Modified Septic Tank: Innovative Onsite Wastewater Treatment System

Abstract

:1. Introduction

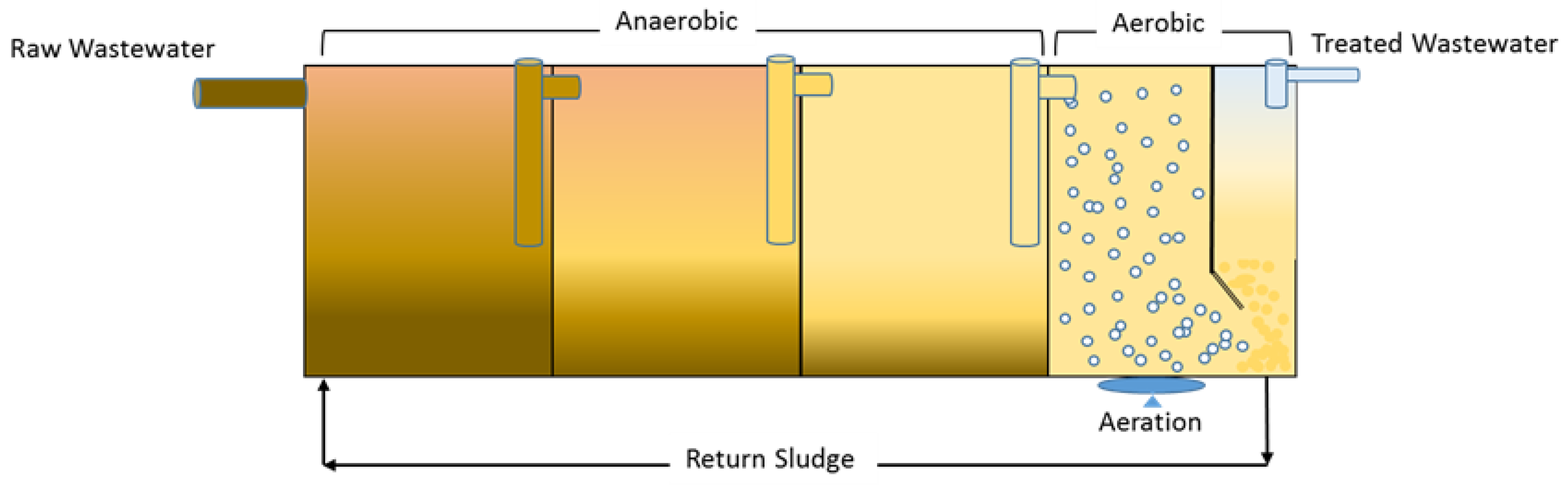

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Mousa, S.M. Water strategies and potential of desalination in Jordan. Desalination 2007, 203, 27–46. [Google Scholar]

- Parkinson, J.; Tayler, K. Decentralized wastewater management in peri-urban areas in low-income countries. Environ. Urban. 2003, 15, 75–89. [Google Scholar] [CrossRef]

- Gikas, P.; Tchobanoglous, G. The role of satellite and decentralized strategies in water resources management. J. Environ. Manag. 2008, 90, 144–152. [Google Scholar] [CrossRef] [PubMed]

- Mazumder, D.; Roy, B. Low cost options for treatment and reuse of municipal wastewater. Indian J. Environ. Prot. 2000, 20, 529–532. [Google Scholar]

- Wang, S. Values of decentralized systems that avoid investments in idle capacity within the wastewater sector: A theoretical justification. J. Environ. Manag. 2014, 136, 68–75. [Google Scholar] [CrossRef] [PubMed]

- Nasr, F.A.; Mikhaeil, B. Treatment of domestic wastewater using modified septic tank. Desalin. Water Treat. 2015, 56, 2073–2081. [Google Scholar] [CrossRef]

- Withers, P.J.; Jordan, P.; May, L.; Jarvie, H.P.; Deal, N.E. Do septic tank systems pose a hidden threat to water quality? Front. Ecol. Environ. 2014, 12, 123–130. [Google Scholar] [CrossRef]

- Capodaglio, A.G. Integrated, Decentralized Wastewater Management for Resource Recovery in Rural and Peri-Urban Areas. Resources 2017, 6, 22. [Google Scholar] [CrossRef]

- Abbassi, B.; Al Baz, I. Integrated wastewater management: A review. In Handbook Efficient Management of Wastewater, 1st ed.; Al Baz, I., Ed.; Springer: Berlin, Germany, 2008; pp. 29–40. [Google Scholar]

- Flasche, K. Possible Applications and Performance of Small-Scale Wastewater Treatment Plants. Ph.D. Thesis, University of Hanover, Hanover, Germany, 2002. [Google Scholar]

- Green, W.; Ho, G. Small scale sanitation technologies. Water Sci. Technol. 2005, 51, 29–38. [Google Scholar] [PubMed]

- Wilderer, P.A. UN water action decade: A unique challenge and chance for water engineers. Water Sci. Technol. 2005, 51, 99–107. [Google Scholar] [PubMed]

- Ontario Mninstry of Environment and Climate Change. Status of the Hauled Sewage Industry & Costing Toward the Development of Environmental Standards for Hauled Sewage in Ontario. Hauled Sewage Costing Summary Report; 2017. Available online: http://oasisontario.on.ca/wp-content/uploads/2017/05/DRAFT-Summary-of-Costing-Report.pdf (accecced on 4 February 2018).

- Ahmed, W.; Neller, R.; Katouli, M. Evidence of septic system failure determined by a bacterial biochemical fingerprinting method. J. Appl. Microbiol. 2005, 98, 910–920. [Google Scholar] [CrossRef] [PubMed]

- Bradley, B.R.; Daigger, G.T.; Rubin, R.; Tchobanoglous, G. Evaluation of onsite wastewater treat-ment technologies using sustainable development cri-teria, Clean Technol. Environ. Policy 2002, 4, 87–99. [Google Scholar]

- Meuler, S.; Paris, S.; Hackner, T. Membrane bio-reactors for decentralized wastewater treatment and reuse. Water Sci. Technol. 2008, 58, 285–294. [Google Scholar] [CrossRef] [PubMed]

- Appling, D.; Habteselassie, M.Y.; Radcliffe, D.; Bradshaw, J.K. Preliminary Study on the Effect of Wastewater Storage in Septic Tank on E. coli Concentration in Summer. Water 2013, 5, 1141–1151. [Google Scholar] [CrossRef]

- Sharma, M.K.; Kazmi, A.A. Anaerobic onsite treatment of black water using filter-based packaged system as an alternative of conventional septic tank. Ecol. Eng. 2015, 75, 457–461. [Google Scholar] [CrossRef]

- Anil, R.; Neera, A.L. Modified Septic Tank Treatment System. Proc. Technol. 2016, 24, 240–247. [Google Scholar] [CrossRef]

- Nasr, F.A.; Mikhaeil, B. Treatment of domestic wastewater using conventional and baffled septic tanks. Environ. Technol. 2013, 34, 2337–2343. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, V.A.; Nga, P.T.; Nguyen, H.T.; Morel, A. Improved septic tank and, a promising decentralized wastewater treatment alternative in Vietnam. In Proceedings of the GMSARN International Conference on Sustainable Development: Issues and Prospects for GMS, Hanoi, Vietnam, 6–7 December 2006. [Google Scholar]

- Klinger, J.; Goldscheider, N.; Hötzl, H. SMART-IWRM: Integrated Water Resources Management in the Lower Jordan Rift Valley; Project Report 2nd Phase; KIT Scientific Reports; KIT Scientific Publishing: Karlsruhe, Germany, 2015; ISBN 978-3-7315-0393-4. [Google Scholar]

- APHA; AWWA; WEF. Standard Methods for Examination of Water and Wastewater, 21st ed.; American Public Health Association; American Water Works Association; Water Environment Federation: New York, NY, USA, 2005. [Google Scholar]

- Igbinosa, E.O.; Okoh, A.I. Impact of discharge wastewater effluents on the physico-chemical qualities of a receiving watershed in a typical rural community. Int. J. Environ. Sci. Tech. 2009, 6, 175–182. [Google Scholar] [CrossRef]

- Department of Standards and Measures. Jordanian Standards No. JS893/2006, Regulation and Standards for Reclaimed Domestic Wastewater; Department of Standards and Measures: Amman, Jordan, 2006.

- Ávila, C.; Reyes, C.; Bayona, J.M.; García, J. Emerging organic contaminant removal depending on primary treatment and operational strategy in horizontal subsurface flow constructed wetlands: Influence of redox. Water Res. 2013, 47, 315–325. [Google Scholar] [CrossRef] [PubMed]

- Massoud, M.A.; Tarhini, A.; Nasr, J.A. Decentralized approaches to wastewater treatment and management: Applicability in developing countries. J. Environ. Manag. 2009, 90, 652–659. [Google Scholar] [CrossRef] [PubMed]

- Sarathai, Y.; Koottatep, T.; Morel, A. Hydraulic characteristics of an anaerobic baffled reactor as onsite wastewater treatment system. J. Environ. Sci. 2010, 22, 1319–1326. [Google Scholar] [CrossRef]

- Abbassi, B. Performance Evaluation of Decentralized Wastewater Treatment and On-Site Wastewater Reuse at Jordan Traffic Institute. J. Food Agric. Environ. 2008, 6, 518–523. [Google Scholar]

- Diaz-Elsayed, N.; Xu, X.; Balaguer-Barbosa, M.; Zhang, Q. An evaluation of the sustainability of onsite wastewater treatment systems for nutrient management. Water Res. 2017, 121, 186–196. [Google Scholar] [CrossRef] [PubMed]

- Agidi, S.; Vedachalam, S.; Mancl, K.; Lee, J. Effectiveness of onsite wastewater reuse system in reducing bacterial contaminants measured with human-specific IMS/ATP and qPCR. J. Environ. Manag. 2013, 115, 167–174. [Google Scholar] [CrossRef] [PubMed]

- Feng, L.; Yang, G.; Yang, Q.; Zhu, L.; Xu, X.; Gao, F. Enhanced simultaneous nitrification and denitrification via addition of biodegradable carrier Phragmites communis in biofilm pretreatment reactor treating polluted source water. Ecol. Eng. 2015, 84, 346–353. [Google Scholar] [CrossRef]

- Hreiz, R.; Latifi, M.A.; Roche, N. Optimal design and operation of activated sludge processes: State-of-the-art. Chem. Eng. J. 2015, 281, 900–920. [Google Scholar] [CrossRef]

| Phase | Loading Rate (m3/d) | Detention Time in Anaerobic Chambers (d) | Detention Time in the Aerobic Chamber (d) |

|---|---|---|---|

| 1 | 1.2 | 3.56 | 0.79 |

| 2 | 1.6 | 2.67 | 0.59 |

| 3 | 2.0 | 2.14 | 0.47 |

| Phase | Parameter | Raw Wastewater | MST-A Effluent | MST-S Effluent |

|---|---|---|---|---|

| 1 | pH | 7.9 ± 0.1 | 8.0 ± 0.1 | 8.1 ± 0.2 |

| EC (μS/cm) | 1864 ± 516 | 1798 ± 588 | 1917 ± 542 | |

| DO (mg/L) | 0.1 ± 0.1 | 3.7 ± 0.6 | 2.1 ± 1.0 | |

| ORP (mV) | −236 ± 27 | −57 ± 73 | 149 ± 65 | |

| TSS (mg/L) | 314 ± 168 | 7 ± 4 | 18 ± 8 | |

| Turbidity (NTU) | 997 ± 225 | 9 ± 6 | 59 ± 10 | |

| Temperature (°C) | 19.9 ± 3.3 | 19.5 ± 3.9 | 19.4 ± 3.7 | |

| 2 | pH | 7.5 ± 0.2 | 7.7 ± 0.2 | 7.5 ± 0.3 |

| EC (μS/cm) | 2470 ± 399 | 2357 ± 578 | 2468 ± 389 | |

| DO (mg/L) | 1.0 ± 1.3 | 3.6 ± 1.9 | 3.3 ± 1.3 | |

| ORP (mV) | −208 ± 49 | −1 ± 108 | −107 ± 98 | |

| TSS (mg/L) | 239 ± 107 | 13 ± 6 | 18 ± 10 | |

| Turbidity (NTU) | 317 ± 161 | 30 ± 26 | 43 ± 61 | |

| Temperature (°C) | 18.2 ± 2.8 | 17.8 ± 3.5 | 17.6 ± 3.2 | |

| 3 | pH | 7.2 ± 0.2 | 7.7 ± 0.2 | 7.5 ± 0.2 |

| EC (μS/cm) | 2016 ± 513 | 2125 ± 624 | 2011 ± 680 | |

| DO (mg/L) | 0.8 ± 0.3 | 3.2 ± 1.5 | 3.5 ± 2.9 | |

| ORP (mV) | −239 ± 31 | −39 ± 126 | −120 ± 110 | |

| TSS (mg/L) | 267 ± 360 | 16 ± 4 | 19 ± 6 | |

| Turbidity (NTU) | 283 ± 76 | 22 ± 17 | 34 ± 24 | |

| Temperature (°C) | 21.4 ± 3.3 | 21.4 ± 3.5 | 21.3 ± 3.3 |

| Phase | Parameter | Raw Wastewater | MST-A Effluent | MST-S Effluent |

|---|---|---|---|---|

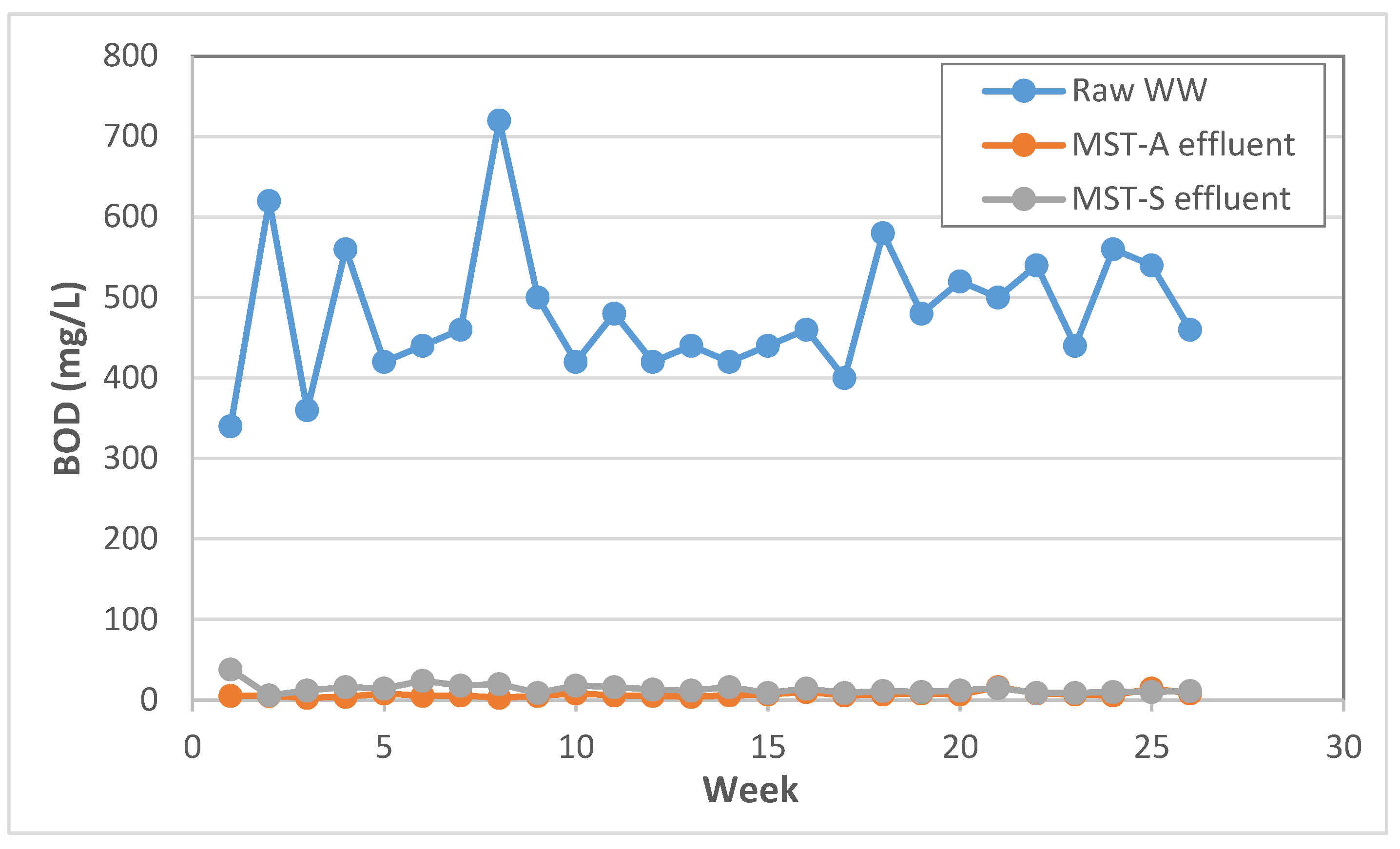

| 1 | BOD5 (mg/L) | 481 ± 83 | 8 ± 3 | 14 ± 6 |

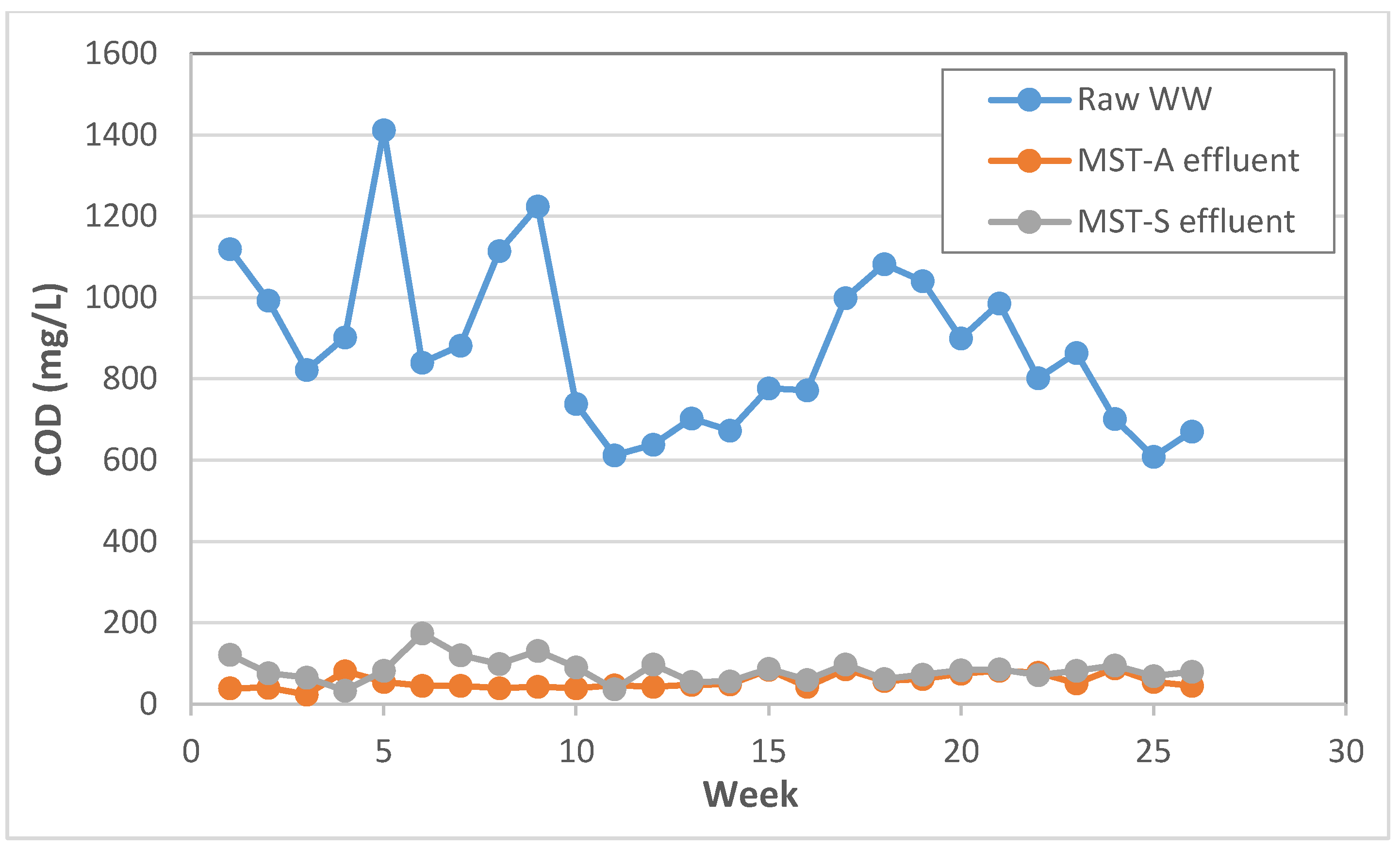

| COD (mg/L) | 918 ± 314 | 55± 18 | 84 ± 30 | |

| TN (mg/L) | 114.0 ± 29.6 | 46.6 ± 26.5 | 81.1 ± 21.9 | |

| NH4-N (mg/L) | 69.9 ± 32.3 | 8.8 ± 31.9 | 6.7 ± 18.7 | |

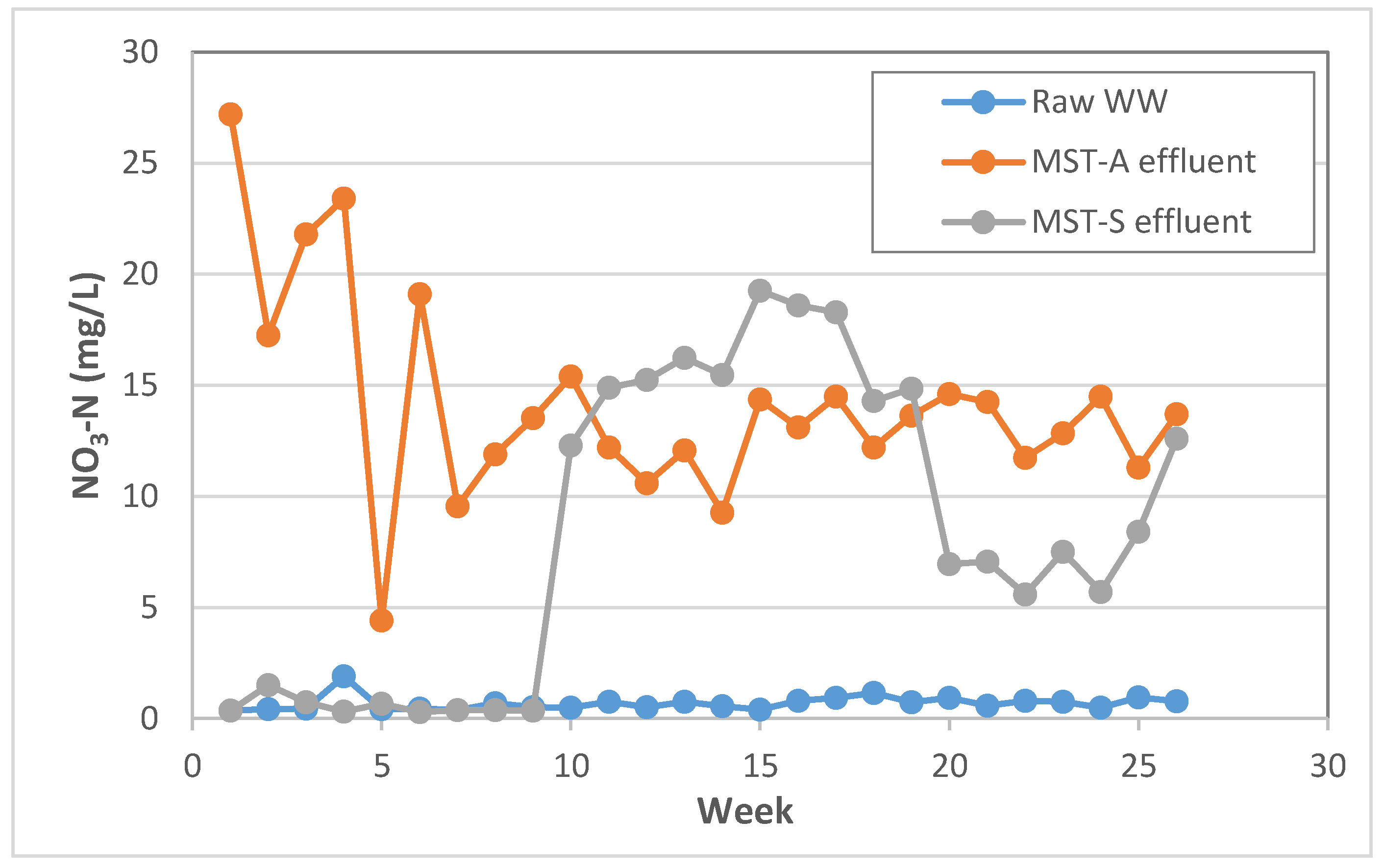

| NO3-N (mg/L) | 0.7 ± 0.3 | 14.9 ± 6.7 | 8.2 ± 7.0 | |

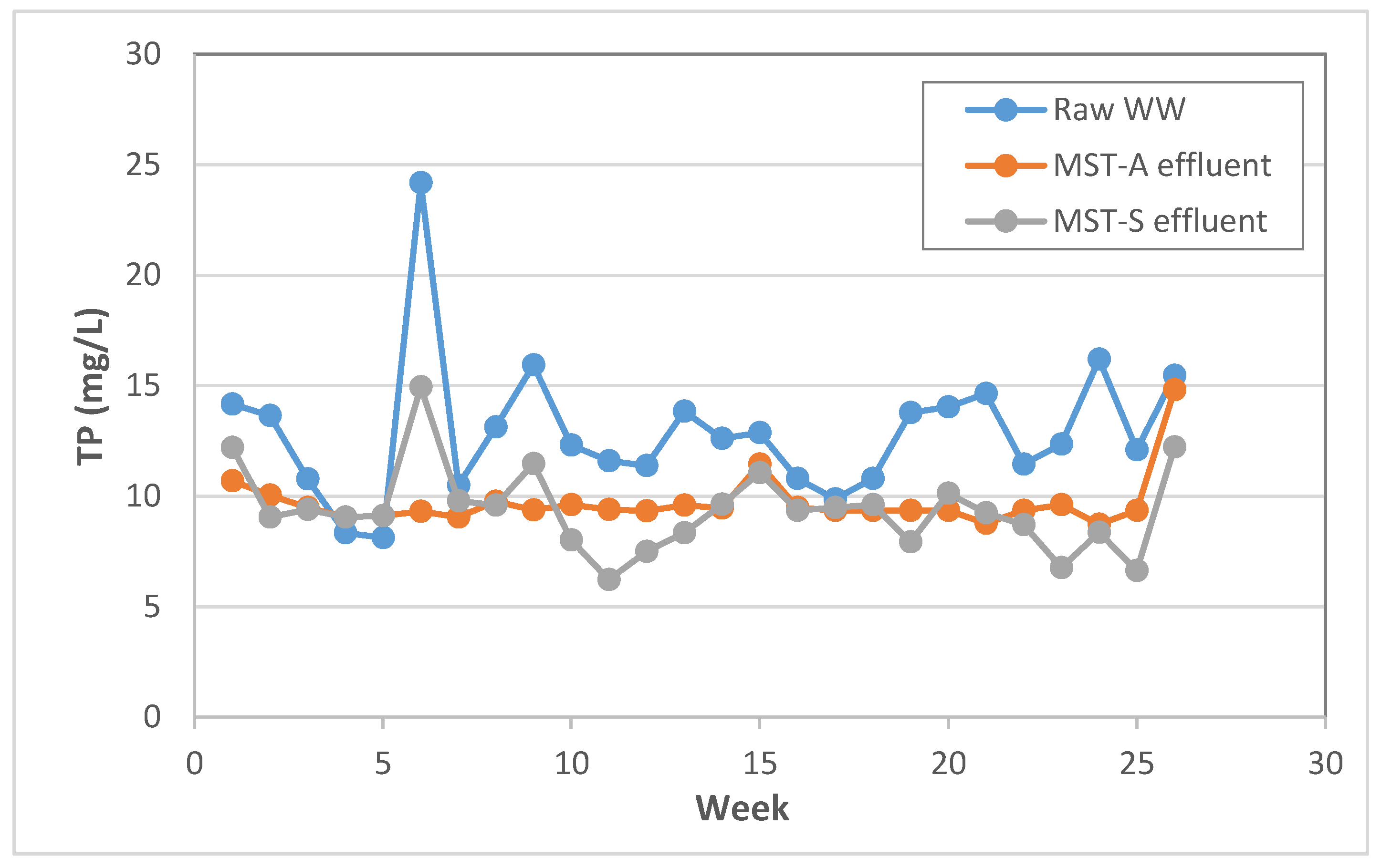

| TP (mg/L) | 12.9 ± 3.1 | 9.7 ± 6.7 | 9.4 ± 1.9 | |

| PO4-P (mg/L) | 7.7 ± 3.7 | 8.1 ± 3.3 | 7.4 ± 2.7 | |

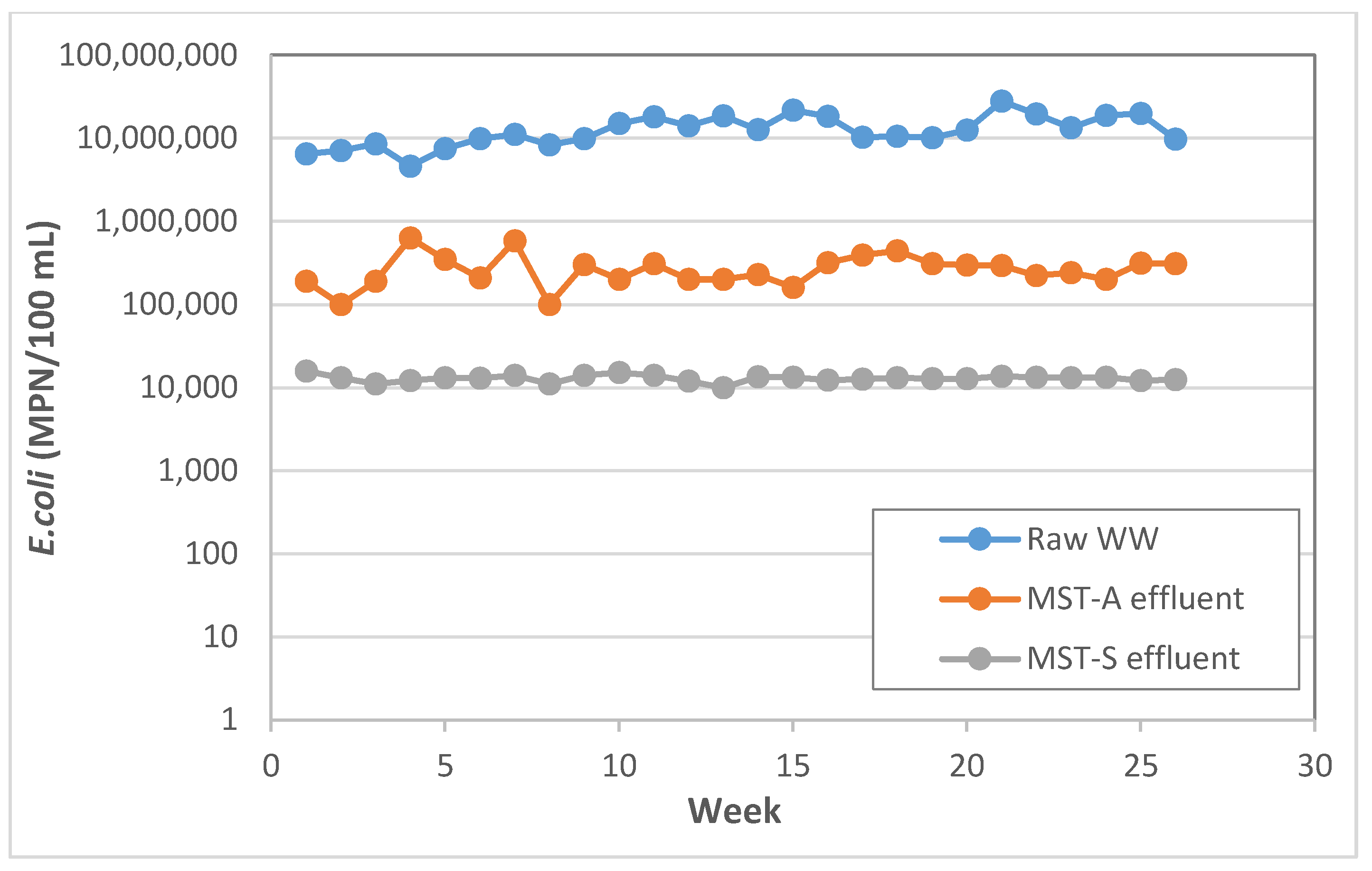

| E. coli (MPN/100 mL) | 1.3 × 107 ± 5.6 × 106 | 2.6 × 105 ± 1.3 × 105 | 1.3 × 104 ± 1.2 × 103 | |

| 2 | BOD5 (mg/L) | 336 ± 64 | 18 ± 15 | 14 ± 11 |

| COD (mg/L) | 627 ± 158 | 58 ± 20 | 70 ± 26 | |

| TN (mg/L) | 64.7 ± 14.8 | 43.5 ± 15.4 | 73.9 ± 34.1 | |

| NH4-N (mg/L) | 52.2 ± 14.0 | 23.2 ± 15.1 | 13.4 ± 11.7 | |

| NO3-N (mg/L) | 0.4 ± 0.2 | 7.2 ± 5.1 | 13.1 ± 15.2 | |

| TP (mg/L) | 7.1 ± 2.0 | 6.7 ± 1.5 | 6.6 ± 1.4 | |

| PO4-P (mg/L) | 5.7 ± 2.2 | 6.8 ± 1.6 | 6.6 ± 1.4 | |

| E. coli (MPN/100 mL) | 1.3 × 107 ± 3.0 × 105 | 4.2 × 105 ± 3.3 × 105 | 3.2 × 104 ± 4.3 × 104 | |

| 3 | BOD5 (mg/L) | 469 ± 62 | 25 ± 5 | 23 ± 36 |

| COD (mg/L) | 770 ± 183 | 88 ± 35 | 95 ± 36 | |

| TN (mg/L) | 84.6 ± 24.5 | 62.8 ± 17.1 | 66.1 ± 15.9 | |

| NH4-N (mg/L) | 70.8 ± 15.6 | 39.8 ± 22.2 | 39.2 ± 19.6 | |

| NO3-N (mg/L) | 0.5 ± 0.1 | 7.4 ± 6.7 | 9.3 ± 11.2 | |

| TP (mg/L) | 9.8 ± 2.8 | 9.5 ± 2.5 | 9.0 ± 2.2 | |

| PO4-P (mg/L) | 8.0 ± 2.9 | 8.3 ± 2.7 | 8.2 ± 2.3 | |

| E. coli (MPN/100 mL) | 3.0 × 107 ± 3.0 × 106 | 2.2 × 105 ± 8.4 × 104 | 2.7 × 104 ± 1.5 × 104 |

| Hydraulic Loading, m3/d | Energy Requirement, kWh/c.y |

|---|---|

| 1.2 | 65 |

| 1.6 | 49 |

| 2.0 | 39 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbassi, B.E.; Abuharb, R.; Ammary, B.; Almanaseer, N.; Kinsley, C. Modified Septic Tank: Innovative Onsite Wastewater Treatment System. Water 2018, 10, 578. https://doi.org/10.3390/w10050578

Abbassi BE, Abuharb R, Ammary B, Almanaseer N, Kinsley C. Modified Septic Tank: Innovative Onsite Wastewater Treatment System. Water. 2018; 10(5):578. https://doi.org/10.3390/w10050578

Chicago/Turabian StyleAbbassi, Bassim E., Raihan Abuharb, Bashaar Ammary, Naser Almanaseer, and Christopher Kinsley. 2018. "Modified Septic Tank: Innovative Onsite Wastewater Treatment System" Water 10, no. 5: 578. https://doi.org/10.3390/w10050578

APA StyleAbbassi, B. E., Abuharb, R., Ammary, B., Almanaseer, N., & Kinsley, C. (2018). Modified Septic Tank: Innovative Onsite Wastewater Treatment System. Water, 10(5), 578. https://doi.org/10.3390/w10050578