Performance of a Full-Scale Biogas Plant Operation in Greece and Its Impact on the Circular Economy

Abstract

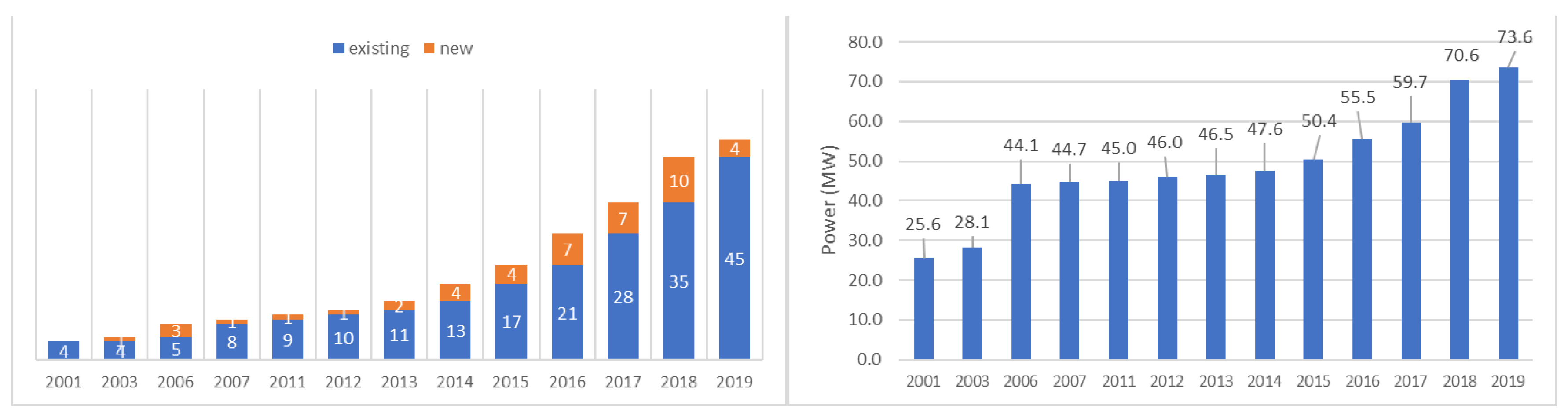

1. Introduction

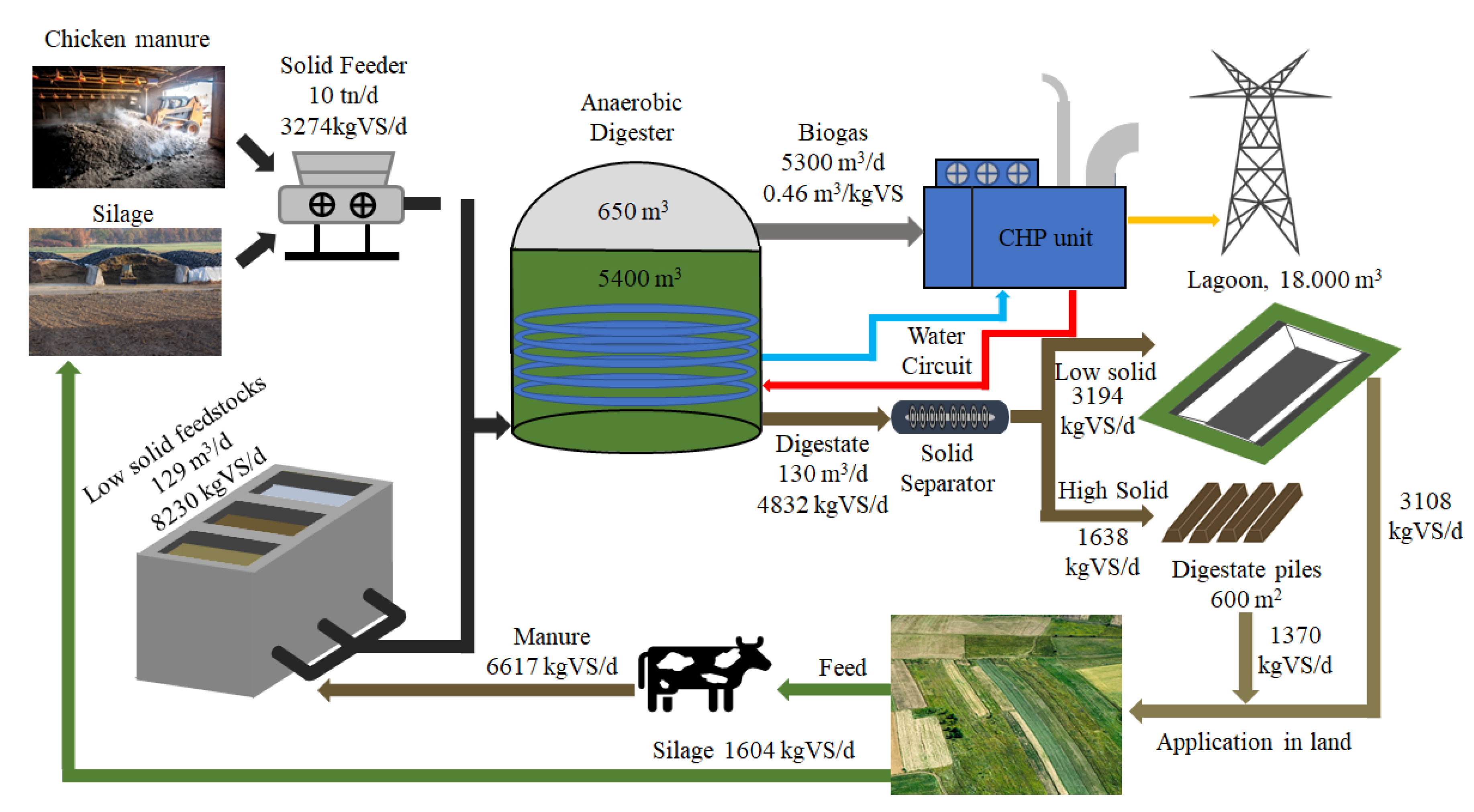

2. Materials and Methods

2.1. The Digester’s Design

2.2. Feedstocks’ Characterization

2.3. Digester’s Operation

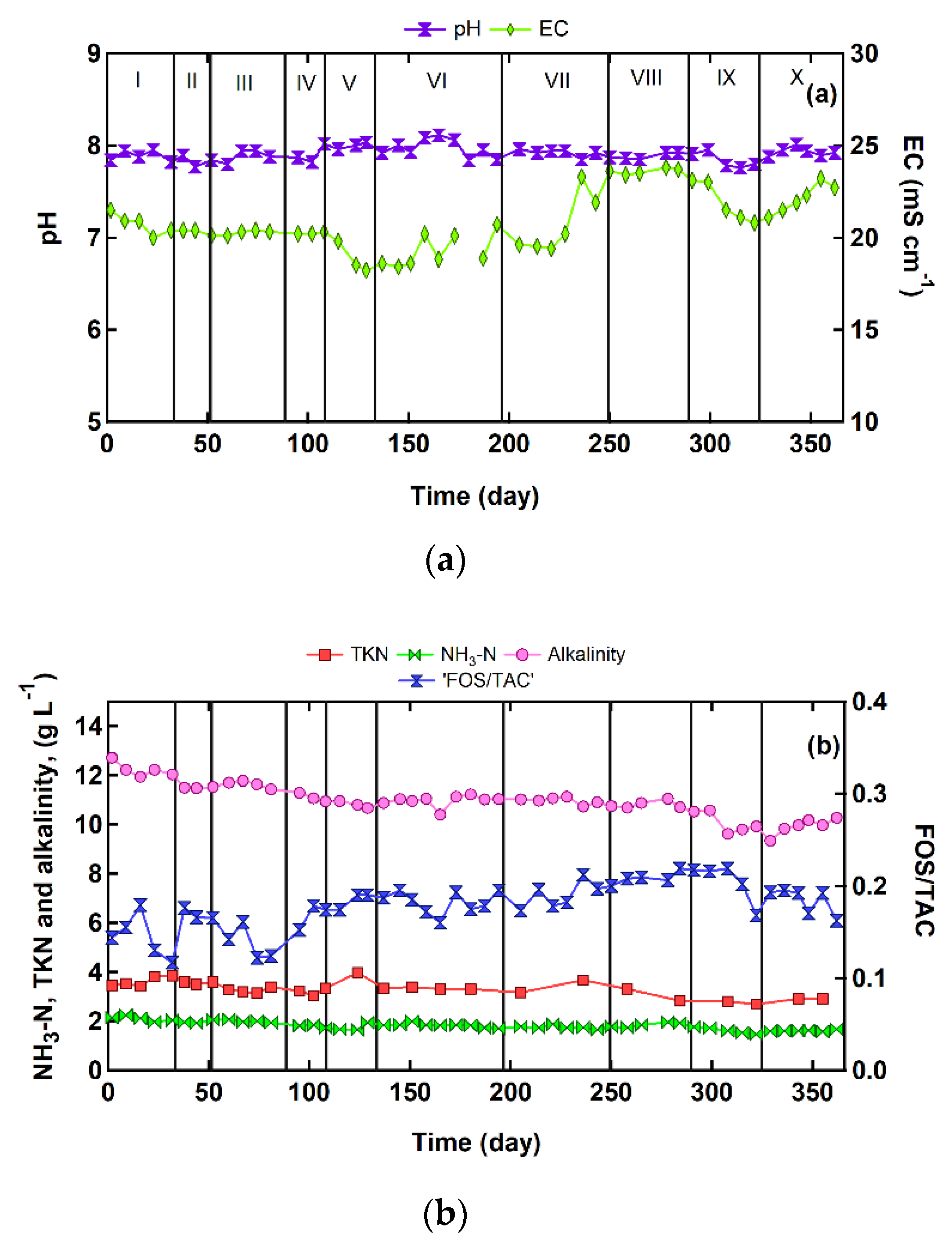

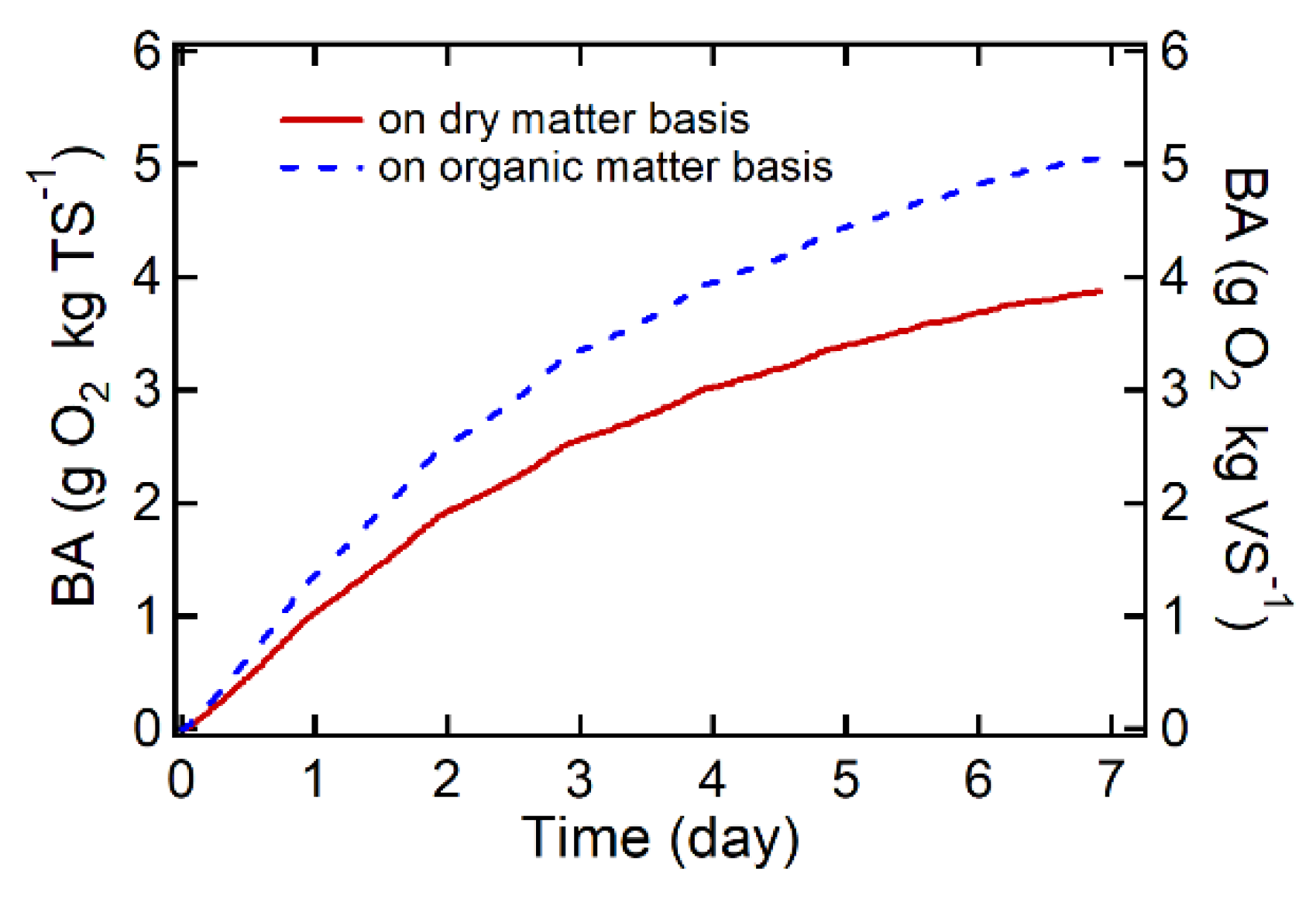

2.4. Assessment of the Digestate’s Stability

2.5. Analytical Methods

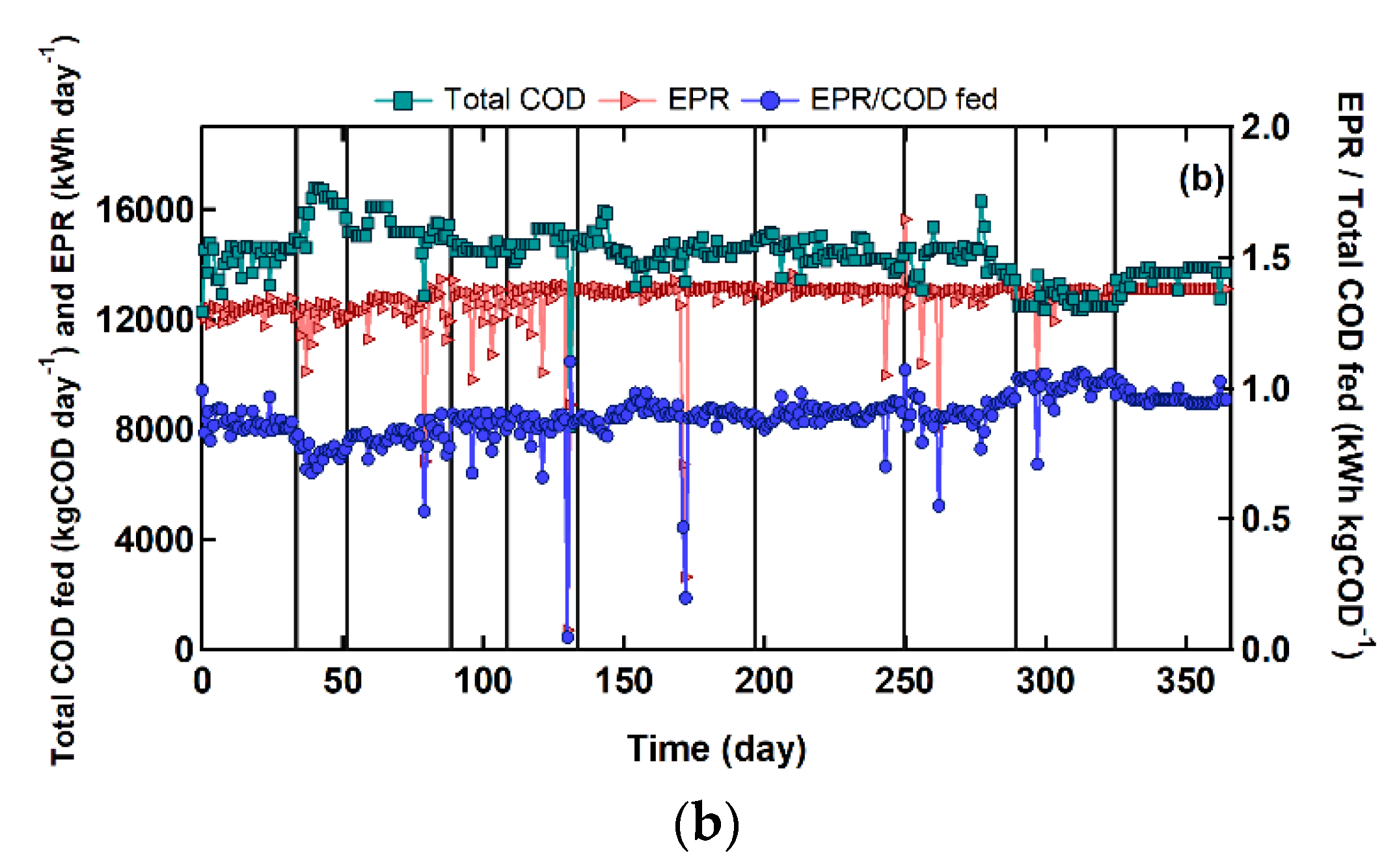

3. Results and Discussion

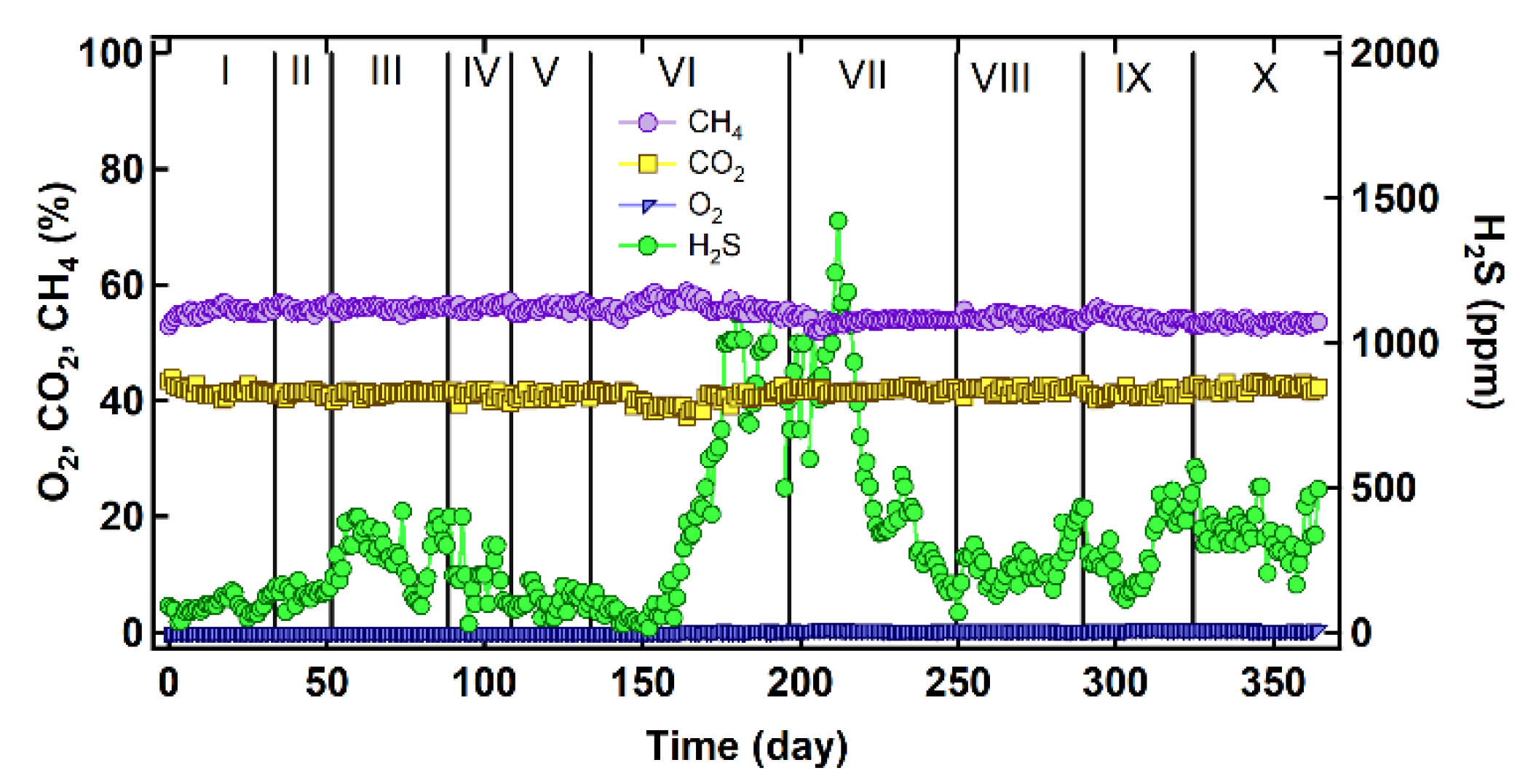

3.1. Full-Scale Digester’s Performance

3.2. Desulfurization

3.3. Recycling Digestate

3.4. Economic Considerations

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Phase Time (Day) | I | II | III | IV | V | VI | VII | VIII | IX | X |

|---|---|---|---|---|---|---|---|---|---|---|

| 0–33 | 34–51 | 52–88 | 89–108 | 109–133 | 134–196 | 197–249 | 250–289 | 290–324 | 325–365 | |

| Total COD Feeding (t COD day−1) | 14.2 ± 0.6 | 16.1 ± 0.7 | 15.3 ± 0.6 | 14.6 ± 0.2 | 14.6 ± 1.4 | 14.5 ± 0.5 | 14.5 ± 0.4 | 14.3 ± 0.6 | 12.7 ± 0.3 | 13.6 ± 0.3 |

| Total VS Feeding (t VS day−1) | 11.6 ± 0.5 | 12.6 ± 0.5 | 12.0 ± 0.3 | 11.8 ± 0.2 | 11.6 ± 1.1 | 11.8 ± 0.4 | 11.6 ± 0.4 | 11.3 ± 0.4 | 10.1 ± 0.2 | 10.9 ± 0.2 |

| Total OLR (kg COD m−3 day−1) | 3.4 ± 0.1 (3.3–3.4) | 3.8 ± 0.2 (3.8–3.9) | 3.6 ± 0.1 (3.6–3.7) | 3.5 ± 0.0 (3.5–3.5) | 3.5 ± 0.3 (3.4–3.6) | 3.5 ± 0.1 (3.4–3.5) | 3.4 ± 0.1 (3.4–3.5) | 3.4 ± 0.2 (3.4–3.5) | 3.0 ± 0.1 (3.0–3.0) | 3.3 ± 0.1 (3.2–3.3) |

| COD/TKN | 29 ± 1 | 30 ± 1 | 30 ± 1 | 29 ± 0 | 29 ± 2 | 28 ± 1 | 28 ± 1 | 28 ± 3 | 34 ± 1 | 28 ± 1 |

| HRT (day) | 31 ± 2 | 28 ± 1 | 29 ± 1 | 28 ± 1 | 30 ± 6 | 29 ± 1 | 29 ± 1 | 30 ± 0 | 30 ± 0 | 30 ± 1 |

References

- European Commission Roadmap 2050. Policy; Publications Office of the European Union: Luxembourg, 2012; pp. 1–9. ISBN 978-92-79-21798-2. [Google Scholar] [CrossRef]

- Cavinato, C.; Fatone, F.; Bolzonella, D.; Pavan, P. Thermophilic anaerobic co-digestion of cattle manure with agro-wastes and energy crops: Comparison of pilot and full scale experiences. Bioresour. Technol. 2010, 101, 545–550. [Google Scholar] [CrossRef]

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef]

- Pobeheim, H.; Munk, B.; Johansson, J.; Guebitz, G.M. Influence of trace elements on methane formation from a synthetic model substrate for maize silage. Bioresour. Technol. 2010, 101, 836–839. [Google Scholar] [CrossRef]

- Comino, E.; Riggio, V.A.; Rosso, M. Biogas production by anaerobic co-digestion of cattle slurry and cheese whey. Bioresour. Technol. 2012, 114, 46–53. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, G.; Peng, L.; Su, H.; Tan, T. The anaerobic co-digestion of food waste and cattle manure. Bioresour. Technol. 2013, 129, 170–176. [Google Scholar] [CrossRef] [PubMed]

- Fitamo, T.; Boldrin, A.; Boe, K.; Angelidaki, I.; Scheutz, C. Co-digestion of food and garden waste with mixed sludge from wastewater treatment in continuously stirred tank reactors. Bioresour. Technol. 2016, 206, 245–254. [Google Scholar] [CrossRef] [PubMed]

- Jha, P.; Schmidt, S. Reappraisal of chemical interference in anaerobic digestion processes. Renew. Sustain. Energy Rev. 2017, 75, 954–971. [Google Scholar] [CrossRef]

- Garuti, M.; Langone, M.; Fabbri, C.; Piccinini, S. Methodological approach for trace elements supplementation in anaerobic digestion: Experience from full-scale agricultural biogas plants. J. Environ. Manag. 2018, 223, 348–357. [Google Scholar] [CrossRef]

- Alatriste-Mondragón, F.; Samar, P.; Cox, H.H.J.; Ahring, B.K.; Iranpour, R. Anaerobic Codigestion of Municipal, Farm, and Industrial Organic Wastes: A Survey of Recent Literature. Water Environ. Res. 2006, 78, 607–636. [Google Scholar] [CrossRef]

- Shah, F.A.; Mahmood, Q.; Rashid, N.; Pervez, A.; Raja, I.A.; Shah, M.M. Co-digestion, pretreatment and digester design for enhanced methanogenesis. Renew. Sustain. Energy Rev. 2015, 42, 627–642. [Google Scholar] [CrossRef]

- Zupančič, G.D.; Uranjek-Ževart, N.; Roš, M. Full-scale anaerobic co-digestion of organic waste and municipal sludge. Biomass Bioenergy 2008, 32, 162–167. [Google Scholar] [CrossRef]

- Nägele, H.J.; Steinbrenner, J.; Hermanns, G.; Holstein, V.; Haag, N.L.; Oechsner, H. Innovative additives for chemical desulphurisation in biogas processes: A comparative study on iron compound products. Biochem. Eng. J. 2017, 121, 181–187. [Google Scholar] [CrossRef]

- Garuti, M.; Langone, M.; Fabbri, C.; Piccinini, S. Monitoring of full-scale hydrodynamic cavitation pretreatment in agricultural biogas plant. Bioresour. Technol. 2018, 247, 599–609. [Google Scholar] [CrossRef]

- Rasheed, R.; Yasar, A.; Ahmad, S.R.; Tabinda, A.B.; Khan, S.A.; Su, Y. Bioenergy recovery analysis from various waste substrates by employing a novel industrial scale AD plant. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 1935–1946. [Google Scholar] [CrossRef]

- Martí-Herrero, J.; Soria-Castellón, G.; Diaz-de-Basurto, A.; Alvarez, R.; Chemisana, D. Biogas from a full scale digester operated in psychrophilic conditions and fed only with fruit and vegetable waste. Renew. Energy 2019, 133, 676–684. [Google Scholar] [CrossRef]

- Björnsson, L.; Murto, M.; Mattiasson, B. Evaluation of parameters for monitoring an anaerobic co-digestion process. Appl. Microbiol. Biotechnol. 2000, 54, 844–849. [Google Scholar] [CrossRef]

- Carrere, H.; Antonopoulou, G.; Affes, R.; Passos, F.; Battimelli, A.; Lyberatos, G.; Ferrer, I. Review of feedstock pretreatment strategies for improved anaerobic digestion: From lab-scale research to full-scale application. Bioresour. Technol. 2016, 199, 386–397. [Google Scholar] [CrossRef]

- Zhurka, M.; Spyridonidis, A.; Vasiliadou, I.A.; Stamatelatou, K. Biogas production from sunflower head and stalk residues: Effect of alkaline pretreatment. Molecules 2020, 25, 164. [Google Scholar] [CrossRef]

- Alexandridis, C. Map of biogas plants (in Greek). Bioenergy News 2018, 2, 14–17. [Google Scholar]

- Hellenic Electricity Distribution Network Operator S.A. Available online: https://www.deddie.gr/en/ (accessed on 19 February 2020).

- Obregón Valencia, D.; García Sánchez, H.; Díaz Tang, I. The corrosion behavior of ferrous materials immersed in acidic-media using D-optimal design. Multidiscip. Model. Mater. Struct. 2019, 16, 647–656. [Google Scholar] [CrossRef]

- Komilis, D.P.; Tziouvaras, I.S. A statistical analysis to assess the maturity and stability of six composts. Waste Manag. 2009, 29, 1504–1513. [Google Scholar] [CrossRef] [PubMed]

- APHA. Standard Methods for the Examination of Water & Wastewater, 20th ed.; American Public Health Association/American Water Works Association/Water Environment Federation: Washington, DC, USA, 2005. [Google Scholar]

- Spyridonidis, A.; Skamagkis, T.; Lambropoulos, L.; Stamatelatou, K. Modeling of anaerobic digestion of slaughterhouse wastes after thermal treatment using ADM1. J. Environ. Manag. 2018, 224, 49–57. [Google Scholar] [CrossRef] [PubMed]

- Bouallagui, H.; Touhami, Y.; Ben Cheikh, R.; Hamdi, M. Bioreactor performance in anaerobic digestion of fruit and vegetable wastes. Process Biochem. 2005, 40, 989–995. [Google Scholar] [CrossRef]

- Weiland, P. Biomass digestion in agriculture: A successful pathway for the energy production and waste treatment in Germany. Eng. Life Sci. 2006, 6, 302–309. [Google Scholar] [CrossRef]

- Khoufi, S.; Louhichi, A.; Sayadi, S. Optimization of anaerobic co-digestion of olive mill wastewater and liquid poultry manure in batch condition and semi-continuous jet-loop reactor. Bioresour. Technol. 2015, 182, 67–74. [Google Scholar] [CrossRef]

- Drosg, B. Process Monitoring in Biogas Plants; IEA Bioenergy: Paris, France, 2013; pp. 1–38. ISBN 978-1-910154-02-1. [Google Scholar]

- Carrera-Chapela, F.; Donoso-Bravo, A.; Jeison, D.; Díaz, I.; Gonzalez, J.A.; Ruiz-Filippi, G. Development, identification and validation of a mathematical model of anaerobic digestion of sewage sludge focusing on H2S formation and transfer. Biochem. Eng. J. 2016, 112, 13–19. [Google Scholar] [CrossRef]

- Okoro, O.V.; Sun, Z. Desulphurisation of Biogas: A Systematic Qualitative and Economic-Based Quantitative Review of Alternative Strategies. ChemEngineering 2019, 3, 76. [Google Scholar] [CrossRef]

- Naegele, H.J.; Lindner, J.; Merkle, W.; Lemmer, A.; Jungbluth, T.; Bogenrieder, C. Effects of temperature, pH and O2 on the removal of hydrogen sulfide from biogas by external biological desulfurization in a full scale fixed-bed trickling bioreactor (FBTB). Int. J. Agric. Biol. Eng. 2013, 6, 69–81. [Google Scholar] [CrossRef]

- Thompson, J.C.; He, B.B. Characterization of crude glycerol from biodiesel production from multiple feedstocks. Appl. Eng. Agric. 2006, 22, 261–265. [Google Scholar] [CrossRef]

- Antonious, G.F.; Perkins, E.; Cantor, A.H. Chicken manure increased concentration of organic sulfur compounds in field-grown onions. J. Environ. Sci. Health Part B Pestic. Food Contam. Agric. Wastes 2009, 44, 481–487. [Google Scholar] [CrossRef]

- Ouazzane, H.; Laajine, F.; El Yamani, M.; El Hilaly, J.; Rharrabti, Y.; Amarouch, M.Y.; Mazouzi, D. Olive mill solid waste characterization and recycling opportunities: A review. J. Mater. Environ. Sci. 2017, 8, 2632–2650. [Google Scholar]

- Allegue, L.B.; Hinge, J. Biogas Upgrading Evaluation of Methods for H2S Removal; Danish Technological Institute: Taastrup, Denmark, 2014; Volume 31. [Google Scholar]

- Hvitved-Jacobsen, T.; Vollertsen, J.; Nielsen, A.H. Sewer Processes: Microbial and Chemical Process Engineering of Sewer Networks, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2013; ISBN 978-1-4398-8177-4. [Google Scholar]

- Valli, L.; Rossi, L.; Fabbri, C.; Sibilla, F.; Gattoni, P.; Dale, B.E.; Kim, S.; Ong, R.G.; Bozzetto, S. Greenhouse gas emissions of electricity and biomethane produced using the Biogasdoneright™ system: Four case studies from Italy. Biofuels Bioprod. Bioref. 2017, 11, 847–860. [Google Scholar] [CrossRef]

- Ahn, H.K.; Mulbry, W.; White, J.W.; Kondrad, S.L. Pile mixing increases greenhouse gas emissions during composting of dairy manure. Bioresour. Technol. 2011, 102, 2904–2909. [Google Scholar] [CrossRef]

- Liebetrau, J.; Reinelt, T.; Clemens, J.; Hafermann, C.; Friehe, J.; Weiland, P. Analysis of greenhouse gas emissions from 10 biogas plants within the agricultural sector. Water Sci. Technol. 2013, 67, 1370–1379. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Biological Treatment of Biowaste. Available online: http://europa.eu.int/comm/environment/waste/facts_en.htm (accessed on 1 September 2020).

- Nkoa, R. Agricultural benefits and environmental risks of soil fertilization with anaerobic digestates: A review. Agron. Sustain. Dev. 2014, 34, 473–492. [Google Scholar] [CrossRef]

- Molaey, R.; Bayrakdar, A.; Sürmeli, R.Ö.; Çalli, B. Anaerobic digestion of chicken manure: Mitigating process inhibition at high ammonia concentrations by selenium supplementation. Biomass Bioenergy 2018, 108, 439–446. [Google Scholar] [CrossRef]

- Stamatelatou, K.; Antonopoulou, G.; Ntaikou, I.; Lyberatos, G. The Effect of Physical, Chemical, and Biological Pretreatments of Biomass on its Anaerobic Digestibility and Biogas Production. Biogas Prod. Pretreat. Methods Anaerob. Dig. 2012, 3, 55–90. [Google Scholar] [CrossRef]

- Carrère, H.; Dumas, C.; Battimelli, A.; Batstone, D.J.; Delgenès, J.P.; Steyer, J.P.; Ferrer, I. Pretreatment methods to improve sludge anaerobic degradability: A review. J. Hazard. Mater. 2010, 183, 1–15. [Google Scholar] [CrossRef]

- Carballa, M.; Duran, C.; Hospido, A. Should we pretreat solid waste prior to anaerobic digestion? An assessment of its environmental cost. Environ. Sci. Technol. 2011, 45, 10306–10314. [Google Scholar] [CrossRef]

- Nguyen, L.N.; Johir, M.A.H.; Commault, A.; Bustamante, H.; Aurisch, R.; Lowrie, R.; Nghiem, L.D. Impacts of mixing on foaming, methane production, stratification and microbial community in full-scale anaerobic co-digestion process. Bioresour. Technol. 2019, 281, 226–233. [Google Scholar] [CrossRef]

- Ganidi, N.; Tyrrel, S.; Cartmell, E. Anaerobic digestion foaming causes—A review. Bioresour. Technol. 2009, 100, 5546–5554. [Google Scholar] [CrossRef] [PubMed]

- Mattioli, A.; Gatti, G.B.; Mattuzzi, G.P.; Cecchi, F.; Bolzonella, D. Co-digestion of the organic fraction of municipal solid waste and sludge improves the energy balance of wastewater treatment plants: Rovereto case study. Renew. Energy 2017, 113, 980–988. [Google Scholar] [CrossRef]

| Parameter (Unit) | TS (g kgww−1) | VS (g kgww−1) | COD (gCOD kgww−1) | Total Nitrogen TKN (g kgww−1) | COD/ΤKΝ | pH |

|---|---|---|---|---|---|---|

| Cow manure, CM | 67 ± 20 (48–86) | 55 ± 16 (39–71) | 66 ± 3 (63–69) | 2.6 ± 0.2 (2.5–2.8) | 25.4 ± 2.0 (23.4–27.3) | 6.99 ± 0.24 (6.75–7.23) |

| Chicken manure, ChM | 627 ± 28 (603–652) | 522 ± 11 (512–532) | 746 ± 67 (687–805) | 35.9 ± 2.2 (33.9–37.8) | 20.8 ± 1.7 (19.3–22.3) | N.D. |

| Corn silage, CS | 293 ± 13 (280–306) | 278 ± 13 (265–291) | 399 ± 14 (380–418) | 3.8 ± 0.2 (3.6–4.1) | 104.8 ± 6.0 (96.5–113) | N.D. |

| Wheat/Ray Silage, WS | 299 ± 8 (287–310) | 220 ±2 (217–222) | 377 ± 23 (351–403) | 4.5 ± 0.5 (4.0–5.1) | 84.0 ± 8.6 (72.1–95.9) | N.D. |

| Cheese whey, CW | 121 ± 1 (119–123) | 100 ± 2 (97–103) | 159 ± 8 (151–167) | 2.7 ± 0.1 (2.6–2.8) | 58.6 ± 0.1 (58.5–58.6) | 4.06 ± 0.08 (3.98–4.14) |

| Olive mill wastewater, OMW | 70.7 ± 0.3 (70–71) | 53.3 ± 0.6 (53–54) | 137 ± 6 (128–146) | 1.14 ± 0.04 (1.1–1.2) | 119.8 ± 5.8 (111.7–127.8) | 4.28 ± 0.28 (3.89–4.67) |

| Glycerin, Gl | 812 ± 52 (752–871) | 769 ± 55 (707–831) | 1242 ± 35 (1208–1276) | N.D. | N.D. | 9.28 ± 1.8 (6.79–11.77) |

| Molasses, Ml | 768 ± 23 (736–800) | 645 ± 41 (589–701) | 695 ± 23 (669–721) | 14.6 ± 1.5 (12.5–16.7) | 48 ± 4.0 (42.1–53.4) | 5.50 |

| Feedstock | Average Daily Feeding (t day−1) | CH4 Yield (m3 CH4 tWW−1) | CH4 Production (m3 CH4 day−1) |

|---|---|---|---|

| Chicken manure | 3.2 | 136 | 434 |

| Olive mill wastewater | 4.4 | 24 | 106 |

| Cheese whey | 2.5 | 41 | 103 |

| Corn silage | 3 | 97 | 290 |

| Wheat/ray silage | 3.5 | 57 | 200 |

| Cow manure | 120 | 12 | 1440 |

| Glycerin | 1.2 | 460 | 552 |

| Molasses | 0.16 | 216 | 35 |

| Total | - | - | 3195 |

| Substrate | Distance Required for Feeding (km t−1 day−1) |

|---|---|

| Cow manure | 0.778 |

| Corn silage | 0.900 |

| Wheat/ray silage | 0.900 |

| Olive mill wastewater | 2.000 |

| Chicken manure | 5.000 |

| Cheese whey | 8.800 |

| Glycerin | 17.500 |

| Molasses | 19.130 |

| Substrate | Aquisition Cost (€ tWW−1) | CH4 Yield (m3 CH4 tVS−1) | VS (kg tWW−1) | CH4 Yield (m3 CH4 tWW−1) | Production Cost (€ m3CH4−1) | Production Cost (€ kWh−1) | Profit (€ kWh−1) |

|---|---|---|---|---|---|---|---|

| Chicken manure | 10 | 260 | 522 | 136 | 0.07 | 0.02 | 0.207 |

| Olive mill wastewater | 4.5 | 450 | 53 | 24 | 0.19 | 0.05 | 0.178 |

| Cheese whey | 10 | 413 | 100 | 41 | 0.24 | 0.06 | 0.165 |

| Cow manure | 3.5 | 218 | 55 | 12 | 0.29 | 0.07 | 0.153 |

| Glycerin | 177 | 468 | 769 | 360 | 0.49 | 0.12 | 0.104 |

| Corn silage | 50 | 348 | 278 | 97 | 0.52 | 0.13 | 0.097 |

| Triticale silage | 40 | 260 | 220 | 57 | 0.70 | 0.17 | 0.052 |

| Molasses | 170 | 335 | 645 | 216 | 0.79 | 0.19 | 0.031 |

| Feedstock a | Digestor b | T (°C) | HRT (day) | OLR (kg VS m−3 day−1) | BY (m3 kg VS−1) | CH4 (%) | Energy (MWhel year−1) | Power (W) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| DR, MS | 2 CSTR in series, R | 20 | 1 | 0.39 | [12] | ||||

| CM, MaS, FPW, B | Two-stage digester | 47 | 33 | 5.39 | 0.45 | 52.3 | 8789 | 1000 | [2] |

| DR, MS | 2 CSTR in parallel | 30–40 | 1.38 ± 0.78 | 0.5 | 57 ± 3 | 2847 | [49] | ||

| Pretreated PS, MaS, M, CoM | 3 CSTR in series | 42–43 | 30–35 | 2.92 | 0.38 ± 0.04 | 58.7 ± 0.6 | 6433 ± 330 | 725 | [14] |

| MaS, WS, CM | 2 CSTR in series, R | 40–42 | 107 ± 18 | 1.83 ± 0.16 | 0.25 ± 0.01 | 51.9 ± 1.7 | 380 | [9] | |

| PS, MS, ChM MG | 2 CSTR in parallel and a Post Fermenter | 40–42 | 40 ± 2 | 2.33 ± 0.19 | 0.35 ± 0.03 | 53.7 ± 1.5 | 999 | [9] | |

| CM, PW | 3 digesters | 35–37 | 0.112 | 62 | 170 | 150 | [15] | ||

| CM, ChM, CS, WS, CWW, OMW Gl, M | One-stage digester | 40 | 29.4 ± 2.1 | 2.7 | 0.46 ± 0.05 | 55 ± 1.3 | 4631 | 500 | This study |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spyridonidis, A.; Vasiliadou, I.A.; Akratos, C.S.; Stamatelatou, Κ. Performance of a Full-Scale Biogas Plant Operation in Greece and Its Impact on the Circular Economy. Water 2020, 12, 3074. https://doi.org/10.3390/w12113074

Spyridonidis A, Vasiliadou IA, Akratos CS, Stamatelatou Κ. Performance of a Full-Scale Biogas Plant Operation in Greece and Its Impact on the Circular Economy. Water. 2020; 12(11):3074. https://doi.org/10.3390/w12113074

Chicago/Turabian StyleSpyridonidis, Apostolos, Ioanna A. Vasiliadou, Christos S. Akratos, and Κaterina Stamatelatou. 2020. "Performance of a Full-Scale Biogas Plant Operation in Greece and Its Impact on the Circular Economy" Water 12, no. 11: 3074. https://doi.org/10.3390/w12113074

APA StyleSpyridonidis, A., Vasiliadou, I. A., Akratos, C. S., & Stamatelatou, Κ. (2020). Performance of a Full-Scale Biogas Plant Operation in Greece and Its Impact on the Circular Economy. Water, 12(11), 3074. https://doi.org/10.3390/w12113074