A Tree-Based Machine Learning Method for Pipeline Leakage Detection

Abstract

:1. Introduction

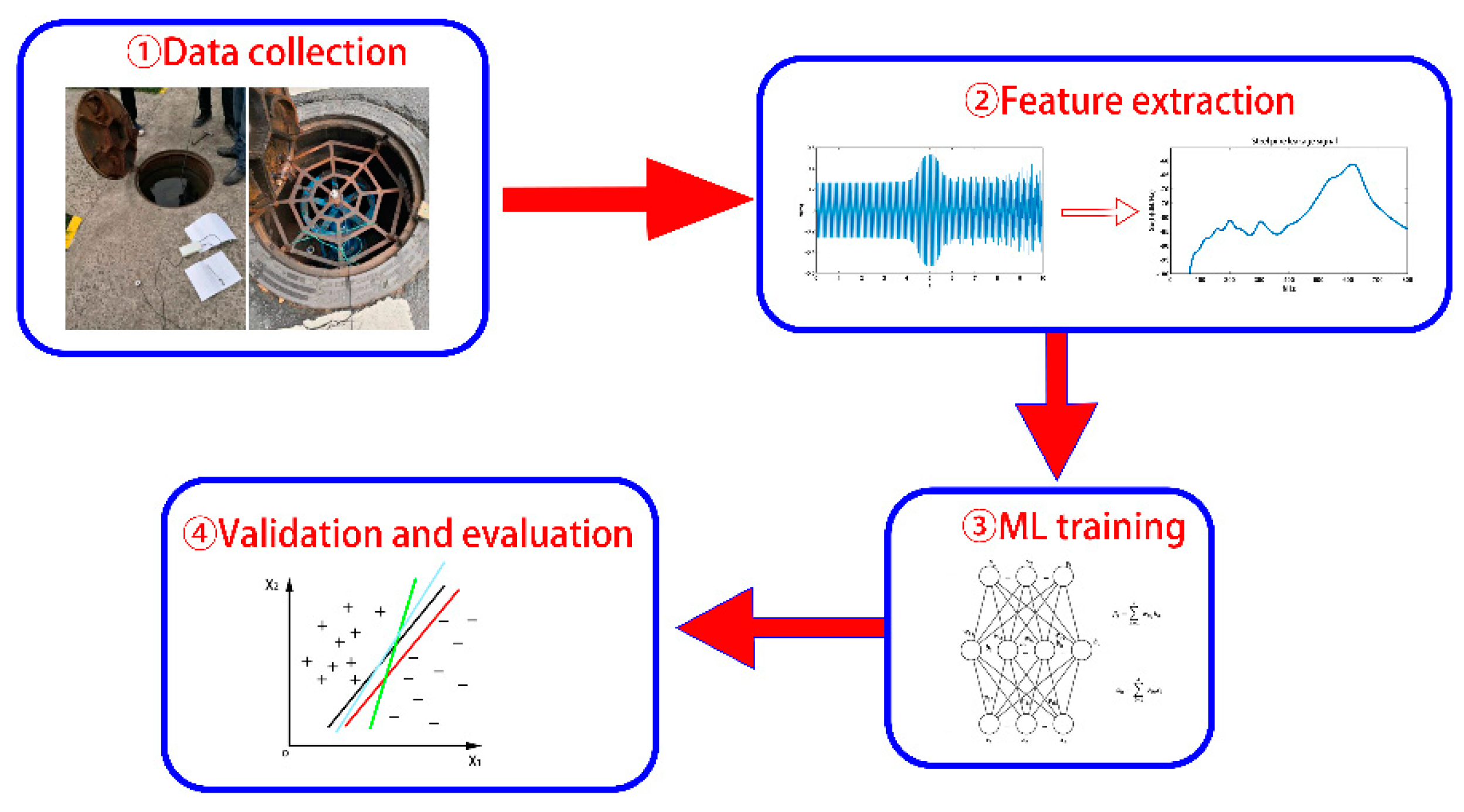

2. Methodology

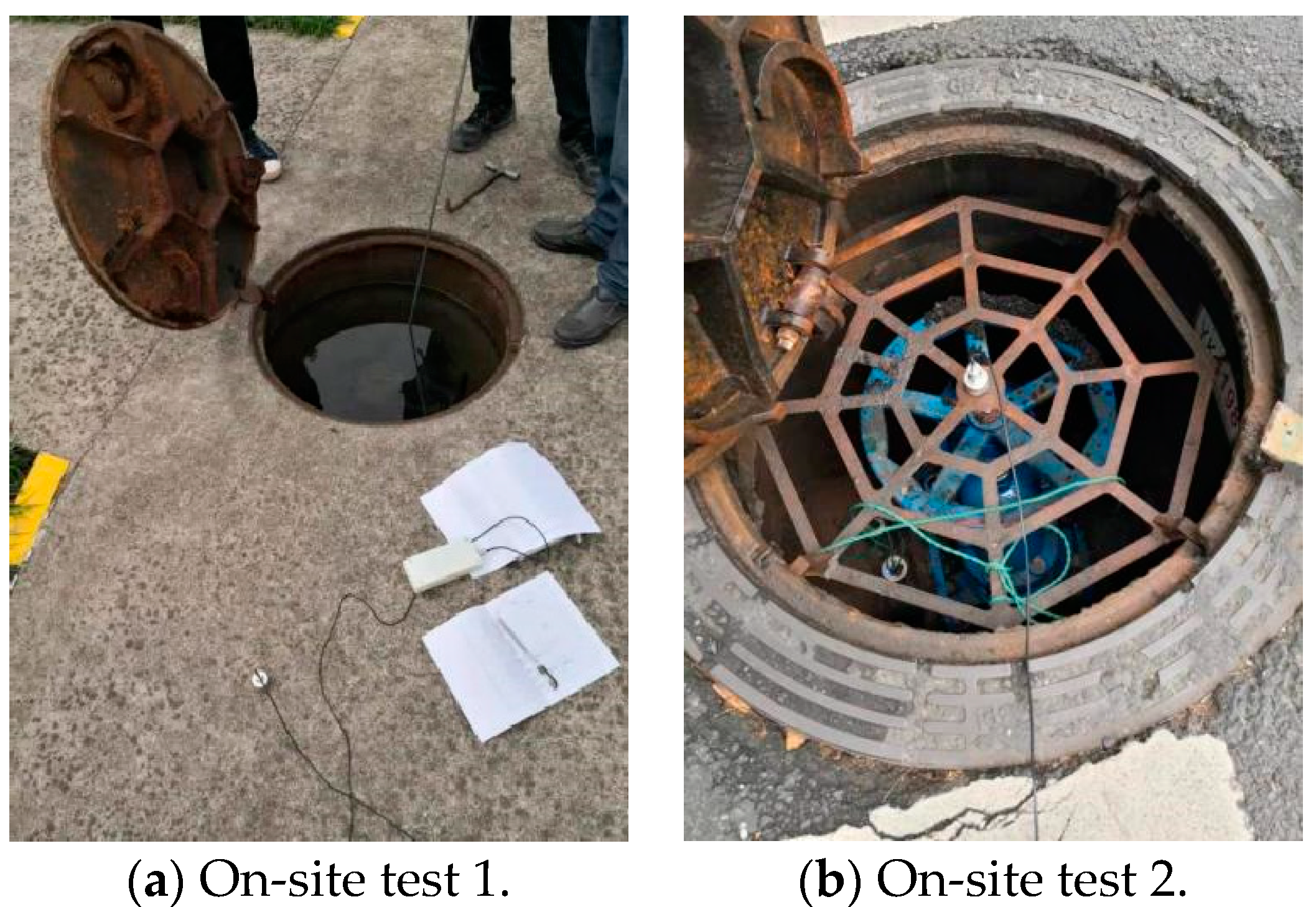

2.1. Data Collection

2.2. Feature Set

2.2.1. Dominant Frequency

2.2.2. Spectral Flatness

2.2.3. Spectral Roll-Off Rate

2.2.4. One-D MFCC

2.3. ML Models

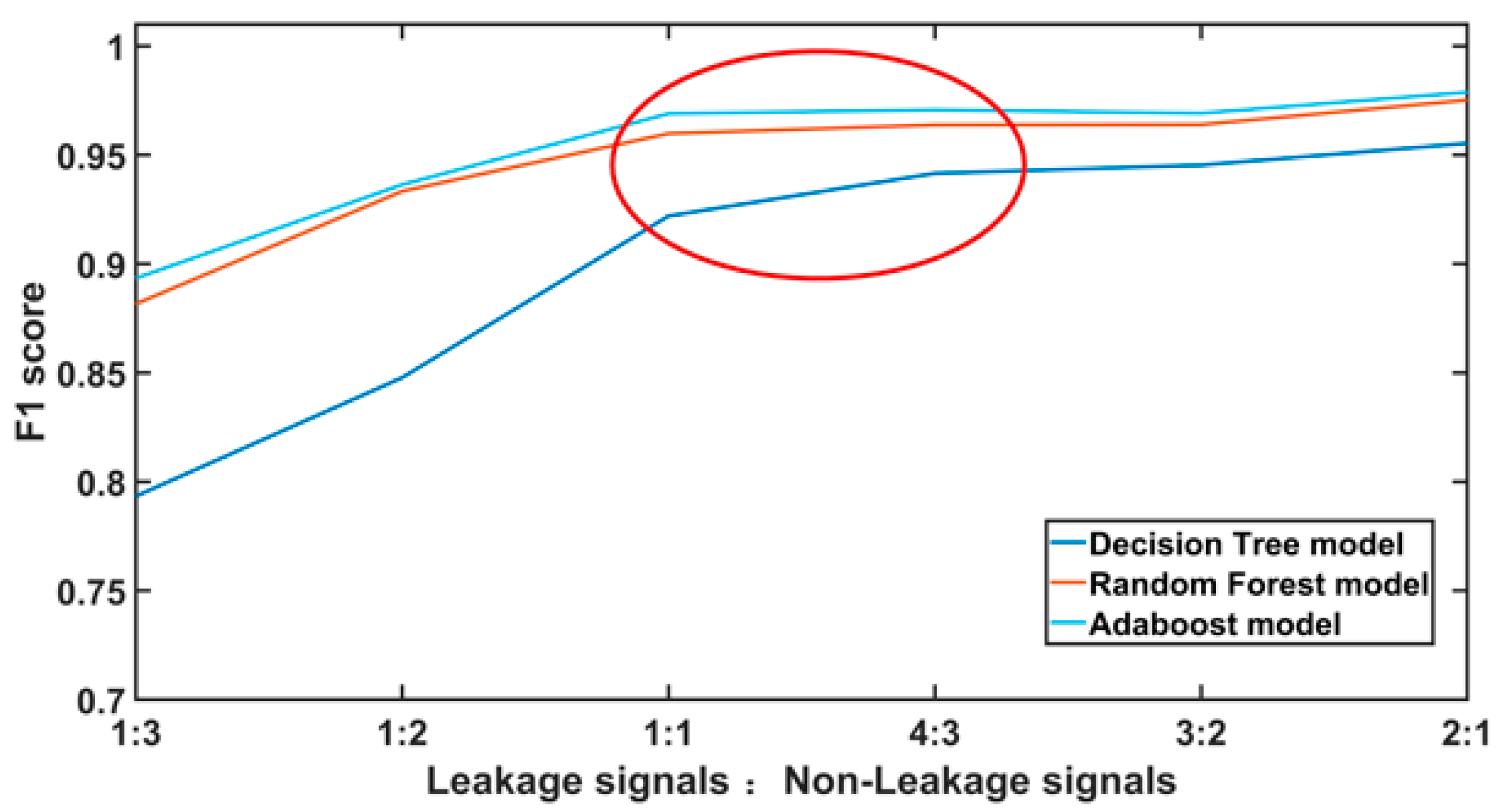

2.3.1. Data Balance

2.3.2. Decision Tree

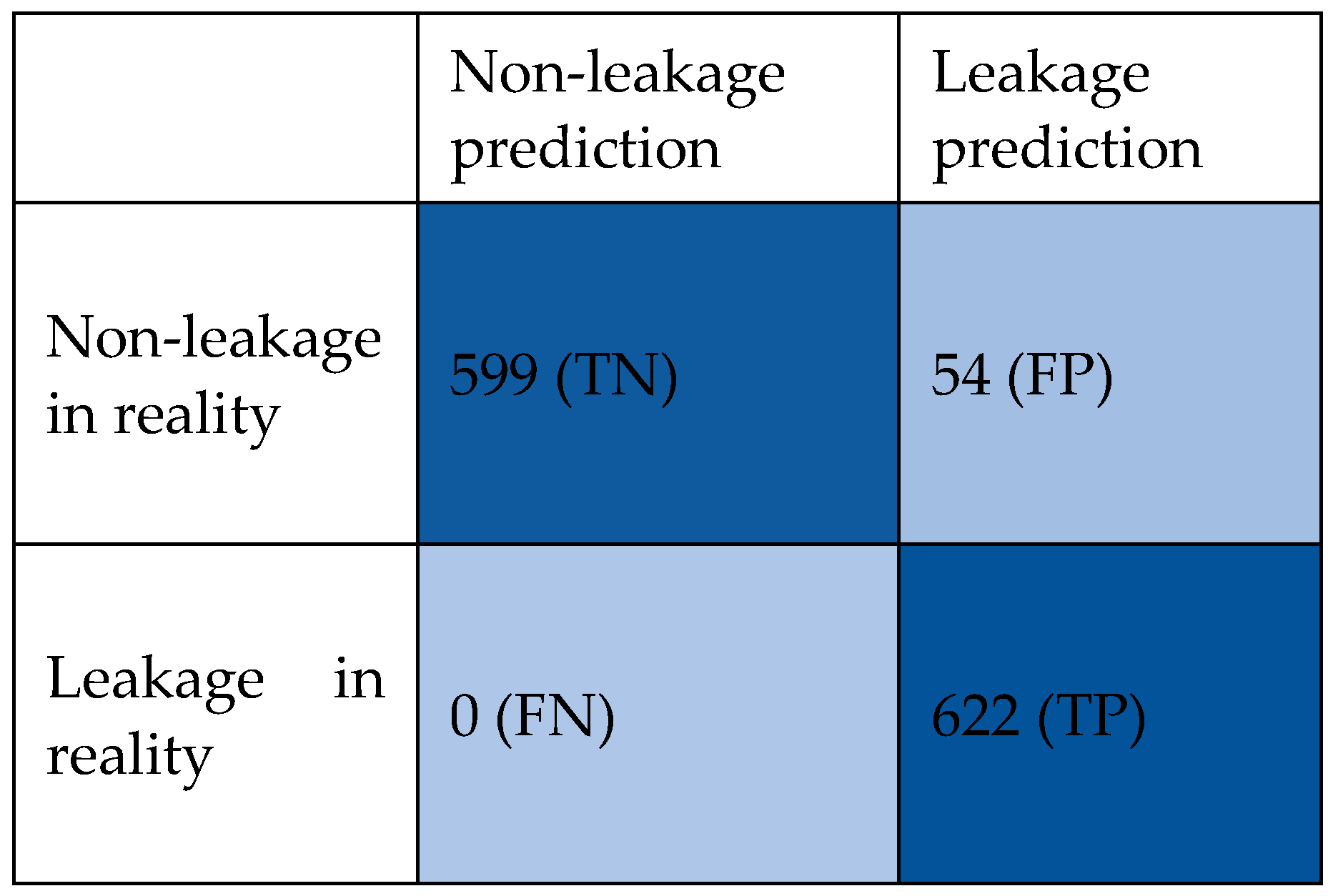

3. Performance of the ML Models

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hongwei, L.; Mou, L.; Song, Y. The application of water quality safety evaluation for urban water supply system. In Proceedings of the World Automation Congress, Puerto Vallarta, Mexico, 24–28 June 2012; pp. 1–3. [Google Scholar]

- Kanakoudis, V.; Tsitsifli, S. Potable water security assessment—A review on monitoring, modelling and optimization techniques, applied to water distribution networks. Desalination Water Treat. 2017, 99, 18–26. [Google Scholar] [CrossRef]

- Zhou, Z.-J.; Hu, C.-H.; Yang, J.-B.; Xu, D.-L.; Zhou, D.-H. Online updating belief rule based system for pipeline leak detection under expert intervention. Expert Syst. Appl. 2009, 36, 7700–7709. [Google Scholar] [CrossRef]

- Mandal, S.K.; Chan, T.S.; Tiwari, M.K. Leak detection of pipeline: An integrated approach of rough set theory and artificial bee colony trained SVM. Expert Syst. Appl. 2012, 39, 3071–3080. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, X.; Li, Y.; Tie, Y.; Zhang, Y.; Gao, J. Water Pipeline Leakage Detection Based on Machine Learning and Wireless Sensor Networks. Sensors 2019, 19, 5086. [Google Scholar] [CrossRef] [PubMed]

- Qu, Z.; Feng, H.; Zeng, Z.; Zhuge, J.; Jin, S. A SVM-based pipeline leakage detection and pre-warning system. Measurement 2010, 43, 513–519. [Google Scholar] [CrossRef]

- Gao, Y.; Brennan, M.; Joseph, P.; Muggleton, J.; Hunaidi, O. On the selection of acoustic/vibration sensors for leak detection in plastic water pipes. J. Sound Vib. 2005, 283, 927–941. [Google Scholar] [CrossRef]

- El-Zahab, S.; Asaad, A.; Abdelkader, E.M.; Zayed, T. Collective thinking approach for improving leak detection systems. Smart Water 2017, 2, 3. [Google Scholar] [CrossRef]

- Yu, L.; Li, S. Acoustic emission (AE) based small leak detection of galvanized steel pipe due to loosening of screw thread connection. Appl. Acoust. 2017, 120, 85–89. [Google Scholar] [CrossRef]

- Fan, H.; Tariq, S.; Zayed, T. Acoustic leak detection approaches for water pipelines. Autom. Constr. 2022, 138, 104226. [Google Scholar] [CrossRef]

- Xiao, R.; Hu, Q.; Li, J. Leak detection of gas pipelines using acoustic signals based on wavelet transform and Support Vector Machine. Measurement 2019, 146, 479–489. [Google Scholar] [CrossRef]

- Quy, T.B.; Kim, J.-M. Leak detection in a gas pipeline using spectral portrait of acoustic emission signals. Measurement 2020, 152, 107403. [Google Scholar] [CrossRef]

- Banjara, N.K.; Sasmal, S.; Voggu, S. Machine learning supported acoustic emission technique for leakage detection in pipelines. Int. J. Press. Vessel. Pip. 2020, 188, 104243. [Google Scholar] [CrossRef]

- Rahimi, M.; Alghassi, A.; Ahsan, M.; Haider, J. Deep Learning Model for Industrial Leakage Detection Using Acoustic Emission Signal. Informatics 2020, 7, 49. [Google Scholar] [CrossRef]

- Song, Y.; Li, S. Gas leak detection in galvanised steel pipe with internal flow noise using convolutional neural network. Process Saf. Environ. Prot. 2021, 146, 736–744. [Google Scholar] [CrossRef]

- Kampelopoulos, D.; Papastavrou, G.N.; Kousiopoulos, G.P.; Karagiorgos, N.; Goudos, S.K.; Nikolaidis, S. Machine Learning Model Comparison for Leak Detection in Noisy Industrial Pipelines. In Proceedings of the 2020 9th International Conference on Modern Circuits and Systems Technologies (Mocast), Bremen, Germany, 7–9 September 2020. [Google Scholar]

- Tariq, S.; Bakhtawar, B.; Zayed, T. Data-driven application of MEMS-based accelerometers for leak detection in water distribution networks. Sci. Total Environ. 2022, 809, 151110. [Google Scholar] [CrossRef] [PubMed]

- Herre, J.; Allamanche, E.; Hellmuth, O. Robust matching of audio signals using spectral flatness features. In Proceedings of the 2001 IEEE Workshop on the Applications of Signal Processing to Audio and Acoustics (Cat. No. 01TH8575), New Platz, NY, USA, 24 October 2001. [Google Scholar]

- Kos, M.; Kai, Z.; Vlaj, D. Acoustic classification and segmentation using modified spectral roll-off and variance-based features. Digit. Signal Process. 2013, 23, 659–674. [Google Scholar] [CrossRef]

- Muda, L.; Begam, M.; Elamvazuthi, I. Voice Recognition Algorithms using Mel Frequency Cepstral Coefficient (MFCC) and Dynamic Time Warping (DTW) Techniques. arXiv 2010, arXiv:1003.4083. [Google Scholar]

- Choi, J.; Gu, B.; Chin, S.; Lee, J.-S. Machine learning predictive model based on national data for fatal accidents of construction workers. Autom. Constr. 2020, 110, 102974. [Google Scholar] [CrossRef]

| Name | Meaning |

|---|---|

| TN | Non-leakage both in reality and in prediction |

| FP | Non-leakage in reality but leakage in prediction |

| FN | Leakage in reality but non-leakage in prediction |

| TP | Leakage both in reality and in prediction |

| Precision | |

| Training accuracy | in training |

| Validation accuracy | in validation |

| Recall rate | |

| F1_score | |

| False Positive Rate |

| Training Accuracy | Validation Accuracy | Precision | Recall Rate | False Positive Rate | F1_Score | |

|---|---|---|---|---|---|---|

| Decision Tree | 99.96% | 90.91% | 90.20% | 94.69% | 9.80% | 0.9239 |

| Random Forest | 99.82% | 95.27% | 92.01% | 100% | 8.27% | 0.9584 |

| Adaboost | 99.96% | 95.80% | 92.80% | 99.52% | 7.35% | 0.9604 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, Y.; Cheng, W. A Tree-Based Machine Learning Method for Pipeline Leakage Detection. Water 2022, 14, 2833. https://doi.org/10.3390/w14182833

Shen Y, Cheng W. A Tree-Based Machine Learning Method for Pipeline Leakage Detection. Water. 2022; 14(18):2833. https://doi.org/10.3390/w14182833

Chicago/Turabian StyleShen, Yongxin, and Weiping Cheng. 2022. "A Tree-Based Machine Learning Method for Pipeline Leakage Detection" Water 14, no. 18: 2833. https://doi.org/10.3390/w14182833