrossRef]

- Sato, M.; Kuwano, R. Laboratory testing for evaluation of the influence of a small degree of internal erosion on deformation and stiffness. Soils Found. 2018, 58, 547–562. [Google Scholar] [CrossRef]

- Xie, Q.; Liu, J.; Han, B.; Li, H.; Li, Y.; Li, X. Critical Hydraulic Gradient of Internal Erosion at the Soil–Structure Interface. Processes 2018, 6, 92. [Google Scholar] [CrossRef]

- Nguyen, C.D.; Benahmed, N.; Andò, E.; Sibille, L.; Phillippe, P. Experimental investigation of microstructural changes in soils eroded by suffusion using X-ray tomography. Acta Geotech. 2019, 14, 749–765. [Google Scholar] [CrossRef]

- Ke, L.; Takahashi, A. Experimental investigations on suffusion characteristics and its mechanical consequences on saturated cohesionless soil. Soils Found. 2014, 54, 713–730. [Google Scholar] [CrossRef]

- Ke, L.; Takahashi, A. Triaxial erosion test for evaluation of mechanical consequences of internal erosion. Geotech. Test. J. 2014, 37, 347–364. [Google Scholar] [CrossRef] [Green Version]

- Ke, L.; Takahashi, A. Drained monotonic responses of suffusional cohesionless soils. J. Geotech. Geoenviron. Eng. 2015, 141, 04015033. [Google Scholar] [CrossRef]

- Wang, S.; Chen, J.; Sheng, J.; Luo, Y. Laboratory investigation of stress state and grain composition affecting internal erosion in soils containing a suspended cut-off wall. KSCE J. Civ. Eng. 2015, 20, 1283–1293. [Google Scholar] [CrossRef]

- Xiao, M.; Shwiyhat, N. Experimental investigation of the effects of suffusion on physical and geomechanic characteristics of sandy soils. Geotech. Test. J. 2012, 35, 1–11. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A Discrete Numerical Model for Granular Assemblies. Geotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Scholtes, L.; Hicher, P.Y.; Sibille, L. Multiscale approaches to describe mechanical responses induced by particle removal in granular materials. Comptes Rendus Mec. 2010, 338, 627–638. [Google Scholar] [CrossRef]

- Muir Wood, D.; Maeda, K.; Nukudani, E. Modeling mechanical consequences of erosion. Geotechnique 2010, 60, 447–457. [Google Scholar] [CrossRef]

- Kawano, K.; O’Sullivan, C.; Shire, T. Using DEM to assess the influence of stress and fabric inhomogeneity and anisotropy on susceptibility to suffusion. In Proceedings of the ICSE 2016 (8th International Conference on Scour and Erosion), Oxford, UK, 12–15 September 2016. [Google Scholar]

- Hicher, P.Y. Modelling the impact of particle removal on granular material behavior. Geotechnique 2013, 63, 118–128. [Google Scholar] [CrossRef]

- Hama, N.A.; Ouahbi, T.; Taibi, S.; Souli, H.; Fleureau, J.M.; Pantet, A. Analysis of mechanical behaviour and internal stability of granular materials using discrete element method. Int. J. Numer. Anal. Methods Geomech. 2016, 40, 1712–1729. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, L.M.; Chang, D.S. Stress-strain behaviour of granular soils subjected to internal erosion. J. Geotech. Geoenviron. Eng. 2016, 142, 06016014. [Google Scholar] [CrossRef]

- Aboul Hosn, R.; Sibille, L.; Benahmed, N.; Chareyre, B. A discrete numerical model involving partial fluid-solid coupling to describe suffusion effects in soils. Comput. Geotech. 2018, 95, 30–39. [Google Scholar] [CrossRef] [Green Version]

- Mehizadeh, A.; Disfani, M.M.; Evans, R.P.; Arulrajah, A. Progressive internal erosion in a gap-graded internally unstable soil-mechanical and geometrical effects. Int. J. Geomech. 2017, 18, 04017160. [Google Scholar] [CrossRef]

- LIGGGHTS. LIGGGHTS (R)-Public Documentation, Version 3.X. Available online: http://www.cfdem.com (accessed on 18 February 2015).

- OpenFOAM. OpenFOAM—The Open Source CFD Toolbox. The OpenFOAM Foundation. 2015. Available online: http://www.openfoam.org (accessed on 22 May 2015).

- Xiao, Q.; Wang, J.-P. CFD–DEM simulations of seepage-induced erosion. Water 2020, 12, 678. [Google Scholar] [CrossRef]

- Xiao, Q. Simulating the hydraulic heave phenomenon with multiphase fluid flows using CFD-DEM. Water 2020, 12, 1077. [Google Scholar] [CrossRef]

- Ke, L.; Takahashi, A. Strength reduction of cohesionless soil due to internal erosion induced by one-dimensional upward seepage flow. Soil Found. 2012, 52, 698–711. [Google Scholar] [CrossRef]

- De Frias Lopez, R.; Silfwerbrand, J.; Jelagin, D.; Birgisson, B. Force transmission and soil fabric of binary granular mixtures. Geotechnique 2016, 66, 578–583. [Google Scholar] [CrossRef]

- Prasomsri, J.; Takahashi, A. The role of fines on internal instability and its impact on undrained mechanical response of gap-graded soils. Soils Found. 2020, 60, 1468–1488. [Google Scholar] [CrossRef]

- Rosenberry, D.O.; Pitlick, J. Effects of sediment transport and seepage direction on hydraulic properties at the sediment–water interface of hyporheic settings. J. Hydrol. 2009, 373, 377–391. [Google Scholar] [CrossRef]

- Di Felice, R. The voidage function for fluid-particle interaction systems. Int. J. Multiph. Flow 1994, 20, 153–159. [Google Scholar] [CrossRef]

- Mehizadeh, A.; Disfani, M.M.; Shire, T. Post-erosion mechanical response of internally unstable soil of varying size and flow regime. Can. Geotech. J. 2021, 58, 531–539. [Google Scholar] [CrossRef]

- Thornton, C. Numerical simulation of deviatoric shear deformation of granular media. Géotechnique 2000, 50, 43–53. [Google Scholar] [CrossRef]

- Papadopoulos, L.; Porter, M.A.; Daniels, K.E.; Bassett, D.S. Network analysis of particles and grains. J. Complex Netw. 2018, 6, 4850565. [Google Scholar] [CrossRef]

- Newman, M.E.J. The structure and function of complex networks. SIAM Rev. 2003, 45, 167–256. [Google Scholar] [CrossRef]

- Watts, D.J.; Strogatz, S.H. Collective dynamics of ‘small-world’ networks. Nature 1998, 393, 440–442. [Google Scholar] [CrossRef] [PubMed]

- Desu, R.K.; Annabattula, R.K. Particle size effects on the contact force distribution in compacted polydisperse granular assemblies. Granul. Matter 2019, 21, 29. [Google Scholar] [CrossRef]

- Shire, T.; O’Sullivan, C. Micromechanical assessment of an internal stability criterion. Acta Geotech. 2013, 8, 81–90. [Google Scholar] [CrossRef]

- Lee, K.-L.; Yang, F.-L. Relaxation-type nonlocal inertial-number rheology for dry granular flows. Phys. Rev. E 2017, 96, 062909. [Google Scholar] [CrossRef] [PubMed]

- Lopera Perez, J.C.; Kwok, C.Y.; O’Sullivan, C.; Huang, X.; Hanley, K.J. Assessing the quasi-static conditions for shearing in granular media within the critical state soil mechanics framework. Soils Found. 2016, 56, 152–159. [Google Scholar] [CrossRef] [Green Version]

| FC30 | FC40 | FC60 | |

|---|---|---|---|

| Mass ratio (fine/coarse) | 3:7 | 4:6 | 6:4 |

| Solid volume (m3) |

| Young’s Modulus | Radii of Particles | Friction Coefficient | Poission’s Ratio | Restitution Coefficient |

|---|---|---|---|---|

| 600 MPa | 0.25 mm 1 mm | 0.5 | 0.45 | 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Q. Impact of Piping Erosion Process on the Temporal–Spatial Mechanisms of Soil. Water 2022, 14, 2841. https://doi.org/10.3390/w14182841

Xiao Q. Impact of Piping Erosion Process on the Temporal–Spatial Mechanisms of Soil. Water. 2022; 14(18):2841. https://doi.org/10.3390/w14182841

Chicago/Turabian StyleXiao, Qiong. 2022. "Impact of Piping Erosion Process on the Temporal–Spatial Mechanisms of Soil" Water 14, no. 18: 2841. https://doi.org/10.3390/w14182841