Water Footprint Management for Sustainable Growth in the Bangladesh Apparel Sector

Abstract

1. Introduction

2. Materials and Method

2.1. Imported Cotton, Cotton Yarn and Cotton Fabric

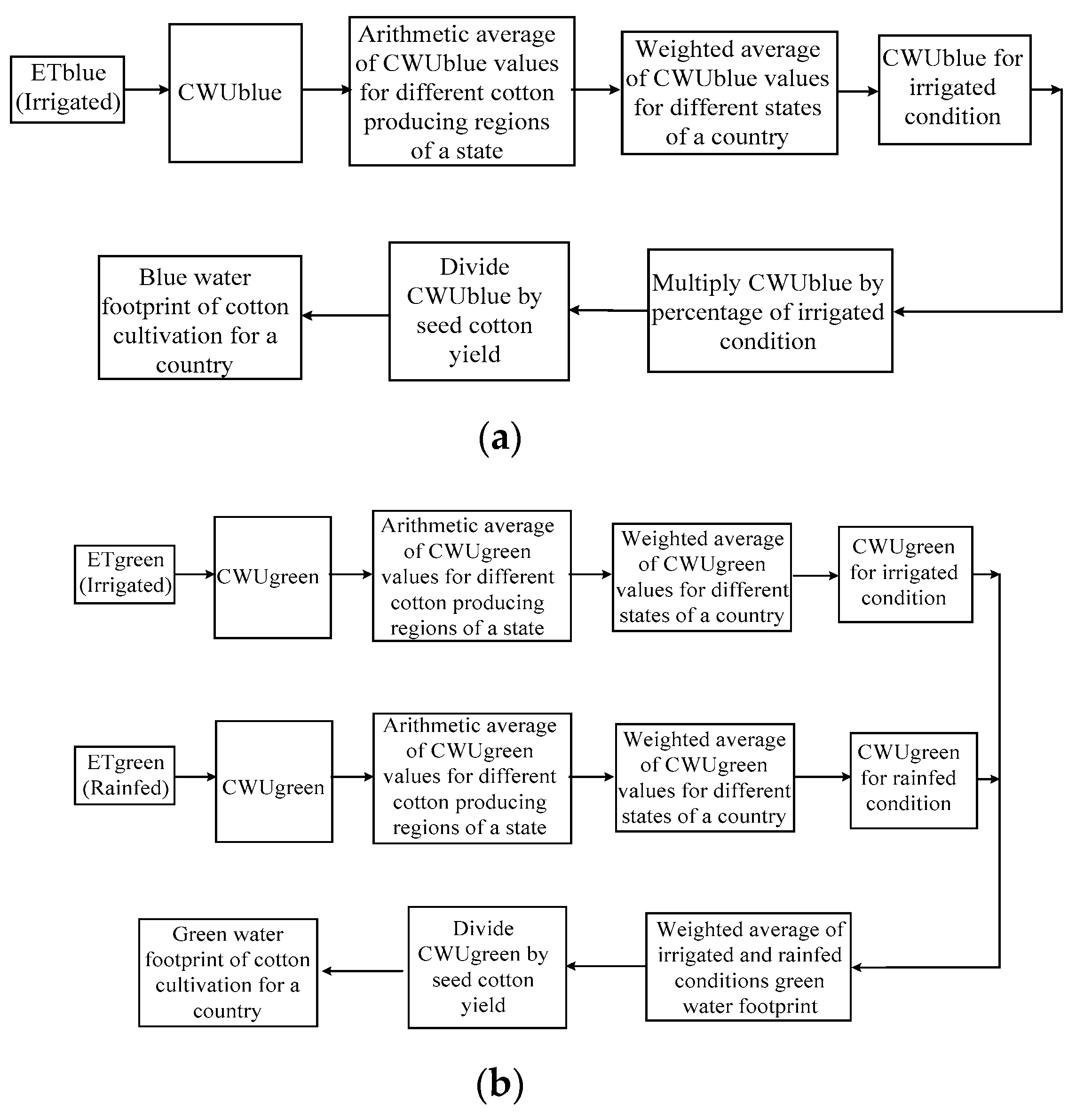

2.2. Water Footprint of Cotton Cultivation

- α = the leaching–runoff fraction, defined as the fraction of applied chemicals reaching freshwater bodies,

- Appl = application rate of chemicals on or into the soil (in mass/time),

- cmax = the maximum acceptable concentration for a pollutant and

- cnat = natural concentration for a pollutant in the receiving water body.

2.3. Water Footprint of Textile Industry

2.3.1. Raw Material for Textile Industry

2.3.2. Water Footprint Calculation for Textile Industry

- Effl = effluent volume,

- Abstr = water volume of the abstraction,

- ceffl = concentration of the pollutant in the effluent and

- cact = actual concentration of the intake water.

2.4. Water Footprint of Workers

2.5. Water Footprint for Transportation

3. Results

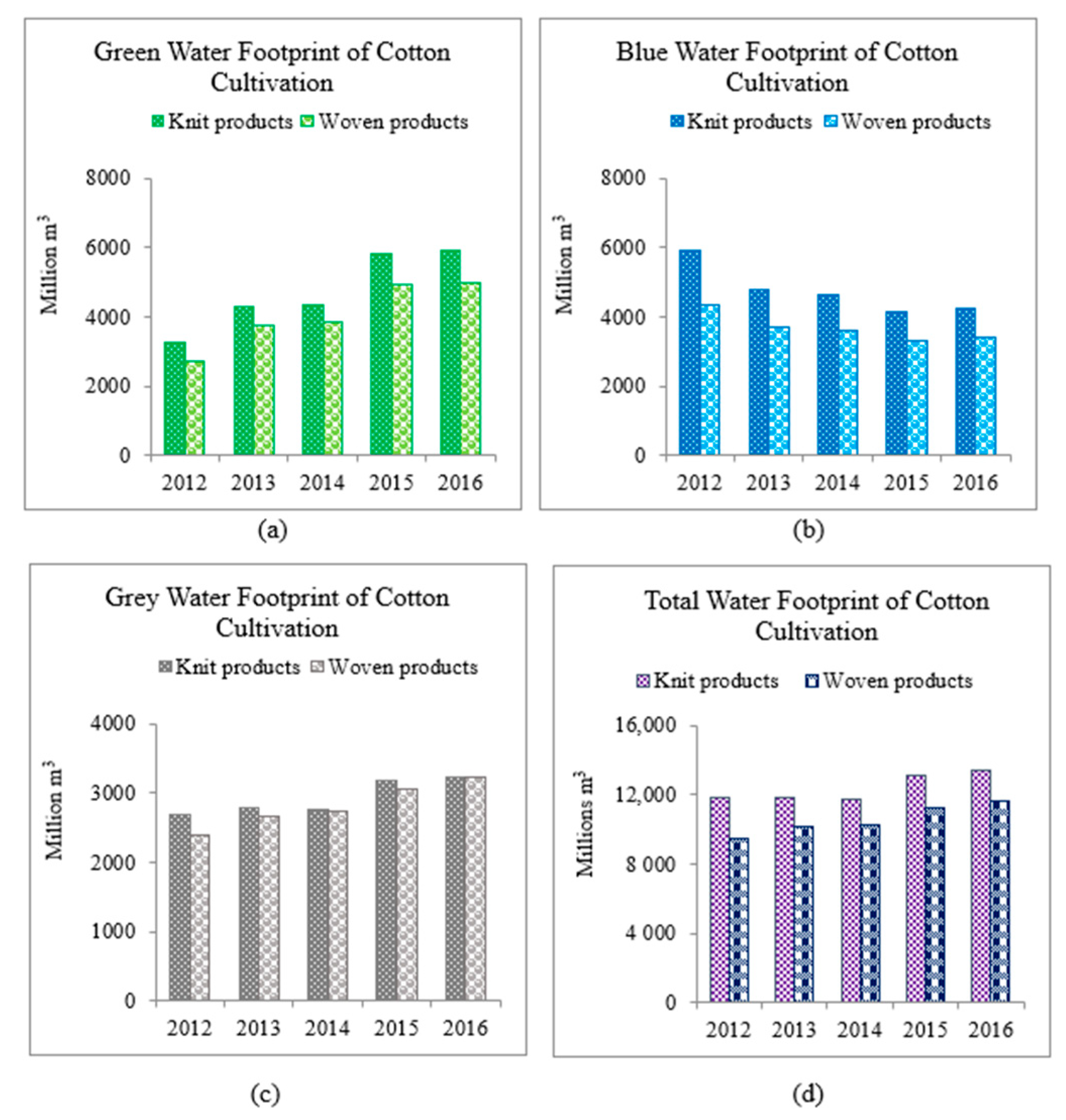

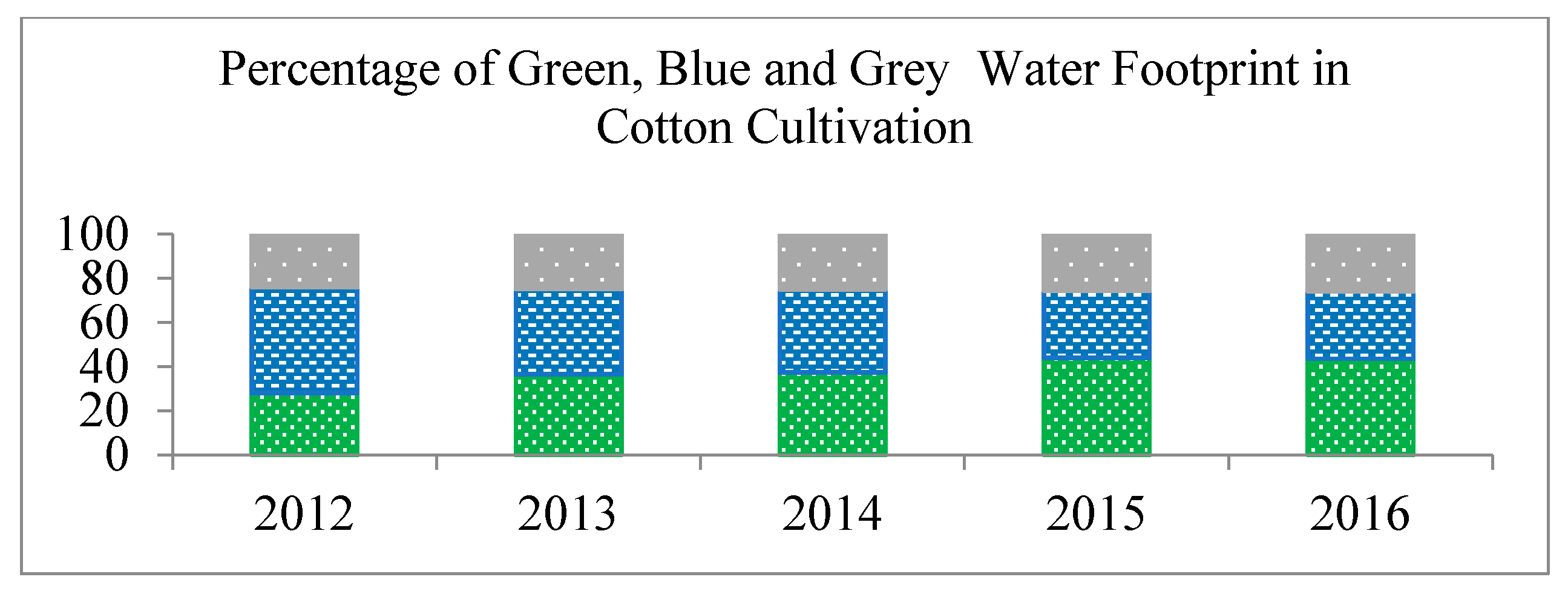

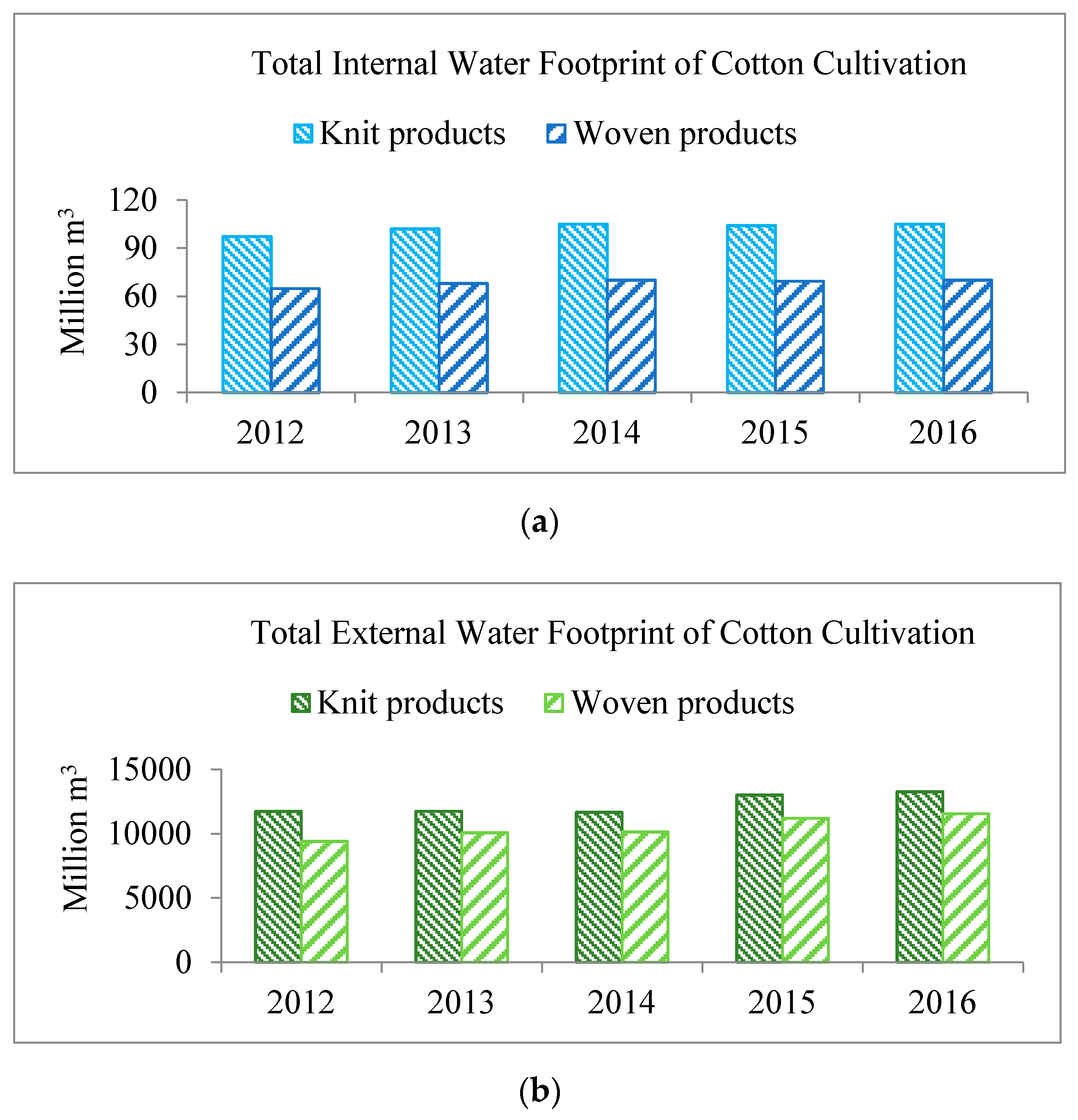

3.1. Water Footprint of Cotton Cultivation

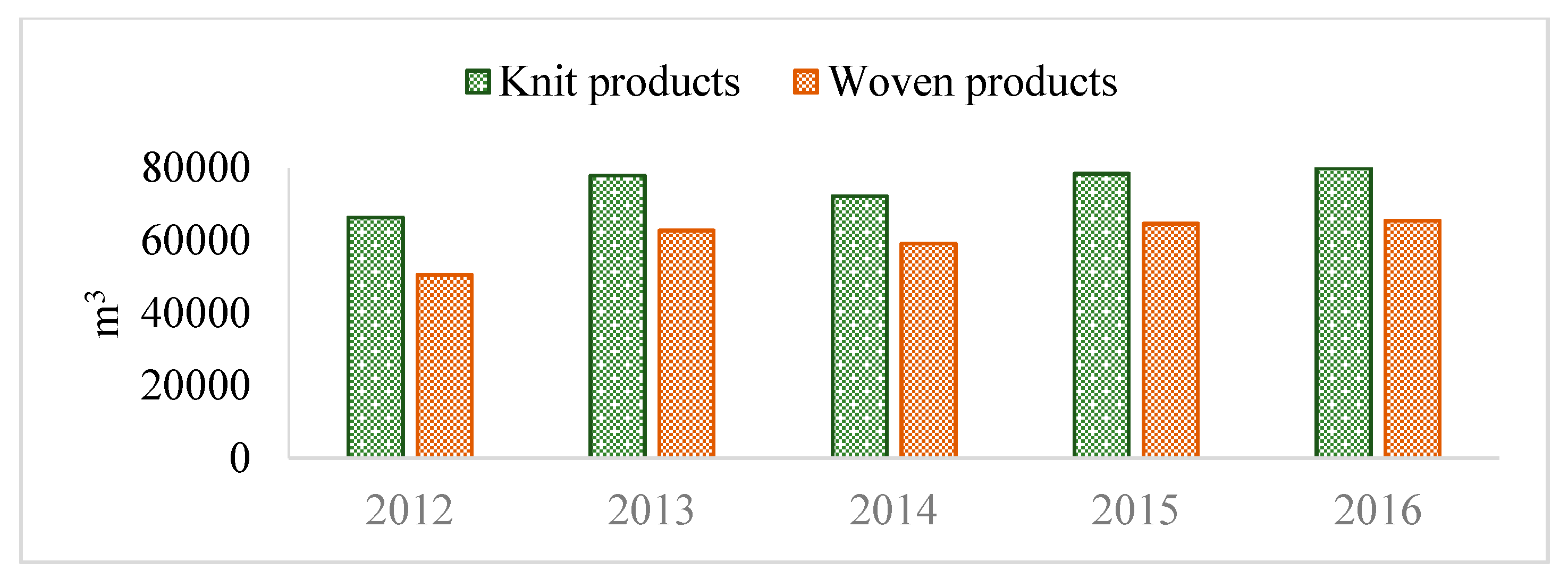

3.2. Water Footprint for Transportation

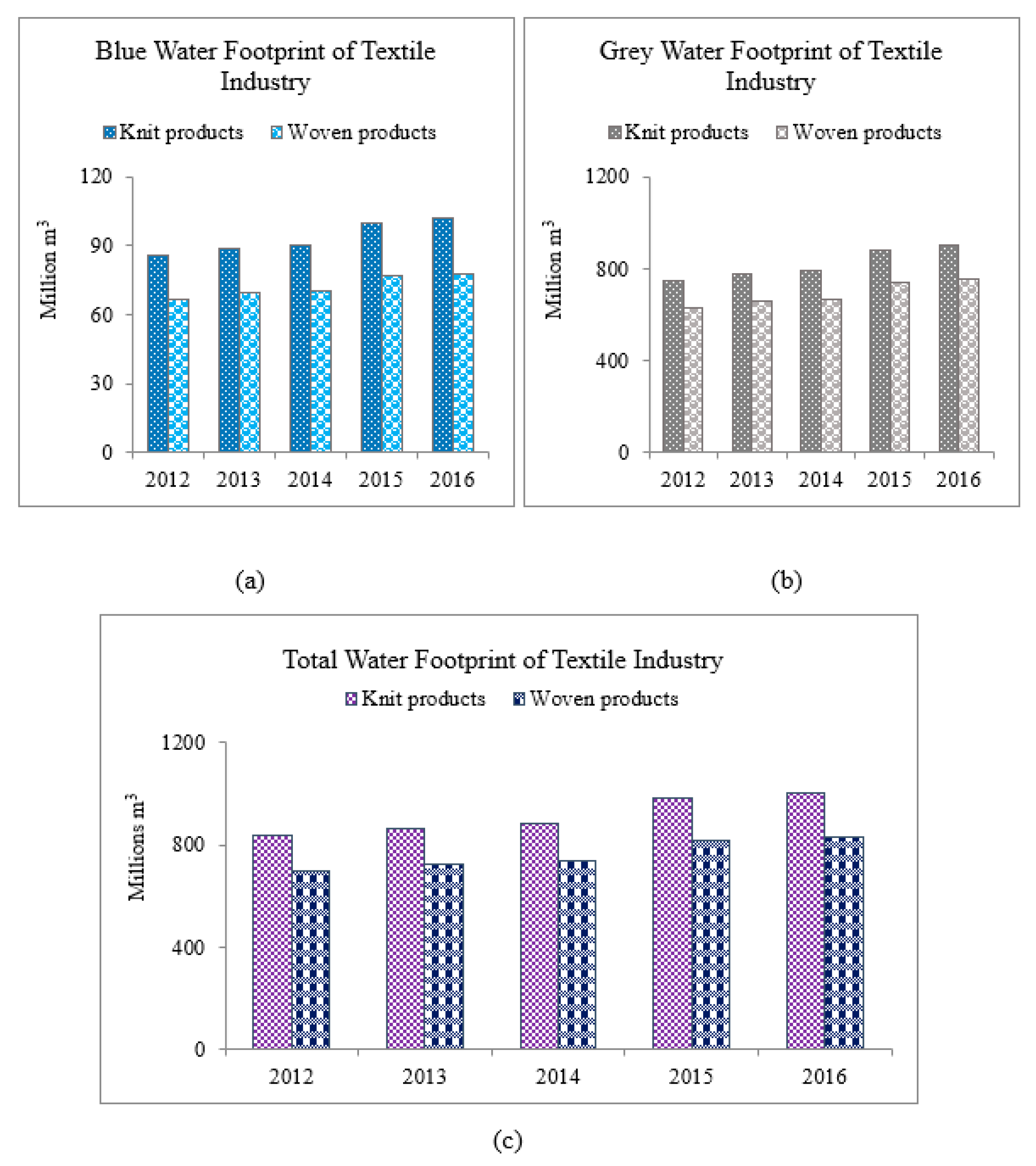

3.3. Water Footprint of Textile Industry

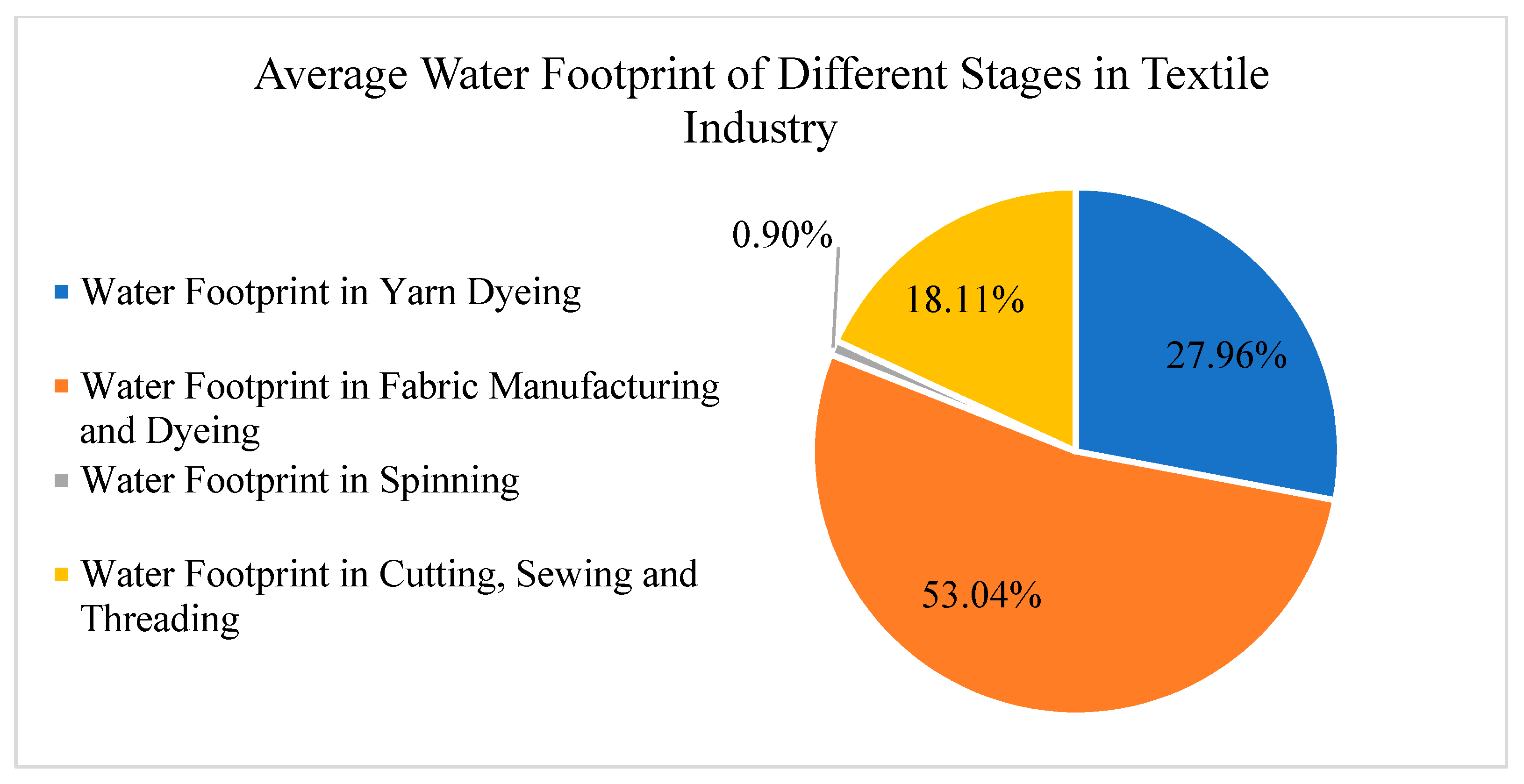

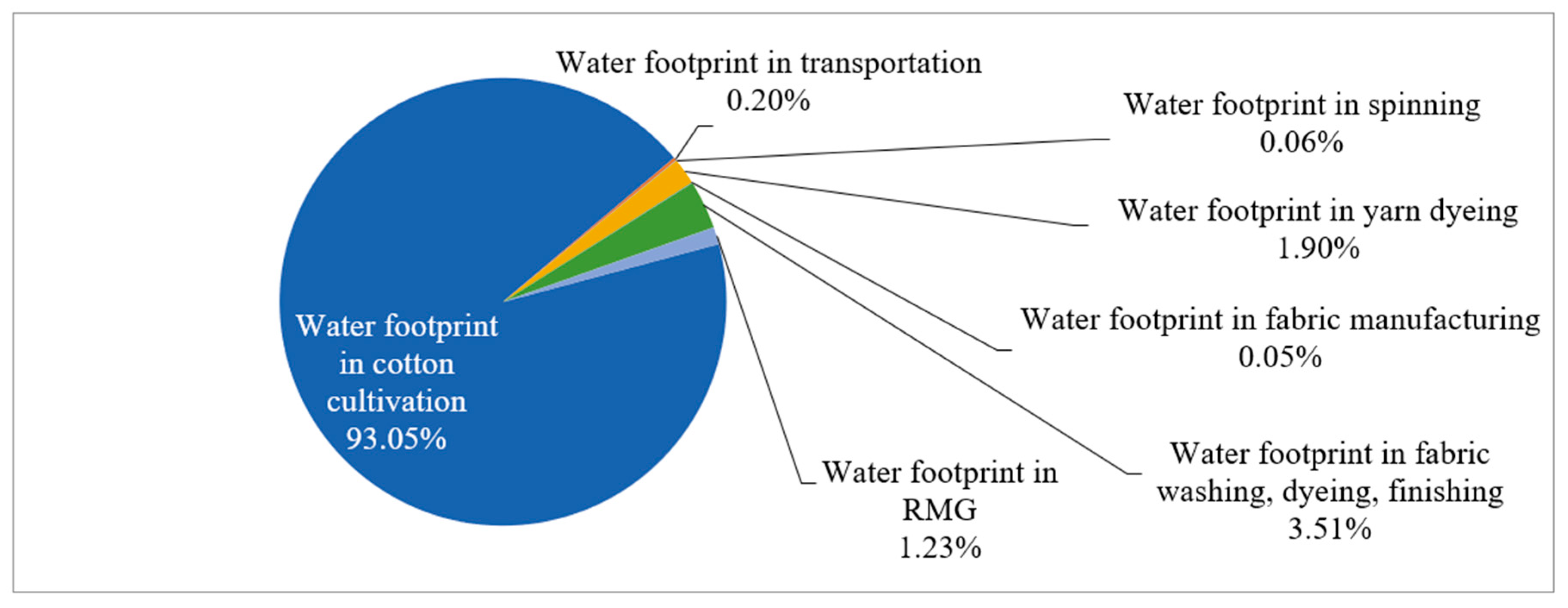

3.4. Water Footprint in Different Stages from Cotton Cultivation to Final Product

3.5. Total Water Footprint of RMG Production

3.6. Water Footprint Calculation for Different Products

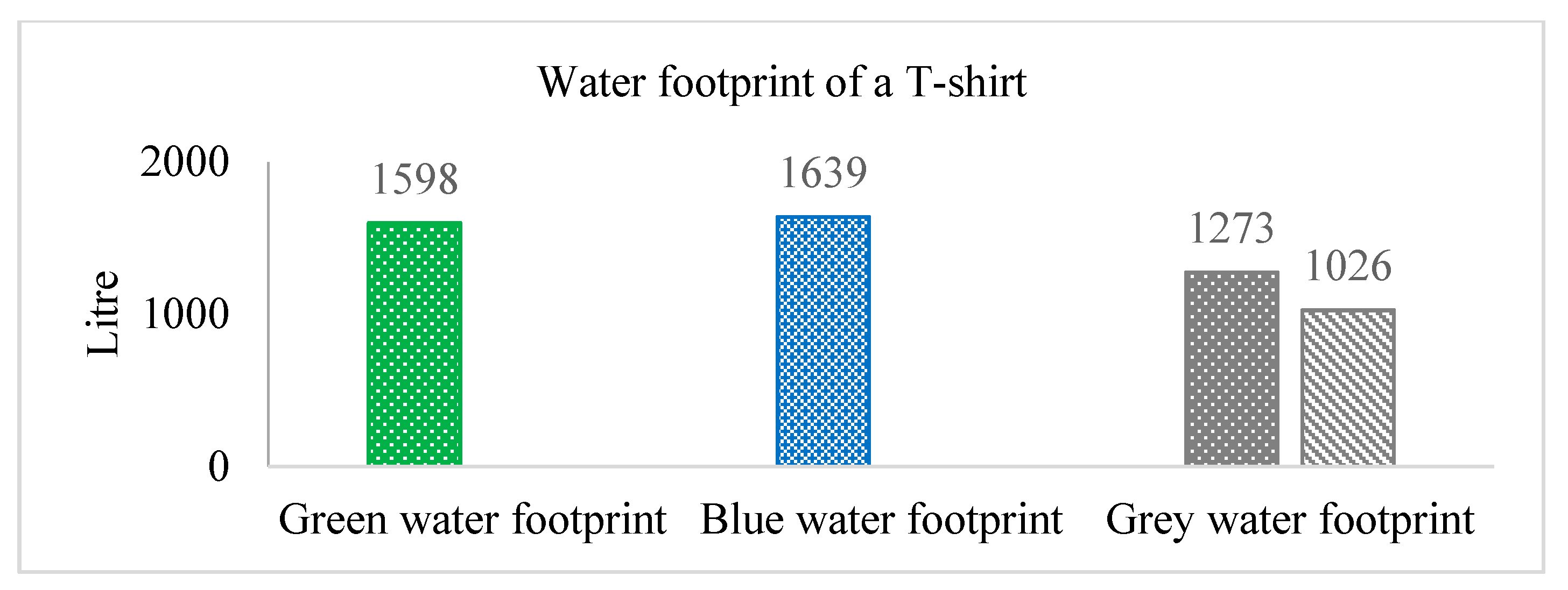

3.6.1. Water Footprint of a T-Shirt

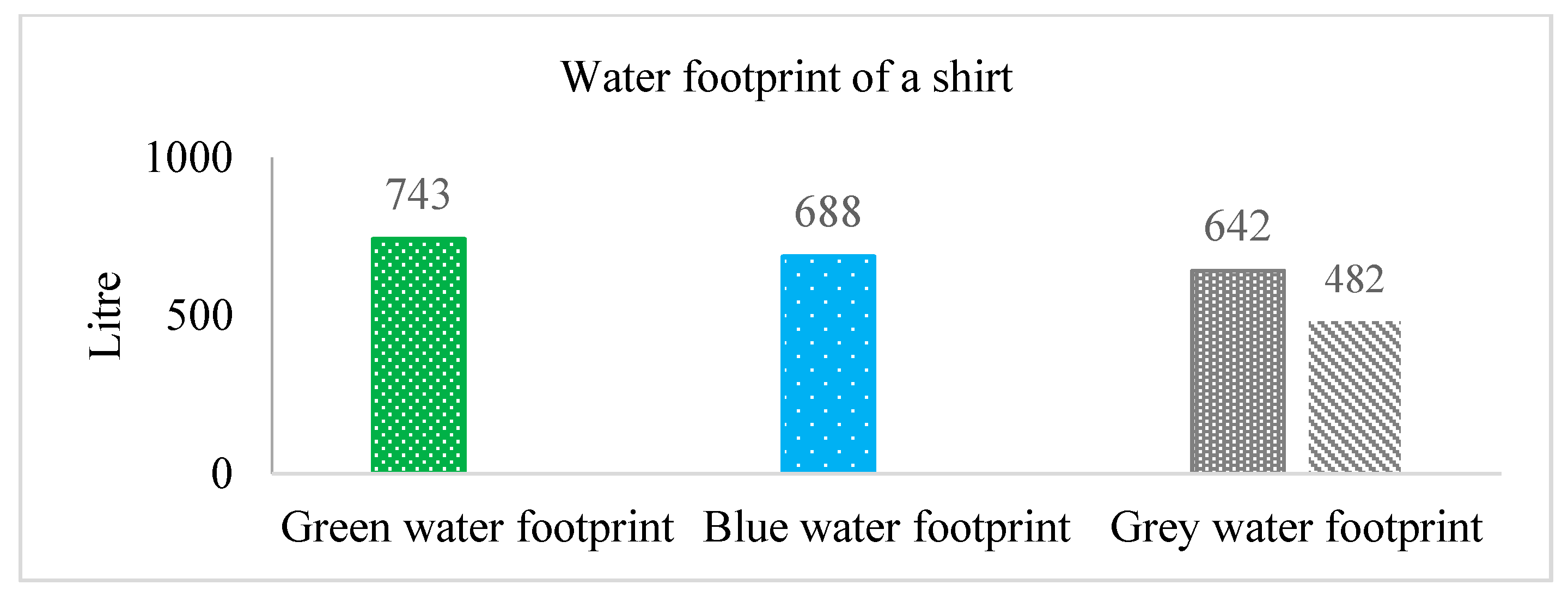

3.6.2. Water Footprint for a Shirt

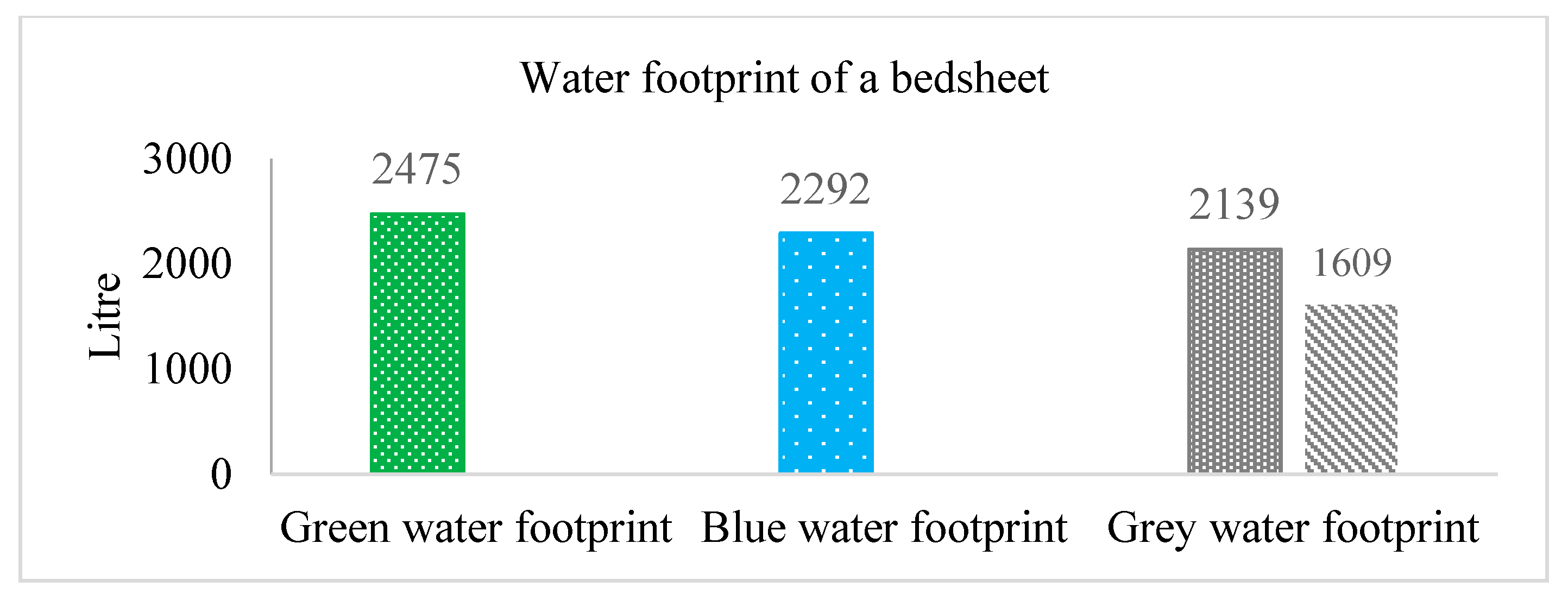

3.6.3. Water Footprint for a Single Bedsheet

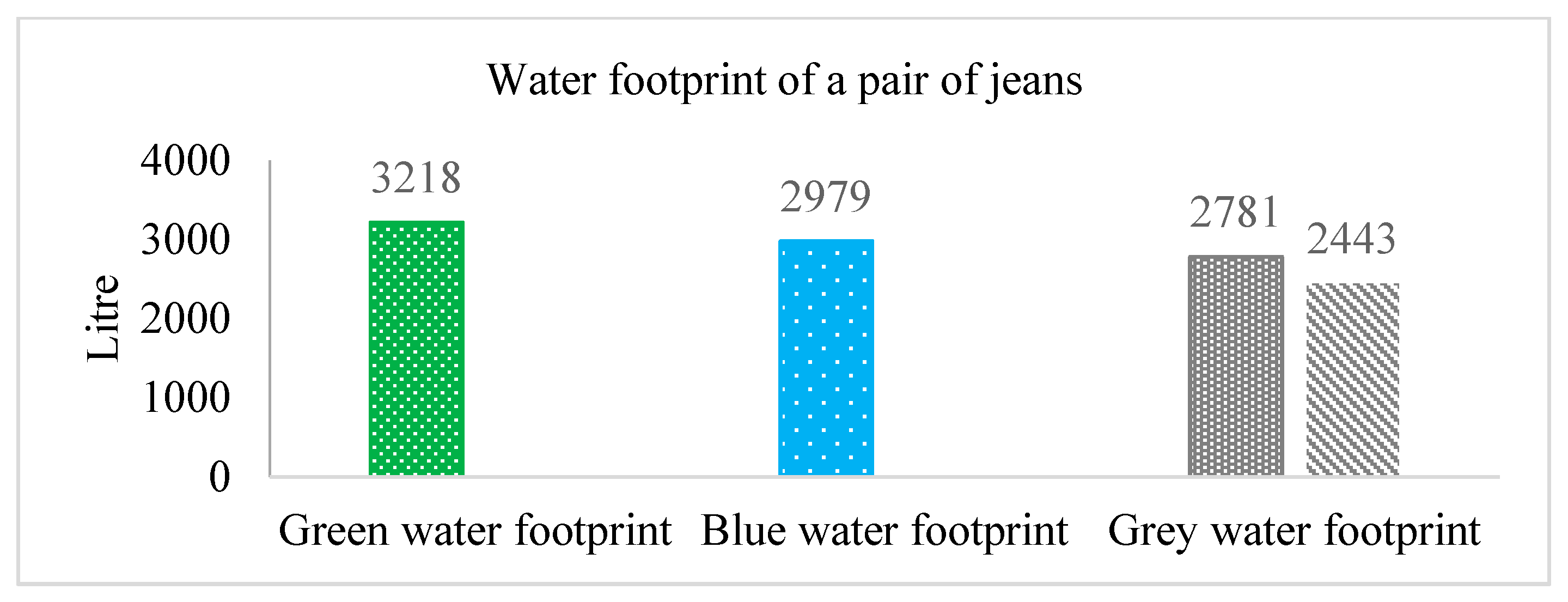

3.6.4. Water Footprint for a Pair of Jeans

4. Discussion

4.1. Cotton Cultivation

4.2. Textile Industry

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Country | Imported Cotton (%) | ||||

|---|---|---|---|---|---|

| 2012 | 2013 | 2014 | 2015 | 2016 | |

| Uzbekistan | 26 | 25 | 20 | 13 | 13 |

| India | 37 | 40 | 40 | 50 | 50 |

| East and West Africa | 7 | 13 | 13 | 18 | 18 |

| Turkmenistan | 11 | 3 | 3 | 2 | 2 |

| USA | 5 | 7 | 7 | 3 | 3 |

| Australia | 6 | 3 | 5 | 4 | 4 |

| Egypt | 2 | 2 | 3 | 3 | 3 |

| Brazil | 2 | 3 | 4 | 4 | 4 |

| Pakistan | 4 | 4 | 5 | 3 | 3 |

| Country | Imported Cotton Yarn (%) | ||||

|---|---|---|---|---|---|

| 2012 | 2013 | 2014 | 2015 | 2016 | |

| India | 75.49 | 69.04 | 66.16 | 69.22 | 66.59 |

| China | 15.09 | 22.23 | 25.89 | 22.68 | 23.89 |

| Pakistan | 8.63 | 7.59 | 7.09 | 7.33 | 7.11 |

| USA | 0.06 | 0.15 | 0.17 | 0.14 | 0.65 |

| Uzbekistan | 0.39 | 0.69 | 0.33 | 0.11 | 1.21 |

| Egypt | 0.32 | 0.29 | 0.37 | 0.52 | 0.54 |

| Country | Imported Cotton Woven Fabric (%) | ||||

|---|---|---|---|---|---|

| 2012 | 2013 | 2014 | 2015 | 2016 | |

| India | 14.42 | 13.63 | 11.76 | 14.07 | 9.48 |

| China | 73.20 | 72.13 | 70.05 | 71.11 | 64.38 |

| Pakistan | 12.15 | 14.20 | 17.97 | 14.24 | 25.33 |

| USA | 0.18 | 0.04 | 0.18 | 0.57 | 0.29 |

| Brazil | 0.03 | 0.004 | 0.03 | 0.001 | 0.51 |

| Year | Cotton (Metric ton) | Cotton Yarn (Metric ton) | Cotton Woven Fabric (Metric ton) |

|---|---|---|---|

| 2012 | 1,088,623 | 231,901 | 203,793 |

| 2013 | 1,153,940 | 236,133 | 228,761 |

| 2014 | 1,175,712 | 247,783 | 255,686 |

| 2015 | 1,349,892 | 264,432 | 265,830 |

| 2016 | 1,371,665 | 280,044 | 294,335 |

| Country | Seed Cotton Yield (ton/ha) | ||||

|---|---|---|---|---|---|

| 2012 | 2013 | 2014 | 2015 | 2016 | |

| Uzbekistan | 2.6447 | 2.5682 | 2.6133 | 2.5985 | 2.6133 |

| India | 1.5174 | 1.6165 | 1.6102 | 1.6110 | 1.6201 |

| East and West Africa | 1.0003 | 1.0212 | 1.0210 | 1.0200 | 1.024 |

| Turkmenistan | 1.1429 | 1.0363 | 1.0364 | 1.0350 | 1.0300 |

| USA | 2.7251 | 2.4997 | 2.5886 | 2.5895 | 2.5800 |

| Australia | 4.9567 | 5.5315 | 5.4783 | 5.4794 | 5.5000 |

| Egypt | 2.9426 | 3.6122 | 3.3859 | 3.399 | 3.4000 |

| Brazil | 3.5958 | 3.6201 | 3.7513 | 3.8001 | 3.8501 |

| Pakistan | 2.2113 | 2.2724 | 2.3021 | 2.3301 | 2.3500 |

| China | 3.2000 | 3.2471 | 3.2941 | 3.3000 | 3.3101 |

Appendix B

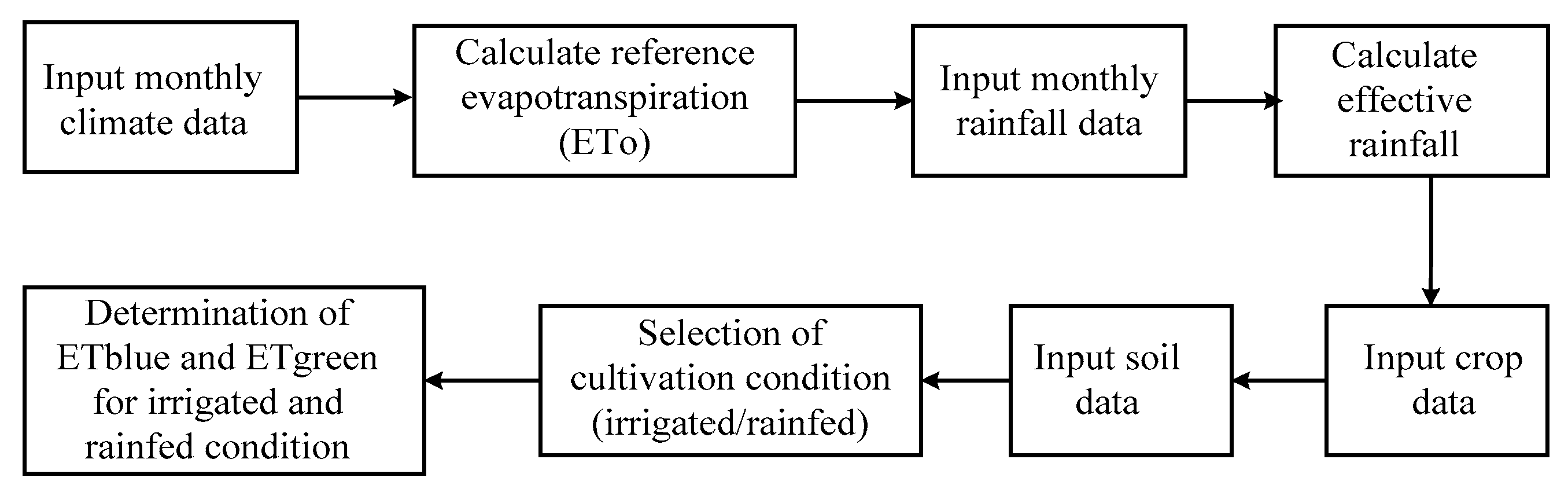

Appendix B.1. Blue and Green Water Footprint Calculation Procedure for Cotton Cultivation

- ETo = reference evapotranspiration (mm/day),

- Rn = net radiation at the crop surface (MJ/m2/day),

- G = soil heat flux density (MJ/m2/day),

- T = mean daily air temperature at 2 m heights (°C),

- u2 = wind speed at 2 m height (m/s),

- es = saturation vapor pressure (kPa),

- ea = actual vapor pressure (kPa),

- Δ = slope of saturation vapor pressure curve (kPa/°C) and

- a = psychrometric constant (kPa/°C)

| Country | Regions | Percentage |

|---|---|---|

| India | Gujarat | 30 |

| Maharashtra | 23 | |

| Punjab | 2 | |

| Andhra Pradesh and Telegana | 25 | |

| Karnataka | 6 | |

| Haryana | 4 | |

| Tamil Nadu | 1 | |

| Rajasthan | 5 | |

| Madhya Pradesh | 6 | |

| West and East Africa | Burkina Faso | 19 |

| Benin | 15 | |

| Mali | 22 | |

| Senegal | 3 | |

| Cote d’Ivoire | 14 | |

| Nigeria | 9 | |

| Togo | 7 | |

| Uganda | 3 | |

| Tanzania | 7 | |

| Uzbekistan | Samarkand, Kashkadar, Dzhiak | 36 |

| Bukhara | 14 | |

| Fergana | 11 | |

| Khorezm, Karnapak | 18 | |

| Andizhan | 11 | |

| Tashkent | 10 | |

| Brazil | Mato Grosso | 44 |

| Bahia | 23 | |

| Goias | 13 | |

| Sao Paulo | 6 | |

| Mato Grosso do Sul | 6 | |

| Minas Gerais | 4 | |

| Parana | 3 | |

| Turkmenistan | Ahal | 50 |

| Mary | 50 | |

| Egypt | Cairo | 33 |

| Alexandria | 33 | |

| Asswan | 33 | |

| China | Urumqi | 100 |

| Country | Regions | Percentage |

|---|---|---|

| Bangladesh | Faridpur | 20 |

| Jessore | 20 | |

| Mymensingh | 20 | |

| Khulna | 20 | |

| Dinajpur | 20 | |

| USA | Texas | 65 |

| Georgia | 23 | |

| California | 11 | |

| Pakistan | Punjab | 75 |

| Sindh | 25 | |

| Australia | New South Wales | 70 |

| Queensland | 30 |

Appendix C

Appendix C.1. Crop Data

| Crop Parameter | Initial | Development | Mid Season | Late Season | Total |

|---|---|---|---|---|---|

| Crop coefficient, Kc | 0.35 | - | 1.15 | 0.75 | - |

| Stage (days) | 30 | 50 | 55 | 45 | - |

| Rooting depth (m) | 0.3 | - | 0.9 | - | - |

| Critical depletion fraction | 0.6 | - | 0.6 | 0.6 | - |

| Yield response fraction, Ky | 0.5 | 0.5 | 0.6 | 0.3 | 1.5 |

| Crop height (m) | - | - | 1 | - | - |

Appendix C.2. Soil Data

| Country | State | City | Soil Type | Planting Season |

|---|---|---|---|---|

| India | Gujarat | Ahmadabad | Sandy loam | June–July |

| Bharuch | Sandy loam | |||

| Rajkot | Black cotton | |||

| Bhavnagar | Black cotton | |||

| Surendranagar | Medium black | |||

| Maharashtra | Jalagon | Black cotton | June–July | |

| Akola | Black cotton | |||

| Aurangabad | Deep and medium black | |||

| Ahmednagar | Deep and medium black | |||

| Amravati | Deep and medium black | |||

| Punjab | Ludhiana | Sandy | April | |

| Faridkot | Sandy | |||

| Andhra Pradesh | Kurnool | Red earth and black cotton | July–August | |

| Anantapur | Stony red | |||

| Guntur | Black cotton | |||

| Prakasam | Red | |||

| Karnataka | Raichur | Mixed red and black | June–August | |

| Bellary | Deep black | |||

| Gulbarga | Black cotton | |||

| Bijapur | Black cotton | |||

| Hariyana | Hisar | Black cotton | April–May | |

| Jind | Sandy loam | |||

| Tamil Nadu | Coimabatore | Black cotton, loamy, clayey | August–September | |

| Madurai | Black cotton, Loam and clay loam | |||

| Salem | Red sandy | |||

| Rajasthan | Sri Ganganagar | Medium black | April–May | |

| Ajmer | Medium black, red sandy loam | |||

| Madhya Pradesh | Sanawad | Black cotton | June–July | |

| Khargone | Black cotton |

| Region of African Continent | Country | City | Soil Type | Planting Season |

|---|---|---|---|---|

| West Africa | Burkina Faso | Bobo | Loamy sand, clay loam | May–June |

| Boromo | Loamy sand, clay loam | |||

| Fada N’Gourma | Loamy sand, clay loam | |||

| Ouagadougou | Loamy sand, clay loam | |||

| Benin | Parakou | Silty clay loam | May–June | |

| Nattingou | Silty clay loam | |||

| Bohicon | Silty clay loam | |||

| Kandi | Silty clay loam | |||

| Mali | Bamako | Sandy loam | June–July | |

| Segou | Sandy loam | |||

| Sikasso | Sandy loam | |||

| Senegal | Kedougou | Medium | June–July | |

| Ziguinchor | Medium | |||

| Kolda | Medium | |||

| Cote d’Ivoire | Korhogo | Sandy | May–July | |

| Ferkessedougou | Sandy | |||

| Nigeria | Katsina | Reddish brown | May–June | |

| Kaduna | Reddish brown | |||

| Kano | Reddish brown | |||

| Bauchi | Reddish brown | |||

| Togo | Loam | Sandy loam, silty loam | May | |

| Uganda | Gulu | Sandy, sandy loam | May–June | |

| Kitgum | Sandy, sandy loam | |||

| Lira | Sandy | |||

| Masindi | Sandy, sandy loam | |||

| Mbale | Sandy loam | |||

| East Africa | Tanzania | Simiyu Bariadi | Sandy clay, clayey | December |

| Shinyanga | Shallow red clay, shallow black cotton | |||

| Mwanza | Sandy |

| Country | City | Soil Type | Planting Season |

|---|---|---|---|

| Uzbekistan | Bukhara | Silty clay loam | March–April |

| Fergana | Silty clay loam | ||

| Khorezm | Hard and loamy | ||

| Andizhan | Sandy loam | ||

| Tashkent | Silty clay loam | ||

| Samarkand | Silty clay loam | ||

| Kashkadar | Silty clay loam | ||

| Dzhiak | Silty clay loam | November–January | |

| Brazil | Mato Grosso | Sandy loam | |

| Bahia | Sandy loam | ||

| Goias | Clay | ||

| Sao Paulo | Sandy loam | ||

| Parana | Clay | ||

| Mato Grosso do Sul | Clay | ||

| Minas Gerais | Clay | ||

| Turkmenistan | Ahal | Sandy desert | March |

| Mary | Sandy desert | ||

| Egypt | Cairo | Alluvial | September–November |

| Alexandria | Alluvial | ||

| Asswan | Alluvial | ||

| China | Urumqi | Silt loam | March–May |

| Bangladesh | Faridpur | Clay loam | May–June |

| Jessore | Clay loam | ||

| Khulna | Sandy loam | ||

| Mymensingh | Sandy loam | ||

| Dinajpur | Sandy loam |

| Country | State | City | Soil type | Planting Season |

|---|---|---|---|---|

| USA | Texas | Amarillo | Loamy sand, loamy | May–June |

| Lubbock | Clayey | |||

| El Paso | Clay loam | |||

| Abilene | Sandy loam, loamy | |||

| Georgia | Macon Lewis | Loamy sand | March–May | |

| Savannah | Loamy sand | |||

| California | Fresno | Sandy loam | March | |

| Pakistan | Punjab | Bahawalpur | Laom | May–June |

| Rahimyar Khan | Clay loam | |||

| Multan | ||||

| Sindh | Sanghar | Sandy clay loam | March–April | |

| Khairpur | Sandy clay loam | |||

| Ghotki | Sandy clay loam | |||

| Australia | New South Wales | Namoi | Clay | September–October |

| Macquarie Valley | Clay | |||

| Queensland | St. George | Clay | September–October |

| Soil Type | Total Available Moisture, mm/m | Maximum Infiltration Rate, mm/day | Maximum Rooting Depth, cm | Initial Available Moisture, mm/m |

|---|---|---|---|---|

| Light soil | 60 | 40 | 90 | 60 |

| Medium soil | 290 | 40 | 90 | 290 |

| Heavy soil | 200 | 40 | 90 | 200 |

| Red sandy | 100 | 30 | 90 | 100 |

| Red loamy | 180 | 30 | 90 | 180 |

| Red sandy loam | 140 | 30 | 90 | 140 |

Appendix D

Appendix D.1. Fertilizer Application Rate

Appendix E

Appendix F

Appendix G

| Stages in Textile Industry | Number of Workers |

|---|---|

| No. of farmers | 8/acre |

| Yarn manufacturing | 40/ton |

| Yarn dyeing | 30/ton |

| Fabric manufacturing | 100/3 ton |

| Fabric washing | 100/13.5 ton |

| Fabric dyeing, printing and finishing | 10/ton |

| Water KPI, L/day | 30/person |

| Water abstract (intake), L/day | 31.5/person |

Appendix H

| Country | Time (Traveled by Sea): Days |

|---|---|

| Uzbekistan | 22.58 |

| India | - |

| East and West Africa | 27.88 |

| USA | 23.5 |

| Pakistan | 4.54 |

| Brazil | 22.83 |

| Australia | 8.46 |

| Egypt | 7.96 |

| Turkmenistan | 23.5 |

| China | 6.88 |

References

- Islam, M.M.; Khan, A.M.; Islam, M.M. Textile Industries in Bangladesh and Challenges of Growth. Res. J. Eng. Sci. 2013, 2278, 9472. [Google Scholar]

- Uddin, M. RMG Industry as the Major Employment Sector. 2019. Available online: https://www.thedailystar.net/supplements/28th-anniversary-supplements/entrepreneurship-key-youth-employment/news/rmg-industry-the-major-employment-sector-1702951 (accessed on 15 March 2017).

- Natasha, R.Y.C.; Jeny, U.M. Design & Product Development (DPD) Expansion: Key Factors for Sustainable Growth of RMG Sector’s in Bangladesh. 2018. Available online: https://www.researchgate.net/publication/328333897_Design_Product_Development_DPD_Expansion_Key_factors_for_sustainable_growth_of_RMG_Sector%27s_in_Bangladesh (accessed on 1 October 2020).

- Khan, M.S.; Selim, S.; Evans, A.E.; Chadwick, M. Characterizing and Measuring Textile Effluent Pollution using a Material Balance Approach: Bangladesh Case Study. In Proceedings of the 9th International Conference on Mechanical Engineering (ICME), Dhaka, Bangladesh, 18–20 December 2011. [Google Scholar]

- Khan, M.S.; Knapp, J.; Clemett, A.; Chadwick, M.; Mahmood, M.; Sharif, M.I. Managing and Monitoring Effluent Treatment Plants; Managing Industrial Pollution from Small and Medium Scale Industries in Bangladesh Booklet Series; SEI, BCAS, University of Leeds Dhaka: Dhaka, Bangladesh, 2006. [Google Scholar]

- Islam, M.; Chowdhury, M.; Billah, M.; Tusher, T.; Sultana, N. Investigation of Effluent Quality Discharged from The Textile Industry of Purbani Group, Gazipur, Bangladesh and Its Management. Bangladesh. J. Environ. Sci. 2012, 23, 123–130. [Google Scholar]

- Haque, F.; Khandaker, M.M.R.; Chakraborty, R.; Khan, M.S. Identifying Practices and Prospects of Chemical Safety and Security in the Bangladesh Textiles Sector. J. Chem. Educ. 2020, 97, 1747–1755. [Google Scholar] [CrossRef]

- Dey, S.; Islam, A. A Review on Textile Wastewater Characterization in Bangladesh. Res. Environ. 2015, 5, 15–44. [Google Scholar]

- El-Gohary, F.; Tawfik, A.; Mahmoud, U. Comparative Study Between Chemical Coagulation/Precipitation (C/P) Versus Coagulation/Dissolved Air Flotation (C/DAF) for Pre-Treatment of Personal Care Products (PCPs) Wastewater. Desalination 2010, 1, 106–112. [Google Scholar] [CrossRef]

- Nergis, Y.; Sharif, M.; Akhtar, N.; Hussain, A. Quality Characterization and Magnitude of Pollution Implication in Textile Mills Effluents. J. Qual. Technol. Manag. 2009, 5, 153–161. [Google Scholar]

- Rott, U.; Minke, R. Overview of Wastewater Treatment and Recycling in the Textile Processing Industry. Water Sci. Technol. 1999, 40, 137–144. [Google Scholar] [CrossRef]

- Sultana, M.S.; Islam, M.S.; Saha, R.; Al-Mansur, M. Impact of the effluents of textile dyeing industries on the surface water quality inside DND embankment. Narayanganj. Bangladesh J. Sci. Indust. Res. 2009, 44, 65–80. [Google Scholar] [CrossRef]

- Ali, M.; Ahmed, S.; Khan, M. Characteristics and Treatment Process of Wastewater in a Nylon Fabric Dyeing. Plant. J. Chem. Eng. 2005, 23, 17–22. [Google Scholar] [CrossRef][Green Version]

- Restiani, P. Water Governance Mapping Report: Textile Industry Water Use in Bangladesh; Stockholm International Water Institute (SIWI) and Sweden Textile Water Initiative (STWI): Stockholm, Sweden, 2016. [Google Scholar]

- Anas, A. Textile Plants are Dhaka’s Water Problem and also its Solution. 2015. Available online: http://citiscope.org/story/2015/textile-plants-are-dhakas-water-problem-and-also-its-solution (accessed on 16 July 2017).

- Ahmad, Z. Study on Groundwater Depletion and Land Subsidence in Dhaka City. Master’s Thesis, Bangladesh University of Engineering & Technology (BUET), Dhaka, Bangladesh, 2006. [Google Scholar]

- Nevill, J.C.; Hancock, P.J.; Murray, B.R.; Ponder, W.F.; Humphreys, W.F.; Phillips, M.L.; Groom, P.K. Groundwater-dependent Ecosystems and the Dangers of Groundwater Overdraft: A Review and an Australian Perspective. Pacific Conserv. Biol. 2010, 16, 187–208. [Google Scholar] [CrossRef]

- Hoekstra, A.Y.; Chapagain, A.K.; Van Oel, P.R. Advancing Water Footprint Assessment Research: Challenges in Monitoring Progress towards Sustainable Development Goal 6. Water 2017, 9, 438. [Google Scholar] [CrossRef]

- Hoekstra, A.Y. Virtual water trade. In Proceedings of the International Expert Meeting on Virtual Water Trade, Delft, The Netherlands, 12–13 December 2002. [Google Scholar]

- Falkenmark, M.; Rockström, J. Balancing Water for Humans and Nature: The New Approach in Ecohydrology; Earthscan: Sterling, VA, USA, 2004. [Google Scholar]

- Watson, N. Globalization of Water: Sharing the Planet’s Freshwater Resources–By Arjen Y Hoekstra and Ashok K Chapagain. Area 2011, 43, 116–117. [Google Scholar] [CrossRef]

- Hoekstra, A.Y.; Chapagain, A.K.; Aldaya, M.M.; Mekonnen, M.M. The water footprint assessment manual. In Setting the Global Standard; Earthscan: London, UK, 2011. [Google Scholar]

- LeBlanc, R. Water Footprint and Its Growing Importance. Available online: https://www.thebalance.com/water-footprint-and-its-growing-importance-2878071 (accessed on 16 July 2017).

- USDA. Gain Report. Bangladesh Cotton and Products Annual. 2017. Available online: https://www.fas.usda.gov/data/bangladesh-cotton-and-products-annual-1 (accessed on 2 August 2017).

- Hossain, L.; Sarker, S.K.; Khan, M.S. Evaluation of present and future wastewater impacts of textile dyeing industries in Bangladesh. Environ. Dev. 2018, 26, 23–33. [Google Scholar] [CrossRef]

- Emerging Textiles.com. India Yarn Prices: Domestic and Export Markets. 2017. Available online: http://www.emergingtextiles.com/?q=art&s=170118-india-spun-yarn-market-prices&r=free&i=samplearticle (accessed on 3 August 2017).

- Emerging Textiles.com. China Yarn Prices: Domestic and Import Markets. 2017. Available online: http://www.emergingtextiles.com/?q=art&s=170228-yarn-market-price-china&r=free (accessed on 3 August 2017).

- Sikirica, N. Water Footprint Assessment Bananas and Pineapples; Dole Food Company, Soil & More International: Driebergen, The Netherlands, 2011; Volume 41. [Google Scholar]

- Food and Agriculture Organization. Chapter 6: ETcSingle Crop Coeficient (Kc). Available online: http://www.fao.org/docrep/X0490E/x0490e0b.htm (accessed on 3 August 2017).

- Food and Agriculture Organization. Land & Water. Available online: http://www.fao.org/land-water/databases-and-software/cropwat/en/#:~:text=CROPWAT%20is%20a%20decision%20support,soil%2C%20climate%20and%20crop%20data (accessed on 14 June 2017).

- Chapagain, A.K.; Hoekstra, A.; Savenije, H.; Gautam, R. The Water Footprint of Cotton Consumption: An Assessment of the Impact of Worldwide Consumption of Cotton Products on the Water Resources in the Cotton Producing Countries. Ecol. Econ. 2006, 60, 186–203. [Google Scholar] [CrossRef]

- Aldaya, M.M.; Chapagain, A.K.; Hoekstra, A.Y.; Mekonnen, M.M. The Water Footprint Assessment Manual: Setting the Global Standard; Routledge: Abingdon, UK, 2012. [Google Scholar]

- Chapagain, A.K.; Hoekstra, A.Y. The Global Component of Freshwater Demand and Supply: An Assessment of Virtual Water Flows Between Nations As a Result of Trade in Agricultural and Industrial Products. Water Int. 2008, 33, 19–32. [Google Scholar] [CrossRef]

- Liu, W.; Antonelli, M.; Liu, X.; Yang, H. Towards Improvement of Grey Water Footprint Assessment: With an Illustration for Global Maize Cultivation. J. Clean. Prod. 2017, 147, 1–9. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Hoekstra, A.Y. Global gray water footprint and water pollution levels related to anthropogenic nitrogen loads to fresh water. Environ. Sci. Technol. 2015, 4, 12860–12868. [Google Scholar] [CrossRef]

- Chapagain, A.; Hoekstra, A.; Savenije, H.; Gautam, R. The Water footprint of Cotton Consumption. Value of Water Research Report Series No. 18. UNESCO-IHE, The Netherlands. Available online: http://www.waterfootprint.org/Reports/Report18.pdf (accessed on 20 June 2017).

- Liton, M.R.I.; Islam, T.; Saha, S. Present Scenario and Future Challenges in Handloom Industry in Bangladesh. Soc. Sci. 2016, 5, 70–76. [Google Scholar]

- Islam, M.I. Bangladesh Spinning Sector Focuses to Higher Capacity Utilization and Diversification of Yarn. 2017. Available online: https://www.textiletoday.com.bd/bangladesh-spinning-sector-focuses-higher-capacity-utilization-diversification-yarn/ (accessed on 4 November 2017).

- Sarker, S.K. Material Balance Approach to Measure Water Pollution Load of Industrial Development in Bangladesh. Master’s Thesis, Bangladesh University of Engineering and Technology, Dhaka, Bangladesh, 2017. [Google Scholar]

- Bangladesh Garment Manufacturers and Exporters Association. Value of Total Apparel Export. 2017. Available online: http://www.bgmea.com.bd/home/pages/TradeInformation (accessed on 2 March 2017).

- Rodrigue, J.-P.; Comtois, C.; Slack, B. The Geography of Transport Systems, 4th ed.; Routledge Taylor & Francis Group: Abington, UK, 2009. [Google Scholar]

- Organic Touch. Organic Cotton Yarn. Available online: http://www.parkotex.com/_en/organic-cotton-yarn/193/menu (accessed on 10 September 2017).

- Ardena Transport. Export of Uzbek Cotton. 2017. Available online: http://www.ardenatransport.com/en/project/export-uzbek-cotton (accessed on 23 November 2017).

- Wu, M.; Mintz, M.; Wang, M.; Arora, S. Consumptive Water Use in the Production of Ethanonl and Petroleum Gasoline. 2009. Available online: https://www.osti.gov/biblio/947085 (accessed on 3 June 2017).

- Islam, M.M.; Mahmud, K.; Faruk, O.; Billah, S. Assessment of environmental impacts for textile dyeing industries in Bangladesh. In Proceedings of the International Conference on Green Technology and Environmental Conservation (GTEC-2011), Chennai, India, 15–17 December 2011; pp. 173–181. [Google Scholar]

- Mathur, N.; Bhatnagar, P.; Sharma, P. Review of the mutagenicity of textile dye products. Univers. J. Environ. Res. Technol. 2012, 2, 1–18. [Google Scholar]

- Strazzullo, P.; D’Elia, L.; Kandala, N.-B.; Cappuccio, F.P. Salt intake, stroke, and cardiovascular disease: Meta-analysis of prospective studies. BMJ 2009, 339, b4567. [Google Scholar] [CrossRef]

- PARCL. Approximate Weight of Goods. Available online: https://www.parcl.com/education/forwarders/docs/parcl-approximate-weight-of-goods.pdf (accessed on 10 March 2017).

- Shopclues.com. Bombay Dyeing Bedsheet Blue Single Bed 100 Cotton Heavy Discount. Available online: http://www.shopclues.com/bombay-dyeing-bedsheet-blue-single-bed-100-cotton-heavy-discount.html (accessed on 2 November 2017).

- Exchange, T. Quick Guide to Organic Cotton. Textile Exchange. 2017. Available online: https://textileexchange.org/wp-content/uploads/2017/06/Textile-Exchange_Quick-Guide-To-Organic-Cotton_2017.pdf (accessed on 2 November 2017).

- Safaya, S.; Zhang, G.; Mathews, R. Toward Sustainable Water Use in the Cotton Supply Chain: A Comparative Assessment of the Water Footprint of Agricultural Practices in India; Water Footprint Network, The Hague, Netherlands/C&A Foundation: Zug, Switzerland, 2016. [Google Scholar]

- Lakhal, S.Y.; Sidibé, H.; H’Mida, S. Comparing conventional and certified organic cotton supply chains: The case of Mali. Int. J. Agricult. Res. Gov Ecol. 2008, 7, 243–255. [Google Scholar] [CrossRef]

- Tabib, D.M.F.A.I. Prospects and Challenges of Organic Cotton in Bangladesh. 2016. Available online: https://www.global-standard.org/images/stories/GOTS_ConfBangla16/7-Fakhre-Alam-Ibne-Tabib-CDB-Organic-Cotton-Bangladesh-.pdf (accessed on 3 November 2017).

- Policy Paper Series. Promoting Zero Liquid Discharge Mandate for the Bangladesh Textile Industry. Available online: http://www.ipekpp.com/admin/upload_files/Report_1_19_Promoting_1175846345.pdf (accessed on 11 March 2017).

- Newell, A. Quenching Cotton’s Thirst: Reducing the Use of Water in the Cotton Lifecycle. Available online: https://www.triplepundit.com/story/2016/quenching-cottons-thirst-reducing-use-water-cotton-lifecycle/57196 (accessed on 3 May 2020).

- Roberts, K.B. Water Crisis in Bangladesh: Overpumping in Dhaka May Threaten Regional Groundwater Resources Outside the City. Available online: https://phys.org/news/2016-09-crisis-bangladesh-overpumping-dhaka-threaten.html (accessed on 29 August 2017).

- Sah, R.C. Groundwater Depletion and its Impact on Environment in Kathmandu Valley. Nepal. 2001. Available online: https://www.Elaw.org/content/nepal-groundwater-depletion-and-its-impact-environment-kathmandu-valley (accessed on 23 August 2017).

- Islam, J.B.; Sarkar, M.; Rahman, A.L.; Ahmed, K.S. Quantitative assessment of toxicity in the Shitalakkhya River, Bangladesh. Egypt. J. Aqua. Res. 2015, 41, 25–30. [Google Scholar] [CrossRef]

- Krinner, G. Impact of lakes and wetlands on boreal climate. J. Geophys. Res. Atmos. 2003, 108, 4520. [Google Scholar] [CrossRef]

- Cole, J.J.; Prairie, Y.T.; Caraco, N.F.; McDowell, W.H.; Tranvik, L.J.; Striegl, R.G.; Duarte, C.M.; Kortelainen, P.; Downing, J.A.; Middelburg, J.J. Plumbing the global carbon cycle: Integrating inland waters into the terrestrial carbon budget. Ecosystems 2007, 10, 172–185. [Google Scholar] [CrossRef]

- Qureshi, A.S.; McCornick, P.G.; Sarwar, A.; Sharma, B.R. Challenges and Prospects of Sustainable Groundwater Management in the Indus Basin, Pakistan. Water Res. Manag. 2010, 24, 1551–1569. [Google Scholar] [CrossRef]

- Tamilnadu Water Investment Company Limited. Zero Liquid Discharge Facility for Textile Dyeing Effluents & Pulp and Paper Effluents; Deutsche Gesellschaft für Internationale Zusammenarbeit (giz): Bonn, Germany, 2013. [Google Scholar]

- Battacharjee, S.; Bharadwaj, R. Zero Liquid Discharge: Options for Bangladesh Textile Industry. 2014. Available online: http://www.iipinetwork.org/wp-content/uploads/2016/12/ZLD-Excerpt-from-Apparel-Story-magazine_IIP.pdf (accessed on 29 August 2017).

- Knowledge Partnership Programme; UKaid, I.G. Paving the Way for Learning: Exposure Visit by Bangladesh Garments Manufacturing and Export Association (BGMEA) Members on Zero Liquid Discharge Technology, Chennai and Tirupur. 2015. Available online: http://ipekpp.com/pdf/Achievements/Achievement_BGMEA_textile_exposure_visit_FINAL.pdf (accessed on 29 August 2017).

- Uzbekistan- Republic of Cotton and Products Annual. 2014. Available online: http://www.thefarmsite.com/reports/contents/UzbekistanCotton2April2014.pdf (accessed on 10 April 2017).

- Hussain, S. Bangladesh Cotton and Products Annual 2013. In GAIN Report Number: BG3005; USDA Foreign Agricultural Service: Washington DC, USA, 2013. [Google Scholar]

- Anas, A. Bangladesh Cotton Imports to Double in Six Years. Available online: http://www.pri-bd.org/main/view_news/bangladesh-cotton-imports-to-double-in-six-years-conference-told_98 (accessed on 3 August 2017).

- Bangladesh Bank. Import Payments. Available online: https://www.bb.org.bd/pub/publictn.php (accessed on 3 August 2017).

- Indexmundi. Bangladesh Cotton Production by Year. Available online: https://www.indexmundi.com/agriculture/?country=bd&commodity=cotton&graph=production (accessed on 10 August 2017).

- Wang, T.K.; Audebert, R. Flocculation Mechanisms of A Silica Suspension by Some Weakly Cationic Polyelectrolytes. J. Colloid Int. Sci. 1987, 119, 459–465. [Google Scholar] [CrossRef]

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration-Guidelines for Computing Crop Water Requirements-FAO Irrigation and Drainage Paper 56; FAO: Rome, Italy, 1998; Volume 300, p. D05109. [Google Scholar]

- Cotton Incorporated. Cotton Water Requirements. Available online: http://www.cottoninc.com/fiber/agriculturaldisciplines/engineering/irrigation-management/cotton-water-requirements/ (accessed on 16 September 2017).

- Sood, D. Cotton and Products Annual. USA. 2017. Available online: https://apps.fas.usda.gov/newgainapi/api/report/downloadreportbyfilename?filename=Cotton%20and%20Products%20Annual_New%20Delhi_India_4-2-2018.pdf (accessed on 10 September 2017).

- Atlas on Regional Integration in West Africa, Cotton. 2006. Available online: https://Oecd.org/regional/atlasonregionalintegrationinwestafrica.htm (accessed on 10 September 2017).

- Sirtioglu, I. Cotton and Products Annual. USA. 2016. Available online: https://apps.fas.usda.gov/newgainapi/api/report/downloadreportbyfilename?filename=Cotton%20and%20Products%20Annual_Tashkent_Uzbekistan%20-%20Republic%20of_4-4-2016.pdf (accessed on 10 September 2017).

- Person, J. Top 10 Cotton States in Production/Total Number of Bales. 2012. Available online: http://janiceperson.com/cotton/top-10-cotton-states-area-production-bales-yield-acre-2012/ (accessed on 17 September 2017).

- United States Department of Agriculture. Pakistan Cotton Conditions Improve. USA. 2016. Available online: https://ipad.fas.usda.gov/highlights/2016/10/Pakistan/index.htm (accessed on 3 August 2017).

- Queensland Government. Cotton Production in Queensland. 2015. Available online: https://www.daf.qld.gov.au/plants/field-crops-and-pastures/broadacre-field-crops/cotton (accessed on 15 August 2017).

- Uzbekistan: Climate Change and Agriculture Country Note, Climate Change and Agriculture Country Note. 2010. Available online: http://documents.worldbank.org/curated/en/362081468131400417/Uzbekistan-Climate-change-and-agriculture-country-note (accessed on 3 August 2017).

- Osakwe, E. Cotton Fact Sheet: India. 2009. Available online: http://staging.icac.org/econ_stats/country_facts/e_india.pdf (accessed on 3 August 2017).

- Fletcher, K. Sustainable Fashion and Textiles: Design Journeys, 2nd ed.; Routledge: Abington, UK, 2013. [Google Scholar]

- Stone, J. Plant Modification for More Efficient Water Use; Elsevier: Stillwater, OK, USA, 2012. [Google Scholar]

- Naheed, G.; Rasul, G. Recent water requirement of cotton crop in Pakistan. Pak. J. Meteor 2010, 6, 75–84. [Google Scholar]

- Grose, L. Sustainable Cotton Production and Processing; California College of the Arts San Francisco: Oakland, CA, USA, 2009. [Google Scholar]

- Australian Cotton Industries Statistics. Cotton Annual. 2017. Available online: https://www.cottonaustralia.com.au/assets/general/Publications/Cotton-Annuals/Cotton-Annual-2017.pdf (accessed on 29 November 2017).

- Central Asian Countries Initiative for Land Management. Table of Technologies Database. Available online: http://www.cacilm.org/en/visual/table (accessed on 17 August 2017).

- Commodity Intelligence Report. China: 2017/18 Cotton Production Outlook. 2017. Available online: https://ipad.fas.usda.gov/highlights/2017/08/china/index.htm (accessed on 17 August 2017).

- Tabib, M.F.A.I. The Way of Sustainable Cotton Production. 2005. Available online: http://www.cottonbangladesh.com/October2011/SustainableCotton.htm (accessed on 17 August 2017).

- International Cotton Advisory Committee. Measuring Sustainability in Cotton Farming Systems. Towards a Guidance Framework. 2015. Available online: https://www.crdc.com.au/publications/measuring-sustainability-cotton-farming-systems-towards-guidance-framework (accessed on 27 November 2017).

- Stewart, J.M.; Oosterhuis, D.; Heitholt, J.J.; Mauney, J.R. Physiology of Cotton; Springer Science & Business Media: New York, NY, USA, 2009. [Google Scholar]

- Smith, M.; Kivumbi, D. Use of The FAO CROPWAT Model in Deficit Irrigation Studies. Available online: http://www.fao.org/docrep/004/Y3655E/y3655e05.htm (accessed on 3 August 2017).

- Malhotra, K. Brief Note on Types of Soil in Gujarat. 2014. Available online: http://www.importantindia.com/12355/brief-note-on-types-of-soil-in-gujarat/ (accessed on 15 August 2017).

- Mondal, P. Cotton Cultivation in India: Conditions, Types, Production and Distribution. Available online: http://www.yourarticlelibrary.com/cultivation/cotton-cultivation-in-india-conditions-types-production-and-distribution/20949/ (accessed on 15 August 2017).

- Khadi, B.M. Impact of Bt-cotton on agriculture in India. In Proceedings of the Ninth International Symposium on Biosafety of Genetically Modified Organisms Biosafety Research and Environmental Risk Assessment, Jeju Island, Korea, 24–29 September 2006; Sabesh, M., Ed.; Approved Package of Practices for Cotton: Gujarat State, India, 2006–2007. Available online: http://www.cicr.org.in/pop/gj.pdf (accessed on 16 April 2017).

- Jagannath, P.S.; Waykole, D.M.M. Status of Cotton Global to Khandesh; Indira Institute of Management and Nahata Commerce College: Pune, India, 2013. [Google Scholar]

- Cotton: Soils and Climate. Available online: http://ikisan.in/mh-cotton-Soils-Climate.html (accessed on 15 August 2017).

- District Profile. Available online: http://www.kvk.pravara.com/pages/District%20Profile/District%20Profile.htm (accessed on 15 August 2017).

- Vasudeva, V. Cotton Sowing May Dip in Punjab. In The Hindu; India, The Hindu Group: Chennai, India, 2016; Available online: https://www.thehindu.com/news/national/other-states/cotton-sowing-may-dip-in-punjab/article8443732.ece (accessed on 15 October 2017).

- Food and Agriculture Organization. Chapter 2: Soil and Water. Available online: http://www.fao.org/docrep/r4082e/r4082e03.htm (accessed on 15 August 2017).

- ENVIS Centre. Soil Types. 2015. Available online: http://punenvis.nic.in/index2.aspx?slid=205&sublinkid=1127&langid=1&mid=1 (accessed on 15 August 2017).

- Andhra Pradesh: Cotton Update for Kharif. Anantpur Dist Cotton Acreage Estimates: Drastic Revision Cautions Traders. Available online: http://www.commoditiescontrol.com/eagritrader/staticpages/index.php?id=96 (accessed on 15 August 2017).

- Sciencing, Different Soils of Andhra Pradesh. 2017. Available online: https://sciencing.com/different-soils-of-andhra-pradesh-12383628.html (accessed on 2 November 2017).

- Gopalakrishnan, N.; Manickam, S.; Prakash, A.H. Problems and Prospects of Cotton in Different Zones of India. Available online: https://www.cicr.org.in/pdf/ELS/general3.pdf (accessed on 30 September 2017).

- Vittal, K.; Rajendran, T.; Chary, G.R.; Sankar, G.M.; Srijaya, T.; Ramakrishna, Y.; Samra, J.; Singh, G. Districtwise Promising Technologies for Rainfed Cotton based Production System in India; All India Co-ordinated Research Project for Dryland Agriculture; Central Research Institute for Dryland Agriculture, Indian Council of Agricultural Research: Hyderabad, India, 2004. [Google Scholar]

- Raju, B.Y. Andhra Pradesh Vision 2020; New Age International Limited: Delhi, India, 2001. [Google Scholar]

- eFresh. Crop Cultivation of Cotton. Available online: http://www.efreshglobal.com/eFresh/Content/Prod_Cotton.aspx?u=ppperi (accessed on 15 August 2017).

- Agropedia. Soils of Karnakata. 2010. Available online: http://agropedia.iitk.ac.in/content/soils-karnataka (accessed on 15 August 2017).

- Naya Haryana. Time to Improve Cotton Production in Haryana. Available online: http://www.nayaharyana.com/agriculture/time-improve-cotton-production-haryana/ (accessed on 15 August 2017).

- Manav, S. Whitefly Detected in Cotton-producing Districts: Survey, in The Tribune. 2016. Available online: https://www.tribuneindia.com/news/archive/features/whitefly-detected-in-cotton-producing-districts-survey-248196 (accessed on 15 August 2017).

- The Agriculture Department. Kharip Crops. Available online: http://agriharyana.gov.in/variouscrops.htm (accessed on 15 August 2017).

- Department of Economics and Statistics, Season and Crop Report 2005–06. India. Available online: https://statistics.py.gov.in/season-and-crop-report-2005-06 (accessed on 15 August 2017).

- World Blaze. Top 10 Largest Cotton Producing States of India. Available online: http://www.worldblaze.in/top-10-largest-cotton-producing-states-in-india/ (accessed on 15 August 2017).

- Fullstopindia. The Business of Cotton in India. Available online: http://archive.india.gov.in/citizen/agriculture/index.php?id=12 (accessed on 15 August 2017).

- Portal, T.A. Cotton: Season and Varieties. 2016. Available online: http://agritech.tnau.ac.in/agriculture/agri_seasonandvarieties_cotton.html (accessed on 15 August 2017).

- Directorate of Horticulture and Plantation Crops. Coimabatore. 2017. Available online: http://tnhorticulture.tn.gov.in/horti/coimbatore (accessed on 15 August 2017).

- Department of Agriculture, M.D. Basic Details and Schemes Implementation Details. Available online: http://www.madurai.tn.nic.in/agri.html (accessed on 15 August 2015).

- Singh, G. Technological Gap in Cotton Production Technology Among the Growers of Sriganganagar District of Rajasthan; Swami Keshwanand Rajasthan Agricultural University: Bikaner, India, 2011. [Google Scholar]

- Madhya Pradesh: Cotton Update for Kharif. Cotton Acreage Exceeds Target in Khargone District. Available online: http://www.commoditiescontrol.com/eagritrader/staticpages/index.php?id=105 (accessed on 15 August 2017).

- The Cotton Corporation of India. Maharashtra. 2011. Available online: http://cotcorp.gov.in/maharashtra.aspx (accessed on 15 August 2017).

- The Gazetteers Department. Agriculture and Irrigation. Available online: http://amravati.nic.in/gazetteer/gazetteerB/agri_soils.html (accessed on 15 August 2017).

- Textile Exchange. Growing Regions: Africa. Available online: http://farmhub.textileexchange.org/learning-zone/growing-regions/africa (accessed on 3 October 2017).

- Cotton Technical Assistance Programme for Africa. Country Profile: Burkina Faso. Available online: http://www.cottontapafrica.org/burkina-faso.html (accessed on 15 August 2017).

- Better Cotton Initiative. Mali. Available online: http://bettercotton.org/about-better-cotton/where-is-better-cotton-grown/mali/ (accessed on 15 August 2017).

- Gao, J.; Liu, J.; Peng, H.; Wang, Y.; Cheng, S.; Lei, Z. Preparation of a low-cost and eco-friendly superabsorbent composite based on wheat bran and laterite for potential application in Chinese herbal medicine growth. R. Soc. Open Sci. 2018, 5, 180007. [Google Scholar] [CrossRef]

- Better Cotton Initiative. Senegal. Available online: http://bettercotton.org/about-better-cotton/where-is-better-cotton-grown/senegal/ (accessed on 15 August 2017).

- Kirby, N.M.; Mudie, S.T.; Hawley, A.M.; Cookson, D.J.; Mertens, H.D.; Cowieson, N.; Samardzic-Boban, V. A low-background-intensity focusing small-angle X-ray scattering undulator beamline. J. Appl. Crystal. 2013, 46, 1670–1680. [Google Scholar] [CrossRef]

- Reuters Staff. Ivory Coast 2015–16 Cotton Forecast Output Revised Lower. Available online: http://af.reuters.com/article/ivoryCoastNews/idAFL5N10W2LT20150821 (accessed on 15 August 2017).

- Uckles, D.B.; Teka, A.E.; Siname, O.O.; Aliba, G.; Aliano, G.G. Cover Crops in West Africa. Available online: https://www.idrc.ca/sites/default/files/openebooks/270-8/index.html (accessed on 7 October 2017).

- Cotton Technical Assistance Programme for Africa. Country Profile: Nigeria. Available online: http://www.cottontapafrica.org/nigeria.html (accessed on 15 August 2017).

- Issman, L.; Talmon, Y. Cryo-SEM specimen preparation under controlled temperature and concentration conditions. J. Microsc. 2012, 1, 60–69. [Google Scholar] [CrossRef]

- Agriculture Nigeria. Soil and Water. Available online: http://agriculturenigeria.com/research/introduction/soil-and-water (accessed on 15 August 2017).

- Aregheore, E.M. Country Pasture/Forage Resource Profiles. Available online: http://www.fao.org/ag/agp/agpc/doc/counprof/nigeria/nigeria.htm (accessed on 15 August 2017).

- Agriculture Nigeria. Cotton (Gossypium Species). Available online: http://agriculturenigeria.com/farming-production/crop-production/cash-crops/cotton (accessed on 15 August 2017).

- Sant’Anna, R. Major Soils for Food Production in Africa. Available online: http://www.fao.org/3/T1696E/t1696e07.htm (accessed on 27 November 2017).

- United States Department of Agriculture. Tanzania: Mid-season Drought Reduces 2015/16 Cotton Output. Available online: https://pecad.fas.usda.gov/highlights/2015/09/TZ/index.htm (accessed on 15 August 2017).

- Zhao, F.; Repo, E.; Song, Y.; Yin, D.; Hammouda, S.B.; Chen, L.; Kalliola, S.; Tang, J.; Tam, K.C.; Sillanpää, M. Polyethylenimine-cross-linked cellulose nanocrystals for highly efficient recovery of rare earth elements from water and a mechanism study. Green Chem. 2017, 19, 4816–4828. [Google Scholar] [CrossRef]

- The United Republic of Tanzania, The President’s Office Regional Administration, and Local Government Simiyu Region. Simiyu Region Investment Guide; Tanzania, UNDP-ESRF: Simiyu, Tanzania, 2017.

- Kalumuna, M.C.; Masuki, K.F.G.; Mkavidanda, A.T.; Wickama, J.M. Responses of Cotton, Maize and Rice to Fertilizers in Sukumaland; Tanzania, ARI-Mlingano: Mlingano, Tanzania, 2000. [Google Scholar]

- Matata, P. Environmental Law Regulations of Pesticide Usage: Challenges of Enforcement and Compliance in the Shinyanga Region, Tanzania; Anchor Academic Publishing: Hamburg, Gernman, 2013. [Google Scholar]

- Kabissa, J.C. Cotton in Tanzania: Breaking the Jinx, 6th ed.; Tanaznia Educational Publishers: Bukoba, Tanzania, 2015. [Google Scholar]

- Nyamekye, C.; Thiel, M.; Schönbrodt-Stitt, S.; Zoungrana, B.J.B.; Amekudzi, L.K. Soil and Water Conservation in Burkina Faso, West Africa. Sustainability 2018, 10, 3182. [Google Scholar] [CrossRef]

- Minai, J.O. Assessing the Spatial Variability of Soils in Uganda. Master’s Thesis, Purdue University, West Lafayette, IN, USA, 2015. [Google Scholar]

- Mbogga, M. Climate Profiles and Climate Change Vulnerability Assessment for the Mbale Region of Uganda. 2013. Available online: https://www.adaptation-undp.org/sites/default/files/downloads/tacc_mbale_climate_profile_and_cc_vulnerability_assessment_report_final.pdf (accessed on 23 August 2017).

- Cotton Sector Profile. Available online: http://www.ugandainvest.go.ug/uia/images/Download_Center/SECTOR_PROFILE/Cotton_Sector_Profile.pdf (accessed on 14 August 2017).

- Norris, P.K. Cotton Production in Egypt; US Department of Agriculture: Washington, DC, USA, 1934; p. 451. [Google Scholar]

- Cotton Development Organization. Available online: https://www.cdouga.org/production/production-trends-earnings/ (accessed on 10 August 2017).

- Food and Agriculture Organization. Chapter 2. Agro-Ecological Zones and Land Quality. Available online: http://www.fao.org/docrep/006/Y4711E/y4711e05.htm (accessed on 18 August 2017).

- Khan, S. Cotton Farming in Uzbekistan Is rModern Slavery. 2016. Available online: https://muftah.org/cotton-farming-uzbekistan-modern-slavery/#.WZZGvtIjHIV (accessed on 18 August 2017).

- UGF. Regions of Cotton Production. Available online: http://harvestreport.uzbekgermanforum.org/ (accessed on 18 August 2017).

- Wheat Atlas. Uzbekistan, Andizan: General Information. Available online: http://wheatatlas.org/(X(1)S(eouzvmrp0khpr1jnv5acflnc))/station/UZB/29201?AspxAutoDetectCookieSupport=1 (accessed on 18 August 2017).

- Young, A. Tropical Soils and Soil Survey; CUP Archive, Cambridge University Press: Cambridge, UK, 1980; Volume 9, pp. 1–48. [Google Scholar]

- Lal, R.; Follett, R.F.; Stewart, B.; Kimble, J.M. Soil Carbon Sequestration to Mitigate Climate Change and Advance Food Security. Soil Sci. 2007, 12, 943–956. [Google Scholar] [CrossRef]

- Lacerda, M.P.; Demattê, J.A.; Sato, M.V.; Fongaro, C.T.; Gallo, B.C.; Souza, A.B. Tropical Texture Determination by Proximal Sensing Using a Regional Spectral Library and Its Relationship with Soil Classification. Remote Sens. 2016, 8, 701. [Google Scholar] [CrossRef]

- Kiawu, J.; Valdes, C.; MacDonald, S. Brazil’s Cotton Industry: Economic Reform and Development. In Cotton and Wool Outlook No. (CWS-11d-01); USDA: Washington, DC, USA, 2011; pp. 1–31. Available online: https://www.ers.usda.gov/publications/pub-details/?pubid=35850 (accessed on 15 June 2017).

- Buol, S.W.; Southard, R.J.; Graham, R.C.; McDaniel, P.A. Soil Genesis and Classification; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Naumov, A. Mapping Spatial and Temporal Potassium Balances in Brazilian Soils of South-west Goias; Embrapa Solos-Artigo em periódico indexado (ALICE), International Fertilizer Correspondent: Horgen, Switzerland, 2008; Available online: http://www.alice.cnptia.embrapa.br/alice/handle/doc/339722 (accessed on 18 September 2017).

- Schiavo, J.A.; Neto, D.; Hypólito, A.; Pereira, M.G.; Rosset, J.S.; Secretti, M.L.; Pessenda, L.C.R. Characterization and Classification of Soils in the Taquari River Basin-Pantanal Region, State of Mato Grosso do Sul, Brazil. Rev. Bras. Ciência Solo 2012, 3, 697–708. [Google Scholar] [CrossRef]

- Hilbeck, A.; Andow, D.A.; Fontes, E. Environmental Risk Assessment of Genetically Modified Organisms Methodologies for Assessing Bt Cotton in Brazil; CABI: Wallingford, UK, 2006; Volume 2, pp. 1–20. [Google Scholar]

- Spera, S.A.; Cohn, A.S.; VanWey, L.K.; Mustard, J.F.; Rudorff, J.F.; Risso, J. Adami, M. Recent Cropping Frequency, Expansion, and Abandonment in Mato Grosso, Brazil had Selective Land Characteristics. Environ. Res. Lett. 2014, 9, 064010. [Google Scholar] [CrossRef]

- Carvalho, P.C.D.F. Country Pasture/Forage Resource Profiles. Available online: http://www.fao.org/ag/agp/agpc/doc/counprof/brazil/brazil.htm#2.SOI (accessed on 18 August 2017).

- Hasanov, H. Cotton Sowing Starts in Turkmenistan. Available online: https://en.trend.az/casia/turkmenistan/2256280.html (accessed on 18 August 2017).

- Trending Top Most. Top 10 Largest Cotton Producing Countries in The World. Available online: http://www.trendingtopmost.com/worlds-popular-list-top-10/2017-2018-2019-2020-2021/agriculture/largest-cotton-producing-countries-world-best-quality-highest/ (accessed on 18 August 2017).

- Robinson, W.O.; Edgington, G.; Byers, H.G. Chemical Studies of Infertile Soils Derived from Rocks High in Magnesium and Generally high in Chromium and Nickel; No. 1488-2016-124356; USDA: Washington, DC, USA, 1935.

- Karvy Comtrade Limited, Cotton Seasonal Report. 2009. Available online: http://www.karvycommodities.com/downloads/karvySpecialReports/karvysSpecialReports_20090313_01.pdf (accessed on 29 August 2017).

- Cotton Development Board. Cotton Development Program. Available online: http://cdb.portal.gov.bd/site/page/84e5a06c-0463-47cf-a0c4-24ac18d77484 (accessed on 18 August 2017).

- Rahman, M.A. Cotton Research and Production in Bangladesh; Cotton Development Board, Government of Bangladesh: Dhaka, Bangladesh, 2018.

- Banglapedia. Forest Soil. Available online: http://en.banglapedia.org/index.php?title=Forest_Soil (accessed on 18 August 2017).

- Banglapedia. Crop. Available online: http://en.banglapedia.org/index.php?title=Crop (accessed on 18 August 2017).

- Amin, S.; Chakravarty, D.K.; Huda, N.; Khan, S. Agricultural Education; The National Curriculum & Textbook Board: Dhaka, Bangladesh, 1931.

- Huq, S.I.; Shoaib, J.M. The Soils of Bangladesh; Springer: Dordrecht, The Netherlands, 2013. [Google Scholar]

- Banglapedia. Seven Soil Tracts. Available online: http://en.banglapedia.org/index.php?title=Seven_Soil_Tracts (accessed on 18 August 2017).

- Pakistan Bureau of Statistics, Crops Area and Production By Districts (1981-82 TO 2008-09). Available online: http://www.pbs.gov.pk/content/crops-area-and-production-districts-1981-82-2008-09 (accessed on 18 August 2017).

- Noonari, S.; Memon, M.I.N.; Bhatti, M.A.; Perzado, M.B.; Wagan, S.A.; Memon, A.A.; Chandio, A.A.S.; Kalwar, G.Y.; Shah, S.T.; Jamroo, A.S. Comparative Economics Analysis of the Bt. Cotton V/S Conventional Cotton Production in Khairpur District, Sindh, Pakistan. Int. J. Bus. Econ. Res. 2015, 4, 72–85. [Google Scholar] [CrossRef]

- Mohsin, M.; Jamal, F.; Khan, A.A.; Ajmal, F. Transformation of Fertile Agricultural Soil into Housing Schemes: A Case of Bahawalpur City, Punjab, Pakistan. Int. Rev. Soc. Sci. Hum. 2014, 2, 141–156. [Google Scholar]

- Australian Government: Department of Agriculture and Water Resources. Cotton. 2015. Available online: http://www.agriculture.gov.au/ag-farm-food/crops/cotton (accessed on 15 August 2017).

- Cotton Australia. Where Is It Grown? Available online: http://cottonaustralia.com.au/australian-cotton/basics/where-is-it-grown (accessed on 15 August 2017).

- Department of Primary Industries. The Ideal Soil for Cotton. Available online: http://www.dpi.nsw.gov.au/agriculture/soils/guides/soilpak-series/soilpak (accessed on 15 August 2017).

- NASS, U. Usual Planting and Harvesting Dates for US Field Crops. In Agricultural Handbook; USDA: Washington, DC, USA, 1997. [Google Scholar]

- Cotton Insect Management Guide. Cotton Production Regions of Texas. Available online: http://cottonbugs.tamu.edu/cotton-production-regions-of-texas/ (accessed on 15 August 2017).

- Cotton Counts. Cotton from Field to Fabric. Available online: https://www.cotton.org/pubs/cottoncounts/fieldtofabric/crops.cfm (accessed on 15 August 2017).

- AgMRC: Agricultural Market Resource Center. Cotton. 2012. Available online: http://www.agmrc.org/commodities-products/fiber/cotton/ (accessed on 15 August 2017).

- Georgia Integrated Pest Management, Crop Profile for Cotton in Georgia. 2006. Available online: https://ipmdata.ipmcenters.org/documents/cropprofiles/GAcotton.pdf (accessed on 4 November 2017).

- Texas AgriLife Extension Service, Crop Profile for Cotton in Texas. Texas, USA. 1999. Available online: http://agrilife.org/aes/files/2010/06/Crop-Profile-for-Cotton-in-Texas2.pdf (accessed on 30 August 2017).

- Farris, S.; Schaich, K.M.; Liu, L.; Piergiovanni, L.; Yam, K.L. Development of polyion-complex hydrogels as an alternative approach for the production of bio-based polymers for food packaging applications: A review. Trends Food Sci. Technol. 2009, 8, 316–332. [Google Scholar] [CrossRef]

- Jaime-Garcia, R.; Cotty, A.P.J. Spatial Relationships of Soil Texture and Crop Rotation to Aspergillus Flavus Community Structure in South Texas. Phytopathology 2006, 6, 599–607. [Google Scholar] [CrossRef][Green Version]

- Blackstock, D.A. Soil Survey of Lubbock County, Texas; United States Department of Agriculture, Soil Conservation Service (USDA): Washington, DC, USA, 1979.

- SLBC. Command Area Development, Chapter 6. India. Available online: https://pdfslide.net/reader/f/chapter-6-slbc-command-area-d-6pdf-124-chapter-6-slbc-command-area-development (accessed on 15 August 2017).

- Production Technology of Cotton in Bangladesh. 2012. Available online: http://cottonbd.blogspot.com/ (accessed on 15 August 2017).

- Department of Chemical Engineering. Environmental Impact Assessment For Western Bangladesh Bridge Improvement Project; Bangladesh University of Engineering and Technology: Dhaka, Bangladesh, 2014. [Google Scholar]

- Environmental Conservation Rules, Department of Environment; Ministry of Environment and Forest: Dhaka, Bangladesh, 1997.

- Sea_Distances.Org. Available online: https://sea-distances.org/ (accessed on 3 August 2017).

- Sabesh, M. Approved Package of Practices for Cotton: Gujarat State. 2006. Available online: https://tnaucottondatabase.files.wordpress.com/2012/03/gj.pdf (accessed on 15 August 2017).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hossain, L.; Khan, M.S. Water Footprint Management for Sustainable Growth in the Bangladesh Apparel Sector. Water 2020, 12, 2760. https://doi.org/10.3390/w12102760

Hossain L, Khan MS. Water Footprint Management for Sustainable Growth in the Bangladesh Apparel Sector. Water. 2020; 12(10):2760. https://doi.org/10.3390/w12102760

Chicago/Turabian StyleHossain, Laila, and Mohidus Samad Khan. 2020. "Water Footprint Management for Sustainable Growth in the Bangladesh Apparel Sector" Water 12, no. 10: 2760. https://doi.org/10.3390/w12102760

APA StyleHossain, L., & Khan, M. S. (2020). Water Footprint Management for Sustainable Growth in the Bangladesh Apparel Sector. Water, 12(10), 2760. https://doi.org/10.3390/w12102760