An Examination of the Dependency between Maximum Equilibrium Local Scour Depth and the Grain Size/Structure Size Ratio

Abstract

1. Introduction and Background Information

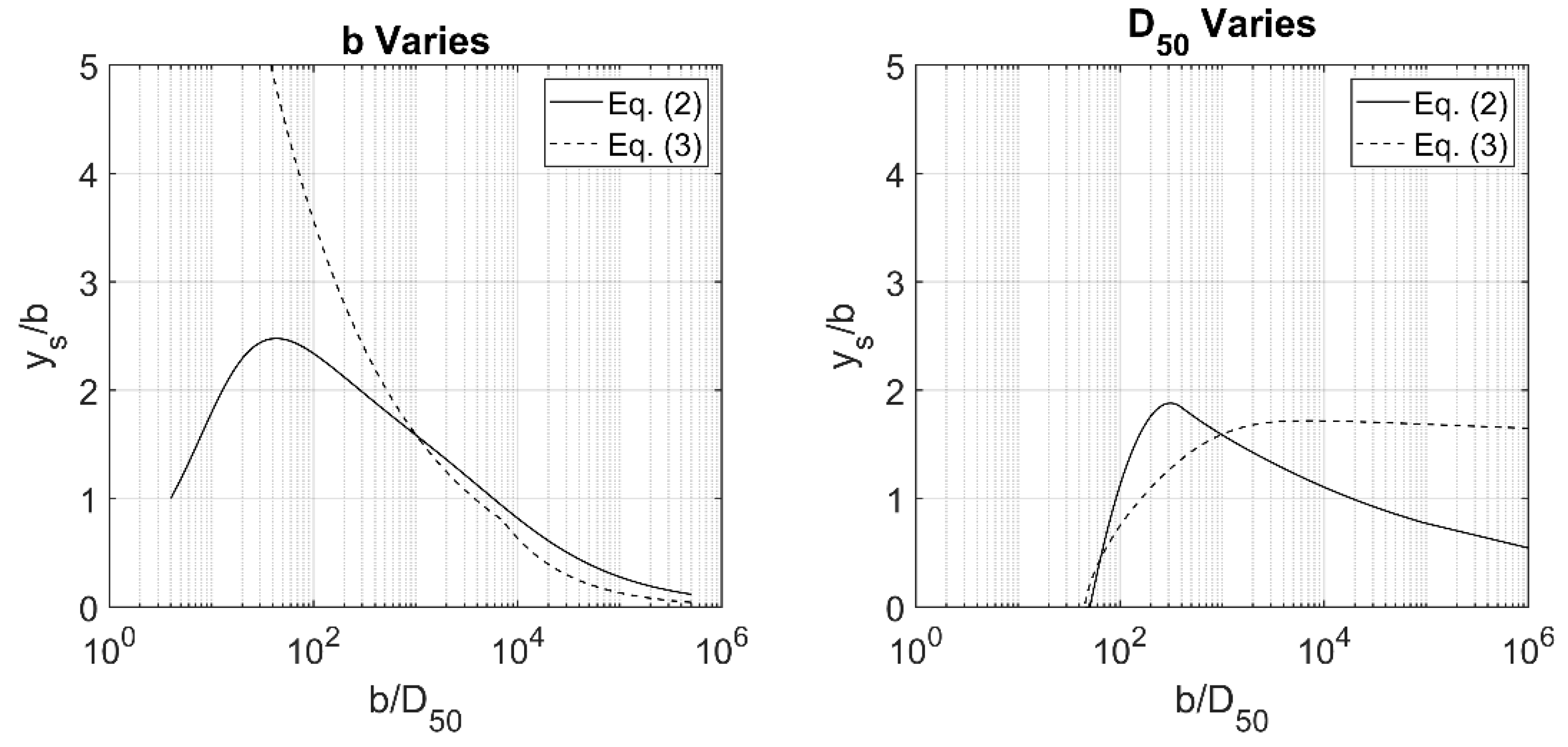

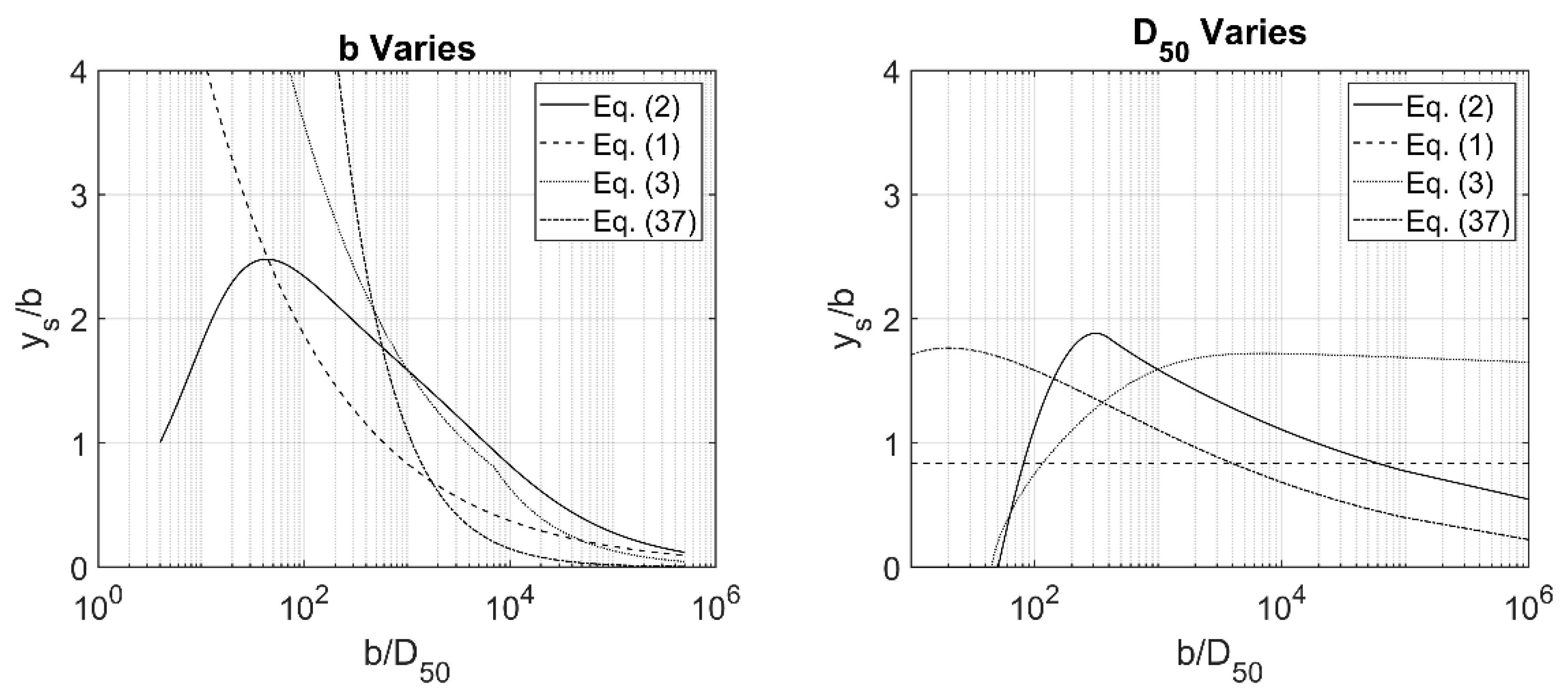

- Existing empirical local scour responses to a range of values.

- The Sheppard [16] potential flow theory explanation for the local scour dependency.

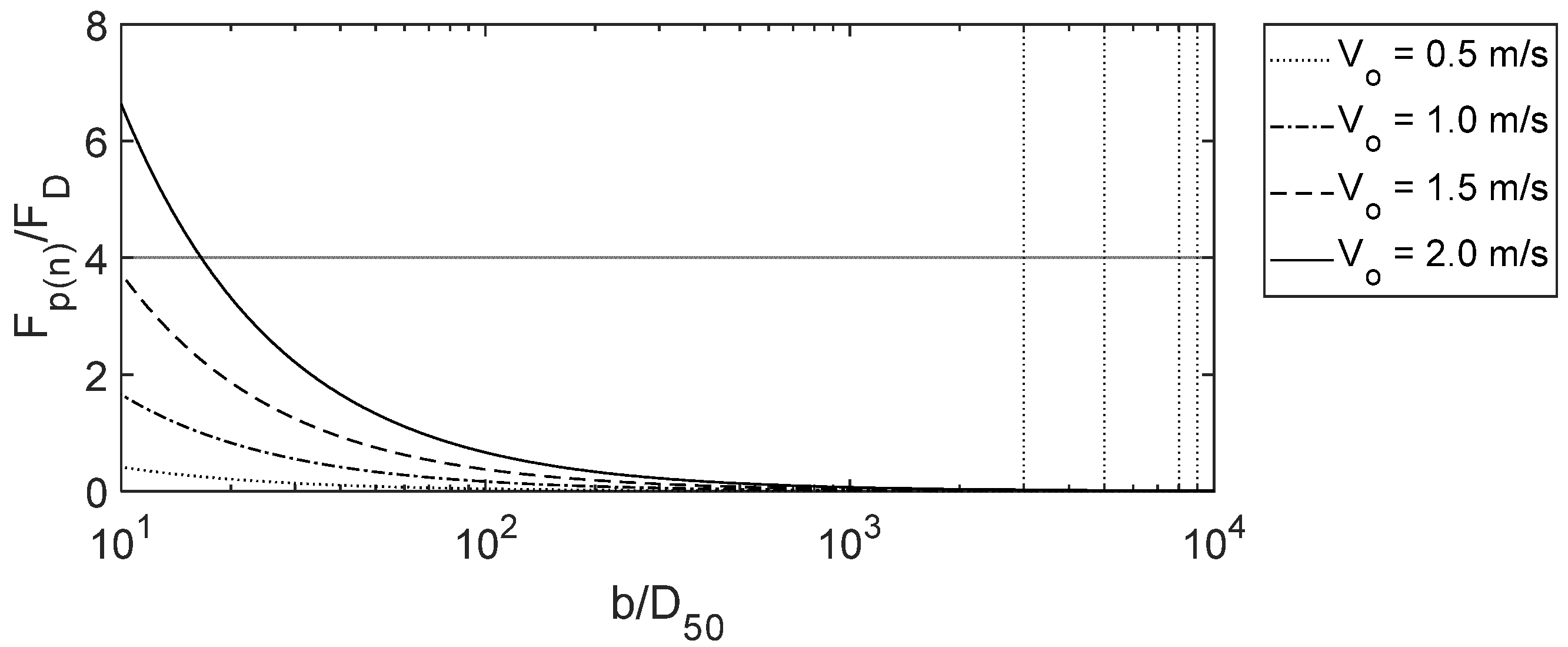

- A newly developed method that also shows dependency based upon near-bed turbulence.

2. Results

2.1. The CSU Formulation

2.2. The Texas A&M Formulation

2.3. Sheppard’s b/D50 Dependency Due to Potential Flow Theory

2.4. A New b/D50 Explanation Based Upon Turbulence

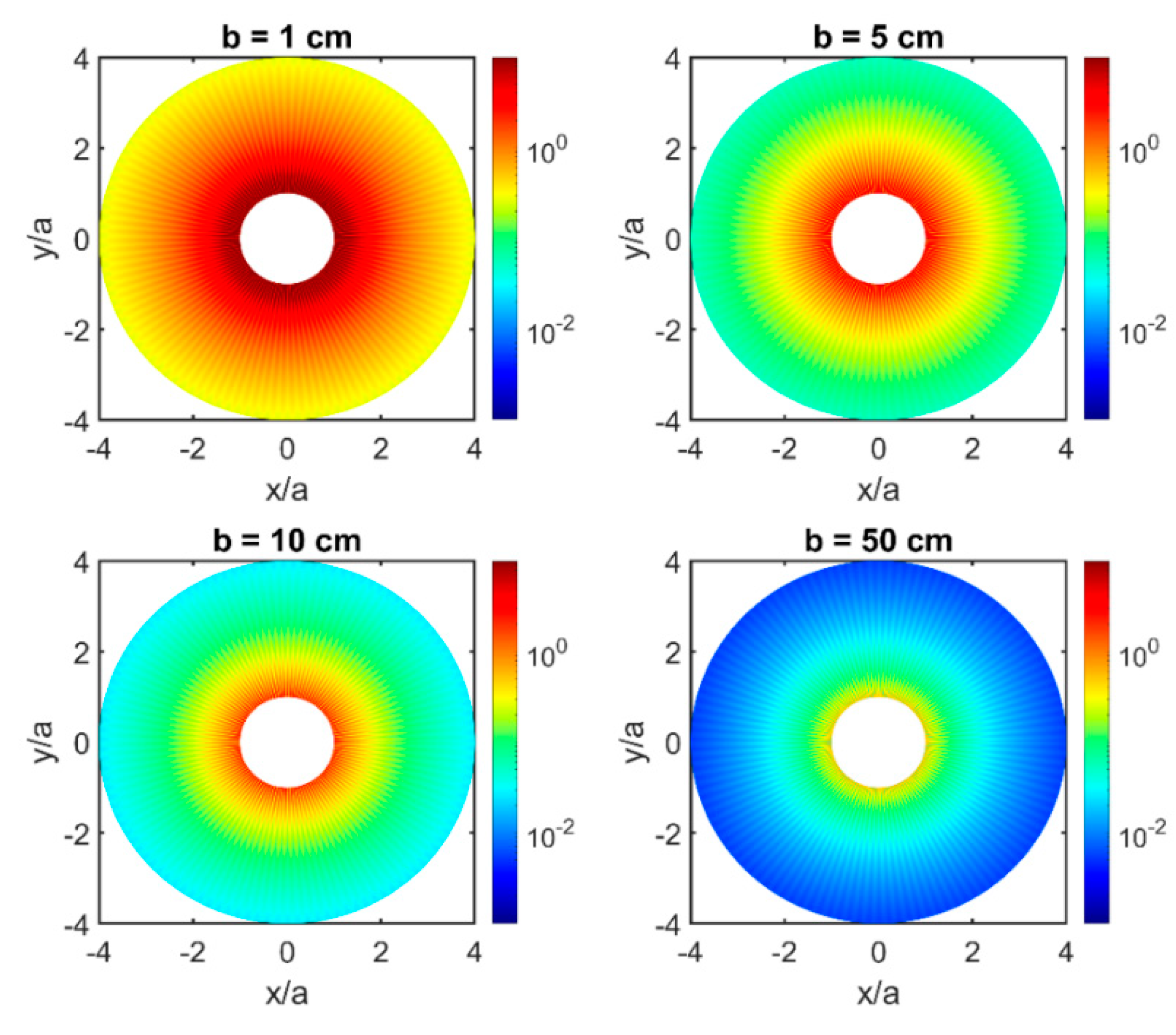

- The presence of the pile initiates turbulent eddies at a distance scale, L.

- Turbulence obeys Kolmogorov scaling in the sense that energy cascades from large to small scales and energy dissipated at small scales is replenished by larger-scale eddies.

- Dissipation occurs at a scale set by the sediment.

- Energy is lost from the moving water when sediment is lifted and accelerated to on a time scale set by the diffusion time at the scale of the sediment.

3. Discussion, Summary, and Conclusions

- This paper presented a review of steady flow local scour dependency on the ratio between structure size and grain size. As noted in this manuscript, the current state-of-the-art empirical formulations for steady flow equilibrium scour depth appear to take this ratio into account to some extent. The formulation from FDOT takes the ratio into account directly, while the formulation from the Briaud group takes the ratio into account indirectly. The CSU equation appears to miss the dependency because is not taken into account.

- Work from Sheppard [16] gave an apparent reason for the dependency between the structure/grain size ratio and equilibrium scour depth. As Sheppard [16] showed, flow around a pile causes a pressure gradient. However, flow around the soil particles themselves also causes smaller pressure gradients around the particles. The superposition of these two pressure gradients leads to the dependency between scour depth and the grain size/structure size ratio.

- This paper also presented a possible new explanation for the dependency between equilibrium scour depth and the structure/grain size ratio using a turbulent energy spectrum decay argument. This formulation was similar to the well-known CSU equation in the sense that in addition to the dependency between equilibrium scour depth and , equilibrium scour depth also appears to be a function of the local velocity.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Arneson, L.A.; Zevenburgen, L.W.; Lagasse, P.F.; Clopper, P.E. Evaluating Scour at Bridges, 5th ed.; Federal Highway Administration: Washington, DC, USA, 2012.

- Laursen, E.M. Scour at Bridge Crossings. J. Hydraul. Div. 1960, 86, 39–54. [Google Scholar]

- Jain, S.C.; Fischer, R.E. Scour Around Bridge Piers at High Froude Numbers; Federal Highway Administration, US Department of Transportation: Washington, DC, USA, 1979.

- Laursen, E.M. Predicting Scour at Bridge Piers and Abutments; Arizona Department of Transportation: Phoenix, AZ, USA, 1980.

- Richardson, E.V.; Simons, D.B.; Lagasse, P.F. River Engineering for Highway Encroachments—Highways in the River Environment; Federal Highway Administration: Washington, DC, USA, 2001.

- Melville, B.W.; Sutherland, A.J. Design Method for Local Scour at Bridge Piers. J. Hydraul. Eng. 1988, 114, 1210–1226. [Google Scholar] [CrossRef]

- Jones, J.S. Comparison of prediction equations for bridge pier and abutment scour. In Proceedings of the Transportation Research Record 950, Second Bridge Engineering Conference, Washington, DC, USA, 24–26 September 1984. [Google Scholar]

- Mueller, D.S. Local Scour at Bridge Piers in Nonuniform Sediment under Dymamic Conditions; Colorado State University: Fort Collins, CO, USA, 1996. [Google Scholar]

- Landers, M.N.; Mueller, D.S.; Richardson, E.V. U.S. Geological Survey Field Measurements of Pier Scour; Lagasse, R.A., Ed.; ASCE: Reston, VA, USA, 1999. [Google Scholar]

- FDOT. FDOT Bridge Scour Manual; Florida Department of Transportation: Tallahassee, FL, USA, 2005.

- Ettema, R. Scour at Bridges; University of Auckland, School of Engineering: Auckland, New Zealand, 1980. [Google Scholar]

- Froehlich, D.C. Analysis of on-site scour at Bridge Piers. In Proceedings of the Hydraulic Engineering Conference, Colorado Springs, CO, USA, 8–12 August 1988. [Google Scholar]

- Garde, R.J.; Ranga Raju, K.G.; Kothyari, U.C. Effect of Unsteadiness and Stratification on Local Scour; International Science Publisher: New York, NY, USA, 1993. [Google Scholar]

- Sheppard, D.M.; Zhao, G.; Ontowirjo, B. Local scour near single piles in steady currents. In Proceedings of the 1st International Conference on Water Resources Engineering, San Antonio, TX, USA, 14–18 August 1995; pp. 1809–1813. [Google Scholar]

- Sheppard, D.M.; Odeh, M.; Glasser, T. Large Scale Clear-Water Local Pier Scour Experiments. J. Hydraul. Eng. 2004, 130, 957–963. [Google Scholar] [CrossRef]

- Sheppard, D.M. An Overlooked Local Sediment Scour Mechanism. Transp. Res. Rec. 2004, 1890, 107–111. [Google Scholar] [CrossRef]

- Sheppard, D.M.; Miller, W. Live-Bed Local Pier Scour Experiments. J. Hydraul. Eng. 2006, 132, 635–642. [Google Scholar] [CrossRef]

- Oh, S.J. Experimental Study of Bridge Scour in Cohesive Soil. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, December 2009. [Google Scholar]

- Shields, A.F. Application of Similarly Principles and Turbulence Research to Bed-Load Movement; CalTech: Pasadena, CA, USA, 1936. [Google Scholar]

- Guo, J.J.; Guo, J. Hunter rouse and shields diagram. In Advances in Hydraulics and Water Engineering; World Scientific Pub Co Pte Lt: Singapore, 2002; pp. 1096–1098. [Google Scholar]

- Crowley, R.W.; Bloomquist, D.; Hayne, J.R.; Holst, C.M.; Shah, F.D. Estimation and Measurement of Bed Material Shear Stresses in Erosion Rate Testing Devices. J. Hydraul. Eng. 2012, 138, 990–994. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Crowley, R.; Cottrell, W.; Singleton, A. An Examination of the Dependency between Maximum Equilibrium Local Scour Depth and the Grain Size/Structure Size Ratio. Water 2020, 12, 3117. https://doi.org/10.3390/w12113117

Crowley R, Cottrell W, Singleton A. An Examination of the Dependency between Maximum Equilibrium Local Scour Depth and the Grain Size/Structure Size Ratio. Water. 2020; 12(11):3117. https://doi.org/10.3390/w12113117

Chicago/Turabian StyleCrowley, Raphael, William Cottrell, and Alexander Singleton. 2020. "An Examination of the Dependency between Maximum Equilibrium Local Scour Depth and the Grain Size/Structure Size Ratio" Water 12, no. 11: 3117. https://doi.org/10.3390/w12113117

APA StyleCrowley, R., Cottrell, W., & Singleton, A. (2020). An Examination of the Dependency between Maximum Equilibrium Local Scour Depth and the Grain Size/Structure Size Ratio. Water, 12(11), 3117. https://doi.org/10.3390/w12113117