Scaling up Microbial Fuel Cells for Treating Swine Wastewater

Abstract

1. Introduction

2. Materials and Methods

2.1. Swine Wastewater Used as Influent

2.2. Electricity Generation Using Two Different Anodes

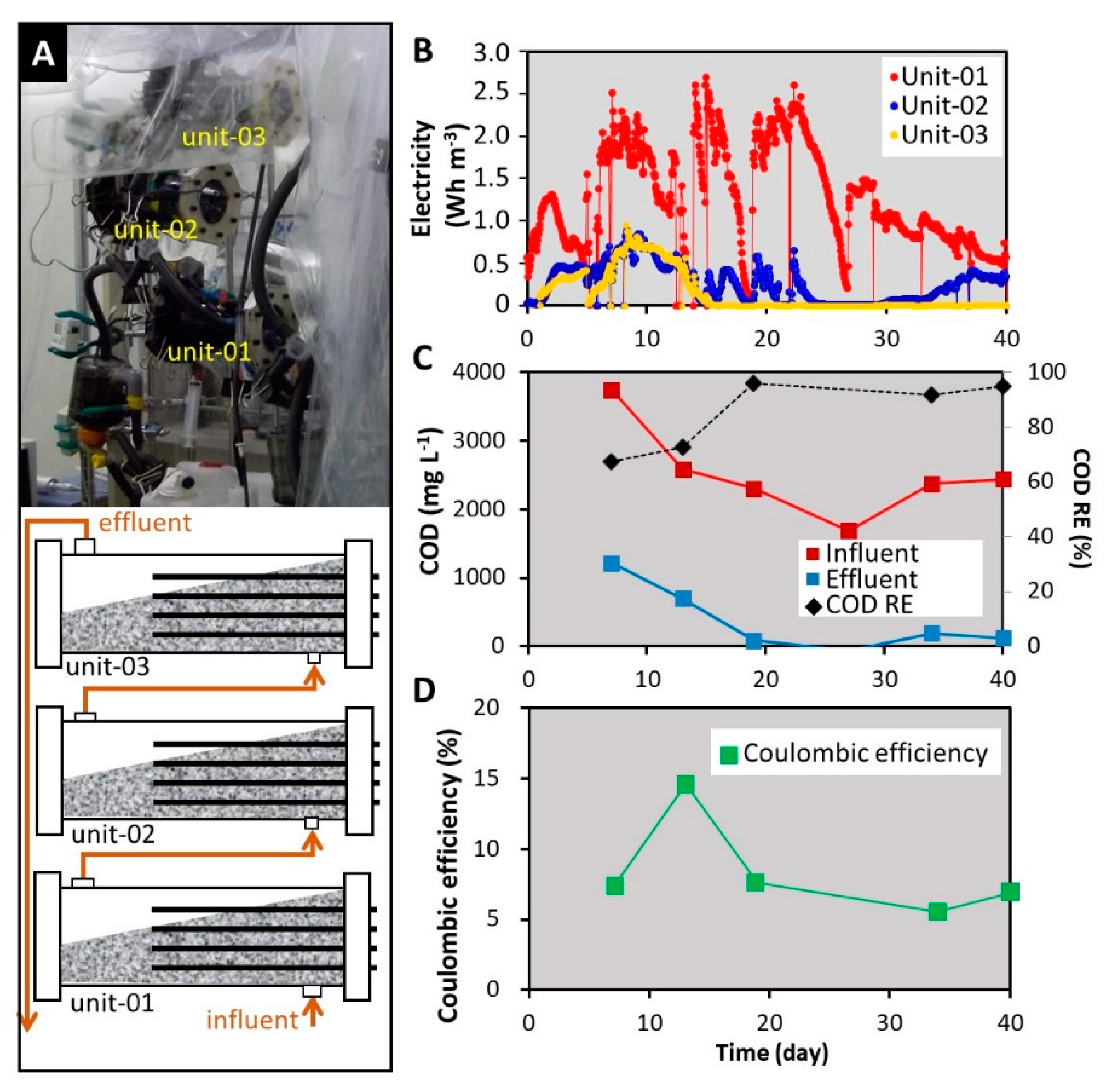

2.3. Microbial Fuel Cells with 1.5 L Capacity

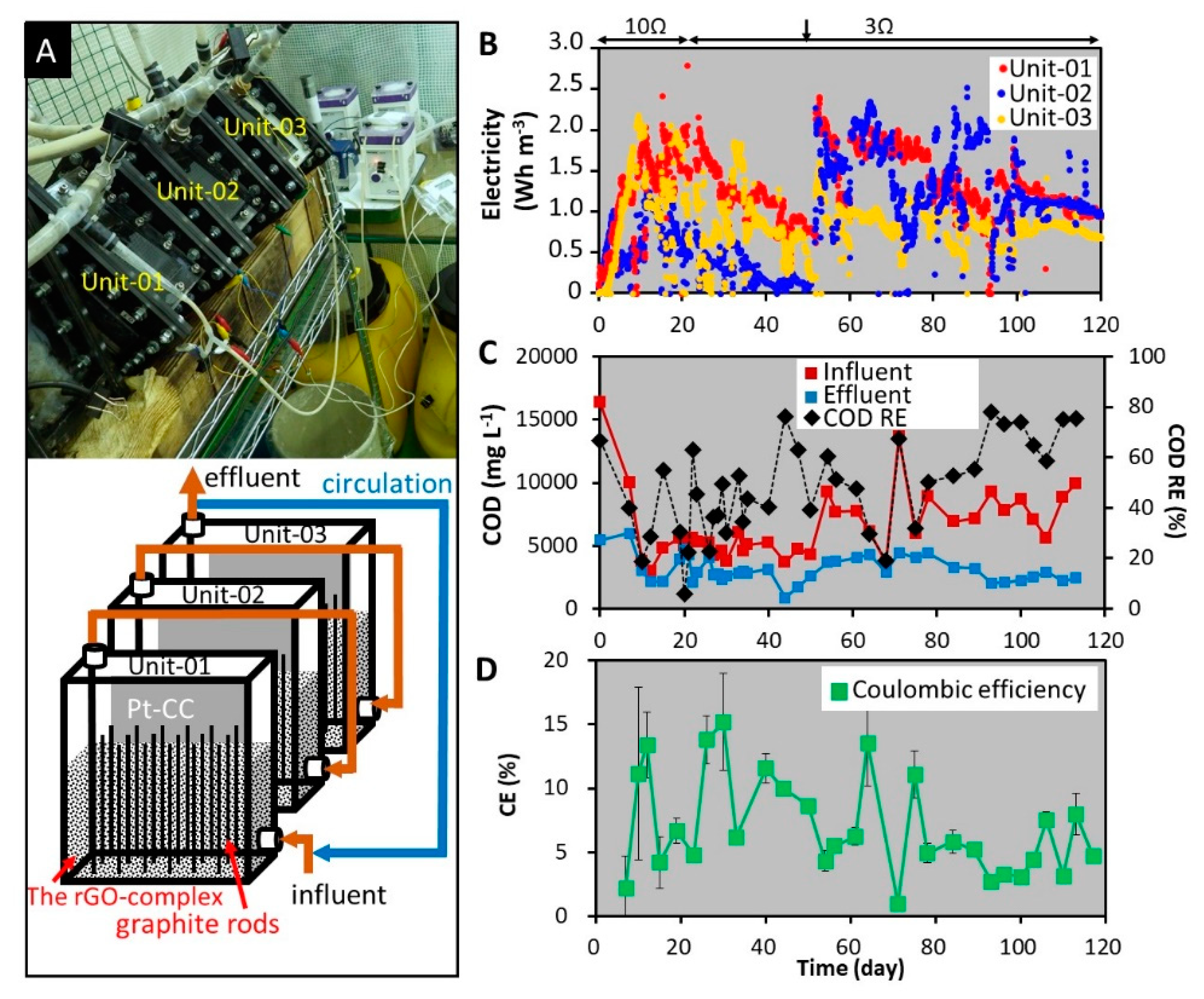

2.4. Microbial Fuel Cells with 12 L Capacity

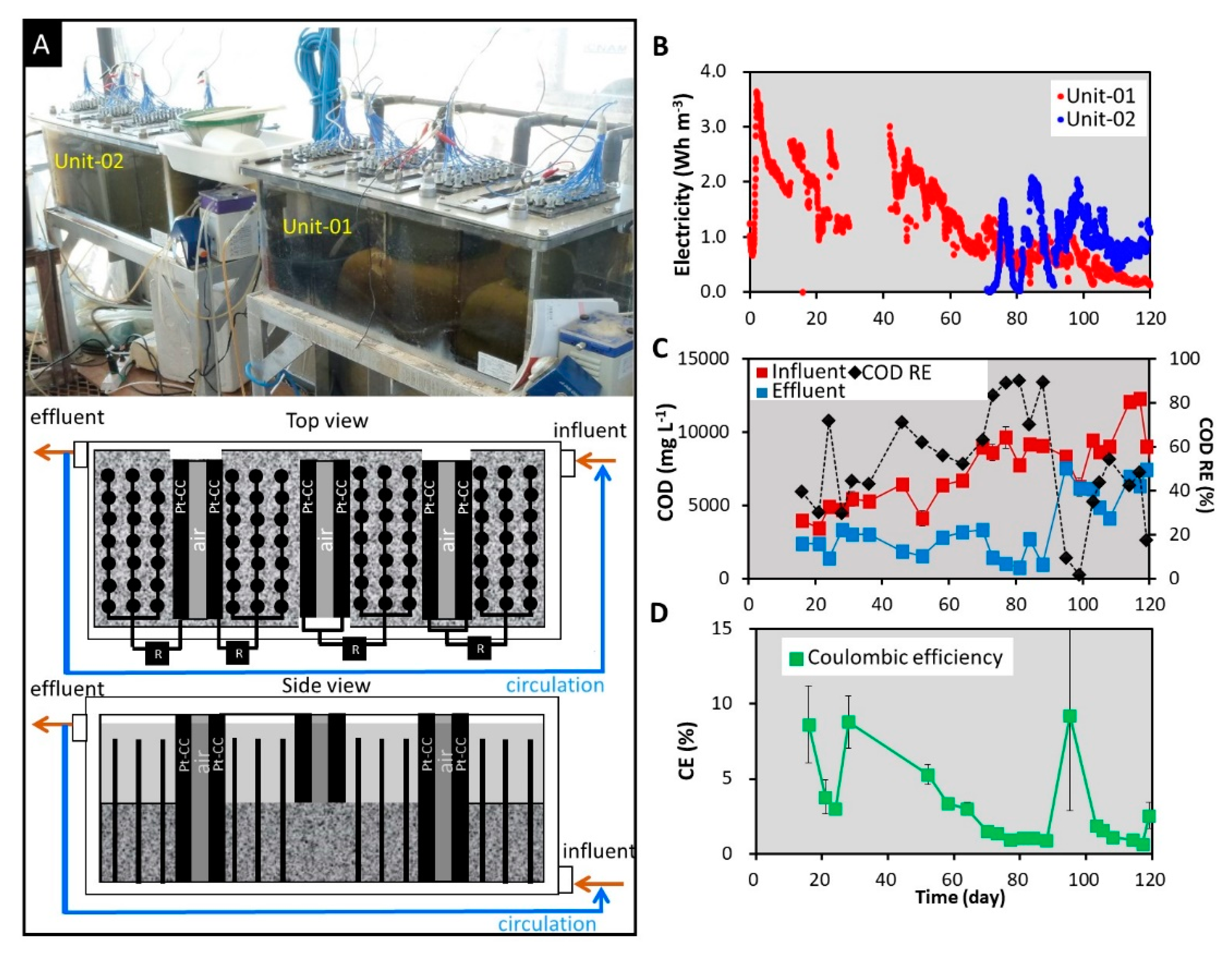

2.5. Microbial Fuel Fells with 100 L Capacity

2.6. Chemical Analysis

2.7. Coulombic Efficiency

3. Results and Discussion

3.1. Electricity Generation Using Two Different Anodes

3.2. Performance of the 1.5 L-MFC

3.3. Performance of the 12 L-MFC

3.4. Performance of the 100 L-MFC

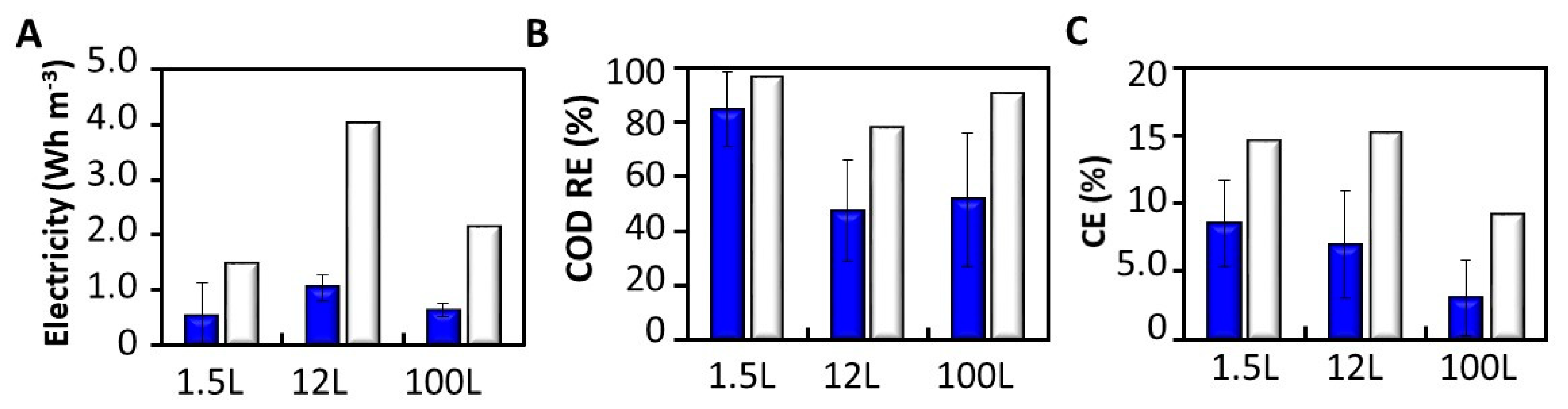

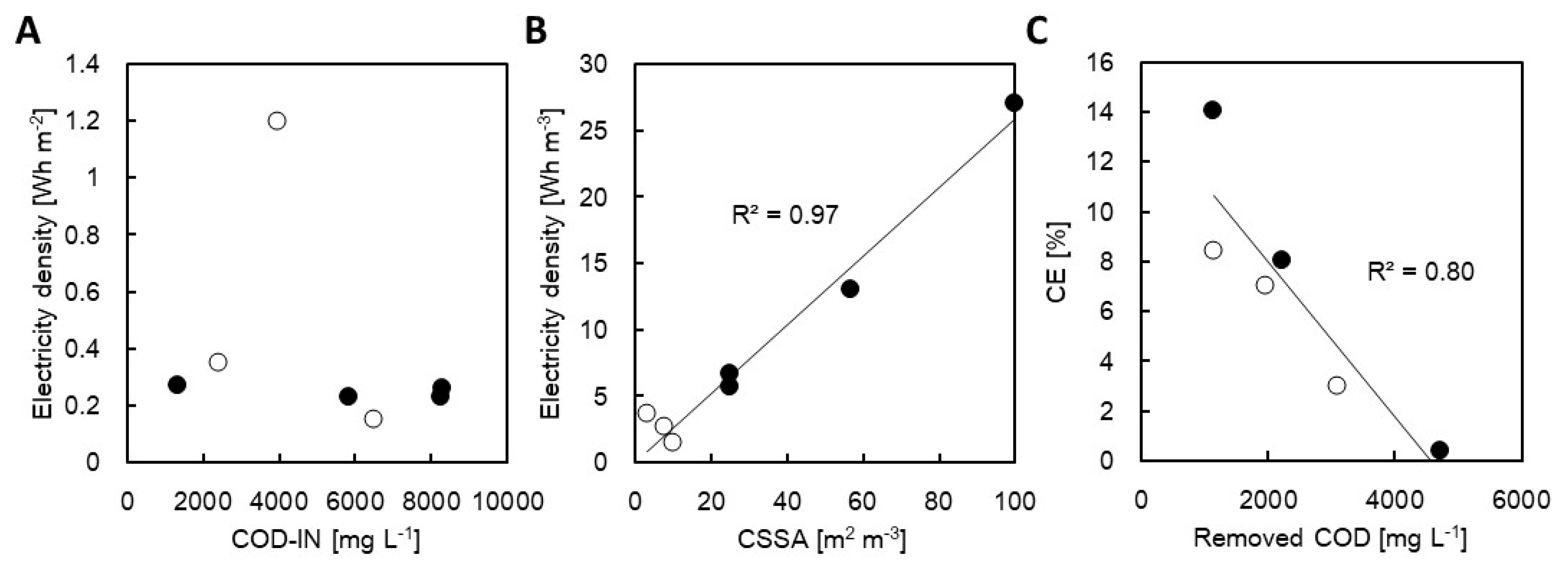

3.5. Effects of Scaling up Microbial Fuel Cells

3.6. Comparison of MFC Performance with Previous Reports

3.7. Net Energy Balance when Combining MFC and Post-Aeration

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ministry of Agriculture, Forestry and Fisheries (MAFF). Production and Management of Livestock Manure; Ministry of Agriculture, Forestry and Fisheries: Tokyo, Japan, 2016. (In Japanese) [Google Scholar]

- Oshida, T.; Fukuyasu, T.; Kohzaki, K. Direct treatment of animal waste water by public sewerage in urban district. Waste Manag. Res. 1994, 5, 357–363. [Google Scholar] [CrossRef][Green Version]

- McCarty, P.L.; Bae, J.; Kim, J. Domestic wastewater treatment as a net energy producer—Can this be achieved? Environ. Sci. Technol. 2011, 45, 7100–7106. [Google Scholar] [CrossRef] [PubMed]

- Logan, B.E.; Rabaey, K. Conversion of wastes into bioelectricity and chemicals by using microbial electrochemical technologies. Science 2012, 337, 686–690. [Google Scholar] [CrossRef] [PubMed]

- Green, F.B.; Lundquist, T.J.; Oswald, W.J. Energetics of advanced integrated wastewater pond systems. Water Sci. Technol. 1995, 31, 9–20. [Google Scholar] [CrossRef]

- Kondusamy, D.; Kalamdhad, A.S. Pre-treatment and anaerobic digestion of food waste for high rate methane production—A review. J. Environ. Chem. Eng. 2014, 2, 1821–1830. [Google Scholar] [CrossRef]

- New Energy and Industrial Technology Development Organization (NEDO). White Paper on Renewable Energy Technologies, 2nd ed.; New Energy and Industrial Technology Development Organization: Kawasaki, Japan, 2014. (In Japanese) [Google Scholar]

- Gallert, C.; Bauer, S.; Winter, J. Effect of ammonia on the anaerobic degradation of protein by a mesophilic and thermophilic biowaste population. Appl. Microbiol. Biotechnol. 1998, 50, 495–501. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Cheng, J.J.; Creamer, K.S. Inhibition of anaerobic digestion process: A review. Bioresour. Technol. 2008, 99, 4044–4064. [Google Scholar] [CrossRef] [PubMed]

- Kato, K. Regulation of wastewater in the Water Pollution Control Law and waste water standards of nitrogen and phosphorus in livestock industry. Anim. Husb. Environ. Inf. 2004, 24, 19–25. (In Japanese) [Google Scholar]

- Watanabe, K. Recent developments in microbial fuel cell technologies for sustainable bioenergy. J. Biosci. Bioeng. 2008, 106, 528–536. [Google Scholar] [CrossRef] [PubMed]

- Ahn, Y.; Logan, B.E. Effectiveness of domestic wastewater treatment using microbial fuel cells at ambient and mesophilic temperatures. Bioresour. Technol. 2010, 101, 469–475. [Google Scholar] [CrossRef]

- Malaeb, L.; Katuri, K.P.; Logan, B.E.; Maab, H.; Nunes, S.P.; Saikaly, P.E. A hybrid microbial fuel cell membrane bioreactor with a conductive ultrafiltration membrane biocathode for wastewater treatment. Environ. Sci. Technol. 2013, 47, 11821–11828. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, X.; Logan, B.E.; Lee, H. Brewery wastewater treatment using air-cathode microbial fuel cells. Appl. Microbiol. Biotechnol. 2008, 78, 873–880. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Feng, Y.J.; Lee, H. Electricity production from beer brewery wastewater using single chamber microbial fuel cell. Water Sci. Technol. 2008, 57, 1117–1121. [Google Scholar] [CrossRef]

- Clauwaert, P.; Rabaey, K.; Aelterman, P.; De Schamphelaire, L.; Pham, T.H.; Boeckx, P.; Boon, N.; Verstraete, W. Biological denitrification in microbial fuel cells. Environ. Sci. Technol. 2007, 41, 3354–3360. [Google Scholar] [CrossRef]

- Zhuang, L.; Zheng, Y.; Zhou, S.; Yuan, Y.; Yuan, H.; Chen, Y. Scalable microbial fuel cell (MFC) stack for continuous real wastewater treatment. Bioresour. Technol. 2012, 106, 82–88. [Google Scholar] [CrossRef]

- Feng, Y.; He, W.; Liu, J.; Wang, X.; Qu, Y.; Ren, N. A horizontal plug flow and stackable pilot microbial fuel cell for municipal wastewater treatment. Bioresour. Technol. 2014, 156, 132–138. [Google Scholar] [CrossRef] [PubMed]

- He, W.; Wallack, M.J.; Kim, K.Y.; Zhang, X.; Yang, W.; Zhu, X.; Feng, Y.; Logan, B.E. The effect of flow modes and electrode combinations on the performance of a multiple module microbial fuel cell installed at wastewater treatment plant. Water Res. 2016, 105, 351–360. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Ge, Z.; Grimaud, J.; Hurst, J.; He, Z. Long-term performance of liter-scale microbial fuel cells treating primary effluent installed in a municipal wastewater treatment facility. Environ. Sci. Technol. 2013, 47, 4941–4948. [Google Scholar] [CrossRef]

- Dong, Y.; Qu, Y.; He, W.; Du, Y.; Liu, J.; Han, X.; Feng, Y.A. A 90-liter stackable baffled microbial fuel cell for brewery wastewater treatment based on energy self-sufficient mode. Bioresour. Technol. 2015, 195, 66–72. [Google Scholar] [CrossRef]

- Lu, M.; Chen, S.; Babanova, S.; Phadke, S.; Salvacion, M.; Mirhosseini, A.; Chan, S.; Carpenter, K.; Cortese, R.; Bretschger, O. Long-term performance of a 20-L continuous flow microbial fuel cell for treatment of brewery wastewater. J. Power Sources 2017, 356, 274–287. [Google Scholar] [CrossRef]

- Oh, S.T.; Kim, J.R.; Premier, G.C.; Lee, T.H.; Kim, C.; Sloan, W.T. Sustainable wastewater treatment: How might microbial fuel cells contribute. Biotechnol. Adv. 2010, 28, 871–881. [Google Scholar] [CrossRef] [PubMed]

- Yoshida, N.; Goto, Y.; Miyata, Y. Selective growth of and electricity production by marine exoelectrogenic bacteria in self-aggregated hydrogel of microbially reduced graphene oxide. C 2016, 2, 15. [Google Scholar] [CrossRef]

- Yoshida, N.; Miyata, Y.; Doi, K.; Goto, Y.; Nagao, Y.; Tero, R.; Hiraishi, A. Graphene oxide-dependent growth and self-aggregation into a hydrogel complex of exoelectrogenic bacteria. Sci. Rep. 2016, 6, 21867. [Google Scholar] [CrossRef]

- Goto, Y.; Yoshida, N. Microbially reduced graphene oxide shows efficient electricity recovery from artificial dialysis wastewater. J. Gen. Appl. Microbiol. 2017, 63, 165–171. [Google Scholar] [CrossRef] [PubMed]

- Yoshida, N.; Miyata, Y.; Mugita, A.; Iida, K. Electricity recovery from municipal sewage wastewater using a hydrogel complex composed of microbially reduced graphene oxide and sludge. Materials 2016, 9, 742. [Google Scholar] [CrossRef]

- Cheng, S.; Liu, H.; Logan, B.E. Increased performance of single-chamber microbial fuel cells using an improved cathode structure. Electrochem. Commun. 2006, 8, 489–494. [Google Scholar] [CrossRef]

- Goto, Y.; Yoshida, N. Preliminary evaluation of a microbial fuel cell treating artificial dialysis wastewater using graphene oxide. AIP Conf. Proc. 2016, 1709, 020007. [Google Scholar]

- Liu, H.; Logan, B.E. Electricity generation using an air-cathode single chamber microbial fuel cell in the presence and absence of a proton exchange membrane. Environ. Sci. Technol. 2004, 38, 4040–4046. [Google Scholar] [CrossRef]

- Liu, H.; Cheng, S.; Logan, B.E. Power generation in fed-batch microbial fuel cells as a function of ionic strength, temperature, and reactor configuration. Environ. Sci. Technol. 2005, 39, 5488–5493. [Google Scholar] [CrossRef] [PubMed]

- Logan, B.E.; Wallack, M.J.; Kim, K.-Y.; He, W.; Feng, Y.; Saikaly, P.E. Assessment of microbial fuel cell configurations and power densities. Environ. Sci. Technol. Lett. 2015, 2, 206–214. [Google Scholar] [CrossRef]

- Ghangrekar, M.M.; Shinde, V.B. Performance of membrane-less microbial fuel cell treating wastewater and effect of electrode distance and area on electricity production. Bioresour. Technol. 2007, 98, 2879–2885. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.R.; Zuo, Y.; Regan, J.M.; Logan, B.E. Analysis of ammonia loss mechanisms in microbial fuel cells treating animal wastewater. Biotechnol. Bioeng. 2008, 99, 1120–1127. [Google Scholar] [CrossRef]

- Ge, Z.; He, Z. Long-term performance of a 200 liter modularized microbial fuel cell system treating municipal wastewater: Treatment, energy, and cost. Environ. Sci.: Water Res. Technol. 2016, 2, 274–281. [Google Scholar] [CrossRef]

- Kim, J.R.; Dec, J.; Bruns, M.A.; Logan, B.E. Removal of odors from swine wastewater by using microbial fuel cells. Appl. Environ. Microbiol. 2008, 74, 2540–2543. [Google Scholar] [CrossRef]

- Ichihashi, O.; Hirooka, K. Removal and recovery of phosphorus as struvite from swine wastewater using microbial fuel cell. Bioresour. Technol. 2012, 114, 303–307. [Google Scholar] [CrossRef]

- Ding, W.; Cheng, S.; Yu, L.; Huang, H. Effective swine wastewater treatment by combining microbial fuel cells with flocculation. Chemosphere 2017, 182, 567–573. [Google Scholar] [CrossRef]

- Min, B.; Kim, J.R.; Oh, S.E.; Regan, J.M.; Logan, B.E. Electricity generation from swine wastewater using microbial fuel cells. Water Res. 2005, 39, 4961–4968. [Google Scholar] [CrossRef] [PubMed]

- Nurmiyanto, A.; Kodera, H.; Kindaichi, T.; Ozaki, N.; Aoi, Y.; Ohashi, A. Dominant Candidatus Accumulibacter phosphatis enriched in response to phosphate concentrations in EBPR process. Microbes Environ. 2017, 32, 260–267. [Google Scholar] [CrossRef] [PubMed]

- He, Z. Microbial fuel cells: Now let us talk about energy. Environ. Sci. Technol. 2013, 47, 332–333. [Google Scholar] [CrossRef]

- Maktabifard, M.; Zaborowska, E.; Makinia, J. Achieving energy neutrality in wastewater treatment plants through energy savings and enhancing renewable energy production. Rev. Environ. Sci. Bio/Technol. 2018, 17, 655–689. [Google Scholar] [CrossRef]

- Sugioka, M.; Yoshida, N.; Iida, K. On site evaluation of a tubular microbial fuel cell using an anion exchange membrane for sewage water treatment. Front. Energy Res. 2019, 7, 480714. [Google Scholar]

| Reference | Previous Research | This Study | ||||||

|---|---|---|---|---|---|---|---|---|

| 17 | 36 | 37 | 38 | 39 | 0.5 L | 4 L | 50 L | |

| Type | SAC a | SAC | SAC | SAC | SAC | SAC | SAC | AIC b |

| Unit scale (L) | 0.30 | 0.028 | 0.07 | 0.4 | 0.028 | 0.5 | 4 | 50 |

| CA c [cm2] | 187 | 7 | 47 | 400 | 7 | 39 | 400 | 1569 |

| CSSA [m2 m−3] | 64 | 25 | 67 | 100 | 25 | 7.8 | 10 | 3.1 |

| CC d | MnO2 e | Pt f | Pt g | AC h | Ptf | Pt g | Pt g | Pt g |

| Membrane | CEM i | Nafion | PTFE | PTFE | PTFE | PTFE | PTFE | PTFE |

| Temp. [°C] | 30 | 30 | RT j | 30 | 30 | RT | RT | 28.5–5.9 |

| IN-COD k [mg/L] | 5845 | 8270l | 60000 | 1313 | 8230 l | 2325 | 6500 | 7200 |

| EF-COD m [mg L−1] | 1110 | 1320l | 2900–9400 | 156 | 6090 l | 355 | 3400 | 3500 |

| Operation | C | FB n | FB | FB | FB | C | C | C |

| HRT | 5.7–23 h | 260 h | 3–17 d | 84 h | 44 h | 3 d | 3 d | 5 d |

| Electricity [Wh m−2] | 0.23 | Max: 0.23 | Max: 2.3 | Max: 0.27 | Max: 0.26 | Max: 0.35 Ave: 0.048 | Max: 0.15 Ave: 0.09 | Max: 1.2 Ave: 0.25 |

| [Wh m−3] | 15 | Max: 5.8 | Max: 154 | Max: 27 | Max: 6.6 | Max: 2.7 Ave: 1.2 | Max: 1.5 Ave: 0.9 | Max: 3.7 Ave: 0.8 |

| COD RE [%] | 81 | 84 | 91 | 88 | 27 | 85 | 49 | 52 |

| CE [%] | 0.3–0.5 | 47 | 14 | 8 | 5.6–15 | 1.0–15 | 0.7–9.2 | |

| EGE p [kwh kg-COD−1] | 0.044 | 0.035 | 0.026 | |||||

| Measurement | 1.5 L | 12 L | 100 L |

|---|---|---|---|

| COD-IN a (mg L−1) | 2300 | 6500 | 7200 |

| COD-EF b (MFC) (mg L−1) | 360 | 3400 | 3500 |

| COD-EF b (aeration) (mg L−1) | 10 | 10 | 10 |

| MFC-HRT c (d) | 3 | 3 | 5 |

| EGE d (kwh kg-COD−1) | 0.044 | 0.035 | 0.026 |

| EC e (kwh kg-COD−1) | ‒0.6 | ‒0.6 | ‒0.6 |

| MFC f (kwh m−3) | 0.086 | 0.11 | 0.096 |

| Aeration g (kwh m−3) | ‒1.4 | ‒3.9 | ‒4.3 |

| Post-aeration h (kwh m−3) | ‒0.21 | ‒2.0 | ‒2.1 |

| Net energy (kwh m−3) | ‒0.12 | ‒1.9 | ‒2.0 |

| Energy reduction (%) | 91 | 50 | 54 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goto, Y.; Yoshida, N. Scaling up Microbial Fuel Cells for Treating Swine Wastewater. Water 2019, 11, 1803. https://doi.org/10.3390/w11091803

Goto Y, Yoshida N. Scaling up Microbial Fuel Cells for Treating Swine Wastewater. Water. 2019; 11(9):1803. https://doi.org/10.3390/w11091803

Chicago/Turabian StyleGoto, Yuko, and Naoko Yoshida. 2019. "Scaling up Microbial Fuel Cells for Treating Swine Wastewater" Water 11, no. 9: 1803. https://doi.org/10.3390/w11091803

APA StyleGoto, Y., & Yoshida, N. (2019). Scaling up Microbial Fuel Cells for Treating Swine Wastewater. Water, 11(9), 1803. https://doi.org/10.3390/w11091803