1. Introduction

A major problem for human populations in semi-arid environments is the lack of water for domestic consumption. On average, a person needs 200 L of water [

1] per day to meet their basic needs. In situations of water scarcity, this volume is lower, and according to [

2], it ranges from 50 (intermediate access) to 100 (optimum access) L per capita per day; in emergency situations, the value is 20 L per capita per day. The authors in [

3] affirmed that 81 L per capita per day was sufficient for one non-agricultural economy that used water efficiently. These volumes of water per person are very difficult to obtain in environments where the average annual rainfall is low (less than 800 mm), a value that characterizes the semi-arid environment [

4]. This difficulty is even more important when considering that the rivers that exist in these environments are not permanent but go through periods without flow and the occurrence of a dry period has a probability greater than 60% [

4].

In this context, a major challenge for governments is to enable the supply of water for domestic consumption in urban communities that are located in semi-arid environments, especially in the context of global climate change. In some semi-arid regions climate change can even be beneficial, According to [

5] in China, northern boundaries of multiple cropping systems have been shifted northward due to climate change and the projected China’s crop planting areas for triple-cropping system would expand and multiple cropping systems would increase national cereal production, but in general climate change it is a big problem. For example, Israel is highly sensitive to the potential impacts of this phenomenon, with increases in temperature and decreased precipitation [

6]; Northeastern Brazil has declining rainfall and rising temperatures [

7]; and Northwestern China (Yellow River Basin) may decline by up to 25.7% runoff [

8].

A water supply system consists of a water source, water treatment in water treatment plants, and storage and distribution to the consumer. This challenge is important when considering cities with hundreds of thousands, sometimes many millions of inhabitants, which directly represent the supply of millions of cubic meters of drinking water. This geopolitical situation demands large investments in infrastructure that may become useless or uneconomical if there are changes to the weather patterns.

The environmental planning process in terms of water supply systems in cities in these regions is complex and not trivial. This situation arises due to the stochastic seasonality of rainfall, a fact that brings years with plenty of water, and others with long lasting droughts [

9]. This characteristic is exacerbated as the randomness of rainfall is increasing due to global climate change [

10].

Coastal areas that have water “imported” or underground resources are suffering an increase of cuts in water supply due to changes in the weather patterns, which has generated recurrent droughts [

11]. The increase in the stochastic characteristic of rainfall in semiarid regions has generated lasting drought, for example, the drought in Northeastern Brazil in 2013, which was the most severe in 50 years [

12].

Some of the solutions to solve the water supply problem for human consumption in cities include: (1) Storage in reservoirs; (2) Use of groundwater; (3) Desalinization of seawater; and (4) Inter-Basin Water Transfer.

In relation to water storage in reservoirs, this type of water supply system is very sensitive to climate change, which has seen more frequent severe droughts, thus the recharge of the reservoirs is being impaired mainly in extreme events [

13]. Climate change is affecting populations in coastal environments around the world, especially in areas in tropical and subtropical regions to the south of the planet, so it is important to start developing disaster plans and detailed studies on drinking water as there is a serious concern about the supply of water to the population [

14].

Regarding the use of groundwater sources under the soil, this method has a strategic place in times of climate change, mainly because aquifers can provide water for long periods, even during long and severe droughts [

15]. In some coastal areas and islands, the reliance on groundwater sources is immense [

16]. However, a major problem is intruded salt water into the coastal aquifers, especially when increasing the use of these resources in arid environments, which leads to overexploitation and saltwater intrusion [

17]. According to [

18], the overexploitation of groundwater has positive effects such as the re-infiltration of excess irrigation water with the recharge of the aquifer, recovery of saline soils, increase in vegetation cover, change from a non-irrigated to an irrigated regime. Nevertheless, over time the effects become increasingly negative including continuous failure in piezometric levels with increased costs for the continuous failure in piezometric levels with increased costs of pumping; the abandonment of wells; diminishing groundwater reserves; induced compaction of the land surface; change in the physical and chemical characteristics of the groundwater; modification induced in the river flow regime; impact or desiccation of wetlands and springs; and changes in the groundwater extraction systems.

In terms of the provision of drinking water through the desalination process, the use of water from desalination processes is increasing in arid regions due to increased water demand from population growth, the industrial expansion, tourism, and agriculture [

19]. In general, desalinization is not a universal solution for fresh water supply in all regions with water scarcity as it is cost prohibitive [

19]. There are three issues with desalination: the desperate need to meet demand; dramatic improvement in the energy consumption of modern systems; and reducing costs in desalination processes [

20].

The transfer of inter-basin water is when rainfall is higher in a watershed and the need is greater in another; in this context a solution is interconnection between basins, however, this can cause environmental damage to the involved basin [

21] as any inter-basin transfer generates complex phenomena (physical, chemical, biological, and hydrological) in these changed systems [

22]. The transfer of inter-basin water is designed to ensure access to this feature through artificial water transport to locations where people need it; this action is typically an engineering measure oriented to meet the demand and causes major social challenges [

23].

Based on the above discussion, it is clear that the debate on water supply systems in semi-arid areas in coastal environments is not over. For each proposed conventional solution, there are difficulties and restrictions, which indicate the need for innovative ideas. Innovation refers not only to new products, results, and processes introduced in the world (absolute innovation), but also includes existing techniques that are used of new ways (diffusion).

An innovative solution has been the use of submarine pipelines to import water to islands from nearby continents or larger islands with available water in Seychelles, Malaysia and China [

24]. Recently, the construction of an 80 km long undersea pipeline of 1600 mm in 250 m depth in the Mediterranean was achieved to transfer water from the Anamurium Plant in Turkey to the Güzelyalı Pumping Station in Northern Cyprus has made underwater adductions a realistic option for transboundary drinking water transfers [

25].

In trying to provide an innovative proposal, this paper proposed a solution to the water supply of cities in coastal semi-arid environments through the underwater adduction of rivers. The idea was to make the abstraction of drinking water in the mouths of great rivers near the semi-arid regions. This water would be led by a pipeline below water level that would follow the route of the seacoast, where the energy to carry the raw water would be supplied by wind turbines offshore.

3. Results and Discussion

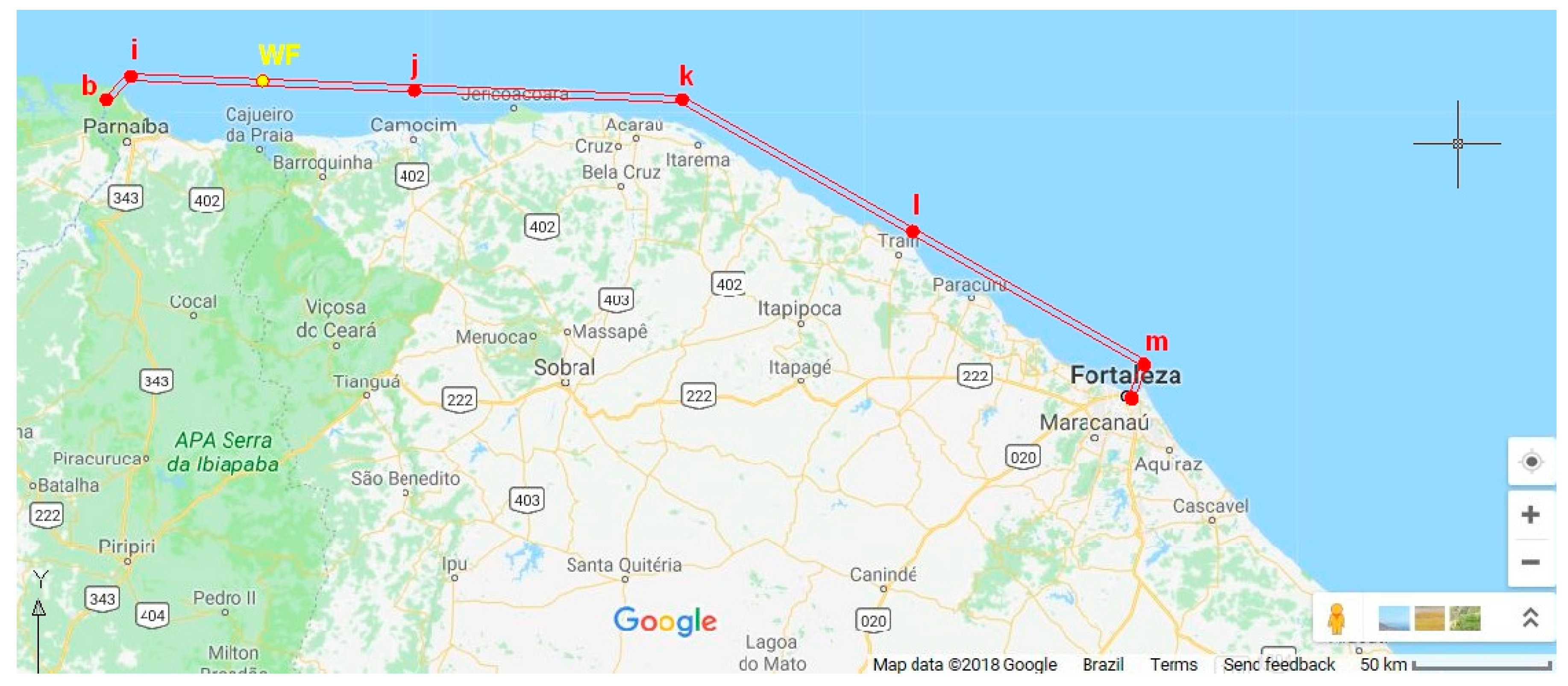

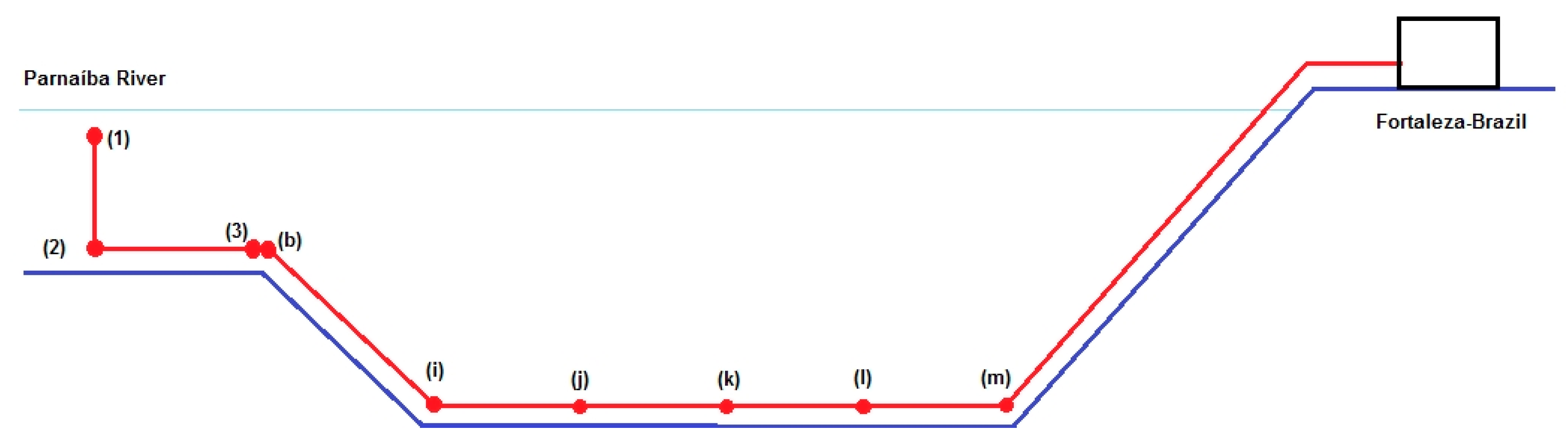

Stretches of the pipelines were calculated and are represented in

Table 4,

Table 5 and

Table 6. Our results were estimates based on calculations according to the literature. The discharge line was almost all the same level and the electrical power supply was completely from wind power. The layout of the pipelines defined by

Figure 11,

Figure 12 and

Figure 13 characterizes each system, depending on the water demand and selected rivers. The stretches of the route Parnaíba/Fortaleza were calculated and are represented in

Figure 11, and its characterization is presented in

Table 4 for Scenarios 1 and 2.

The diameter of the pipelines was found through the Bresse formula (Equation (1)), for the function of flow rate demanded for the metropolises. From this diameter, considering the speed flow and the length of the stretch, was found the overall head losses of each stretch through Equation (2).

The power of the hydraulic pump was found through Equation (7) considering a pump efficiency of 92% and the overall head losses. The electric power of the motor to drive the pump was given by Equation (12) in function of flow rate, discharge, pump efficiency, electrical efficiency, and mechanical efficiency.

In this project, we did not list the reservation delivery structures, distribution tank, Moorhen treatment systems and distribution network, which according to [

1] are part of the water distribution system, as this study aimed to only technically and economically check the transportation of raw water.

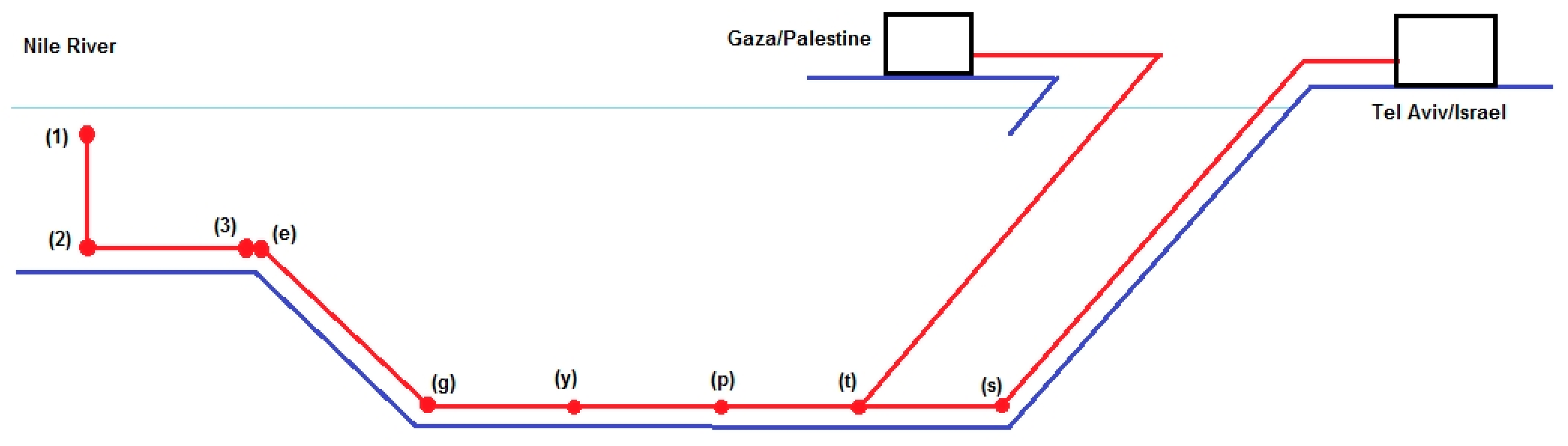

The stretches of the Nile route/Tel Aviv-Gaza are represented in

Figure 12; the characterization of the sections of this route is shown in

Table 5 for Scenarios 1 and 2.

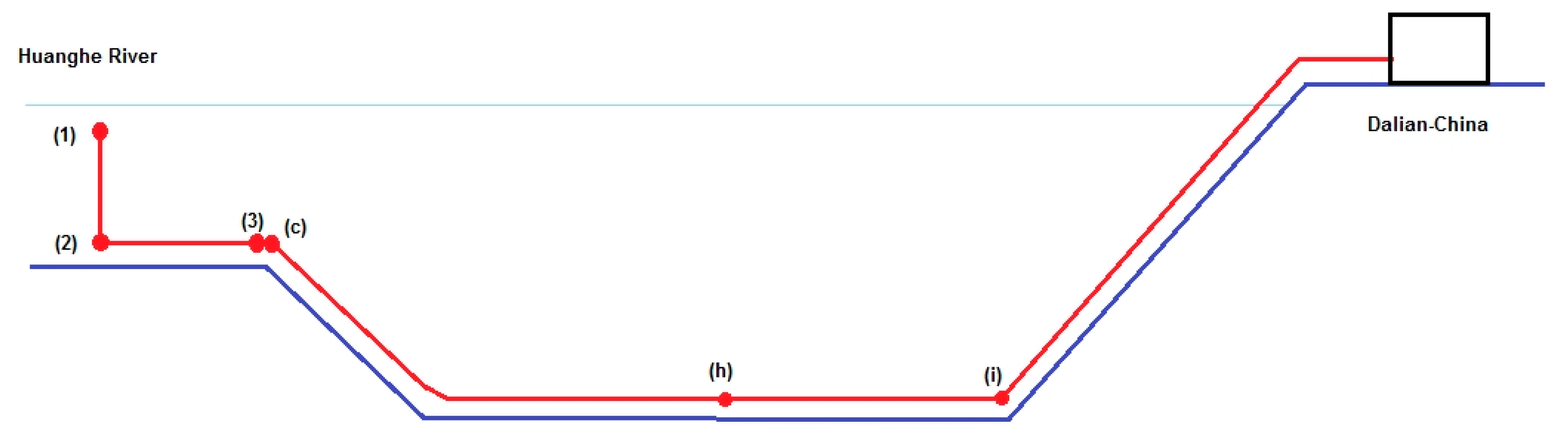

The stretches of the route of the Huanghe/Dalian-China is represented in

Figure 13, the characterization of the sections of this route is shown in

Table 6 for Scenarios 1 and 2.

According to [

1], when the water in the catchment has solids suspended with very high value, it is important to design a sand trap to settle these solids, thus avoiding their direct capture. Considering the characteristics of the Huanghe River in China, the construction is necessary to prevent damage to the pumping system. With a speed flow greater than the 0.6 m/s limit [

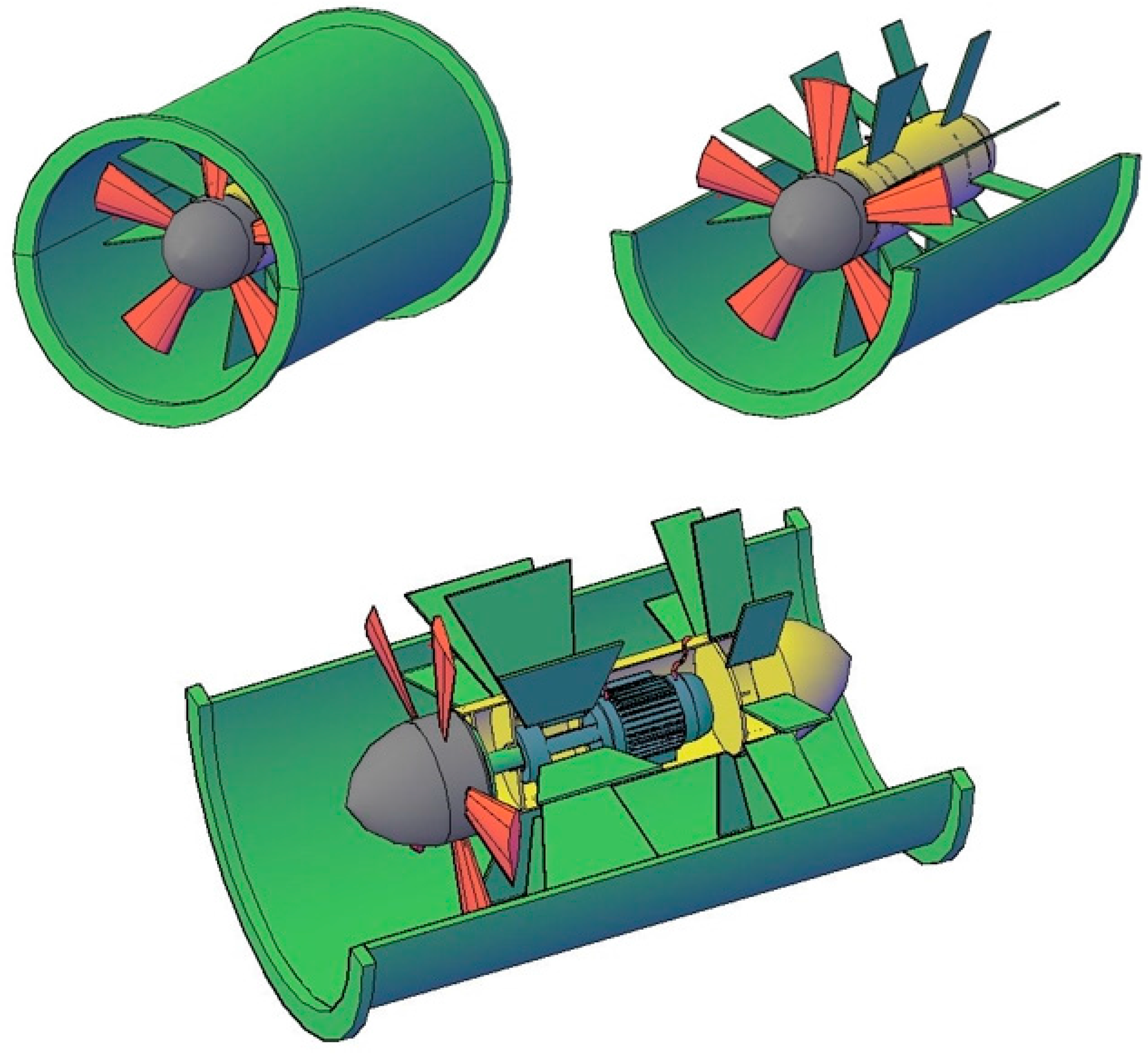

63], there is no risk of deposition of sediment volumes along the pipe and maneuvering stations. From the definition of underwater pipes were calculated the axial hydraulic pumps that offer the energy of the water flow so that the flow is obtained in response to demand in the metropolises. The conceptual design of the axial pump is shown in

Figure 14.

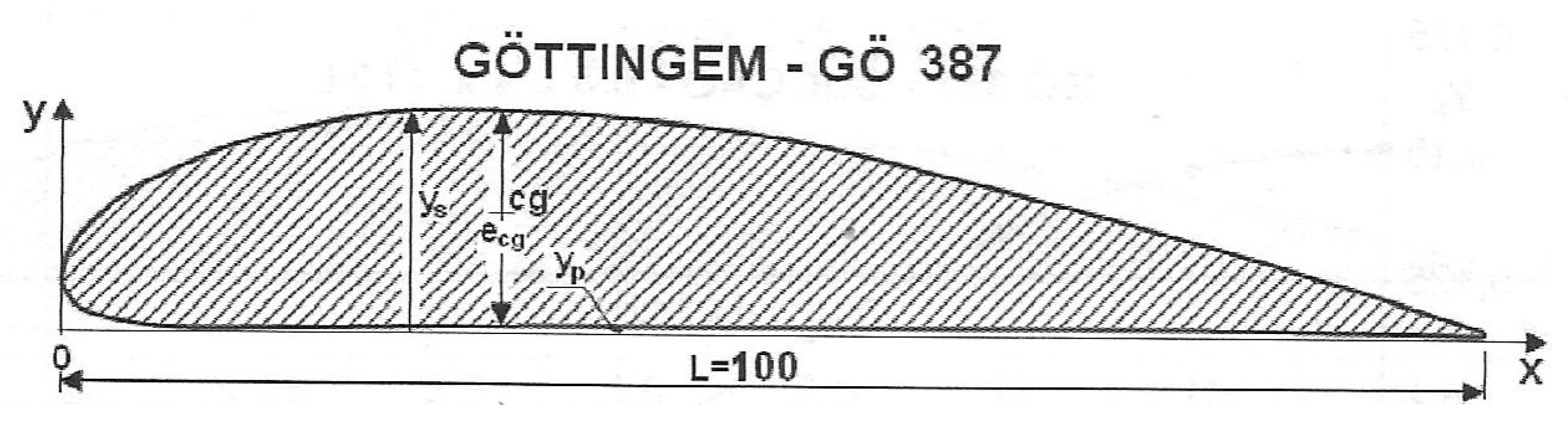

Considering the hydrofoil GO-387, the rotation of the hydraulic pump was found through Equation (8) as a function of the flow rate, the discharge, and the specific rotation obtained through Equation (9) that takes into account the suction height, water temperature, and the barometric height.

The pump rotor diameter was calculated by Equation (10), which relates the pump rotation (Equation (8)) and the tangential velocity of the flow. The hub diameter was calculated by Equation (11) as a function of the specific rotor rotation and pipeline diameter. The diameter of the drive shaft was given by Equation (13) as a function of the nominal motor power, safety factor, and shear stress of the chosen steel.

The number of blades of the pump rotor was calculated through Equation (14) as a function of the specific rotation of the rotor; the blade pitch was given by Equation (15); and the length of the hydrofoil rope by Equation (16) as a function of the relative flow velocity, relative flow angle, discharge, southern speed, and number of rotor blades. The angle of attack of the blade was given by Equation (17) as a function of the coefficient of support of the hydrofoil, the thickness of the hydrofoil, and the rope of the profile.

The preliminary hydrodynamic design of the rotors of the hydraulic pumps prescribed a special care with the cavitation phenomenon, which was reduced by the low-speed of the pumps at a low flow speed (0.88 m/s); however, even with these operating conditions, it is possible that cavitation occurs. This preliminary design of the axial rotor did not focus on the optimization of same, both in terms of cavitation as in efficiency. For the final design of the rotors, the top gap and the geometric design of the impellers—mainly in terms of displacement of the profiles in the region near the tip of the blade—need to be assessed, according to [

64]. This optimization was outside the scope of this work but is necessary for obtaining the best efficiency of the pump.

Table 4,

Table 5 and

Table 6 show that the power of the electric motors needed to drive the pumps was high, so installation of such engines is not trivial in submerged water pumps, both in terms of cooling the engines as the structural seal as well as the axes. In this context, it evaluated the possibility of an electrical motor with a water-cooled system such as DC motors DCW [

65], which are cooled by the heat exchanger air/water and reach up to 10 MW of power. According to [

66], an estimate of the total cost of electric motors is US

$ 110.00/kW. There are Chinese companies that specialize in pump submerged axial flows and since many products with very similar flow capacities to those required in this design are already on the market such as some commercial axial pump [

67], it would be necessary to make adjustments to the designed rotor and the pump power required.

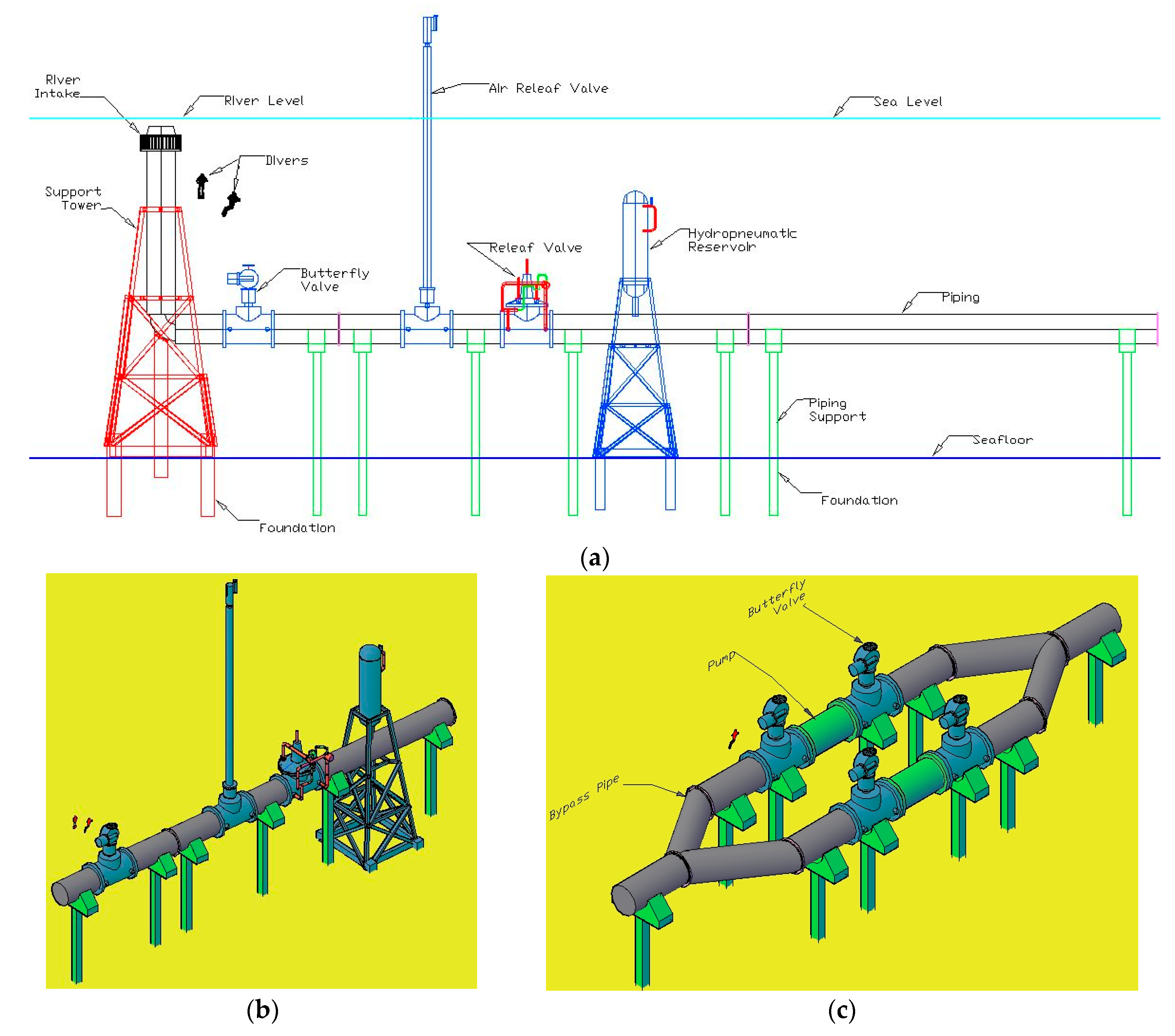

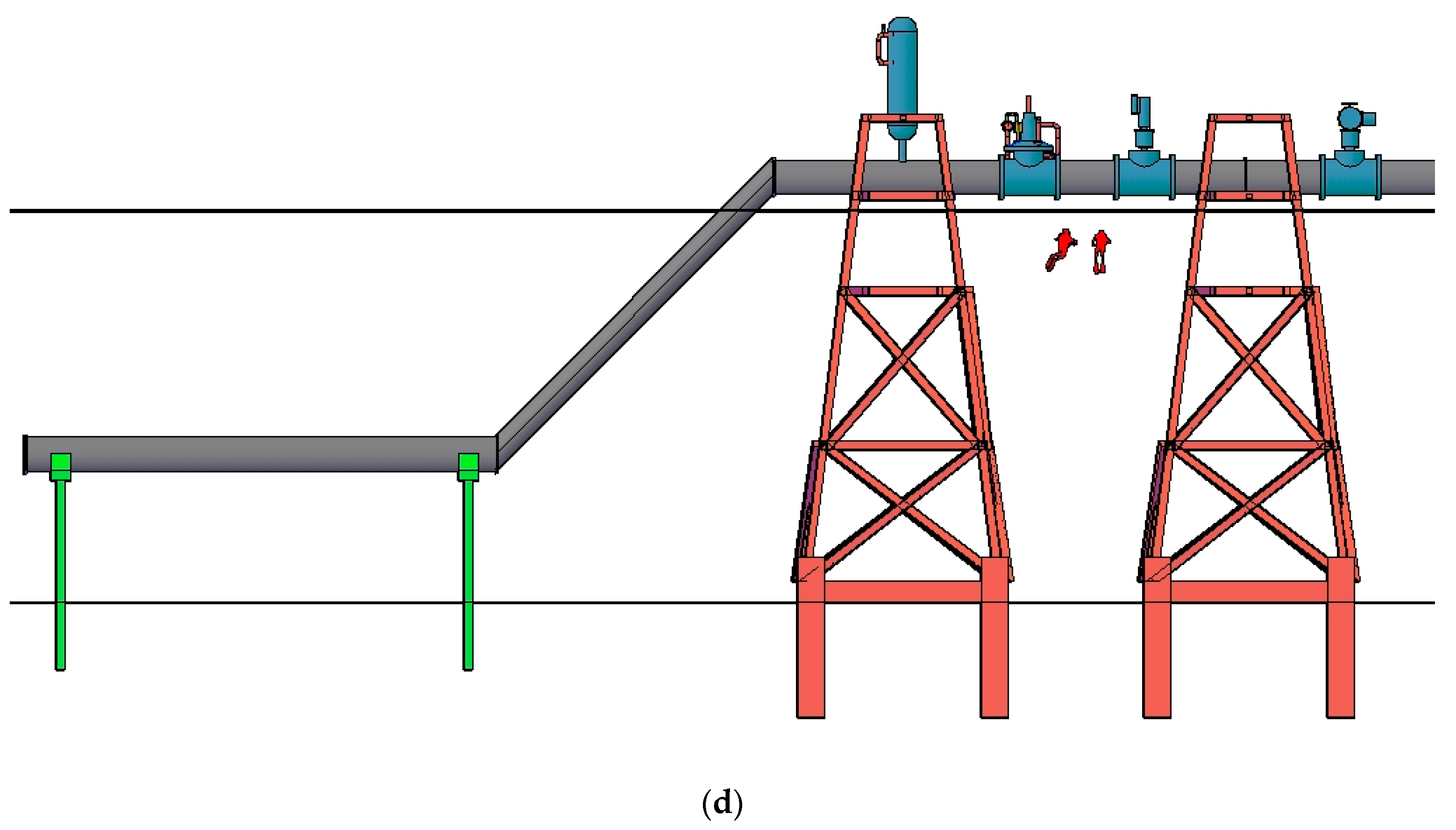

The conceptual design of stations of pipeline is shown in

Figure 16.

The relief valve is integrated with a check valve to prevent in the event of an accident, there is a disastrous return of water flow. According to [

68], it is a common practice in complex systems to improve reliability through systems and structures in standby (redundant) so that if one of the systems fail, the standby system takes action to avoid damage and loss to the end user. In this context, the pumping stations were equipped with two axial pumps, one in operation and one in standby, setting a redundant system. This configuration, though costly from the standpoint of equipment and structures, provides high reliability in underwater pipes.

The maintenance, repair, and replacement of the pumps will be undertaken by a system composed of trenchers machines and remoted operated vehicles (ROV) that specialize in the maintenance of submarine oil pipelines [

69]. The pump lift and possible repairs will be carried out by an adapted wind turbine installation vessel [

70].

All controls of the valves and pumps will be conducted by a modular electronics system via logical programmable controllers (PLC) that are combined in a control center to make real-time diagnostics of every pipeline.

The estimated dimensions show that it is a large system, with flows reaching tens of cubic meters per second. In such systems, special attention should be given to the hydraulic transients generated for the opening maneuvers, closing, or shunt [

1]. In this context, the effects of water hammer were evaluated, which were calculated using Equation (6) as a function of flow speed and celerity (Equation (4)). The critical time for opening was found through Equation (5) as a function of celerity and pipe length. Based on this evaluation were the dimensioned armor and structural screens of reinforced concrete pipe and the security systems (relief valves and hydropneumatic tanks) as well as the maneuver times (closing and the opening of the butterfly valve or flow derivations). The focus was to avoid intense transient in this context for safety purposes, the pipe was dimensioned for the worst case scenario represented by a rapid maneuver, defined as the time where the maneuver was smaller than the critical time. The reinforced concrete pipe was coated externally with polyethylene. The strength of concrete was designed with a fck of 250 MPa and the reinforcing steel was the CA50 with fyk = 500 MPa. The thickness of the tube wall was standardized to 150 mm. With these determinations, it was possible to measure the area of the steel reinforcement and the area of the structural concrete, steel screen tube, which were calculated according to the method described by [

71,

72]. The resistance of the polyethylene layer was neglected. In the

Table 10,

Table 11 and

Table 12 show the values of the speed, hydraulic transients, critical maneuver times, the stresses applied to the tubes, the areas of the armor and the areas of steel screen per linear meter of pipe for each section of the route of the pipeline in each metropolis. All values had a safety factor of 2.

The pipe installation on the seabed will be undertaken by a specially adapted wind turbine installation vessel. According to [

70], the time to install an offshore wind turbine can reach 18 h, and by [

73], the cost of installation of the foundation of one offshore turbine is US

$ 290,000.00, therefore one hour of work costs around US

$ 16,439.00. Whereas it is much simpler to install a concrete pipe on the seabed, which can be used as basis of the pipe laying vessel [

74] with an estimated rate of installation of 140 m/h (around a third of rate of the PLV ship), so for the installation of 1 km, 7.14 h is needed, so it has an estimated cost of US

$ 115,000.00/km for the pipe installation.

With the setup of the defining pipeline and their paths completed, it was possible to allocate the wind farms and to scale them. For security, the wind farms will be available in addition to the required turbines, with two more turbines: one for emergency backup purposes [

68], and the other for the maintenance schedule [

57], so that there will always be an operational turbine on standby and the other in maintenance. The preliminary design of the wind farms is presented in

Table 13 and

Table 14.

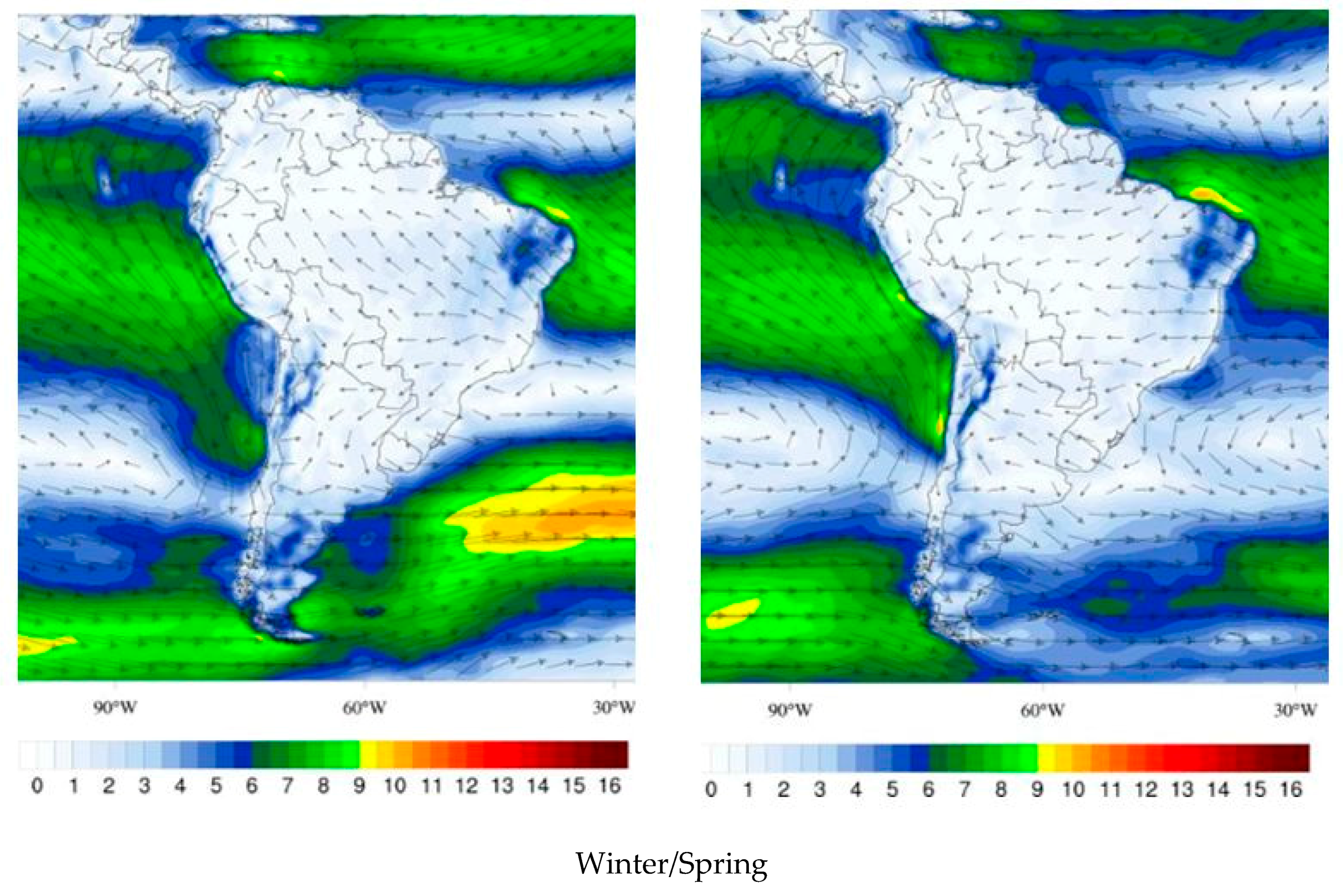

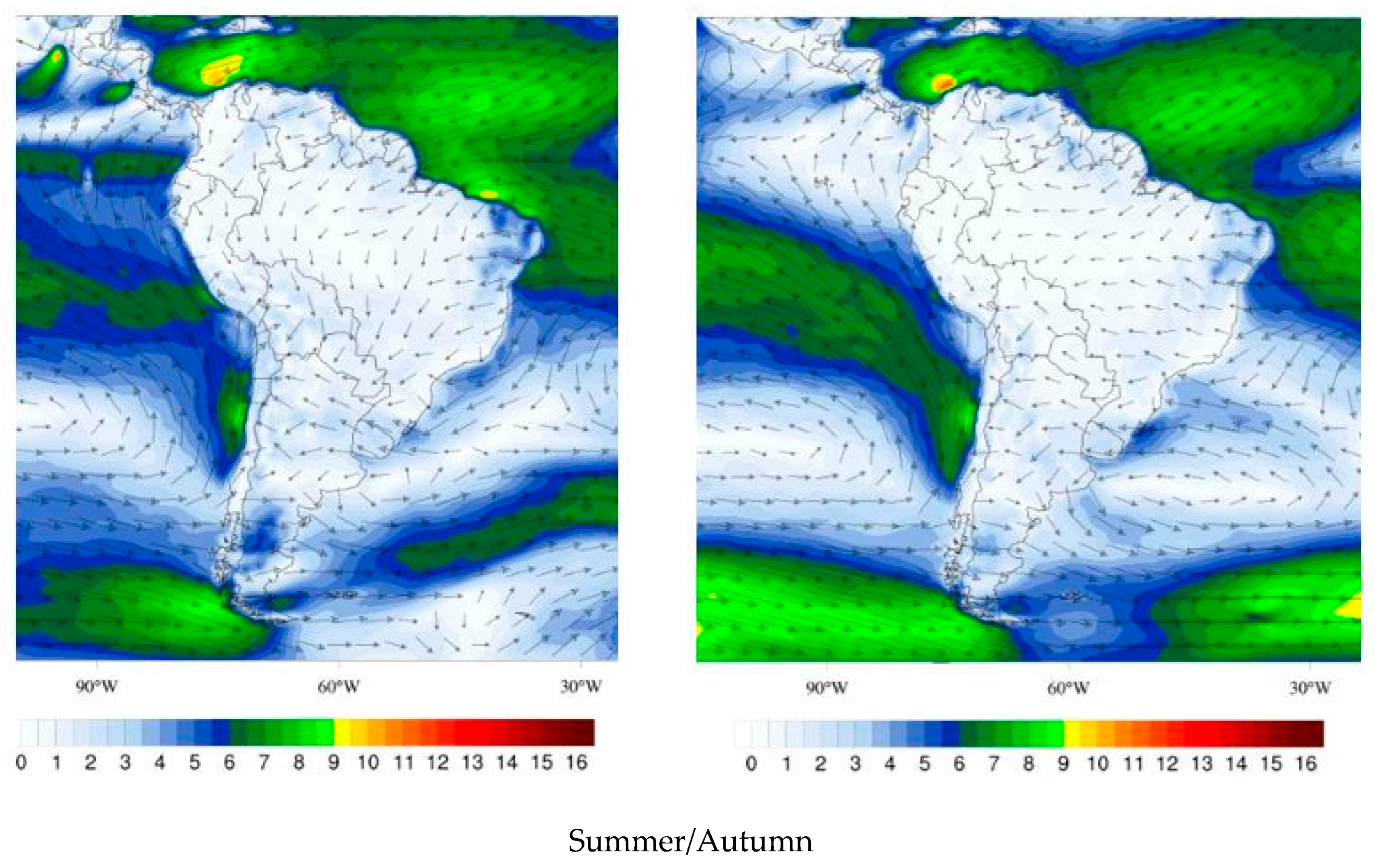

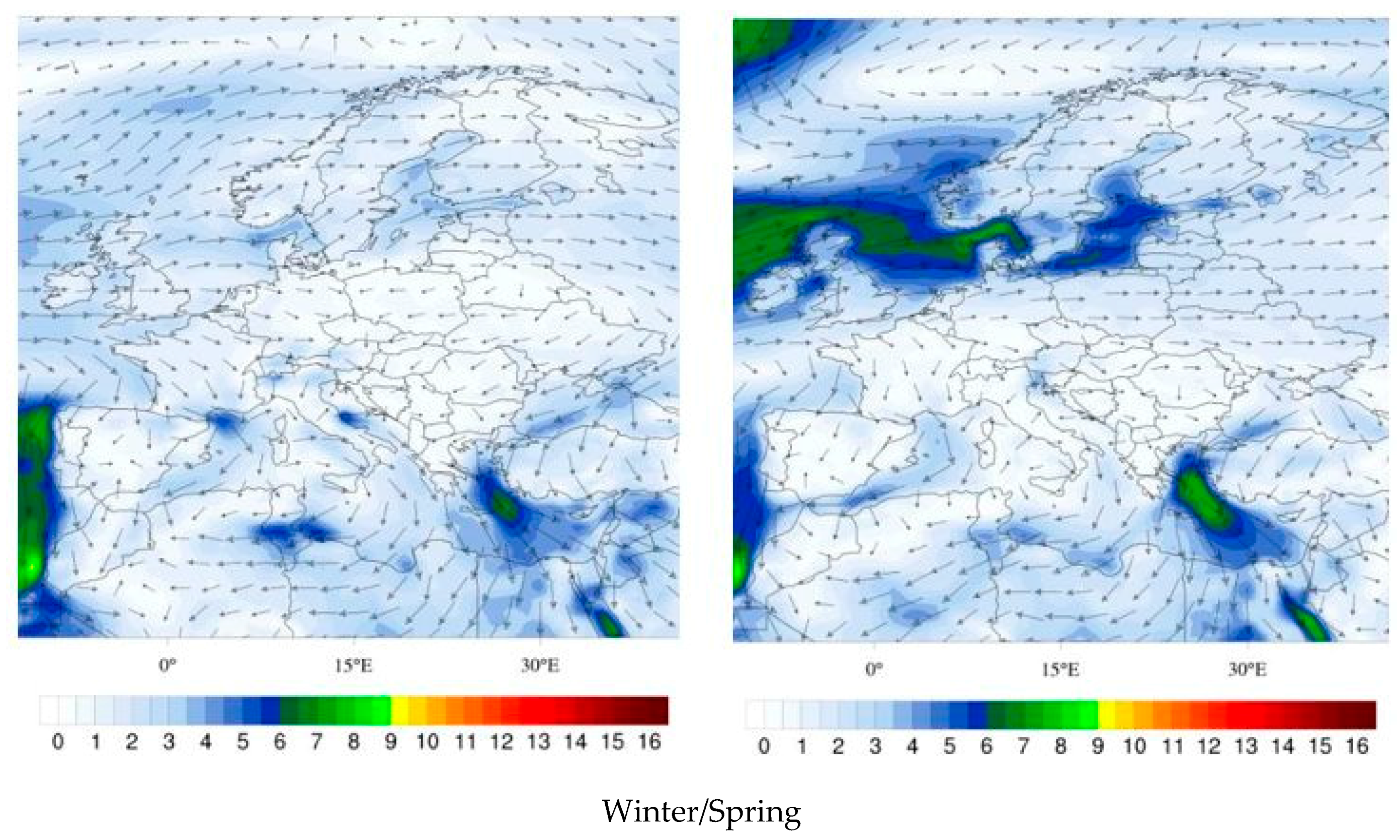

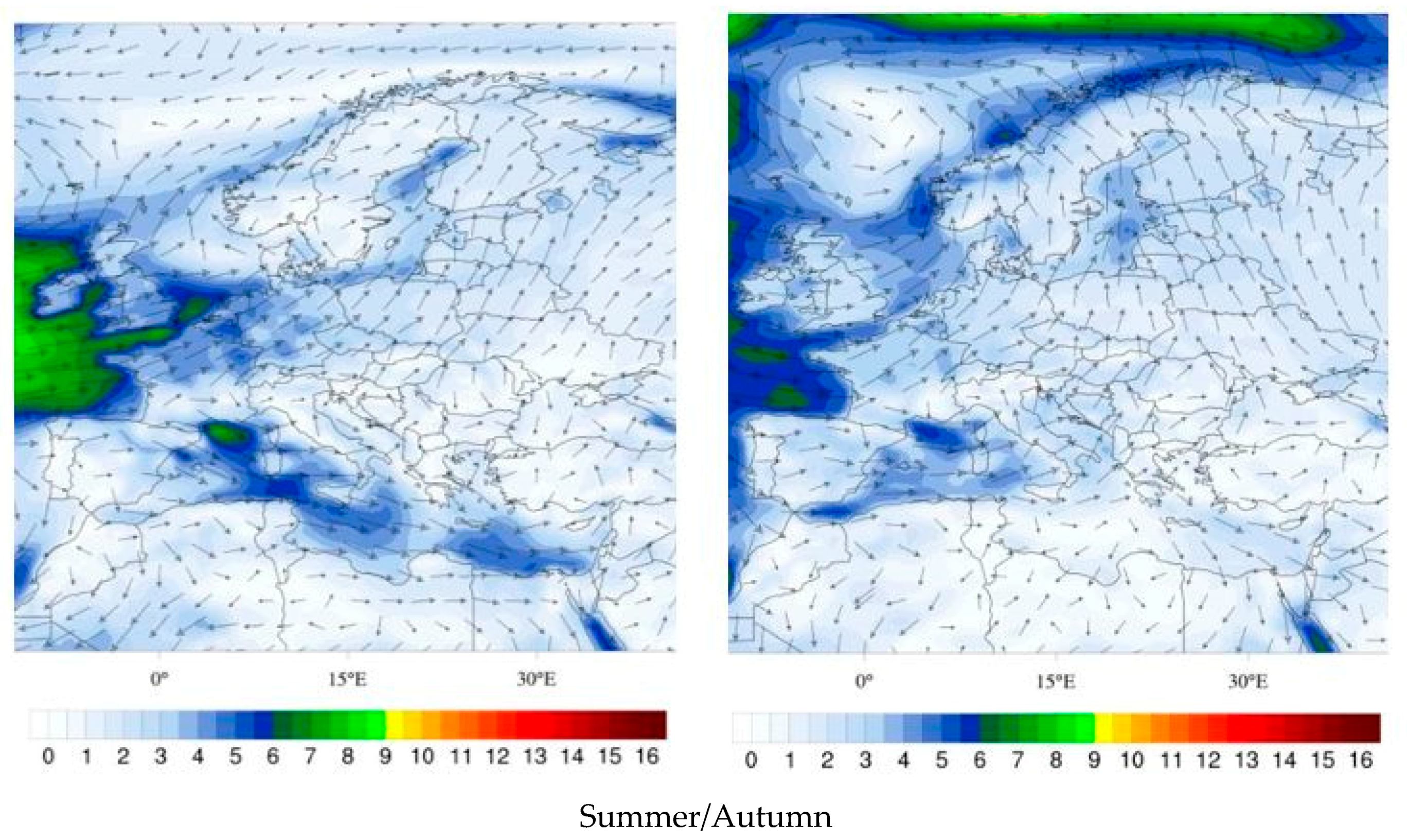

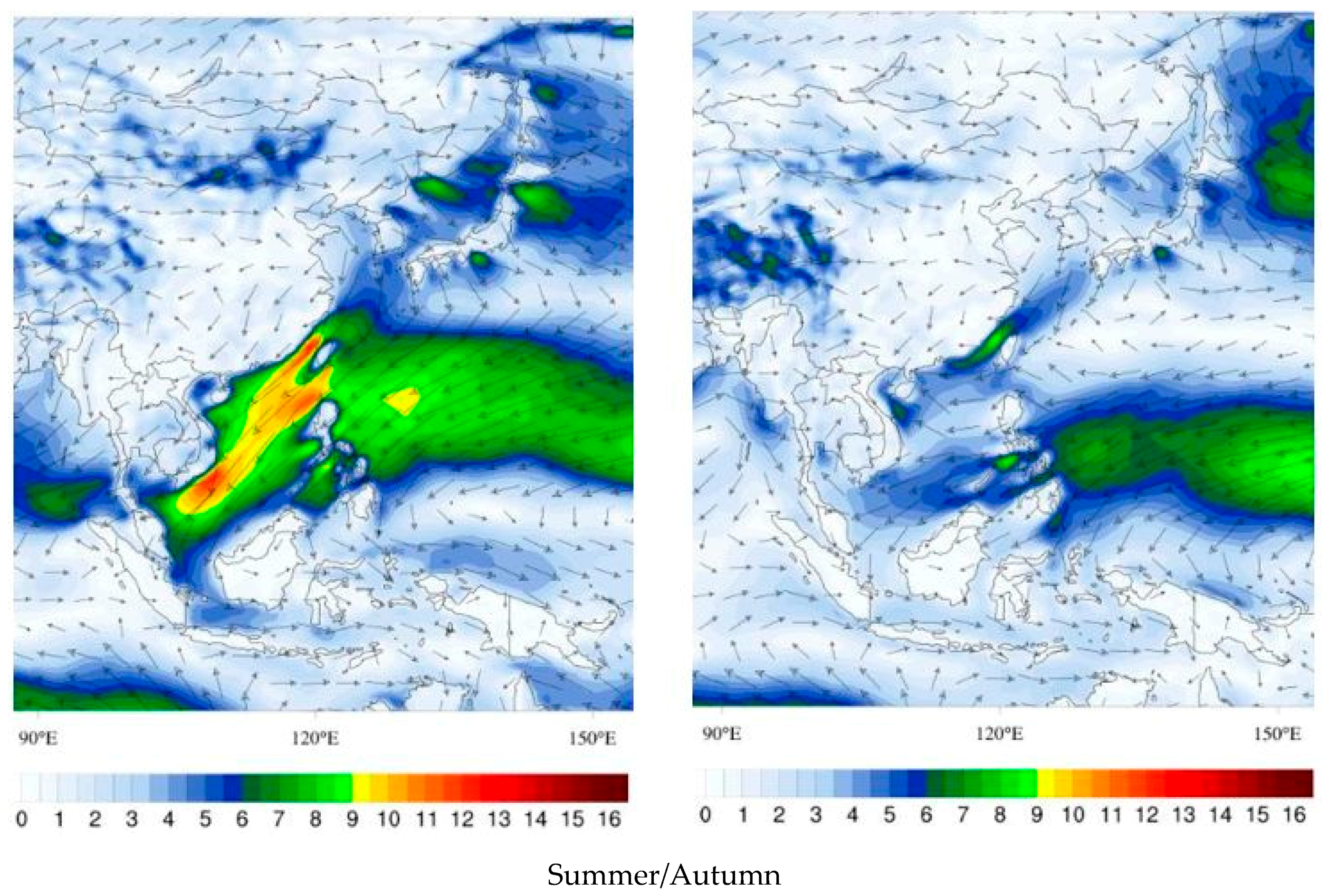

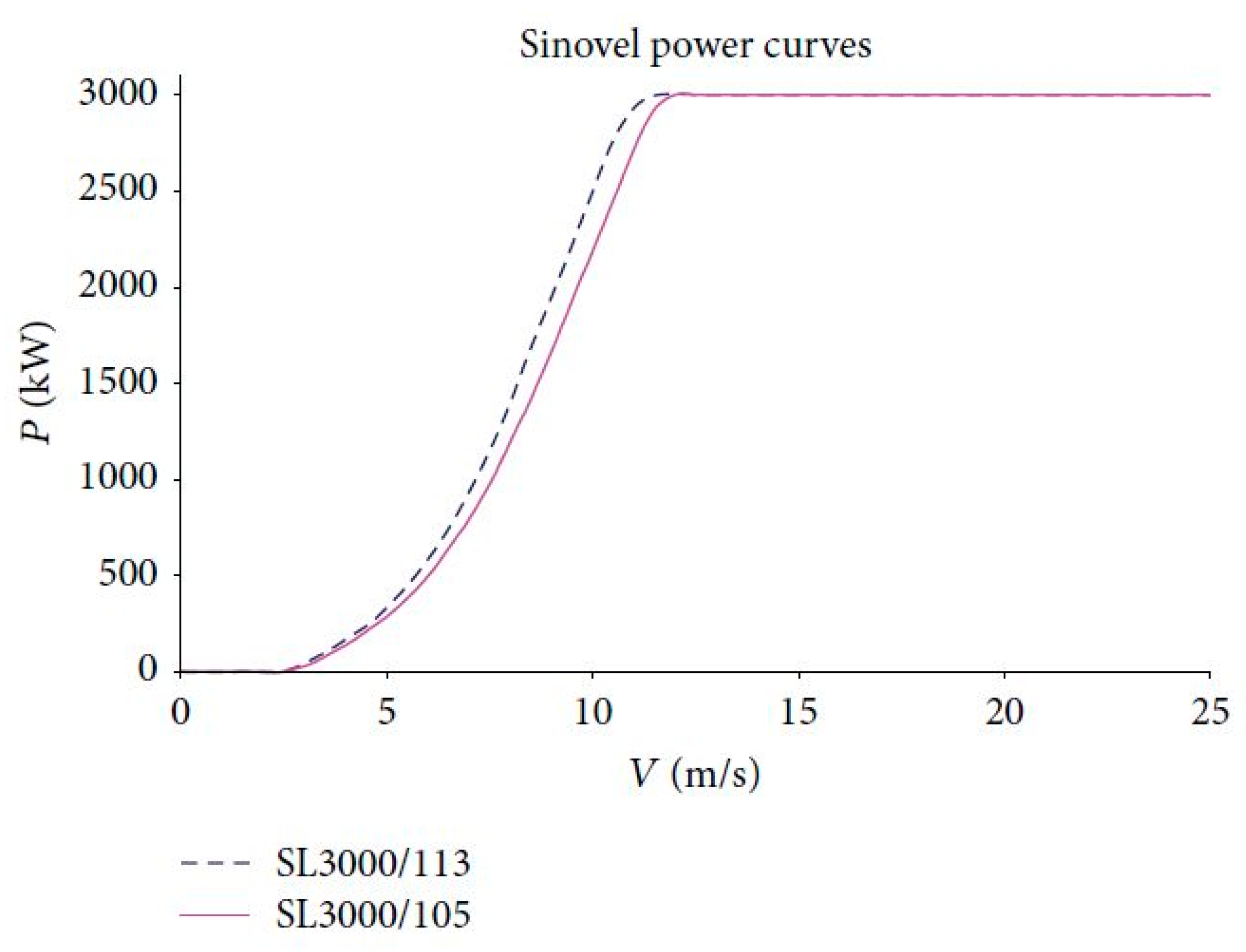

The power curve of the wind turbine offshore Sinovel SL3000-113 is shown in

Figure 10 [

59], the location of the wind farms in the path of the pipelines is shown in

Figure 2,

Figure 3 and

Figure 4; the wind maps in each coverage area of the metropolis are shown in

Figure 5,

Figure 6 and

Figure 7. The preliminary design of the wind farms is presented in the following tables:

For the power demand of the electric motors and the total generation of wind farms is perceived that only Pipeline Parnaíba/Fortaleza, Brazil had an independent operating capacity without a link to the mainland electricity distribution network, as in all seasons there was a net power reserve as the Brazilian northeastern coast winds are intense all year.

For the system of the Nile/Tel Aviv-Gaza and Huanghe/Dalian, there were deficits in several seasons, this required a connection to the mainland grid electricity distribution to meet the demand of the electric motors when the wind regime was not able to trigger the wind turbines.

According to [

75], the energy cost, operational cost, maintenance cost, and capital investment were the main contributors to the water production cost. The energy cost is responsible for about 50% of the produced water cost. In this context, it is clear that with the use of offshore wind energy, the cost of raw water transport can be reduced by half, indicating the great feasibility of using offshore wind turbines, even considering that wind farms in China and Egypt will have long periods of inactivity due to low winds.

However, if the excess energy of the wind periods in the continental power grid could be shed, it is possible to compensate for periods without wind using the continental electrical power, thus making the system viable energetically. Currently in Brazil, companies can release the excess energy of an independent power generation system in the utility distribution network, earning credits for later use [

76]. This fact enables Brazilian wind farms to throw their surplus power to the grid, which in addition to the energy-sustaining underwater pipe also generates income. In assessing

Table 13 and

Table 14, it can be deduced that there is a significant annual net energy reserve in Chinese wind farms and although there are seasons without wind, the wind energy in seasons where there is electrical power generation is higher than the demand for electric motors, which compensates for windless seasons. If by chance there is a distributed generation policy similar to that of Brazil, this would completely allow the Chinese wind farms making the Huanghe/Dalian system to have sustainable energy.

The wind farms of the Nile/Tel Aviv-Gaza system, the net reserve was small, but still, the argument is similar to the distributed generation case for Huanghe/Dalian. With all sizing and definitions of elements and systems of underwater pipes, it was possible to estimate the budget as well as the assessment of the investment. The following tables show the estimated budget for each pipeline.

Table 15 and

Table 16 are the estimated budget for each pipeline (scenario 1 and 2).

The estimated cost of investment to the order of US

$ 250 million is very good since the value to construct the Anamurium Plant, which has a very close design to this proposal, was made with US

$ 400 million [

25]. In the Turkish-Cypriot system, although the pipeline’s total extension was only 106 km, the declared value of US

$ 400 million included constructing a large dam with an estimated cost of US

$ 330 million [

86], therefore the pipeline itself was estimated at US

$ 70 million.

With the values of the investment costs for the underwater pipes and the annual cost of maintenance, is was possible to make an economic analysis of the investment. The hurdle rate was set to 10.4%, the rate used by [

62]. The value of raw water per cubic meter delivered in large cities was: Fortaleza-CE-Brazil = US

$ 0.0355 [

87]; Tel Aviv-Israel = US

$ 0.3500 [

88]; Dalian-China = US

$ 0.0790 [

89]. Depreciation was considered to be 3.3%, which represented the full value of the investment at the end of useful life.

The Present Worth Value was calculated by Equation (19) in terms of useful life, minimum internal rate return, cash flow, and capital investment. The Internal Rate of Return was calculated by Equation (20) in function of the disbursements, the investment time, the useful life. The payback was calculated by Equation (21) as a function of revenue at time, cost at time, and capital investment.

Table 17 presents an economic simulation of such a hypothesis, considering the hurdle rate of 10.4% [

62].

Considering the scenario (200 L/capita/day), in the case of the Parnaíba/Fortaleza system, it had sufficient water availability and the wind conditions for wind power are ideal, but due to the low value of raw water per cubic meter (US

$ 0.0355) there is no economic viability. It is interesting to note that this value is fixed by the State Government of Ceará by decree [

87], requiring the Company of Water Resources Management to adopt this value regardless of the operation and climatic conditions of the region. Obviously, this very low value is not motivated by the “technical”, cost component, but certainly, there is a political consideration, as described by [

22,

90].

A second hypothesis for an underwater pipeline to Fortaleza would be the use of the excellent wind conditions of the region to install, in addition to the wind turbines required for the supply of energy to electric motors (6 turbines), another (34 turbines) for the sole purpose of generating electricity and launched in mainland network, thus producing dividends given that the value of MWh in Brazil for wind energy is around US

$ 38.85 [

91]. In this situation,

Table 18 show that there is U

$S 33,229,022.90 of dividends that makes the project feasible.

It can be argued that this assumption changes the core business, instead of being the raw water supply, it would become the generation of electricity. However, this solution would impact greatly on the welfare of the population, and also increase the volume of existing drinking water in Fortaleza currently, thus forming a reserve for possible drought, or use for trade and industry.

Another component to viability is that there is no need for expropriations like in a transposition setting, building land pipeline, or large water reservoir, reference [

92] affirmed that high amounts paid as compensation to homeowners, urban and rural in Brazil, have been a constant in the expropriation of shares of land for social interest in charge of the government, which has generated a great deal of judicial debts of the federal, state, and municipal governments. This cost there is not in the case of an underwater pipeline as the mouths of rivers and the land submerged offshore are in an exclusive area owned by the government. Reference [

92] pointed out that due to urbanization, these systems were becoming more complex and that both the regulatory agencies and consumers exerted pressure for the system to run efficiently with low operating costs. This generates a great pressure from society ongovernment agencies so that they carry out environmental management to avoid the lack of water [

93].

In addition, the value of security that the underwater pipeline will provide needs to be considered given that with this solution, there is no risk of water rationing. In homes in poor areas, the type of construction allows a higher relative humidity and a more proper environment for adult forms of mosquito transmitter diseases (Aedes Aegypti), therefore, there are more areas of reproduction and environmental conditions that may help the survival of adult forms of Aedes Aegypti [

94]. Due to extreme drought events that directly affect the economy of a city [

95], the reduction of infestations of Aedes Aegpty due to the elimination of water supply cuts for the poorest populations [

96] is very important.

In the case of Dalian in Scenario 1 (200 L/capita/day), the estimates indicated an ideal application as the water and energy there had an excellent internal rate of return (IRR) and good payback i.e., was highly viable economically and technically.

Regarding the underwater pipeline Nile/Tel Aviv-Gaza, the economic evaluation demonstrated a phenomenal viability with an IRR of around 47.6%, which was exceptional in Scenario 1. In terms of energy, the wind turbines were sufficient to maintain the electric motors. However, the main fact is that the source of water belongs neither to Israel nor Palestine, but to Egypt. Therefore, for this proposal to be feasible, Egypt must agree to provide water to Israel and Palestine, which implies non-trivial geopolitical negotiations. However, if Egypt agrees to participate in the project, it will receive a payment per cubic meter from the supply of water to other countries. This payment (through the volume of water in question) would generate sizeable dividends that could be used to improve the welfare of the Egyptian population as well as actions to preserve and improve the watershed of the Nile.

In this context, considering a hurdle rate of 10.4% [

62] and a fair price for Egyptian water at US

$ 0.05 per cubic meter, there would be an amount paid to Egypt of US

$ 20,293,416.00 per year. Even with this expenditure, the price of water delivered to Tel Aviv/Gaza would be 57.14% (US

$ 0.15 per cubic meter) lower than the current rate, yet with an internal rate of return of 10.70% and a payback of 8.89 years. This scenario is very encouraging and demonstrates that a desalinization plant together with the conventional plants of Israel have high costs and are only economically viable in very specific regions or desperate situations [

20].

Scenario 2 is interesting as the environmental impacts and interference in the urban water cycle has delayed the rainy season and created more intense dry spells during the rainy season [

97]. Extreme weather events may affect the water supply system so that the normal water supply to residences cannot be maintained, which can also have an impact on public health [

13], therefore 81 L/capita/day is a sufficient volume for economies with efficient water use [

3].

However, the economic evaluation of the systems in this scenario is not very interesting. The Parnaíba/Fortaleza system continued without feasibility; the Huanghe/Dalian system became unprofitable with very long payback, and the Tel Aviv-Gaza/Nile system did not achieve a minimum attractive rate of return.

Both scenarios (1 and 2) indicated that there may be a contradiction between the economic interests (200 L/capita/day) and environmental interests (81 L/capita/day) in the case of the transport of raw water. In Lesotho, there were significant improvements in social and economic terms after the interconnection between river basins; however, there were serious unintended ecological impacts, with implications for people living near rivers and dams [

98].

This contradiction represents the paradox where the current world society finds itself; on the one hand there is a need for the efficient use of limited and scarce natural resources, and on the other, the need to consume these resources unnecessarily for profit. Almost all ancient civilizations had as an antecedent to their defeats the drastic reduction of the capacity of support from the environment, be it by ecological damages either by end of reserves, or even by climatic changes [

9].

The adduction of rivers tries to mitigate this adverse context; however, it also has difficulties and restrictions including the impacts of diverting freshwater flows from the deltas and mouths of the rivers but is a real possibility in semiarid costal environments given the limited alternatives for these regions.