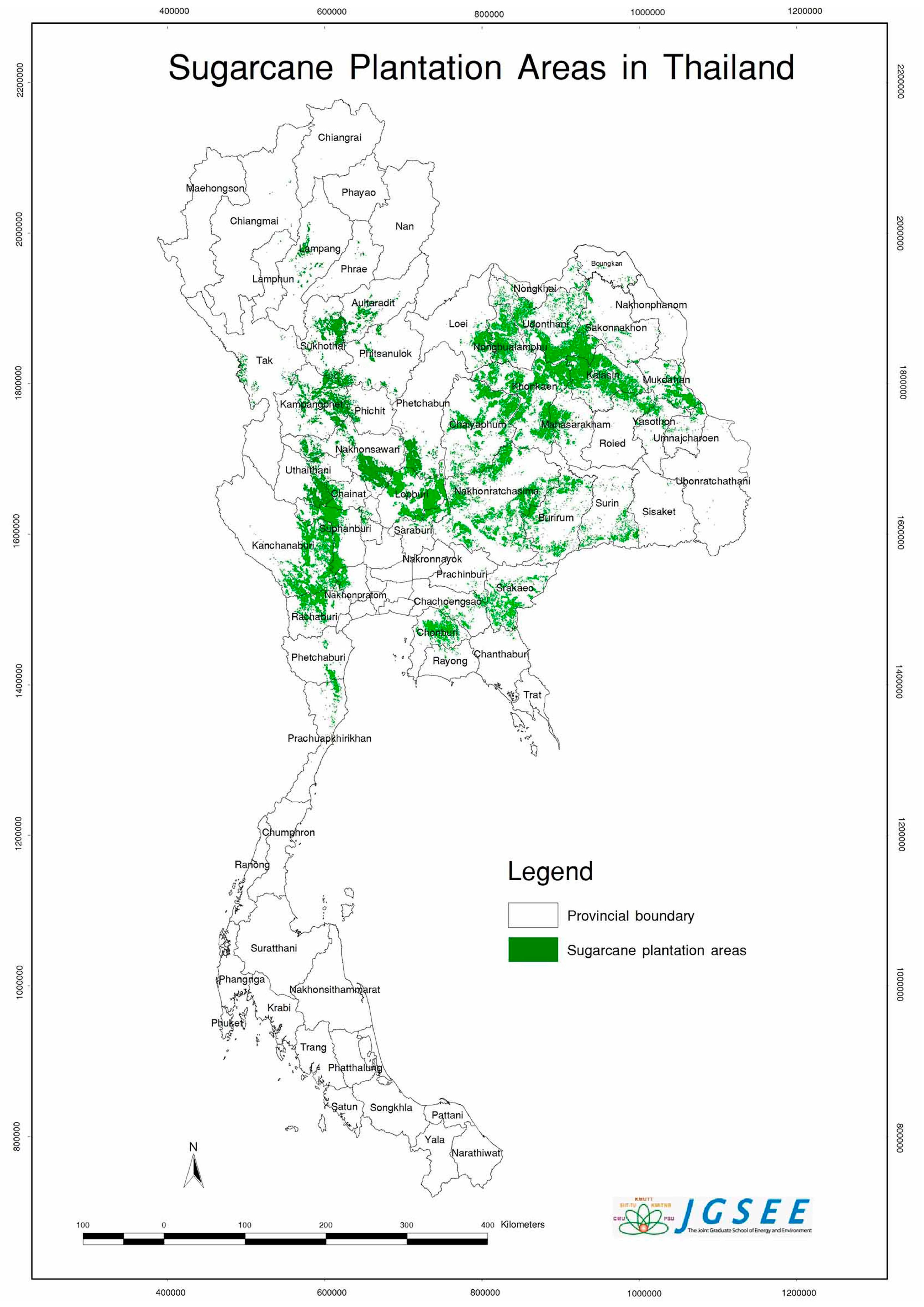

3.1. Sugarcane Biomass Fuel Load in Thailand

The moisture content of different components of the above-ground biomass of sugarcane, including, cane stalk, fresh leaves, dry leaves, and dead leaves of the top five sugarcane cultivars cultivated in Thailand, as collected from the no-burning and pre-harvest burning surveyed sites, is reported in

Table 2. The average value of cane stalk moisture content was found to be 72.13% on a wet weight basis. This is consistent with the work conducted in Puerto Rico by Alexander [

11], who reported stalk moisture content in the range of 70%–75% on net wet weight basis. From

Table 2, it is observed that fresh leaves represent the component of the plant that possesses the highest moisture content, with a mean value of 75.74%. On the other hand, the moisture content of dry and dead leaves are quite similar, although the dead leaves are slightly drier, with average fuel moisture content values of 12.30% and 9.83%, respectively. The low moisture content of these two components makes them a perfect fuel for burning, whether it is a pre-harvest or post-harvest one. Also, it is observed that the variation in moisture content of sugarcane biomass is directly influenced by the sugarcane cultivar and farming system, e.g., with or without irrigation, or plant or ratoon crop.

Table 2.

Moisture content of surveyed sugarcane biomass.

Table 2.

Moisture content of surveyed sugarcane biomass.

| Sites | Sugarcane Cultivars | Crop Class | Water Supply | Moisture Content (% wb) |

|---|

| Cane Stalks | Fresh Leaves | Dry Leaves | Ground Leaves |

|---|

| S1 | K 88-92 | Plant crop | no | 73.83 | 79.42 | 17.62 | 14.40 |

| S2 | LK 92-11 | 4th ratoon crop | Supplementary | 71.00 | 72.34 | 12.35 | 12.50 |

| S3 | Uthong 8 | 2nd ratoon crop | Full irrigation | 72.31 | 76.52 | 12.06 | 7.32 |

| S4 | Uthong 1 | 1st ratoon crop | no | 74.34 | 72.34 | 9.94 | 5.72 |

| S5 | Suphanburi 80 | 2nd ratoon crop | Supplementary | 72.50 | 76.40 | 10.00 | 7.00 |

| S6 | LK 92-11 | 2nd ratoon crop | Supplementary | 68.00 | 78.40 | 12.00 | 10.00 |

| S7 | LK 92-11 | Plant crop | Full irrigation | 72.95 | 74.80 | 12.16 | 11.86 |

| Mean | 72.13 | 75.74 | 12.30 | 9.83 |

| Standard error (SE) | 2.12 | 2.76 | 2.56 | 3.25 |

The RPR values collected from the 13 surveyed sites are summarized in

Table 3. They are in the range of 0.24–0.47 with a mean value of 0.37. This is close to the RPR value of 0.35 reported by Warcharapirak and Pattanakiat [

12] for sugarcane in Thailand. It should be noted that in the literature, this ratio varies largely within the range of 0.1–0.5. The main reasons for this variation are the variety of farming conditions and measurement techniques used [

4,

13,

14,

15,

16,

17,

18]. Based on observation from our experimental site survey, the variation in RPRs in this study is on large part due to the variety of crop cultivars (

Table 2), and to some extent to climatic conditions, number of ratoon crops and farming systems. The LK 92-11 cultivar possesses the highest RPRs and Suphanburi 80 the lowest (

Table 3). Also, the higher the number of ratoon crops is, the higher the RPR is, as demonstrated from the values determined for LK 92-11 cultivar.

Based on a sugarcane production of 98.40 Tg, on a fresh mass basis; this equivalent to 27.42 Tg on a dry mass basis as reported by the Office of Agricultural Economic (OAE) for 2012 [

1]; and a mean RPR value of 0.37, the quantity of sugarcane residues (

i.e., sugarcane biomass fuel) produced in 2012 was estimated. It was determined to amount to 10.15 Tg, on a dry mass basis, which corresponds to a sugarcane biomass fuel load of about 0.79 kg∙m

−2, on a dry mass basis. This result is within the range of values reported by other research studies in Thailand,

i.e., 0.47–1.72 kg∙m

−2 [

12,

18,

19]. It should be noted that the biomass fuel load found in this study is approximately 20% higher than the default value provided in the 2006 IPCC guidelines,

i.e., 0.65 kg∙m

−2 [

8].

Table 4 summarizes the amount of sugarcane biomass fuel estimated for the three regions and the whole country in 2012. The Northeast is the region where the harvesting area is the largest, and so the highest quantity of sugarcane residues is produced.

Table 3.

Sugarcane residue-to-product ratio (RPR) in Thailand in 2012.

Table 3.

Sugarcane residue-to-product ratio (RPR) in Thailand in 2012.

| Sites | Sugarcane Cultivars | Crop Class | Water Supply | Cane Yield | Sugarcane Residue | RPR |

|---|

| (kg∙m−2) | (kg∙m−2) |

|---|

| S1 | K 88-92 | Plant crop | no | 3.77 | 1.14 | 0.30 |

| S2 | LK 92-11 | 4th ratoon crop | Supplementary | 2.92 | 1.39 | 0.47 |

| S3 | Uthong 8 | 2nd ratoon crop | Full irrigation | 3.08 | 1.12 | 0.36 |

| S4 | Uthong 1 | 1st ratoon crop | no | 2.93 | 0.97 | 0.33 |

| S5 | Suphanburi 80 | 2nd ratoon crop | Supplementary | 2.21 | 0.53 | 0.24 |

| S6 | LK 92-11 | 2nd ratoon crop | Supplementary | 2.72 | 1.13 | 0.42 |

| S7 | LK 92-11 | Plant crop | Full irrigation | 3.05 | 1.14 | 0.38 |

| S8 | K 88-92 | Plant crop | no | 1.83 | 0.68 | 0.37 |

| S9 | LK 92-11 | 1st ratoon crop | Supplementary | 2.20 | 0.94 | 0.44 |

| S10 | K 92-77 | 2nd ratoon crop | Supplementary | 2.57 | 1.05 | 0.47 |

| S11 | K 88-92 | 2nd ratoon crop | no | 2.13 | 0.58 | 0.27 |

| S12 | Suphanburi 80 | 2nd ratoon crop | Supplementary | 2.12 | 0.50 | 0.24 |

| S13 | LK 92-11 | 3rd ratoon crop | Supplementary | 2.22 | 1.05 | 0.47 |

| Mean | | | 2.60 | 0.94 | 0.37 |

| Standard error (SE) | | | 0.54 | 0.28 | 0.09 |

Table 4.

Sugarcane harvesting areas and associated sugarcane biomass residues (Mg on dry mass basis) in Thailand in 2012.

Table 4.

Sugarcane harvesting areas and associated sugarcane biomass residues (Mg on dry mass basis) in Thailand in 2012.

| Regions | Harvesting Area * (ha) | Biomass Fuel (Mg) | Biomass Fuel Load (kg∙m−2) |

|---|

| Northern | 348,770 | 2,981,437 | 0.85 |

| Northeast | 518,395 | 3,836,985 | 0.74 |

| Central | 414,939 | 3,328,716 | 0.80 |

| Whole kingdom | 1,282,104 | 10,147,139 | 0.79 |

3.2. Combustion Factor from Sugarcane Field Open Burning

The combustion factors determined for the pre-harvest and post-harvest burning systems using the data collected from the 10 sites surveyed are detailed in

Table 5. It is observed that the mean value of the combustion factor of the pre-harvest burning system is lower than that of the post-harvest burning system,

i.e., 0.64

vs. 0.83. It is noted that for the post-harvest burning system, whether its purpose is to protect the ratoon for the regrowth or to assure soil preparation for new crop plantation, the average value of the combustion factor is the same, which confirms that the combustion factor depends mainly on the fuel characteristics and physical arrangement. For the case of the pre-harvest burning system, we also investigated the combustion factor of each component of the sugarcane biomass fuel, as detailed in

Table 6. Dead leaves are the component characterized by the highest combustion factor (mean = 0.93), followed by dry leaves (mean = 0.88) and fresh leaves (mean = 0.21). The overall mean value of 0.64 determined in this study for the pre-harvest burning system is about 25% lower than the default value of 0.80 recommended by the 2006 IPCC Guidelines. This seems to indicate that pre-harvest burning in Thailand is performed when the proportion of fresh leaves is still high comparatively to those reviewed by IPCC to establish the default value. It should be noted that the site-specific overall mean combustion factor of 0.83 of the post-harvest burning system cannot be compared to the IPCC default value because this latter is actually provided for the pre-harvest burning. From

Table 6, it can be noted that another parameter that may influence the combustion factor is the cultivar, especially regarding fresh leaves. Based on the data reported in

Table 6, it is observed that the water supply system for sugarcane cultivation does not affect the combustion factor.

Table 5.

Combustion factor vs. sugarcane field burning practice in Thailand.

Table 5.

Combustion factor vs. sugarcane field burning practice in Thailand.

| Burning Practice | Combustion Factors |

|---|

| Mean Value | SE |

|---|

| B1: Pre-harvest burning | 0.64 | 0.05 |

| B2: Post-harvest burning system for fire protection | 0.83 | 0.03 |

| B3: Post-harvest burning system for soil preparation | 0.83 | 0.04 |

Table 6.

Combustion factors of different fractions of sugarcane biomass residues burned in case of pre-harvest burning.

Table 6.

Combustion factors of different fractions of sugarcane biomass residues burned in case of pre-harvest burning.

| Sites | Combustion Factors |

|---|

| Fresh Leaves | Dry Leaves | Dead Leaves | Overall |

|---|

| S4 | 0.24 | 0.88 | 0.92 | 0.64 |

| S5 | 0.21 | 0.83 | 0.89 | 0.61 |

| S6 | 0.21 | 0.93 | 0.95 | 0.71 |

| S7 | 0.17 | 0.88 | 0.95 | 0.60 |

| Mean | 0.21 | 0.88 | 0.93 | 0.64 |

| Standard error (SE) | 0.02 | 0.05 | 0.03 | 0.05 |

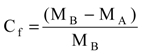

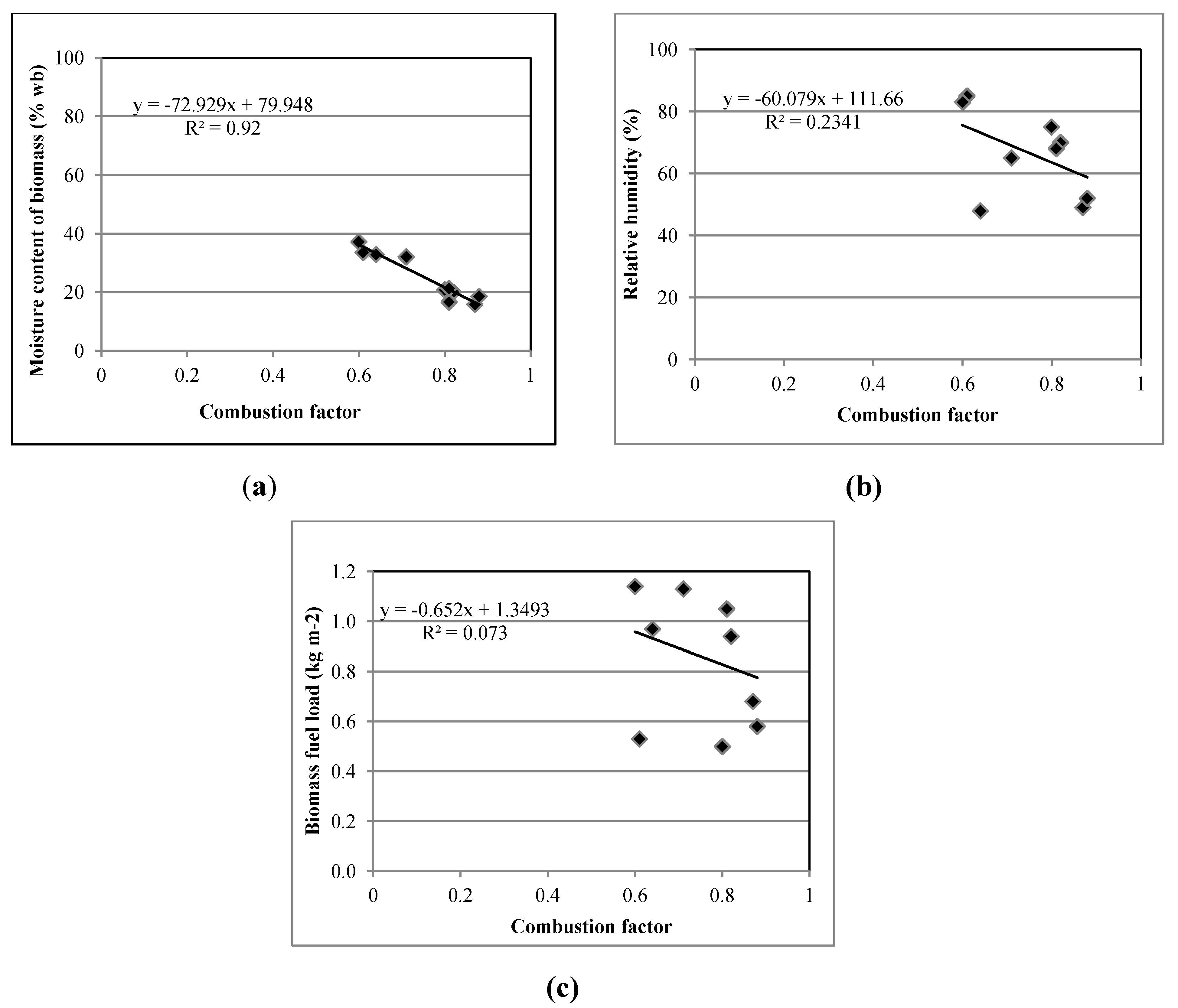

On the other hand, high variability of the combustion factor can be observed for all components and from one site to another. This underlines a certain relationship between combustion factor and biomass fuel moisture content. In order to investigate the variables that may influence the combustion factor, and consequently the combustion behavior and its associated emissions of pollutants, the combustion factor data were plotted

versus sugarcane biomass fuel moisture content, biomass fuel load, and atmospheric relative humidity (

Figure 3). It is observed that the combustion factor has a strong correlation with biomass fuel moisture content (R

2 = 0.92), confirming that fuel moisture content is the most significant variable influencing the combustion factor. Some correlation can be observed with relative humidity, but with much less significance (R

2 = 0.234). Finally, no significant relationship is found between the combustion factor and biomass fuel load.

In addition, it was observed from all the 13 site surveys that biomass fuel physical properties; such as fuel bed compactness, fuel bed arrangement, fuel bed bulk density, etc.; can significantly influence the combustion efficiency. It was found that fuel bed composed mainly of dry and dead leaves, i.e., low bulk density and compactness was burned efficiently, contributing to a high combustion factor. Also, in case of post-harvest burning, the residues resulting from manual harvesting were found to be easily ignited and burned, leading to a higher combustion factor, comparatively to those from mechanical harvesting. This observation may be explained by the difference in fuel bed arrangement: in case of manual harvesting, the residues possess a high surface-to-volume ratio, which is much lower than those from mechanical harvesting since these latter were shred into pieces before spreading onto the ground to form the fuel bed.

Figure 3.

Correlation between combustion factor and (a) biomass fuel moisture content; (b) atmospheric relative humidity; and (c) biomass fuel load.

Figure 3.

Correlation between combustion factor and (a) biomass fuel moisture content; (b) atmospheric relative humidity; and (c) biomass fuel load.

3.3. Estimation of Air Pollutant Emission Fluxes from Sugarcane Field Burning in Thailand

Using the data obtained in this study, for a sugarcane biomass fuel load of 0.79 kg∙m

−2 and combustion factor of 0.64 for the pre-harvest burning system and 0.83 for the post-harvest burning system, the amount of sugarcane biomass fuel consumed by fire in Thailand was determined to amount to 0.51 kg∙m

−2 and 0.66 kg∙m

−2 for each system, respectively. These results indicate that the consumption of sugarcane biomass fuel for the post-harvest burning system is 30% higher than the pre-harvest burning system. As a consequence, the intensity of air pollutant emissions from a post-harvest burning system is expected to be about 30% higher than from a pre-harvest burning system. As stated in the previous section, the default values provided by the 2006 IPCC Guidelines [

8]; with sugarcane biomass fuel load of 0.65 kg∙m

−2 and combustion factor of 0.80, leading to sugarcane biomass fuel consumption by fire of 0.52 kg∙m

−2; are recommended for pre-harvest burning. The value of sugarcane biomass fuel consumption determined in this study for the pre-harvest burning system is in good agreement with the value recommended by IPCC,

i.e., 0.51 kg∙m

−2 vs. 0.52 kg∙m

−2 (

Table 7).

Table 7.

Comparison of emission fluxes from sugarcane open burning estimated from default values of 2006 IPCC guidelines and results obtained in this study.

Table 7.

Comparison of emission fluxes from sugarcane open burning estimated from default values of 2006 IPCC guidelines and results obtained in this study.

| Pollutants | EF * (g∙kg−1) | Sugarcane Biomass Consumption (kg∙m−2) | Emissions (g∙m−2) |

|---|

| Using IPCC Default Values * | Using Results from This Study | Using IPCC Default Values * | Using Results from This Study |

|---|

| Pre-Harvest Burning | Post-Harvest Burning | Pre-Harvest Burning | Post-Harvest Burning |

|---|

| CO2 | 1515 | 0.52 | 0.51 | 0.66 | 787.80 | 765.98 | 993.39 |

| CO | 92 | 0.52 | 0.51 | 0.66 | 47.84 | 46.52 | 60.32 |

| CH4 | 2.7 | 0.52 | 0.51 | 0.66 | 1.40 | 1.37 | 1.77 |

| N2O | 0.07 | 0.52 | 0.51 | 0.66 | 0.04 | 0.04 | 0.05 |

| NOx | 2.5 | 0.52 | 0.51 | 0.66 | 1.30 | 1.26 | 1.64 |

Due to the absence of country-specific emission factors associated to sugarcane field burning in Thailand, default values recommended in the 2006 IPCC Guidelines [

8] were used. The obtained emission fluxes for key greenhouse gases are reported in

Table 7. As expected, the fluxes using IPCC default values and those estimated from the pre-harvest burning system biomass fuel consumption are very close,

i.e., with only 3% difference, while the emission fluxes in the case of the post-harvest burning system are 26% higher. This finding underlines the importance of using country-specific information concerning sugarcane field burning practices. Although pre-harvest burning is more frequently practiced and concerns larger plantation areas than post-harvest burning, using the IPCC recommended default values would significantly underestimate the overall emissions, as only pre-harvest burning would be considered. However, it should be pointed out that sugarcane plantations affected by post-harvest burning can only be tracked via site surveys, and consequently are difficult to find in official statistics, while areas subject to pre-harvest burning can be monitored using the amount of burned canes delivered to sugar mills. Because of this difficulty in evaluating the plantation areas subject to post-harvest burning for all sugarcane producing countries, the global emissions from sugarcane field burning are expected to be underestimated.