Effect of Inlet/Outlet Configuration on Water Quality in a Rainwater Harvesting Tank

Abstract

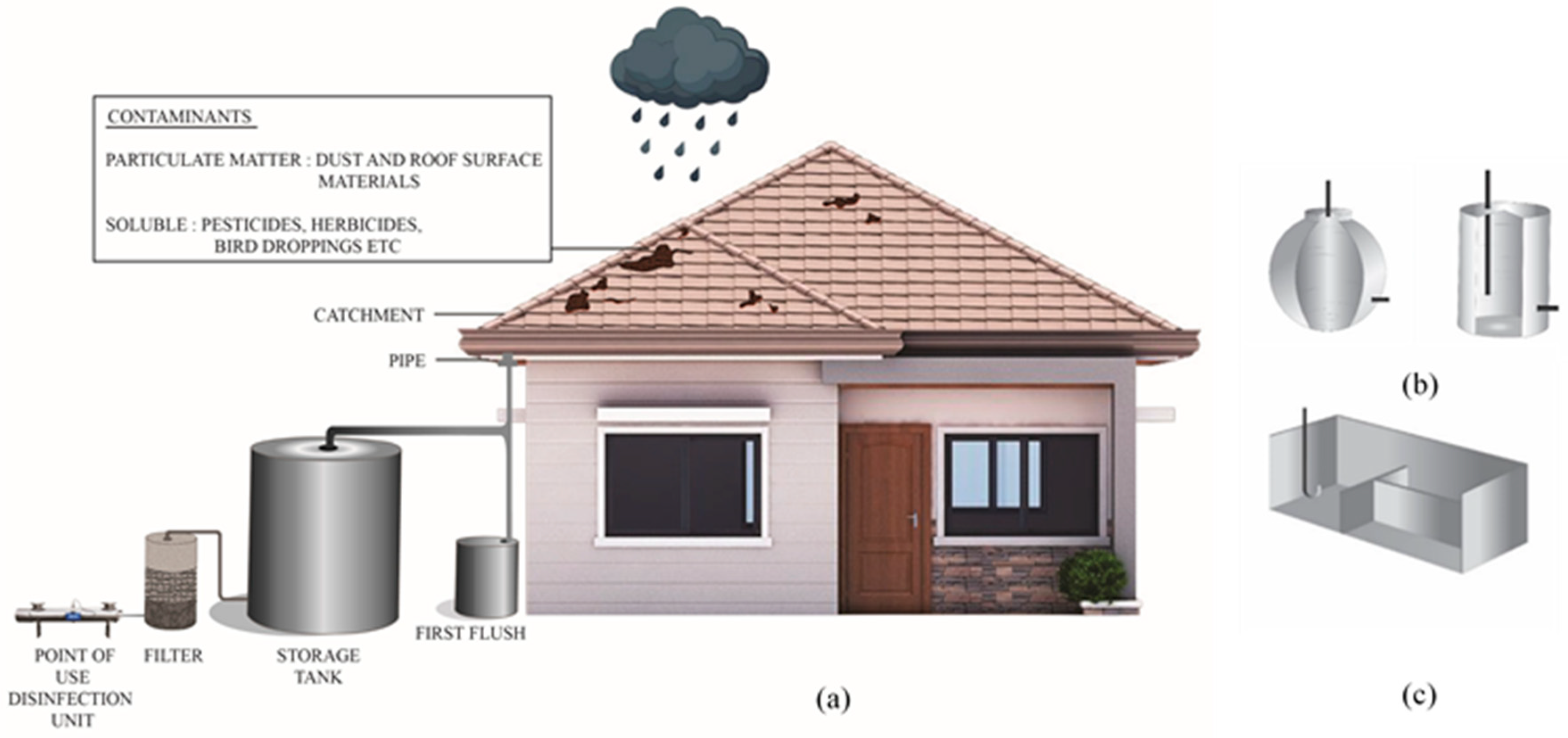

1. Introduction

2. Materials and Methods

2.1. Experimental Method

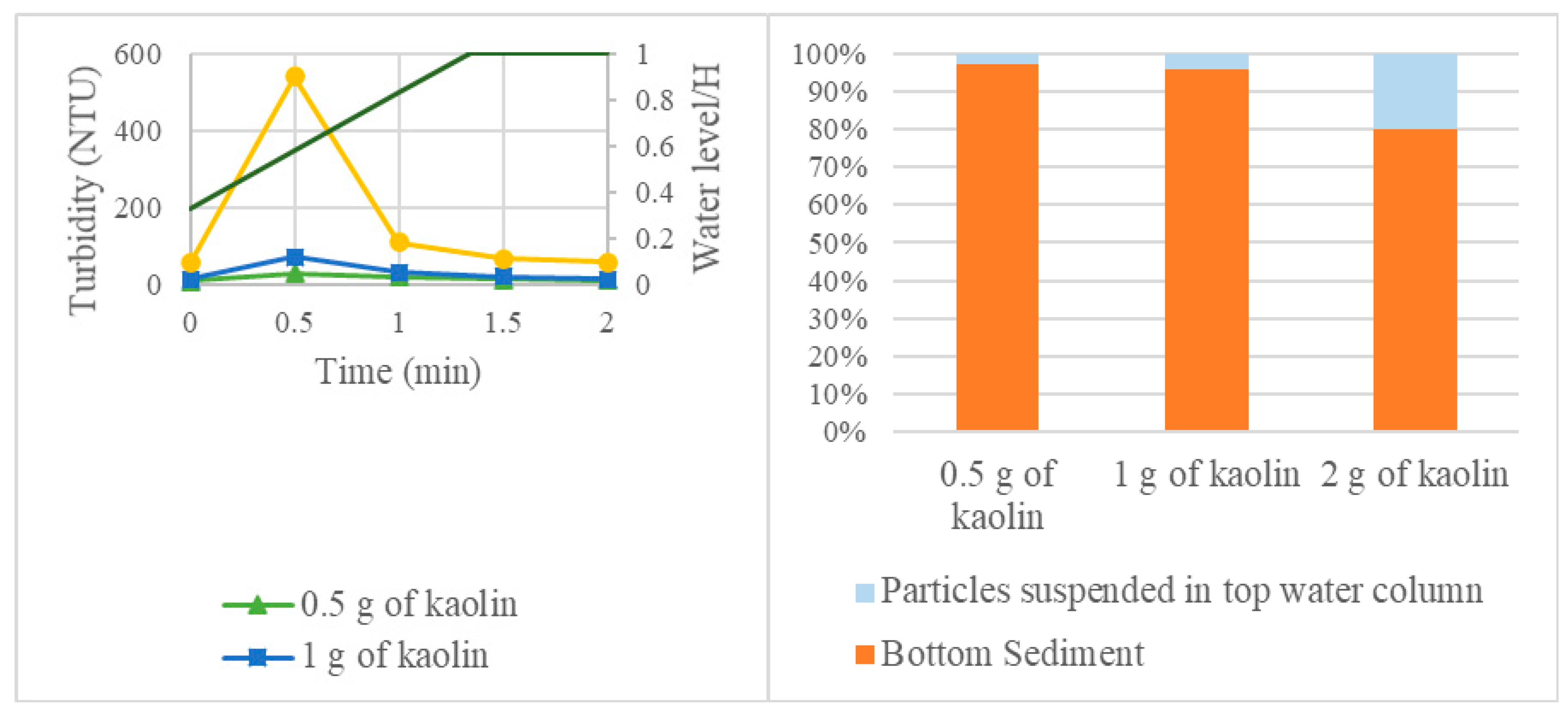

2.1.1. Sediment Resuspension Experiment

2.1.2. Pulse Conservative Tracer Experiment

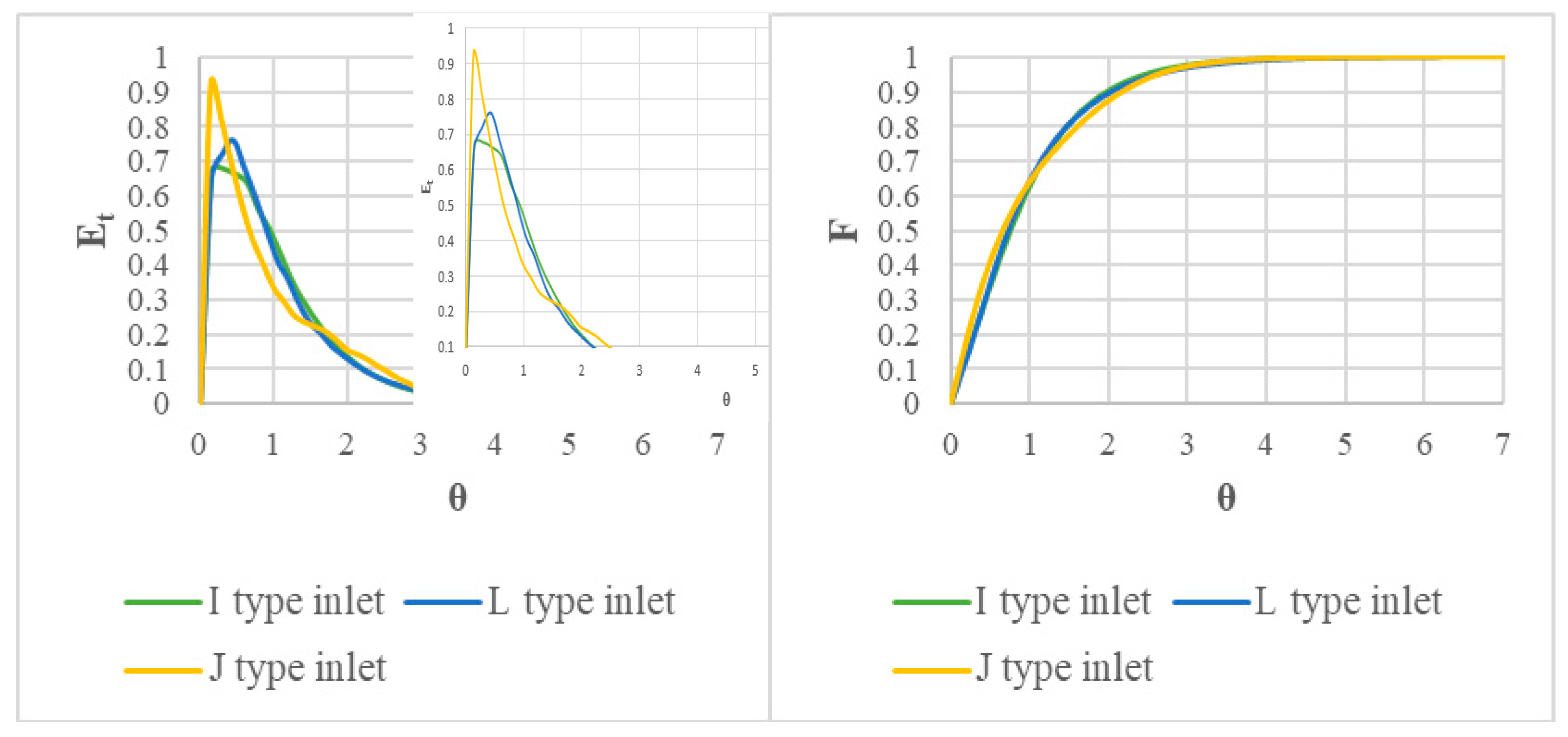

2.2. Analysis Method: Residence Time Distribution (RTD)

3. Results and Discussion

3.1. Effect of Inlet Type

3.2. Effect of Inlet Height

3.3. Effect of Flow Rate

3.4. Effect of Outlet Height and Initial Water Level

3.5. Effect of Bottom Sediment

3.6. Proposed Tank Design/Modifications

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- WHO/UNICEF. Joint Monitoring Programme (JMP) Report; WHO: Geneva, Switzerland; UNICEF: New York, NY, USA, 2014. [Google Scholar]

- UNICEF. Committing to Child Survival: A Promise Renewed—Progress Report; UNICEF: New York, NY, USA, 2014. [Google Scholar]

- Won, Y.; Han, M.; Park, H.; Kim, M. Optimal rainwater tank design for control of particulate contaminants. Water Sci. Tech.-Water Sup. 2019, 19, 574–579. [Google Scholar] [CrossRef]

- Coombes, P.J.; Kuczera, G.; Kalma, J.D.; Argue, J.R. An evaluation of the benefits of source control measures at the regional scale. Urb. Water 2002, 4, 307–320. [Google Scholar] [CrossRef]

- Coombes, P.J.; Kuczera, G.; Kalma, J.D.; Dunstan, R.H. Rainwater quality from roofs, tanks and hot water systems at Figtree Place. In Proceedings of the 3rd International Hydrology and Water Resource Symposium, Perth, Australia, 20–23 November 2000; pp. 1042–1047. [Google Scholar]

- Campisano, A.; Butler, D.; Ward, S.; Burns, M.J.; Friedler, E.; DeBusk, K.; Fisher-Jeffes, L.N.; Ghisi, E.; Rahman, A.; Furumai, H.; et al. Urban rainwater harvesting systems: Research, implementation and future perspectives. Water Res. 2017, 121, 195–209. [Google Scholar] [CrossRef] [PubMed]

- Simmons, G.; Hope, V.; Lewis, G.; Whitmore, J.; Wanzhen, G. Contamination of potable roof collected rainwater in Auckland, New Zealand. Water Res. 2001, 35, 1518–1524. [Google Scholar] [CrossRef]

- Sanchez, A.S.; Cohim, E.; Kalid, R.A. A review on physiochemical and microbiological contamination of roof-harvested rainwater in urban areas. Sustain. Water Qual. Ecol. 2015, 6, 119–137. [Google Scholar] [CrossRef]

- Han, M.Y.; Saleh, H.I.; Lee, I.Y.; Kim, Y.J. Characterization of harvested rainwater quality from Seoul city-Korea. In Proceedings of the 8th International Water Technology Conference, Alexandria, Egypt, 26–28 March 2004. [Google Scholar]

- Lee, J.Y.; Bak, G.; Han, M. Quality of roof-harvested rainwater—Comparison of different roofing materials. Environ. Pollut. 2012, 162, 422–429. [Google Scholar] [CrossRef] [PubMed]

- Spinks, A.T.; Coombes, P.; Dunstan, R.H.; Kuczera, G. Water quality treatment processes in domestic rainwater harvesting systems. In Proceedings of the 28th International Hydrology and Water Resources Symposium: About Water, Barton, ACT, Australia, 1 January 2003; Boyd, M.J., Ball, J.E., Babister, M.K., Green, J., Eds.; Institution of Engineers: Kolkata, India; pp. 2227–2234, ISBN 0858240602. [Google Scholar]

- Van Metre, P.C.; Mahler, B.J. The contribution of particles washed from rooftops to contaminant loading to urban streams. Chemosphere 2003, 52, 1727–1742. [Google Scholar] [CrossRef]

- Thomas, T. The limitations of roofwater harvesting in developing countries. Waterlines 2014, 33, 139–145. [Google Scholar] [CrossRef]

- Egodawatta, P.; Thomas, E.; Goonetilleke, A. Understanding the physical processes of pollutant build-up and wash-off on roof surfaces. Sci. Total Environ. 2009, 407, 1834–1841. [Google Scholar] [CrossRef] [PubMed]

- Spinks, A.; Berghout, B.; Dunstan, R.; Coombes, P.; Kuczera, G. Tank sludge as a sink for bacterial and heavy metal contaminants and its capacity for settlement, re-suspension and flocculation enhancement. In Proceedings of the 12th International Rainwater Catchment Systems Association Conference, New Delhi, India, 15–18 November 2005. [Google Scholar]

- Scott, R.; Waller, D. water quality analysis of a rainwater cistern system in Nova Scotia, Canada. In Proceedings of the 3rd International Rainwater Collection System Association Conference. Section F: Water Quality, Khon Kaen, Thailand, 14–16 January 1987; pp. 1–16. [Google Scholar]

- Master Plumbers and Mechanical Services Association of Australia. Rainwater Tank Design and Installation Handbook; Standards Australia: Sydney, NSW, Australia, 2008. [Google Scholar]

- Novak, C.A.; Van Giesen, E.; DeBusk, K.M. Designing Rainwater Harvesting Systems: Integrating Rainwater into Building Systems, Reprint; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; ISBN 978-1-118-41047-9. [Google Scholar]

- Haq, S.A. Harvesting Rainwater from Buildings, Reprint; Springer International Publishing: Berlin, Germany, 2018; ISBN 978-3-319-46362-9. [Google Scholar]

- Younos, T.; Parece, T.E. Sustainable Water Management in Urban Environments, the Handbook of Environmental Chemistry; Springer: Berlin, Germany, 2016; Volume 47, pp. 209–231. ISBN 978-3-319-29337-0. [Google Scholar]

- Magyar, M.; Ladson, T.; Mitchell, V.; Diaper, C. The effect of rainwater tank design on outlet water quality. Aust. J. Water Res. 2011, 15, 71–84. [Google Scholar]

- Amos, C.; Rahman, A.; Gathenya, J. Economic analysis and feasibility of rainwater harvesting systems in urban and peri-urban environments: A review of the global situation with a special focus on Australia and Kenya. Water 2016, 8, 149. [Google Scholar] [CrossRef]

- Kahinda, J.M.; Taigbenu, A.E. Rainwater harvesting in South Africa: Challenges and opportunities. Phys. Chem. Earth Parts A/B/C 2011, 36, 968–976. [Google Scholar] [CrossRef]

- Pe Plus- Products- Water Tanks. Available online: http://www.peplus.lk/products/watertanks.html (accessed on 29 May 2020).

- Housing and Building Research Institute. Bangladesh National Building Code; Housing and Building Research Institute: Dhaka, Bangladesh, 2011.

- Daejung Chemicals & Metals, South Korea. Available online: http://www.daejungchem.co.kr/main/main.asp (accessed on 7 November 2019).

- Ministry of Land, Infrastructure and Transport. Korea Precipitation Frequency Data; Ministry of Land, Infrastructure and Transport: Sejong, Korea, 2016. [Google Scholar]

- Benjamin, M.; Lawler, M.; Desmond, F. Continuous Flow Reactors: Hydraulic Characteristics. In Water Quality Engineering: Physical/Chemical Treatment Processes, 1st ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; pp. 29–70. ISBN 978-1-118-16965-0. [Google Scholar]

- Maus, C.; Uhl, M. Tracer studies for the modelling of sedimentation tanks. In Proceedings of the Seventh International Conference on Sustainable Techniques and Strategies in Urban Water Management, Lyon, France, 27 June–1 July 2010; GRAIE: Lyon, France, 2010. [Google Scholar]

- Werner, T.M.; Kadlec, R.H. Application of residence time distributions to stormwater treatment systems. Ecol. Eng. 1996, 7, 213–234. [Google Scholar] [CrossRef]

| Experiment | Parameter Investigated | Inlet Type | Inlet Height/H | Flow Rate (L/min) | Initial Water Level/H | Amount of Kaolin Settled after 24 h (g) | Outlet Height/H |

|---|---|---|---|---|---|---|---|

| Sediment resuspension | Effect of inlet type | I, L, J | 0.25 | 1.5 | 0.33 | 2 | 0.33 |

| Effect of inlet height | J | 0.1, 0.25, 0.5 | 1.5 | 0.33 | 2 | 0.33 | |

| Effect of flow rate | J | 0.25 | 1.5, 2, 2.5 | 0.33 | 2 | 0.33 | |

| Effect of initial water height | J | 0.25 | 1.5 | 0.33, 0.5, 0.75 | 2 | 0.33 | |

| Effect of amount of bottom sediment | J | 0.25 | 1.5 | 0.33 | 0.5, 1, 2 | 0.33 | |

| Tracer test | Effect of inlet type | I, L, J | 0.25 | 1.5 | 0.33 | - | 0.33 |

| Effect of inlet height | J | 0.1, 0.25, 0.5 | 1.5 | 0.33 | - | 0.33 | |

| Effect of flow rate | J | 0.25 | 1.5, 2.2 | 0.33 | - | 0.33 | |

| Effect of outlet height | J | 0.25 | 1.5 | 0.33 | - | 0.33, 0.6 |

| Time (min) | Conductivity (µS/cm) | Concentration (mg/L) | Δti | Ck | θ | Et | F |

|---|---|---|---|---|---|---|---|

| 0.25 | 1146.0 | 453.45 | 0.25 | 457.98 | 0.15 | 0.67 | 0.10 |

| 0.50 | 1149.0 | 454.95 | 0.25 | 454.20 | 0.31 | 0.67 | 0.21 |

| 0.75 | 1129.0 | 444.95 | 0.25 | 449.95 | 0.47 | 0.66 | 0.32 |

| 1.00 | 1095.0 | 427.95 | 0.25 | 436.45 | 0.63 | 0.63 | 0.42 |

| 1.25 | 988.4 | 374.65 | 0.25 | 401.30 | 0.78 | 0.55 | 0.51 |

| 1.50 | 908.0 | 334.45 | 0.25 | 354.55 | 0.94 | 0.49 | 0.60 |

| 1.75 | 804.3 | 282.60 | 0.25 | 308.52 | 1.10 | 0.42 | 0.67 |

| 2.0 | 702.0 | 231.45 | 0.25 | 257.02 | 1.26 | 0.34 | 0.73 |

| 2.25 | 624.9 | 192.90 | 0.25 | 212.17 | 1.42 | 0.28 | 0.78 |

| 2.50 | 556.8 | 158.85 | 0.25 | 175.88 | 1.58 | 0.24 | 0.83 |

| 2.75 | 498.9 | 129.90 | 0.25 | 144.38 | 1.74 | 0.19 | 0.86 |

| 3.00 | 446.3 | 103.60 | 0.25 | 166.75 | 1.89 | 0.15 | 0.89 |

| 3.25 | 408.0 | 84.45 | 0.25 | 94.03 | 2.05 | 0.13 | 0.91 |

| 3.50 | 373.1 | 67.00 | 0.25 | 75.73 | 2.21 | 0.10 | 0.93 |

| 3.75 | 348.4 | 54.65 | 0.25 | 60.83 | 2.37 | 0.08 | 0.94 |

| 4.00 | 327.3 | 44.10 | 0.25 | 49.38 | 2.53 | 0.07 | 0.95 |

| 4.25 | 309.5 | 35.20 | 0.25 | 39.65 | 2.68 | 0.05 | 0.96 |

| 4.50 | 295.6 | 28.25 | 0.25 | 31.72 | 2.84 | 0.04 | 0.97 |

| 4.75 | 284.5 | 22.70 | 0.25 | 25.48 | 3.00 | 0.03 | 0.98 |

| 5.00 | 274.6 | 17.75 | 0.25 | 20.22 | 3.16 | 0.03 | 0.98 |

| Inlet Type | σ2 (min2) | Mass Recovery % | θ at 95% Mass Recovery | |

|---|---|---|---|---|

| I | 2.45 | 2.49 | 99.13 | 2.52 |

| L | 2.53 | 2.92 | 97.85 | 2.59 |

| J | 2.89 | 3.51 | 93.09 | 2.64 |

| Outlet Height | σ2 (min2) | |

|---|---|---|

| 0.33 H | 1.9 | 2.51 |

| 0.6 H | 2.4 | 4.92 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dissanayake, J.; Han, M. Effect of Inlet/Outlet Configuration on Water Quality in a Rainwater Harvesting Tank. Water 2020, 12, 1970. https://doi.org/10.3390/w12071970

Dissanayake J, Han M. Effect of Inlet/Outlet Configuration on Water Quality in a Rainwater Harvesting Tank. Water. 2020; 12(7):1970. https://doi.org/10.3390/w12071970

Chicago/Turabian StyleDissanayake, Janith, and Mooyoung Han. 2020. "Effect of Inlet/Outlet Configuration on Water Quality in a Rainwater Harvesting Tank" Water 12, no. 7: 1970. https://doi.org/10.3390/w12071970

APA StyleDissanayake, J., & Han, M. (2020). Effect of Inlet/Outlet Configuration on Water Quality in a Rainwater Harvesting Tank. Water, 12(7), 1970. https://doi.org/10.3390/w12071970