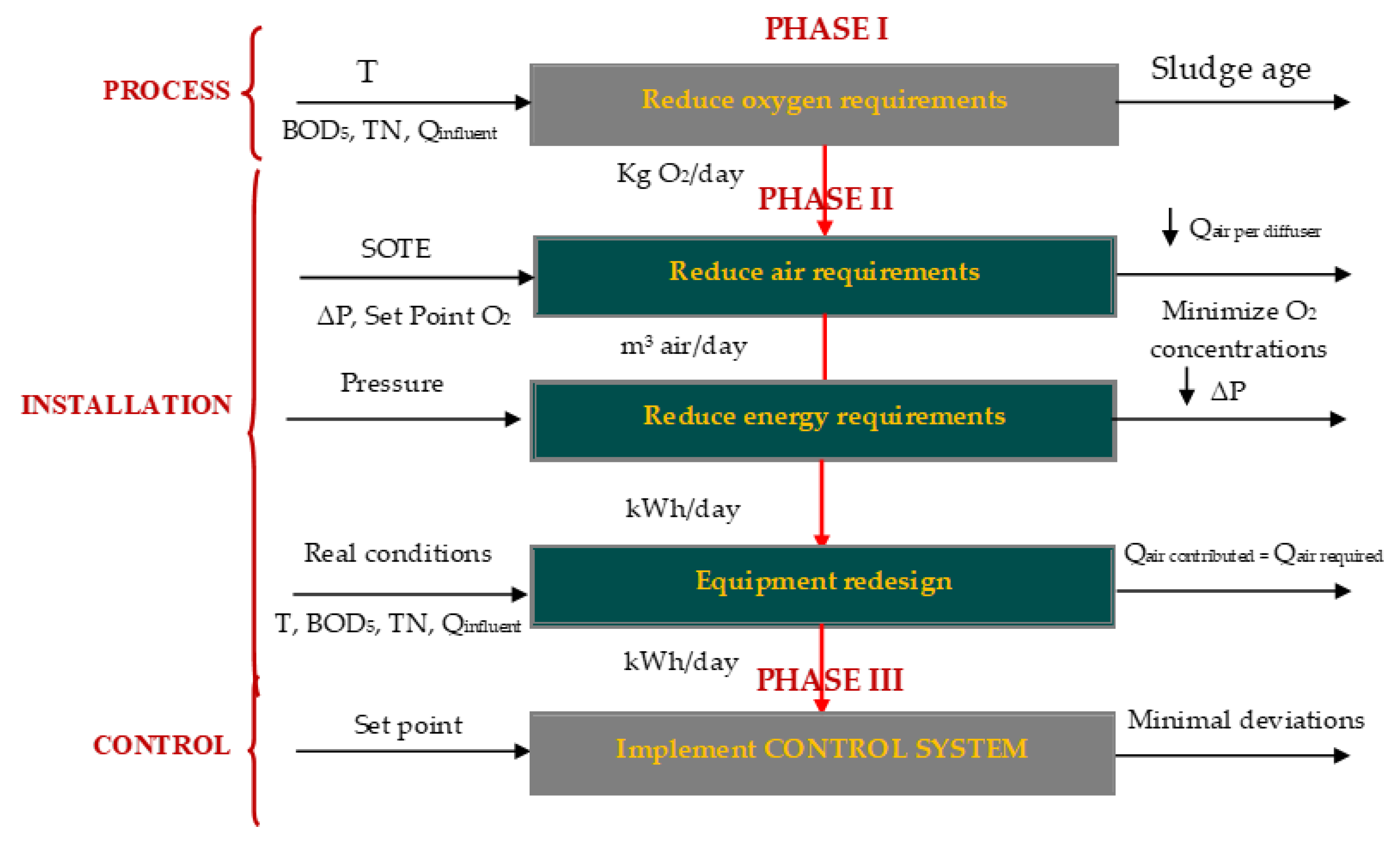

Methodology for Energy Optimization in Wastewater Treatment Plants. Phase II: Reduction of Air Requirements and Redesign of the Biological Aeration Installation

Abstract

:1. Introduction

2. Methods and Materials

2.1. Presentation of the Activated Sludge Aeration System at the San Pedro del Pinatar WWTP

- 1st anoxic chamber without diffusers and with submerged agitation.

- 2nd oxic chamber without submerged agitation, aeration, and diffuser density of 49.57%.

- 3rd oxic chamber with submerged agitation, aeration, and diffuser density of 29.06%.

- 4th oxic chamber with agitation, aeration, and diffuser density of 21.37%.

- Non-homogeneous aeration over the entire surface of the biological reactor.

- The preferential paths detected into the biological reactor.

- The deficiencies in agitation and mixing inside the biological reactor.

- The deterioration and obsolescence of the diffusers.

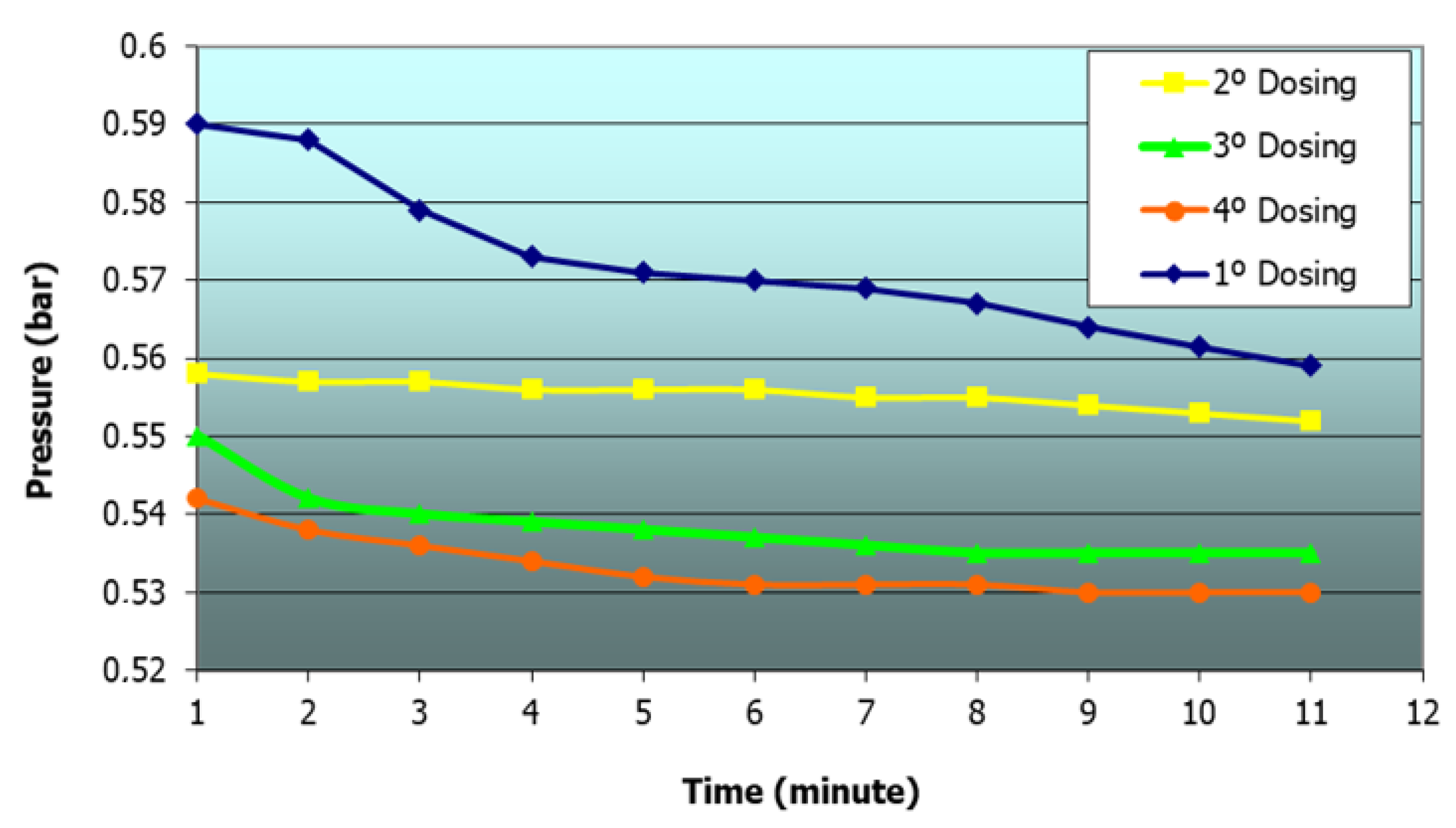

- The high pressure drops in the air line.

- The lack of adjustment of the oxygen concentration in the different oxic chambers of the biological reactor.

- The need to renew and redesign pumping and aeration equipment that does not meet real needs.

2.2. Tests for the Energy Optimization of a Biological Treatment Process

- Qinfluent is the inlet flow of wastewater to the biological reactor;

- SOTE is the oxygen transfer efficiency at standard conditions of pressure and temperature;

- ΔP is the pressure drop in air line;

- Qair is the flow of air injected into the biological reactor.

2.2.1. Step 1. Reduce Air Requirements

- ➢

- Test to select the best-operating conditions it developed in phase I [1], which consisted of working with a minimum sludge retention time (SRT) or a low concentration of solids in the suspension in the mixed liquor (MLSS).

- ➢

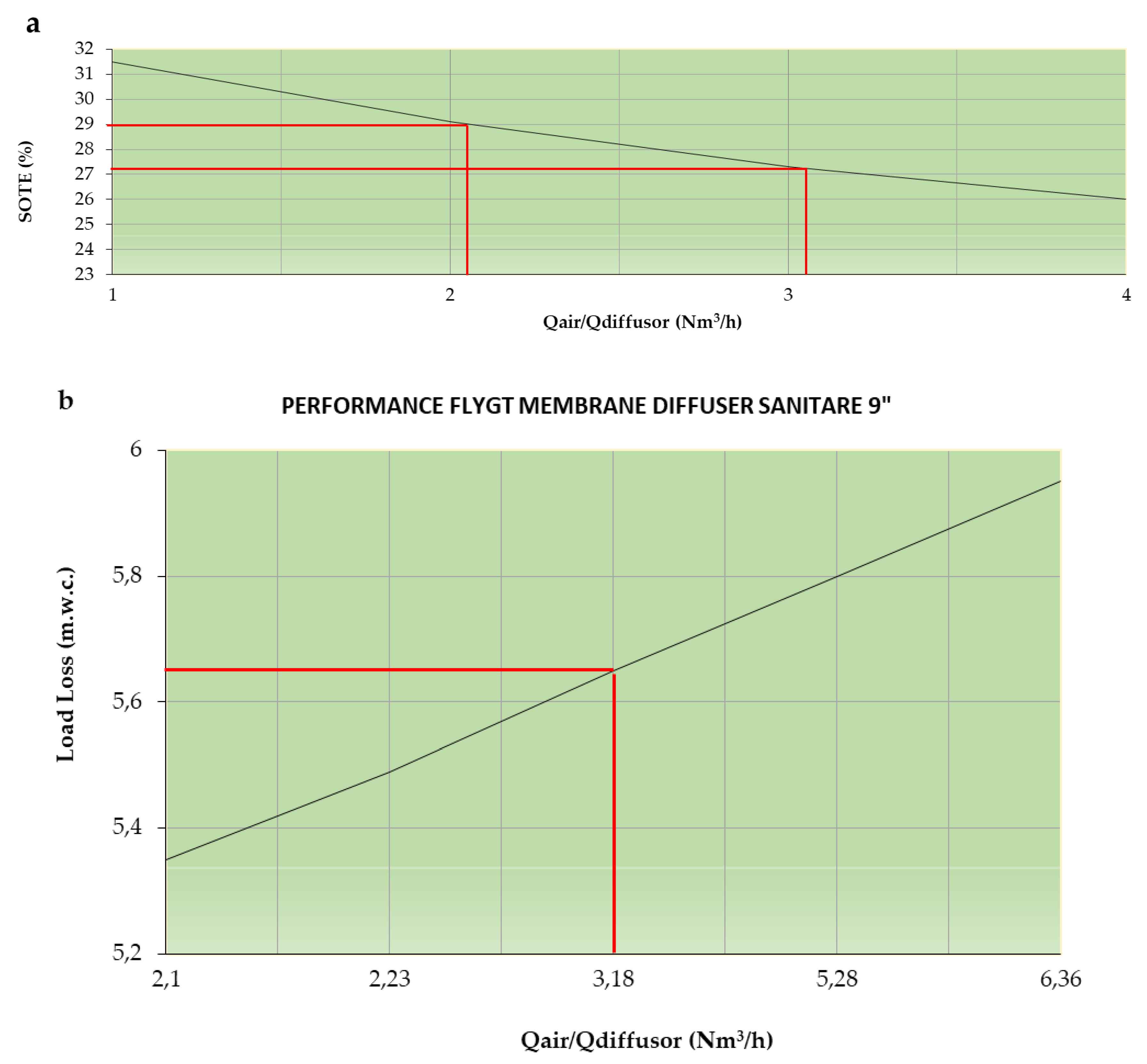

- Tests to regulate the airflow injected by the diffusers.

- Yi and Ye represent the molar fractions of oxygen (O2) at the inlet and outlet, respectively.

- YCDi and YCDe are the molar fractions of carbon dioxide (CO2) at the inlet and outlet, respectively.

- YWi and YWe represent the molar water vapor fractions at the inlet and outlet, respectively.

- β is a function of the salinity of the process water;

- Ω is a function of environmental atmospheric pressure;

- τ is a function of the process temperature.

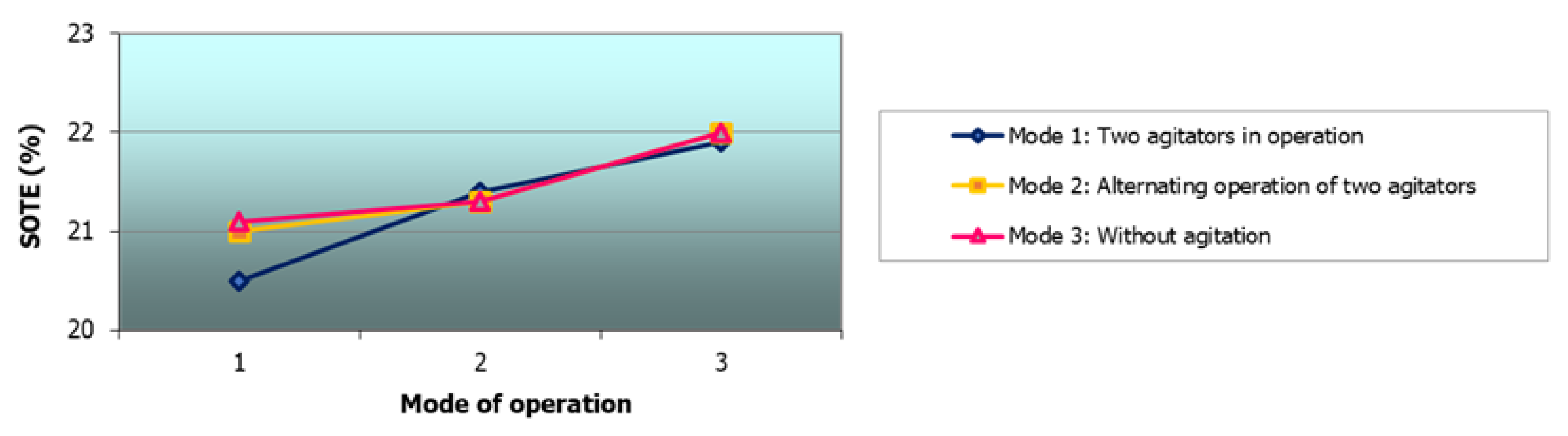

- With the agitation running continuously during the operation of the aeration blower (mode 1),

- With an alternating operation of the agitation (mode 2)

- With the submersible mixers stopped during the entire biological aeration phase (mode 3)

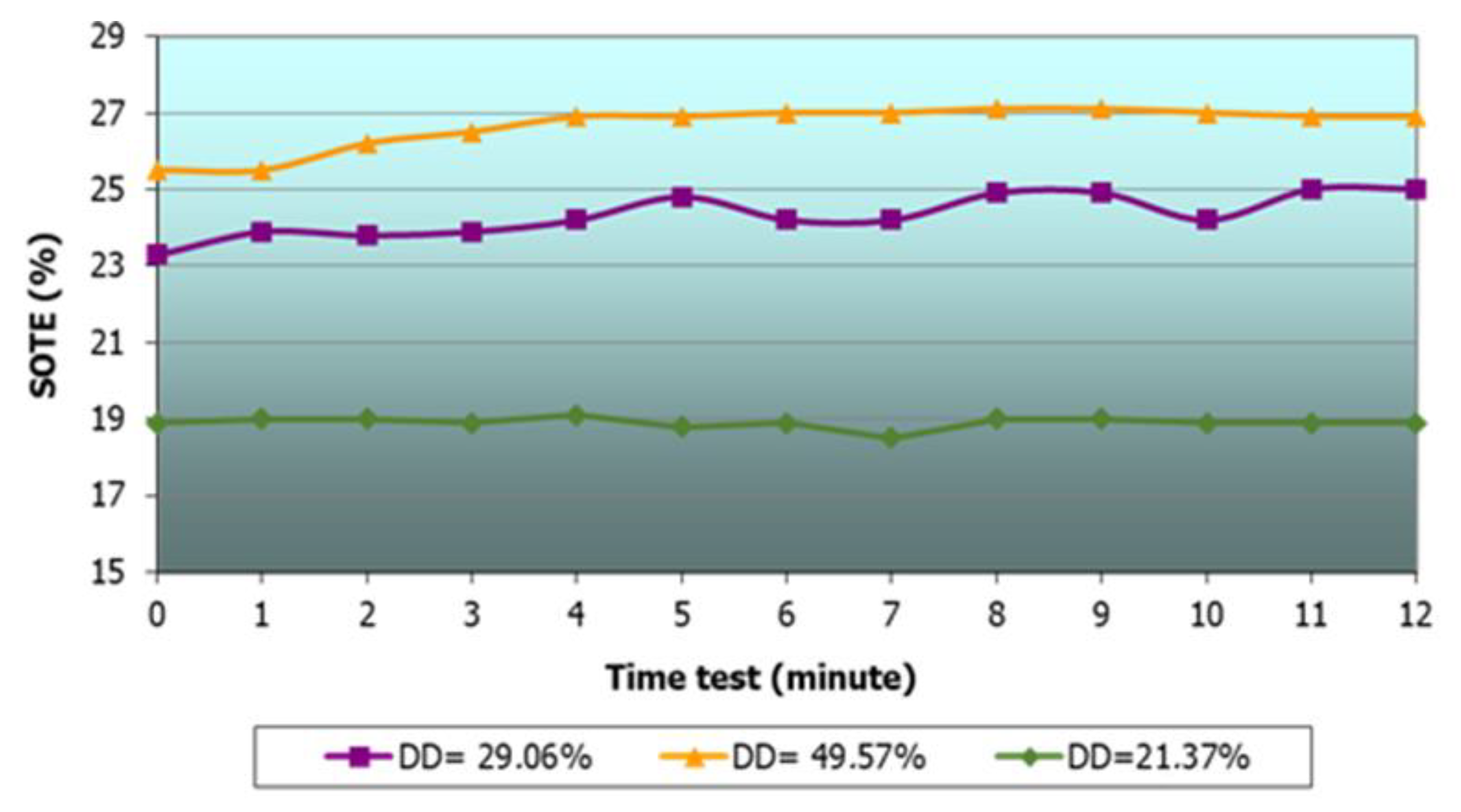

- Keeping only the air inlet line of the oxic chamber 2 open (DD = 49.57%);

- Keeping only the air inlet line of oxic chamber 3 open (DD = 29.06%);

- Keeping only the air inlet line of the oxic chamber 4 open (DD = 21.37%).

- (1)

- The geometry of the domain of the modeled fluid was defined, using the CAD computer-aided drawing software.

- (2)

- This geometry was divided into uniform cells of adequate size to obtain the necessary calculation precision.

- (3)

- The boundary conditions of the fluid domain that could affect the simulation were established. In order to make the model as close as possible to reality.

- (4)

- The specific equations for the calculation were defined according to the needs.

- (5)

- The simulation phase was started by establishing an initial solution for each cell and each variable, a value estimated on the basis of experience. From that point, the simulation began to solve the equations in an iterative way until a sufficiently adjusted final solution was obtained.

- (6)

- The last stage consisted in the visualization of the simulation and analysis of the results.

2.2.2. Step 2. Reduce Energy Requirements in the Biological Process

2.2.3. Step 3. Equipment Redesign

3. Results and Discussion

3.1. Step 1. Reduce air requirements

3.1.1. Results of Tests to Select the Best Operating Conditions

- Reduce the oxygen concentration required in biological reactors. Experimental studies by Henkel et al. [51] and Cornel et al. [58] have shown that the values of α decrease significantly as the concentrations of volatile suspended solids in the mixed liquor (MLVSS) increase, resulting in an approximately linear relationship between the two.

3.1.2. Results of Tests to Regulate the Airflow Injected through the Diffusers

3.1.3. Results of Tests to Determine the Age and Condition of Air-Injection Components

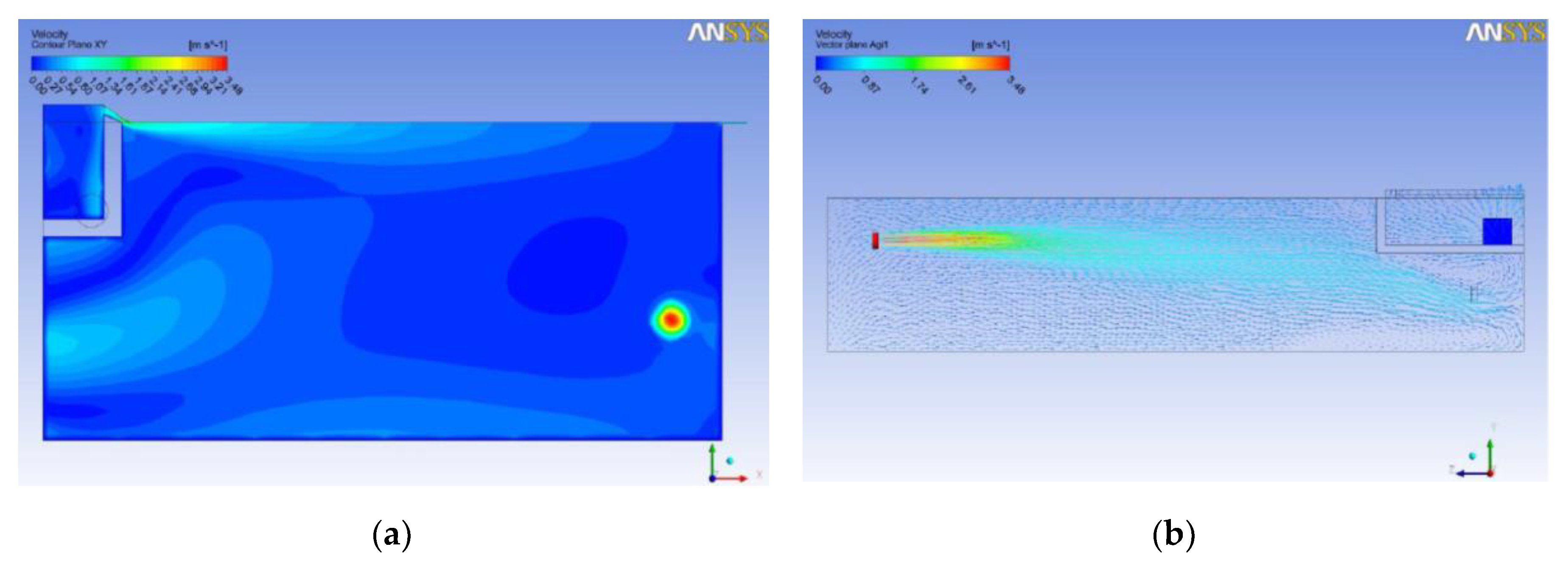

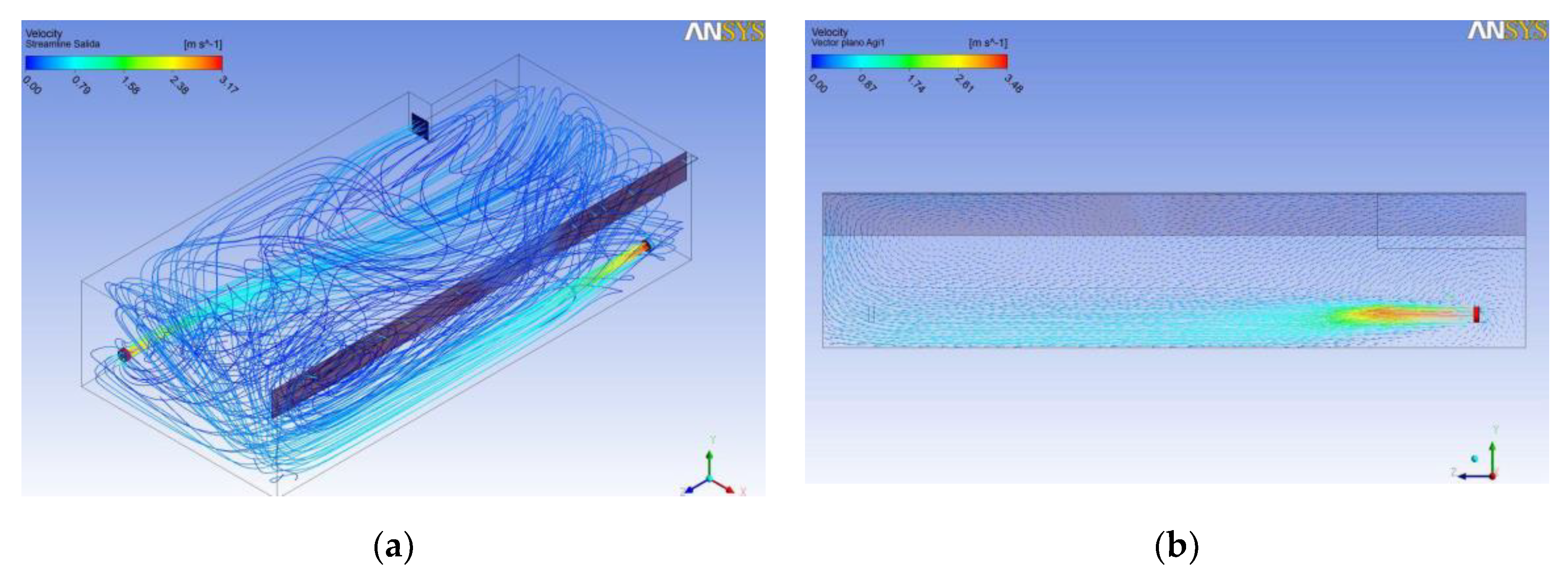

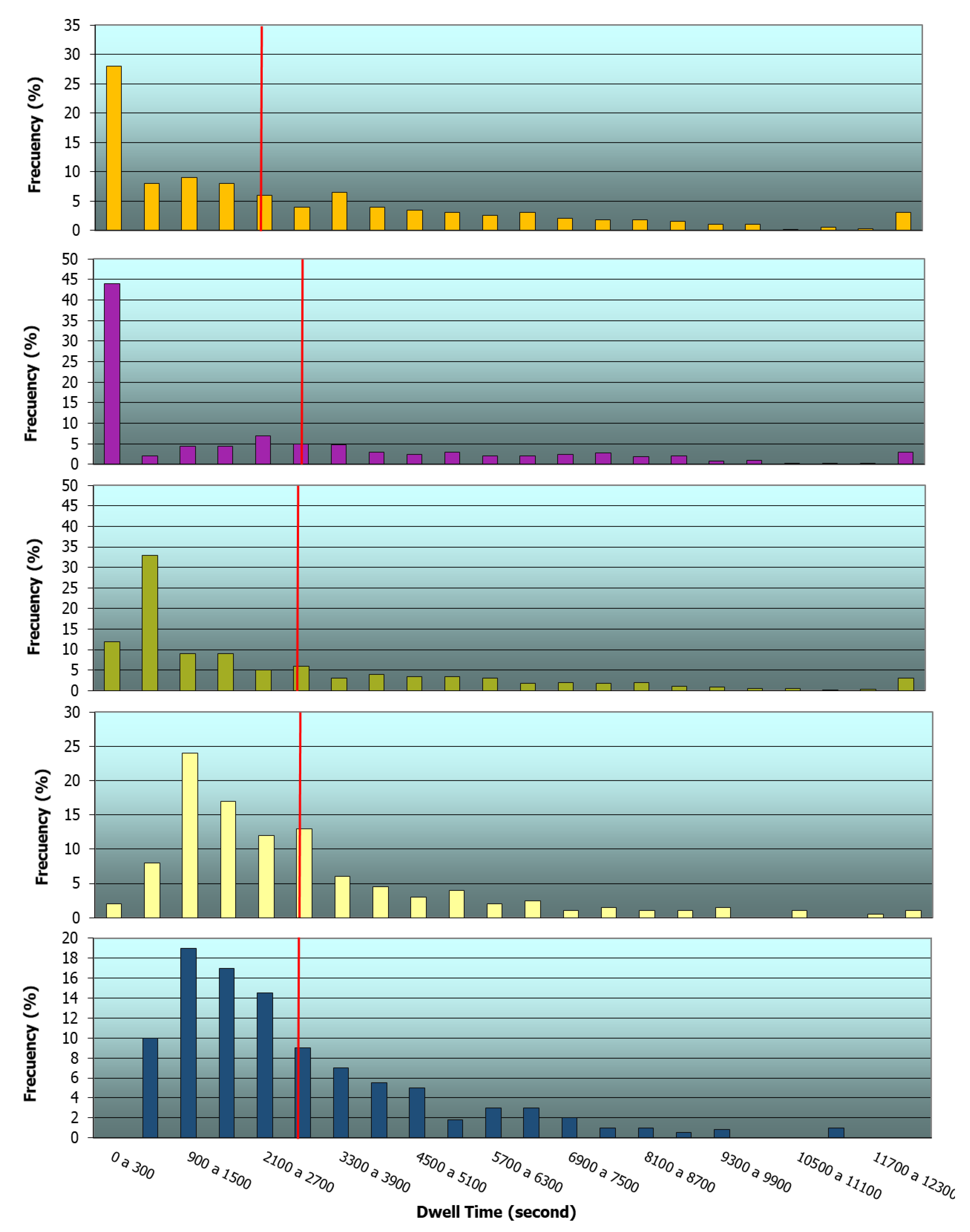

3.1.4. Results of the Hydraulic Tests to Know the Behavior of the Flows Inside the Biological Reactor

3.2. Step 2. Reduce Energy Requirements in the Biological Process

Results of the Tests for the Pressure Drop Detection in the Network of Pipes and Air Injection Elements

3.3. Step 3. Equipment Redesign

- The optimization of the operating conditions in the biological reactor, with considerable reductions in the concentration of solids in the biological reactor and, therefore, the concentration of solids in the membrane chamber of the MBR system, favored the reduction of the mixed liquor recirculation coefficient at the reactor inlet by half, with a 50% reduction in the pumped flow. This allowed us to replace one of the existing 37 kW drive units with a 22 kW one, to adapt the unit to the new conditions and work at the optimum point of its efficiency curve [60,61,62].

- Replace the deteriorated diffusion membranes, with standard EPDM technology, with advanced formula diffusers of high-efficiency Silver Series II. This replacement increased the SOTE value by up to 3%, with specific reductions in the total injected airflow of about 12% [63].

- Optimize the distribution of the flows along the biological reactor, for this purpose:

- Agitators were installed in the No. 2 oxic chamber of both reactors. The new agitation equipment installed is of permanent magnetization and improved hydraulics to increase its efficiency in terms of thrust (N/kWh). That is, to provide the same thrust (measured in Newtons) with much less power and, therefore, with lower energy consumption.

- The operating cycles of the agitators were modified. The aim is to achieve homogenization of the mixed liquor by avoiding the disturbances produced by the agitators in the aeration that lead to over-consumption.

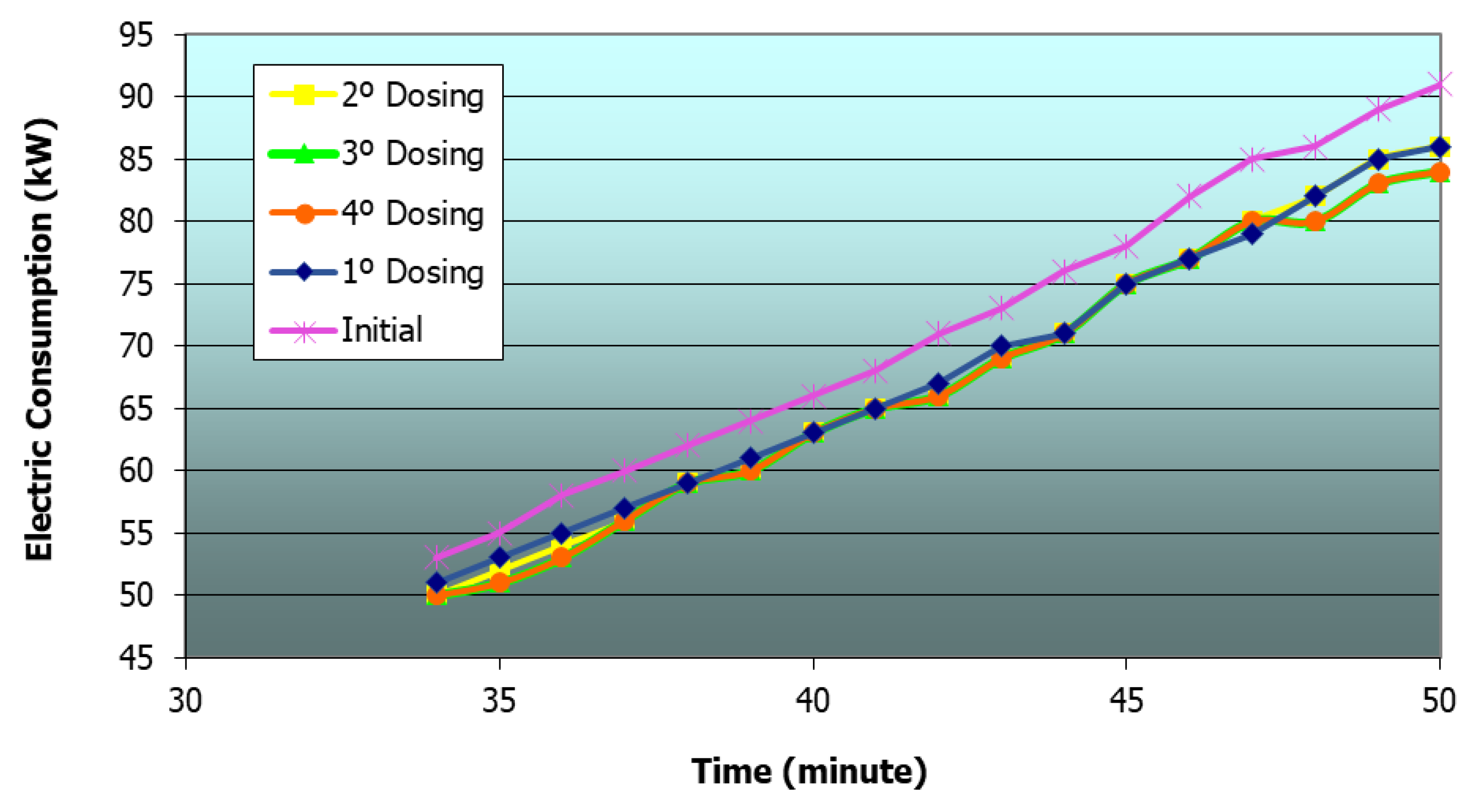

- An automatic control system for pressure loss in the air line was incorporated into the biological reactor with a continuous cleaning system for the diffusers by automatically dosing formic acid into the air line.

- A new air production equipment model ZS55 by ATLAS COPCO® (Nacka, Sweden) oil-free positive displacement screw technology was installed, which, combined with the existing blowers, provided a nominal airflow sufficient to fully cover the oxygen requirements of the process under minimum, medium, and maximum flow, and contaminant load conditions. The new screw blower provided energy savings of up to 30% and maximum reliability by operating in the best-performance range (80–100%) and reductions in maintenance costs due to lower vibration, lower heat dissipation, etc. [64].

- As an overall optimization measure, an advanced control system was developed and implemented for the management of the activated sludge biological aeration stage and the membrane biological reactor aeration stage, specific for the San Pedro del Pinatar WWTP, but extrapolated to any type of WWTP, which integrated all the fundamental variables measured automatically in the biological reactor (MLSS, oxygen concentration, SOTE, airline pressure, control parameters of the treated water quality, etc.) whose signals are collected in the plant PLC [65,66,67]. This control system is developed in phase III of the proposed methodology to achieve energy optimization of the aeration stage in the WWTP.

3.4. Result of the Study on WWTP Final Energy Consumption

4. Conclusions

- ➢

- replacing deteriorated diffusers with more efficient injection technologies,

- ➢

- adjusting the airflow injected in each diffuser to the optimum established in performance tables,

- ➢

- reducing the pressure losses in the aeration line, by adjusting the flows and working pressures, and automatic elimination of the existing incrustations,

- ➢

- modifying the water entry point into the biological reactor, and installing agitation equipment in chambers lacking them, which allows eliminating preferential paths and dead zones, and

- ➢

- reducing the external recirculation coefficient.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lozano, A.B.; del Cerro, F.; Llorens, M. Methodology for Energy Optimization in Wastewater Treatment Plants. Phase I: Control of the Best Operating Conditions. Sustainability 2019, 11, 3919. [Google Scholar] [CrossRef] [Green Version]

- Bakker, A.; Smith, J.M.; Myers, K.J. How to disperse gases in liquids. Chem. Eng. 1994, 101, 98–102. [Google Scholar]

- Gogate, P.R.; Beenackers, A.A.; Pandit, A.B. Multiple-impeller systems with a special emphasis onbioreactors: A critical review. Biochem. Eng. J. 2000, 6, 109–144. [Google Scholar] [CrossRef]

- Rosso, D.; Stenstrom, M.K.; Larson, L.E. Aeration of large-scale municipal wastewater treatment plants: State of the art. Water Sci. Technol. 2008, 57, 973–978. [Google Scholar] [CrossRef]

- Zhiyong, Z.; Dongdong, S.; Jing, L.; Xiaobei, Z.; Minjie, G. Improving oxygen transfer efficiency by developing a novel energy-saving impeller. Chem. Eng. Res. Des. 2018, 130, 199–207. [Google Scholar] [CrossRef]

- Rosso, D.; Stenstrom, M.K. Surfactant effects on α-factors in aeration systems. Water Res. 2006, 40, 1397–1404. [Google Scholar] [CrossRef] [PubMed]

- Henkel, J.; Cornel, P.; Wagner, M. Oxygen transfer in activated sludge—New insights and potentials for cost saving. Water Sci. Technol. 2011, 63, 3034–3038. [Google Scholar] [CrossRef] [PubMed]

- Åmand, L.; Olsson, G.; Carlsson, B. Aeration control—A review. Water Sci. Technol. 2013, 67, 2374–2398. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tchobanoglous, G.; David Stensel, H.; Tsuchihashi, R.; Burton, F.; Metcalf & Eddy, Inc. Wastewater Engineering: Treatment and Resource Recovery; McGraw-Hill: Penn Plaza, NY, USA, 2013. [Google Scholar]

- Irizar, I.; Beltrán, S.; Urchegui, G.; Izko, G.; Fernández, O.; Maiza, M. Lessons learnt from the application of advanced controllers in the Mekolalde WWTP: Good simulation practices in control. Water Sci. Technol. 2014, 69, 1289–1297. [Google Scholar] [CrossRef] [PubMed]

- Olsson, G. Measurement and control in chemical and environmental engineering. In Proceedings of the International Scandinavian Congress on Chemical Engineering (Kem-Tek 3), Copenhagen, Denmark, 28–30 January 1974. [Google Scholar]

- Rancaño, A. Energy optimization of sludge treatment at Ceutí WWTP: Aeration control by means of an adaptive predictive expert control system (ADEX). In Proceedings of the V Technical Conference on Sanitation and Purification, Water Sanitation Organization of the Region of Murcia (WSERM), Murcia, Spain, 25–26 November 2009; pp. 1–59. Available online: http://www.esamur.com/historico (accessed on 20 July 2018).

- Le Moullec, Y.; Gentric, C.; Potier, O.; Leclerc, J.P. CFD simulation of the hydrodynamics and reactions in an activated sludge channel reactor of wastewater treatment. Chem. Eng. Sci. 2010, 65, 492–498. [Google Scholar] [CrossRef]

- Gresch, M.; Braun, D.; Gujer, W. Using reactive tracers to detect flow field anomalies in water treatment reactors. Water Res. 2011, 45, 1984–1994. [Google Scholar] [CrossRef] [PubMed]

- Glover, G.C.; Printemps, C.; Essemiani, K.; Meinhold, J. Modelling of water treatment plants-How far shall we go with sophisticated modeling tools? Water Sci. Technol. 2006, 53, 79–89. [Google Scholar] [CrossRef] [PubMed]

- Essemiani, K.; Vermande, S.; Marsal, S.; Phan, L.; Meinhold, J. Optimization of WWWTP units using CFD —A tool grown for real scale application. In Proceedings of the 2nd IWA Leading-Edge Conference on Water and Wastewater Treatment Technologies, Prague, Czech Republic, 1–4 June 2004. [Google Scholar]

- Samstag, R.W.; Ducoste, J.J.; Griborio, A.; Nopens, I.; Batstone, D.J.; Wicks, J.D.; Saunders, S.; Wicklein, E.A.; Kenny, G.; Laurent, J. CFD for wastewater treatment: An overview. Water Sci. Technol. 2016, 74, 549–563. [Google Scholar] [CrossRef] [PubMed]

- Wicklein, E.; Batstone, D.J.; Ducoste, J.; Laurent, J.; Griborio, A.; Wicks, J.; Saunders, S.; Samstag, R.; Potier, O.; Nopens, I. Good modelling practice in applying computational fluid dynamics for WWTP modelling. Water Sci. Technol. 2016, 73, 969–982. [Google Scholar] [CrossRef]

- United Nations Organization (UNO). Transforming Our World: The 2030 Agenda for Sustainable Development; A/RES/70/1; UNO: New York, NY, USA, 2015; pp. 1–41. Available online: https://sustainabledevelopment.un.org/content/documents/21252030%20Agenda%20for%20Sustainable%20Development%20web.pdf (accessed on 26 November 2018).

- Energy Strategy 2020. Available online: https://ec.europa.eu/energy/en/topics/energy-strategy-and-energy-union/2020-energy-strategy (accessed on 20 June 2018).

- Energy Strategy 2030. Available online: https://ec.europa.eu/energy/en/topics/energy-strategy-and-energy-union/2030-energy-strategy (accessed on 20 June 2018).

- Wang, H.; Yang, Y.; Keller, A.; Li, X.; Feng, S.; Dong, Y.-N. Comparative analysis of energy intensity and carbon emissions in wastewater treatment in USA, Germany, China and South Africa. Appl. Energy 2016, 184, 873–881. [Google Scholar] [CrossRef] [Green Version]

- Gil, M. Dynamic model of active sludge processes. Int. J. Numer. Methods Calc. Des. Eng. 1990, 6, 387–395. [Google Scholar]

- Simón Andreu, P.; Lardín, C.; Moreno, B.; Ponsoda, J.M.; Rancaño, A. Energy optimization of sludge treatment of the WWTP of Ceutí: Part I: Selection of operating conditions. Water Technol. 2010, 322, 54–63. [Google Scholar]

- American Society of Civil Engineers (ASCE). Standard Guidelines for in-Process Oxygen Transfer Testing (ASCE18) and Standards ASCE19; American Society of Civil Engineers: New York, NY, USA, 1996. [Google Scholar]

- German Association for the water environment. Standard ATV-M209 E. Measurement of the oxygen transfer in activated sludge aeration tanks with clean water and mixed liquor. In German ATV Rules and Standards; Publishing Company of ATV-DWA: Hennef, Germany, 1996. [Google Scholar]

- Rosso, D.; Iranpour, R.; Stenstrom, M. Fifteen years of off-gas transfer efficiency measurements on fine-pore aerators: Key role of sludge age and normalized air flux. Water Environ. Res. 2005, 77, 266–273. [Google Scholar] [CrossRef]

- Schuchardt, A.; Libra, J.A.; Sahlmann, C.; Wiesmann, U.; Gnirss, R. Evaluation of oxygen transfer efficiency under process conditions using the dynamic off-gas method. Environ. Technol. 2007, 28, 479–489. [Google Scholar] [CrossRef]

- Simón Andreu, P.; Lardín Mifsut, C.; Sanchez Betrán, A.V.; González Herrero, R.; Morales Gómez, J.; Gambín Manzano, J.M.; Marçal Gaitx, A. Comparative study of oxygen transfer in different aeration systems in WWTPs in the Region of Murcia. Water Technol. 2016, 21, 58–62. [Google Scholar]

- Simón Andreu, P.; Lardín Mifsut, C.; del Cacho Sanz, C.; García Yuste, M. Oxygen transfer: Rapid assessment of the efficiency of aeration systems. Water Technol. 2015, 15, 92–101. [Google Scholar]

- Beltrán Calaff, S.; Lizarralde Aguirrezabal, I.; Ayesa Iturrate, E.; Gorriti Cabrejas, J.; Ortega Conde, F.; de la Sota, A.; Villanueva del Casal, J.M. Estimation of the potential for savings in the aeration systems of the WWTPs by measuring the transfer of oxygen. Water Technol. 2014, 9, 64–72. [Google Scholar]

- Simón Andreu, P.; Lardín, C.; Abellan, M.; Ponsoda, J.M. Formic acid cleaning of membrane diffusers for aeration of an active sludge process. Water Technol. 2009, 311, 2–9. [Google Scholar]

- Van Haandel, A.; Van der Lubbe, J. Handbook of Biological Wastewater Treatment: Design and Optimization of Activated Sludge Systems, 2nd ed.; IWA Publishing: London, UK, 2012. [Google Scholar]

- Brannock, M. Computational Fluid Dynamics Tools for the Design of Mixed Anoxic Wastewater Treatment Vessels. Ph.D. Thesis, University of Queensland, Brisbane, Australia, 2003. [Google Scholar]

- Dudley, J. Process testing of aerators in oxidation ditches. Water Res. 1995, 29, 2217–2219. [Google Scholar] [CrossRef]

- Le Moullec, Y.; Potier, O.; Gentric, C.; Leclerc, J.P. Activated sludge pilot plant: Comparison between experimental and predicted concentration profiles using three different modelling approaches. Water Res. 2011, 45, 3085–3097. [Google Scholar] [CrossRef] [PubMed]

- Simón Andreu, P.P.; Lardín Mifsut, C.; Abellán Soler, M. Energy optimization in WWTPs in the Region of Murcia. Civ. Eng. 2012, 168, 93–112. Available online: http://hispagua.cedex.es/sites/default/files/hispagua_articulo/Ingcivil/P-093-112.pdf (accessed on 1 January 2019).

- Burrows, L.J.; Stokes, A.J.; West, J.R.; Forster, C.F.; Martin, A.D. Evaluation of different analytical methods for tracer studies in aeration lanes of activated sludge plants. Water Res. 1999, 33, 367–374. [Google Scholar] [CrossRef]

- Brannock, M.; Wang, Y.; Leslie, G. Mixing characterization of full-scale membrane bioreactors: CFD modelling with experimental validation. Water Res. 2010, 44, 3181–3191. [Google Scholar] [CrossRef]

- Howes, T.; Brannock, M.W.D.; Corre, G. Development of simplified flow models from CFD simulations. In Proceedings of the Third International Conference on CFD in the Minerals and Process Industries, Melbourne, Australia, 10–12 December 2003; Schwarz, P., Ed.; CSIRO: Canberra, Australia, 2003; pp. 1–6. [Google Scholar]

- Climent, J.; Basiero, L.; Martínez-Cuenca, R.; Berlanga, J.G.; Julián-López, B.; Chiva, S. Biological reactor retrofitting using CFD-ASM modelling. Chem. Eng. J. 2018, 348, 1–14. [Google Scholar] [CrossRef]

- Martín Sanchez, J.M.; Rodellar, J. Adaptive Predictive Control: From the Concepts to plant optimization. In Prentice-Hall International Series in Systems and Control Engineering; Prentice Hall: Upper Saddle River, NJ, USA, 1996. [Google Scholar]

- German Association for Water, Wastewater and Waste. Standard ATV-DVWK-A 131E Dimensioning of Single-Stage Activated Sludge Plants. In ATV-DVWK Rules and Standards; DVPW: Berlin, Germany, 2000. [Google Scholar]

- Castell, D.; García Ventoso, M.; Tormos Fibla, I.; Ferrer, C.; Morenilla, J.J.; Bernacer, I.; Basiero, A. Energy Optimization of the Aeration System of a WWTP. Comparative Analysis of Two Technologies. Water Technol. 2011, 327, 2–8. Available online: http://www.sitra.es/sites/default/files/Optimizaci%C3%B3n_energ%C3%A9tica_del_sistema_de_aireaci%C3%B3n_de_una_EDAR_TECNOLOG%C3%8DA_DEL_AGUA_MAR_2011.pdf (accessed on 23 July 2018).

- Malia Baró, J.; Pérez, C.; Marín Sanchez, J.M. Optimization of the biological process in a wastewater treatment plant. In Proceedings of the I Seminar on Advanced Industrial Control Applications. Organized by the Industrial Applications Society of the IEEE (IAS), Madrid, Spain, 19–20 October 2005; pp. 127–155. [Google Scholar]

- Tchobanoglous, G.; Burton, F.L.; Stensel, H.D.; Metcalf & Eddy Inc. Wastewater Engineering: Treatment and Reuse, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2004. [Google Scholar]

- Grady, C.P.L.; Daigger, G.T.; Love, N.G. Biological Wastewater Treatment, 3rd ed.; IWA Publishing: London, UK, 2011. [Google Scholar]

- Oprina, G.; Bunea, F.; Pincovschi, I.; Mandrea, L. Aspects of hydrodynamics and mass transfer in diffused aeration systems. Environ. Eng. Manag. J. 2010, 9, 565–572. [Google Scholar] [CrossRef]

- Krampe, J.; Krauth, K. Oxygen transfer into activated sludge with high MLSS concentrations. Water Sci. Technol. 2003, 47, 297–303. [Google Scholar] [CrossRef]

- Germain, E.; Nelles, F.; Drews, A.; Pearce, P.; Kraume, M.; Reid, E.; Judd, S.J.; Stephenson, T. Biomass effects on oxygen transfer in membrane bioreactors. Water Res. 2007, 41, 1038–1044. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Henkel, J.; Cornel, P.; Wagner, M. Free water content and sludge retention time: Impact on oxygen transfer in activated sludge. Environ. Sci. Technol. 2009, 43, 8561–8565. [Google Scholar] [CrossRef]

- Henkel, J.; Lemac, M.; Wagner, M.; Cornel, P. Oxygen transfer in membrane bioreactors treating synthetic greywater. Water Res. 2009, 43, 1711–1719. [Google Scholar] [CrossRef] [PubMed]

- Fan, H.; Qi, L.; Liu, G.-H.; Zhang, Y.; Chen, X.; Wang, H. Promotion and inhibition of oxygen transfer under fine bubble aeration by activated sludge. Water Environ. J. 2014, 28, 434–441. [Google Scholar] [CrossRef]

- Fan, H.; Qi, L.; Liu, G.-h.; Zhang, Y.; Chen, X.; Wang, H. Aeration optimization through operation at low dissolved oxygen concentrations: Evaluation of oxygen mass transfer ynamics in different activated sludge systems. Water Environ. J. 2017, 55, 224–235. [Google Scholar] [CrossRef]

- Raszka, A.; Chorvatova, M.; Wanner, J. The role and significance of extracellular polymers in activated sludge. Part I: Literature review. Acta Hydrochim. Hydrobiol. 2006, 34, 411–424. [Google Scholar] [CrossRef]

- Mena, P.C.; Ruzicka, M.C.; Rocha, F.A.; Teixeira, J.A.; Drahos, J. Effect of solids on homogeneous-heterogeneous flow regime transition in bubble columns. Chem. Eng. Sci. 2005, 60, 6013–6026. [Google Scholar] [CrossRef] [Green Version]

- Henkel, J.; Siembidalösch, B.; Wagner, M. Floc volume effects in suspensions and its relevance for wastewater engineering. Environ. Sci. Technol. 2011, 45, 8788–8793. [Google Scholar] [CrossRef]

- Cornel, P.; Wagner, M.; Krause, S. Investigation of oxygen transfer rates in full scale membrane bioreactors. Water Sci. Technol. 2003, 47, 313–319. [Google Scholar] [CrossRef] [PubMed]

- Gómez López, A. Hydraulic Flow Modelling to Improve Energy Efficiency in the Wastewater Treatment Plant Project. In Proceedings of the V Technical Conference on Sanitation and Purification; Water Sanitation Organization of the Region of Murcia (WSERM), Murcia, Spain, 25–26 November 2009; pp. 1–43. Available online: http://www.esamur.com/historico (accessed on 20 July 2018).

- Lozano, A.B.; Del Cerro, F. Energy Optimization on the Aeration of Aerobic Bioreactors: Analysis of the Biological Process, Equipment Resizing, and Implementation of a Real-Time Control System Based on the Ammonium/Nitrate Measurement (AN-ISE); Final Degree Work; Department of Chemical Engineering, University of Murcia: Murcia, Spain, 2014. [Google Scholar]

- Chisti, Y. Pneumatically Agitated Bioreactors in Industrial and Environmental Bioprocessing: Hydrodynamics, Hydraulics, and Transport Phenomena. Am. Soc. Mech. Eng. 1998, 51, 33–112. Available online: https://appliedmechanicsreviews.asmedigitalcollection.asme.org/article.aspx?articleid=1396214 (accessed on 20 March 2019). [CrossRef]

- Matas, E.; Rancaño, A.; Carpes, G. Importance of the Control of Recirculation over Energy Optimization in an WWTP; EMASESA Metropolitan Poster: Sevilla, Spain, 2009. [Google Scholar]

- Xylem. Sistemas de Aireación de Alta Eficiencia por Burbujas Finas de Sanitaire. Available online: https://docplayer.es/14438856-Sistemas-de-aireacion-de-alta-eficiciencia-por-burbujas-fina-de.html (accessed on 15 July 2019).

- Morenilla, J.J. Control systems and optimization of energy consumption in WWTP XXV. In Course on Wastewater Treatment and Operation of Wastewater Treatment Plants; CEDEX: Madrid, Spain, 2007; Volume 3, p. 34. [Google Scholar]

- Manesis, S.A.; Sapidis, D.J.; King, E. Intelligent control of wastewater treatment plants. Artif. Intell. Eng. 1998, 12, 275–281. [Google Scholar] [CrossRef]

- Guerrero, J.; Guisasola, A.; Vilanova, R.; Baeza, J.A. Improving the performance of a WWTP control system by model-based setpoint optimization. Environ. Model. Softw. 2011, 26, 492–497. [Google Scholar] [CrossRef]

- Turon, C.; Giró, J.; Ripoll, F.; Clara, P.; Freixó, A. Advanced and intelligent control for energy saving in the biological elimination of nutrients. Chem. Eng. 2011, 490, 90–95. [Google Scholar]

| Situation | NO. of Working Blowers | Operating Frequency (Hz) | Total Air Flow Rate (Nm3/h) | Flow Rate per Diffuser Qair/Qdiffusor (Nm3/h) |

|---|---|---|---|---|

| 1 | 1 | 33 | 2088.9 | 2.10 |

| 2 | 1 | 50 | 3165.0 | 3.18 |

| 3 | 2 | 50 + 33 | 5253.9 | 5.28 |

| 4 | 2 | 50 + 50 | 6330.0 | 6.36 |

| DESIGN VALUES | ACTUAL AVERAGE VALUES | |||||

|---|---|---|---|---|---|---|

| Q (m3/day) | BOD5 (kg O2/day) | TKN (kg N/day) | Q (m3/day) | BOD5 (kg O2/day) | TSS (kg/day) | TKN (kg N/day) |

| 20,000 | 8000 | 1200 | 7578 | 902 | 1091 | 288 |

| T (°C) | Q (Nm3/day) | BOD5 (kg O2/day) | TSS (kg/day) | TKN (kg/day) | Sludge Age (days) | O2 (kg O2/day) |

|---|---|---|---|---|---|---|

| 20 | 8 | 902 | 1 | 288 | 25 | 2 |

| O2 (kg O2/day) | Operation Hours | O2 (kg O2/day) | SOTE pw (%) | Q (Nm3/h) | Q Nominal (Nm3/h) | % Excess |

|---|---|---|---|---|---|---|

| 2197 | 24 | 92 | 26 | 2028 | 3165 | 64 |

| Technology | Aerator Model | ΔP Work (mbar) | Q Air Blower (Nm3/h) | Installed Power (kW) | Average Consumption (%) | Absorbed Power (kW) | Average Consumption (%) |

|---|---|---|---|---|---|---|---|

| Lobular (Model current) | MPR-SEM 40TR | 590 | 3165 | 110 | 100 | 70.48 | 100 |

| Magnetic Levitation | ABS HST 2500-1-L | 590 | 3134 | 75 | 68.18 | 48.53 | 68.86 |

| Screw | ATLAS COPCO ZS55 | 590 | 2340 | 55 | 50 | 47.67 | 67.63 |

| Hybrid | AERZEN D75L | 590 | 2618 | 55 | 50 | 42.61 | 60.45 |

| Case | v < 0.3 m/s | v < 0.15 m/s | v < 0.05 m/s | |||

|---|---|---|---|---|---|---|

| 1 | 1110 m3 | 66.6% | 428 m3 | 25.7% | 44 m3 | 2.7% |

| 2 | 1335 m3 | 80.1% | 787 m3 | 47.2% | 100 m3 | 6.0% |

| 3 | 1349 m3 | 81.4% | 842 m3 | 50.8% | 123 m3 | 7.4% |

| 4 | 1353 m3 | 81.7% | 751 m3 | 45.4% | 79 m3 | 4.8% |

| 5 | 1476 m3 | 89.1% | 1022 m3 | 61.7% | 263 m3 | 16.0% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lozano Avilés, A.B.; Del Cerro Velázquez, F.; Llorens Pascual Del Riquelme, M. Methodology for Energy Optimization in Wastewater Treatment Plants. Phase II: Reduction of Air Requirements and Redesign of the Biological Aeration Installation. Water 2020, 12, 1143. https://doi.org/10.3390/w12041143

Lozano Avilés AB, Del Cerro Velázquez F, Llorens Pascual Del Riquelme M. Methodology for Energy Optimization in Wastewater Treatment Plants. Phase II: Reduction of Air Requirements and Redesign of the Biological Aeration Installation. Water. 2020; 12(4):1143. https://doi.org/10.3390/w12041143

Chicago/Turabian StyleLozano Avilés, Ana Belén, Francisco Del Cerro Velázquez, and Mercedes Llorens Pascual Del Riquelme. 2020. "Methodology for Energy Optimization in Wastewater Treatment Plants. Phase II: Reduction of Air Requirements and Redesign of the Biological Aeration Installation" Water 12, no. 4: 1143. https://doi.org/10.3390/w12041143

APA StyleLozano Avilés, A. B., Del Cerro Velázquez, F., & Llorens Pascual Del Riquelme, M. (2020). Methodology for Energy Optimization in Wastewater Treatment Plants. Phase II: Reduction of Air Requirements and Redesign of the Biological Aeration Installation. Water, 12(4), 1143. https://doi.org/10.3390/w12041143