Characterization and Simulation of a Low-Pressure Rotator Spray Plate Sprinkler Used in Center Pivot Irrigation Systems

Abstract

1. Introduction

2. Materials and Methods

2.1. Sprinkler Features

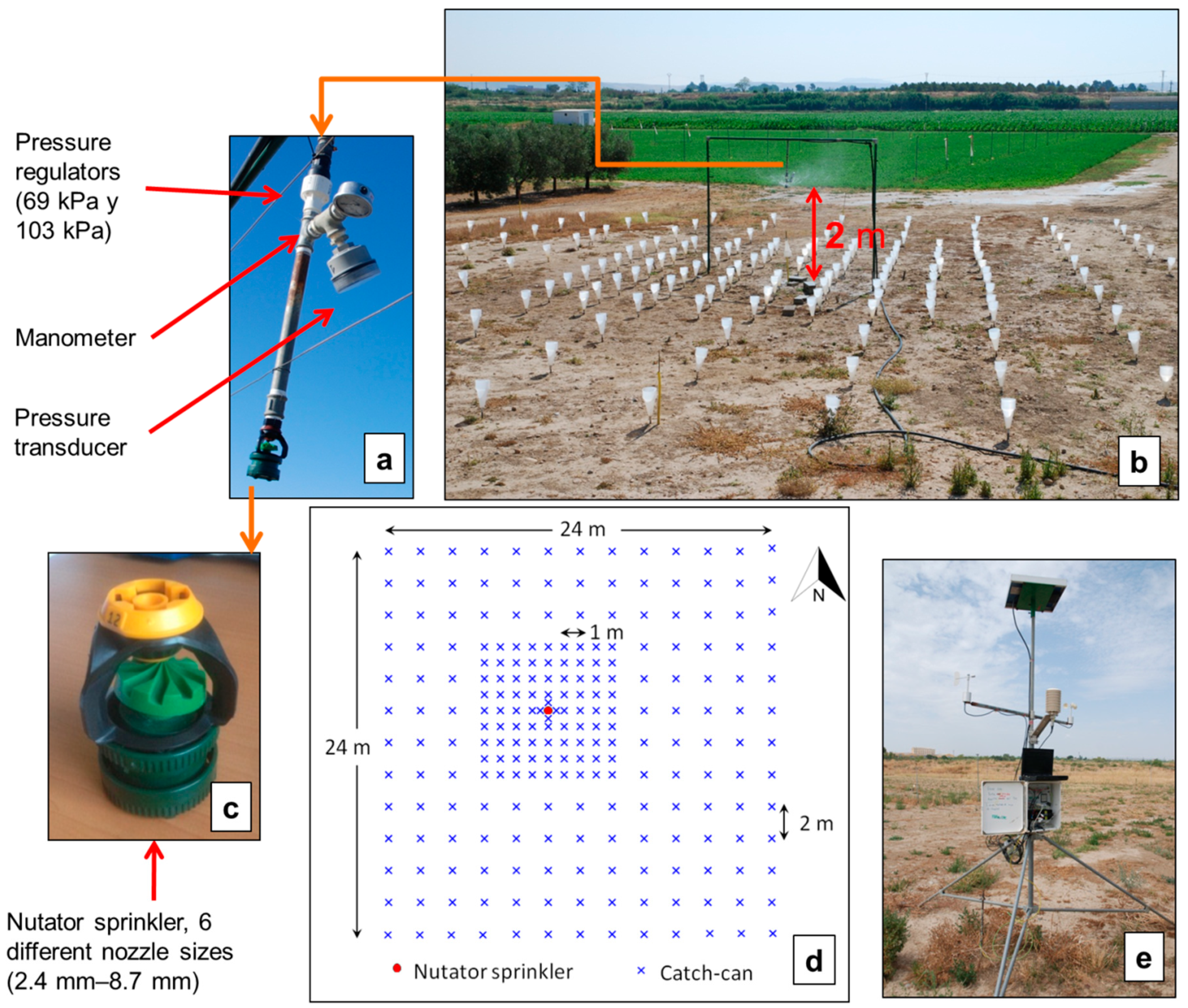

2.2. Experimental Set-Up to Characterize the Water Application Patterns

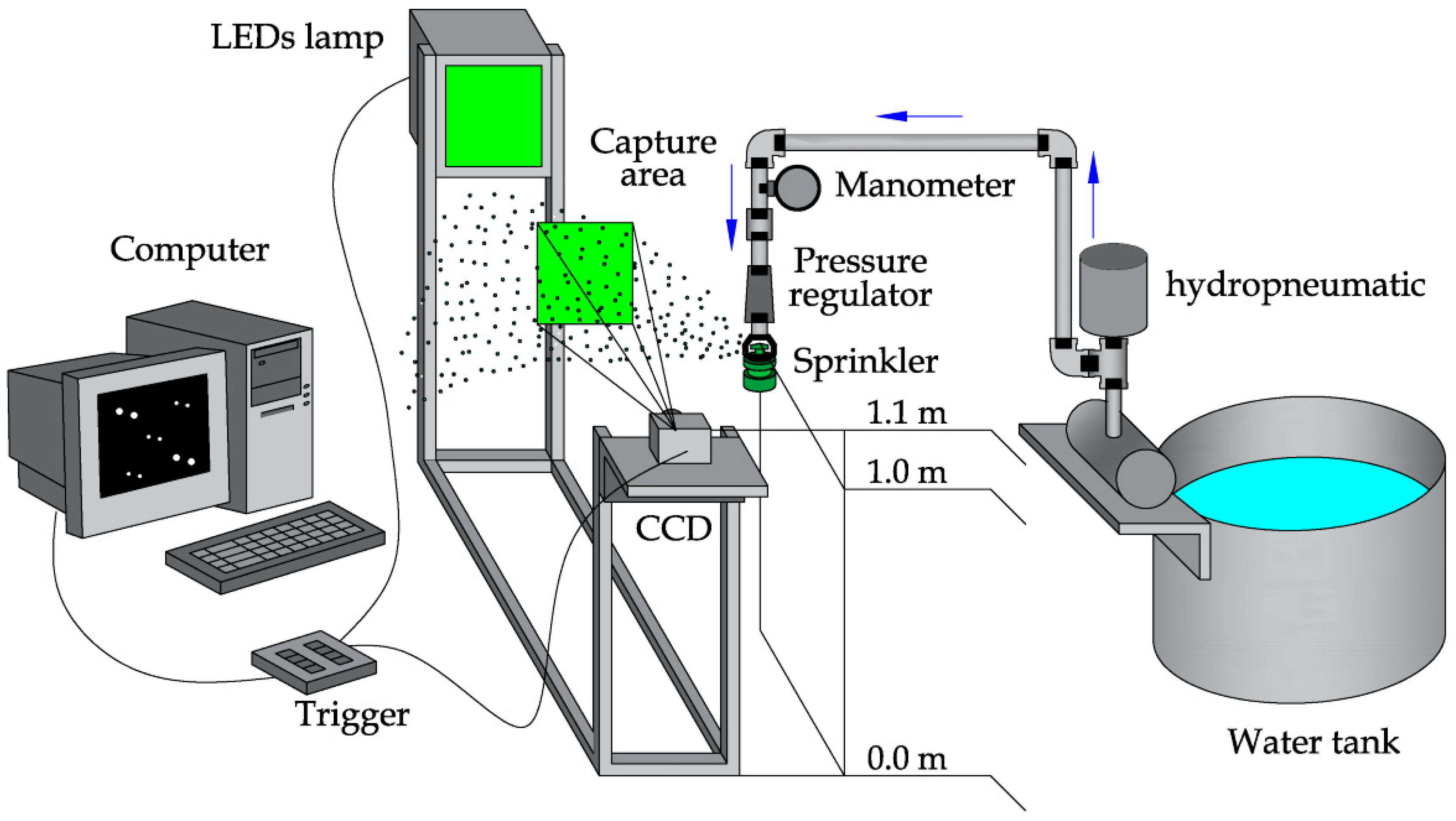

2.3. Experimental Set-Up for Drops Characterization

2.4. Simulation of the Water Application Patterns

2.4.1. Ballistic Simulation

2.4.2. Drop Size Distribution

2.4.3. Drag Model, Calibration and Validation

3. Results and Discussion

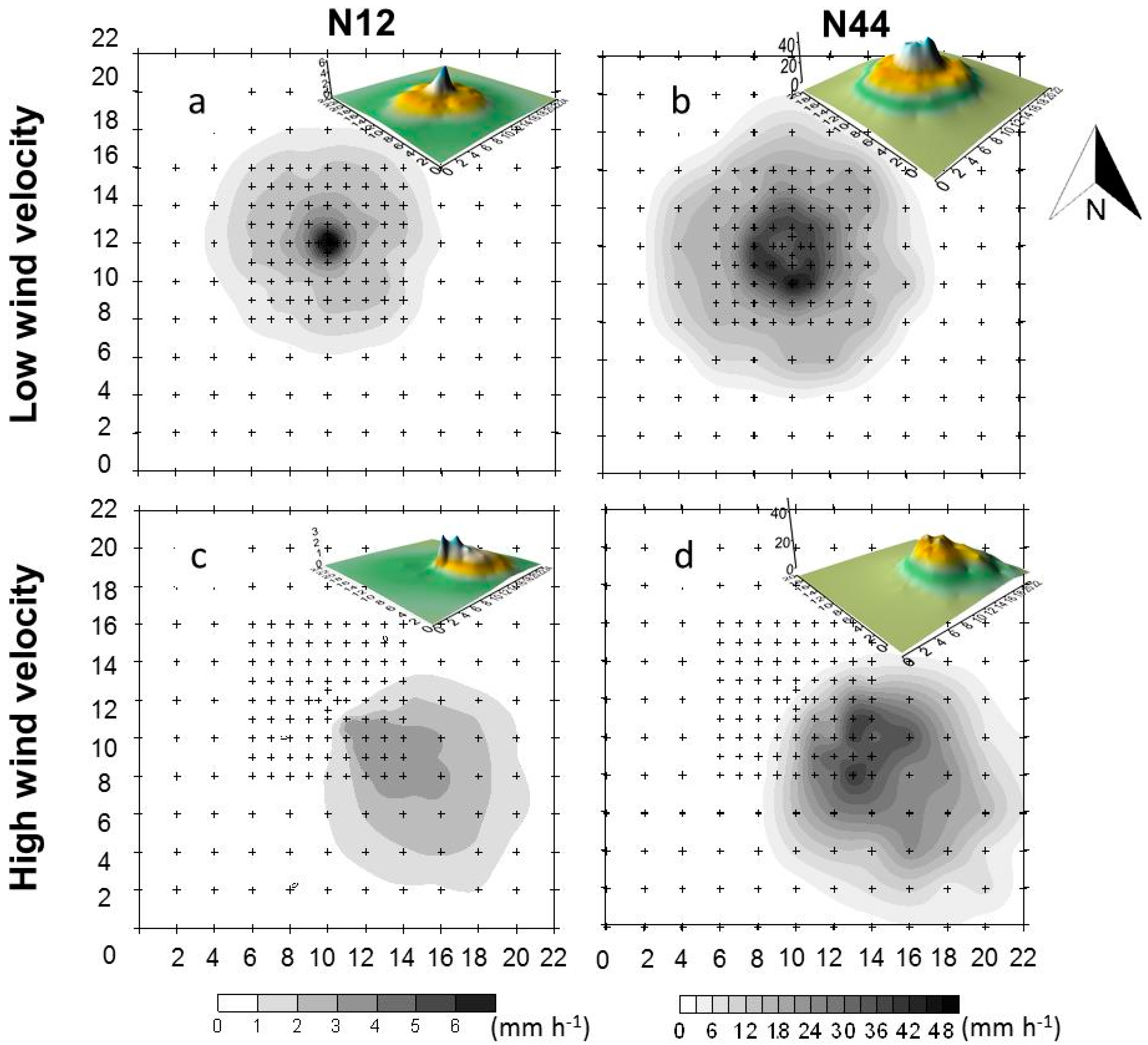

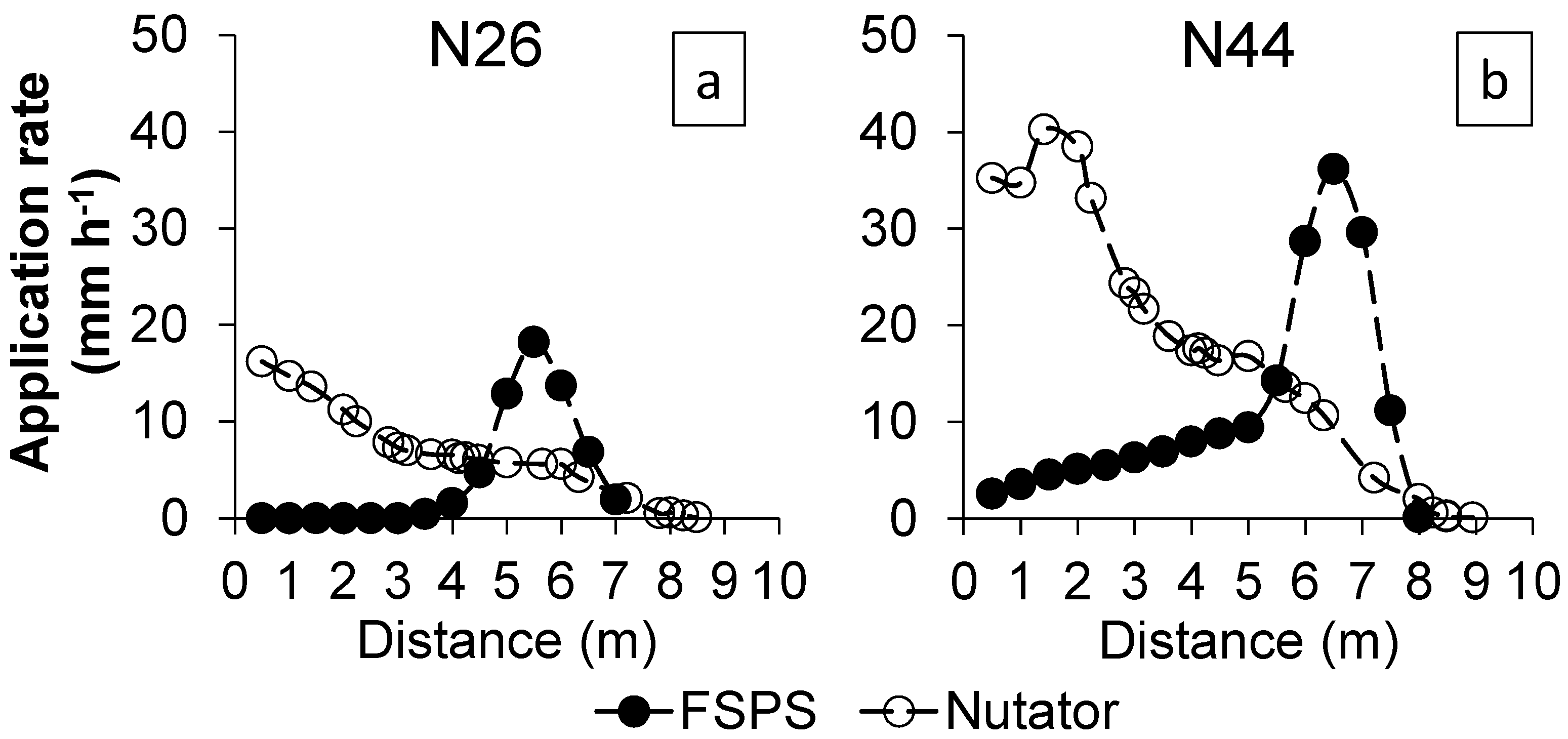

3.1. Water Application Patterns

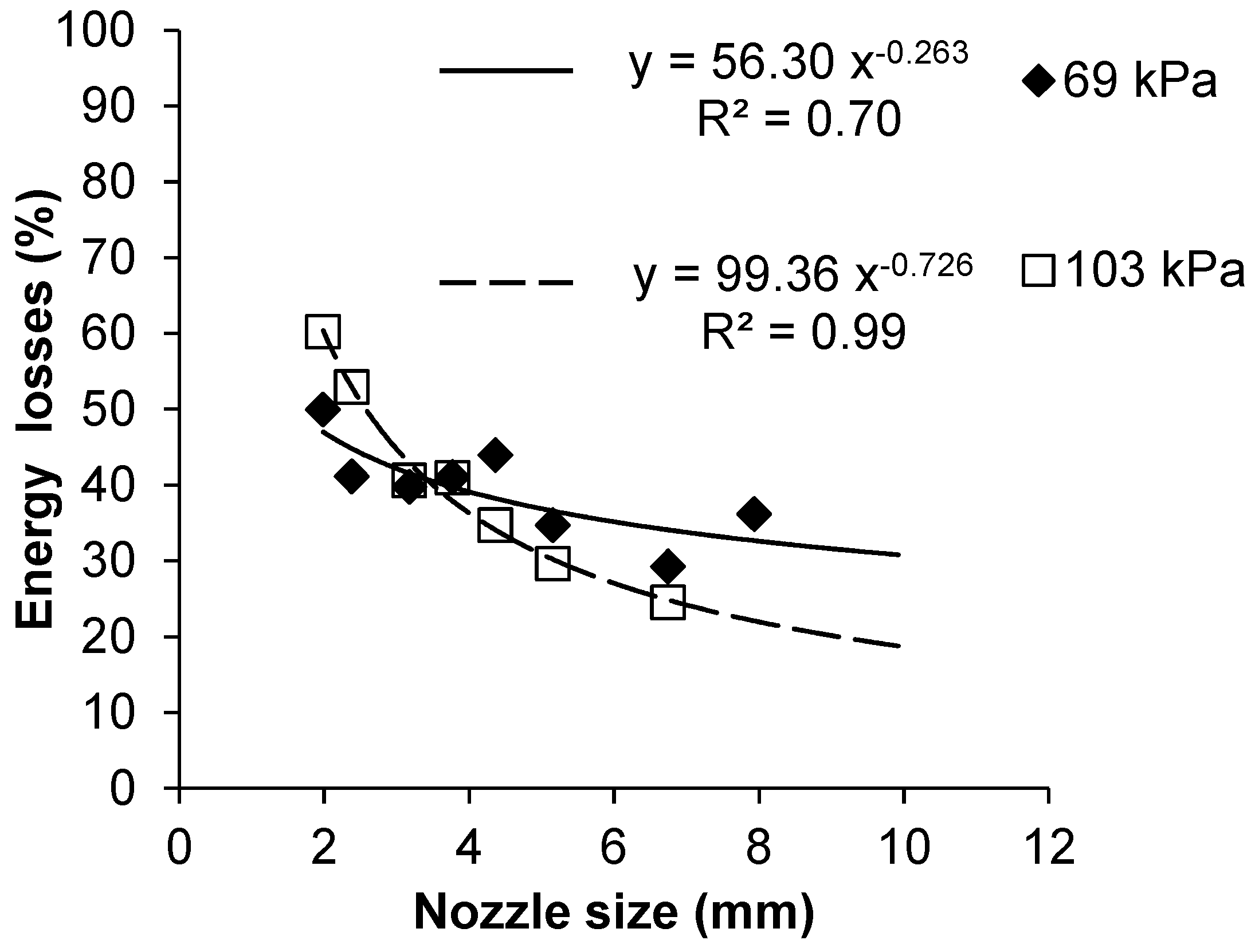

3.2. Energy Losses

3.3. Ballistic Model

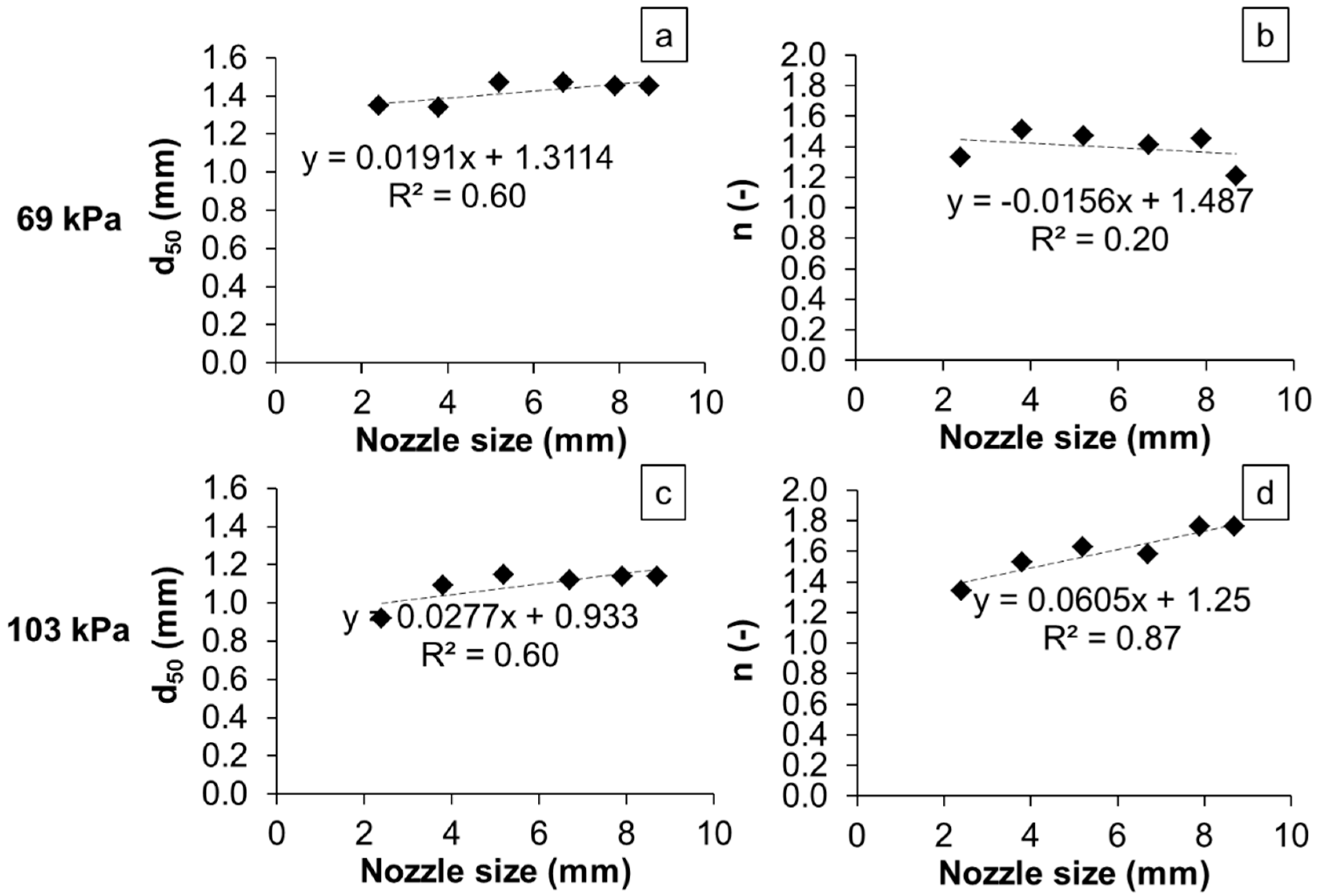

3.3.1. Drop Size Distribution

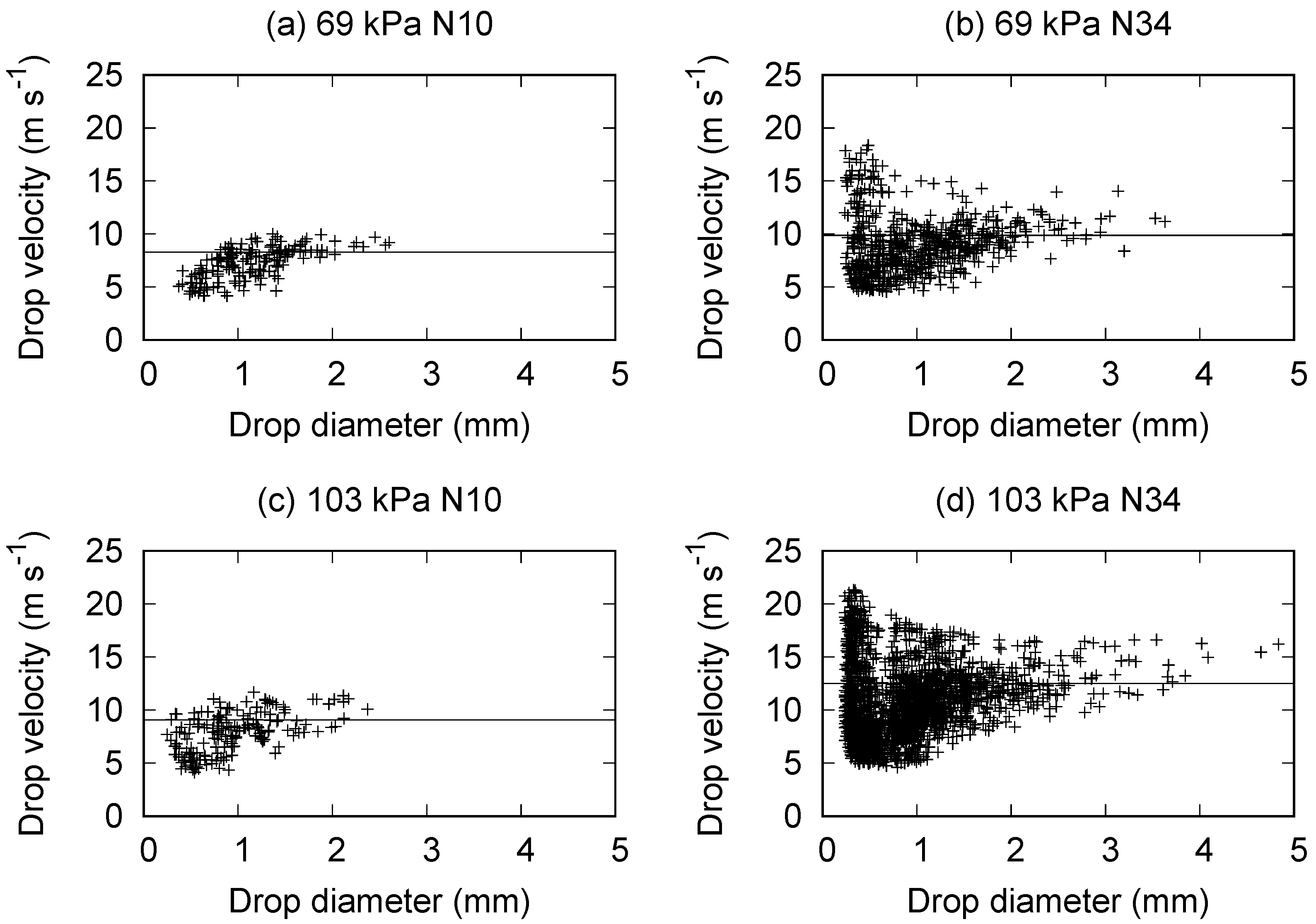

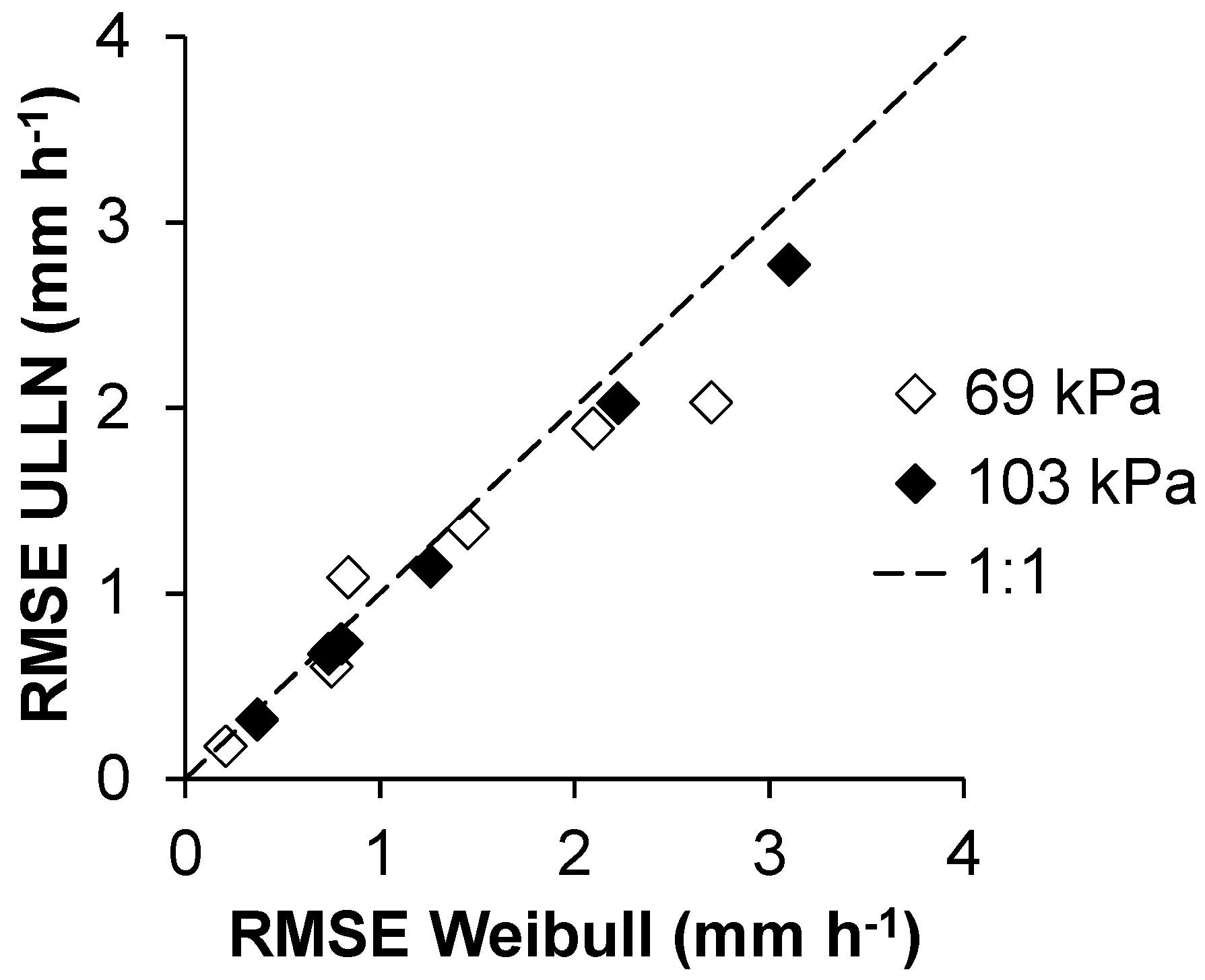

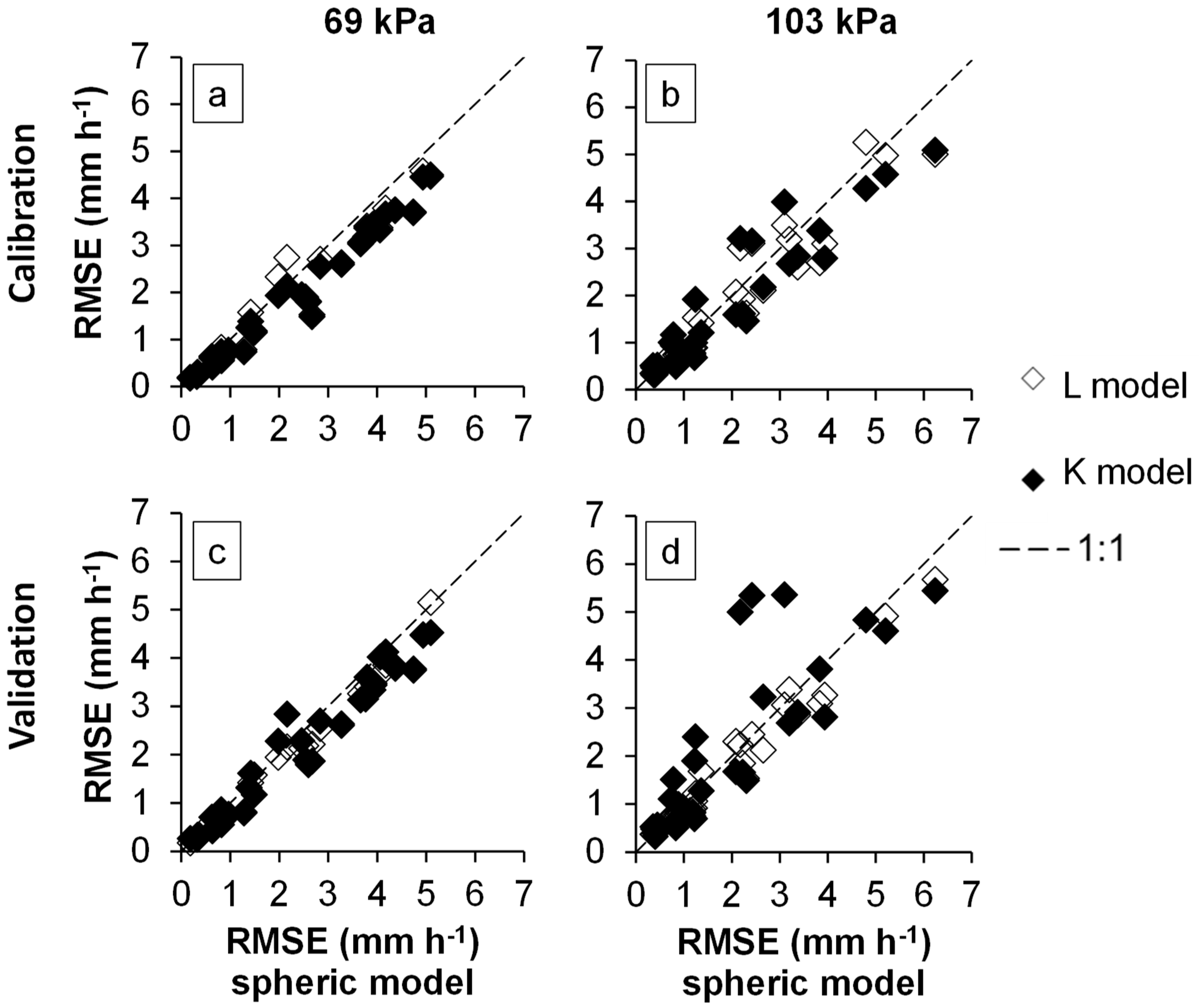

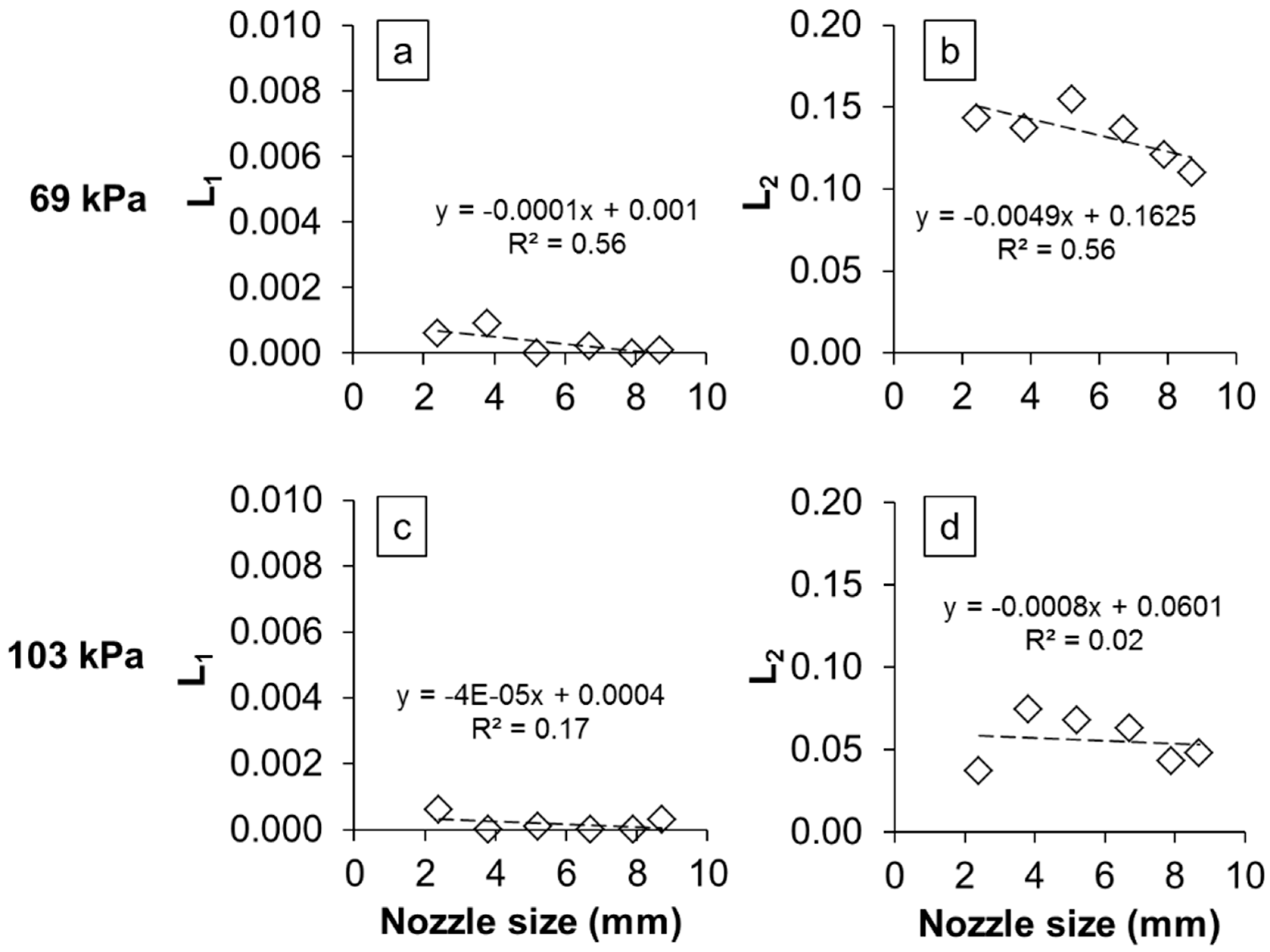

3.3.2. Drag Coefficient, Calibration and Validation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Keller, J.; Bliesner, R.D. Sprinkle and Trickle Irrigation; Van Nostrand Reinhold: New York, NY, USA, 1991. [Google Scholar]

- Tarjuelo, J.M. El Riego por Aspersión y su Tecnología, 3rd ed.; Ediciones Mundi-Prensa: Madrid, España, 1999. [Google Scholar]

- Playán, E.; Garrido, S.; Faci, J.M.; Galán, A. Characterizing pivot sprinklers using an experimental irrigation machine. Agric. Water Manag. 2004, 70, 177–193. [Google Scholar] [CrossRef]

- ESYRCE. Encuesta de Superficies y Rendimientos de Cultivos en España; Ministerio de Agricultura Pesca y Alimentación: Madrid, España, 2017; p. 101.

- National Agricultural Statistics Service (USDA). 2014 Census of Agriculture. Farm and Ranch Irrigation Survey; USDA: Washington, DC, USA, 2013; Volume 3, pp. 100–103.

- Faci, J.M.; Salvador, R.; Playán, E.; Sourell, H. A comparison of fixed and rotating spray plate sprinklers. J. Irrig. Drain. Eng. ASCE 2001, 127, 224–233. [Google Scholar] [CrossRef]

- Moreno, M.A.; Ortega, J.F.; Córcoles, J.I.; Martínez, A.; Tarjuelo, J.M. Energy analysis of irrigation delivery systems: Monitoring and evaluation of proposed measures for improving energy efficiency. Irrig. Sci. 2010, 28, 445–460. [Google Scholar] [CrossRef]

- Tarjuelo, J.M.; Rodríguez-Díaz, J.A.; Abadía, R.; Camacho, E.; Rocamora, C.; Moreno, M.A. Efficient water and energy use in irrigation modernization: Lessons from Spanish case studies. Agric. Water Manag. 2015, 162, 67–77. [Google Scholar] [CrossRef]

- Mugele, R.A.; Evans, H.D. Droplet size distribution in sprays. Ind. Eng. Chem. 1951, 43, 1317–1324. [Google Scholar] [CrossRef]

- Solomon, K.H.; Kincaid, D.C.; Bezdek, J.C. Drop size distribution for irrigation spray nozzles. Trans. ASAE 1985, 28, 1966–1974. [Google Scholar] [CrossRef]

- Molle, B.; Le Gat, Y. Model of water application under pivot sprinkler: II. Calibration and results. J. Irrig. Drain. Eng. 2000, 126, 348–354. [Google Scholar] [CrossRef]

- Legat, Y.; Molle, B. Model of water application under pivot sprinkler. 1: Theoretical grounds. J. Irrig. Drain. Eng. 2000, 126, 343–347. [Google Scholar]

- Ouazaa, S.; Burguete, J.; Paniagua, P.; Salvador, R.; Zapata, N. Simulating water distribution patterns for fixed spray plate sprinkler using the ballistic theory. Span. J. Agric. Res. 2014, 12, 850–863. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, B.; Fang, H.; Zhu, D.; Yang, L.; Li, Z. Experimental and simulation investigation on the kinetic energy dissipation rate of a fixed Spray-plate sprinkler. Water 2018, 10, 1365. [Google Scholar] [CrossRef]

- Li, J.; Kawano, H.; Yu, K. Droplet size distributions from different shaped sprinkler nozzles. Trans. ASAE 1994, 37, 1871–1878. [Google Scholar] [CrossRef]

- Kincaid, D.C.; Solomon, K.H.; Oliphant, J.C. Drop size distributions for irrigation sprinklers. Trans. ASAE 1996, 39, 839–845. [Google Scholar] [CrossRef]

- Montero, J.; Tarjuelo, J.M.; Carrión, P. Sprinkler droplet size distribution measured with an optical spectropluviometer. Irrig. Sci. 2003, 22, 47–56. [Google Scholar] [CrossRef]

- Salvador, R.; Bautista-Capetillo, C.; Burguete, J.; Zapata, N.; Playán, E. A photographic method for drop characterization in agricultural sprinklers. Irrig. Sci. 2009, 27, 307–317. [Google Scholar] [CrossRef]

- Bautista-Capetillo, C.; Robles, O.; Salinas-Tapia, H.; Playán, E. A particle tracking velocimetry technique for drop characterization in agricultural sprinklers. Irrig. Sci. 2014, 32, 437–447. [Google Scholar] [CrossRef]

- Fukui, Y.; Nakanishi, K.; Okamura, S. Computer evaluation of sprinkler irrigation uniformity. Irrig. Sci. 1980, 2, 23–32. [Google Scholar] [CrossRef]

- Tarjuelo, J.M.; Carrión, P.; Valiente, M. Simulación de la distribución del riego por aspersión en condiciones de viento. Investig. Agrar. Prod. Prot. Veg. 1994, 9, 255–272. [Google Scholar]

- Carrión, P.; Tarjuelo, J.M.; Montero, J. SIRIAS: A simulation model for sprinkler irrigation: I. Description of the model. Irrig. Sci. 2001, 20, 73–84. [Google Scholar] [CrossRef]

- Dechmi, F.; Playán, E.; Cavero, J.; Faci, J.M.; Martínez-Cob, A. Wind effects on solid set sprinkler irrigation depth and yield of maize (Zea mays). Irrig. Sci. 2003, 22, 67–77. [Google Scholar] [CrossRef]

- Playán, E.; Zapata, N.; Faci, J.M.; Tolosa, D.; Lacueva, J.L.; Pelegrín, J.; Salvador, R.; Sánchez, I.; Lafita, A. Assessing sprinkler irrigation uniformity using a ballistic simulation model. Agric. Water Manag. 2006, 84, 89–100. [Google Scholar] [CrossRef]

- Zerihun, D.; Sanchez, C.A.; Warrick, A.W. Sprinkler irrigation droplet dynamics. I: Review and theoretical development. J. Irrig. Drain. Eng. 2016, 142, 04016007. [Google Scholar] [CrossRef]

- Robles, O.; Latorre, B.; Zapata, N.; Burguete, J. Self-calibrated ballistic model for sprinkler irrigation with a field experiments data base. Agric. Water Manag. 2019, in press. [Google Scholar] [CrossRef]

- Seginer, I.; Nir, D.; von Bernuth, D. Simulation of wind distorted sprinkler patterns. J. Irrig. Drain. Eng. ASCE 1991, 117, 285–306. [Google Scholar] [CrossRef]

- Ouazaa, S. Development of Models for Solid-Set and Center-Pivot Sprinkler Irrigation Systems. Ph.D. Thesis, University of Zaragoza, Zaragoza, Spain, July 2015. Available online: http://digital.csic.es/handle/10261/117636 (accessed on 10 February 2019).

- Félix-Félix, J.R.; Salinas-Tapia, H.; Bautista-Capetillo, C.; García-Aragón, J.; Burguete, J.; Playán, E. A modified particle tracking velocimetry technique to characterize sprinkler irrigation drops. Irrig. Sci. 2017, 35, 515–531. [Google Scholar] [CrossRef]

- Salinas-Tapia, H.; García, A.J.; Moreno, H.D.; Barrientos, G.B. Particle tracking velocimetry (PTV) algorithm for non-uniform and nonspherical particles. In Proceedings of the Electronics, Robotics and Automotive Mechanics Conference CERMA, Cuernavaca, México, 26–29 September 2006; Volume 2, pp. 322–327. [Google Scholar]

- Sánchez-Burillo, G.; Delirhasannia, R.; Playán, E.; Paniagua, P.; Latorre, B.; Burguete, J. Initial drop velocity in a fixed spray plate sprinkler. J. Irrig. Drain. Eng. 2013, 139, 521–531. [Google Scholar] [CrossRef]

- Vories, E.D.; Von Bernuth, R.D.; Mickelson, R.H. Simulating sprinkler performance in wind. J. Irrig. Drain. Eng. 1987, 113, 119–130. [Google Scholar] [CrossRef]

- GitHub. MPCOTool: The Multi-Purposes Calibration and Optimization Tool. By Burguete, J. and Latorre, B.. Available online: http://github.com/jburguete/mpcotool (accessed on 9 January 2019).

- Burnham, K.P.; Anderson, D.R. Model Selection and Multimodel Inference, 2nd ed.; Springer: New York, NY, USA, 2002; p. 488. [Google Scholar]

- Christiansen, J.E. Irrigation by Sprinkling; Bulletin 670; University of California, College of Agriculture, Agricultural Experiment Station: Berkeley, CA, USA, 1942; p. 124. [Google Scholar]

| Nozzle Size (mm) | 69 kPa | 103 kPa | ||||||

|---|---|---|---|---|---|---|---|---|

| Exp + | Wind Velocity (m s−1) | Irrigation Time (h) | Pressure SD (kPa) ψ | Exp + | Wind Velocity (m s−1) | Irrigation Time (h) | Pressure SD (kPa) ψ | |

| 2.4 | 4 | 1.1–6.9 | 1.8–3.0 | 0.4 | 6 | 0.7–8.3 | 2.8–3.4 | 0.7 |

| 3.8 | 5 | 1.6–6.1 | 1.8–3.0 | 0.7 | 6 | 0.9–6.1 | 2.1–3.1 | 1.0 |

| 5.2 | 5 | 1.3–7.7 | 1.0–2.8 | 0.4 | 6 | 0.4–9.4 | 1.5–2.1 | 0.7 |

| 6.7 | 4 | 0.9–7.4 | 1.0–1.9 | 0.5 | 5 | 0.8–8.5 | 1.0–1.1 | 0.8 |

| 7.9 | 7 | 0.9–5.7 | 1.0–1.3 | 0.5 | 6 | 0.6–8.2 | 1.0–1.1 | 0.9 |

| 8.7 | 8 | 1.2–7.6 | 1.0–1.4 | 0.5 | 4 | 0.6–9.7 | 1.0 | 0.9 |

| Pressure (kPa) | Nozzle Size (mm) | Measured Volume (L h−1) | Wetted Radii (m) | Maximum Application Rate (mm h−1) | r |

|---|---|---|---|---|---|

| 69 | 2.4 | 130.5 | 6.5 | 2.2 | 0.93 |

| 3.8 | 418.0 | 8.7 | 5.9 | 0.93 | |

| 5.2 | 816.0 | 8.6 | 10.0 | 0.98 | |

| 6.7 | 1366.7 | 8.4 | 17.3 | 0.97 | |

| 7.9 | 1927.9 | 8.4 | 25.3 | 0.97 | |

| 8.7 | 2295.7 | 9.0 | 30.0 | 0.97 | |

| 103 | 2.4 | 209.2 | 7.6 | 6.4 | 0.87 |

| 3.8 | 560.4 | 8.6 | 10.2 | 0.94 | |

| 5.2 | 1053.0 | 8.6 | 16.2 | 0.96 | |

| 6.7 | 1701.3 | 9.2 | 24.0 | 0.98 | |

| 7.9 | 2445.6 | 9.2 | 32.2 | 0.98 | |

| 8.7 | 2901.0 | 9.9 | 40.3 | 0.97 |

| Pressure (kPa) | Nozzle Size (mm) | Number of Drops Analyzed | Drop Diameter (mm) | Drop Velocity (m s−1) | Drop Angle (°) |

|---|---|---|---|---|---|

| 69 | 2.0 | 220 | 1.1 | 7.3 | 17.8 |

| 2.4 | 187 | 1.1 | 7.6 | 17.6 | |

| 3.2 | 470 | 1.1 | 7.5 | 18.0 | |

| 3.8 | 345 | 1.2 | 7.7 | 17.5 | |

| 4.4 | 1058 | 1.0 | 7.1 | 18.2 | |

| 5.2 | 751 | 0.9 | 8.2 | 18.3 | |

| 6.7 | 629 | 1.0 | 9.0 | 17.7 | |

| 7.9 | 1053 | 1.0 | 8.9 | 18.2 | |

| 103 | 2.0 | 180 | 0.9 | 7.8 | 17.1 |

| 2.4 | 542 | 1.0 | 8.8 | 17.0 | |

| 3.2 | 326 | 1.1 | 9.3 | 17.2 | |

| 3.8 | 636 | 1.1 | 9.7 | 17.1 | |

| 4.4 | 538 | 1.0 | 10.0 | 17.5 | |

| 5.2 | 710 | 1.1 | 10.5 | 17.4 | |

| 6.7 | 1909 | 0.9 | 10.8 | 17.4 |

| Pressure (kPa) | Nozzle Size (mm) | d50 (mm) | n | Application Rate (mm h−1) | RMSE (mm h−1) | R |

|---|---|---|---|---|---|---|

| 69 | 2.4 | 1.35 | 1.33 | 0.99 | 0.21 | 0.96 |

| 3.8 | 1.34 | 1.51 | 1.75 | 0.75 | 0.93 | |

| 5.2 | 1.47 | 1.47 | 3.51 | 0.84 | 0.97 | |

| 6.7 | 1.47 | 1.41 | 6.21 | 1.45 | 0.96 | |

| 7.9 | 1.45 | 1.45 | 8.76 | 2.10 | 0.97 | |

| 8.7 | 1.45 | 1.21 | 11.3 | 2.70 | 0.98 | |

| 103 | 2.4 | 0.92 | 1.34 | 1.14 | 0.37 | 0.95 |

| 3.8 | 1.09 | 1.53 | 2.41 | 0.74 | 0.96 | |

| 5.2 | 1.15 | 1.63 | 4.52 | 0.80 | 0.99 | |

| 6.7 | 1.12 | 1.58 | 6.43 | 1.26 | 0.99 | |

| 7.9 | 1.14 | 1.76 | 9.25 | 2.22 | 0.98 | |

| 8.7 | 1.14 | 1.76 | 11.5 | 3.10 | 0.97 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Robles Rovelo, C.O.; Zapata Ruiz, N.; Burguete Tolosa, J.; Félix Félix, J.R.; Latorre, B. Characterization and Simulation of a Low-Pressure Rotator Spray Plate Sprinkler Used in Center Pivot Irrigation Systems. Water 2019, 11, 1684. https://doi.org/10.3390/w11081684

Robles Rovelo CO, Zapata Ruiz N, Burguete Tolosa J, Félix Félix JR, Latorre B. Characterization and Simulation of a Low-Pressure Rotator Spray Plate Sprinkler Used in Center Pivot Irrigation Systems. Water. 2019; 11(8):1684. https://doi.org/10.3390/w11081684

Chicago/Turabian StyleRobles Rovelo, Cruz Octavio, Nery Zapata Ruiz, Javier Burguete Tolosa, Jesús Ramiro Félix Félix, and Borja Latorre. 2019. "Characterization and Simulation of a Low-Pressure Rotator Spray Plate Sprinkler Used in Center Pivot Irrigation Systems" Water 11, no. 8: 1684. https://doi.org/10.3390/w11081684

APA StyleRobles Rovelo, C. O., Zapata Ruiz, N., Burguete Tolosa, J., Félix Félix, J. R., & Latorre, B. (2019). Characterization and Simulation of a Low-Pressure Rotator Spray Plate Sprinkler Used in Center Pivot Irrigation Systems. Water, 11(8), 1684. https://doi.org/10.3390/w11081684