Numerical Modelling and Simulation of Two-Phase Flow Flushing Method for Pipeline Cleaning in Water Distribution Systems

Abstract

1. Introduction

2. Experiments

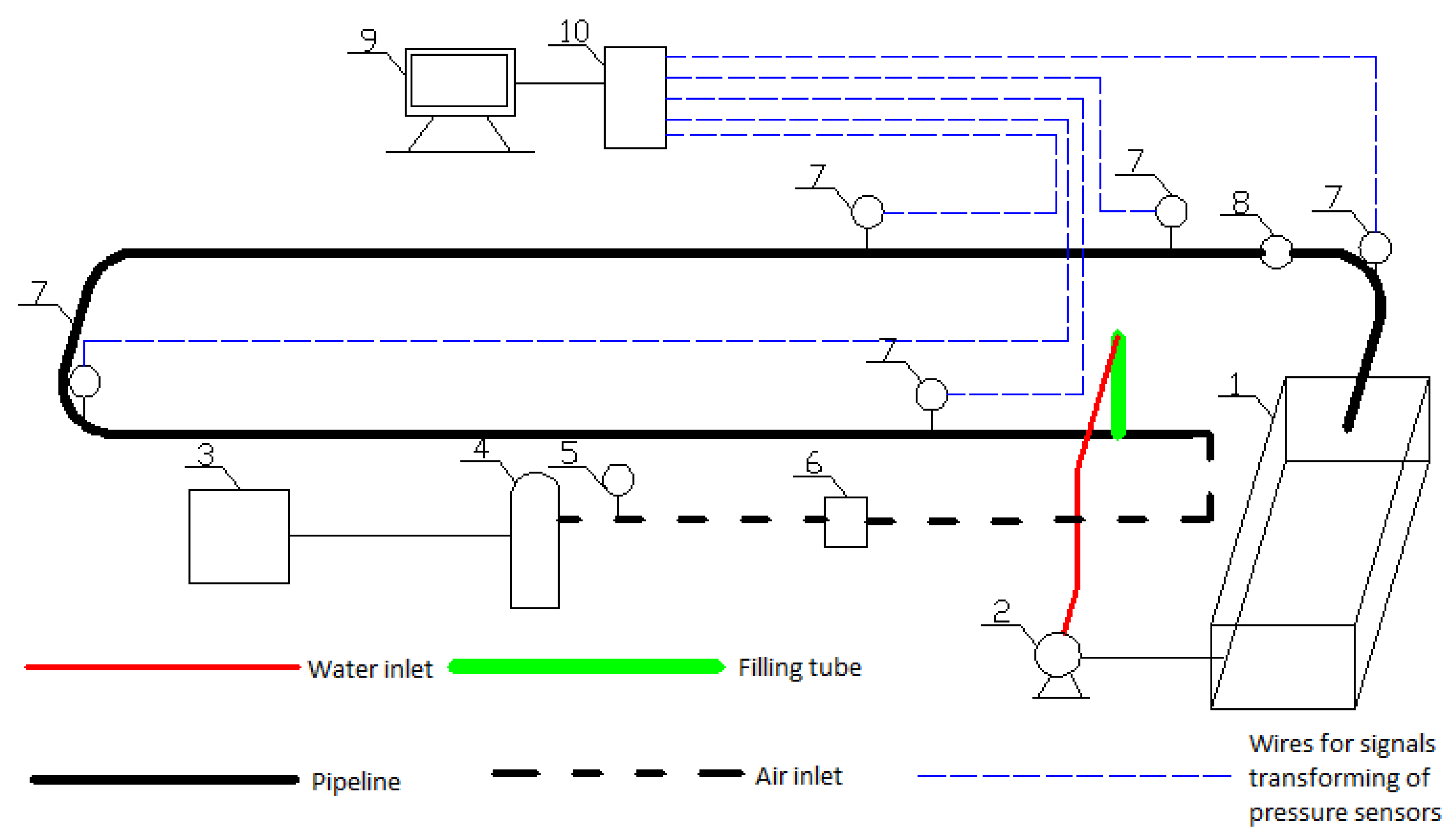

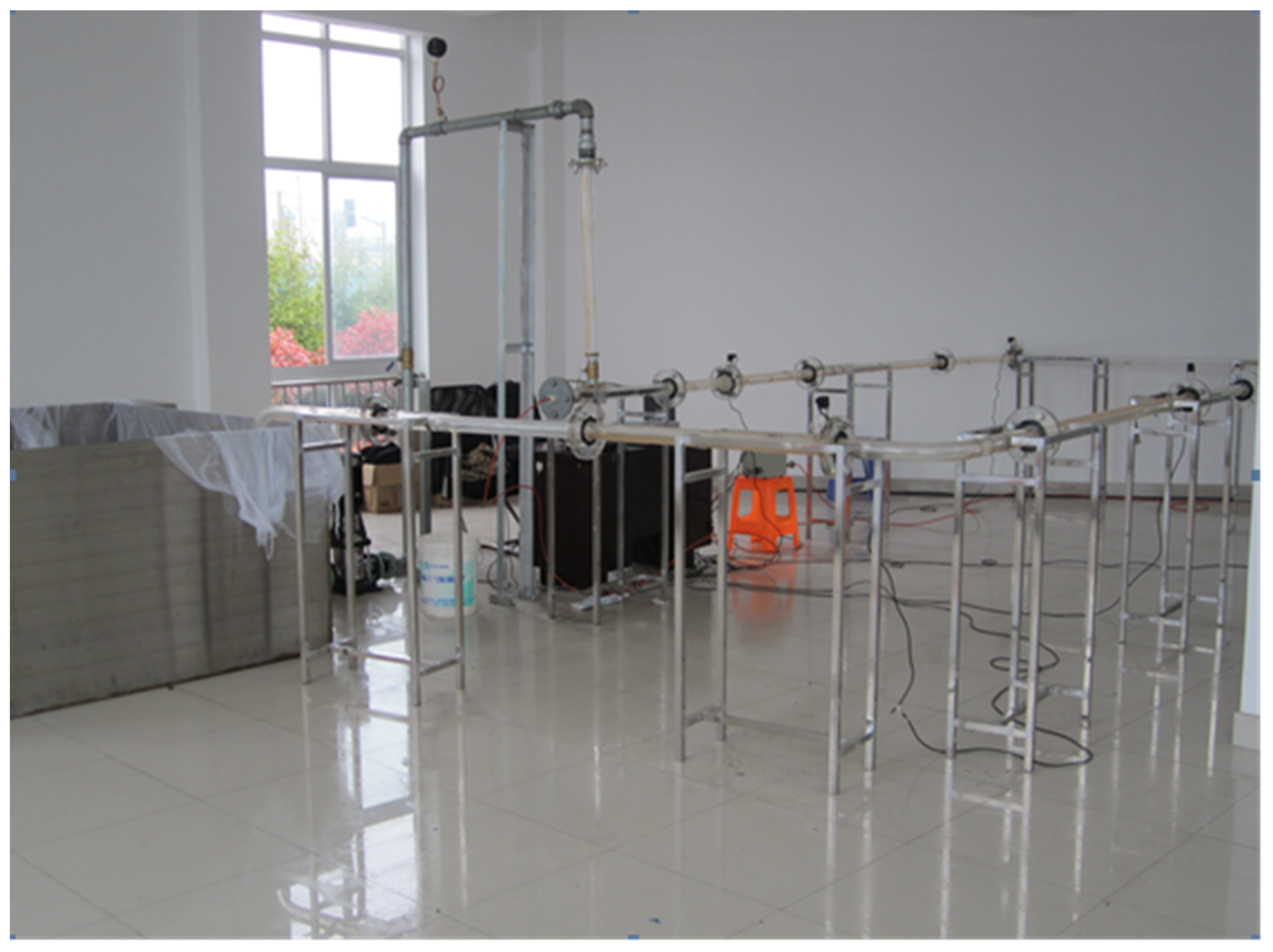

2.1. Experimetal Setup

2.2. Experimental Results

3. Numerical Modelling and Simulation

3.1. Mathmatical Modelling

3.1.1. Turbulent Flow Modelling

3.1.2. Multi-Phase Flow Modelling

3.2. Physical Modelling

3.2.1. Model Simplification

3.2.2. Mesh Generation

3.3. Conditions

3.3.1. Parameters and Conditions

3.3.2. Boundary Conditions

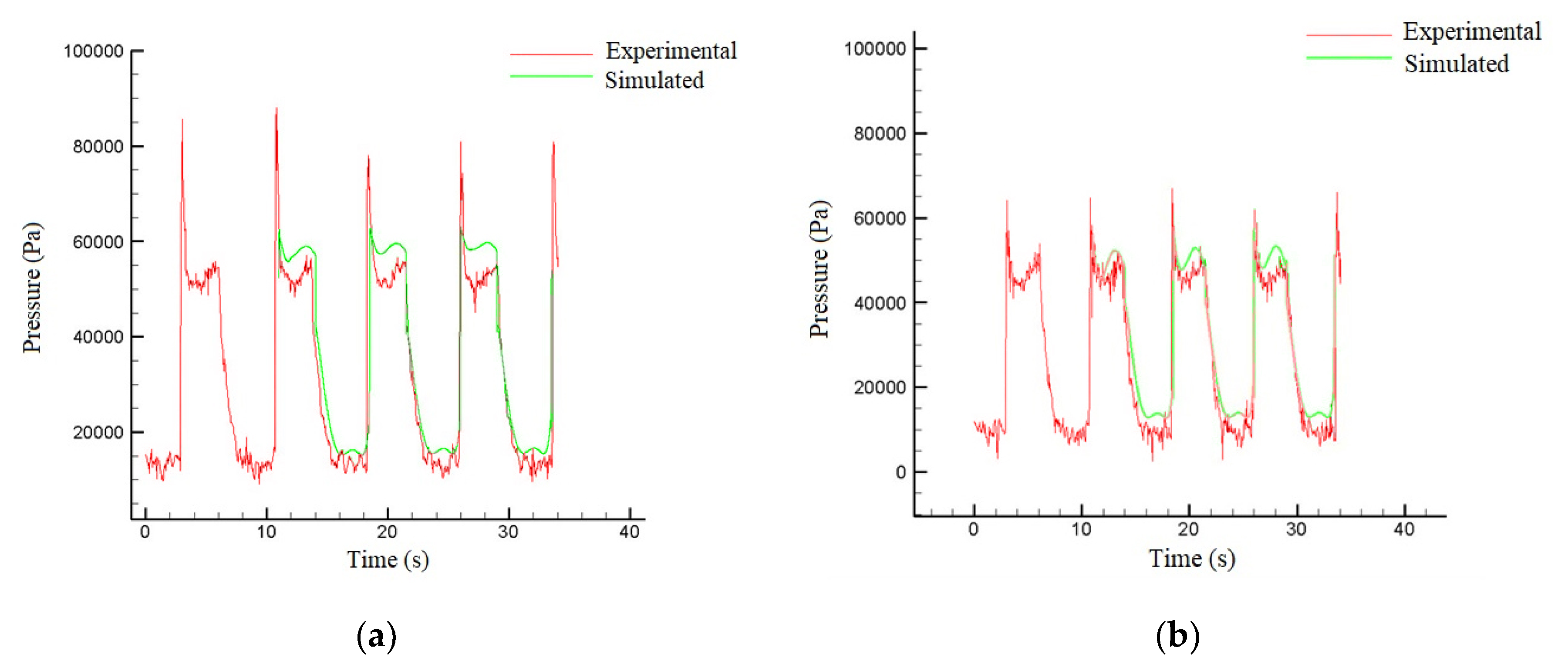

3.4. Model Verification

3.5. Simulation Results

3.5.1. Mapping of the Pressure Distribution

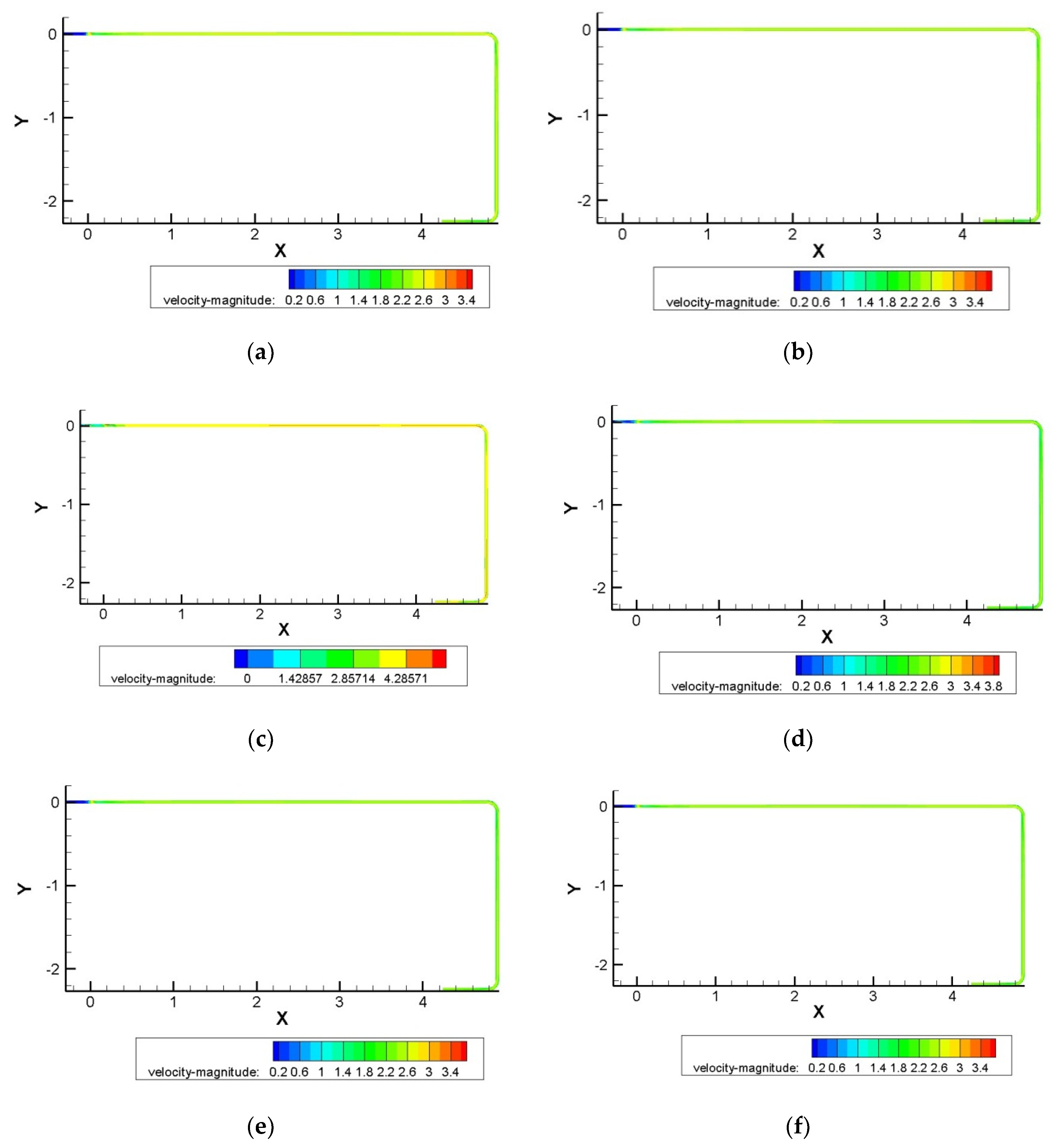

3.5.2. Mapping of the Water-Phase Velocity Distribution

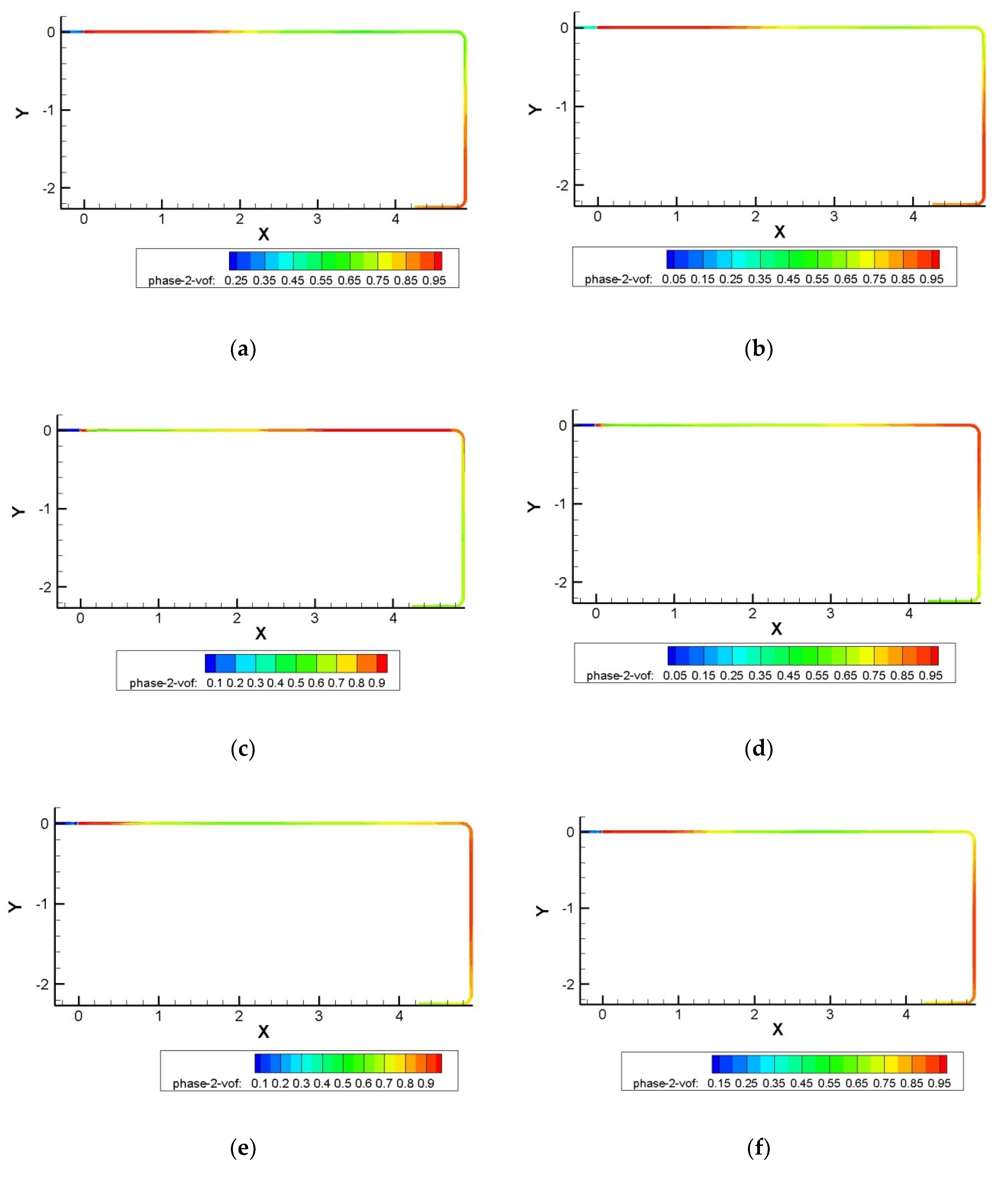

3.5.3. Mapping of the Water-Phase Volume Ratio Distribution

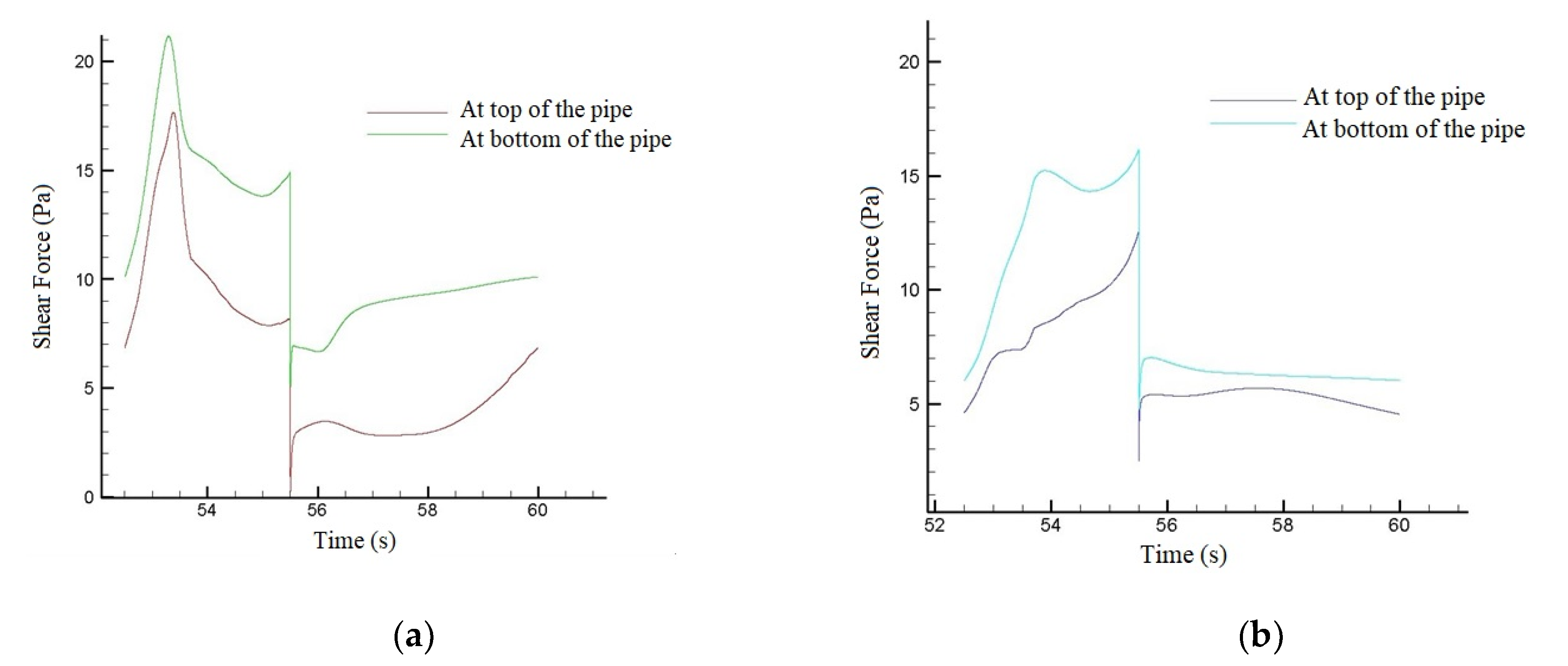

3.5.4. Shear Force

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhong, D.; He, F.; Ma, W.; Yuan, Y.; Wang, Z. Study on the Inactivation of Pseudomonas sp. and the degradation of trichloroethylene by Fenton-like reaction. Water 2018, 10, 1376. [Google Scholar] [CrossRef]

- El-Chakhtoura, J.; Prest, E.; Saikaly, P.; van Loosdrecht, M.; Hammes, F.; Vrouwenvelder, H. Dynamics of Bacterial Communities Before and After Distribution in a Full-scale Drinking Water Network. Water Res. 2015, 74, 180–190. [Google Scholar] [CrossRef] [PubMed]

- Douterelo, I.; Husband, S.; Boxall, J.B. The Bacteriological Composition of Biomass Recovered by Flushing an Operational Drinking Water Distribution System. Water Res. 2014, 54, 100–114. [Google Scholar] [CrossRef] [PubMed]

- Husband, P.S.; Boxall, J.B. Asset Deterioration and Discoloration in Water Distribution Systems. Water Res. 2011, 45, 113–124. [Google Scholar] [CrossRef] [PubMed]

- Husband, P.S.; Boxall, J.B. Field Studies of Discoloration in Water Distribution Systems: Model Verification and Practical Implications. J. Environ. Eng. ASCE 2010, 136, 86–94. [Google Scholar] [CrossRef]

- Zhao, H.B.; Li, X.; Zhao, M. The “Growth-Ring” of the Water Distribution Pipeline. In Hygiene in Water Distribution Pipeline, 1st ed.; China Architecture & Building Press: Beijing, China, 2008. (In Chinese) [Google Scholar]

- Teng, H.; Guan, Y.T.; Zhu, W.P. Effect of Biofilm on Cast Iron Pipe Corrosion in Drinking Water Distribution System: Corrosion Scales Characterisation and Microbial Community Structure Investigation. Corros. Sci. 2008, 50, 2816–2823. [Google Scholar] [CrossRef]

- Li, S.; Zhang, X.J. The Growth and Development of the Biological Membrane on the Water Distribution Pipe Wall and their Influence Factors. China Water Wastewater 2003, 19, 49–52. (In Chinese) [Google Scholar]

- Wang, T.; Liu, H.; Wei, H.; Ge, W. Numerical Simulation of Two-phase Flow in the Pipeline Cleaning used Barometric Pulse Method. In Proceedings of the 2011 International Symposium on Water Resource and Environmental Protection, Xi’an, China, 20–22 May 2011; pp. 3131–3135. [Google Scholar]

- Tang, Z.; Wu, W.; Han, X.; Zhao, M. An Experimental Study of Two-Phase Pulse Flushing Technology in Water Distribution Systems. Water 2017, 9, 927. [Google Scholar] [CrossRef]

- Coronado-Hernández, O.E.; Fuertes-Miquel, V.S.; Besharat, M.; Ramos, H.M. Experimental and Numerical Analysis of a Water Emptying Pipeline Using Different Air Valves. Water 2017, 9, 98. [Google Scholar] [CrossRef]

- Coronado-Hernández, O.E.; Fuertes-Miquel, V.S.; Angulo-Hernández, F.N. Emptying Operation of Water Supply Networks. Water 2018, 10, 22. [Google Scholar] [CrossRef]

- Fuertes-Miquel, V.S.; Coronado-Hernández, O.E.; Iglesias-Rey, P.L.; Mora-Meliá, D. Transient Phenomena During the Emptying Process of a Single Pipe with Water-Air Interaction. J. Hydraul. Res. 2019, 57, 318–326. [Google Scholar] [CrossRef]

- Coronado-Hernández, O.E.; Fuertes-Miquel, V.S.; Besharat, M.; Ramos, H.M. Subatmospheric Pressure in a Water Draining Pipeline with an Air Pocket. Urban Water J. 2018, 15, 346–352. [Google Scholar] [CrossRef]

- Coronado-Hernández, O.E.; Fuertes-Miquel, V.S.; Iglesias-Rey, P.L.; Martínez-Solano, F.J. Rigid Water Column Model for Simulating the Emptying Process in a Pipeline Using Pressurized Air. J. Hydraul. Eng. 2018, 144, 06018004. [Google Scholar] [CrossRef]

- Besharat, M.; Coronado-Hernández, O.E.; Fuertes-Miquel, V.S.; Viseu, M.T.; Ramos, H.M. Backflow Air and Pressure Analysis in Emptying a Pipeline Containing an Entrapped Air Pocket. Urban Water J. 2018, 15, 769–779. [Google Scholar] [CrossRef]

- Coronado-Hernández, Ó.E.; Besharat, M.; Fuertes-Miquel, V.S.; Ramos, H.M. Effect of a Commercial Air Valve on the Rapid Filling of a Single Pipeline: A Numerical and Experimental Analysis. Water 2019, 11, 1814. [Google Scholar] [CrossRef]

- Besharat, M.; Dadfar, A.; Viseu, M.T.; Brunone, B.; Ramos, H.M. Transient-Flow Induced Compressed Air Energy Storage (TI-CAES) System towards New Energy Concept. Water 2020, 12, 601. [Google Scholar] [CrossRef]

- Besharat, M.; Coronado-Hernández, O.E.; Fuertes-Miquel, V.S.; Viseu, M.T.; Ramos, H.M. Computational fluid dynamics for sub-atmospheric pressure analysis in pipe drainage. J. Hydraul. Res. 2020, 58, 553–565. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Z.; Wu, W.; Han, X.; Zhao, M.; Luo, J.; Fu, C.; Tao, R. Numerical Modelling and Simulation of Two-Phase Flow Flushing Method for Pipeline Cleaning in Water Distribution Systems. Water 2020, 12, 2470. https://doi.org/10.3390/w12092470

Tang Z, Wu W, Han X, Zhao M, Luo J, Fu C, Tao R. Numerical Modelling and Simulation of Two-Phase Flow Flushing Method for Pipeline Cleaning in Water Distribution Systems. Water. 2020; 12(9):2470. https://doi.org/10.3390/w12092470

Chicago/Turabian StyleTang, Zhaozhao, Wenyan Wu, Xiaoxi Han, Ming Zhao, Jingting Luo, Chen Fu, and Ran Tao. 2020. "Numerical Modelling and Simulation of Two-Phase Flow Flushing Method for Pipeline Cleaning in Water Distribution Systems" Water 12, no. 9: 2470. https://doi.org/10.3390/w12092470

APA StyleTang, Z., Wu, W., Han, X., Zhao, M., Luo, J., Fu, C., & Tao, R. (2020). Numerical Modelling and Simulation of Two-Phase Flow Flushing Method for Pipeline Cleaning in Water Distribution Systems. Water, 12(9), 2470. https://doi.org/10.3390/w12092470