Emptying Operation of Water Supply Networks

Abstract

:1. Introduction

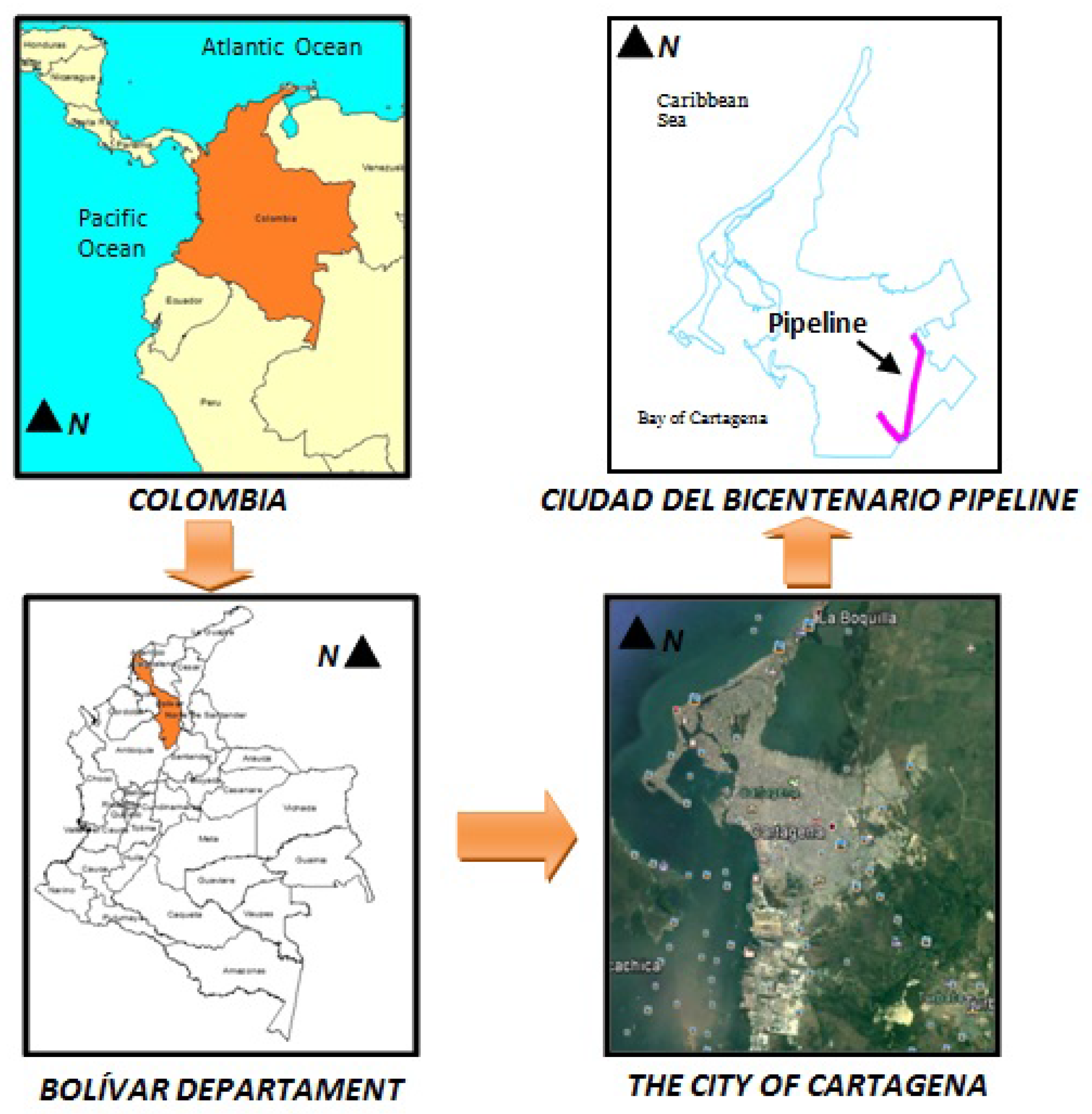

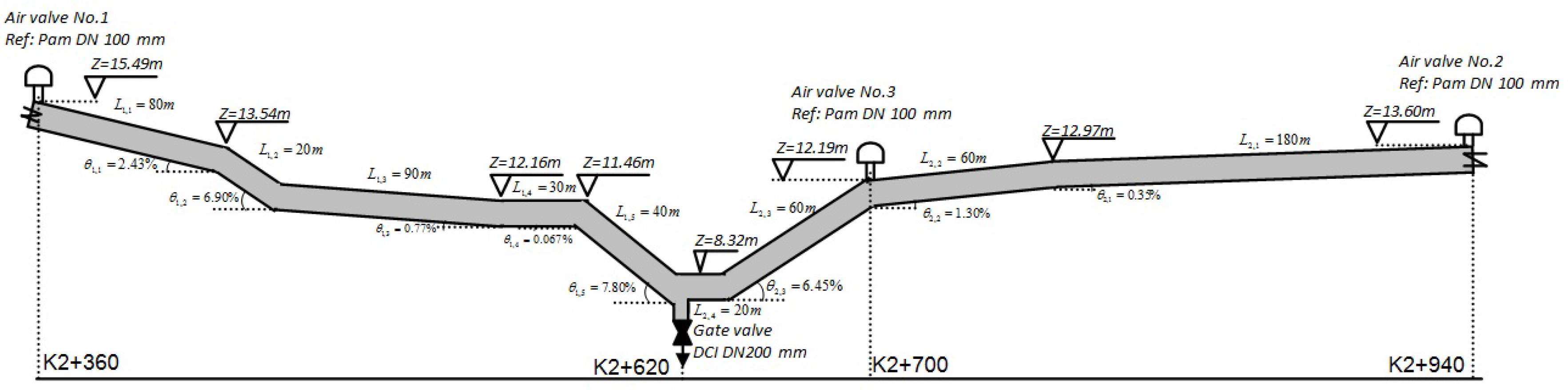

2. Pipeline Description

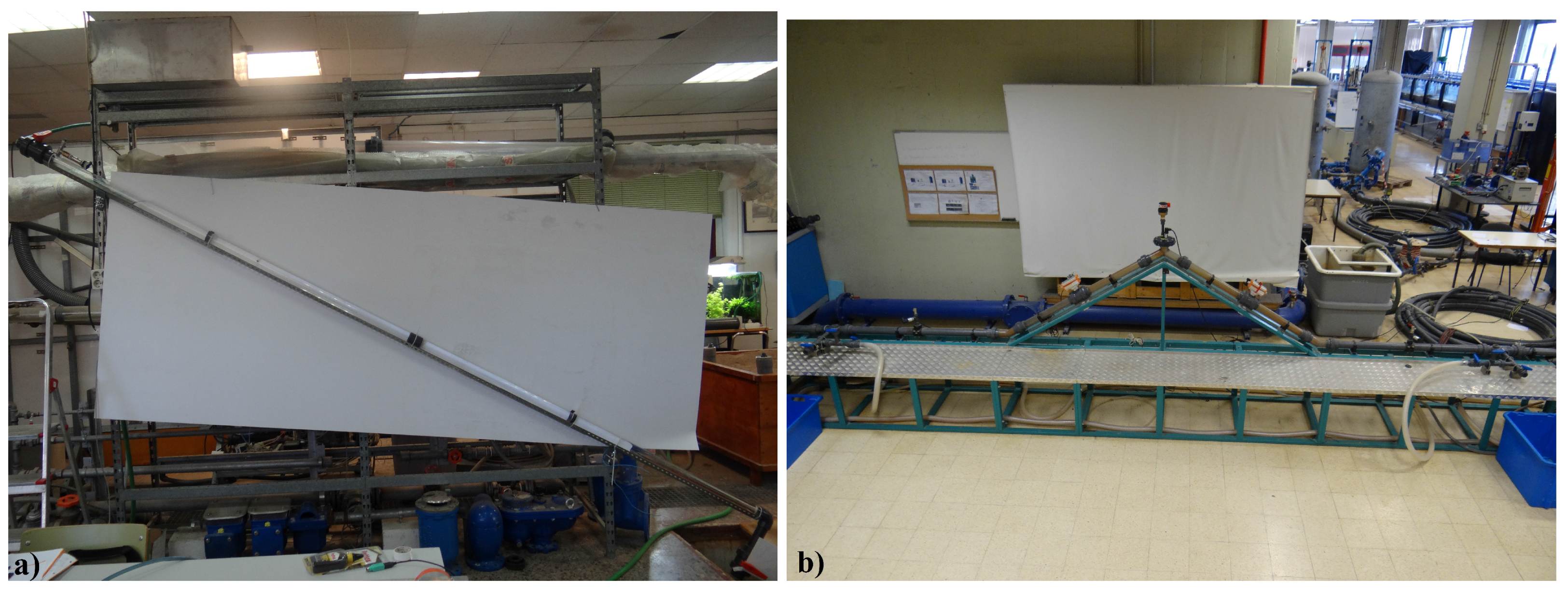

3. Application of the Mathematical Model

3.1. Equations

- Mass oscillation equation applied to the emptying column 1

- Emptying column 1 position

- Mass oscillation equation applied to the emptying column 2

- Emptying column 2 position

- Evolution of the air pocket 1

- Continuity equation of the air pocket 1

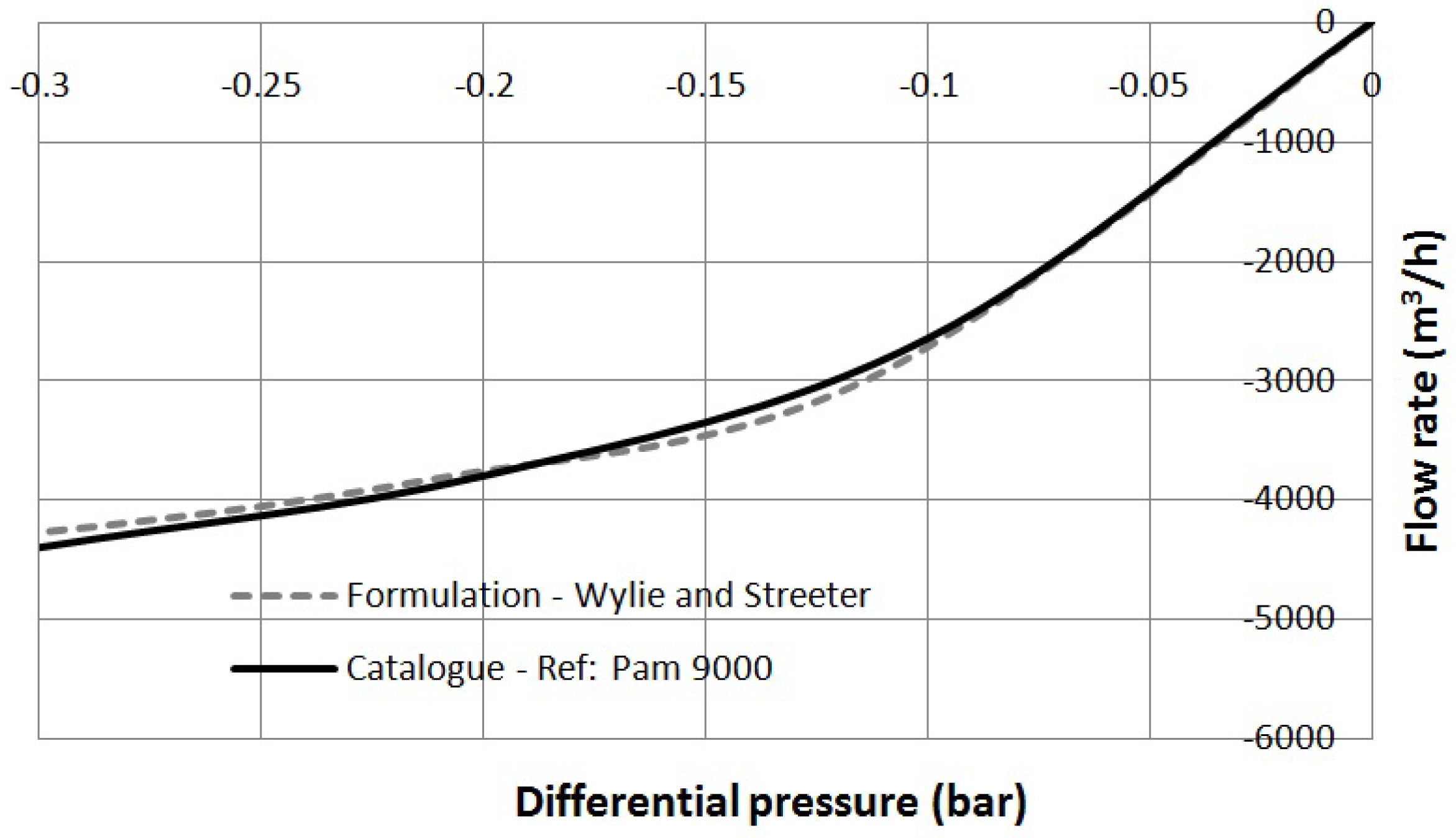

- Air valve 1 characterization

- Evolution of the air pocket 2

- Continuity equation of the air pocket 2

- Air valve 2 characterization

- Air valve 3 characterization

3.2. Initial and Boundary Conditions

3.3. Gravity Term

4. Results and Discussion

4.1. Absolute Pressure and Air Pocket Density

4.2. Length of the Emptying Columns

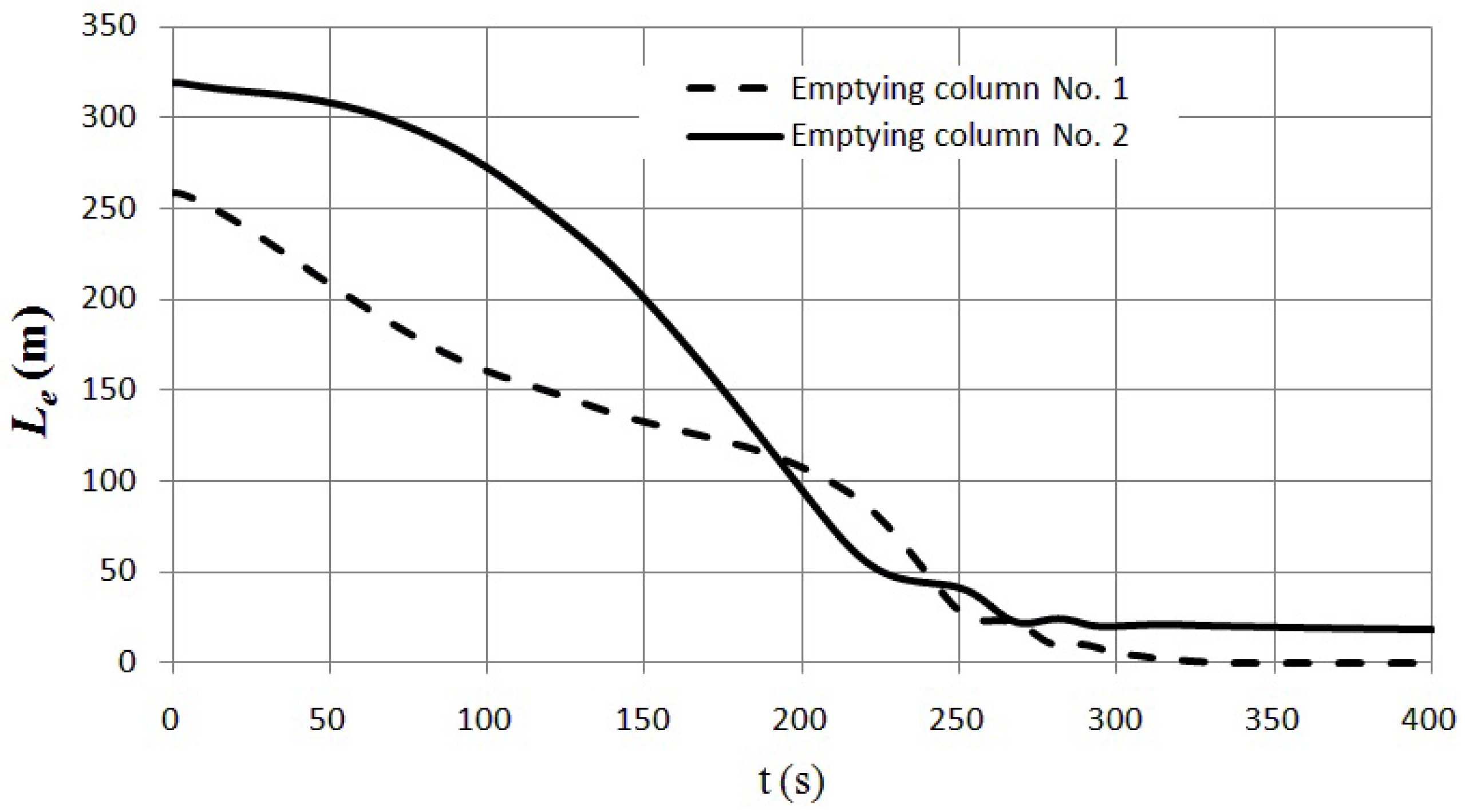

4.3. Water and Air Flow of Emptying Columns

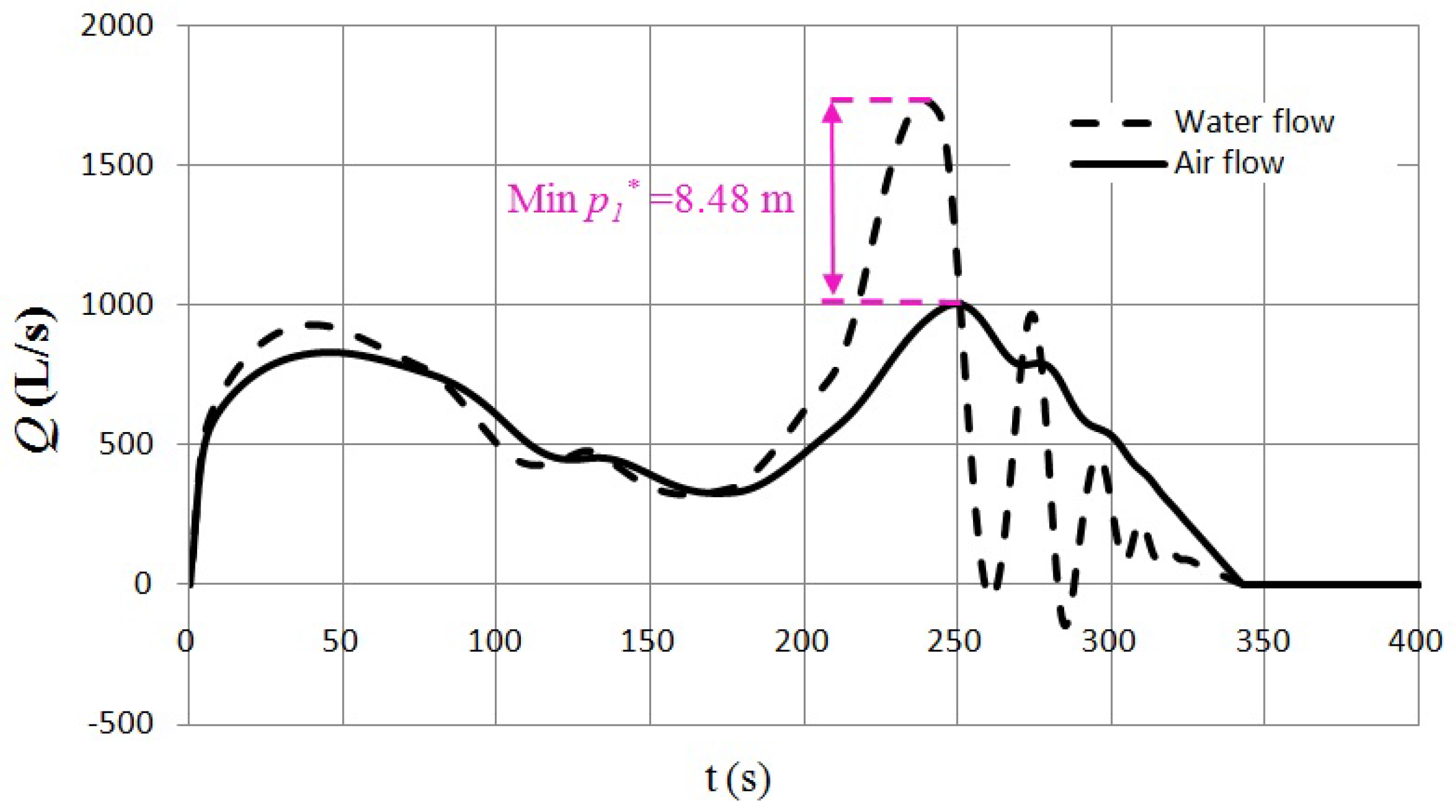

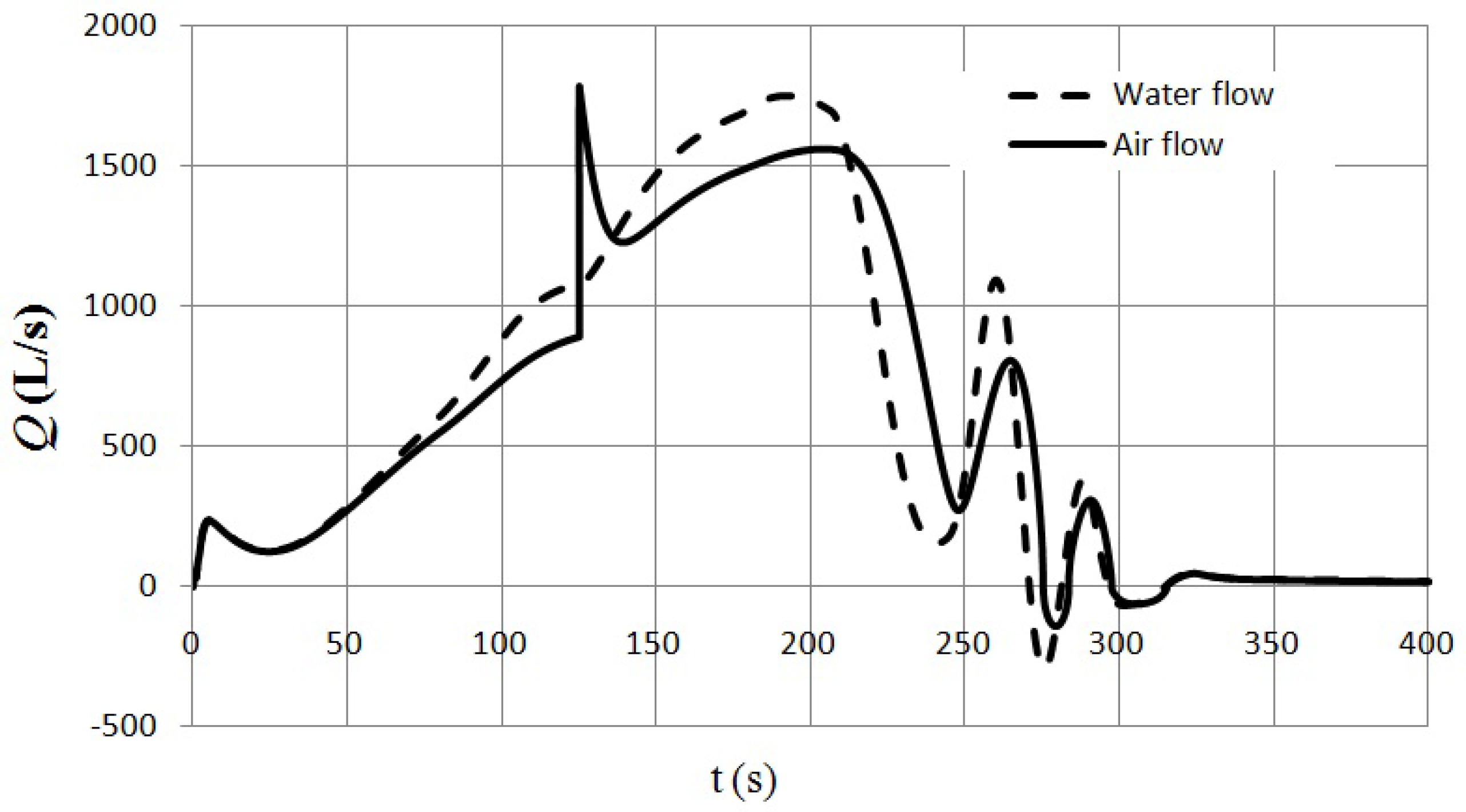

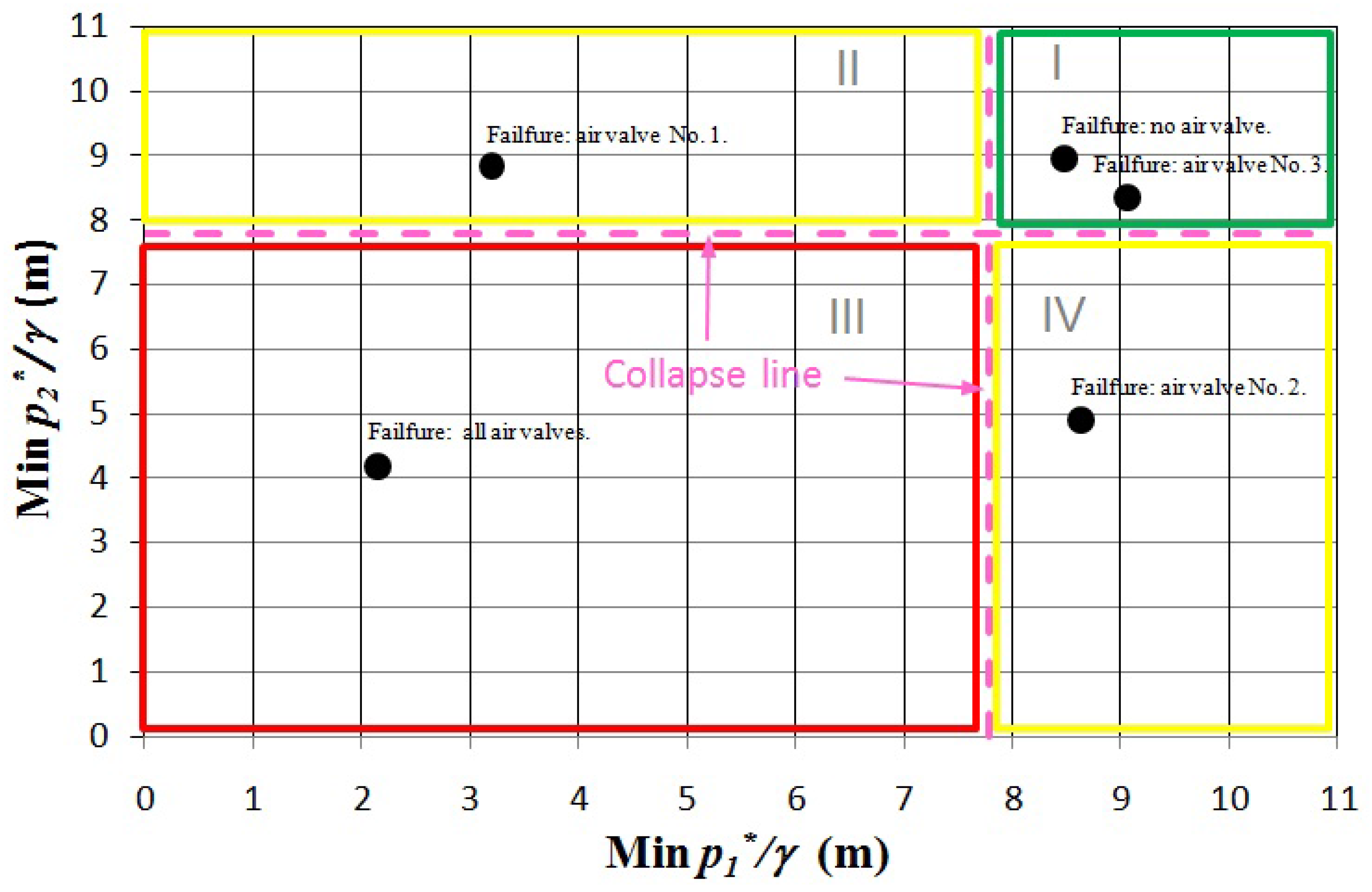

4.4. Risk of Pipeline Collapse

5. Conclusions

- The mathematical model can be used for computing air valve sizes, maneuvering drain valves, and knowing the drainage time of pipelines to prevent the collapse of the hydraulic system.

- The minimum value of sub-atmospheric pressure is one of the most critical situations during the emptying process, which is adequately predicted by the mathematical model.

- Air valves should be selected appropriately along the pipe systems admitting the required air to avoid sub-atmospheric pressure conditions. If air valves have not been well sized, then extreme negative pressures are reached, which can cause the collapse of pipe systems. The mathematical model can be used to check the air valves behaviour during the emptying maneuvers in actual installations.

- The Ciudad del Bicentenario pipeline can resist the minimum value of sub-atmospheric pressure showing that there is no risk of collapse since the total volume of admitted air is similar to the volume of drained water. Both air valve sizes and the maneuver of the gate valve were adequately designed, so they can be used to empty the pipeline without risk of collapse. Annual maintenance is required for the air valves located at the ends of the installation since a failure of these devices can cause the collapse of branch pipes according to the sensitivity analysis.

- Horizontal branches in pipelines are not recommended because part of the water column can remain inside of the installation and free surface flow is presented, generating a slow drainage of the system.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| A | cross-sectional area of pipe (m); |

| cross sectional area of the air valves (m); | |

| inflow discharge coefficient of the air valves (–); | |

| D | internal pipe diameter (m); |

| f | friction factor (–); |

| g | gravity acceleration (m/s); |

| and | length of emptying columns 1 and 2, respectively (m); |

| and | total length of pipes 1 and 2, respectively (m); |

| branch length (m); | |

| k | polytropic coefficient (–); |

| and | absolute pressure of air pockets 1 and 2, respectively (Pa); |

| atmospheric pressure (Pa); | |

| R | gas constant (J/kg/K); |

| resistance coefficient of the gate valve (s/m); | |

| t | time (s); |

| absolute temperature of the air (K) | |

| , , and | admitted air flow by air valves 1, 2, and 3, respectively (m/s); |

| and | water velocity of emptying columns 1 and 2, respectively (m/s); |

| and | air density of air pockets 1 and 2, respectively (kg/m); |

| air density in normal conditions (kg/m); | |

| water density (kg/m); | |

| and | difference elevation of water columns 1 and 2, respectively; |

| branch slope |

References

- Apollonio, C.; Balacco, G.; Fontana, N.; Giugni, M.; Marini, G.; Piccinni, A.F. Hydraulic Transients Caused by Air Expulsion During Rapid Filling of Undulating Pipelines. Water 2016, 8, 25. [Google Scholar] [CrossRef]

- Balacco, G.; Apollonio, C.; Piccinni, A.F. Experimental Analysis of Air Valve Behaviour During Hydraulic Transients. J. Appl. Water Eng. Res. 2015, 3, 3–11. [Google Scholar] [CrossRef]

- Izquierdo, J.; Fuertes, V.S.; Cabrera, E.; Iglesias, P.; García-Serra, J. Pipeline start-up with entrapped air. J. Hydraul. Res. 1999, 37, 579–590. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, D.; Karney, B. Investigation of hydraulic transients of two entrapped air pockets in a water pipeline. J. Hydraul. Eng. 2013, 139, 949–959. [Google Scholar] [CrossRef]

- Coronado-Hernández, O.E.; Fuertes-Miquel, V.S.; Besharat, M.; Ramos, H.M. Experimental and Numerical Analysis of a Water Emptying Pipeline Using Different Air Valves. Water 2017, 9, 98. [Google Scholar] [CrossRef]

- American Water Works Association (AWWA). Manual of Water Supply Practices—M51: Air-Release, Air-Vacuum, and Combination Air Valves; American Water Works Association: Denver, CO, USA, 2001. [Google Scholar]

- Ramezani, L.; Karney, B.; Malekpour, A. The Challenge of Air Valves: A Selective Critical Literature Review. J. Water Resour. Plan. Manag. 2015, 141, 10. [Google Scholar] [CrossRef]

- Covas, D.; Stoianov, I.; Ramos, H.M.; Graham, N.; Maksimović, C.; Butler, D. Water hammer in pressurized polyethylene pipes: Conceptual model and experimental analysis. Urban Water J. 2010, 1, 177–197. [Google Scholar] [CrossRef]

- Martins, S.C.; Ramos, H.M.; Almeida, A.B. Conceptual analogy for modelling entrapped air action in hydraulic systems. J. Hydraul. Res. 2015, 53, 678–686. [Google Scholar] [CrossRef]

- Pozos-Estrada, O.; Sánchez-Huerta, A.; Breña-Naranjo, J.; Pedrozo-Acuña, A. Failure analysis of a water supply pumping pipeline system. Water 2016, 8, 395. [Google Scholar] [CrossRef]

- Abreu, J.; Cabrera, E.; Izquierdo, J.; García-Serra, J. Flow Modeling in Pressurized Systmes Revisited. J. Hydraul. Eng. 1999, 125, 1154–1169. [Google Scholar] [CrossRef]

- Escarameia, M. Air Problems in Pipelines: A Design Manual; HR Wallingford Ltd.: Wallingford, UK, 2005. [Google Scholar]

- Wylie, E.; Streeter, V. Fluid Transients in Systems; Prentice Hall: Englewood Cliffs, NJ, USA, 1993. [Google Scholar]

- Bianchi, A.; Mambretti, S.; Pianta, P. Practical formulas for the dimensioning of air valves. J. Hydraul. Eng. 2007, 133, 1177–1180. [Google Scholar] [CrossRef]

- Fuertes-Miquel, V.S.; Coronado-Hernández, O.E.; Iglesias-Rey, P.L.; Mora-Melia, D. Transient phenomena during the emptying process of a single pipe with water-air interaction. J. Hydraul. Res. 2017. accepted. [Google Scholar]

- Ramezani, L.; Karney, B.; Malekpour, A. Encouraging Effective Air Management in Water Pipelines: A Critical Review. J. Water Resour. Plan. Manag. 2016, 142, 12. [Google Scholar] [CrossRef]

- Aguas de Cartagena. Construction drawing of the “Conducción agua potable Ciudad del Bicentenario Planta-Perfil K2+500.35 al K3+160.00”. 2013. [Google Scholar]

- Flowtite Technology. Product Guide—Amiantit Fiberglass Industries Limited (AFIL); Amiantit: Dammam, Saudi Arabia, 2008. [Google Scholar]

- Saint-Gobain. 612 Potable Water—Double Orifice Air Valve; Saint-Gobain Pam: Derbyshire, UK, 2009. [Google Scholar]

- Fuertes-Miquel, V.S.; López-Jiménez, P.A.; Martínez-Solano, F.J.; López-Patiño, G. Numerical modelling of pipelines with air pockets and air valves. Can. J. Civ. Eng. 2016, 43, 1052–1061. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, D.; Karney, B. Phenomenon of white mist in pipelines rapidly filling with water with entrapped air pocket. J. Hydraul. Eng. 2013, 139, 1041–1051. [Google Scholar] [CrossRef]

- Martin, C.S. Entrapped air in pipelines. In Proceedings of the Second International Conference on Pressure Surges; British Hydromechanics Research Association: London, UK, 1976. [Google Scholar]

- Graze, H.R.; Megler, V.; Hartmann, S. Thermodynamic behaviour of entrapped air in an air chamber. In Proceedings of the 7th International Conference on Pressure Surges and Fluid Transients in Pipelines and Open Channels; Boldy, A.P., Ed.; Mechanical Engineering Publications: New York, NY, USA, 1996; pp. 549–560. [Google Scholar]

- Leon, A.; Ghidaoui, M.; Schmidt, A.; Garcia, M. A robust two-equation model for transient-mixed flows. J. Hydraul. Res. 2010, 48, 44–56. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coronado-Hernández, O.E.; Fuertes-Miquel, V.S.; Angulo-Hernández, F.N. Emptying Operation of Water Supply Networks. Water 2018, 10, 22. https://doi.org/10.3390/w10010022

Coronado-Hernández OE, Fuertes-Miquel VS, Angulo-Hernández FN. Emptying Operation of Water Supply Networks. Water. 2018; 10(1):22. https://doi.org/10.3390/w10010022

Chicago/Turabian StyleCoronado-Hernández, Oscar E., Vicente S. Fuertes-Miquel, and Fredy N. Angulo-Hernández. 2018. "Emptying Operation of Water Supply Networks" Water 10, no. 1: 22. https://doi.org/10.3390/w10010022

APA StyleCoronado-Hernández, O. E., Fuertes-Miquel, V. S., & Angulo-Hernández, F. N. (2018). Emptying Operation of Water Supply Networks. Water, 10(1), 22. https://doi.org/10.3390/w10010022