1. Introduction

The classical idealization of flows over smooth and rough boundaries, successfully extended to mobile boundaries, comprises a logarithmic distribution of the longitudinal velocity in the wall-normal direction. In open channel flows, this log-law should be valid in the overlapping layer between inner and outer flow regions (see, e.g., [

1]) when (i) gradients in the longitudinal direction are small, in particular the pressure gradient; (ii) the channel aspect ratio is high so that the mean flow far from the banks or side walls is two-dimensional in the vertical plane and (iii) the relative submersion is high. The log-law can be written as

where

is the space and time-averaged longitudinal velocity,

is the vertical coordinate above the zero of the log-law (

),

Z is the vertical coordinate above and arbitrary datum,

is the bed’s characteristic roughness height (such that

),

is the von Kármán parameter and

is the friction velocity (the kinematic scale for both inner and outer flow variables), where

is the wall shear stress and

is the fluid density.

For hydraulically rough boundaries, the idealization of inner and outer flow regions may not be sufficient to describe the complexity of the flow in the vicinity of the roughness elements. Several conceptual models have been proposed to include in the description of flow stratification a near-bed layer where bed micro-topography determines mean flow features. For the sake of consistency with the early work of some of the authors, the idealization of Ferreira et al. [

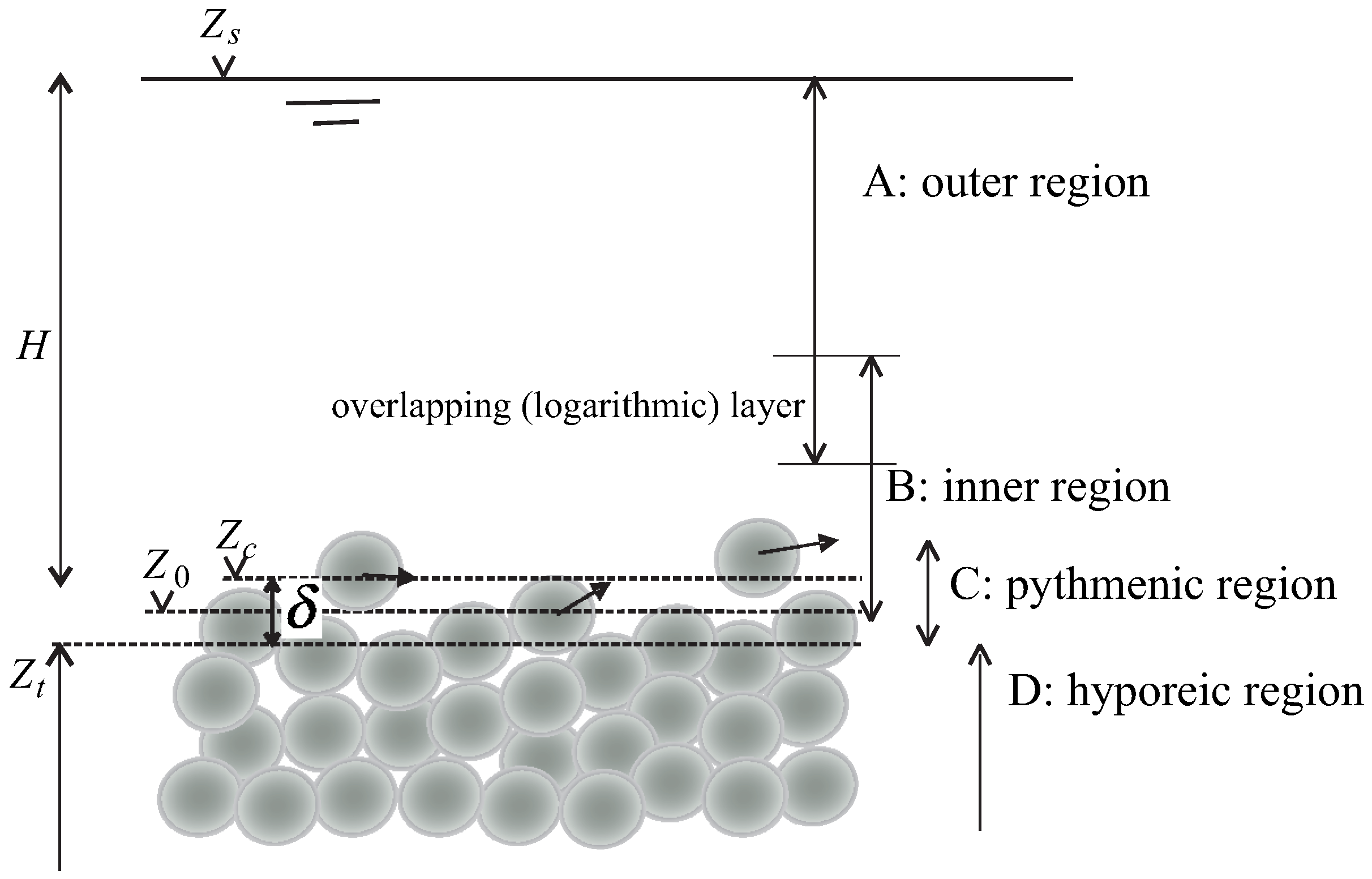

2], depicted in

Figure 1, is followed in this text. In region (A), the turbulent flow is influenced by the free-surface. In the inner region (B), the flow is affected by the characteristics of the rough wall, directly in the lowermost layers and indirectly, through

, in the uppermost layers. The dominant characteristic length scale in region (B) is

, mostly influenced by the diameter of the granular material and its superficial arrangement (the bed micro-topography). The characteristic length scale should be of the order of magnitude of the bed amplitude,

(the wall-normal distance between the planes of the troughs and of the crests) but should be dependent on the type of granular bed and on the Shields parameter [

2].

The lower boundary of the inner region is set at the elevation of the zero of the log-law,

, located

above (or below) the boundary zero.

is known as the displacement height and can be negative if the zero of the log-law is above the boundary zero. It is noted that the boundary zero is arbitrary. In this text, it is assumed to be contained in the plane of the mean elevation of the crests. Assuming wall similarity in the sense of Townsend [

1], i.e., balance of production and dissipation rates of turbulent kinetic energy and near-constant Reynolds shear stresses, in the overlapping layer between the inner and outer regions, the wall-normal profile of the longitudinal velocity is expressed by Equation (

1). In the pythmenic region (C), whose upper boundary can be located above the plane of the crests if the bedload discharge is large, the flow is three-dimensional and mainly determined by the bed micro-topography and granular movement. Below the elevation of the troughs,

, in the hyporheic region (D), the flow may be described by Darcy or Brinkman models [

3].

The universality of the von Kármán parameter in open-channel flows has long been discussed in the literature. For instance, the assumption of a von Kármán parameter different from a constant value (usually between

and

) is discussed in case of flows with low submergence or in the presence of suspended or bedload transport by [

4]. The influence of bed mobility on the value of the von Kármán parameter has been reported for more than 20 years in several experimental studies, normally featuring a reduction of the value of

(e.g., [

5]). Gaudio et al. [

4] have reviewed and published experimental results and have proposed the non-universality of

in flows over sediment beds. These authors have shown that, depending on flow characteristics, bed configuration and bedload transport rate, the von Kármán parameter may assume values ranging between

and

. Gaudio et al. [

6], analyzing the velocity field in a flume with fixed bed and a sediment supply of coarse sand (

= 1 mm), observed a range of

between

and

with a marked reduction of the value of

with increased sediment concentration. These results were obtained assuming a bed Nikuradse sand equivalent roughness of

=

. In this case, the von Kármán parameter was calculated as

, where

a is the slope of the semi-log velocity profiles in the logarithmic layer of the inner region. A zero value of zero-plane displacement was estimated following the procedure presented in Koll [

7].

Recently, Hanmaiahgari et al. [

8] computed the parameters of the log-law in flows over hydraulically rough mobile beds subjected to different conditions: immobile, weakly mobile and temporally varying mobile bed conditions with different stages of bedform development. The von Kármán parameter

was evaluated from the logarithmic law of the wall with the zero of bed-normal axis,

z, set at the plane of the crests of the particles (

). The displacement height

was considered equal to

. Their experimental results showed a decrease of

due to increase of the thickness of roughness sublayer as the mobility of bedforms increases: the von Kármán parameter

varied between

in the case of mobile bedforms and

for immobile bed conditions. Working with bimodal mixtures of sand and gravel (simulating a natural rough bed), the influence of bedload transport on the values of the von Kármán parameter

has been investigated by Ferreira et al. [

2].

Contrary to the experimental findings of the authors discussed above, Ferreira et al. [

2] observed that the vertical profiles of the longitudinal velocity, in case of water-worked beds of sand-gravel mixtures, could be fitted to a log-law either with a flow independent (

) or a flow-dependent von Kármán parameter. They proposed that the value of

depends on the interpretation of the log-law parameters such as boundary zero, the geometric roughness scale

and the displacement height

. They found out that the location of the zero-plane displacement for the log-law could not remain constant and should increase with the increase of the bedload discharge, if

is set to

. On the contrary, assuming the von Kármán parameter as flow dependent, they showed a decrease in terms of displacement height

at the onset of generalized bed load transport, together with a drop on the value of

. In both cases, the zero for the log-law was below the plane of the sediment crests. In the wake of Ferreira et al. [

2], Ferreira [

9] provided a similarity framework to discuss the nature of

in flows over weakly mobile gravel-sand beds and explored a theoretical model for

as a function of turbulence parameters. There are three hypotheses of interpretation of his theoretical framework for the cases of: no-similarity, complete similarity or incomplete similarity in the non-dimensional parameters describing bed composition and bed mobility.

In the first case (no similarity), Ferreira [

9] argued that the vertical distribution of the longitudinal mean velocity would not be logarithmic. If complete similarity exists, on the contrary, all flows characterized by rough mobile beds should be identified by a normalised shear rate in the overlapping layer independent of bed composition and bed mobility and by a constant

, not necessarily equal to

, independent from Reynolds and Shields numbers. This is the case supported by the laboratory results on the structure of turbulence for flows over rough mobile beds (gravel-sand mixtures) reported in [

9]. The author defends that changes in the structure of turbulence in the inner region do not seem to depend continuously on the Shields number and do not imply a reduction of

, in case of mobile bed conditions, with respect to

. In the case of incomplete similarity, Ferreira [

9] proposed a dependency of the constant shear rate on the overlapping layer on bed mobility;

was considered a function of bed composition and Shields number. Both complete and incomplete similarity criteria required a joint discussion of

and of the displacement height

. Ferreira [

9] and Ferreira et al. [

2] argued that different choices of

may lead to different values of

without physical justification.

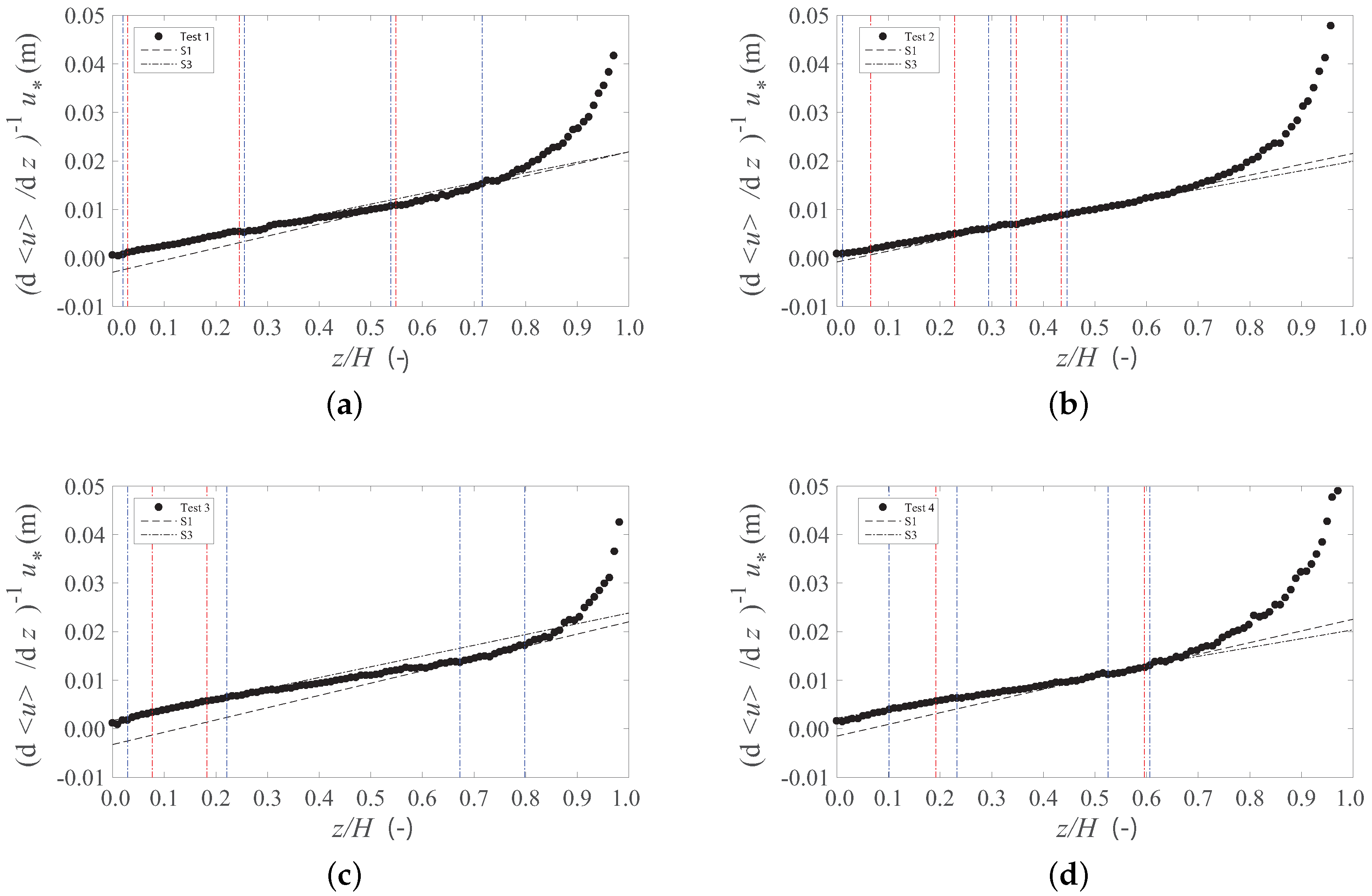

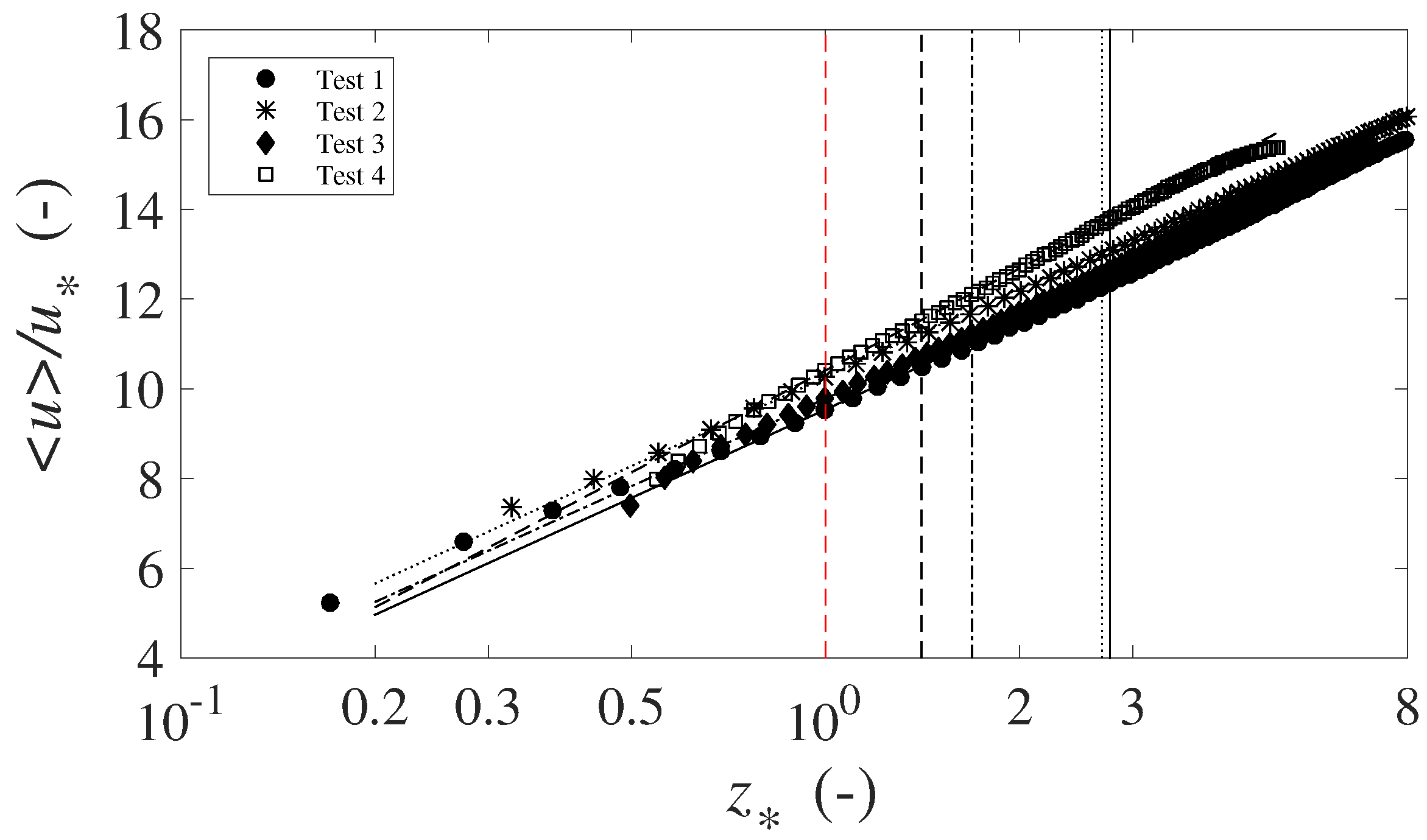

Bearing in mind that most of the studies above featured sediment beds with different degrees of complexity, the key objective of this paper is to provide insights on the definition of the parameters of the log-law in rough mobile granular beds when complexity is reduced to minimum. Factors influencing surface roughness such as grain size distribution, grain shape and density or cohesion are not addressed in this study. Data collection hence took place in flows over cohesionless granular beds composed by monosized spheres—5 mm glass beads—arranged in simple lattices. These are juxtapositions of close packing arrangements with body-centered cubic arrangements. These experimental tests are meant to clarify the description and interpretation of the parameters of the log-law in rough mobile beds casting aside the complexity introduced by working with natural sediment.

The issue of the nonuniqueness of the definition of the log-law parameters is addressed by analyzing and discussing the experimental results under different scenarios: scenarios 1 and 2 consider

constant and equal to

and different definitions of geometric roughness scale

; scenarios 3 and 4 retake the definition of

reported in the first and second scenario respectively, but the von Kármán parameter is, in this case, considered flow-dependent. The procedures adopted to interpret the laboratorial data follow those of Ferreira et al. [

2]. Issues of universality and uniqueness in the definition of the parameters of the log-law are still important topics of research not only for its intrinsic value—advancing fundamental knowledge—but also because of its direct impacts on the quality of the predicting mathematical modelling tools. The log-law is frequently used as a wall function in Computational Fluid Dynamics (see reviews in e.g., [

10] or [

11]), in the context of Reynolds-averaged Navier-Stokes equations (RANS) modelling (e.g., [

12], detached eddy simulation (DES) or even large eddy simulation (LES) modelling ([

13,

14]) or integral Navier-Stokes (NS) equation modelling ([

15]). Furthermore, depth-averaged hydrodynamic and sediment transport models use the parameters of the log-law to estimate the wall shear stress (e.g., [

16,

17,

18]). Improving the accuracy of predictive models for flows over mobile boundaries thus requires investment in the definition of the parameters of the log-law.

2. Laboratory Facilities, Instrumentation and Procedures

Laboratory tests were performed in a

m long and

cm wide prismatic channel, recirculating water and sediment through independent circuits, installed at the Laboratory of Hydraulics and Environment of Instituto Superior Técnico, Lisbon (

Figure 2a). The channel has side glass-walls enabling flow visualization and laser illumination. The flume bed was divided in two main reaches:

a fixed-bed reach comprising

m of large boulders (50 mm average diameter), followed by

m of smooth bottom (PVC) and

m of one layer of glued spherical glass beads (

mm diameter) to ensure the development of a rough-wall boundary layer (

Figure 2a,b);

a mobile reach

m long and

cm deep filled with

mm diameter glass beads, with density

, packed (with some vibration) to a void fraction of

, expressing the mixed nature of the lattice arrangement (face-centered and body centered), seen in

Figure 2c).

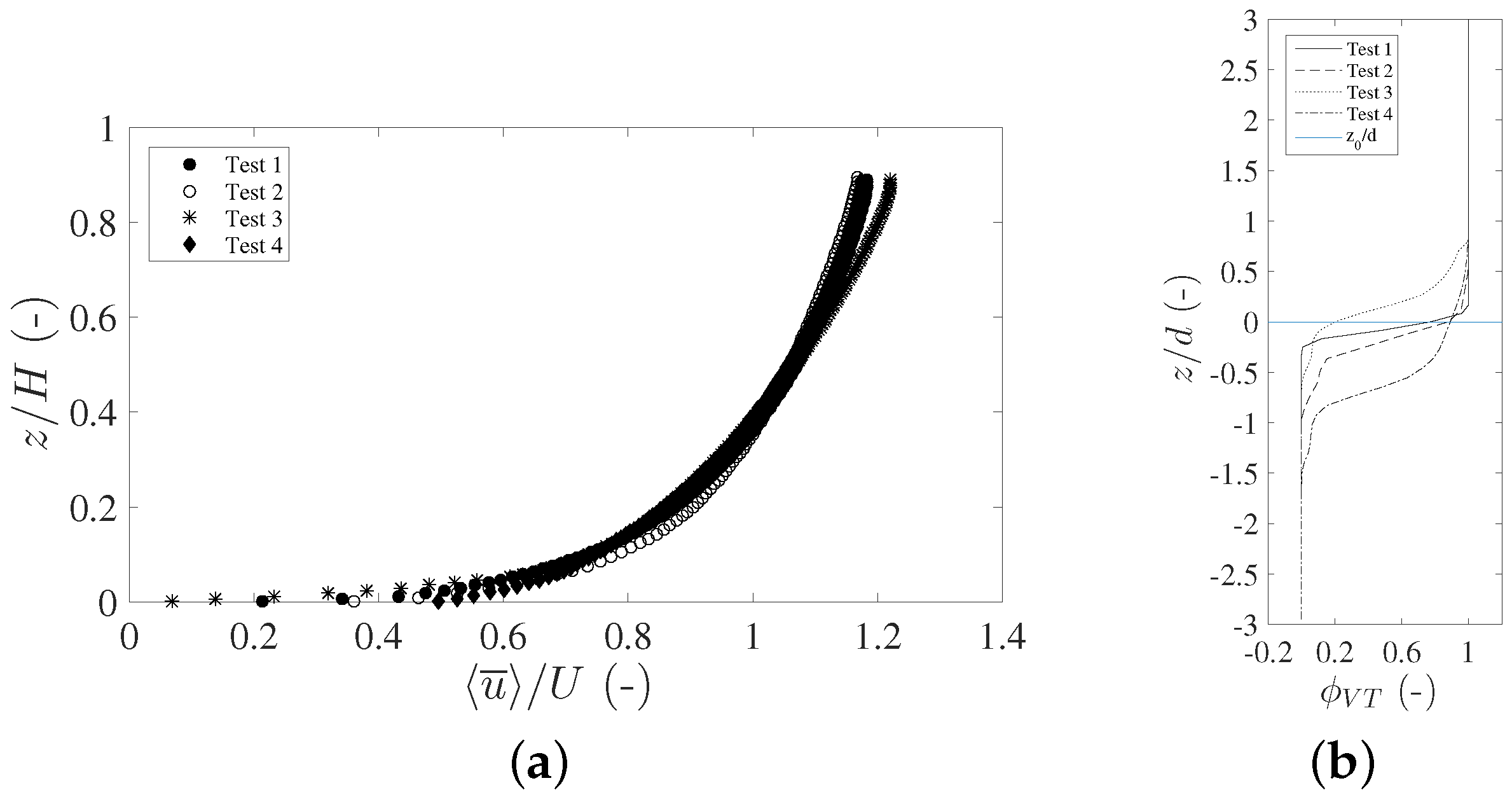

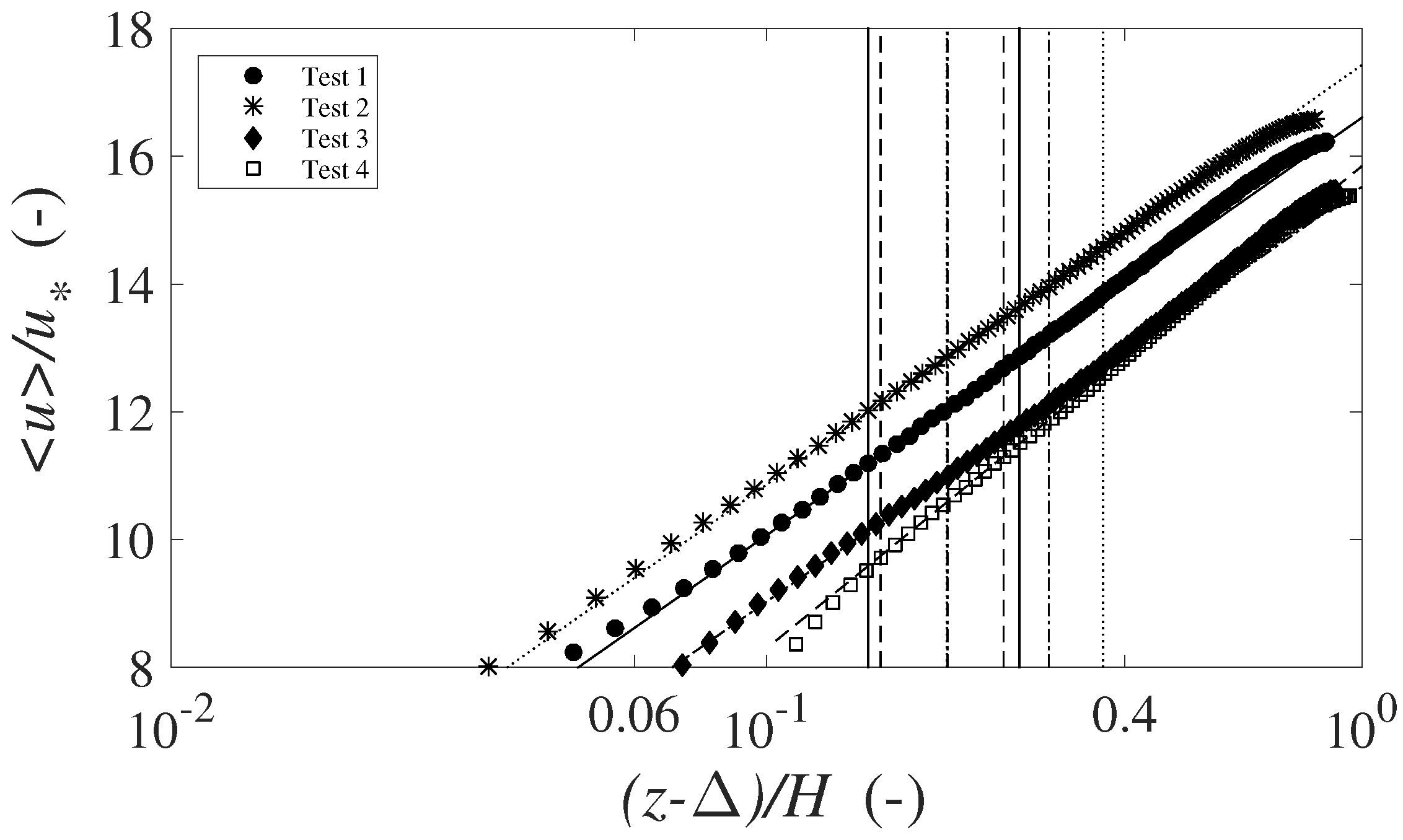

Flow is nearly uniform. In all tests, the energy slope may deviate less than from the channel slope. Since the phenomena of interest to this paper take place in the inner flow layer, this fact is considered not important. Data collected for four experimental tests are discussed in this text: test 1 was performed under sub-threshold conditions (no particles moving), while tests 2, 3 and 4 are respectively characterized by bedload rate of , and beads/s.

Free surface elevation and bed level were measured with mm precision point gage in five transversal sections of the flume and in three lateral positions per cross-section.

The water discharge at the flume inlet was controlled by two digital flowmeters respectively installed on the main water recirculating pump and on the secondary pump recirculating water and sediments. The inlet of the sediments was at

m, measured from the main water inlet. The secondary pump provided a constant flow rate of

m

/s. The flowrate released by the main pump was adjusted depending on the test to obtain the total flow rates reported, among other main characterizing variables, in

Table 1.

The other variables in

Table 1 are: the mean flow depth,

H, defined as the wall-normal distance between

and

(see

Figure 1); the slope of the flume,

; the depth-averaged mean longitudinal velocity,

U; the friction velocity and bed shear stress computed from the equation of conservation of momentum in

x direction, assuming uniform flow, respectively

=

and

=

, where

is the water density,

is the volumetric weight of the water and

is the hydraulic radius; and the friction velocity and the bed shear stress calculated from the wall-normal profile of the wall-normal component of the turbulence kinetic energy, respectively

and

. The friction velocity

was computed as the maximum of the profile

. Coefficient

C is not universal; Nezu et al. [

19], for instance, assumed

. If the relative importance of the terms of the turbulence kinetic energy is the same as in Nezu et al. [

19], the coefficient proposed by Soulsby and Dyer [

20] would be

and the coefficient in Stapleton and Huntley [

21] would be

C =

. In this study, a constant value of

was employed as it minimized the mean square error between

and

.

Table 2 shows the values of the relevant non-dimensional parameters: Froude number,

, Shields parameter,

, Reynolds number of the mean flow,

(where

is the fluid’s kinematic vicosity), bed Reynolds number,

and non-dimensional bedload discharge,

. The bedload discharge rate

was determined by using the particle counting system described in detail in Mendes et al. [

22]. This device was installed at the downstream end of the mobile bed reach of the flume. The pressure variations produced by the impacts of the sediment particles falling on the membrane boxes (placed over the entire width of the channel) were registered and analyzed. The accumulated count registered once flow and sediments’ equilibrium conditions were achieved was then translated into solid flow discharge per each test. The bedload rate was evaluated as

, where

m

is the volume of the glass particles,

n is the number of beads impacting on the bead counter per second and

b is the channel’s width.

The instantaneous flow velocity (longitudinal

u and vertical

w) was measured with a two-dimensional and two-component (2D2C) Particle Image Velocimetry (PIV) system, in three different longitudinal positions:

cm,

cm and

cm from the right channel sidewall, where the position at

cm represents the center longitudinal section of the flume. The observation window for flow velocity measurements was placed at

m from the beginning of the mobile bed reach, covering a length that comprises between 6 cm and 12 cm, depending on the test, and covers the entire flow depth. An acetate sheet was placed on the water surface to ensure optical stability and absence of laser sheet reflections. The PIV system consisted of an 8 bit 1600 × 1200 px

CCD camera and a double-cavity solid state laser with pulse energy of 30 mJ at wavelength of 532 nm. The system was operated at 15 Hz with a time between pulses within the range from 380

s to 500

s. Polyurethane particles with mean diameter of 50 mm in a range from 30 to 70 mm and specific density of

g/cm

were used as solid targets. Such tracer particles have a cut-off frequency of approximately 2500 Hz for a significance level of

(Ferreira and Aleixo [

23]). Hence, turbulence with frequencies lower than 2500 Hz is likely to be well-represented by the motion of the tracer particles. Since the PIV was operated at 15 Hz, the Nyquist frequency of the time series is

Hz, much smaller than the cut-off frequency. Hence, the employed seeding particles do not constitute an extra limitation to the time resolution of the PIV.

The duration of each PIV time series was 5 min of consecutive data corresponding to 4500 image couples per each measurement position. DynamicStudio software (version 3.41, Dantec Dynamics®, Skovlunde, Denmark) allowed for processing image pairs with the adaptive correlation algorithm. The initial interrogation area was of 128 × 128 px, while the final was of 16 × 16 px, with an overlap of 50%.

4. Conclusions

The experimental analysis reported in this work allowed for testing different definitions of the parameters of the log-law in the specific case of rough mobile bed composed of monosized artificial sediments. Four experimental tests were carried out to assess the effect of bed mobility and increasing bedload transport rates on the wall-normal profile of the longitudinal flow velocity.

The study reveals that a well-fitting log-law profile within the overlapping between outer and inner region ( is achieved assuming a flow-dependent von Kármán parameter , together with geometric roughness scale and parameter B subjected to a best fit procedure (scenario 3) or imposing B = and computing from a roughness function (scenario 4). No substantial dependence of von Kármán parameter on bedload discharge rates was encountered and was found ranging between and , depending on the test, contrary to the wider range of reported in the literature for beds composed of natural sediment.

The zero of the logarithmic profiles was found very near the sediment crests and slightly increasing with bedload transport (scenario 3). Scenario 4 presented small values of as well, although higher than those achieved in scenario 3.

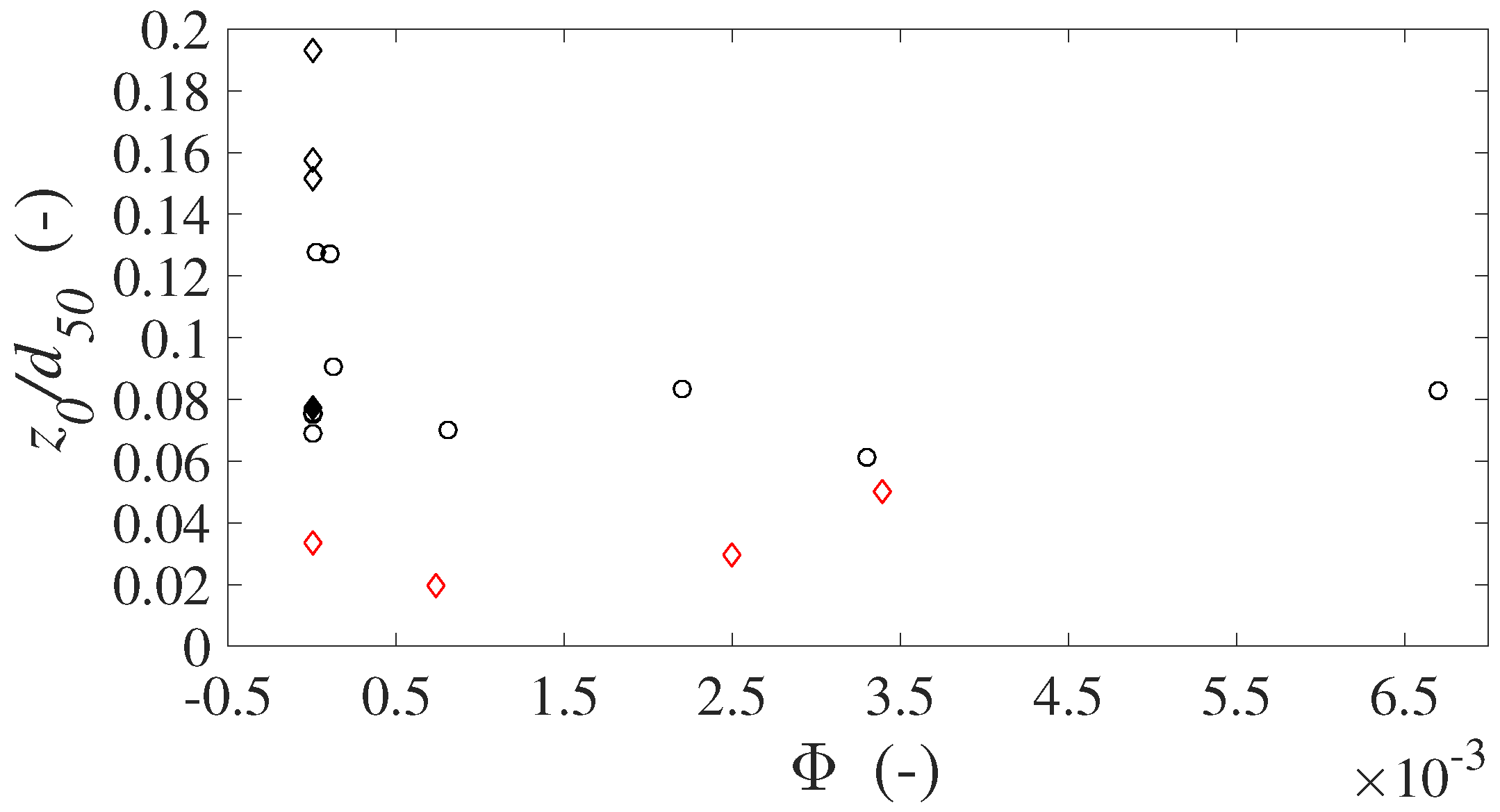

A comparison between the variation of the roughness height

normalized by the particle diameter as a function of the bedload discharge, obtained in our simple bed configuration and shown in Ferreira et al. [

2] for natural beds composed of gravel-sand mixtures, emphasised that the roughness height increases with bed diversity, typical of natural river beds.

The roughness scale is lower in the present tests and higher in the tests with natural sediment, due to the simple configuration of the present bed which prevents the formation of bedload sheets or complex micro-topographical structures.

In the case of glass spheres, the roughness scale increases with bedload transport—it should express the increase in work expended by the flow in maintaining these particles in motion.

The hypothesis that complexity associated with bed micro-topography is more relevant to influence the mean flow than size of the larger elements or bed mobility can thus be put forward and verified.