State and Strategy of Production, Market and Integrated Management of Mineral Water, South Korea

Abstract

1. Introduction

2. Materials and Methods

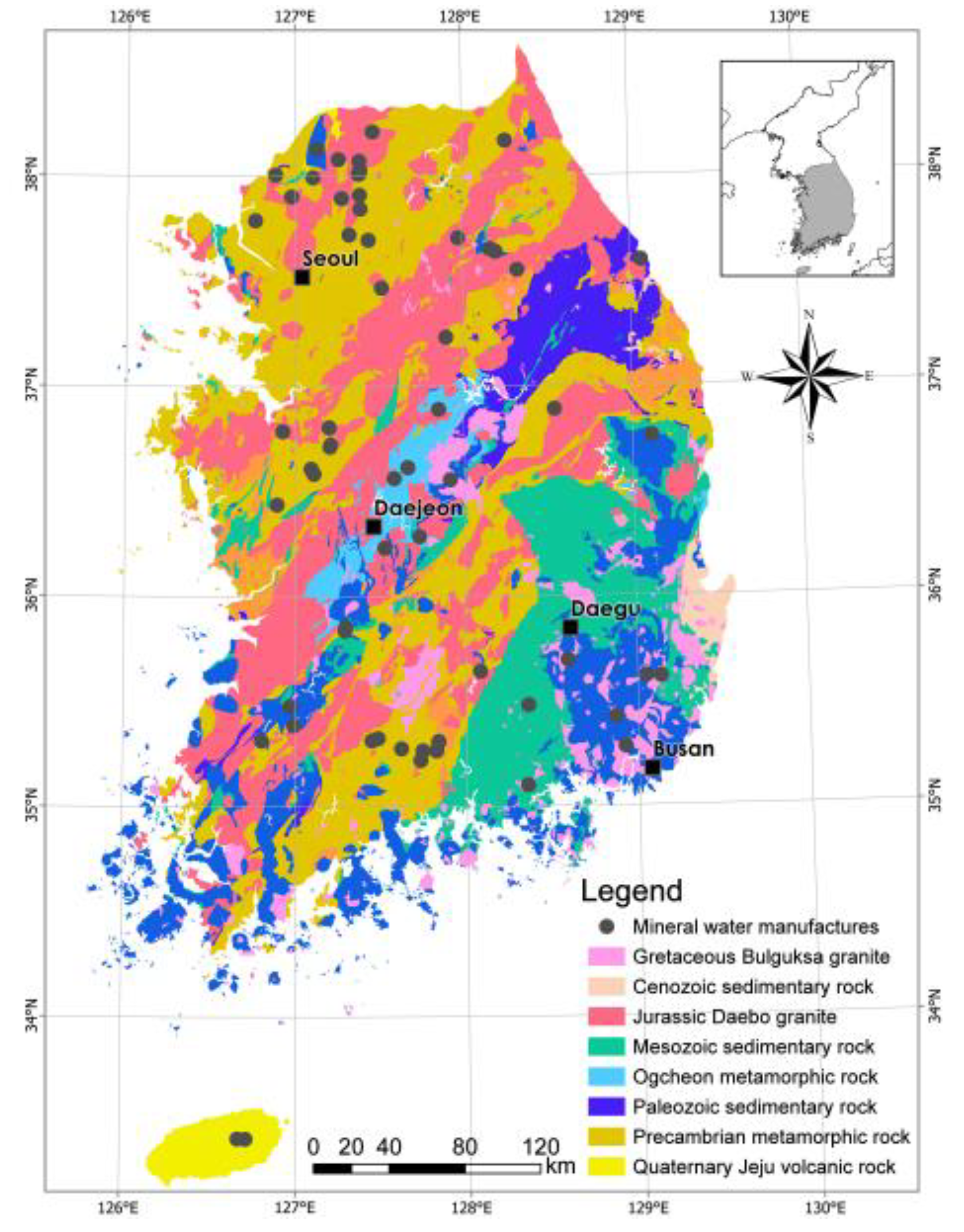

2.1. Geological Settings of Mineral Water Manufacturers

2.2. Database Preparation

2.3. Statistical Methods

2.4. Integrated Management

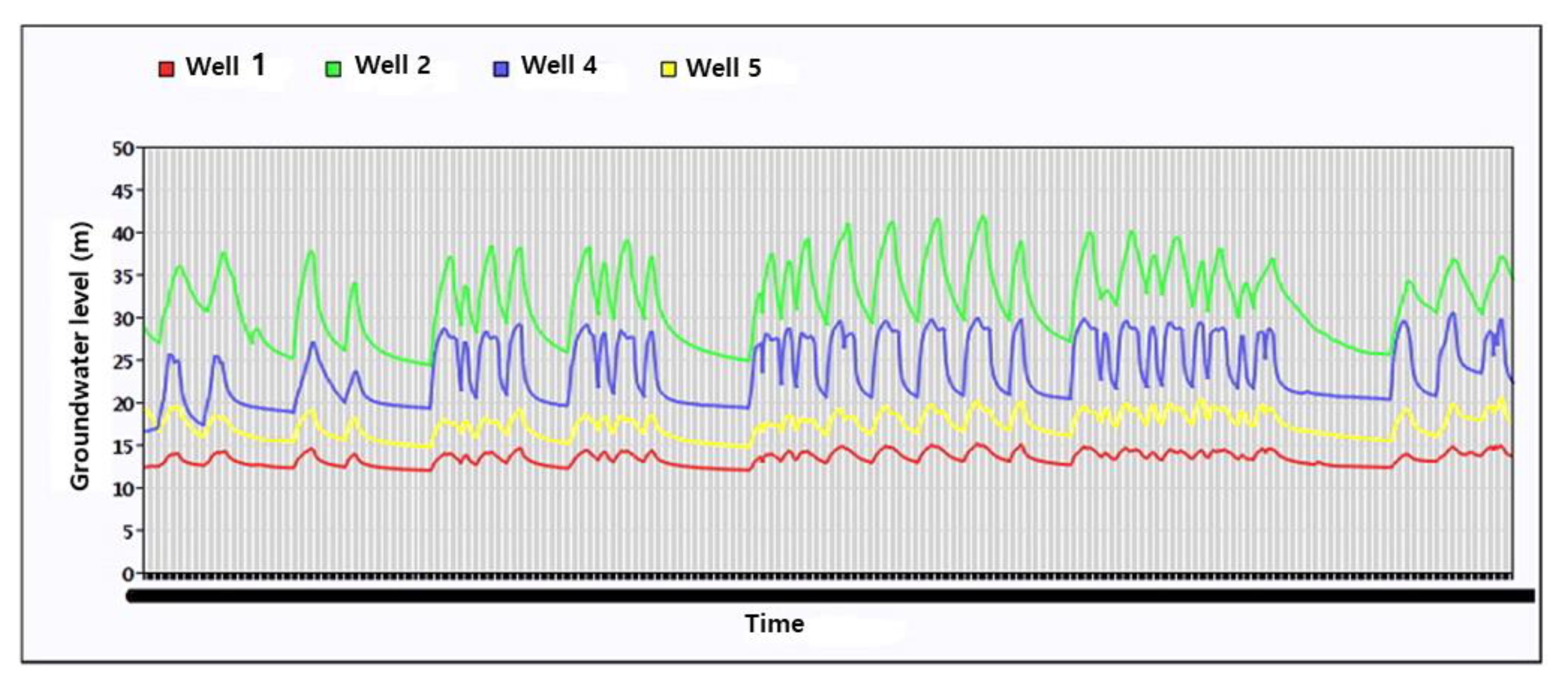

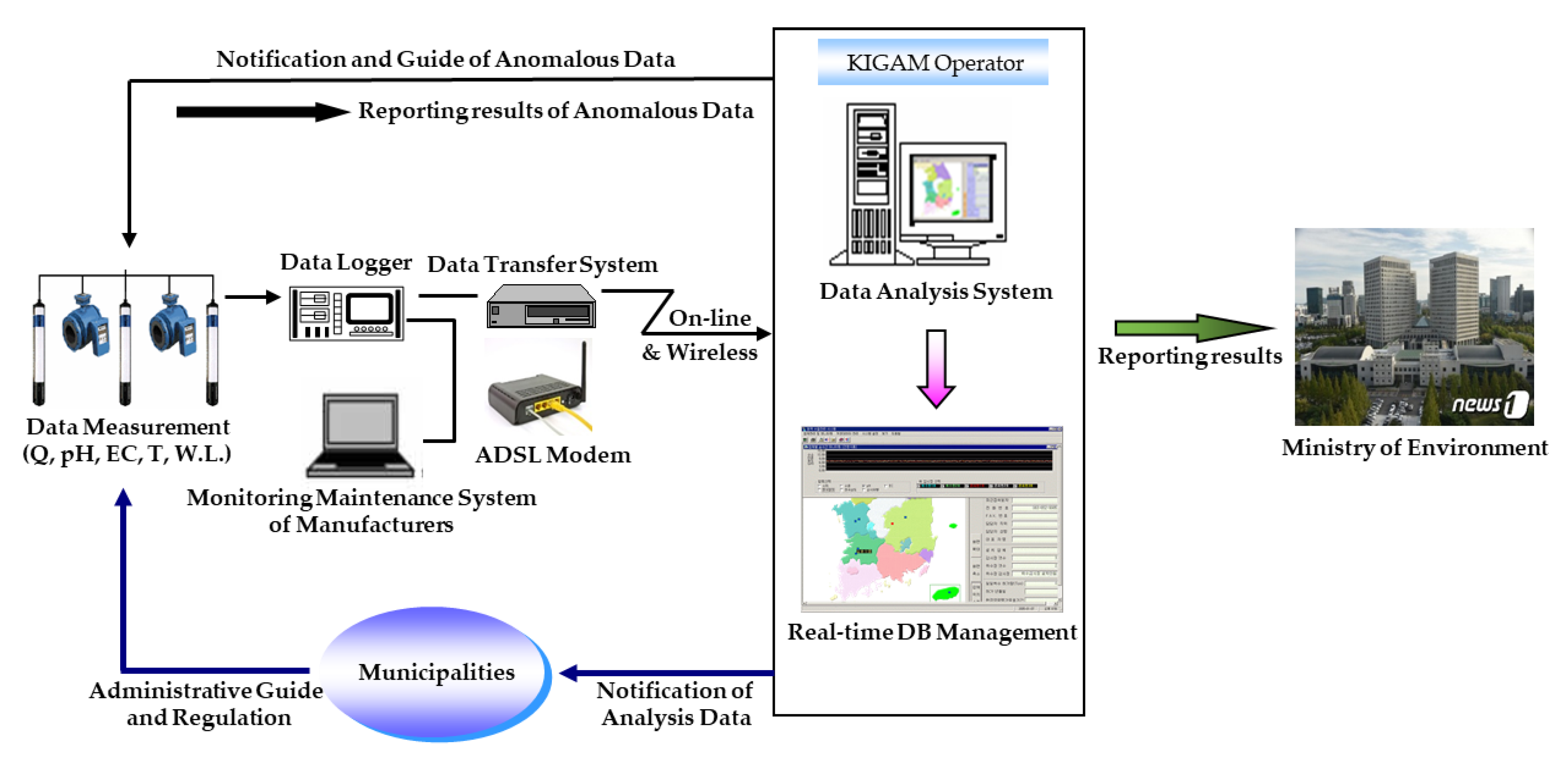

2.4.1. Acquisition and Transmission of Mineral Water Data

2.4.2. IMS Design

2.5. Uncertainties and Shortcomings

3. Results and Discussion

3.1. Chemical Characteristics of Mineral Water

3.1.1. pH Value

3.1.2. Electrical Conductivity (EC)

3.1.3. Temperature

3.1.4. Cation Concentration

3.1.5. Anion Concentrations

3.2. Permission and Production Amounts of Mineral Water

3.3. Market of Mineral Water

3.4. Integrated Management System of the Mineral Water

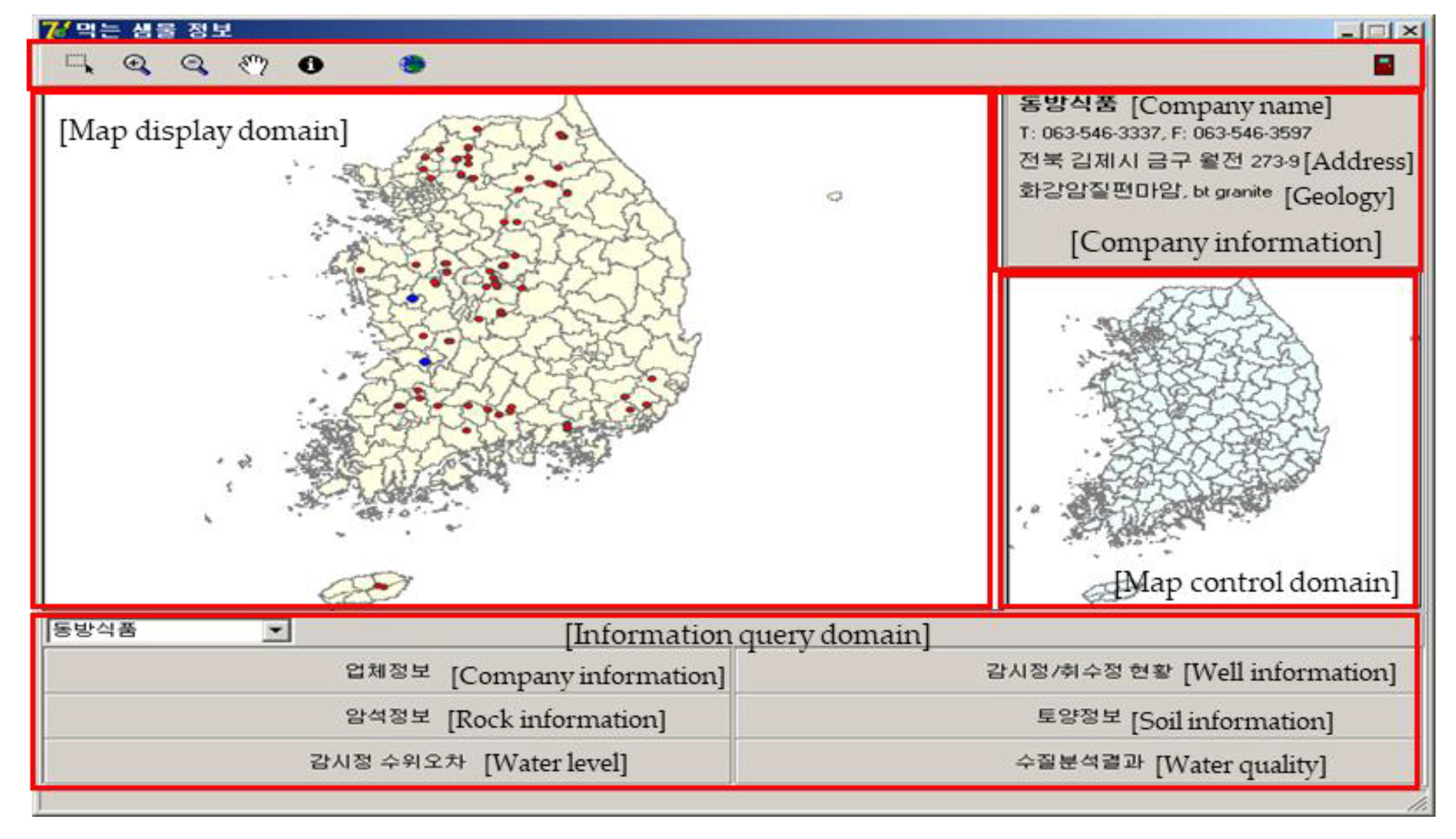

3.4.1. IMS Building

3.4.2. Information Query

3.4.3. Assessment of IMS

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Baba, A.; Erees, F.S.; Hıçsönmez, Ü.; Çam, S.; Özdılek, H.G. An assessment of the quality of various bottled mineral water marketed in Turkey. Environ. Monit. Assess. 2007, 139, 277–285. [Google Scholar] [CrossRef]

- Lee, B.D. Integrated management system of natural mineral water information. In Proceedings of the Korea Society of Engineering Geology Conference, Gyeongju, Korea, 8 April 2010; pp. 8–9. [Google Scholar]

- Ministry of Environment (MOE). Drinking Water Management Act. Ministry of Environment of Korea. Legislation 17091. Available online: http://www.law.go.kr/LSW/lsLinkProc.do?&lsNm=%EB%A8%B9%EB%8A%94%EB%AC%BC%EA%B4%80%EB%A6%AC%EB%B2%95&chrClsCd=010202&mode=20&ancYnChk=0# (accessed on 21 February 2020).

- Ministry of Environment (MOE). A Study on Characterization Plan of Natural Mineral Water; Ministry of Environment: Sejong, Korea, 2011.

- Ministry of Environment (MOE). Management System of Natural Mineral Water (III); Ministry of Environment: Seoul, Korea, 2000.

- Lee, B.-D.; Oh, Y.-H.; Cho, B.W.; Yun, U.; Choo, C.-O. Hydrochemical properties of groundwater used for korea bottled waters in relation to geology. Water 2019, 11, 1043. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Yi, M.-J.; Yoo, Y.-K.; Ahn, K.-H.; Kim, G.-B.; Won, J.-H. A review of the national groundwater monitoring network in Korea. Hydrol. Process. 2007, 21, 907–919. [Google Scholar] [CrossRef]

- Lee, C.-M.; Hamm, S.-Y.; Jeon, H.-T.; Kim, M.; Kim, H.-K.; Kim, K. Water policy of korea for supplying safe groundwater in rural areas. Water 2017, 9, 508. [Google Scholar] [CrossRef]

- Turek, A.; Kim, C.-B. U-Pb zircon ages fro Precambrian rocks in southwestern Ryeongnam and southeastern Gyeonggi massifs Korea. Geochem. J. 1996, 30, 231–249. [Google Scholar] [CrossRef]

- Jwa, Y.-J. Possible source rocks of Mesozoic granites in South Korea: Implications for crustal evolution in NE Asia. Trans. R. Soc. Edinb. Earth Sci. 2004, 95, 181–198. [Google Scholar] [CrossRef]

- Uchida, E.; Choi, S.; Baba, D.; Wakisaka, Y. Petrogenesis and solidification depth of the Jurassic Daebo and Cretaceous Bulguksa granitic rocks in South Korea. Resour. Geol. 2012, 62, 281–295. [Google Scholar] [CrossRef]

- Tsusue, A.; Mizuta, T.; Watanabe, M.; Min, K.G. Jurassic and Cretaceous granitic rocks in South Korea. Min. Geol. 1984, 31, 261–280. [Google Scholar]

- Cho, M.; Cheong, W.; Ernst, W.; Yi, K.; Kim, J. SHRIMP U-Pb ages of detrital zircons in metasedimentary rocks of the central Ogcheon fold-thrust belt, Korea: Evidence for tectonic assembly of Paleozoic sedimentary protoliths. J. Asian Earth Sci. 2013, 63, 234–249. [Google Scholar] [CrossRef]

- Oh, C.W.; Kim, S.W.; Ryu, I.-C.; Okada, T.; Hyodo, H.; Itaya, T. Tectono-metamorphic evolution of the Okcheon Metamorphic Belt, South Korea: Tectonic implications in East Asia. Isl. Arc. 2004, 13, 387–402. [Google Scholar] [CrossRef]

- Brenna, M.; Cronin, S.; Smith, I.; Sohn, Y.K.; Maaß, R. Spatio-temporal evolution of a dispersed magmatic system and its implications for volcano growth, Jeju Island Volcanic Field, Korea. Lithos 2012, 148, 337–352. [Google Scholar] [CrossRef]

- Sohn, Y.K.; Park, K.H. Early-stage volcanism and sedimentation of Jeju Island revealed by the Sagye borehole, SW Jeju Island, Korea. Geosci. J. 2004, 8, 73–84. [Google Scholar] [CrossRef]

- Won, J.-H.; Lee, J.-Y.; Kim, J.-W.; Koh, G.-W. Groundwater occurrence on Jeju Island, Korea. Hydrogeol. J. 2005, 14, 532–547. [Google Scholar] [CrossRef]

- Won, J.-H.; Kim, J.-W.; Koh, G.-W.; Lee, J.-Y. Evaluation of hydrogeological characteristics in Jeju Island, Korea. Geosci. J. 2005, 9, 33–46. [Google Scholar] [CrossRef]

- Subramani, T.; Elango, L.; Damodarasamy, S.R. Groundwater quality and its suitability for drinking and agricultural use in Chithar River Basin, Tamil Nadu, India. Environ. Earth Sci. 2005, 47, 1099–1110. [Google Scholar] [CrossRef]

- Garg, V.K.; Suthar, S.; Singh, S.; Sheoran, A.; Nagpal, G.; Meenakshi; Jain, S. Drinking water quality in villages of southwestern Haryana, India: Assessing human health risks associated with hydrochemistry. Environ. Earth Sci. 2008, 58, 1329–1340. [Google Scholar] [CrossRef]

- Wu, H.; Chen, J.; Qian, H.; Zhang, X. Chemical characteristics and quality assessment of groundwater of exploited aquifers in Beijiao Water Source of Yinchuan, China: A case study for drinking, irrigation, and industrial purposes. J. Chem. 2015, 2015, 1–14. [Google Scholar] [CrossRef]

- Fournier, R.O.; Rowe, J.J. The solubility of amorphous silica in water at high temperatures and high pressures. Am. Mineral. 1977, 62, 1052–1056. [Google Scholar]

- Rimstidt, J. Quartz solubility at low temperatures. Geochim. Cosmochim. Acta 1997, 61, 2553–2558. [Google Scholar] [CrossRef]

- Rimstidt, J.; Barnes, H. The kinetics of silica-water reactions. Geochim. Cosmochim. Acta 1980, 44, 1683–1699. [Google Scholar] [CrossRef]

- Drever, J.I. The Geochemisty of Natural Waters, 2nd ed.; Prentice-Hall: Englewood Cliffs, NJ, USA, 1988. [Google Scholar]

- Ministry of Environment (MOE). Standard for Drinking Water Quality. Ministry of Environment of Korea. Legislation 792 (acted on 1 January 2019). Available online: http://www.law.go.kr/%20lsInfoP.do?%20urlMode=laInfoP&lsId=007134#0000 (accessed on 15 January 2020).

- Guo, F.; Jiang, G. Nitrogen budget of a typical subterranean river in peak cluster karst area. Environ. Earth Sci. 2009, 58, 1741–1748. [Google Scholar] [CrossRef]

- Wu, L.; Peng, C.; Zhang, S.; Peng, Y. Nitrogen removal via nitrite from municipal landfill leachate. J. Environ. Sci. 2009, 21, 1480–1485. [Google Scholar] [CrossRef]

- Jeju Province Development CO. The Story of Jeju Sandasoo; Design Leader Jeju: Jeju, Korea, 2019. [Google Scholar]

- The Korea Herald. Available online: http://www.koreaherald.com/view.php?ud=20170614000848 (accessed on 10 February 2020).

| Samples | K | Na | Ca | Mg | SiO2 | F | Cl | SO4 | NO3-N | HCO3 | EC | pH | T (°C) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PMR1 | 0.63 | 2.07 | 5.49 | 1.02 | 6.97 | 0.17 | 1.81 | 4.90 | 1.67 | 19.32 | 57.40 | 7.34 | 8.03 |

| PMR2 | 2.26 | 3.31 | 9.63 | 1.62 | 8.80 | 0.12 | 4.50 | 10.04 | 4.06 | 17.08 | 108.42 | 7.43 | 9.92 |

| PMR3 | 1.12 | 8.98 | 20.06 | 5.39 | 21.70 | 0.60 | 8.52 | 7.06 | 0.90 | 95.74 | 166.96 | 7.76 | 17.38 |

| PMR4 | 0.64 | 2.92 | 8.24 | 1.91 | 15.47 | 0.08 | 1.92 | 2.19 | 0.79 | 39.14 | 76.83 | 7.76 | 14.10 |

| PMR5 | 0.57 | 5.18 | 21.53 | 1.23 | 13.50 | 0.59 | 3.38 | 5.03 | 0.86 | 79.30 | 142.50 | 7.77 | 13.75 |

| PMR6 | 1.63 | 14.10 | 48.84 | 7.82 | 26.47 | 0.96 | 3.75 | 14.43 | 0.18 | 197.25 | 349.53 | 7.00 | 14.41 |

| PMR7 | 1.20 | 17.80 | 37.43 | 3.46 | 16.13 | 0.69 | 14.57 | 30.67 | 0.33 | 110.56 | 303.50 | 6.99 | 15.88 |

| PMR8 | 0.85 | 9.47 | 24.34 | 0.73 | 12.20 | 1.12 | 3.79 | 13.11 | 0.89 | 91.01 | 179.46 | 7.74 | 12.95 |

| PMR9 | 0.76 | 5.12 | 5.36 | 1.15 | 24.78 | 0.12 | 1.55 | 1.63 | 0.46 | 35.84 | 70.20 | 6.95 | 13.70 |

| PMR10 | 0.97 | 4.25 | 6.78 | 1.06 | 15.84 | 0.15 | 2.48 | 5.48 | 2.57 | 26.84 | 73.22 | 6.59 | 12.05 |

| PMR11 | 1.67 | 8.55 | 23.46 | 5.79 | 27.44 | 0.28 | 4.03 | 3.16 | 0.47 | 121.41 | 202.02 | 6.65 | 15.30 |

| PMR12 | 0.83 | 3.69 | 8.70 | 2.99 | 9.77 | 0.05 | 2.38 | 8.38 | 0.63 | 41.18 | 86.53 | 7.39 | 9.85 |

| PMR13 | 1.91 | 10.73 | 24.00 | 5.72 | 29.23 | 0.19 | 5.83 | 7.19 | 0.91 | 118.95 | 232.70 | 6.87 | 15.00 |

| PMR14 | 1.39 | 13.08 | 25.04 | 5.00 | 32.50 | 0.25 | 8.34 | 8.90 | 1.98 | 98.88 | 228.26 | 6.93 | 14.92 |

| PMR15 | 1.08 | 6.88 | 24.27 | 4.35 | 15.40 | 0.12 | 2.99 | 11.75 | 0.01 | 99.63 | 173.40 | 7.54 | 17.80 |

| PMR16 | 0.90 | 6.13 | 14.23 | 1.65 | 14.90 | 0.12 | 3.45 | 13.18 | 0.19 | 54.30 | 128.38 | 7.21 | 14.68 |

| PMR17 | 1.68 | 5.08 | 14.16 | 2.17 | 13.34 | 0.49 | 1.83 | 8.45 | 1.05 | 62.70 | 120.94 | 7.92 | 14.28 |

| PMR18 | 2.06 | 6.03 | 19.00 | 1.70 | 19.90 | 0.15 | 3.4 | 11.0 | 0.25 | 76 | 157 | 7.57 | 16 |

| PMR19 | 0.84 | 4.25 | 9.92 | 1.04 | 17.67 | 0.19 | 2.60 | 3.75 | 1.44 | 46.26 | 102.30 | 8.13 | 17.33 |

| PMR20 | 0.79 | 3.84 | 7.33 | 0.90 | 20.64 | 0.13 | 1.56 | 2.48 | 0.68 | 28.68 | 59.22 | 7.24 | 15.86 |

| PMR21 | 2.03 | 10.80 | 21.76 | 5.10 | 32.36 | 0.35 | 5.68 | 6.92 | 0.96 | 108.34 | 207.02 | 6.79 | 15.58 |

| PMR22 | 0.49 | 4.83 | 4.33 | 0.41 | 8.73 | 0.27 | 1.51 | 6.08 | 0.16 | 23.64 | 55.76 | 7.33 | 11.93 |

| PMR23 | 1.13 | 5.46 | 13.95 | 12.23 | 7.19 | 0.19 | 3.31 | 9.46 | 1.02 | 101.31 | 202.24 | 7.70 | 14.32 |

| PMR24 | 0.75 | 8.87 | 26.46 | 4.17 | 17.84 | 0.12 | 8.19 | 12.34 | 0.42 | 100.35 | 206.38 | 7.27 | 14.32 |

| PMR25 | 2.75 | 9.93 | 27.00 | 5.14 | 19.88 | 0.67 | 4.62 | 8.38 | 0.51 | 122.00 | 234.33 | 7.33 | 16.00 |

| PMR26 | 2.67 | 16.16 | 34.64 | 3.71 | 21.60 | 1.03 | 9.21 | 10.71 | 0.01 | 148.23 | 271.00 | 7.61 | 17.18 |

| MG1 | 1.06 | 2.86 | 13.50 | 3.40 | 9.19 | 0.73 | 1.4 | 6.8 | 1.58 | 55 | 154 | 7.07 | - |

| MG2 | 0.44 | 9.98 | 7.67 | 1.20 | 41.76 | 0.12 | 3.19 | 4.21 | 0.08 | 41.42 | 87.42 | 7.10 | 17.93 |

| MG3 | 0.51 | 17.39 | 17.84 | 5.65 | 11.24 | 0.65 | 3.66 | 14.81 | 1.98 | 113.22 | 221.42 | 8.19 | 14.63 |

| MG4 | 0.81 | 9.46 | 25.73 | 1.79 | 23.74 | 0.30 | 3.83 | 8.14 | 0.49 | 106.15 | 208.66 | 7.19 | 15.36 |

| MG5 | 0.82 | 6.76 | 10.07 | 1.52 | 25.56 | 0.42 | 4.31 | 2.91 | 0.67 | 49.29 | 103.26 | 7.96 | 16.15 |

| MG6 | 0.58 | 16.74 | 19.34 | 1.57 | 22.10 | 1.65 | 4.58 | 4.64 | 0.93 | 92.72 | 191.36 | 7.10 | 13.70 |

| MG7 | 0.28 | 12.54 | 20.66 | 0.67 | 20.20 | 1.14 | 4.06 | 26.44 | 0.12 | 65.88 | 174.18 | 7.75 | 18.92 |

| MG8 | 1.06 | 8.07 | 17.34 | 2.24 | 23.26 | 0.26 | 3.80 | 12.67 | 1.94 | 62.77 | 148.20 | 6.81 | 14.65 |

| MG9 | 0.40 | 6.95 | 9.94 | 1.86 | 30.46 | 0.29 | 3.04 | 3.20 | 0.22 | 57.65 | 106.58 | 7.28 | 16.04 |

| MG10 | 0.46 | 18.70 | 34.43 | 1.51 | 22.85 | 1.18 | 23.22 | 6.15 | 0.71 | 127.34 | 198.63 | 7.56 | 16.03 |

| MG11 | 0.63 | 8.08 | 14.66 | 2.32 | 8.65 | 0.24 | 1.95 | 8.01 | 1.34 | 73.26 | 152.08 | 7.43 | 13.82 |

| MG12 | 1.67 | 4.95 | 13.10 | 4.08 | 21.10 | 0.38 | 2.5 | 5.5 | 0.62 | 59 | 120 | 7.92 | 16.7 |

| MG13 | 0.52 | 5.64 | 11.20 | 1.53 | 18.80 | 0.23 | 2.12 | 1.33 | 1.00 | 51.48 | 93.26 | 7.17 | 14.63 |

| MG14 | 0.85 | 9.52 | 17.74 | 3.43 | 30.98 | 0.34 | 4.47 | 12.17 | 1.90 | 75.95 | 161.70 | 6.57 | 14.24 |

| MG15 | 0.59 | 12.46 | 11.68 | 1.44 | 29.72 | 0.29 | 7.03 | 6.76 | 4.33 | 50.02 | 138.10 | 6.43 | 15.44 |

| MG16 | 0.41 | 17.70 | 18.30 | 0.33 | 22.13 | 1.43 | 37.30 | 2.87 | 0.10 | 34.53 | 194.48 | 7.12 | 16.23 |

| MG17 | 0.37 | 6.83 | 12.50 | 1.33 | 19.46 | 0.70 | 1.34 | 3.08 | 0.32 | 64.36 | 102.76 | 7.54 | 12.50 |

| MG18 | 1.21 | 4.63 | 11.46 | 0.89 | 16.46 | 0.33 | 1.33 | 3.12 | 0.59 | 48.19 | 86.80 | 7.74 | 14.96 |

| MG19 | 0.80 | 6.02 | 13.66 | 1.44 | 15.54 | 0.17 | 4.89 | 7.62 | 2.33 | 46.67 | 117.80 | 7.05 | 12.15 |

| MG20 | 0.11 | 5.23 | 22.50 | 0.83 | 26.70 | 0.07 | 2.3 | 40.4 | 0.04 | 38 | 142 | 7.89 | 16.8 |

| MG21 | 0.10 | 4.74 | 16.72 | 0.84 | 22.98 | 0.07 | 2.15 | 26.68 | 0.06 | 39.04 | 134.10 | 7.81 | 16.68 |

| MG22 | 0.43 | 5.25 | 12.44 | 0.95 | 18.38 | 0.85 | 2.99 | 5.88 | 1.16 | 41.48 | 100.90 | 7.14 | 13.93 |

| MG23 | 0.53 | 4.74 | 8.67 | 1.43 | 21.00 | 0.13 | 1.80 | 1.00 | 1.04 | 45.87 | 88.52 | 7.42 | 11.04 |

| OMR1 | 1.21 | 13.60 | 31.76 | 13.52 | 13.90 | 0.49 | 4.22 | 24.64 | 0.06 | 167.75 | 315.60 | 7.82 | 15.42 |

| OMR2 | 1.88 | 6.04 | 50.58 | 7.69 | 31.28 | 0.73 | 2.93 | 80.32 | 0.55 | 106.37 | 353.50 | 7.63 | 15.58 |

| OMR3 | 1.36 | 3.78 | 34.30 | 3.63 | 13.00 | 0.05 | 6.83 | 3.14 | 2.24 | 113.48 | 199.50 | 7.51 | 13.80 |

| OMR4 | 1.26 | 4.83 | 33.70 | 18.20 | 11.50 | 0.17 | 3.1 | 33.1 | 0.13 | 171 | 323 | 7.78 | 14.2 |

| OMR5 | 1.27 | 7.79 | 39.04 | 8.97 | 19.98 | 0.14 | 10.12 | 32.05 | 0.71 | 130.54 | 266.18 | 6.73 | 16.44 |

| OMR6 | 0.65 | 7.77 | 41.43 | 14.33 | 11.00 | 0.13 | 19.23 | 19.97 | 1.34 | 150.98 | 329.00 | 7.28 | 12.80 |

| OMR7 | 1.46 | 3.63 | 21.82 | 2.47 | 10.87 | 0.17 | 5.60 | 7.29 | 1.68 | 74.42 | 119.18 | 7.61 | 13.06 |

| OMR8 | 0.85 | 4.46 | 30.73 | 3.20 | 9.97 | 0.09 | 2.42 | 25.64 | 0.00 | 92.01 | 210.33 | 8.10 | 13.20 |

| OMR9 | 0.83 | 8.07 | 31.05 | 12.05 | 12.35 | 0.33 | 3.77 | 23.79 | 0.45 | 137.25 | 261.00 | 7.64 | 15.15 |

| OMR10 | 1.09 | 7.24 | 24.09 | 5.48 | 24.50 | 0.32 | 7.90 | 13.44 | 0.87 | 110.06 | 224.74 | 7.65 | 14.44 |

| OMR11 | 1.33 | 7.26 | 42.20 | 11.96 | 11.44 | 0.18 | 8.44 | 18.13 | 1.52 | 149.45 | 303.33 | 7.40 | 15.90 |

| QJV1 | 2.09 | 5.30 | 2.99 | 2.28 | 26.34 | 0.06 | 5.78 | 1.59 | 0.11 | 36.91 | 80.34 | 7.74 | 14.72 |

| QJV2 | 2.56 | 7.49 | 6.40 | 6.79 | 36.50 | 0.06 | 8.52 | 1.87 | 0.62 | 63.20 | 141.14 | 7.35 | 16.04 |

| K | Na | Ca | Mg | SiO2 | F | Cl | SO4 | NO3-N | HCO3 | EC | pH | T (°C) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PMR | Max. | 2.75 | 17.80 | 48.84 | 12.23 | 32.50 | 1.12 | 14.57 | 30.67 | 4.06 | 197.25 | 349.53 | 8.13 | 17.80 |

| Min. | 0.49 | 2.07 | 4.33 | 0.41 | 6.97 | 0.05 | 1.51 | 1.63 | 0.01 | 17.08 | 55.76 | 6.59 | 8.03 | |

| Mean | 1.29 | 7.60 | 18.69 | 3.36 | 18.09 | 0.35 | 4.43 | 8.72 | 0.90 | 79.39 | 161.37 | 7.34 | 14.33 | |

| Med. | 1.10 | 6.08 | 19.53 | 2.58 | 16.90 | 0.19 | 3.44 | 8.38 | 0.73 | 85.16 | 161.98 | 7.34 | 14.54 | |

| Std. | 0.65 | 4.20 | 11.09 | 2.72 | 7.41 | 0.31 | 3.09 | 5.76 | 0.89 | 45.00 | 80.27 | 0.41 | 2.41 | |

| MG | Max. | 1.67 | 18.70 | 34.43 | 5.65 | 41.76 | 1.65 | 37.30 | 40.40 | 4.33 | 127.34 | 221.42 | 8.19 | 18.92 |

| Min. | 0.10 | 2.86 | 7.67 | 0.33 | 8.65 | 0.07 | 1.33 | 1.00 | 0.04 | 34.53 | 86.80 | 6.43 | 11.04 | |

| Mean | 0.64 | 8.92 | 15.70 | 1.84 | 21.84 | 0.52 | 5.53 | 9.32 | 1.02 | 62.60 | 140.31 | 7.36 | 15.11 | |

| Med. | 0.58 | 6.89 | 14.16 | 1.53 | 21.60 | 0.32 | 3.31 | 6.45 | 0.81 | 56.27 | 140.20 | 7.31 | 14.96 | |

| Std. | 0.36 | 4.76 | 6.12 | 1.24 | 7.41 | 0.45 | 8.20 | 9.64 | 1.00 | 25.22 | 42.20 | 0.45 | 3.64 | |

| OMR | Max. | 1.88 | 13.60 | 50.58 | 18.20 | 31.28 | 0.73 | 19.23 | 80.32 | 2.24 | 170.80 | 353.50 | 8.10 | 16.44 |

| Min. | 0.65 | 3.63 | 21.82 | 2.47 | 9.97 | 0.05 | 2.42 | 3.14 | 0.00 | 74.42 | 119.18 | 6.73 | 12.80 | |

| Mean | 1.20 | 6.77 | 34.61 | 9.23 | 15.43 | 0.25 | 6.77 | 25.59 | 0.87 | 127.55 | 264.12 | 7.56 | 14.54 | |

| Med. | 1.26 | 7.24 | 33.70 | 8.97 | 12.35 | 0.17 | 5.60 | 23.79 | 0.71 | 130.54 | 266.18 | 7.63 | 14.44 | |

| Std. | 0.34 | 2.81 | 8.30 | 5.20 | 6.88 | 0.20 | 4.85 | 20.43 | 0.74 | 31.08 | 70.35 | 0.35 | 1.24 | |

| QJV | Max. | 2.56 | 7.49 | 6.40 | 6.79 | 36.50 | 0.06 | 8.52 | 1.87 | 0.62 | 63.20 | 141.14 | 7.74 | 16.04 |

| Min. | 2.09 | 5.30 | 2.99 | 2.28 | 26.34 | 0.06 | 5.78 | 1.59 | 0.11 | 36.91 | 80.34 | 7.35 | 14.72 | |

| Mean | 2.32 | 6.39 | 4.70 | 4.54 | 31.42 | 0.06 | 7.15 | 1.73 | 0.36 | 50.05 | 110.74 | 7.55 | 15.38 | |

| Med. | 2.32 | 6.39 | 4.70 | 4.54 | 31.42 | 0.06 | 7.15 | 1.73 | 0.36 | 50.05 | 110.74 | 7.55 | 15.38 | |

| Std. | 0.33 | 1.54 | 2.42 | 3.19 | 7.18 | 0.00 | 1.94 | 0.20 | 0.36 | 18.59 | 42.99 | 0.27 | 0.93 |

| Province | Numbers of Manufacturers | Daily Permitted Volume (m3/day) | Daily Production Amounts (m3/day) | Production Rate (%) |

|---|---|---|---|---|

| Chungbuk | 4 | 2752 | 1565 | 57 |

| Chungnam | 7 | 3969 | 982 | 25 |

| Gangwon | 8 | 3087 | 771 | 25 |

| Gyeonggi | 16 | 12,837 | 4638 | 36 |

| Gyeongbuk | 4 | 2710 | 458 | 17 |

| Gyeongnam | 11 | 8366 | 1736 | 21 |

| Jeonbuk | 3 | 2160 | 500 | 23 |

| Jeonnam | 4 | 1490 | 157 | 11 |

| Jeju | 2 | 3800 | 2948 | 78 |

| Sejong | 1 | 620 | 82 | 13 |

| Ulsan | 2 | 854 | 335 | 39 |

| Total | 62 | 42,645 | 14,172 | 33 |

| Year | Sales Volume (m3/day) | Sales Amount (Million Dollar) | Sales Volume Increase (%) | Sales Amount Increase (%) |

|---|---|---|---|---|

| 1995 | 471,514 | 60.5 | ||

| 1996 | 893,002 | 114.9 | 189.4 | 189.9 |

| 1997 | 873,678 | 87.8 | 185.3 | 145.1 |

| 1998 | 940,356 | 75.3 | 199.4 | 124.5 |

| 1999 | 1,147,982 | 106.2 | 243.5 | 175.5 |

| 2000 | 1,429,970 | 130.2 | 303.3 | 215.2 |

| 2001 | 1,851,234 | 169.1 | 392.6 | 279.5 |

| 2002 | 2,024,537 | 179.6 | 429.4 | 296.9 |

| 2003 | 1,970,204 | 156.7 | 417.8 | 259.0 |

| 2004 | 2,259,584 | 174.3 | 479.2 | 288.1 |

| 2005 | 2,441,586 | 186.6 | 517.8 | 308.4 |

| 2006 | 2,550,832 | 214.4 | 541.0 | 354.4 |

| 2007 | 2,726,058 | 231.7 | 578.1 | 383.0 |

| 2008 | 3,049,812 | 256.3 | 646.8 | 423.6 |

| 2009 | 3,251,537 | 272.4 | 689.6 | 450.2 |

| 2010 | 3,362,100 | 301.7 | 713.0 | 498.7 |

| 2011 | 3,094,669 | 357.9 | 656.3 | 591.6 |

| 2012 | 3,253,001 | 388.1 | 689.9 | 641.5 |

| 2013 | 3,543,000 | 433.3 | 751.4 | 716.2 |

| 2014 | 3,358,498 | 478.9 | 712.3 | 791.6 |

| 2015 | 3,611,683 | 535.2 | 766.0 | 884.6 |

| 2016 | 4,359,408 | 564.5 | 924.6 | 933.1 |

| 2017 | 4,711,975 | 571.9 | 999.3 | 945.3 |

| 2018 | 4,770,722 | 574.9 | 1011.8 | 950.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, B.D.; Oh, Y.H.; Kim, W.B.; Hwang, J.; Lim, W.-R.; Choi, S.-J.; Hamm, S.-Y. State and Strategy of Production, Market and Integrated Management of Mineral Water, South Korea. Water 2020, 12, 1615. https://doi.org/10.3390/w12061615

Lee BD, Oh YH, Kim WB, Hwang J, Lim W-R, Choi S-J, Hamm S-Y. State and Strategy of Production, Market and Integrated Management of Mineral Water, South Korea. Water. 2020; 12(6):1615. https://doi.org/10.3390/w12061615

Chicago/Turabian StyleLee, Byeong Dae, Yong Hwa Oh, Won Bin Kim, Jaehong Hwang, Woo-Ri Lim, Sung-Ja Choi, and Se-Yeong Hamm. 2020. "State and Strategy of Production, Market and Integrated Management of Mineral Water, South Korea" Water 12, no. 6: 1615. https://doi.org/10.3390/w12061615

APA StyleLee, B. D., Oh, Y. H., Kim, W. B., Hwang, J., Lim, W.-R., Choi, S.-J., & Hamm, S.-Y. (2020). State and Strategy of Production, Market and Integrated Management of Mineral Water, South Korea. Water, 12(6), 1615. https://doi.org/10.3390/w12061615