Abstract

Constructed wetlands are one of the best technologies for wastewater treatment in small towns, small businesses or farms and/or livestock breeding. In this work, a wastewater depuration ecological system implemented in a hybrid constructed wetland to remove nutrients and organic matter from small urban agglomerations is studied. It comprises two processing stages: a primary treatment carried out in two hydrolytic up-flow sludge bed digesters working in parallel and a secondary one made up of two vertical flow constructed wetlands, which are alternatively used, followed by a horizontal flow constructed wetland. An internal recirculation system connects the output of the vertical flow constructed wetlands to the input of the hydrolytic up-flow sludge bed digesters with the aim of promoting the nitrification-denitrification process. High nutrients and organic matter removal efficiencies were observed when treating highly polluted wastewater from an animal farm. Therefore, this ecological depuration system, designed with an internal recirculation to enhance nitrogen reduction, may be considered an efficient alternative to treat wastewater from small urban agglomerations and diffuse contamination from agricultural industries and livestock farms polluting surface waters with nitrates, which may cause serious environmental problems, such as eutrophication.

1. Introduction

It is widely recognized that diffuse pollution is one of the major causes of poor water quality in surface waters [1,2]. An excess of nutrients in surface waters (mainly nitrogen and phosphorus) causes major environmental problems as eutrophication [3]. This problem is especially important in rural areas, because agriculture and farming activities, such as irrigation and cleaning operations, can drag fertilizers and slurry, which are subsequently driven into rivers, lakes and seas, producing a significant increase of the concentration of nitrogen in their waters [4]. Therefore, it may be assumed to be a generalized and growing problem, which affects the quality of both surface and groundwater, and may have important effects on human health [5].

Water policies have succeeded in protecting water resources, especially by introducing highly restrictive limits to water discharges from wastewater treatment plants (WWTP) of big urban agglomerations, in order to minimize the eutrophication of water bodies [6]. However, in rural areas, regulations concerning the quality of effluent water are less restrictive and, moreover, there is high decentralization and geographical dispersion in discharge points. These facts hamper the use of centralized treatment of wastewater and the quality control on water resource.

Because of those facts and the high construction and maintenance costs of conventional WWTPs, the use of constructed wetlands (CWs) has become a good alternative for wastewater treatment in rural areas [7]. These wetlands have a number of advantages, such as good organic matter removal performance [8], low construction and maintenance costs, almost no environmental impact (unnoticed in many cases) and being well suited to small populations, small industries and agricultural or livestock facilities. CWs have been designed to utilize natural processes to treat wastewater, but in a more controlled environment than in nature.

There are two main configurations of CWs [9]: free water surface constructed wetland (FWSCW) and sub-surface flow (SSF), which, in turn, may be vertical flow constructed wetlands (VFCW) and horizontal flow constructed wetlands (HFCW). In addition, hybrid systems are also used, which combine some or all of the previous systems to complement each other. In many cases, a primary treatment stage is also included to eliminate total suspended solids (TSS), in order to prevent wetland from clogging [10]. Constructed wetlands have proved to be able to provide high organic matter removal performance, when compared with different kinds of urban and agri-food industry wastewater treatment technologies. Nevertheless, their nutrient removal performance, mainly that of nitrogen, has been poor [11]. Some researches [12,13] report ammonia nitrogen and total nitrogen removal efficiencies of 35% and 53%, respectively, for domestic water, because of the lack of sufficient dissolved oxygen. Similar performances have been showed for wastewater released from livestock using CWs as depuration system [14]. These removal efficiencies can be increased by artificial forced aeration systems in CWs [15]. Nevertheless, it has been recently shown that total nitrogen removal efficiency in CWs drops under conditions of excessive dissolved oxygen, because it might restrain the denitrification process [12,16]. For this reason, in this work, a hybrid constructed wetland with an internal recirculation system connecting the output of the vertical flow constructed wetland to the input of the hydrolytic up-flow sludge bed digesters has been developed and studied as an alternative to the forced aeration system, with the aim of improving nitrogen removal. This system has been validated by processing farm wastewater with a small contribution of urban wastewater, because this is the worst scenario related to the influent load.

Due to the climate crisis, the European norm only establishes the need for an appropriate wastewater treatment in small urban agglomerations (<2000 population), and it is left to the responsible authorities of each country to establish the limits of the processed water released from those wastewater treatment plants. Currently, theses authorities have imposed ammonia and total nitrogen limit values to effluents from those kinds of facilities [6]. Therefore, the hybrid constructed wetland presented in this work may be an efficient technology to deal with the actual challenge to treat wastewater from small urban agglomerations.

The study was carried out in a research, training and innovation facility of the health sector. It has an animal farm for clinical trials which generated wastewater that needed be treated before released into sewerage network. The composition of this wastewater was similar to that released by livestock farms with an urban wastewater component from the staff of this research center.

The main aims of the treatment plant were to minimize the environmental impact of wastewater with high pollutant load that it receives and to ensure that its effluents accomplish with legal requirements. The plant comprises two stages, with an the internal recirculation as control parameter: in the first one a primary treatment is carried out in a hydrolytic up-flow sludge bed (HUSB) [17] to remove suspended solids, perform hydrolysis and carry out the denitrification process, while in the second stage two VFCWs and one HFCW will treat the wastewater to nitrificate ammonia, and to improve the removal efficiency of total suspended solid, organic matter and phosphorous. The combination of these two stages allows improving nitrogen removal efficiency without introducing a forced aeration system. In this work, a high amount of data, recorded throughout more than one year, have been used to verify removal efficiency improvements, showing that the proposed hybrid systems with an internal recirculation provides higher organic matter and nitrogen removal rates than CWs with forced aeration.

2. Materials and Methods

2.1. Research Area and Facilities Description

The facility where the treatment plant was installed, Centro de Cirugía de Mínima Invasión Jesús Usón (CCMIJU), was located near the city of Cáceres, at the southwest of Spain. It is a public non-profit institution devoted to training and researching in minimally invasive surgical techniques. To carry out these activities, it has an animal farm to house animals of different species (mainly pigs and sheep) used for research. The wastewater generated in this farm is processed by a depuration ecological system designed for a population of approximately 400 equivalent inhabitants (EI). Therefore, the treatment plant receives a high pollution load, mainly wastewater from cleaning operations and slurries. The processed water it generates is subsequently discharges into the municipal sewerage network. Figure 1 shows the treatment plant installed in the CCMIJU.

Figure 1.

Treatment plant located in the CCMIJU, at the southwest of Spain.

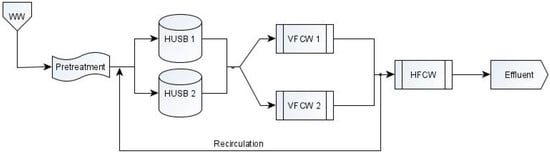

The facility has separate sewage and storm water networks, although the treatment plant only receives wastewater from the sewage one. Prior to be treated this wastewater receives an initial pretreatment where sand and big particles are removed. Then, the water is pumped into two HUSBs digesters working in parallel, with a total volume of 50 m3, where a primary treatment is carried out. Its aim is the retention of suspended solids, hydrolysis of compounds that are hardly degradable in the subsequent processes and denitrification of nitrates provided by water recirculated from the second stage.

The secondary treatment is carried out with a hybrid system made up of two VFCWs working alternately with a total area of 285 m2, which are followed by a HFCW with an area of 105.6 m2. Previous studies have pointed out the high nitrification capacity of these hybrid systems with wastewaters from farms and small communities [18]. In both systems, Phragmites Australis have been planted, to enhance performance of pollutant removal [19].

The two VFCWs work alternately every 3.5 days, a configuration that helps to prevent clogging, as pointed out in some works [20]. At the VFCW outlets there is a recirculation system that pumps a fraction of the treated water back into the entrance of the HUSB. This recirculation is included to improve nitrogen removal by processing the nitrates generated in the VFCWs by the two HUBS in the first stage. The reminder of the treated water is driven to the HFCW. The effluent released from the HFCW is directly poured into the sewerage system of the facility, with parameters according to the regulations.

A diagram of the treatment plant may be seen in Figure 2.

Figure 2.

Diagram of the wastewater treatment system.

As mentioned above, water policies have introduced high restrictive limits to effluents from small urban agglomerations (>2000 EI) related to organic matter (total suspended solids (TSS), chemical oxygen demand (COD) and 5-day biological oxygen demand (BOD5) and nutrients (total nitrogen (TN), total phosphorous (TP)). Nevertheless, this treatment plant was designed to accomplish the requirements set by European Directives for WWTPs in Directive 91/271/ EEC for WWTPs in big urban agglomerations [6]. They are shown in Table 1.

Table 1.

Legal limits of discharges to water courses (Directive 91/271/EEC) for organic matter and solids.

2.1.1. Pretreatment

The main function of pretreatment is the elimination of thick solids such as sand, stones, branches, plastics, which can cause problems in subsequent processes. To do this, a roughing channel with a vertical filter sieve has been installed to remove particles bigger than 2 mm to protect pipes and avoid system clogging.

2.1.2. Primary Treatment. HUSB Anaerobic Digester

Two HUSBs, with a total volume of 50 m3, were installed. They were semi-buried in a vertical position with a water column of 4.75 m. The main design criterion applied to these anaerobic reactors was the ascent rate of flow. It is usual to select a value between 0.3 and 1.0 m h−1 for stationary conditions [21], nevertheless, a lower value of 0.2 m h−1 was selected for these reactors, to promote a stratification of different processes at different heights which are related to the level of nitrates. This stratification should allow reaching anaerobic conditions at the bottom of the reactor, a zone without nitrates at a height of about 0.5 m, and anoxic conditions at the highest zones. The hydraulic retention time (HRT) was selected between 21 and 44 h. The value of the HRT was adjusted by means of recirculation from the outlets of the two VFCWs. Each HUSB has three pipes for sludge extraction, which take samples at 50 mm, 1500 mm and 2500 mm from the bottom.

The main goal of this primary treatment was twofold. The first goal was to remove suspended solids and process slowly biodegradable organic matter, which is hardly processed in the following stage. The second goal, based on the anoxic conditions, was to carry out the denitrification process by using biodegradable organic matter, produced at the bottom of the reactor, and nitrates from recirculation.

In these digesters wastewater enters into the bottom and is processed from the bottom to the top level as described. During this process, sedimentation, filtration and absorption take place, which allow suspended solids to be retained in the reactor and organic matter to be totally or partially biodegraded. The flow of the influent wastewater through sludge promotes the contact between organic substrates and biomass improving the performance of the digester. In the anaerobic degradation process, organic and soluble particle polymers must first be hydrolyzed, and then acidified in volatile fatty acids [17]. Due to the anoxic/anaerobic environment and the contribution of nitrates from the recirculation system, the digester has a favorable environment for denitrification. In this process, nitrates are denitrified by heterotrophic biomass by consuming organic matter. Denitrification is considered as a sequence of processes that start with a transformation of nitrate into nitrite and then nitrite into molecular nitrogen, providing a good performance in nutrient removal [22].

To avoid the presence of suspended solids in the effluent, it may be necessary to periodically remove sludge from the digester, where they accumulate, depending on its concentration in the influent load.

2.1.3. Secondary Treatment

Vertical Flow Constructed Wetland (VFCW)

In the plant studied in this work two identical VFCWs have been installed, which work in parallel and are used alternatively.

They are both excavated in the ground and waterproofed, to prevent contamination of the soil or the water table. They are filled with washed gravels of different sizes. The structure of the VFCW is defined, starting from the bottom, by a 25–30 cm thick drainage layer with 20–40 mm diameter gravel, then a 10 cm thick transition layer with 6–12 mm diameter gravel and, finally, a 70 cm thick filter layer with 2–6 mm diameter gravel.

The VFCWs are planted with Phragmites Australis, with a density of 3 plants per m2. They have been included because of their great contribution to the removal and absorption of nutrients [23]. They provide a noticeable increase in nutrient removal compared to CWs without plants [24,25].

The drainage pipes are located at the bottom of the VFCW, with their ends connected to the external environment, to make it easy air to enter into the filtering medium, and thus improve aerobic processes [26]. As a result of this, nitrification is the most important process in this system.

Wastewater pumping is carried out following a three phases cycle—filling, reaction and emptying—by means of a distribution network on the surface of the VFCW. It has to pass through the different substrate layers, and the biofilm attached to them, and the roots of the Australis Phragmites. Due to the aerobic character of the medium, nitrification is enhanced.

A fraction of the effluent released by the VFCWs can be recirculated to the HUSB inlet to improve nitrification. The remains of that effluent will pass to the next phase of the process, the HFCW. This recirculation has been included in order to better control the nitrification process to improve its performance, as well as to provide a better adjustment of the input flow to both reactors, making it easier the control of the hydraulic load.

Horizontal Flow Constructed Wetland (HFCW)

As in the VFCWs, the HFCW is excavated in the ground and waterproofed to avoid polluting both the soil and the water table. It is filled with a 110 cm thick layer of 8–22 mm diameter washed gravel. The incoming flow was designed to ensure a maximum water height of 105 cm, always below the gravel layer high, to avoid bad odors and proliferation of insects. The HFCW is also planted with Phragmites Australis with a density of 3 plants per m2.

Wastewater from the VFCWs enters the reactor and flows through the gravel to the outlet zone where it is discharged. Meanwhile, pollution is removed by chemical and physical processes. In this reactor, an anaerobic environment predominates, which improves denitrification and creates a perfect symbiosis with VFCWs, complementing their nitrogen treatment. It also helps to reduce suspended solids and pathogens. On the other hand, although there are also aerobic areas in this reactor, they are always close to roots, which provide oxygen, so that nitrification is very limited.

The water treated in this HFCW is released into a manhole and then pumped into the sewer system. Nevertheless, in order to look for a more sustainable water use, this treated water can be used for irrigation [27,28], thanks to the high removal efficiency that the whole treatment process has achieved.

2.2. Sampling and Analytical Process

Four different points were selected to carry out the sampling process: the first was in the influent, before the pretreatment; the second was before the VFCW; the third was before the HCFW; and finally, the fourth point was in the effluent. Those in the influent and the effluent collected data with an autosampler to take 200 mL of wastewater each hour for 24 h, with the aim of capturing average characteristics of wastewater over a period of 1 day in a composite sample. Grab samples were collected from the other two points early in the morning (9–12 a.m.). The volume of those grab samples were 1000 mL, while the volume of the composite samples were 2400 mL (100 mL of each hour sample). They were all kept at 4 °C and processed less than 24 h after sampling.

The treatment plant was weekly monitored from July 2018 to March 2020. A total of 23 composite influent samples and 23 composite output samples were taken, subject to the availability of the autosamplers, in the dates pointed out in Figure 3 and Figure 4. A total of 63 grab samples from the point before the VFCW and other 63 from that before the HCFW were also gathered, although, for the sake of simplicity, they are not shown in Figure 3 and Figure 4.

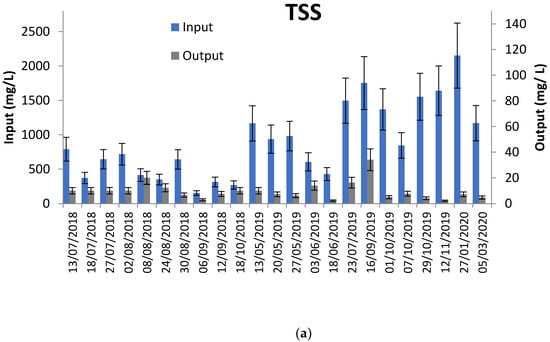

Figure 3.

Organic matter concentrations and total suspended solids (TSS) at the input and the output of the plant. Blue bars show input concentration to the plant and grey bars output concentration of the hydrolytic up-flow sludge bed (HUSB). (a) TSS; (b) chemical oxygen demand (COD); (c) 5-day biological oxygen demand (BOD5).

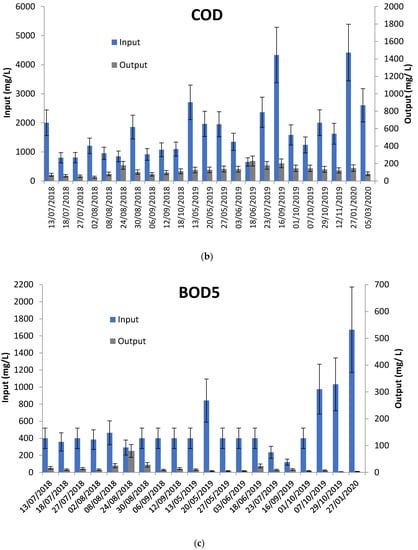

Figure 4.

Nutrient concentrations at the input and the output of the plant. Blue bars show input concentration to the plant and grey bars output concentration of the HUSB. (a) Ammonia (NH4+); (b) total nitrogen (TN); (c) total phosphorous (TP).

Eight variables were measured in each sample: total nitrogen (TN), total phosphorous (TP), ammonia (NH4+), nitrate (NO3−), pH, electrical conductivity (EC), total suspended solids (TSS), chemical oxygen demand (COD) and 5-day biological oxygen demand (BOD5). These variables were obtained according to standard methods for wastewater treatment analysis [29]. The analytical methods for these nine variables were validated according to the ISO/IEC 17025:2017 [30] by the R+D Laboratory of PROMEDIO (Consorcio para la Gestión de los Servicios Medioambientales de la Provincia de Badajoz). Uncertainties associated to their values are presented in Figure 3.

Input load data have been statistically analyzed, in order to highlight their validity. They are shown in Table 2, where average values of each parameter are presented along with their corresponding 95% confident intervals and standard deviations. Maximum and minimum values of each one are also provided in order to identify the presence of possible outliers.

Table 2.

Input load of the treatment plant.

2.3. Removal Efficiency

The removal efficiency of the treatment process for each variable was obtained by comparing concentrations in influent (Ci) and effluent (Ce) water:

3. Results

The pollution load removal efficiency has been studied at the outlets of the depuration system and the transitions between processes, i.e., outlet of the HFCW and outlets of the HUSBs and the FVCWs.

Figure 3 shows organic matter at the input and output of the plant. The input concentrations are showed in blue bars and output concentrations appear in grey bars. When each parameter is analyzed, we can see than the TSS input concentration presents values higher than 2000 ± 273 mg/L, as it may be seen in Figure 3a. However, the output concentrations show values lower than 20 ± 5 mg/L during the whole study period. This means that the removal efficiencies achieve 98.47 ± 0.53% at the plant outlet, as shown in Table 5. It should be mentioned that, most of TSS are removed at the pretreatment and at the HUSB, approximately 71.02 ± 9.71% (see Table 3). With regards to organic matter, Figure 3b,c shows input and output concentrations of COD and BOD5, respectively. COD achieves input values of 4300 ± 954 mg/L and output concentrations lower than 230 ± 57 mg/L. So, a load removal efficiency of 91.22 ± 2.80% is achieved. HUSB and VFCW outputs show COD removal efficiencies higher than 60.66 ± 9.10% and 86.55 ± 4.73%, respectively. The BOD5 removal efficiency presents a pattern similar to that of COD, but now the input concentration achieves maximum values of 1672 ± 501 mg/L, and output concentrations lower than 80 ± 24 mg/L, with a load removal efficiency of 95.60 ± 2.67%. It is worth noting that the VFCW output achieves a removal efficiency of 84.00 ± 5.00%, while that of the HUSB presents a value of 56.67 ± 12.96%. This high efficiency was obtained because, as commented upon in Section 2, during the residence time sedimentation, filtration and absorption take place in the reactor, which allows suspended solids to be retained and organic matter to be totally or partially biodegraded. In addition, organic matter is also consumed in the denitrification processes carried out.

Table 3.

Statistics of accumulated removal efficiencies for the HUSB.

With regard to nutrients, Figure 4 shows nutrient concentrations at the input and the output of the depuration system. NH4+ concentrations (Figure 4a) achieve input values of 330 ± 49 mg/L and output concentrations lower than 68 ± 10 mg/L. Therefore, these values provide a load removal efficiency of 61.00 ± 9.26% (see Table 5). Ammonium removal is carried out in the VFCW, due to the aerobic character of the medium, which enhances the nitrification that takes place in this phase of the depuration process. Ammonium removal is hardly carried out in the HUSB, as only particulate ammonia is removed inside it, which represents a low percentage of the total incoming ammonia. Table 4 shows that the NH4+ removal efficiency at the VFCW outlet achieves a mean value of 45.06 ± 6.99% in this stage of the depuration process. This table shows that the mean value of total nitrogen removal efficiency was 52.79 ± 10.45%. This is due to the vertical flow and the bed height of the reactor, which provide an aerobic process at the top of the bed with nitrification and anoxic and anaerobic conditions at the bottom. This stratification in the bed makes it possible to reach nitrogen removal efficiencies higher than those of ammonia and is also an important biological phosphorous removal process.

Table 4.

Statistics of accumulated removal efficiencies for the vertical flow constructed wetland (VFCW).

The effluents of the VFCWs are recirculated to the inlet of the HUSB where denitrification takes place. The NO3− removal efficiency achieves a mean value of 42.93% ± 14.00. The removal efficiency was related to the recirculation ratio. When this study started, the recirculation ratio was fixed to 50% of the influent. The removal efficiency so obtained was higher than 70%, as shown in Figure 4b. However, during the period between June and October 2019, the influent flow increased due to rainwater leaking into the sewer of the center. This situation produced a decrease in the recirculation ratio of 25%, with a reduction in the nitrogen removal efficiency of 20–30%. Once this infiltration was resolved, and the influent flow was that of design again, the recirculation ratio was increased up to 100%. During this period, between December 2019 and February 2020, the nitrogen removal efficiency reaches 80%. It is worth noting that during the phases of nitrificacion-denitrification pH ranges between 7.03 and 8.33. Theses pH conditions are optimal for nitrification-denitrification processes [31].

TN input concentrations present values higher than 280 ± 54 mg/L, with output concentrations lower than 100 ± 19 mg/L throughout the study period (see Figure 4b). As it may be expected, TN presents similar remove efficiencies at the outlets of the VFCWs and the HUSB, although it is slightly higher in the last one, as it shown in Table 4 and Table 5. This is so because in both the HUSB and the VFCWs the nitrification-denitrification process takes place. Nevertheless, at the plant outlet (HFCW outlet) TN removal efficiency is slightly higher (60.31 ± 9.00%), as here, denitrification is improved, complementing TN removal.

Table 5.

Statistics of accumulated removal efficiencies for the horizontal flow constructed wetland (HFCW).

Finally, TP input concentrations present values higher than 47 ± 7 mg/L with output concentrations lower than 35 ± 5 mg/L (see Figure 4c). So, a TP removal efficiency of 20.45 ± 4.79% is achieved. The removal efficiency was higher at the first stage, around 30–40%, because washed gravel showed a capacity of phosphorus absorption, but once this capacity reaches the saturation level, the phosphorous removal efficiency was reduced to 20%.

Therefore, these results show high organic matter and nutrient removal efficiencies, which are higher than those obtained in CWs with forced aeration. Table 6 shows the nutrient and organic matter removal efficiencies achieved in CW depuration systems published in the literature. It is important to highlight that those removal efficiencies are associated with domestic wastewater. In contrast, in this work the nutrient and organic matter removal efficiencies are associated with wastewater with high concentrations of organic matter and nutrients.

Table 6.

Nutrient and organic matter removal efficiencies achieved in constructed wetlands (CWs) depuration system.

4. Conclusions

In this work, a wastewater depuration ecological system based on constructed wetlands designed to remove nutrients and organic matter in wastewaters from a research facility is studied. This depuration system is a hybrid constructed wetland with two processing stages: a primary treatment carried out in two parallel working hydrolytic up-flow sludge bed digesters and a secondary one made up of two vertical flow constructed wetlands alternatively used, followed by a horizontal flow constructed wetland. This depuration system combines a vertical wetland, as a nitrification system, with an internal recirculation, which carries out a denitrification process in the hydrolytic up-flow sludge bed.

This plant was installed in an animal farm for clinical trials with a population of approximately 400 equivalent inhabitants (EI). It receives high pollution load. The results obtained show the high performance of the plant in removing nutrients and organic matter. The removal efficiencies achieve 98.47 ± 0.53% at the plant outlet for TSS, 91.22 ± 2.80% for COD and 95.62 ± 2.67% for BOD5. So, this depuration system accomplishes the limits imposed in Directive 91/271/ EEC [6] for WWTPs of big urban agglomerations. With regard to nutrients, similar behaviors were observed, especially for nitrogenous compounds. NH4+ presents a removal efficiency of 61.00 ± 9.26% and NO3− and TN achieve a removal efficiency of 42.93 ± 14.00% and 60.31 ± 9.00%, respectively. Therefore, nutrient removal efficiencies higher than those obtained in CWs with forced aeration have been achieved. On the other hand, this hybrid system presents other important advantages over CWs with forced aeration related to low construction and maintenance costs and lower energy consumption requirements. Therefore, it may be considered a good alternative for wastewater treatment in small urban agglomerations, agricultural industries and livestock farms located in decentralized areas, and with a high geographical dispersion of discharge points, which are characterized by high concentrations of organic matter and nutrients and, in addition, their wastewaters present high nitrate concentrations, which could cause significant problems of eutrophication.

Author Contributions

Data curation, M.I.F.-F. and M.G.; Formal analysis, M.I.F.-F., P.T.M.d.l.V. and M.A.J.-M.; Methodology, M.I.F.-F. and P.T.M.d.l.V.; Software, M.I.F.-F. and M.G.; Validation, M.I.F.-F., P.T.M.d.l.V. and M.A.J.-M.; Writing—review & editing, M.I.F.-F., P.T.M.d.l.V. and M.A.J.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Junta de Extremadura through the Grant GR18075 of its Research Groups Support Program (co-financed by FEDER funds) and by the project 0066_IDIAQUA_6_E co-funded by the Cooperation Programmes INTERREG V-A Spain-Portugal (POCTEP) 2014-2020.

Acknowledgments

The authors would like to thanks Centro de Cirugía de Mínima Invasión Jesús Usón (CCMIJU) for their support, as it provided the data used in this work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Harrison, S.; McAree, C.; Mulville, W.; Sullivan, T. The problem of agricultural ‘diffuse’ pollution: Getting to the point. Sci. Total Environ. 2019, 677, 700–717. [Google Scholar] [CrossRef] [PubMed]

- Kill, K.; Pärn, J.; Lust, R.; Mander, Ü.; Kasak, K. Treatment efficiency of diffuse agricultural pollution in a constructed wetland impacted by groundwater seepage. Water (Switzerland) 2018, 10, 1601. [Google Scholar] [CrossRef]

- Smith, V.H.; Tilman, G.D.; Nekola, J.C. Eutrophication: Impacts of excess nutrient inputs on freshwater, marine, and terrestrial ecosystems. Environ. Pollut. 1999, 100, 179–196. [Google Scholar] [CrossRef]

- Karaouzas, I.; Smeti, E.; Vourka, A.; Vardakas, L.; Kalogianni, E. Assessing the ecological effects of water stress and pollution in a temporary river—Implications for water management. Sci. Total Environ. 2018, 618, 1591–1604. [Google Scholar] [CrossRef]

- Gallego, A.; Rodriguez, L.; Hospido, A.; Moreira, M.T.; Feijoo, G. Development of regional characterization factors for aquatic eutrophication. Int. J. Life Cycle Assess. 2010, 15, 32–43. [Google Scholar] [CrossRef]

- European Commission. Directive 91/271/EEC of 21 May 1991 Concerning Urban Wastewater Treatment. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=OJ:L:1991:135:TOC (accessed on 1 June 2020).

- Andreo-Martínez, P.; García-Martínez, N.; Almela, L. Domestic wastewater depuration using a horizontal subsurface flow constructed wetland and theoretical surface optimization: A case study under dry mediterranean climate. Water (Switzerland) 2016, 8, 434. [Google Scholar] [CrossRef]

- Dabrowski, W.; Karolinczak, B.; Malinowski, P.; Boruszko, D. Modeling of pollutants removal in subsurface vertical flow and horizontal flow constructed wetlands. Water (Switzerland) 2019, 11, 180. [Google Scholar] [CrossRef]

- Vymazal, J. Constructed Wetlands: A promising wastewater treatment system for small localities. Water 2010, 2, 530–549. [Google Scholar] [CrossRef]

- Pedescoll, A.; Corzo, A.; Álvarez, E.; García, J.; Puigagut, J. The effect of primary treatment and flow regime on clogging development in horizontal subsurface flow constructed wetlands: An experimental evaluation. Water Res. 2011, 45, 3579–3589. [Google Scholar] [CrossRef]

- Kapellakis, I.E.; Paranychianakis, N.V.; Tsagarakis, K.P.; Angelakis, A.N. Treatment of olive mill wastewater with constructed wetlands. Water (Switzerland) 2012, 4, 260–271. [Google Scholar] [CrossRef]

- Chyan, J.M.; Lin, C.J.; Lin, Y.C.; Chou, Y.A. Improving removal performance of pollutants by artificial aeration and flow rectification in free water surface constructed wetland. Int. Biodeterior. 2016, 113, 146–154. [Google Scholar] [CrossRef]

- Wu, S.; Kuschk, P.; Brix, H.; Vymazal, J.; Dong, R. Development of constructed wetlands in performance intensifications for wastewater treatment: A nitrogen and organic matter targeted review. Water Res. 2014, 57, 40–55. [Google Scholar] [CrossRef] [PubMed]

- Reyes, N.J.; Geronimo, F.K.; Kim, L.-K. Evaluation of the factors influencing the treatment performance of a livestock constructed wetland. Ecol. Eng. 2020, 149, 105811. [Google Scholar] [CrossRef]

- Butterworth, E.; Dotro, G.; Jones, M.; Richards, A.; Onunkwo, P.; Narroway, Y.; Jefferson, B. Effect of artificial aeration on tertiary nitrification in a full-scale subsurface horizontal flow constructed wetland. Ecol. Eng. 2013, 54, 236–244. [Google Scholar] [CrossRef]

- Feng, L.; Liu, Y.; Zhang, J.; Li, C.; Wu, H. Dynamic variation in nitrogen removal of constructed wetlands modified by biochar for treating secondary livestock effluent under varying oxygen supplying conditions. J. Environ. Managem. 2020. [Google Scholar] [CrossRef]

- Álvarez, J.A.; Ruíz, I.; Soto, M. Anaerobic digesters as a pretreatment for constructed wetlands. Ecol. Eng. 2008, 33, 54–67. [Google Scholar] [CrossRef]

- Vymazal, J. Horizontal sub-surface flow and hybrid constructed wetlands systems for wastewater treatment. Ecol. Eng. 2005, 25, 478–490. [Google Scholar] [CrossRef]

- Chen, Z.J.; Tian, Y.H.; Zhang, Y.; Song, B.R.; Li, H.C.; Chen, Z.H. Effects of root organic exudates on rhizosphere microbes and nutrient removal in the constructed wetlands. Ecol. Eng. 2016, 92, 243–250. [Google Scholar] [CrossRef]

- Hua, G.; Kong, J.; Ji, Y.; Li, M. Influence of clogging and resting processes on flow patterns in vertical flow constructed wetlands. Sci. Total Environ. 2018, 621, 1142–1150. [Google Scholar] [CrossRef]

- .Rousseau, P.; Steyer, J.P.; Volcke, F.I.P.; Bernet, N.; Béline, F. Combined anaerobic digestion and biological nitrogen removal for piggery wastewater treatment: A modelling approach. Water Sci. Technol. 2008, 58, 133–141. [Google Scholar] [CrossRef] [PubMed]

- Díez-Montero, R.; De Florio, L.; González-Viar, M.; Herrero, M.; Tejero, I. Performance evaluation of a novel anaerobic-anoxic sludge blanket reactor for biological nutrient removal treating municipal wastewater. Bioresour. Technol. 2016, 209, 195–204. [Google Scholar] [CrossRef] [PubMed]

- García-Ávila, F.; Patiño-Chávez, J.; Zhinín-Chimbo, F.; Donoso-Moscoso, S.; Flores del Pino, L.; Avilés-Añazco, A. Performance of Phragmites Australis and Cyperus Papyrus in the treatment of municipal wastewater by vertical flow subsurface constructed wetlands. Int. Soil Water Conserv. Res. 2019, 7, 286–296. [Google Scholar] [CrossRef]

- Korboulewsky, N.; Wang, R.; Baldy, V. Purification processes involved in sludge treatment by a vertical flow wetland system: Focus on the role of the substrate and plants on N and P removal. Bioresour. Technol. 2012, 105, 9–14. [Google Scholar] [CrossRef] [PubMed]

- Vymazal, J.; Kropfelová, L. Growth of Phragmites australis and Phalaris arundinacea in constructed wetlands for wastewater treatment in the Czech Republic. Ecol. Eng. 2005, 25, 606–621. [Google Scholar] [CrossRef]

- Abdelhakeem, S.G.; Aboulroos, S.A.; Kamel, M.M. Performance of a vertical subsurface flow constructed wetland under different operational conditions. J. Adv. Res. 2016, 7, 803–814. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, X.; Zhao, N.; Shen, Z.; Wang, M.; Guo, Y.; Xu, Y. Effect of aeration modes and influent COD/N ratios on the nitrogen removal performance of vertical flow constructed wetland. Ecol. Eng. 2013, 57, 10–16. [Google Scholar] [CrossRef]

- Al-Mashaqbeh, O.A.; Ghrair, A.M.; Megdal, S.B. Grey water reuse for agricultural purposes in the Jordan valley: Household survey results in Deir Alla. Water (Switzerland) 2012, 4, 580–596. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater; APHA: San Diego, CA, USA, 1995. [Google Scholar]

- ISO/IEC 17025:2017. General Requirements for the Competence of Testing and Calibration Laboratories; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- Vel, M.; Vadivelu, Z.Y.; Fux, C.; Keller, J. The inhibitory effects of nitrite on the energy generation and growth processes o fan enriched Nitrpbacter culture. Environ. Sci. Technol. 2006, 40, 4442–4448. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).