Treatment of Textile Wastewater Using Advanced Oxidation Processes—A Critical Review

Abstract

:1. Introduction

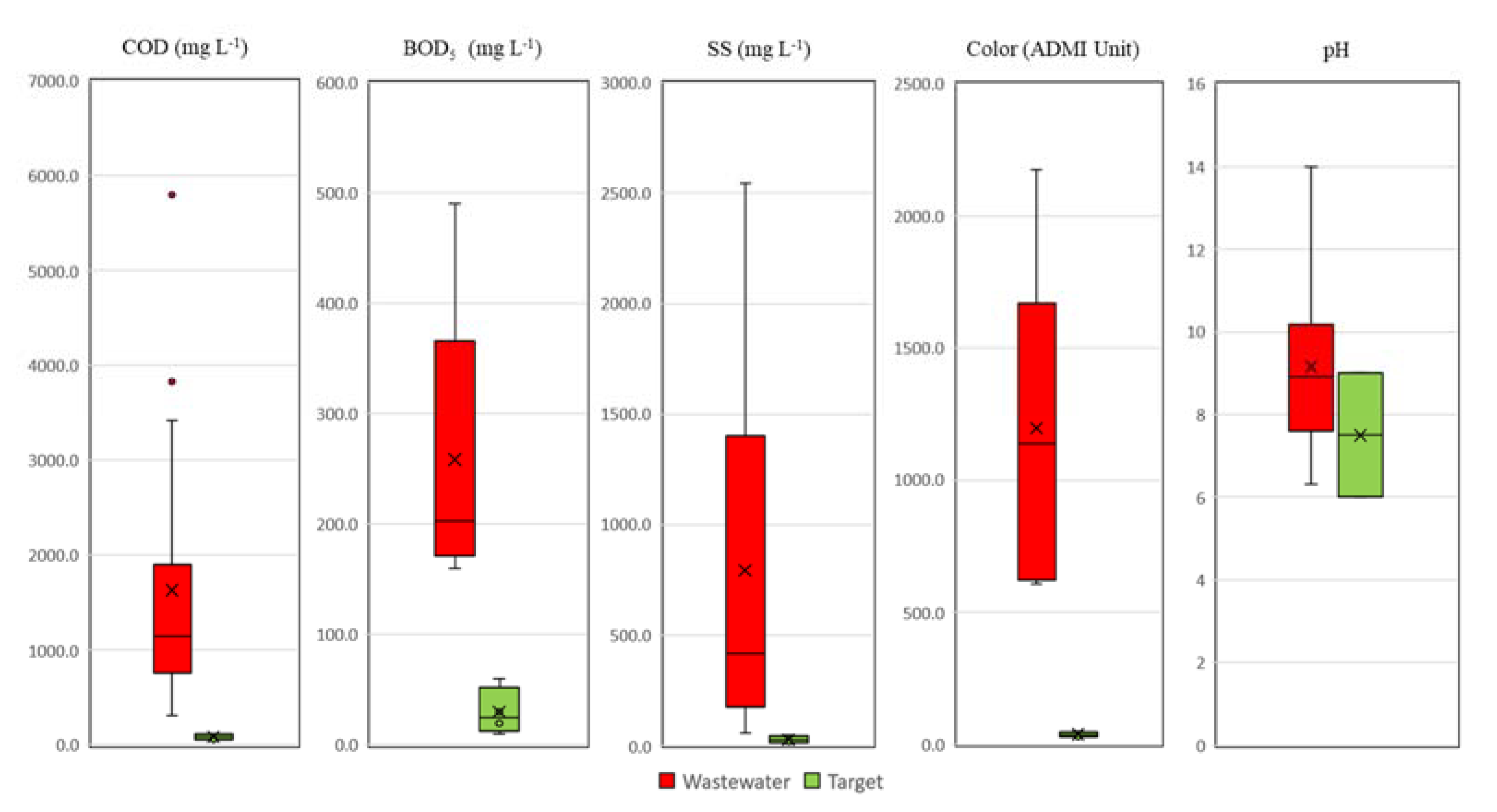

2. Raw Textile Wastewater and Discharge Standard

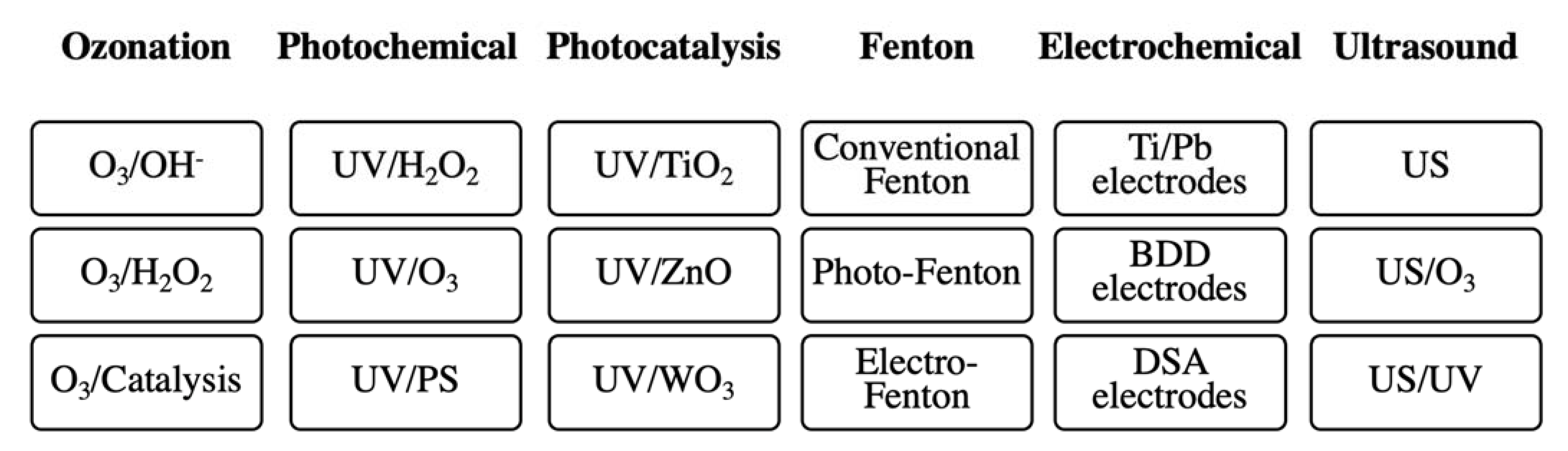

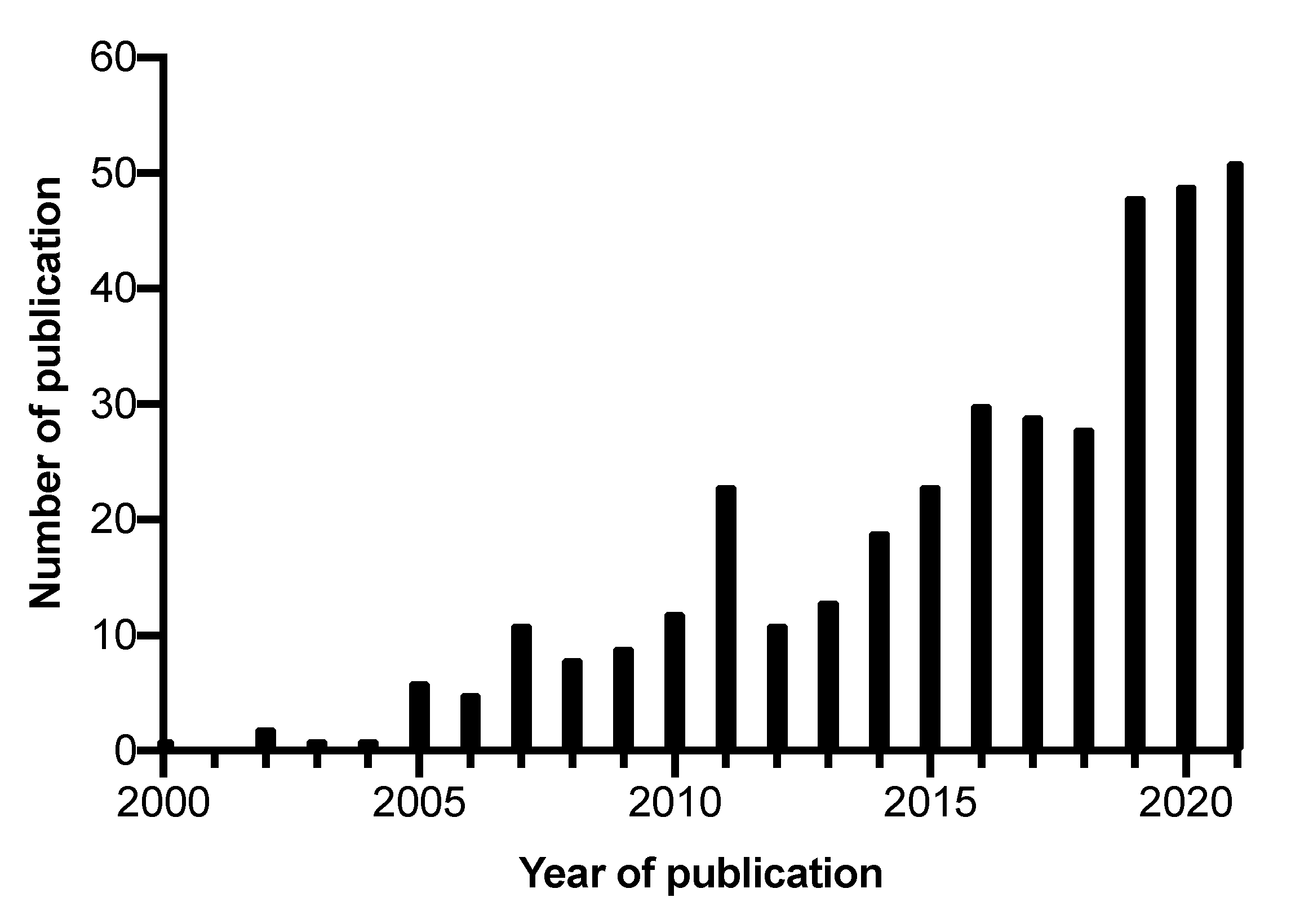

3. Types of AOP and Comparison

3.1. O3-Based AOP

3.1.1. Description

3.1.2. Influencing Parameters

3.2. Photochemical

3.2.1. Description

3.2.2. Influencing Factors

3.3. Photocatalysis

3.3.1. Description

3.3.2. Influencing Factors

3.4. Fenton

3.4.1. Description

3.4.2. Influencing Factors

3.5. Electrochemical

3.5.1. Description

3.5.2. Influencing Factors

3.6. Ultrasound

3.6.1. Description

3.6.2. Influencing Factors

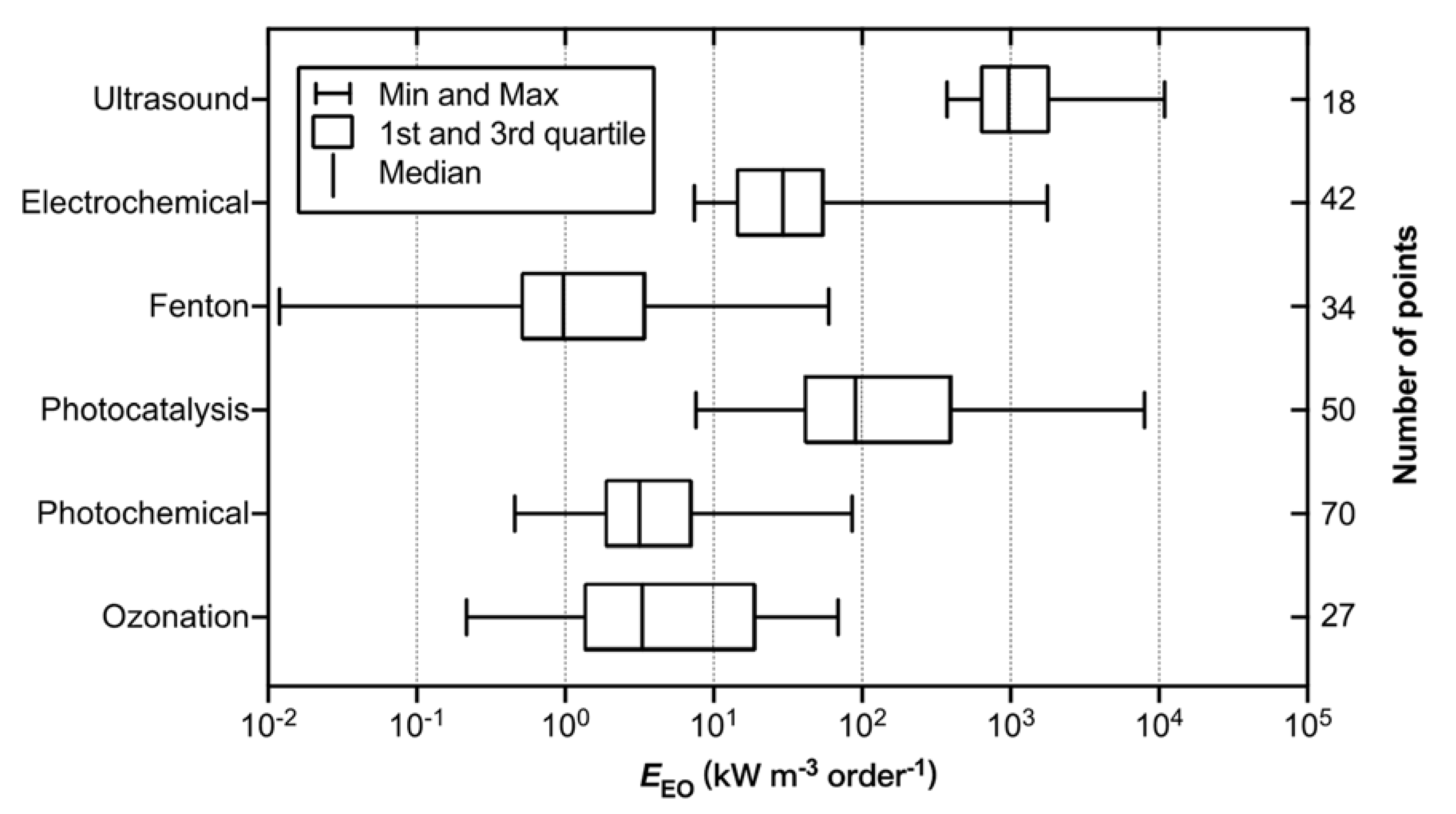

4. Cost Comparison

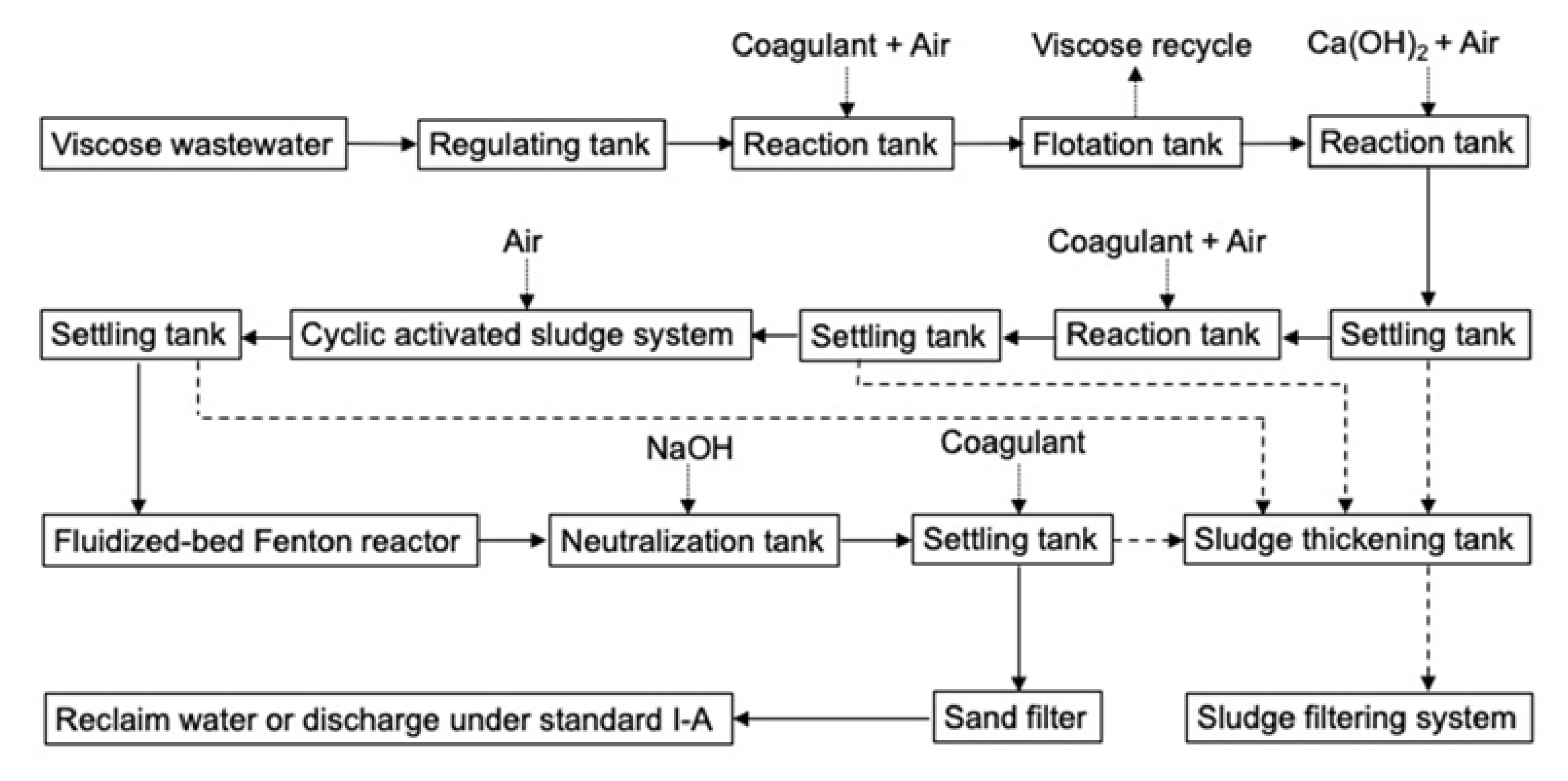

5. Full-Scale Application in a Textile WWTP

6. Conclusions and Future Directions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Al-Mamun, M.R.; Kader, S.; Islam, M.S.; Khan, M.Z.H. Photocatalytic activity improvement and application of UV-TiO2 photocatalysis in textile wastewater treatment: A review. J. Environ. Chem. Eng. 2019, 7, 103248. [Google Scholar] [CrossRef]

- Jegatheesan, V.; Pramanik, B.K.; Chen, J.; Navaratna, D.; Chang, C.Y.; Shu, L. Treatment of textile wastewater with membrane bioreactor: A critical review. Bioresour. Technol. 2016, 204, 202–212. [Google Scholar] [CrossRef]

- Karci, A. Degradation of chlorophenols and alkylphenol ethoxylates, two representative textile chemicals, in water by advanced oxidation processes: The state of the art on transformation products and toxicity. Chemosphere 2014, 99, 1–18. [Google Scholar] [CrossRef]

- Paździor, K.; Bilińska, L.; Ledakowicz, S. A review of the existing and emerging technologies in the combination of AOPs and biological processes in industrial textile wastewater treatment. Chem. Eng. J. 2018, 376, 120597. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L. A technical review of emerging technologies for energy and water efficiency and pollution reduction in the textile industry. J. Clean. Prod. 2015, 95, 30–44. [Google Scholar] [CrossRef] [Green Version]

- Siddique, K.; Rizwan, M.; Shahid, M.J.; Ali, S.; Ahmad, R.; Rizvi, H. Textile wastewater treatment options: A critical review. Enhancing Cleanup Environ. Pollut. 2017, 2, 183–207. [Google Scholar] [CrossRef]

- Holkar, C.R.; Jadhav, A.J.; Pinjari, D.V.; Mahamuni, N.M.; Pandit, A.B. A critical review on textile wastewater treatments: Possible approaches. J. Environ. Manag. 2016, 182, 351–366. [Google Scholar] [CrossRef] [PubMed]

- Kant, R. Textile dyeing industry an environmental hazard. Nat. Sci. 2012, 4, 22–26. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, T.A.; Juang, R.S. Treatment of waters and wastewaters containing sulfur dyes: A review. Chem. Eng. J. 2013, 219, 109–117. [Google Scholar] [CrossRef]

- Asghar, A.; Raman, A.A.A.; Daud, W.M.A.W. Advanced oxidation processes for in-situ production of hydrogen peroxide/hydroxyl radical for textile wastewater treatment: A review. J. Clean. Prod. 2015, 87, 826–838. [Google Scholar] [CrossRef] [Green Version]

- Bae, W.; Won, H.; Hwang, B.; de Toledo, R.A.; Chung, J.; Kwon, K.; Shim, H. Characterization of refractory matters in dyeing wastewater during a full-scale Fenton process following pure-oxygen activated sludge treatment. J. Hazard. Mater. 2015, 287, 421–428. [Google Scholar] [CrossRef]

- Dey, S.; Islam, A. A review on textile wastewater characterization in Bangladesh. Resour. Environ. 2015, 5, 15–44. [Google Scholar] [CrossRef]

- Verma, A.K.; Dash, R.R.; Bhunia, P. A review on chemical coagulation/flocculation technologies for removal of colour from textile wastewaters. J. Environ. Manag. 2012, 93, 154–168. [Google Scholar] [CrossRef] [PubMed]

- Katheresan, V.; Kansedo, J.; Lau, S.Y. Efficiency of various recent wastewater dye removal methods: A review. J. Environ. Chem. Eng. 2018, 6, 4676–4697. [Google Scholar] [CrossRef]

- Dasgupta, J.; Sikder, J.; Chakraborty, S.; Curcio, S.; Drioli, E. Remediation of textile effluents by membrane based treatment. J. Environ. Manag. 2015, 147, 55–72. [Google Scholar] [CrossRef] [PubMed]

- Mirza, N.R.; Huang, R.; Du, E.; Peng, M.; Pan, Z.; Ding, H.; Shan, G.; Ling, L.; Xie, Z. A review of the textile wastewater treatment technologies with special focus on advanced oxidation processes (AOPs), membrane separation and integrated aop-membrane processes. Desalin. Water Treat. 2020, 206, 83–107. [Google Scholar] [CrossRef]

- Rafatullah, M.; Sulaiman, O.; Hashim, R.; Ahmad, A. Adsorption of methylene blue on low-cost adsorbents: A review. J. Hazard. Mater. 2010, 177, 70–80. [Google Scholar] [CrossRef] [PubMed]

- Golob, V.; Vinder, A.; Simonič, M. Efficiency of the coagulation/flocculation method for the treatment of dyebath effluents. Dye Pigment. 2005, 67, 93–97. [Google Scholar] [CrossRef]

- Bello, M.M.; Abdul Raman, A.A. Trend and current practices of palm oil mill effluent polishing: Application of advanced oxidation processes and their future perspectives. J. Environ. Manag. 2017, 198, 170–182. [Google Scholar] [CrossRef]

- Hayat, H.; Mahmood, Q.; Pervez, A.; Bhatti, Z.A.; Baig, S.A. Comparative decolorization of dyes in textile wastewater using biological and chemical treatment. Sep. Purif. Technol. 2015, 154, 149–153. [Google Scholar] [CrossRef]

- Wang, Y.; Ho, S.H.; Cheng, C.L.; Guo, W.Q.; Nagarajan, D.; Ren, N.Q.; Lee, D.J.; Chang, J.S. Perspectives on the feasibility of using microalgae for industrial wastewater treatment. Bioresour. Technol. 2016, 222, 485–497. [Google Scholar] [CrossRef]

- Glaze, W.H.; Kang, J.W.; Chapin, D.H. The chemistry of water treatment processes involving ozone, hydrogen peroxide and ultraviolet radiation. Ozone Sci. Eng. 1987, 9, 335–352. [Google Scholar] [CrossRef]

- Khan, A.H.; Khan, N.A.; Ahmed, S.; Dhingra, A.; Singh, C.P.; Khan, S.U.; Mohammadi, A.A.; Changani, F.; Yousefi, M.; Alam, S.; et al. Application of advanced oxidation processes followed by different treatment technologies for hospital wastewater treatment. J. Clean. Prod. 2020, 269, 122411. [Google Scholar] [CrossRef]

- Gautam, P.; Kumar, S.; Lokhandwala, S. Advanced oxidation processes for treatment of leachate from hazardous waste landfill: A critical review. J. Clean. Prod. 2019, 237, 117639. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Xiao, Y.; Chang, V.W.C.; Lim, T.T. Kinetic and mechanistic investigation of azathioprine degradation in water by UV, UV/H2O2 and UV/persulfate. Chem. Eng. J. 2016, 302, 526–534. [Google Scholar] [CrossRef]

- Baban, A.; Yediler, A.; Lienert, D.; Kemerdere, N.; Kettrup, A. Ozonation of high strength segregated effluents from a woollen textile dyeing and finishing plant. Dye Pigment. 2003, 58, 93–98. [Google Scholar] [CrossRef]

- Turhan, K.; Ozturkcan, S.A. Decolorization and degradation of reactive dye in aqueous solution by ozonation in a semi-batch bubble column reactor. Water Air Soil Pollut. 2013, 224, 1353. [Google Scholar] [CrossRef]

- Aleboyeh, A.; Olya, M.E.; Aleboyeh, H. Electrical energy determination for an azo dye decolorization and mineralization by UV/H2O2 advanced oxidation process. Chem. Eng. J. 2008, 137, 518–524. [Google Scholar] [CrossRef]

- Ince, N.H.; Gönenç, D.T. Treatability of a textile azo dye by UV/H2O2. Environ. Technol. 1997, 18, 179–185. [Google Scholar] [CrossRef]

- Patel, S.G.; Yadav, N.R.; Patel, S.K. Evaluation of degradation characteristics of reactive dyes by UV/fenton, UV/fenton/activated charcoal, and UV/Fenton/TiO2 processes: A comparative study. Sep. Sci. Technol. 2013, 48, 1788–1800. [Google Scholar] [CrossRef]

- Chatzisymeon, E.; Xekoukoulotakis, N.P.; Coz, A.; Kalogerakis, N.; Mantzavinos, D. Electrochemical treatment of textile dyes and dyehouse effluents. J. Hazard. Mater. 2006, 137, 998–1007. [Google Scholar] [CrossRef]

- Malpass, G.R.P.; Miwa, D.W.; Machado, S.A.S.; Motheo, A.J. Decolourisation of real textile waste using electrochemical techniques: Effect of electrode composition. J. Hazard. Mater. 2008, 156, 170–177. [Google Scholar] [CrossRef] [PubMed]

- Behnajady, M.A.; Modirshahla, N.; Shokri, M.; Vahid, B. Effect of operational parameters on degradation of Malachite Green by ultrasonic irradiation. Ultrason. Sonochem. 2008, 15, 1009–1014. [Google Scholar] [CrossRef]

- Dede, O.T.; Aksu, Z.; Rehorek, A. Sonochemical Degradation of C.I. Reactive Orange 107. Environ. Eng. Sci. 2019, 36, 158–171. [Google Scholar] [CrossRef]

- Miklos, D.B.; Remy, C.; Jekel, M.; Linden, K.G.; Drewes, J.E.; Hübner, U. Evaluation of advanced oxidation processes for water and wastewater treatment—A critical review. Water Res. 2018, 139, 118–131. [Google Scholar] [CrossRef]

- Mahamuni, N.N.; Adewuyi, Y.G. Advanced oxidation processes (AOPs) involving ultrasound for waste water treatment: A review with emphasis on cost estimation. Ultrason. Sonochem. 2010, 17, 990–1003. [Google Scholar] [CrossRef]

- Aquino, J.M.; Pereira, G.F.; Rocha-Filho, R.C.; Bocchi, N.; Biaggio, S.R. Electrochemical degradation of a real textile effluent using boron-doped diamond or β-PbO2 as anode. J. Hazard. Mater. 2011, 192, 1275–1282. [Google Scholar] [CrossRef]

- Aquino, J.M.; Rocha-Filho, R.C.; Ruotolo, L.A.M.; Bocchi, N.; Biaggio, S.R. Electrochemical degradation of a real textile wastewater using β-PbO2 and DSA® anodes. Chem. Eng. J. 2014, 251, 138–145. [Google Scholar] [CrossRef]

- Arslan, I.; Balcioglu, I.A. Advanced oxidation of raw and biotreated textile industry wastewater with O3, H2O2/UV-C and their sequential application. J. Chem. Technol. Biotechnol. 2001, 76, 53–60. [Google Scholar] [CrossRef]

- Basha, C.A.; Sendhil, J.; Selvakumar, K.V.; Muniswaran, P.K.A.; Lee, C.W. Electrochemical degradation of textile dyeing industry effluent in batch and flow reactor systems. Desalination 2012, 285, 188–197. [Google Scholar] [CrossRef]

- Bayramoglu, M.; Kobya, M.; Can, O.T.; Sozbir, M. Operating cost analysis of electroagulation of textile dye wastewater. Sep. Purif. Technol. 2004, 37, 117–125. [Google Scholar] [CrossRef]

- Buthiyappan, A.; Abdul Raman, A.A. Energy intensified integrated advanced oxidation technology for the treatment of recalcitrant industrial wastewater. J. Clean. Prod. 2019, 206, 1025–1040. [Google Scholar] [CrossRef]

- Dantas, T.L.P.; Mendonça, V.P.; José, H.J.; Rodrigues, A.E.; Moreira, R.F.P.M. Treatment of textile wastewater by heterogeneous Fenton process using a new composite Fe2O3/carbon. Chem. Eng. J. 2006, 118, 77–82. [Google Scholar] [CrossRef]

- Debik, E.; Kaykioglu, G.; Coban, A.; Koyuncu, I. Reuse of anaerobically and aerobically pre-treated textile wastewater by UF and NF membranes. Desalination 2010, 256, 174–180. [Google Scholar] [CrossRef]

- Haroun, M.; Idris, A. Treatment of textile wastewater with an anaerobic fluidized bed reactor. Desalination 2009, 237, 357–366. [Google Scholar] [CrossRef]

- Kobya, M.; Can, O.T.; Bayramoglu, M. Treatment of textile wastewaters by electrocoagulation using iron and aluminum electrodes. J. Hazard. Mater. 2003, 100, 163–178. [Google Scholar] [CrossRef]

- Ling, Y.; Hu, J.; Qian, Z.; Zhu, L.; Chen, X. Continuous treatment of biologically treated textile effluent using a multi-cell electrochemical reactor. Chem. Eng. J. 2016, 286, 571–577. [Google Scholar] [CrossRef]

- Malik, S.N.; Ghosh, P.C.; Vaidya, A.N.; Mudliar, S.N. Catalytic ozone pretreatment of complex textile effluent using Fe2+ and zero valent iron nanoparticles. J. Hazard. Mater. 2018, 357, 363–375. [Google Scholar] [CrossRef]

- Sandhya, S.; Sarayu, K.; Swaminathan, K. Determination of kinetic constants of hybrid textile wastewater treatment system. Bioresour. Technol. 2008, 99, 5793–5797. [Google Scholar] [CrossRef] [PubMed]

- Schrank, S.G.; dos Santos, J.N.R.; Souza, D.S.; Souza, E.E.S. Decolourisation effects of Vat Green 01 textile dye and textile wastewater using H2O2/UV process. J. Photochem. Photobiol. A Chem. 2007, 186, 125–129. [Google Scholar] [CrossRef]

- Selcuk, H. Decolorization and detoxification of textile wastewater by ozonation and coagulation processes. Dye Pigment. 2005, 64, 217–222. [Google Scholar] [CrossRef]

- Su, C.C.; Pukdee-Asa, M.; Ratanatamskul, C.; Lu, M.C. Effect of operating parameters on the decolorization and oxidation of textile wastewater by the fluidized-bed Fenton process. Sep. Purif. Technol. 2011, 83, 100–105. [Google Scholar] [CrossRef]

- Wang, C.T.; Chou, W.L.; Kuo, Y.M.; Chang, F.L. Paired removal of color and COD from textile dyeing wastewater by simultaneous anodic and indirect cathodic oxidation. J. Hazard. Mater. 2009, 169, 16–22. [Google Scholar] [CrossRef] [PubMed]

- Yen, H.Y. Energy consumption of treating textile wastewater for in-factory reuse by H2O2/UV process. Desalin. Water Treat. 2016, 57, 10537–10545. [Google Scholar] [CrossRef]

- PRC National Standard. Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant; GB 18918-2002; Ministry of Ecology and Environment, the People’s Republic China: Beijing, China, 2013.

- PRC National Standard. China Discharge Standards of Water Pollutants for Dyeing and Finishing of Textile Industry; GB 4287-2012; Ministry of Ecology and Environment, the People’s Republic China: Beijing, China, 2013; pp. 8–16.

- von Gunten, U. Ozonation of drinking water: Part I. Oxidation kinetics and product formation. Water Res. 2003, 37, 1443–1467. [Google Scholar] [CrossRef]

- Agustina, T.E.; Ang, H.M.; Vareek, V.K. A review of synergistic effect of photocatalysis and ozonation on wastewater treatment. J. Photochem. Photobiol. C Photochem. Rev. 2005, 6, 264–273. [Google Scholar] [CrossRef]

- Nawrocki, J.; Kasprzyk-Hordern, B. The efficiency and mechanisms of catalytic ozonation. Appl. Catal. B Environ. 2010, 99, 27–42. [Google Scholar] [CrossRef]

- Staehelln, J.; Hoigne, J. Decomposition of ozone in water in the presence of organic solutes acting as promoters and inhibitors of radical chain reactions. Environ. Sci. Technol. 1985, 19, 1206–1213. [Google Scholar] [CrossRef]

- Arslan, I.; Balcioglu, I.A.; Tuhkanen, T. Advanced oxidation of synthetic dyehouse effluent by O3, H2O2/O3 and H2O2/UV processes. Environ. Technol. 1999, 20, 921–931. [Google Scholar] [CrossRef]

- Karami, M.A.; Amin, M.M.; Nourmoradi, H.; Sadani, M.; Teimouri, F.; Bina, B. Degradation of reactive red 198 from aqueous solutions by advanced oxidation process. Int. J. Environ. Health Eng. 2016, 5, 26. [Google Scholar]

- Khadhraoui, M.; Trabelsi, H.; Ksibi, M.; Bouguerra, S.; Elleuch, B. Discoloration and detoxicification of a Congo red dye solution by means of ozone treatment for a possible water reuse. J. Hazard. Mater. 2009, 161, 974–981. [Google Scholar] [CrossRef]

- Wu, C.H.; Ng, H.Y. Degradation of C.I. Reactive Red 2 (RR2) using ozone-based systems: Comparisons of decolorization efficiency and power consumption. J. Hazard. Mater. 2008, 152, 120–127. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Dong, W.; Yang, W. Decolorization efficiency and kinetics of typical reactive azo dye RR2 in the homogeneous Fe(II) catalyzed ozonation process. Chem. Eng. J. 2013, 233, 14–23. [Google Scholar] [CrossRef]

- Wu, C.H.; Kuo, C.Y.; Chang, C.L. Decolorization of C.I. Reactive Red 2 by catalytic ozonation processes. J. Hazard. Mater. 2008, 153, 1052–1058. [Google Scholar] [CrossRef]

- Erol, F.; Özbelge, T.A. Catalytic ozonation with non-polar bonded alumina phases for treatment of aqueous dye solutions in a semi-batch reactor. Chem. Eng. J. 2008, 139, 272–283. [Google Scholar] [CrossRef]

- Wu, C.H.; Lai, C.H.; Chung, W.Y. Electrical energy per order and photodegradation efficiency of advanced oxidation processes. Appl. Mech. Mater. 2013, 291–294, 764–767. [Google Scholar] [CrossRef]

- Quan, X.; Luo, D.; Wu, J.; Li, R.; Cheng, W.; Ge, S. Ozonation of acid red 18 wastewater using O3/Ca(OH)2 system in a micro bubble gas-liquid reactor. J. Environ. Chem. Eng. 2017, 5, 283–291. [Google Scholar] [CrossRef] [Green Version]

- Gül, Ş.; Özcan, Ö.; Erbatur, O. Ozonation of C.I. Reactive Red 194 and C.I. Reactive Yellow 145 in aqueous solution in the presence of granular activated carbon. Dye Pigment. 2007, 75, 426–431. [Google Scholar] [CrossRef]

- Turhan, K.; Durukan, I.; Ozturkcan, S.A.; Turgut, Z. Decolorization of textile basic dye in aqueous solution by ozone. Dye Pigment. 2012, 92, 897–901. [Google Scholar] [CrossRef]

- Karrer, N.J.; Ryhiner, G.; Heinzle, E. Applicability test for combined biological-chemical treatment of wastewaters containing biorefractory compounds. Water Res. 1997, 31, 1013–1020. [Google Scholar] [CrossRef]

- Churchley, J.H.; Lambert, S.D.; Graham, N.J.D. Ozone for dye waste color removal: Four years operation at leek STW. Ozone Sci. Eng. 1998, 20, 111–120. [Google Scholar] [CrossRef]

- Tabrizi, M.T.F.; Glasser, D.; Hildebrandt, D. Wastewater treatment of reactive dyestuffs by ozonation in a semi-batch reactor. Chem. Eng. J. 2011, 166, 662–668. [Google Scholar] [CrossRef]

- Konsowa, A.H.; Ossman, M.E.; Chen, Y.; Crittenden, J.C. Decolorization of industrial wastewater by ozonation followed by adsorption on activated carbon. J. Hazard. Mater. 2010, 176, 181–185. [Google Scholar] [CrossRef] [PubMed]

- Miralles-Cuevas, S.; Oller, I.; Agüera, A.; Llorca, M.; Sánchez Pérez, J.A.; Malato, S. Combination of nanofiltration and ozonation for the remediation of real municipal wastewater effluents: Acute and chronic toxicity assessment. J. Hazard. Mater. 2017, 323, 442–451. [Google Scholar] [CrossRef]

- Wang, C.; Yediler, A.; Lienert, D.; Wang, Z.; Kettrup, A. Ozonation of an azo dye C.I. Remazol Black 5 and toxicological assessment of its oxidation products. Chemosphere 2003, 52, 1225–1232. [Google Scholar] [CrossRef]

- Wang, J.; Zhuan, R. Degradation of antibiotics by advanced oxidation processes: An overview. Sci. Total Environ. 2020, 701, 135023. [Google Scholar] [CrossRef] [PubMed]

- Muthukumar, M.; Sargunamani, D.; Selvakumar, N.; Venkata Rao, J. Optimisation of ozone treatment for colour and COD removal of acid dye effluent using central composite design experiment. Dye Pigment. 2004, 63, 127–134. [Google Scholar] [CrossRef]

- Tehrani-Bagha, A.R.; Mahmoodi, N.M.; Menger, F.M. Degradation of a persistent organic dye from colored textile wastewater by ozonation. Desalination 2010, 260, 34–38. [Google Scholar] [CrossRef]

- Hai, F.I.; Yamamoto, K.; Fukushi, K. Hybrid treatment systems for dye wastewater. Crit. Rev. Environ. Sci. Technol. 2007, 37, 315–377. [Google Scholar] [CrossRef]

- Bolton, J.R.; Linden, K.G. Standardization of methods for fluence (UV Dose) determination in bench-scale UV experiments. J. Environ. Eng. 2003, 129, 209–215. [Google Scholar] [CrossRef]

- Hoffmann, N. Photochemically Induced Proton Transfers Reactions; Elsevier: Amsterdam, The Netherlands, 2014; ISBN 9780124095472. [Google Scholar]

- Li, M.; Sun, M.; Dong, H.; Zhang, J.; Su, Y.; Qiang, Z. Enhancement of micropollutant degradation in UV/H2O2 process via iron-containing coagulants. Water Res. 2020, 172, 115497. [Google Scholar] [CrossRef]

- Oturan, M.A.; Aaron, J.J. Advanced oxidation processes in water/wastewater treatment: Principles and applications. A review. Crit. Rev. Environ. Sci. Technol. 2014, 44, 2577–2641. [Google Scholar] [CrossRef]

- Shu, H.Y.; Chang, M.C. Pre-ozonation coupled with UV/H2O2 process for the decolorization and mineralization of cotton dyeing effluent and synthesized C.I. Direct Black 22 wastewater. J. Hazard. Mater. 2005, 121, 127–133. [Google Scholar] [CrossRef]

- Oh, W.D.; Dong, Z.; Lim, T.T. Generation of sulfate radical through heterogeneous catalysis for organic contaminants removal: Current development, challenges and prospects. Appl. Catal. B Environ. 2016, 194, 169–201. [Google Scholar] [CrossRef]

- Yang, Q.; Ma, Y.; Chen, F.; Yao, F. Recent advances in photo-activated sulfate radical-advanced oxidation. Chem. Eng. J. 2019, 378, 122–149. [Google Scholar] [CrossRef]

- Rehman, F.; Sayed, M.; Khan, J.A.; Shah, N.S.; Khan, H.M.; Dionysiou, D.D. Oxidative removal of brilliant green by UV/S2O82−, UV/HSO5− and UV/H2O2 processes in aqueous media: A comparative study. J. Hazard. Mater. 2018, 357, 506–514. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S. Activation of persulfate (PS) and peroxymonosulfate (PMS) and application for the degradation of emerging contaminants. Chem. Eng. J. 2018, 334, 1502–1517. [Google Scholar] [CrossRef]

- Litter, M.I. Introduction to Photochemical Advanced Oxidation Processes for Water Treatment; Springer: Berlin/Heidelberg, Germany, 2005; Volume 2. [Google Scholar]

- Arslan, I.; Akmehmet, I.; Bahnemann, D.W. Advanced oxidation of a reactive dyebath effluent: Comparison of O3, H2O2/UV-C and TiO2/UV-A processes. Water Res. 2002, 36, 1143–1154. [Google Scholar]

- Zhang, Y.; Xiao, Y.; Zhong, Y.; Lim, T.T. Comparison of amoxicillin photodegradation in the UV/H2O2 and UV/persulfate systems: Reaction kinetics, degradation pathways, and antibacterial activity. Chem. Eng. J. 2019, 372, 420–428. [Google Scholar] [CrossRef]

- Babu, D.S.; Srivastava, V.; Nidheesh, P.V.; Kumar, M.S. Detoxification of water and wastewater by advanced oxidation processes. Sci. Total Environ. 2019, 696, 133961. [Google Scholar] [CrossRef]

- Rajeshwar, K.; Osugi, M.E.; Chanmanee, W.; Chenthamarakshan, C.R.; Zanoni, M.V.B.; Kajitvichyanukul, P.; Krishnan-Ayer, R. Heterogeneous photocatalytic treatment of organic dyes in air and aqueous media. J. Photochem. Photobiol. C Photochem. Rev. 2008, 9, 171–192. [Google Scholar] [CrossRef]

- Aguedach, A.; Brosillon, S.; Morvan, J.; Lhadi, E.K. Influence of ionic strength in the adsorption and during photocatalysis of reactive black 5 azo dye on TiO2 coated on non woven paper with SiO2 as a binder. J. Hazard. Mater. 2008, 150, 250–256. [Google Scholar] [CrossRef]

- Song, S.; Xu, L.; He, Z.; Ying, H.; Chen, J.; Xiao, X.; Yan, B. Photocatalytic degradation of C.I. Direct Red 23 in aqueous solutions under UV irradiation using SrTiO3/CeO2 composite as the catalyst. J. Hazard. Mater. 2008, 152, 1301–1308. [Google Scholar] [CrossRef] [PubMed]

- Arcanjo, G.S.; Mounteer, A.H.; Bellato, C.R.; da Silva, L.M.M.; Brant Dias, S.H.; da Silva, P.R. Heterogeneous photocatalysis using TiO2 modified with hydrotalcite and iron oxide under UV–visible irradiation for color and toxicity reduction in secondary textile mill effluent. J. Environ. Manag. 2018, 211, 154–163. [Google Scholar] [CrossRef] [PubMed]

- Natarajan, K.; Natarajan, T.S.; Bajaj, H.C.; Tayade, R.J. Photocatalytic reactor based on UV-LED/TiO2 coated quartz tube for degradation of dyes. Chem. Eng. J. 2011, 178, 40–49. [Google Scholar] [CrossRef]

- Fenton, H.J.H. Oxidation of tartaric acid in presence of iron. J. Chem. Soc. Trans. 1894, 65, 899–910. [Google Scholar] [CrossRef] [Green Version]

- Venny; Gan, S.; Ng, H.K. Current status and prospects of Fenton oxidation for the decontamination of persistent organic pollutants (POPs) in soils. Chem. Eng. J. 2012, 213, 295–317. [Google Scholar] [CrossRef]

- Zepp, R.G.; Faust, B.C.; Jürg, H. Hydroxyl radical formation in aqueous reactions (pH 3–8) of Iron(II) with hydrogen peroxide: The photo-fenton reaction. Environ. Sci. Technol. 1992, 26, 313–319. [Google Scholar] [CrossRef]

- Babuponnusami, A.; Muthukumar, K. A review on Fenton and improvements to the Fenton process for wastewater treatment. J. Environ. Chem. Eng. 2014, 2, 557–572. [Google Scholar] [CrossRef]

- Yasar, A.; Yousaf, S. Solar assisted photo fenton for cost effective degradation of textile effluents in comparison to AOPs. Glob. Nest J. 2012, 14, 477–486. [Google Scholar] [CrossRef]

- Panizza, M.; Cerisola, G. Electro-Fenton degradation of synthetic dyes. Water Res. 2009, 43, 339–344. [Google Scholar] [CrossRef]

- Badawy, M.I.; Ali, M.E.M. Fenton’s peroxidation and coagulation processes for the treatment of combined industrial and domestic wastewater. J. Hazard. Mater. 2006, 136, 961–966. [Google Scholar] [CrossRef] [PubMed]

- Mirzaei, A.; Chen, Z.; Haghighat, F.; Yerushalmi, L. Removal of pharmaceuticals from water by homo/hetrogenous Fenton-type processes—A review. Chemosphere 2017, 174, 665–688. [Google Scholar] [CrossRef]

- Zhang, M.; Dong, H.; Zhao, L.; Wang, D.; Meng, D. A review on Fenton process for organic wastewater treatment based on optimization perspective. Sci. Total Environ. 2019, 670, 110–121. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, M.C.M.; Starling, M.C.V.M.; Leão, M.M.D.; de Amorim, C.C. Textile wastewater reuse after additional treatment by Fenton’s reagent. Environ. Sci. Pollut. Res. 2017, 24, 6165–6175. [Google Scholar] [CrossRef]

- Yu, R.F.; Lin, C.H.; Chen, H.W.; Cheng, W.P.; Kao, M.C. Possible control approaches of the Electro-Fenton process for textile wastewater treatment using on-line monitoring of DO and ORP. Chem. Eng. J. 2013, 218, 341–349. [Google Scholar] [CrossRef]

- Moreira, F.C.; Boaventura, R.A.R.; Brillas, E.; Vilar, V.J.P. Electrochemical advanced oxidation processes: A review on their application to synthetic and real wastewaters. Appl. Catal. B Environ. 2017, 202, 217–261. [Google Scholar] [CrossRef]

- Garcia-Segura, S.; Ocon, J.D.; Chong, M.N. Electrochemical oxidation remediation of real wastewater effluents—A review. Process Saf. Environ. Prot. 2018, 113, 48–67. [Google Scholar] [CrossRef]

- Kirk, D.W.; Sharifian, H.; Foulkes, F.R. Anodic oxidation of aniline for waste water treatment. J. Appl. Electrochem. 1985, 15, 285–292. [Google Scholar] [CrossRef]

- Nidheesh, P.V.; Zhou, M.; Oturan, M.A. An overview on the removal of synthetic dyes from water by electrochemical advanced oxidation processes. Chemosphere 2018, 197, 210–227. [Google Scholar] [CrossRef]

- Muddemann, T.; Haupt, D.; Sievers, M.; Kunz, U. Electrochemical reactors for wastewater treatment. ChemBioEng Rev. 2019, 6, 142–156. [Google Scholar] [CrossRef]

- Baddouh, A.; Bessegato, G.G.; Rguiti, M.M.; El Ibrahimi, B.; Bazzi, L.; Hilali, M.; Zanoni, M.V.B. Electrochemical decolorization of Rhodamine B dye: Influence of anode material, chloride concentration and current density. J. Environ. Chem. Eng. 2018, 6, 2041–2047. [Google Scholar] [CrossRef] [Green Version]

- Vlyssides, A.G.; Papaioannou, D.; Loizidoy, M.; Karlis, P.K.; Zorpas, A.A. Testing an electrochemical method for treatment of textile dye wastewater. Waste Manag. 2000, 20, 569–574. [Google Scholar] [CrossRef]

- Sala, M.; Gutiérrez-Bouzán, M.C. Electrochemical treatment of industrial wastewater and effluent reuse at laboratory and semi-industrial scale. J. Clean. Prod. 2014, 65, 458–464. [Google Scholar] [CrossRef]

- Tavares, M.G.; da Silva, L.V.A.; Sales Solano, A.M.; Tonholo, J.; Martínez-Huitle, C.A.; Zanta, C.L.P.S. Electrochemical oxidation of Methyl Red using Ti/Ru0.3Ti0.7O2 and Ti/Pt anodes. Chem. Eng. J. 2012, 204–205, 141–150. [Google Scholar] [CrossRef]

- Orts, F.; del Río, A.I.; Molina, J.; Bonastre, J.; Cases, F. Electrochemical treatment of real textile wastewater: Trichromy procion HEXL®. J. Electroanal. Chem. 2018, 808, 387–394. [Google Scholar] [CrossRef]

- Vahid, B.; Khataee, A. Photoassisted electrochemical recirculation system with boron-doped diamond anode and carbon nanotubes containing cathode for degradation of a model azo dye. Electrochim. Acta 2013, 88, 614–620. [Google Scholar] [CrossRef]

- Chaplin, B.P. Critical review of electrochemical advanced oxidation processes for water treatment applications. Environ. Sci. Process. Impacts 2014, 16, 1182–1203. [Google Scholar] [CrossRef]

- Abdessamad, N.E.H.; Akrout, H.; Hamdaoui, G.; Elghniji, K.; Ksibi, M.; Bousselmi, L. Evaluation of the efficiency of monopolar and bipolar BDD electrodes for electrochemical oxidation of anthraquinone textile synthetic effluent for reuse. Chemosphere 2013, 93, 1309–1316. [Google Scholar] [CrossRef]

- Bensalah, N.; Alfaro, M.A.Q.; Martínez-Huitle, C.A. Electrochemical treatment of synthetic wastewaters containing Alphazurine A dye. Chem. Eng. J. 2009, 149, 348–352. [Google Scholar] [CrossRef]

- Faouzi Elahmadi, M.; Bensalah, N.; Gadri, A. Treatment of aqueous wastes contaminated with Congo Red dye by electrochemical oxidation and ozonation processes. J. Hazard. Mater. 2009, 168, 1163–1169. [Google Scholar] [CrossRef]

- Nakamura, K.C.; Guimarães, L.S.; Magdalena, A.G.; Angelo, A.C.D.; De Andrade, A.R.; Garcia-Segura, S.; Pipi, A.R.F. Electrochemically-driven mineralization of Reactive Blue 4 cotton dye: On the role of in situ generated oxidants. J. Electroanal. Chem. 2019, 840, 415–422. [Google Scholar] [CrossRef]

- Malpass, G.R.P.; Miwa, D.W.; Mortari, D.A.; Machado, S.A.S.; Motheo, A.J. Decolorisation of real textile waste using electrochemical techniques: Effect of the chloride concentration. Water Res. 2007, 41, 2969–2977. [Google Scholar] [CrossRef]

- Solano, A.M.S.; de Araújo, C.K.C.; de Melo, J.V.; Peralta-Hernandez, J.M.; da Silva, D.V.; Martínez-Huitle, C.A. Decontamination of real textile industrial effluent by strong oxidant species electrogenerated on diamond electrode: Viability and disadvantages of this electrochemical technology. Appl. Catal. B Environ. 2013, 130–131, 112–120. [Google Scholar] [CrossRef]

- Richards, W.T.; Loomis, A.L. The chemical effects of high frequency sound waves I. A preliminary survey. J. Am. Chem. Soc. 1927, 49, 3086–3100. [Google Scholar] [CrossRef]

- Destaillats, H.; Colussi, A.J.; Joseph, J.M.; Hoffmann, M.R. Synergistic effects of sonolysis combined with ozonolysis for the oxidation of azobenzene and methyl orange. J. Phys. Chem. A 2000, 104, 8930–8935. [Google Scholar] [CrossRef]

- Khataee, A.; Sheydaei, M.; Hassani, A.; Taseidifar, M.; Karaca, S. Sonocatalytic removal of an organic dye using TiO2/Montmorillonite nanocomposite. Ultrason. Sonochem. 2015, 22, 404–411. [Google Scholar] [CrossRef]

- Bolton, J.R.; Bircher, K.G.; Tumas, W.; Tolman, C.A. Figures-of-merit for the technical development and application of advanced oxidation technologies for both electric- and solar-driven systems. Pure Appl. Chem. 2001, 73, 627–637. [Google Scholar] [CrossRef]

- Casado, J. Towards industrial implementation of Electro-Fenton and derived technologies for wastewater treatment: A review. J. Environ. Chem. Eng. 2019, 7, 102823. [Google Scholar] [CrossRef]

- Daneshvar, N.; Aleboyeh, A.; Khataee, A.R. The evaluation of electrical energy per order (EEO) for photooxidative decolorization of four textile dye solutions by the kinetic model. Chemosphere 2005, 59, 761–767. [Google Scholar] [CrossRef]

- Durán, A.; Monteagudo, J.M.; San Martín, I. Operation costs of the solar photo-catalytic degradation of pharmaceuticals in water: A mini-review. Chemosphere 2018, 211, 482–488. [Google Scholar] [CrossRef] [PubMed]

- Azbar, N.; Yonar, T.; Kestioglu, K. Comparison of various advanced oxidation processes and chemical treatment methods for COD and color removal from a polyester and acetate fiber dyeing effluent. Chemosphere 2004, 55, 35–43. [Google Scholar] [CrossRef] [PubMed]

- Hu, Q.; Xu, L.; Fu, K.; Zhu, F.; Yang, T.; Yang, T.; Luo, J.; Wu, M.; Yu, D. Ultrastable MOF-based foams for versatile applications. Unpublished work. 2021. [Google Scholar]

- Yu, D.; Wang, L.; Yang, T.; Yang, G.; Wang, D.; Ni, H.; Wu, M. Tuning Lewis acidity of iron-based metal-organic frameworks for enhanced catalytic ozonation. Chem. Eng. J. 2021, 404, 127075. [Google Scholar] [CrossRef]

- Yang, T.; Yu, D.; Wang, D.; Yang, T.; Li, Z.; Wu, M.; Petru, M.; Crittenden, J. Accelerating Fe(III)/Fe(II) cycle via Fe(II) substitution for enhancing Fenton-like performance of Fe-MOFs. Appl. Catal. B Environ. 2021, 286, 119859. [Google Scholar] [CrossRef]

| COD (mg L−1) | BOD5 (mg L−1) | SS (mg L−1) | Color (ADMI Unit) | pH | Reference | ||

|---|---|---|---|---|---|---|---|

| Raw textile wastewater | 729 | 558 | 7.11 | [37] | |||

| 550 | 887 | 8.29 | [38] | ||||

| 1476 | 491 | 10.66 | [39] | ||||

| 5800 | 181 | 2000 | 9 | [40] | |||

| 3422 | 1112 | 6.95 | [41] | ||||

| 1600–1900 | 1500 | 12.5 | [42] | ||||

| 1000 | 300 | 2545 | 9.0 | [43] | |||

| 2300 ± 400 | 300 ± 100 | 13 ± 1 | [44] | ||||

| 810 ± 50.4 | 188 ± 15.2 | 64 ± 8.5 | 7.8 | [45] | |||

| 1132.6 ± 2.5 | 1697 ± 7 | 7.7 ± 0.115 | [20] | ||||

| 3422 | 1112 | 6.95 | [46] | ||||

| 1658–1692 | 7.32–7.94 | [47] | |||||

| 838 | 218 | 200 | 1300 | 6.3 | [48] | ||

| 3828 | 433 | 416 | 12.5 | [49] | |||

| 750 | 160 | 9 | [50] | ||||

| 1150 | 170 | 150 | 10 | [51] | |||

| 314–404 | 609–975 | 9.43–9.58 | [52] | ||||

| 1354 | 84.2 | 2175 | 8.84 | [53] | |||

| 413 | 289 | 625 | 8.7 | [54] | |||

| China municipal WWTP discharge standard | Level I-A | 50 | 10 | 10 | 30 | 6–9 | [55] |

| Level I-B | 60 | 20 | 20 | 30 | 6–9 | ||

| Level II | 100 | 30 | 30 | 40 | 6–9 | ||

| Level III | 120 | 60 | 50 | 50 | 6–9 | ||

| China textile WWTP discharge standard | Direct discharge | 80 | 20 | 50 | 50 | 6–9 | [56] |

| Indirect discharge | 200 | 50 | 100 | 80 | 6–9 | ||

| Process | Mechanisms | Pros | Cons |

|---|---|---|---|

| Ozonation | (1) O3 at elevated pH: 3O3 + OH− + H+ ⟶ 2HO• + 4O2 (2) O3/H2O2: 2O3 + H2O2 ⟶ 3O2 + 2HO• | (1) High decolorization (2) High biodegradability | (1) Low mass transfer efficiency (2) Potential toxic by-products (3) Gaseous O3 in the off-gas has to be removed |

| Photochemical | (1) UV/H2O2: H2O2 + hv ⟶ 2HO• (Φ = 1.0) (2) UV/O3: O3 + H2O + hv ⟶ 2HO• + O2 (3) UV/PS: S2O82−+ hv ⟶ 2SO4•- (Φ = 1.8) (4) UV/PMS: HSO5− + hv ⟶ HO• + SO4•- (Φ = 1.04 at pH = 7) | (1) Simple and easy operation (2) Clean and no sludge production (3) Relatively commercial oxidants (4) Disinfect water | (1) Waters with low UV light transmittance cannot be treated (2) Low quantum yield of oxidants |

| Photocatalysis | S + hν ⟶ S (e− + h+) S(h+) + H2O ⟶ H+ + HO• S(e−) + O2 ⟶ O2•− O2•− + H+ ⟶ HO2• HO2• + S(e−) + H+ ⟶ H2O2 H2O2 + S(e−) ⟶ OH− + HO• | (1) Mild operation conditions (2) Photochemically stable and non-toxic catalysts (3) Potential to use sunlight as clean and economic photo-source | (1) Low light use efficiency and low quantum efficiency of HO• generation (2) Mass transfer limitations to the surface of the immobilized catalyst on a substrate; (3) High recombination rate for the photoelectron and holes pairs |

| Fenton | (1) Classical Fenton: Fe2+ + H2O2 → Fe3+ + OH− + HO• (k = 70 M−1s−1) Fe3+ + H2O2 → Fe2+ + HO2• + H+ (k = 0.001–0.01 M−1s−1) (2) Photo-Fenton: H2O2 + hν ⟶ 2HO• Fe(OH)2+ + hν ⟶ Fe2+ + HO• Fe3+ + H2O2 + hν ⟶ Fe2+ + HO• + H+ (3) Electro-Fenton: O2 + 2H+ + 2e− → H2O2 Fe3+ + e− → Fe2+ | (1) No energy input requirement (for classical Fenton process) (2) Relatively inexpensive chemicals (3) Simple and flexible operation | (1) Narrow pH range (2) Large amount of sludge production (3) High concentration of Fe2+ in the effluent |

| Electrochemical | M + H2O ⟶ M(HO•) + H+ + e− R + M(HO•) ⟶ M + mCO2 + nH2O + pX | (1) Environmental compatibility (2) Possibility of automation (3) No chemical required and no sludge produced | (1) Limited mass transfer efficiency (2) High requirement of electricity (3) Potential poisoning effect |

| Ultrasound | (1) US: H2O + ))) ⟶ HO• + H• H• + O2 + ))) ⟶ HOO• where ))) refers to the US irradiation. (2) US/O3: O3 + ))) ⟶ O2(g) + O(3P)(g) O(3P)(g) + H2O(g) ⟶ 2HO•(g) | (1) No chemical required and no sludge produced (2) Improves the effect of chemical reaction | (1) Energy-intensive (2) A large amount of dissolved oxygen required |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Shaad, K.; Vollmer, D.; Ma, C. Treatment of Textile Wastewater Using Advanced Oxidation Processes—A Critical Review. Water 2021, 13, 3515. https://doi.org/10.3390/w13243515

Zhang Y, Shaad K, Vollmer D, Ma C. Treatment of Textile Wastewater Using Advanced Oxidation Processes—A Critical Review. Water. 2021; 13(24):3515. https://doi.org/10.3390/w13243515

Chicago/Turabian StyleZhang, Yiqing, Kashif Shaad, Derek Vollmer, and Chi Ma. 2021. "Treatment of Textile Wastewater Using Advanced Oxidation Processes—A Critical Review" Water 13, no. 24: 3515. https://doi.org/10.3390/w13243515

APA StyleZhang, Y., Shaad, K., Vollmer, D., & Ma, C. (2021). Treatment of Textile Wastewater Using Advanced Oxidation Processes—A Critical Review. Water, 13(24), 3515. https://doi.org/10.3390/w13243515