Influence of Particle Surface Energy and Sphericity on Filtration Performance Based on FLUENT-EDEM Coupling Simulation

Abstract

1. Introduction

2. Numerical Modeling

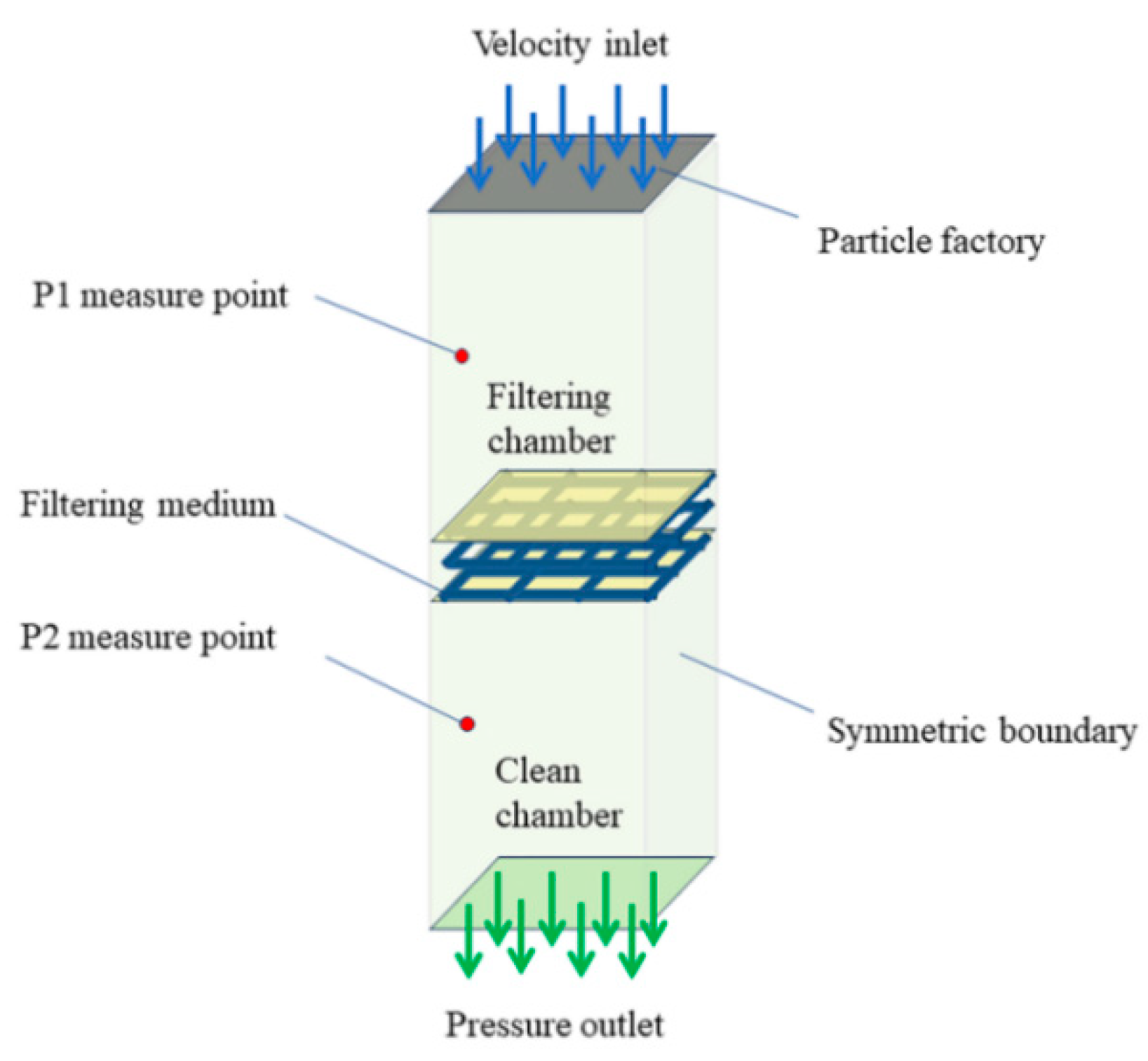

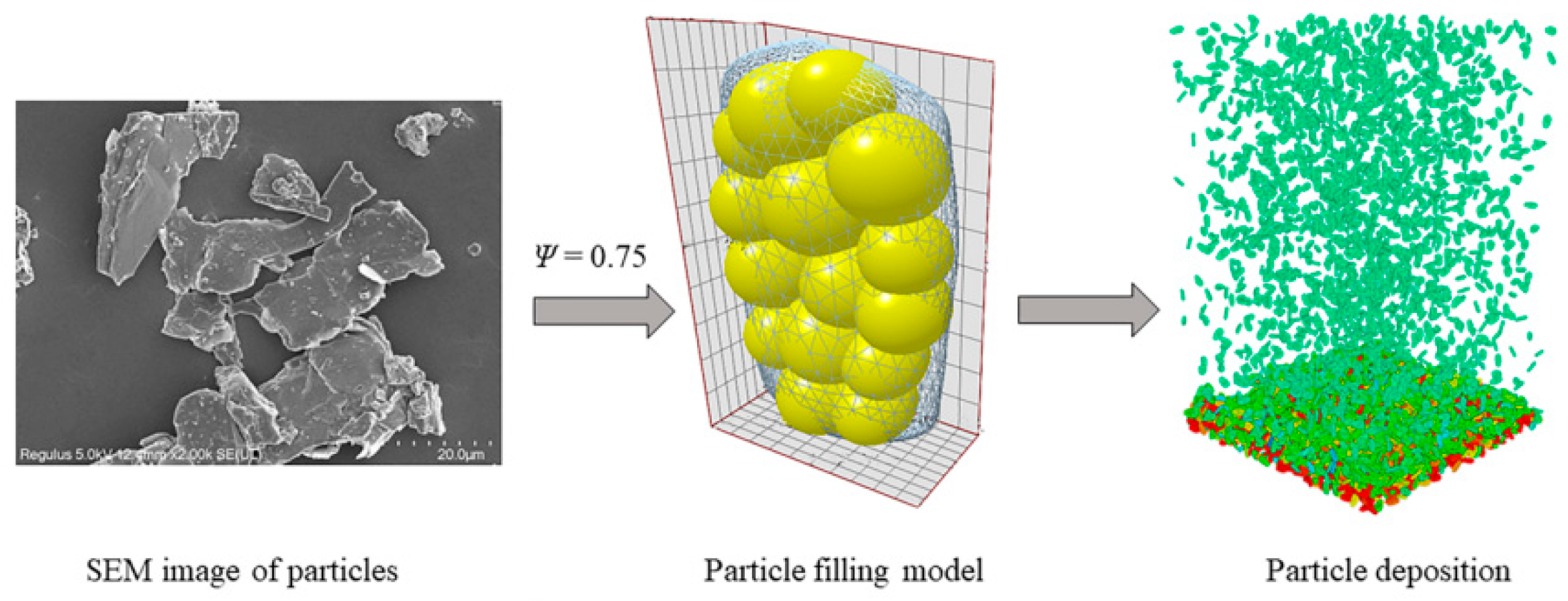

2.1. Filtration Model

2.2. Fluid–Particle Coupling Model

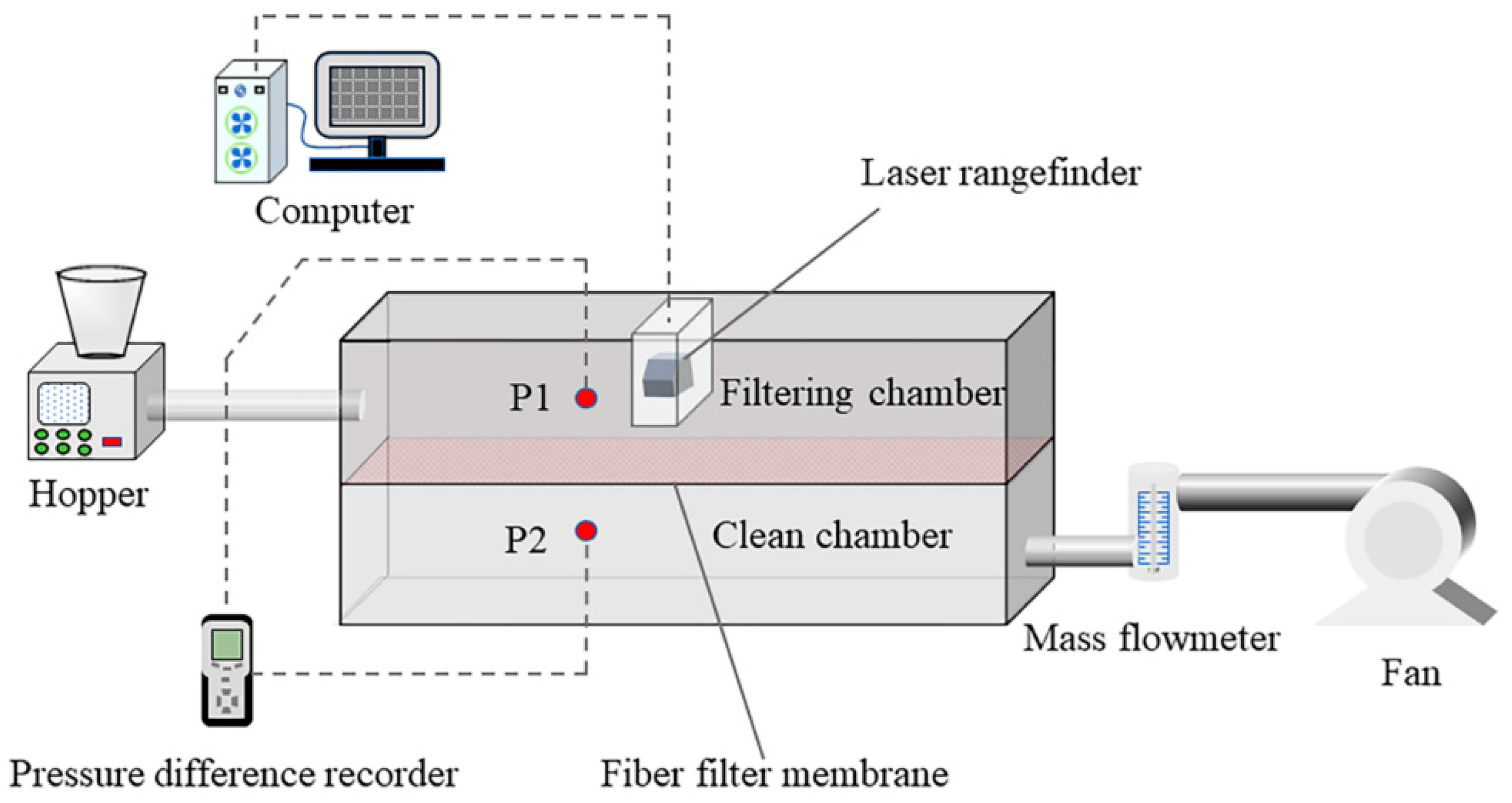

3. Experimental Validation

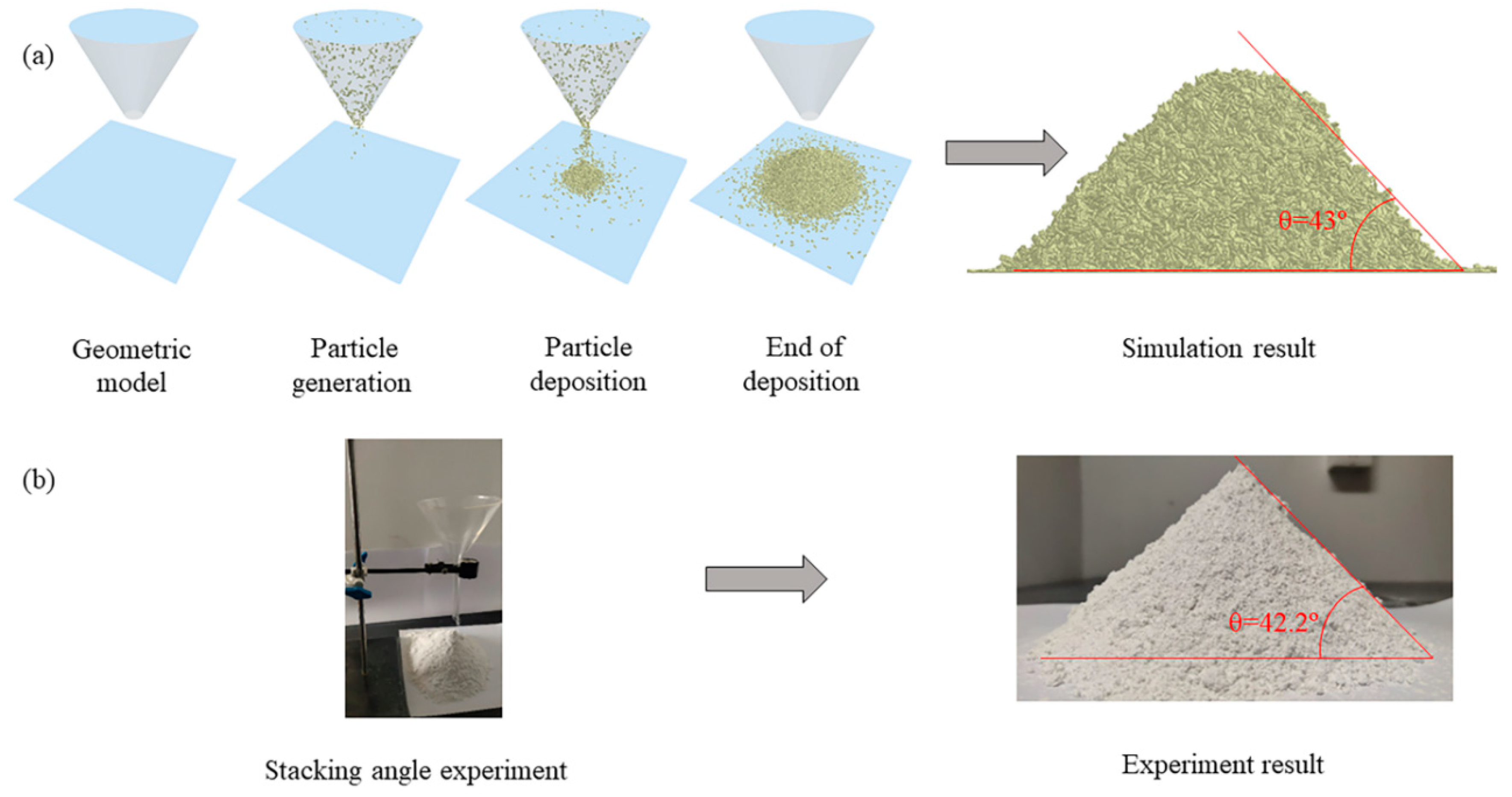

3.1. Validation of Stacking Angle Experiment

3.2. Validation of Filtration Experiment

- (1)

- Turn on the fan and adjust it to the set airflow.

- (2)

- Adjust the required airflow through the flowmeter and wait for the airflow to stabilize.

- (3)

- Turn on the laser rangefinder and pressure difference recorder, add dust to the hopper, and carry out the filtration experiment.

- (4)

- Monitor and measure the formed dust cake in real-time through the laser rangefinder, and record the pressure drop in real-time through the general pressure difference recorder.

4. Results and Discussion

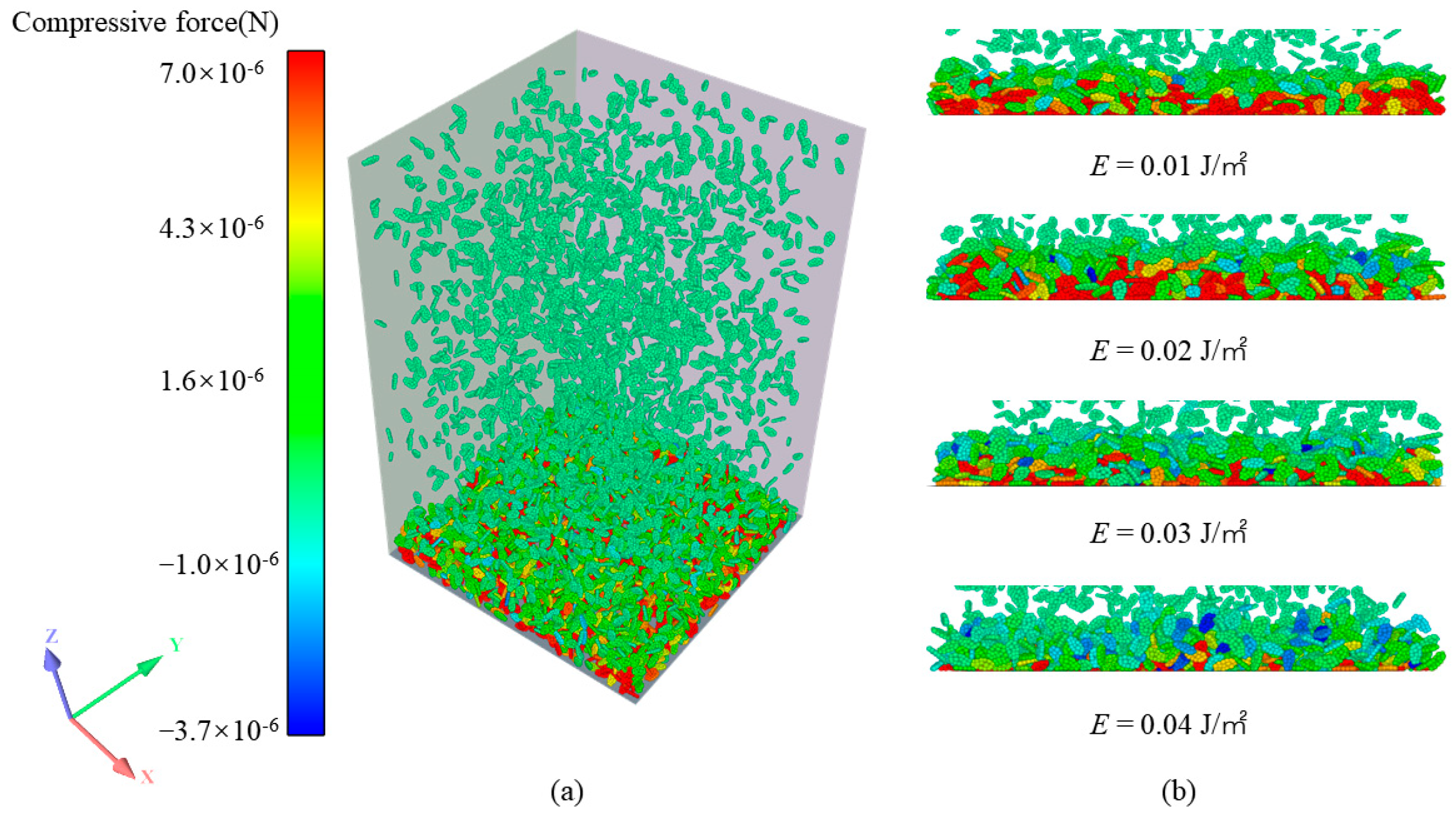

4.1. Filtration Deposition Morphology of Particles under the Different Surface Energies

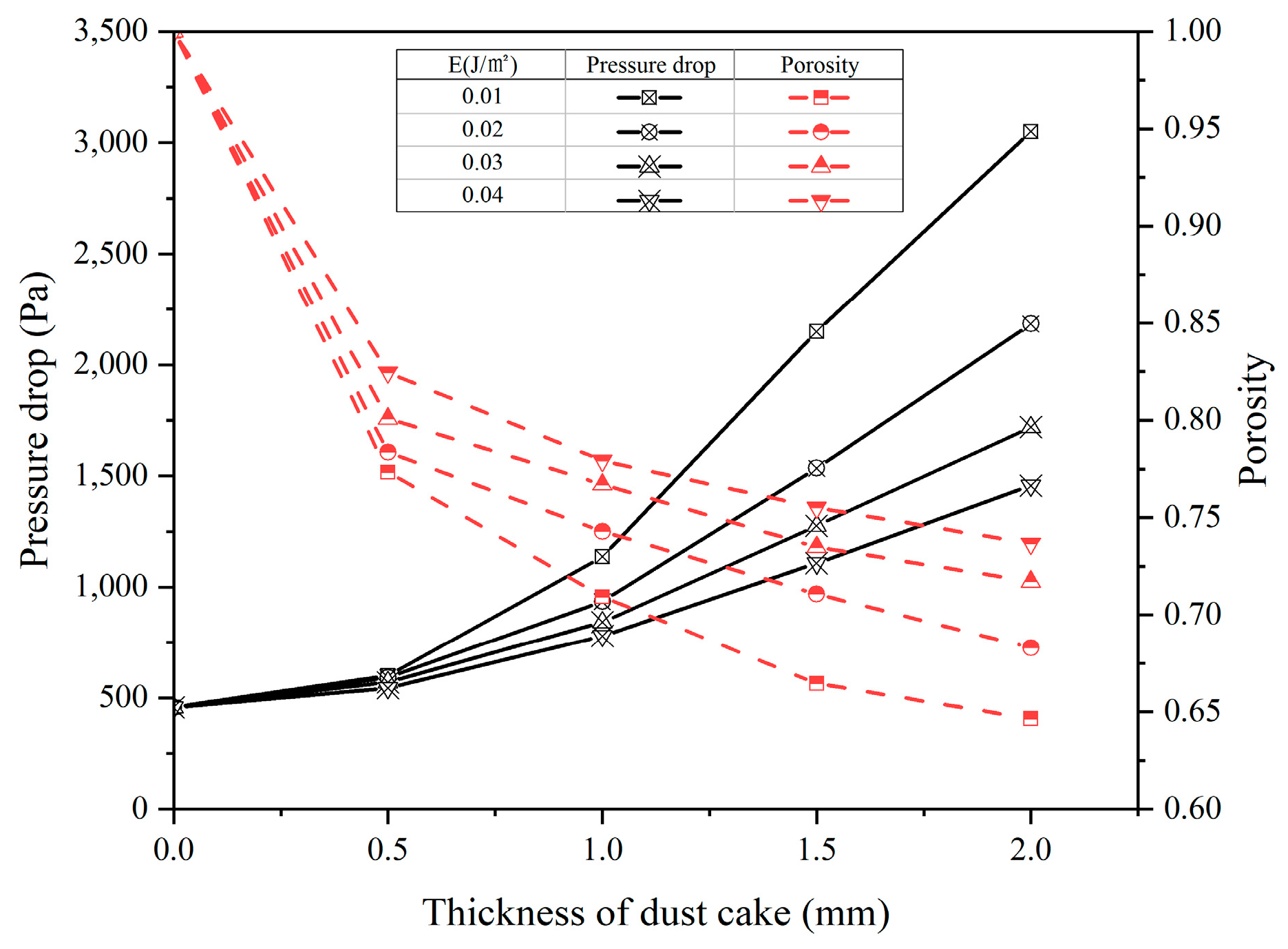

4.2. Effects of Different Particle Surface Energies on Filtration Performance

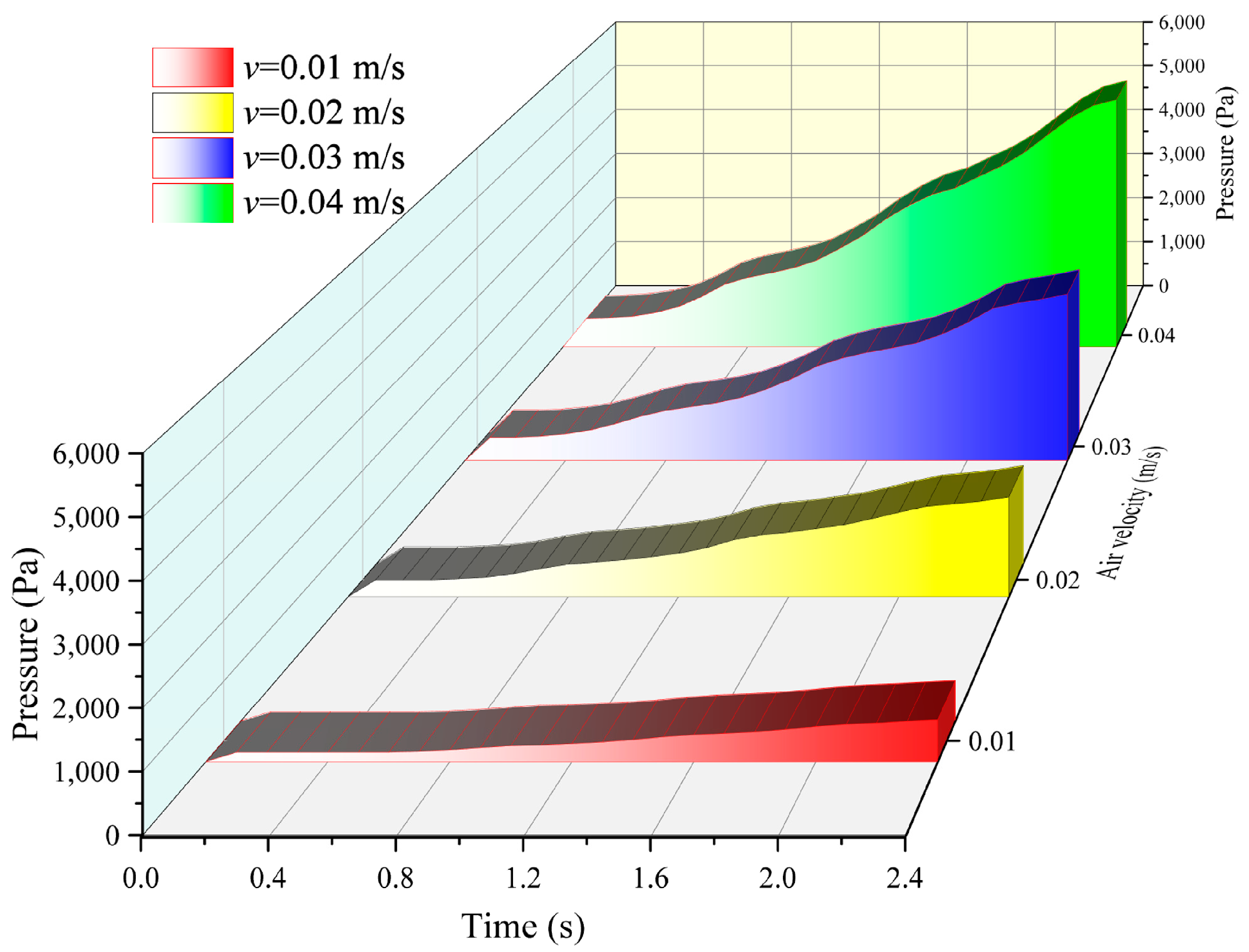

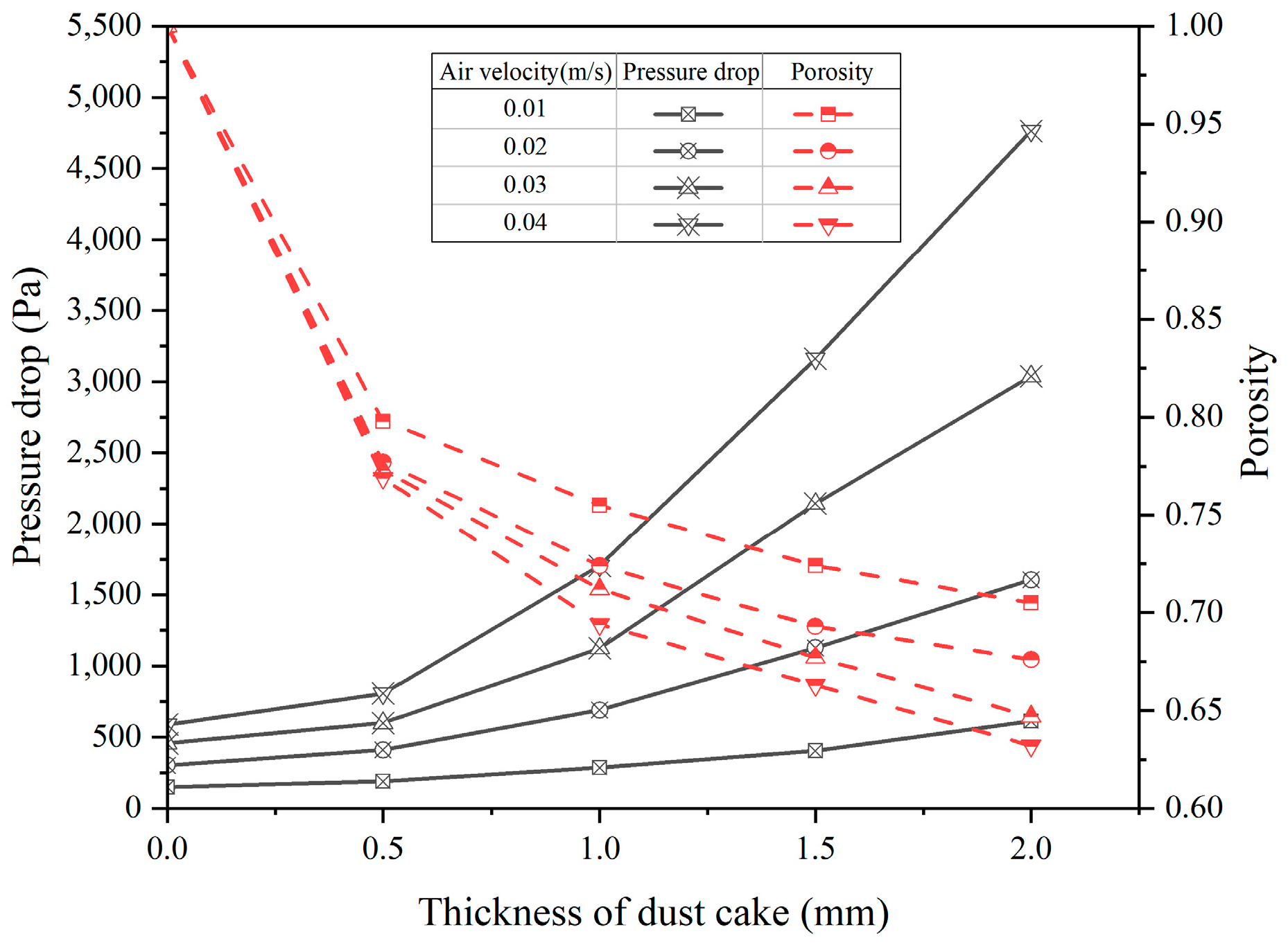

4.3. Effects of Different Filtration Air Velocities on Filtration Performance

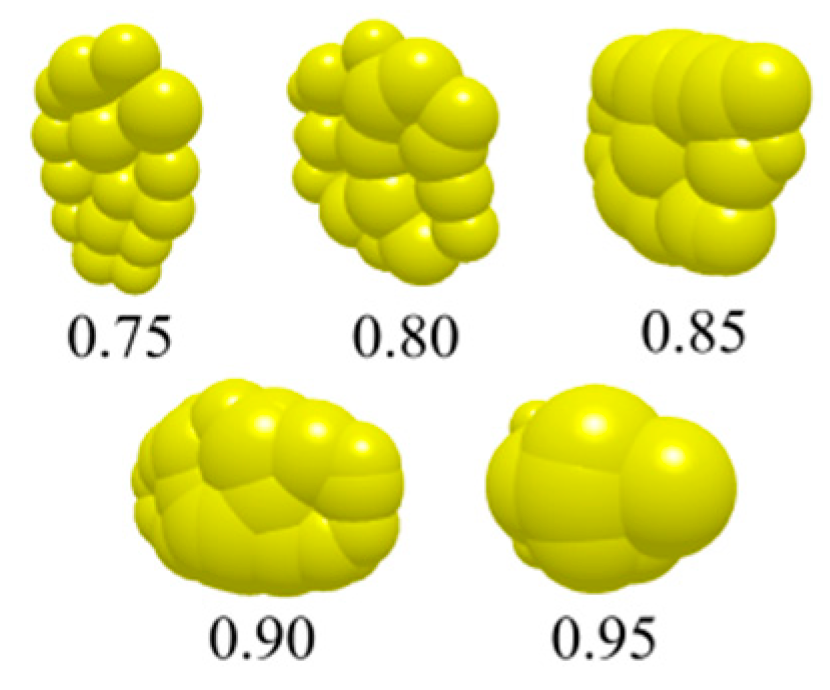

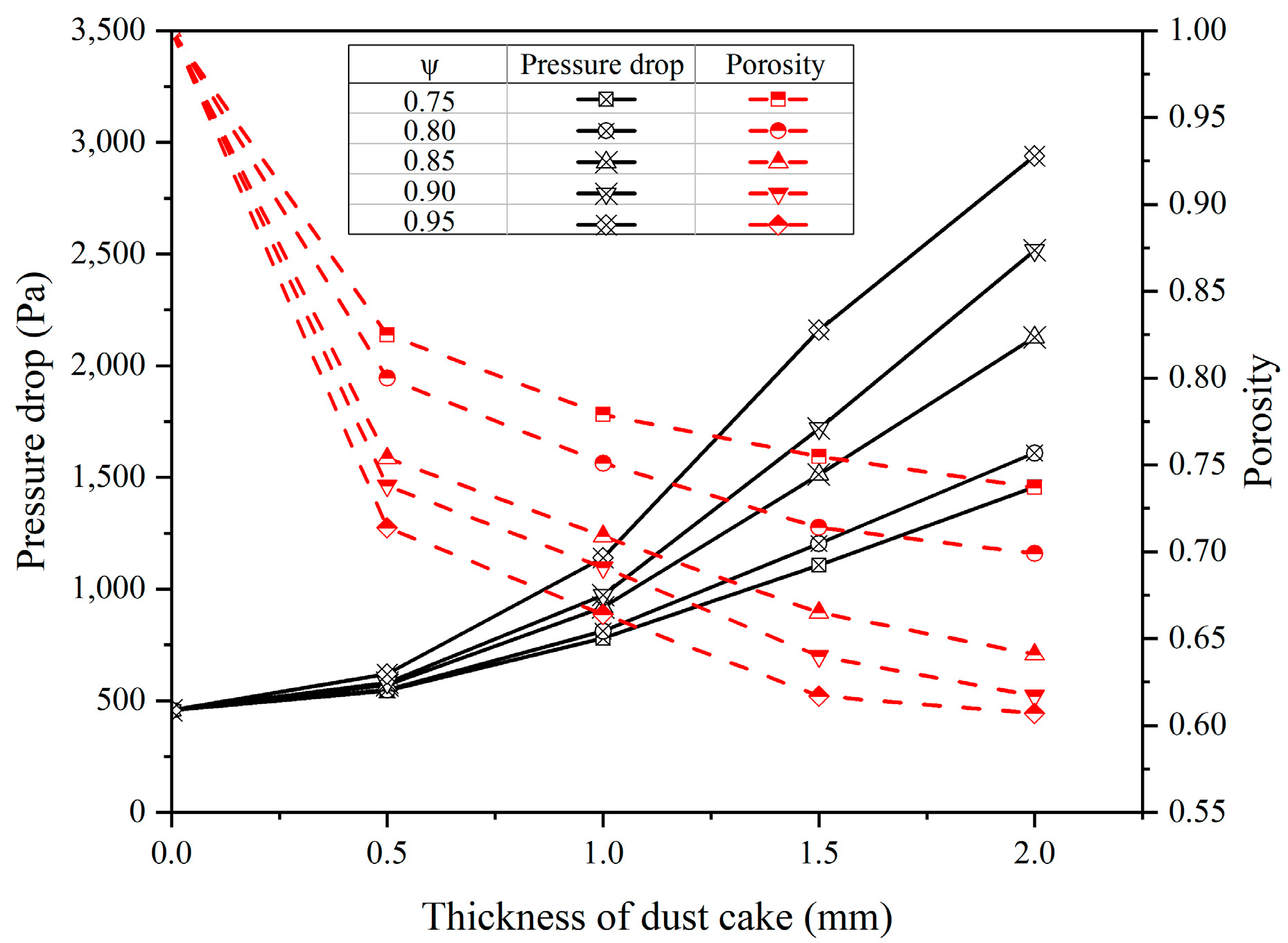

4.4. Effects of Different Particle Sphericities on Filtration Performance

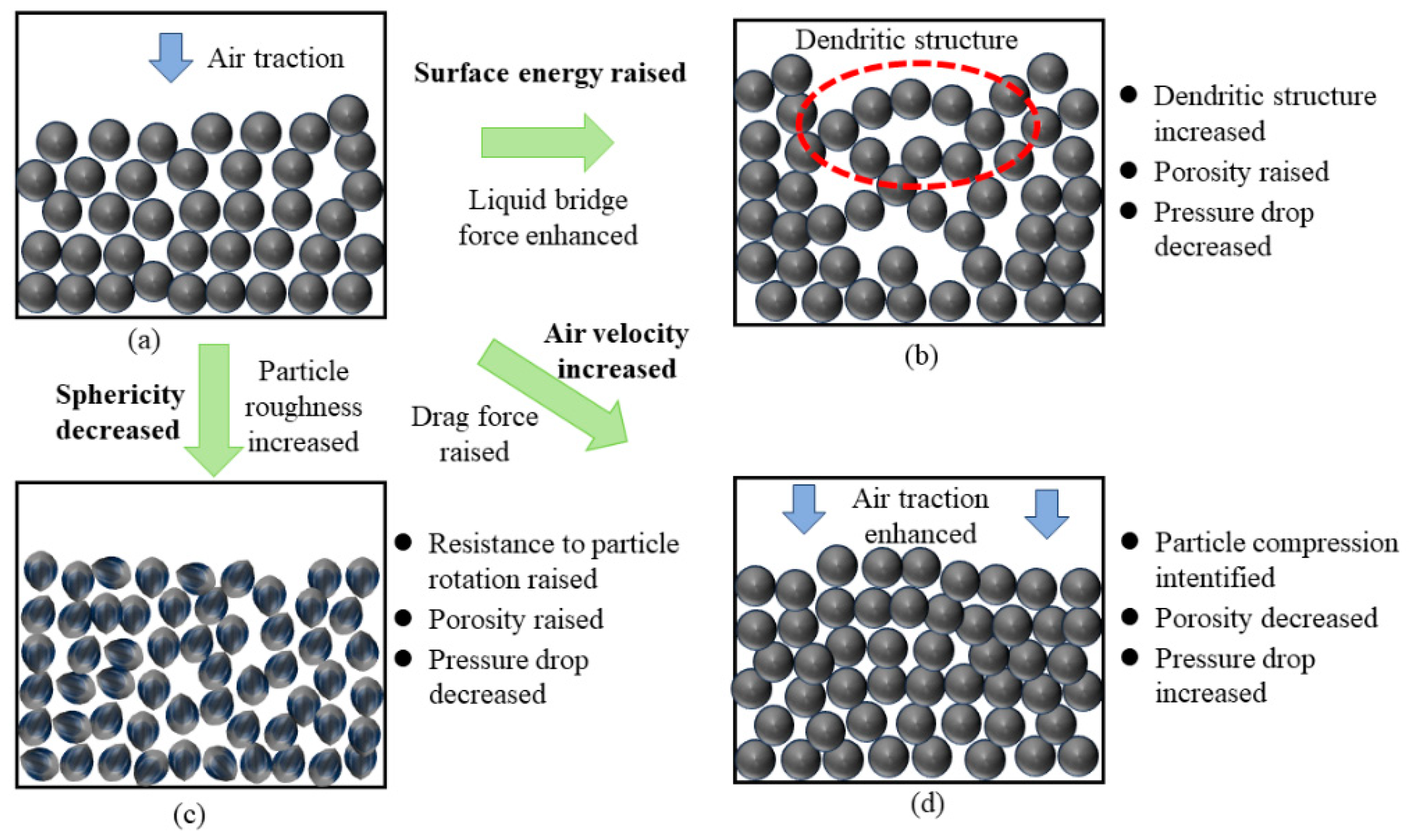

4.5. Analysis of Particle Deposition Mechanism under Different Influencing Factors

5. Conclusions

- (1)

- As the surface energy of the particles increases, the particles agglomerate into a dendritic structure, which can effectively buffer the pressure of the airflow, so that the number of particles under the same thickness is reduced. Therefore, the porosity of the dust cake increases with the increase in particle surface energy, and the pressure drop decreases with the increase in particle surface energy. At a dust cake thickness of 2 mm, with an increase in surface energy from 0.01 J/m2 to 0.04 J/m2, the porosity increased by 9.1% and the pressure drop decreased by 1594 Pa.

- (2)

- The increase in filtration air velocity leads to greater thrust on the particles by the airflow, which destroys adhesion between the particles, causing the dust cake to deposit faster and more densely. This results in a decrease in porosity and an increase in pressure drop. The filtration air velocity v increased from 0.01 m/s to 0.04 m/s, the porosity decreased by 7.3%, and the pressure drop increased by 4152 Pa. Therefore, for the removal of sticky particles, it is advisable to choose a low air velocity.

- (3)

- As the sphericity increases, the particles become smoother and create smaller pores between them, resulting in greater resistance as airflow passes through the dust cake. Consequently, there is an increase in pressure drop. When the sphericity increased from 0.75 to 0.95, the porosity decreased by 13% and the pressure drop increased by 1482 Pa. The greater the sphericity of particles under high surface energy, the more unfavorable to filtration performance.

- (4)

- Particle surface energy, sphericity, and velocity combine to filter particles. The effect of air velocity on particle filtration is the largest in terms of pressure results; however, it is more limited in industrial applications. The range of particle surface energy and sphericity is much larger, and the combined effect of both deserves attention. Their range can be increased in the future to further improve the experiments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, G.; Hu, J.; Chen, S. A review of dust control/removal methods in metal mines in china. Powder Technol. 2023, 430, 119035. [Google Scholar] [CrossRef]

- Eckhoff, R.K. Fighting dust explosion hazards in the process industries. J. Loss Prev. Process Ind. 2020, 67, 104225. [Google Scholar] [CrossRef]

- Yuan, Z.; Khakzad, N.; Khan, F.; Amyotte, P. Dust explosions: A threat to the process Industries. Process Saf. Environ. Prot. 2015, 98, 57–71. [Google Scholar] [CrossRef]

- Islas, A.; Fernández, A.R.; Betegón, C.; Martínez-Pañeda, E.; Pandal, A. Biomass Dust explosions: CFD simulations and venting experiments in a 1 m3 Silo. Process Saf. Environ. Prot. 2023, 176, 1048–1062. [Google Scholar] [CrossRef]

- Sun, Y.; Kinsela, A.S.; Waite, T.D. Elucidation of alveolar macrophage cell response to coal dusts: Role of ferroptosis in pathogenesis of coal workers’ pneumoconiosis. Sci. Total Environ. 2022, 823, 153727. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Lu, X.; Yu, B.; Zuo, L.; Wang, L.; Lei, K.; Fan, P.; Liang, T.; Rennert, T.; Rinklebe, J. Source-specific risk judgement and environmental impact of potentially ioxic elements in fine road dust from an integrated industrial city, north China. J. Hazard. Mater. 2023, 458, 131982. [Google Scholar] [CrossRef]

- Long, Z.; Zhu, H.; Bing, H.; Tian, X.; Wang, Z.; Wang, X.; Wu, Y. Contamination, sources and health risk of heavy metals in soil and dust from different functional areas in an industrial city of panzhihua city, southwest China. J. Hazard. Mater. 2021, 420, 126638. [Google Scholar] [CrossRef] [PubMed]

- Owais, M. Location strategy for traffic emission remote sensing monitors to capture the violated emissions. J. Adv. Transp. 2019, 2019, 6520818. [Google Scholar] [CrossRef]

- Qi, H.; Wang, J.; Gu, X.; Feng, L. Research progress on agglomeration mechanisms and fluidization behavior of cohesive particles. Chin. J. Process Eng. 2019, 19, 55–63. [Google Scholar]

- Pan, S.; Ma, J.; Liu, D.; Chen, X.; Liang, C. Theoretical and experimental insight into the homogeneous expansion of wet particles in a fluidized bed. Powder Technol. 2022, 397, 117016. [Google Scholar] [CrossRef]

- Ennis, B.; Li, J.; Tardos, G.; Pfeffer, R. The influence of viscosity on the strength of an axially strained pendular liquid bridge. Chem. Eng. Sci. 1990, 45, 3071–3088. [Google Scholar] [CrossRef]

- Liu, P.; LaMarche, C.Q.; Kellogg, K.M.; Leadley, S.; Hrenya, C.M. Cohesive grains: Bridging microlevel measurements to macrolevel flow behavior via surface roughness. AIChE J. 2016, 62, 3529–3537. [Google Scholar] [CrossRef]

- LaMarche, C.Q.; Leadley, S.; Liu, P.; Kellogg, K.M.; Hrenya, C.M. Method of quantifying surface roughness for accurate adhesive force predictions. Chem. Eng. Sci. 2017, 158, 140–153. [Google Scholar] [CrossRef]

- Shi, D.; Li, J.; Du, Y.; Wu, Q.; Huang, S.; Huang, H.; Wu, D. Influence of relative humidity on the characteristics of filter cake using particle flow code simulation. Atmosphere 2022, 13, 770. [Google Scholar] [CrossRef]

- Umer, M.; Siraj, M.S. DEM studies of polydisperse wet granular flows. Powder Technol. 2018, 328, 309–317. [Google Scholar] [CrossRef]

- Zhou, G.; Low, Z.-X.; Feng, S.; Zhang, F.; Zhong, Z.; Xing, W. Effect of relative humidity and dust moisture content on filtration performance of bag filter. Sep. Purif. Technol. 2022, 308, 122952. [Google Scholar] [CrossRef]

- Xue, Z.; Qian, F.; Zhu, J.; Dong, W.; Han, Y.; Lu, J. Numerical simulation of deposition characteristics for high moisture viscous particles on the surface of polytetrafluoroethylene microporous membrane filtration materials. Chin. J. Process Eng. 2020, 20, 521–530. [Google Scholar]

- Khirouni, N.; Charvet, A.; Thomas, D.; Bémer, D. Regeneration of dust filters challenged with metallic nanoparticles: Influence of atmospheric aging. Process Saf. Environ. Prot. 2020, 138, 1–8. [Google Scholar] [CrossRef]

- Maddineni, A.K.; Das, D.; Damodaran, R.M. Air-borne particle capture by fibrous filter media under collision effect: A CFD-based approach. Sep. Purif. Technol. 2018, 193, 1–10. [Google Scholar] [CrossRef]

- Shi, X.; Xie, F.; Ji, J.; Tian, Z.; Xu, C.; Sun, A. The collision behaviors of non-spherical regular particle-wall in three-dimensional space: Experimental investigation. Powder Technol. 2024, 434, 119387. [Google Scholar] [CrossRef]

- Nie, Z.; Huang, C.; Zhao, P.; Fang, C. Influence of the interparticle friction coefficient on the mechanical behaviour of breakable granular materials with realistic shape. Adv. Powder Technol. 2023, 34, 104223. [Google Scholar] [CrossRef]

- Han, J.; Shen, K.; Guo, Y.; Xiong, H.; Lin, J. Discrete element simulations of flexible ribbon-like particles. Powder Technol. 2023, 429, 118950. [Google Scholar] [CrossRef]

- Srivastava, A.; Nigam, K.D.P.; Roy, S. Quantification of local structure of disordered packing of spherical particles. Chem. Eng. J. 2019, 377, 119771. [Google Scholar] [CrossRef]

- Lu, L.; Konan, A.; Benyahia, S. Influence of grid resolution, parcel size and drag models on bubbling fluidized bed simulation. Chem. Eng. J. 2017, 326, 627–639. [Google Scholar] [CrossRef]

- Eshraghi, H.; Amani, E.; Saffar-Avval, M. Coarse-graining algorithms for the Eulerian-Lagrangian simulation of particle-laden flows. J. Comput. Phys. 2023, 493, 112461. [Google Scholar] [CrossRef]

- Lu, L.; Gao, X.; Shahnam, M.; Rogers, W.A. Bridging particle and reactor scales in the simulation of biomass fast pyrolysis by coupling particle resolved simulation and coarse grained CFD-DEM. Chem. Eng. Sci. 2020, 216, 115471. [Google Scholar] [CrossRef]

- Jiang, Z.; Rai, K.; Tsuji, T.; Washino, K.; Tanaka, T.; Oshitani, J. Upscaled DEM-CFD model for vibrated fluidized bed based on particle-scale similarities. Adv. Powder Technol. 2020, 31, 4598–4618. [Google Scholar] [CrossRef]

- Ye, Y.; Xu, J.; Ge, W. Soft coarse-grained particle model for particle-fluid systems. Particuology. 2024, 84, 178–193. [Google Scholar] [CrossRef]

- Norouzi, H.R.; Reza, Z.; Rahmat, S.; Navid, M. Coupled Cfd-Dem Modeling: Fomulation, Implementation and Applications to Multiphase Flows; John Wiley & Sons: Chichester, UK, 2016. [Google Scholar]

- Sousani, M.; Hobbs, A.M.; Anderson, A.; Wood, R. Accelerated heat transfer simulations using coupled DEM and CFD. Powder Technol. 2019, 357, 367–376. [Google Scholar] [CrossRef]

- Ozel, A.; Gu, Y.; Milioli, C.C.; Kolehmainen, J.; Sundaresan, S. Towards filtered drag force model for non-cohesive and cohesive particle-gas flows. Phys. Fluids 2017, 29, 103308. [Google Scholar] [CrossRef]

- Khalloufi, M.; Capecelatro, J. Drag force of compressible flows past random arrays of spheres. Int. J. Multiph. Flow 2023, 165, 104496. [Google Scholar] [CrossRef]

- Hærvig, J.; Kleinhans, U.; Wieland, C.; Spliethoff, H.; Jensen, A.L.; Sørensen, K.; Condra, T.J. On the adhesive JKR contact and rolling models for reduced particle stiffness discrete element simulations. Powder Technol. 2017, 319, 472–482. [Google Scholar] [CrossRef]

- Baran, O.; DeGennaro, A.; Ramé, E.; Wilkinson, A.; Nakagawa, M.; Luding, S. DEM simulation of a schulze ring shear tester. In Proceedings of the AIP Conference Proceedings; AIP: Golden, CO, USA, 2009; pp. 409–412. [Google Scholar]

- Pedrolli, L.; Nadimi, S.; Maramizonouz, S.; Achiaga Menor, B.; López, A. Kinetic adhesion test to determine particle surface energy. HardwareX 2023, 14, e00437. [Google Scholar] [CrossRef] [PubMed]

- Moreno Baqueiro Sansao, B.; Kellar, J.J.; Cross, W.M.; Schottler, K.; Romkes, A. Comparison of surface energy and adhesion energy of surface-treated particles. Powder Technol. 2021, 384, 267–275. [Google Scholar] [CrossRef]

- Ma, X.; Wang, W.; Qiu, Y. Numerical simulation of dispersion of adhesive particulate agglomerates in the shear flow field. China Plast. Ind. 2019, 47, 45–48. [Google Scholar]

| Material | Density (kg/m3) | Diameter (μm) | Poisson’s Ratio | Shear Modulus (MPa) |

|---|---|---|---|---|

| 1250-mesh talcum powder | 2700 | 10 | 0.21 | 1 |

| Stainless steel 316 | 7980 | 2.7 | 0.29 | 8.2 × 104 |

| Material | Coefficient of Restitution | Coefficient of Static Friction | Coefficient of Kinetic Friction | Surface Energy (J/m2) |

|---|---|---|---|---|

| Particle–particle | 0.1 | 0.5 | 0.01 | 1 × 10−4 |

| Particle–fiber | 0.15 | 0.5 | 0.01 | 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Q.; Xing, Z.; Chen, D.; Chen, J.; Yang, B.; Zhong, J.; Huang, H.; Ma, Z.; Huang, S.; You, D.; et al. Influence of Particle Surface Energy and Sphericity on Filtration Performance Based on FLUENT-EDEM Coupling Simulation. Atmosphere 2024, 15, 787. https://doi.org/10.3390/atmos15070787

Wu Q, Xing Z, Chen D, Chen J, Yang B, Zhong J, Huang H, Ma Z, Huang S, You D, et al. Influence of Particle Surface Energy and Sphericity on Filtration Performance Based on FLUENT-EDEM Coupling Simulation. Atmosphere. 2024; 15(7):787. https://doi.org/10.3390/atmos15070787

Chicago/Turabian StyleWu, Qing, Zhenqiang Xing, Dejun Chen, Jianwu Chen, Bin Yang, Jianfang Zhong, Hong Huang, Zhifei Ma, Shan Huang, Da You, and et al. 2024. "Influence of Particle Surface Energy and Sphericity on Filtration Performance Based on FLUENT-EDEM Coupling Simulation" Atmosphere 15, no. 7: 787. https://doi.org/10.3390/atmos15070787

APA StyleWu, Q., Xing, Z., Chen, D., Chen, J., Yang, B., Zhong, J., Huang, H., Ma, Z., Huang, S., You, D., Li, J., & Wu, D. (2024). Influence of Particle Surface Energy and Sphericity on Filtration Performance Based on FLUENT-EDEM Coupling Simulation. Atmosphere, 15(7), 787. https://doi.org/10.3390/atmos15070787