Middleware to Operate Smart Photovoltaic Irrigation Systems in Real Time

Abstract

:1. Introduction

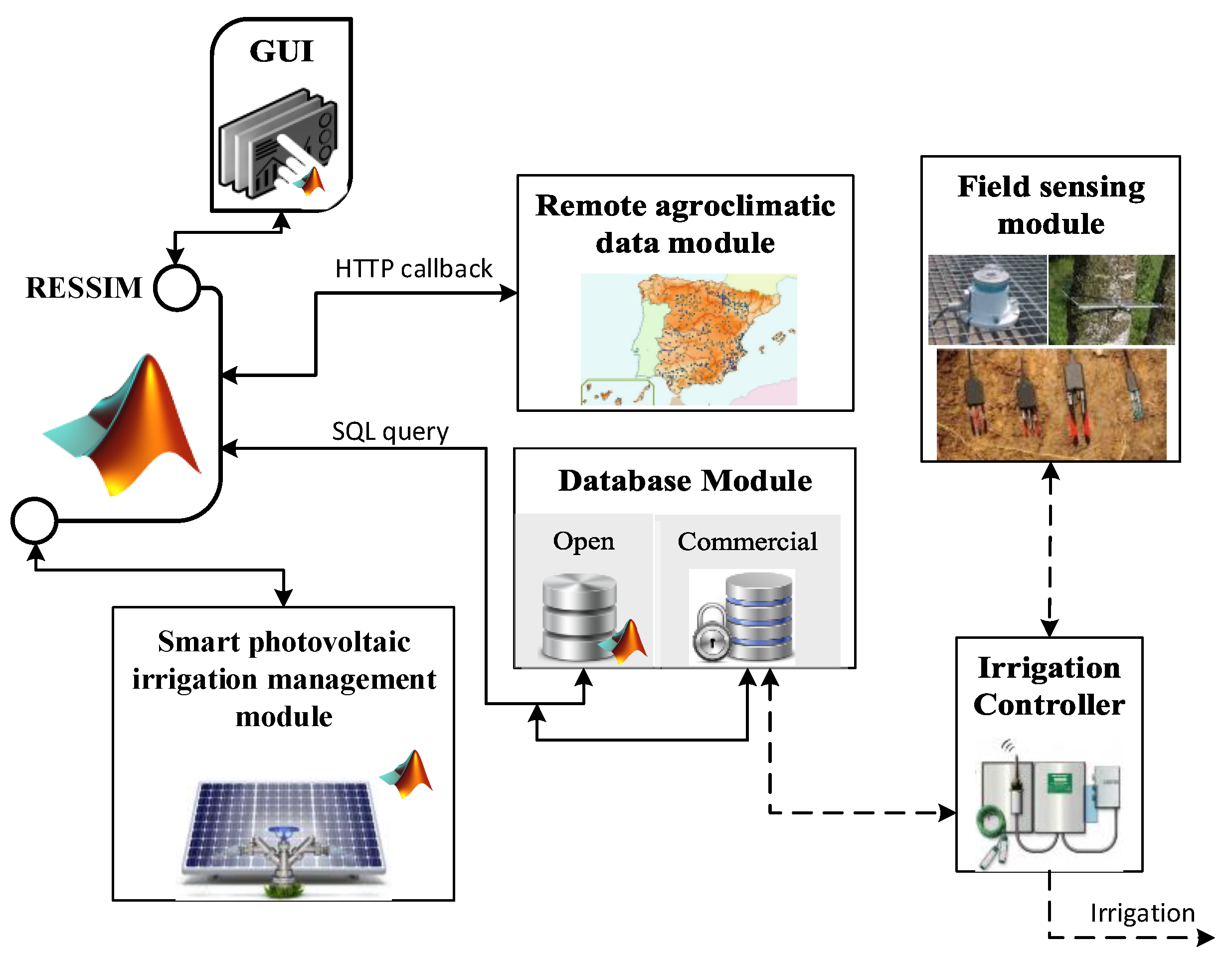

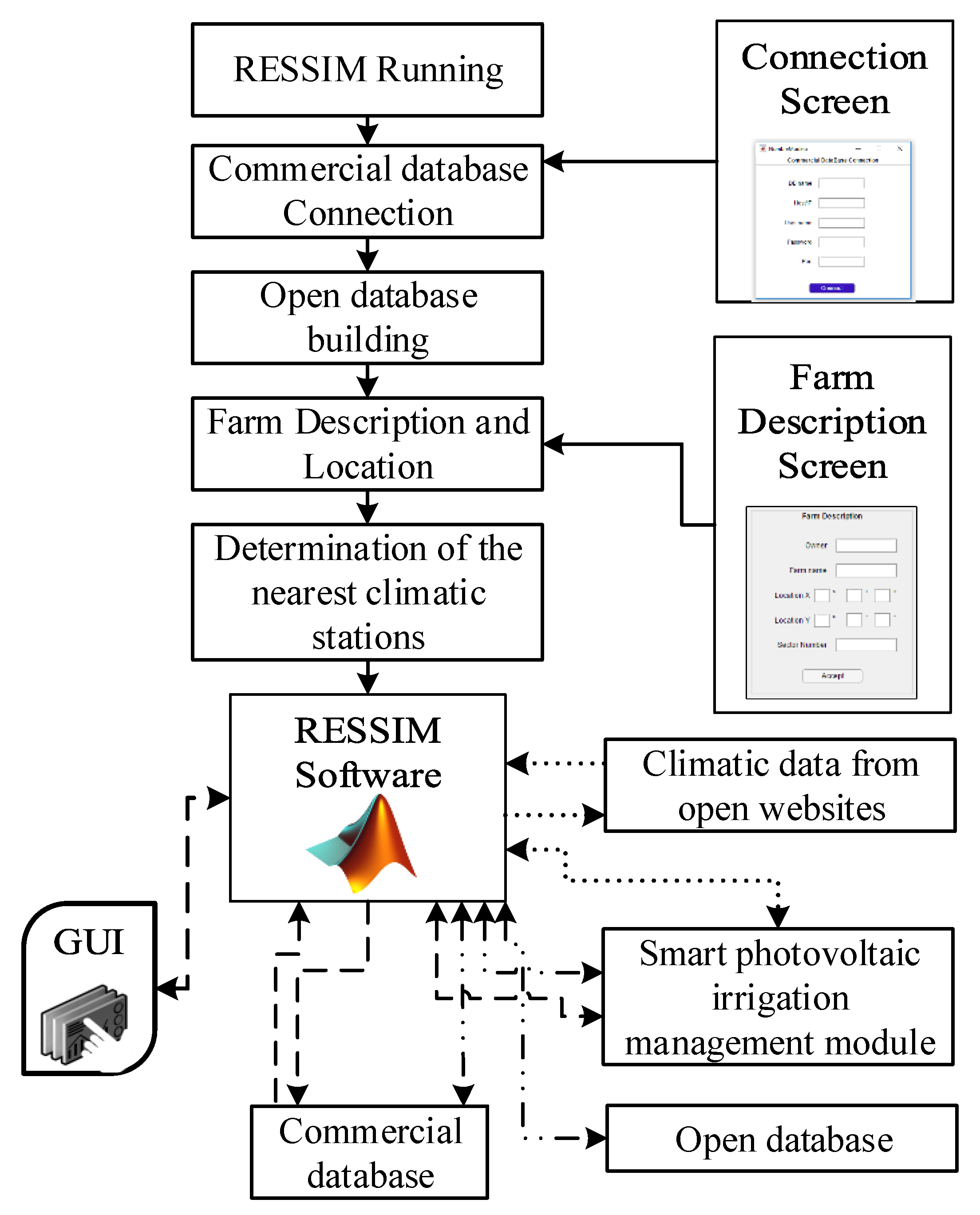

2. RESSIM Design

2.1. Model Description

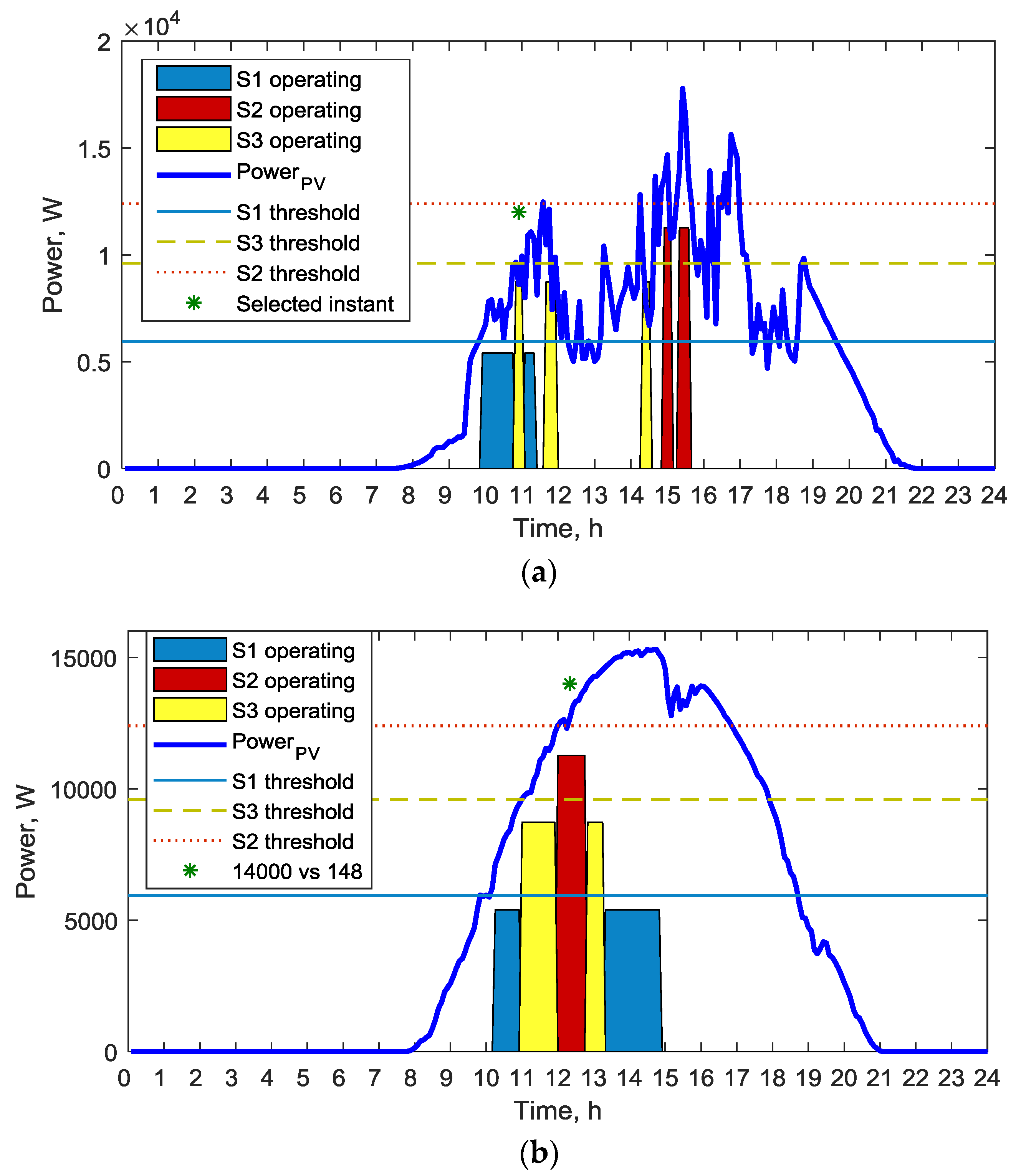

2.1.1. Smart PV Irrigation Management Module

2.1.2. Irrigation Controller

2.1.3. Field Sensing Module and Remote Agroclimatic Data Module

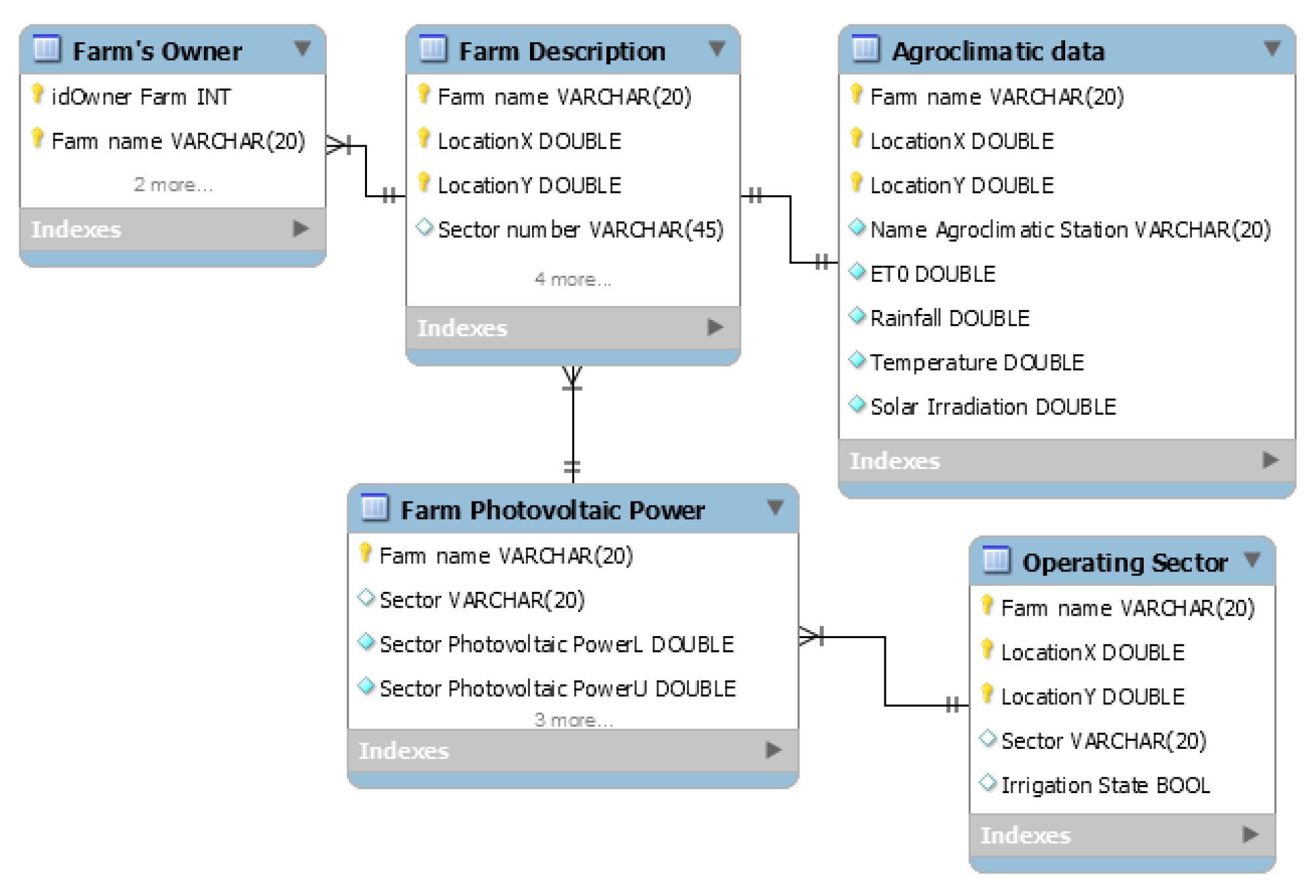

2.1.4. Database Module

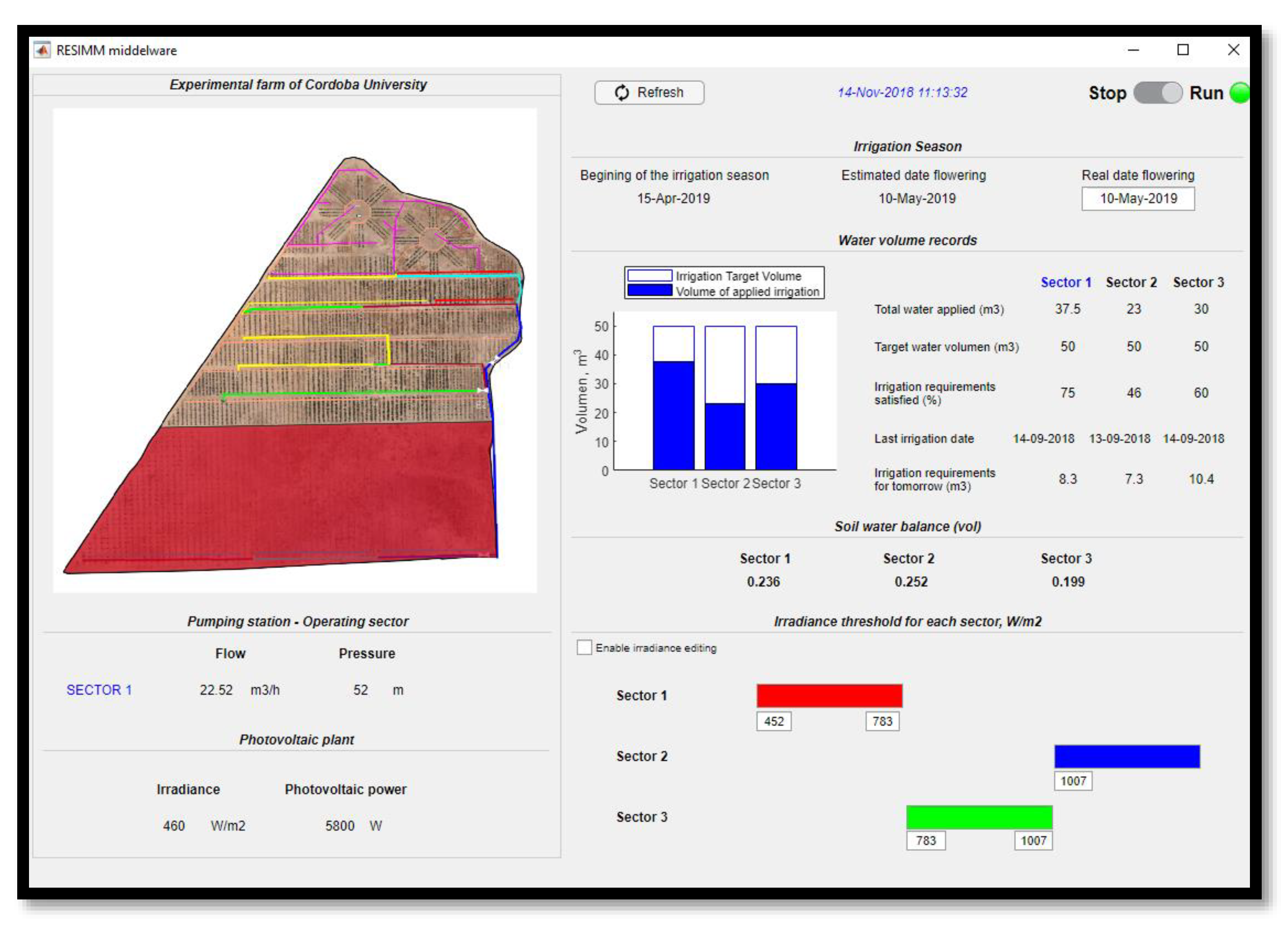

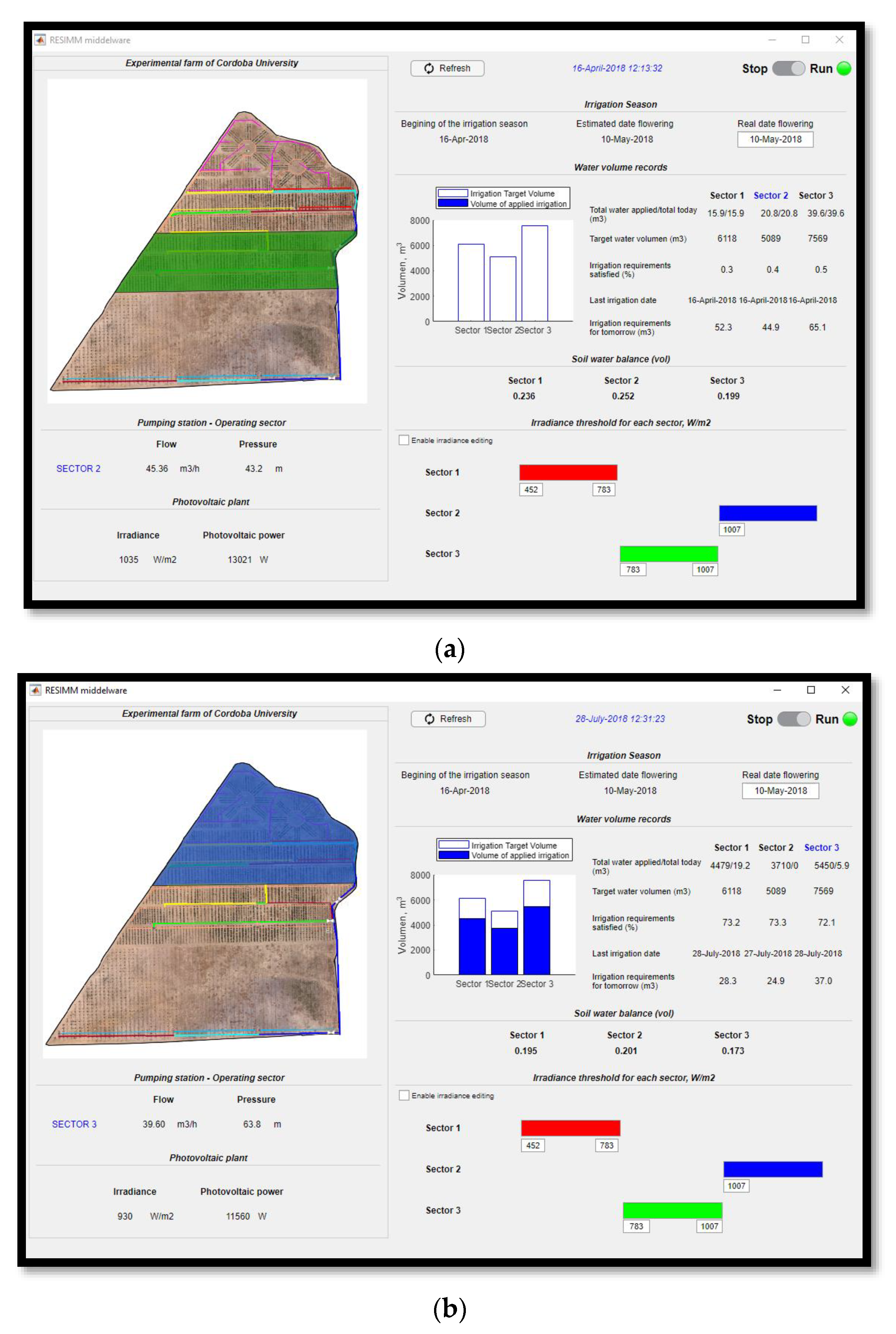

2.1.5. RESSIM Middleware and RESSIM GUI

3. Implementation of RESSIM in a Real Case Study

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Corominas, J. Agua y energía en el riego en la época de la sostenibilidad. Ing. del agua 2010, 17, 219–233. [Google Scholar] [CrossRef]

- Fernández García, I.; Rodríguez Díaz, J.A.; Camacho Poyato, E.; Montesinos, P.; Berbel, J. Effects of modernization and medium term perspectives on water and energy use in irrigation districts. Agric. Syst. 2014, 131, 56–63. [Google Scholar] [CrossRef]

- García Morillo, J.; Martín, M.; Camacho, E.; Díaz, J.A.R.; Montesinos, P. Toward precision irrigation for intensive strawberry cultivation. Agric. Water Manag. 2015, 151, 43–51. [Google Scholar] [CrossRef]

- González Perea, R.; Daccache, A.; Rodríguez Díaz, J.A.; Poyato, E.C.; Knox, J. Modelling impacts of precision irrigation on crop yield and in-field water management. Precis. Agric. 2017, 19, 497–512. [Google Scholar] [CrossRef]

- Hamidat, A.; Benyoucef, B.; Hartani, T. Small-scale irrigation with photovoltaic water pumping system in Sahara regions. Renew. Energy 2003, 28, 1081–1096. [Google Scholar] [CrossRef]

- Vick, B.D.; Almas, L.K. Developing a hybrid solar/wind powered irrigation system for crops in the Great Plains. Appl. Eng. Agric. 2011, 27, 235–245. [Google Scholar] [CrossRef]

- Mérida García, A.; Fernández García, I.; Camacho Poyato, E.; Montesinos Barrios, P.; Rodríguez Díaz, J.A. Coupling irrigation scheduling with solar energy production in a smart irrigation management system. J. Clean. Prod. 2018, 175, 670–682. [Google Scholar] [CrossRef]

- Bhattacharjee, B.; Chakrabarti, A.; Sadhu, P.K. Solar photovoltaic integrated pump for advanced irrigation system. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 3246–3250. [Google Scholar]

- Bouchakour, A.; Borni, A.; Zaghba, L.; Boukebbous, S.E.; Fazzani, A. Fuzzy logic controller to improve photovoltaic water pumping system performance. In Proceedings of the 2018 6th International Renewable and Sustainable Energy Conference (IRSEC), Rabat, Morocco, 5–8 December 2018; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Wang, N.; Zhang, N.; Wang, M. Wireless sensors in agriculture and food industry—recent development and future perspective. Comput. Electron. Agric. 2006, 50, 1–14. [Google Scholar] [CrossRef]

- Murakami, E.; Saraiva, A.M.; Ribeiro, L.C.M.; Cugnasca, C.E.; Hirakawa, A.R.; Correa, P.L.P. An infrastructure for the development of distributed serviceoriented information systems for precision agriculture. Comput. Electron. Agric. 2007, 58, 37–48. [Google Scholar] [CrossRef]

- Peres, E.; Fernandes, M.A.; Morais, R.; Cunha, C.R.; López, J.A.; Matos, S.R.; Ferreira, P.J.S.G.; Reis, M.J.C.S. An autonomous intelligent gateway infrastructure for in-field processing in precision viticulture. Comput. Electron. Agric. 2011, 78, 176–187. [Google Scholar] [CrossRef]

- López-Luque, R.; Reca, J.; Martínez, J. Optimal design of a standalone direct pumping photovoltaic system for deficit irrigation of olive orchards. Appl. Energy 2015, 149, 13–23. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

González Perea, R.; Mérida García, A.; Fernández García, I.; Camacho Poyato, E.; Montesinos, P.; Rodríguez Díaz, J.A. Middleware to Operate Smart Photovoltaic Irrigation Systems in Real Time. Water 2019, 11, 1508. https://doi.org/10.3390/w11071508

González Perea R, Mérida García A, Fernández García I, Camacho Poyato E, Montesinos P, Rodríguez Díaz JA. Middleware to Operate Smart Photovoltaic Irrigation Systems in Real Time. Water. 2019; 11(7):1508. https://doi.org/10.3390/w11071508

Chicago/Turabian StyleGonzález Perea, Rafael, Aida Mérida García, Irene Fernández García, Emilio Camacho Poyato, Pilar Montesinos, and Juan Antonio Rodríguez Díaz. 2019. "Middleware to Operate Smart Photovoltaic Irrigation Systems in Real Time" Water 11, no. 7: 1508. https://doi.org/10.3390/w11071508

APA StyleGonzález Perea, R., Mérida García, A., Fernández García, I., Camacho Poyato, E., Montesinos, P., & Rodríguez Díaz, J. A. (2019). Middleware to Operate Smart Photovoltaic Irrigation Systems in Real Time. Water, 11(7), 1508. https://doi.org/10.3390/w11071508