Adsorptive Behavior of an Activated Carbon for Bisphenol A Removal in Single and Binary (Bisphenol A—Heavy Metal) Solutions

Abstract

1. Introduction

2. Materials and Methods

2.1. Adsorbent

2.2. Reagents

2.3. Methodology

3. Results and Discussions

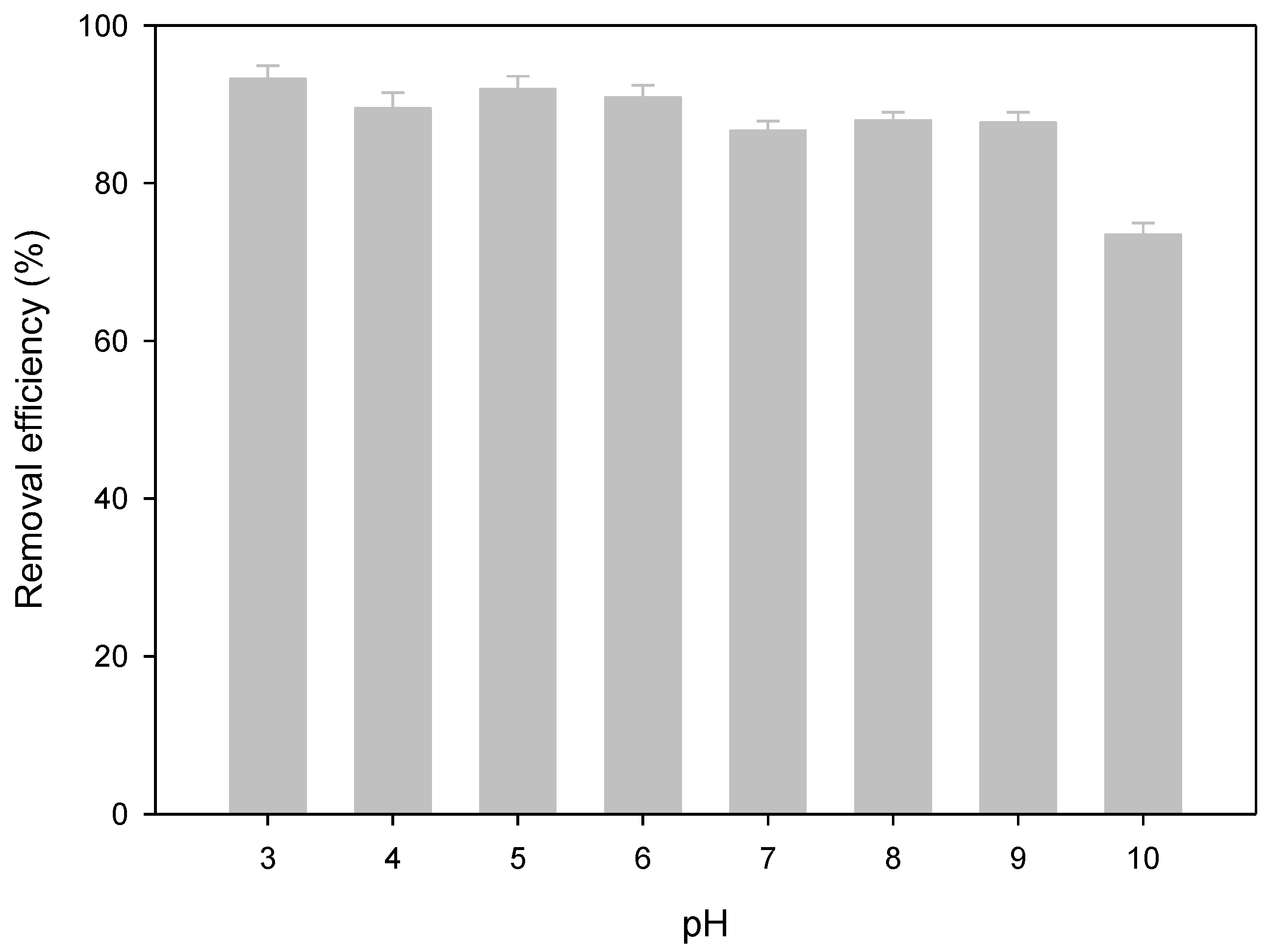

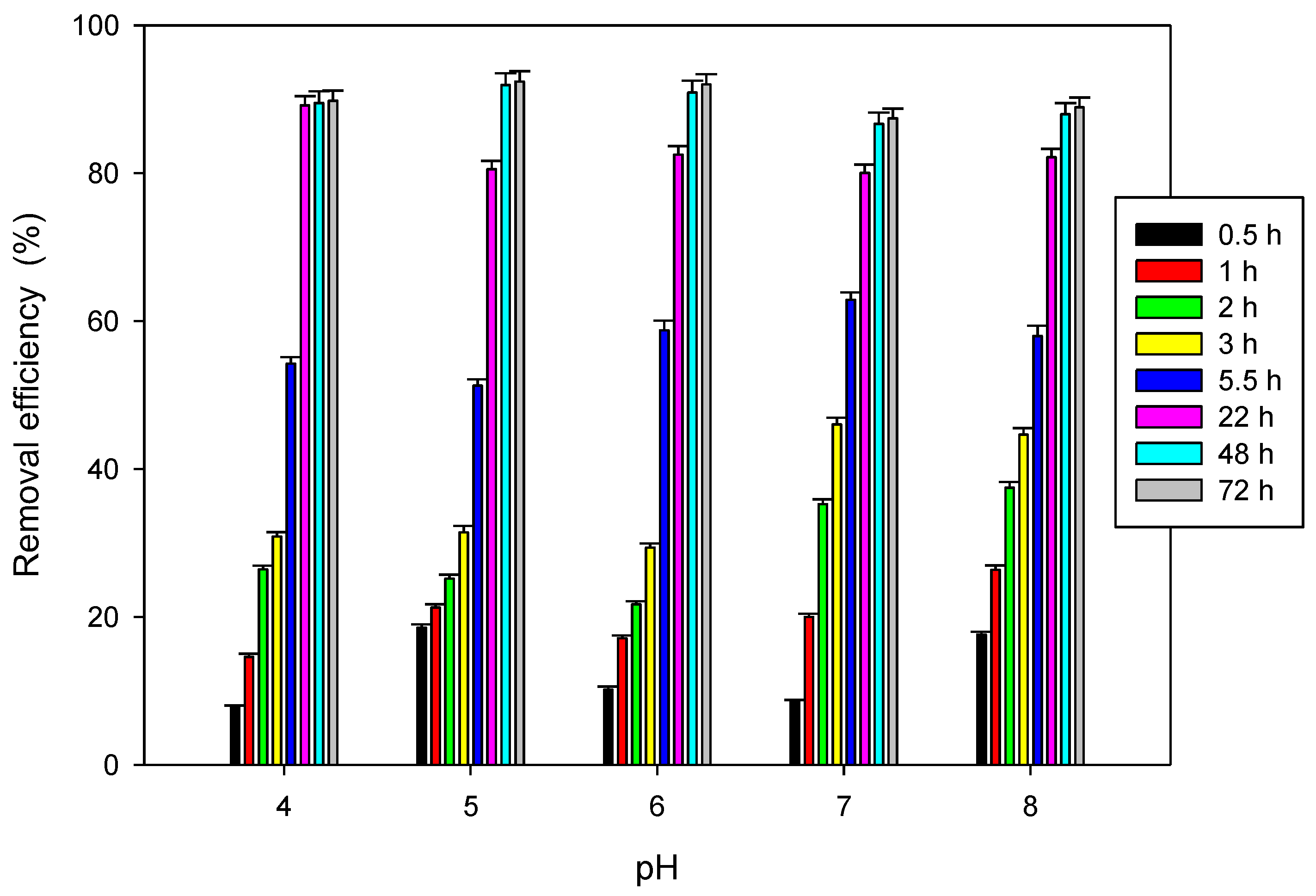

3.1. Influence of pH and Contact Time

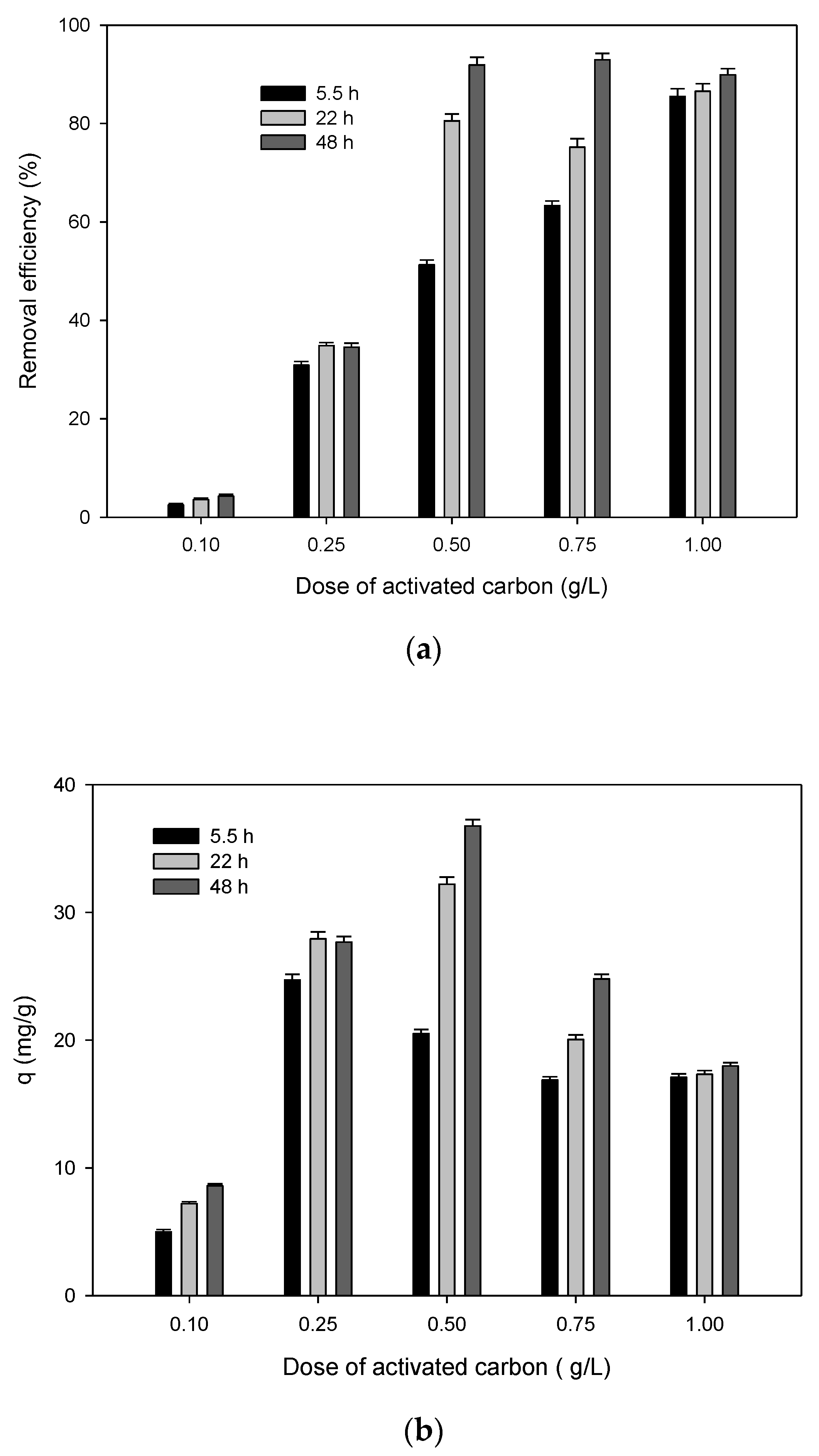

3.2. Influence of Adsorbent Dosage

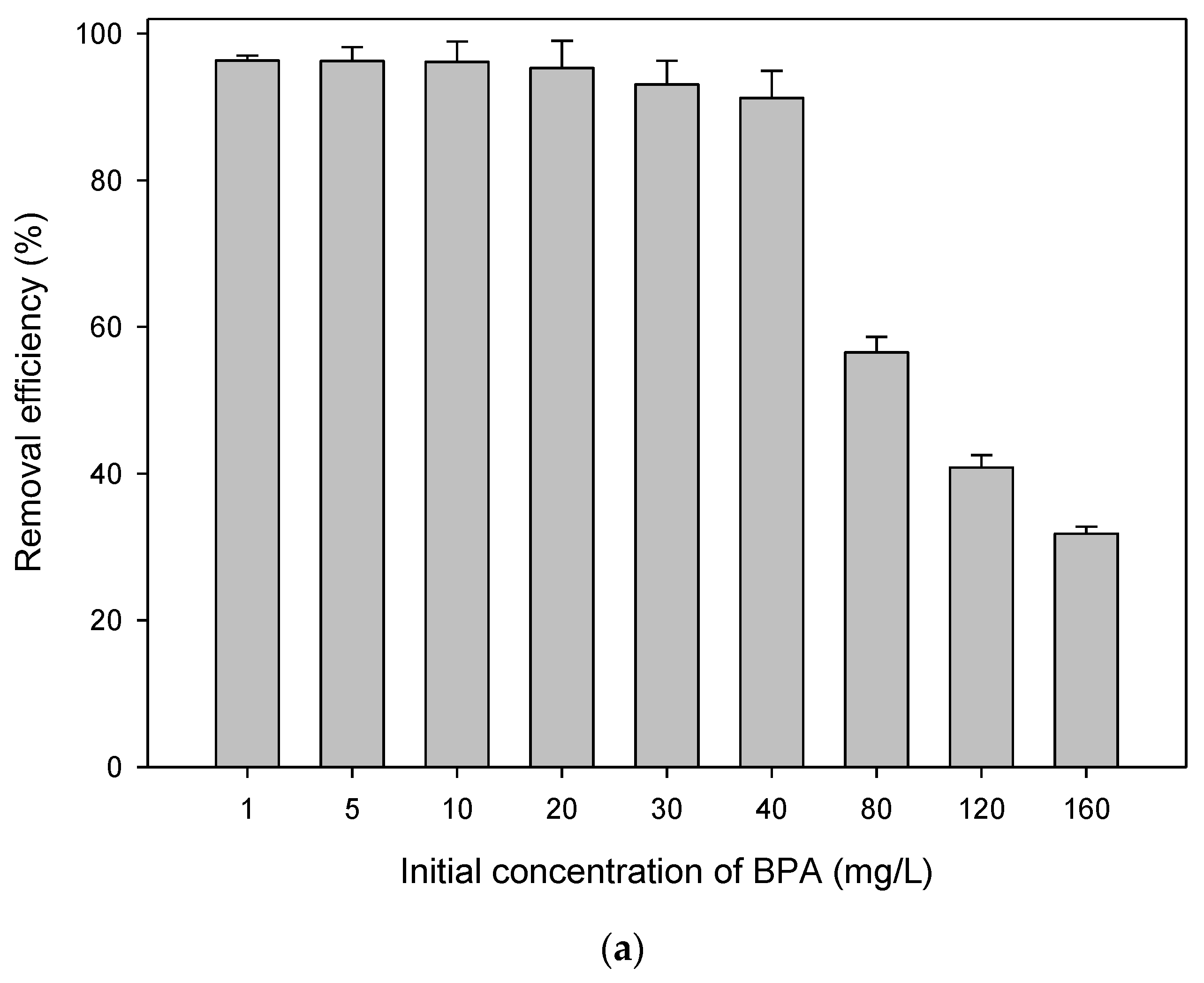

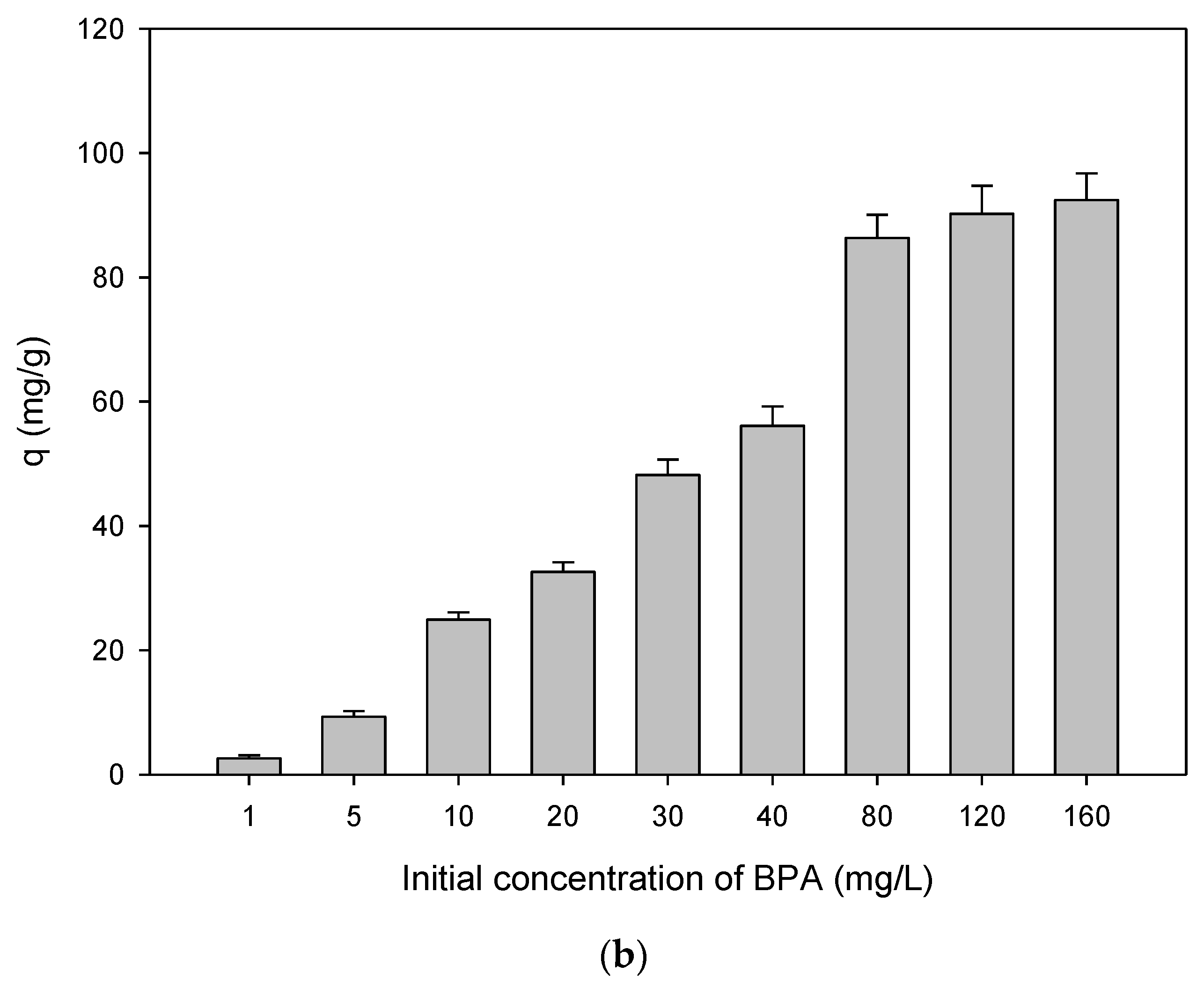

3.3. Influence of the Initial Concentration of BPA

3.4. Kinetic Study

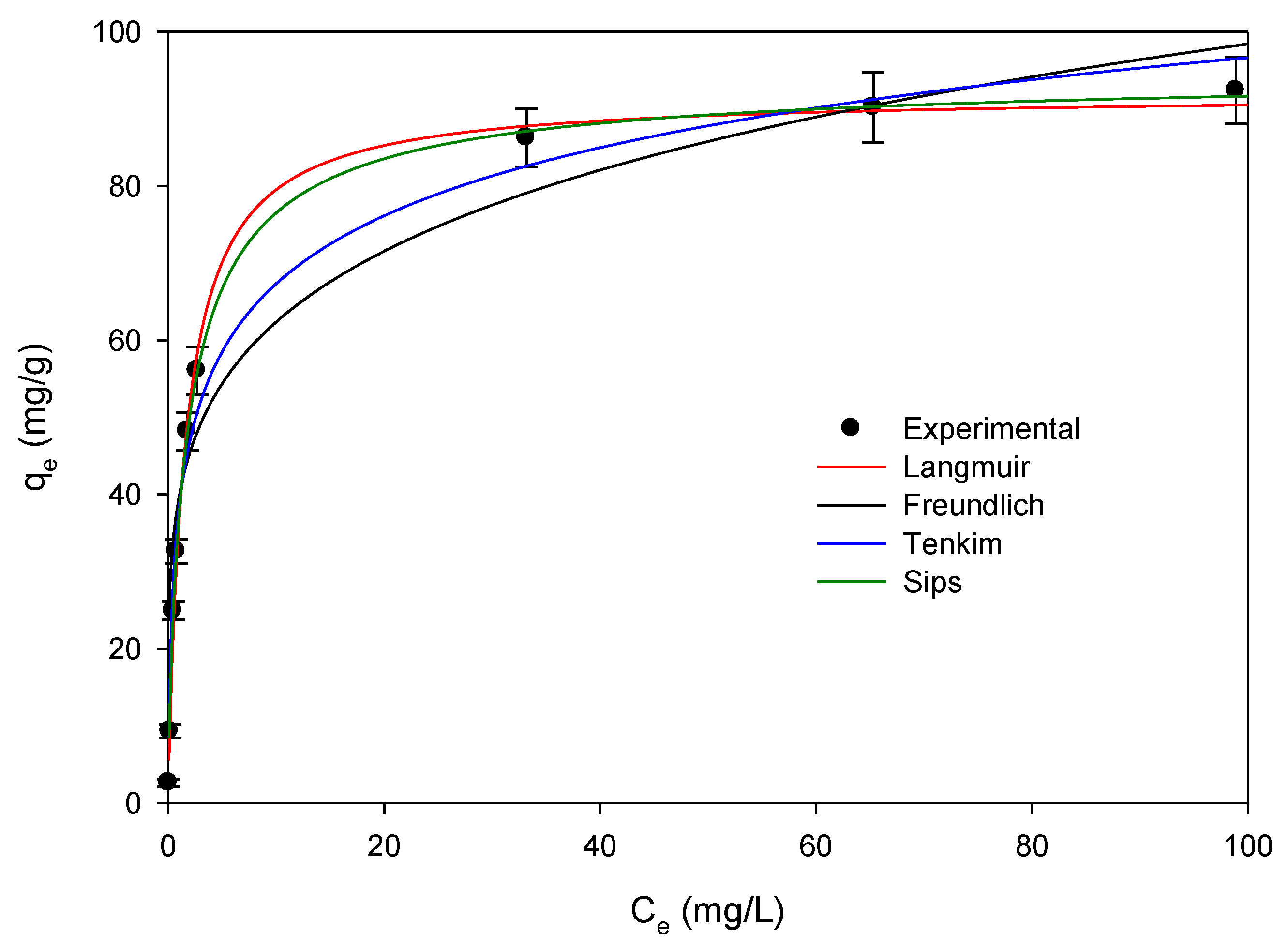

3.5. Equilibrium Study

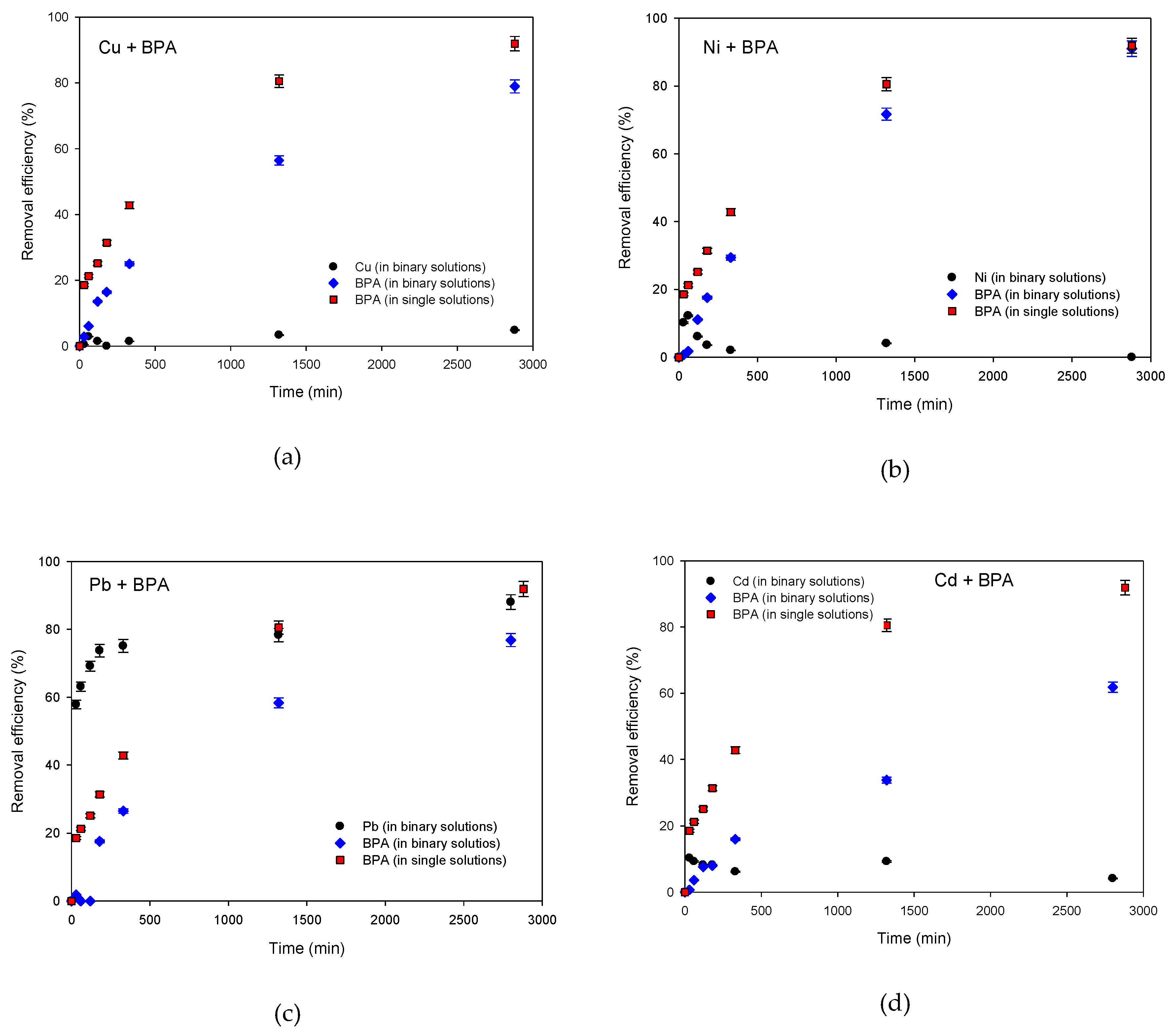

3.6. Adsorption of BPA-Metals Cations Mixtures

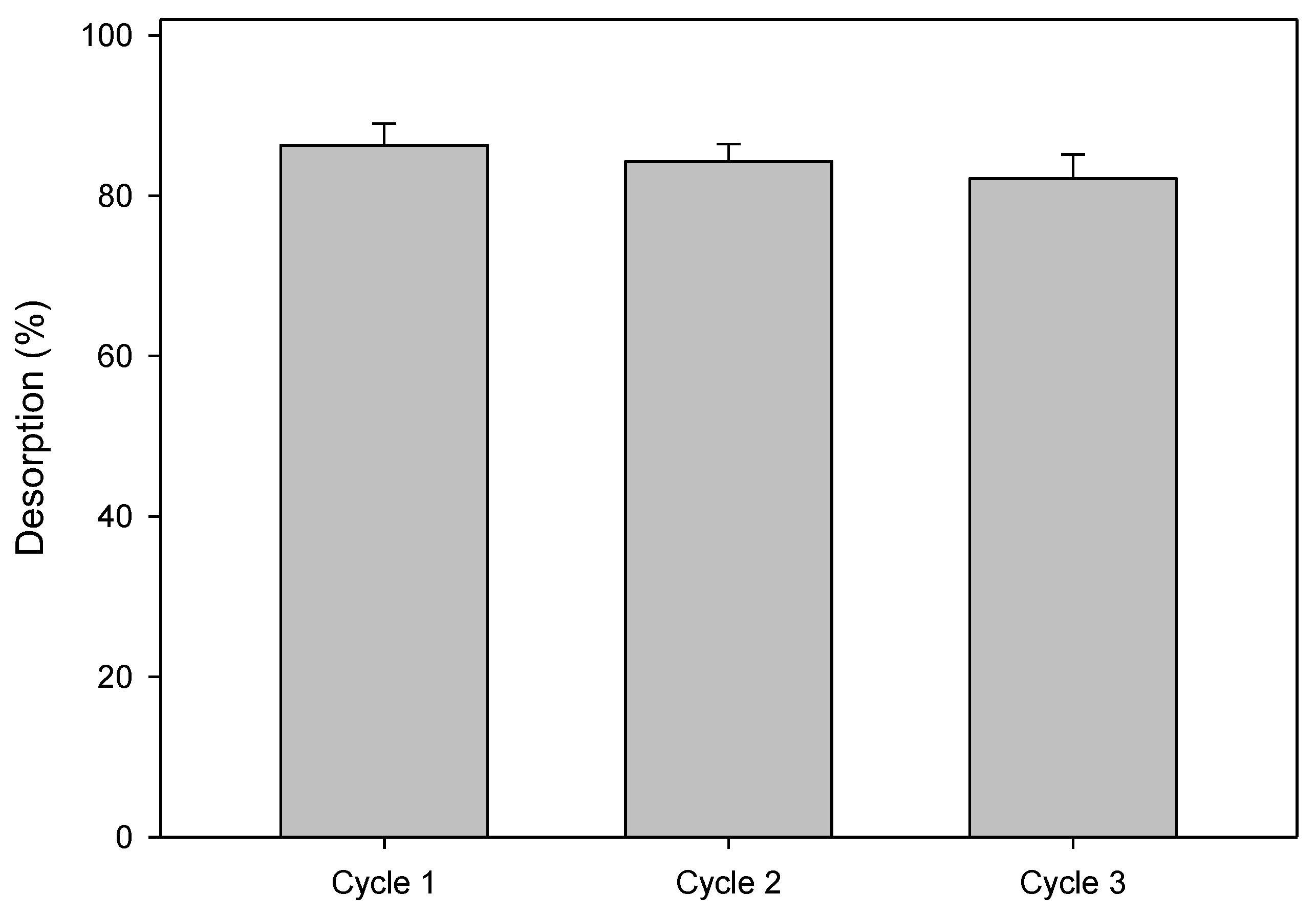

3.7. Cycles of BPA Adsorption/Desorption

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gonsioroski, A.; Mourikes, V.E.; Flaws, J.A. Endocrine disruptors in water and their effects on the reproductive system. Int. J. Mol. Sci. 2020, 21, 1929. [Google Scholar] [CrossRef] [PubMed]

- Rubin, B.S. Bisphenol A: An endocrine disruptor with widespread exposure and multiple effects. J. Steroid Biochem. Mol. Biol. 2011, 127, 27–34. [Google Scholar] [CrossRef] [PubMed]

- Orimolade, B.O.; Adekola, F.A.; Adebayo, G.B. Adsorptive removal of bisphenol A using synthesized magnetite nanoparticles. Appl. Water Sci. 2018, 8, 46. [Google Scholar] [CrossRef]

- ISH Markit. Bisphenol A. Chemical Economics Handbook; HIS Markit: London, UK, 2018. [Google Scholar]

- Inoue, M.; Masuda, Y.; Okada, F.; Sakurai, A.; Takahashi, I.; Sakakibara, M. Degradation of bisphenol A using sonochemical reactions. Water Res. 2008, 42, 1379–1386. [Google Scholar] [CrossRef]

- Ivanov, A.E.; Halthur, T.; Ljunggren, L. Flow permeable composites of lignin and poly(vinyl alcohol): Towards removal of bisphenol A and erythromycin from water. J. Environ. Chem. Eng. 2016, 4, 1432–1441. [Google Scholar] [CrossRef]

- Santhi, V.A.; Sakai, N.; Ahmad, E.D.; Mustafa, A.M. Occurrence of bisphenol A in surface water, drinking water and plasma from Malaysia with exposure assessment from consumption of drinking water. Sci. Total Environ. 2012, 427, 332–338. [Google Scholar] [CrossRef]

- Vandenberg, L.N.; Hauser, R.; Marcus, M.; Olea, N.; Welshons, W.V. Human exposure to bisphenol A (BPA). Reprod. Toxicol. 2007, 24, 139–177. [Google Scholar] [CrossRef]

- Yamamoto, T.; Yasuhara, A.; Shiraishi, H.; Nakasugi, O. Bisphenol A in hazardous waste landfill leachates. Chemosphere 2001, 42, 415–418. [Google Scholar] [CrossRef]

- Phouthavong-Murphy, J.C.; Merrill, A.K.; Zamule, S.; Giacherio, D.; Brown, B.; Roote, C.; Das, P. Phytoremediation potential of switchgrass (Panicum virgatum), two United States native varieties, to remove bisphenol-A (BPA) from aqueous media. Sci. Rep. 2020, 10, 835. [Google Scholar] [CrossRef]

- Liu, G.; Ma, J.; Li, X.; Qin, Q. Adsorption of bisphenol A from aqueous solution onto activated carbons with different modification treatments. J. Hazard. Mater. 2009, 164, 1275–1280. [Google Scholar] [CrossRef]

- Yeo, M.K.; Kang, M. Photodecomposition of bisphenol A on nanometer-sized TiO2 thin film and the associated biological toxicity to zebrafish (Danio rerio) during and after photocatalysis. Water Res. 2006, 40, 1906–1914. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Zhang, M. Adsorption Characteristics and mechanism of bisphenol A by magnetic biochar. Int. J. Environ. Res. Public Health 2020, 17, 1075. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.B.; Zhou, J.L.; Ngo, H.H.; Guo, W.S.; Thomaidis, N.S.; Xu, J. Progress in the biological and chemical treatment technologies for emerging contaminant removal from wastewater: A critical review. J. Hazard. Mater. 2017, 323, 274–298. [Google Scholar] [CrossRef] [PubMed]

- Esplugas, S.; Bila, D.M.; Krause, L.G.T.; Dezotti, M. Ozonation and advanced oxidation technologies to remove endocrine disrupting chemicals (EDCs) and pharmaceuticals and personal care products (PPCPs) in water effluents. J. Hazard. Mater. 2007, 149, 631–642. [Google Scholar] [CrossRef] [PubMed]

- Luo, H.; Cheng, Y.; Zeng, Y.; Luo, K.; He, D.; Pan, X. Rapid removal of organic micropollutants by heterogeneous peroxymonosulfate catalysis over a wide pH range: Performance, mechanism and economic analysis. Sep. Purif. Technol. 2020, 248, 117023. [Google Scholar] [CrossRef]

- Lin, H.; Fang, Q.; Wang, W.; Li, G.; Guan, J.; Shen, Y.; Ye, J.; Liu, F. Prussian blue/PVDF catalytic membrane with exceptional and stable Fenton oxidation performance for organic pollutants removal. Appl. Catal. B Environ. 2020, 273, 119047. [Google Scholar] [CrossRef]

- Rani, M.; Rachna; Shanker, U. Efficient photocatalytic degradation of Bisphenol A by metal ferrites nanoparticles under sunlight. Environ. Technol. Innov. 2020, 19, 100792. [Google Scholar] [CrossRef]

- Nakanishi, A.; Tamai, M.; Kawasaki, N.; Nakamura, T.; Tanada, S. Adsorption characteristics of bisphenol A onto carbonaceous materials produced from wood chips as organic waste. J. Colloid Interface Sci. 2002, 252, 393–396. [Google Scholar] [CrossRef]

- Marsh, H.; Heintz, E.A.; Rodriguez-Reinoso, F. Introduction to Carbon Technologies; University of Alicante: Alicante, Spain, 1997. [Google Scholar]

- Bansal, R.C.; Donnet, J.-B.; Stoeckli, F. Active Carbon; Marcel Dekker: New York, NY, USA, 1988. [Google Scholar]

- Derbyshire, F.; Jagtoyen, M.; Andrews, R.; Rao, A.; Martin-Gullon, I.; Grulke, E. Carbon materials in environmental applications. Chem. Phys. Carbon 2001, 27, 1–66. [Google Scholar]

- Musmarra, D.; Karatza, D.; Lancia, A.; Prisciandaro, M.; Mazziotti di Celso, G. Adsorption of elemental mercury vapors from synthetic exhaust combustion gas onto HGR carbon. J. Air Waste Manag. Assoc. 2016, 66, 698–706. [Google Scholar] [CrossRef][Green Version]

- Rivera-Utrilla, J.; Sánchez-Polo, M.; Gómez-Serrano, V. Activated carbon modifications to enhance its water treatment applications. An overview. J. Hazard. Mater. 2011, 187, 1–23. [Google Scholar] [CrossRef] [PubMed]

- Dias, J.M.; Alvim-Ferraz, M.C.M.; Almeida, M.F.; Rivera-Utrilla, J.; Sánchez-Polo, M. Waste materials for activated carbon preparation and its use in aqueous-phase treatment: A review. J. Environ. Manag. 2007, 85, 833–846. [Google Scholar] [CrossRef]

- Moreno-Castillo, C.; Rivera-Utrilla, J. Carbon materials as adsorbents for the removal of pollutants from the aqueous phase. Mater. Res. Bull. 2001, 26, 890–894. [Google Scholar] [CrossRef]

- Radovic, L.R.; Moreno-Castilla, C.; Rivera-Utrilla, J. Chemistry and Physics of Carbon; Radovic, L.R., Ed.; Marcel Dekker: New York, NY, USA, 2000; Volume 27, p. 227. [Google Scholar]

- Chen, J.; Zhang, L.; Yang, G.; Wang, Q.; Li, R.; Lucia, L.A. Preparation and characterization of activated carbon from hydrochar by phosphoric acid activation and its adsorption performance in prehydrolysis liquor. BioResources 2017, 12, 5928–5941. [Google Scholar] [CrossRef]

- Jagtoyen, M.; Thwaites, M.; Stencel, J.; McEnaney, B.; Derbyshire, F. Adsorbent carbon synthesis from coals by phosphoric acid activation. Carbon 1992, 30, 1089–1096. [Google Scholar] [CrossRef]

- Bhatnagar, A.; Anastopoulos, I. Adsorptive removal of bisphenol A (BPA) from aqueous solution: A review. Chemosphere 2017, 168, 885–902. [Google Scholar] [CrossRef] [PubMed]

- Juhola, R.; Runtti, H.; Kangas, T.; Hu, T.; Romar, H.; Tuomikoski, S. Bisphenol A removal from water by biomass-based carbon: Isotherms, kinetics and thermodynamics studies. Environ. Technol. 2020, 41, 971–980. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, C.; Wu, J.; Luo, Y. Adsorptive removal of bisphenol A using N-doped biochar made of Ulva prolifera. Water Air Soil Pollut. 2017, 228, 327. [Google Scholar] [CrossRef]

- Pan, B.; Lin, D.; Mashayekhi, H.; Xing, B. Adsorption and Hysteresis of Bisphenol A and 17-Ethinyl Estradiol on Carbon Nanomaterials. Environ. Sci. Technol. 2008, 42, 5480–5485. [Google Scholar] [CrossRef]

- Redding, A.M.; Cannon, F.S.; Snyder, S.A.; Vanderford, B.J. A QSAR-like analysis of the adsorption of endocrine disrupting compounds, pharmaceuticals, and personal care products on modified activated carbons. Water Res. 2009, 43, 3849–3861. [Google Scholar] [CrossRef]

- Solak, S.; Vakondios, N.; Tzatzimaki, I.; Diamadopoulos, E.; Arda, M.; Kabay, N.; Yüksel, M. A comparative study of removal of endocrine disrupting compounds (EDCs) from treated wastewater using highly crosslinked polymeric adsorbents and activated carbon. J. Chem. Technol. Biotechnol. 2014, 89, 819–824. [Google Scholar] [CrossRef]

- Wu, Z.; Wei, X.; Xue, Y.; He, X.; Yang, X. Removal effect of atrazine in co-solution with bisphenol A or humic acid by different activated carbons. Materials 2018, 11, 2558. [Google Scholar] [CrossRef] [PubMed]

- Bautista-Toledo, M.I.; Rivera-Utrilla, J.; Ocampo-Pérez, R.; Carrasco-Marín, F.; Sánchez-Polo, M. Cooperative adsorption of bisphenol-A and chromium(III) ions from water on activated carbons prepared from olive-mill waste. Chem. Eng. J. 2014, 73, 338–350. [Google Scholar] [CrossRef]

- Liu, C.; Wu, P.; Zhu, Y.; Tran, L. Simultaneous adsorption of Cd2+ and BPA on amphoteric surfactant activated montmorillonite. Chemosphere 2016, 144, 1026–1032. [Google Scholar] [CrossRef]

- Han, W.; Luo, L.; Zhang, S. Adsorption of bisphenol A on lignin: Effects of solution chemistry. Int. J. Environ. Sci. Technol. 2012, 9, 543–548. [Google Scholar] [CrossRef]

- Hanladakis, J.N.; Velis, C.A.; Weber, R.; Iacovidou, E.; Purnell, P. An overview of chemical additives present in plastics: Migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 2018, 344, 179–199. [Google Scholar] [CrossRef] [PubMed]

- Kyzas, G.Z.; Siafaka, P.I.; Pavlidou, E.G.; Chrissafis, K.J.; Bikiaris, D.N. Synthesis and adsorption application of succinyl-grafted chitosan for the simultaneous removal of zinc and cationic dye from binary hazardous mixtures. Chem. Eng. J. 2015, 259, 438–448. [Google Scholar] [CrossRef]

- Stawinski, W.; Wegrzyn, A.; Freitas, O.; Chmielarz, L.; Mordarski, G.; Figueiredo, S. Simultaneous removal of dyes and metal cations using an acid, acid-base and base modified vermiculite as a sustainable and recyclable adsorbent. Sci. Total Environ. 2017, 576, 398–408. [Google Scholar] [CrossRef] [PubMed]

- Morosanu, I.; Teodosiu, C.; Fighir, D.; Paduraru, C. Simultaneous Biosorption of Micropollutants from Aqueous Effluents by Rapeseed Waste. Process Saf. Environ. Prot. 2019, 132, 231–239. [Google Scholar] [CrossRef]

- Méndez-Díaz, J.D.; Abdel Daiem, M.M.; Rivera-Utrilla, J.; Sánchez-Polo, M.; Bautista-Toledo, I. Adsorption/bioadsorption of phthalic acid, an organic micropollutant present in landfill leachates, on activated carbons. J. Colloid Interface Sci. 2012, 369, 358–365. [Google Scholar] [CrossRef]

- Abdel Daiem, M.M.; Rivera-Utrilla, J.; Sánchez-Polo, M.; Ocampo-Pérez, R. Single, competitive and dynamic adsorption on activated carbon of compounds used as plasticizers and herbicides. Sci. Total Environ. 2015, 537, 335–342. [Google Scholar] [CrossRef] [PubMed]

- Velo-Gala, I.; López-Peñalver, J.J.; Sánchez-Polo, M.; Rivera-Utrilla, J. Role of activated carbon on micropollutants degradation by ionizing radiation. Carbon 2014, 67, 288–299. [Google Scholar] [CrossRef]

- Bernal, V.; Erto, A.; Giraldo, L.; Moreno-Pijarán, J.C. Effect of solution pH on the adsorption of paracetamol on chemically modified activated carbons. Molecules 2017, 22, 1032. [Google Scholar] [CrossRef] [PubMed]

- Pereira, R.C.; Anizelli, P.R.; Di Mauro, E.; Valezi, D.F.; da Costa, A.C.S.; Zaia, C.T.B.V.; Zaia, D.A.M. The effect of pH and ionic strength on the adsorption of glyphosate onto ferrihydrite. Geochem. Trans. 2019, 20, 3. [Google Scholar] [CrossRef] [PubMed]

- Bautista-Toledo, M.I.; Ferro-García, M.A.; Rivera-Utrilla, J.; Moreno-Castilla, C.; Vegas, F.J. Bisphenol A removal from water by activated carbon. Effects of carbon characteristics and solution chemistry. Environ. Sci. Tecnhol. 2005, 39, 6246–6250. [Google Scholar] [CrossRef]

- Tursi, A.; Chatzisymeon, E.; Chidichimo, F.; Beneduci, A.; Chidichimo, G. Removal of endocrine disrupting chemicals from water: Adsorption of bisphenol-A by biobased hydrophobic functionalized cellulose. Int. J. Environ. Res. Public Health 2018, 15, 2419. [Google Scholar] [CrossRef]

- Wang, X.; Xiao, Y. Removal of the endocrine disrupting chemical Bisphenol A from water by activated carbon. Adv. Mater. Res. 2013, 671, 2726–2731. [Google Scholar] [CrossRef]

- Chang, K.L.; Hsieh, J.F.; Ou, B.M.; Chang, M.H.; Hseih, W.Y.; Lin, J.F.; Huang, P.J.; Wong, K.F.; Chen, S.T. Adsorption studies on the removal of an endocrine-disrupting compound (Bisphenol A) using activated carbon from rice straw agricultural waste. Sep. Sci. Technol. 2012, 47, 1514–1521. [Google Scholar] [CrossRef]

- Soni, H.; Padmaja, P. Palm shell based activated carbon for removal of bisphenol A: An equilibrium, kinetic and thermodynamic study. J. Hazard. Mater. 2014, 21, 275–284. [Google Scholar] [CrossRef]

- Bohdziewicz, J.; Liszczyk, G. Evaluation of effectiveness of bisphenol a removal on domestic and foreign activated carbons. Ecol. Chem. Eng. Soc. 2013, 20, 371–379. [Google Scholar] [CrossRef][Green Version]

- Tsai, W.-T.; Lai, C.-W.; Su, T.-Y. Adsorption of bisphenol-A from aqueous solution onto minerals and carbon adsorbents. J. Hazard. Mater. 2006, 134, 169–175. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Shen, H.; Liu, B. Adsorption Properties of polyethersulfone-modified attapulgite hybrid microspheres for bisphenol A and sulfamethoxazole. Int. J. Environ. Res. Public Health 2020, 17, 473. [Google Scholar] [CrossRef]

- Ho, Y.S.; Mckay, G. A comparison of chemisorption kinetic models applied to pollutant removal on various sorbents. Process Saf. Environ. Prot. 1998, 76, 332–340. [Google Scholar] [CrossRef]

- King, P.; Srinivas, P.; Prasanna Kumar, Y.; Prasad, V.S.R.K. Sorption of copper(II) ion from aqueous solution by Tectona grandis l.f. (teak leaves powder). J. Hazard. Mater. 2006, 136, 560–566. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Peng, S.; Hu, S.; Hong, S. Enhanced removal of bisphenol-AF by activated carbon-alginate beads with cetyltrimethyl ammonium bromide. J. Colloid Interface Sci. 2017, 495, 191–199. [Google Scholar] [CrossRef]

- Rouquerol, F.; Rouquerol, J.; Sing, K.S.W.; Llewellyn, P.; Maurin, G. Adsorption by Powders and Porous Solids. Principles, Methodology and Applications, 2nd ed.; Elsevier: New York, NY, USA, 2012. [Google Scholar] [CrossRef]

- Brunauer, S.; Deming, L.S.; Deming, W.E.; Teller, E. On a theory of the Van der Waals adsorption of gases. J. Am. Chem. Soc. 1940, 62, 1723–1732. [Google Scholar] [CrossRef]

- Asada, T.; Oikawa, K.; Kawata, K.; Ishihara, S.; Iyobe, T.; Yamada, A. Study of removal effect of bisphenol A and β-estradiol by porous carbon. J. Health Sci. 2004, 50, 588–593. [Google Scholar] [CrossRef]

- Kuo, C.-Y. Comparison with as-grown and microwave modified carbon nanotubes to removal aqueous bisphenol A. Desalination 2009, 249, 976–982. [Google Scholar] [CrossRef]

- Li, S.; Gong, Y.; Yang, Y.; He, C.; Hu, L.; Zhu, L.; Sun, L.; Shu, D. Recyclable CNTs/Fe3O4 magnetic nanocomposites as adsorbents to remove bisphenol A from water and their regeneration. Chem. Eng. J. 2015, 260, 231–239. [Google Scholar] [CrossRef]

- Xu, J.; Zhu, Y.F. Elimination of bisphenol A from water via graphene oxide adsorption. Acta Phys. Chim. Sinica 2013, 29, 829–836. [Google Scholar]

- Schiewer, S.; Volesky, B. Modeling multi-metal ion exchange in biosorption. Environ. Sci. Technol. 1996, 30, 2921–2927. [Google Scholar] [CrossRef]

- Niu, H.; Volesky, B. Biosorption mechanism for anionic metal species with waste crab shells. Eur. J. Miner. Proc. Environ. Prot. 2003, 3, 75–87. [Google Scholar]

- López-Ramón, V.; Moreno-Castilla, C.; Rivera-Utrilla, J.; Radovic, L.R. Ionic strength effects in aqueous phase adsorption of metals ion son activated carbons. Carbon 2003, 41, 2020. [Google Scholar] [CrossRef]

- Meng, Z.-F.; Zhang, Y.-P.; Zhang, Z.-Q. Simultaneous adsorption of phenol and cadmium on amphoteric modified soil. J. Hazard. Mater. 2008, 159, 492–498. [Google Scholar] [CrossRef] [PubMed]

- Yan, L.; Huang, X.; Shi, H.; Zhang, G. Adsorption characteristics of bisfenol A on tailored activated carbon in aqueous solutions. Water Sci. Technol. 2016, 74, 1744–1751. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.; Hu, W.; Pan, J.; Zhou, H.; Guan, W.; Wang, X.; Dai, J.; Xu, L. Selective adsorption and separation of BPA from aqueous solution using novel molecularly imprinted polymers based on kaolinite/Fe3O4 composites. Chem. Eng. J. 2011, 171, 603–611. [Google Scholar] [CrossRef]

- Bayramoglu, G.; Arica, M.Y.; Liman, G.; Celikbicak, O.; Salih, B. Removal of bisphenol A from aqueous medium using molecularly surface imprinted microbeads. Chemosphere 2016, 150, 275–284. [Google Scholar] [CrossRef]

- Yu, C.; Shan, J.; Chen, Y.; Shao, J.; Zhang, F. Preparation and adsorption properties of rosin-based bisphenol A molecularly imprinted microspheres. Mater. Today Commun. 2020, 24, 101076. [Google Scholar] [CrossRef]

| Median particle diameter (MPD) (mm) | 3 |

| Density (g/L) | 450 |

| Moisture content (%) | 4 |

| Specific surface area (m2/g) | 1201 |

| Pore volumes (mean widths of micropores 0.71 nm) (cm3/g) | 0.406 |

| Pore volumes (diameter between 6.6 and 50 nm) (cm3/g) | 0.046 |

| Pore volumes (diameter > 50 nm) (cm3/g) | 0.409 |

| Concentration of acidic groups (µeq/g) | 907.7 |

| Concentration of basic groups (µeq/g) | 96.0 |

| Point of zero charge (pHpzc) | 7.5 |

| %C | 68.97 |

| %H | 1.03 |

| %N | 0.45 |

| %S | 1.02 |

| %O | 20.23 |

| %Ash | 8.30 |

| Model | Equation | Parameters |

|---|---|---|

| Pseudo-first-order | qe adsorption capacity, mg/g k1 kinetic constant of the pseudo-first-order, h−1 | |

| Pseudo-second-order | qe adsorption capacity, mg/g k2 kinetic constant of the pseudo-second-order, g/mg·h | |

| Elovich | a velocity of initial adsorption, mg/g·h b area of the occupied surface, g/mg | |

| Intraparticle | kp the intraparticle diffusion rate constant (mg/(g·min1/2)) C constant of the intraparticle diffusion model (mg/g) |

| Model | Parameters | ||

|---|---|---|---|

| Pseudo-first-order | k1 = 0.164 | qe = 37.17 | r2 = 0.995 |

| Pseudo-second-order | k2 = 0.004 | qe = 43.06 | r2 = 1.000 |

| Elovich | a = 11.325 | B = 0.099 | r2 = 0.992 |

| Intraparticle diffusion | kp = 5.577 | C = 3.082 | r2 = 0.964 |

| Model | Equation | Parameters |

|---|---|---|

| Langmuir | qm maximum adsorption capacity, mg/g b constant related to the affinity of the adsorbent for the adsorbate | |

| Freundlich | KF equilibrium constant, (mg/g)·(L/mg)1/n n constant related to the affinity between the adsorbent and the adsorbate | |

| Sips | qm maximum adsorption capacity, mg/g b constant related to the affinity of the adsorbent for the adsorbate n parameter characterizing the system’s heterogeneity | |

| Temkin | AT constant of union of the equilibrium (L/g), b Temkin constant, B constant related to the heat of adsorption (J/mol), |

| Model | Parameters | |||

|---|---|---|---|---|

| Langmuir | qm = 91.90 | b = 0.64 | r2 = 0.996 | |

| Freundlich | KF = 39.49 | n = 5.04 | r2 = 0.941 | |

| Sips | qm = 95.06 | b = 0.632 | n = 1.23 | r2 = 1.000 |

| Temkin | b = 194.47 | AT = 19.65 | r2 = 0.981 | |

| Initial Concentration of BPA, mg/L | Partition Coefficients, L/g |

|---|---|

| 1 | 52.00 |

| 5 | 51.40 |

| 10 | 49.80 |

| 20 | 40.75 |

| 30 | 26.78 |

| 40 | 20.78 |

| 80 | 2.60 |

| 120 | 1.38 |

| 160 | 0.93 |

| Time, min | Cd (II) + BPA | Cu (II) + BPA | Ni (II) + BPA | Pb (II) + BPA |

|---|---|---|---|---|

| 0 | 5 | 5 | 5 | 5 |

| 30 | 6.9 | 6.3 | 6.2 | 6.4 |

| 60 | 7.5 | 6.7 | 6.5 | 6.8 |

| 120 | 7.8 | 6.8 | 6.6 | 7.1 |

| 240 | 8.1 | 7.2 | 7.0 | 7.2 |

| 480 | 8.0 | 7.5 | 7.0 | 7.3 |

| 1440 | 8.0 | 7.4 | 7.3 | 7.3 |

| 2880 | 7.9 | 7.6 | 7.5 | 7.5 |

| Cycle | % Removal | q, mg/g |

|---|---|---|

| 1 | 92.5 | 37.00 |

| 2 | 91.4 | 36.56 |

| 3 | 90.2 | 36.08 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martín-Lara, M.A.; Calero, M.; Ronda, A.; Iáñez-Rodríguez, I.; Escudero, C. Adsorptive Behavior of an Activated Carbon for Bisphenol A Removal in Single and Binary (Bisphenol A—Heavy Metal) Solutions. Water 2020, 12, 2150. https://doi.org/10.3390/w12082150

Martín-Lara MA, Calero M, Ronda A, Iáñez-Rodríguez I, Escudero C. Adsorptive Behavior of an Activated Carbon for Bisphenol A Removal in Single and Binary (Bisphenol A—Heavy Metal) Solutions. Water. 2020; 12(8):2150. https://doi.org/10.3390/w12082150

Chicago/Turabian StyleMartín-Lara, M.A., M. Calero, A. Ronda, I. Iáñez-Rodríguez, and C. Escudero. 2020. "Adsorptive Behavior of an Activated Carbon for Bisphenol A Removal in Single and Binary (Bisphenol A—Heavy Metal) Solutions" Water 12, no. 8: 2150. https://doi.org/10.3390/w12082150

APA StyleMartín-Lara, M. A., Calero, M., Ronda, A., Iáñez-Rodríguez, I., & Escudero, C. (2020). Adsorptive Behavior of an Activated Carbon for Bisphenol A Removal in Single and Binary (Bisphenol A—Heavy Metal) Solutions. Water, 12(8), 2150. https://doi.org/10.3390/w12082150