A Study on Monitoring and Supervision of Ship Nitrogen-Oxide Emissions and Fuel-Sulfur-Content Compliance

Abstract

1. Introduction

2. Research Methods

2.1. Online Empirical Test of Models

2.2. Derivation of the Calculation Model for Ship NOx-Emission Intensity

2.3. Derivation of the Calculation Model of Sulfur Content in Ship Fuel

3. Results and Discussion

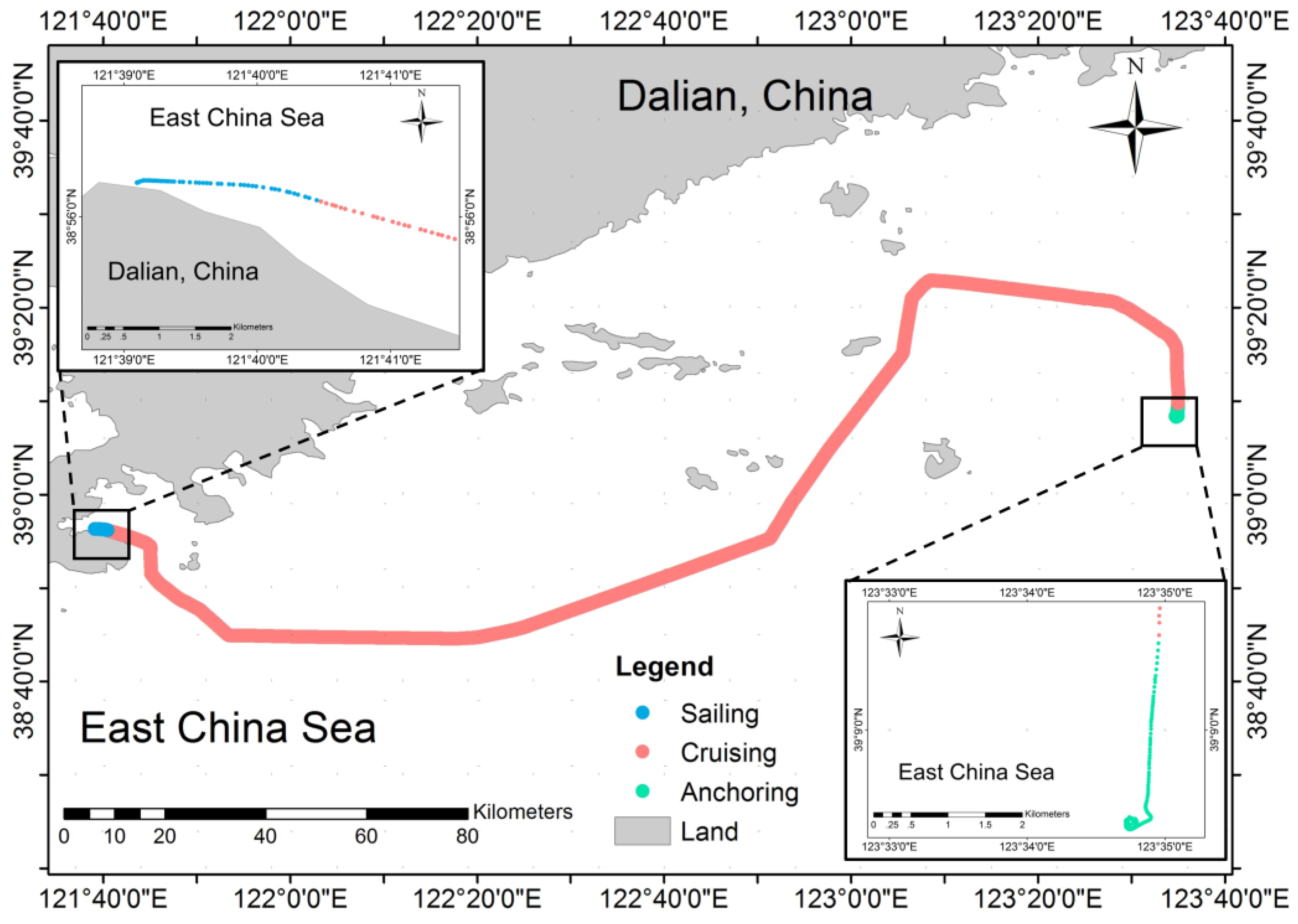

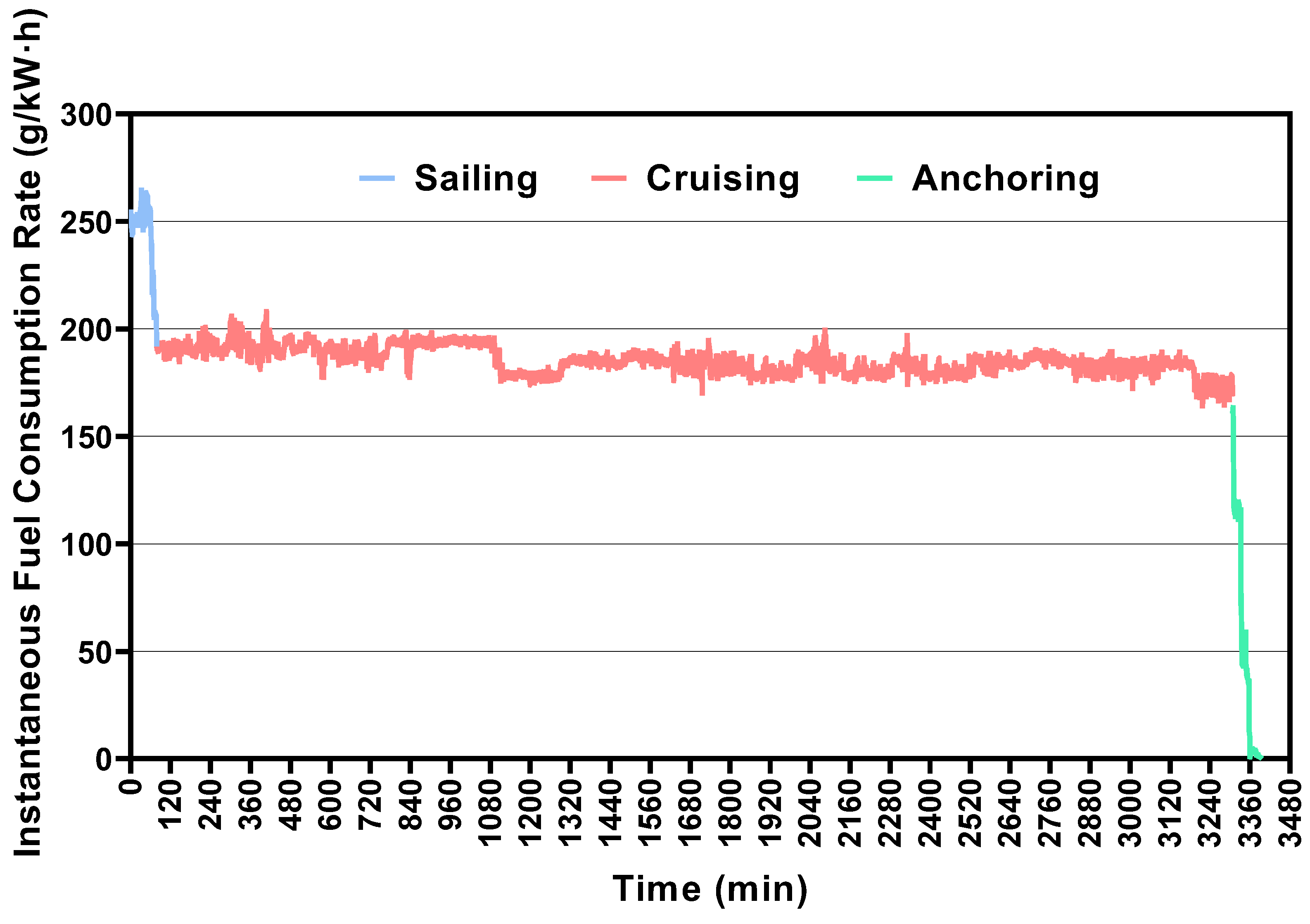

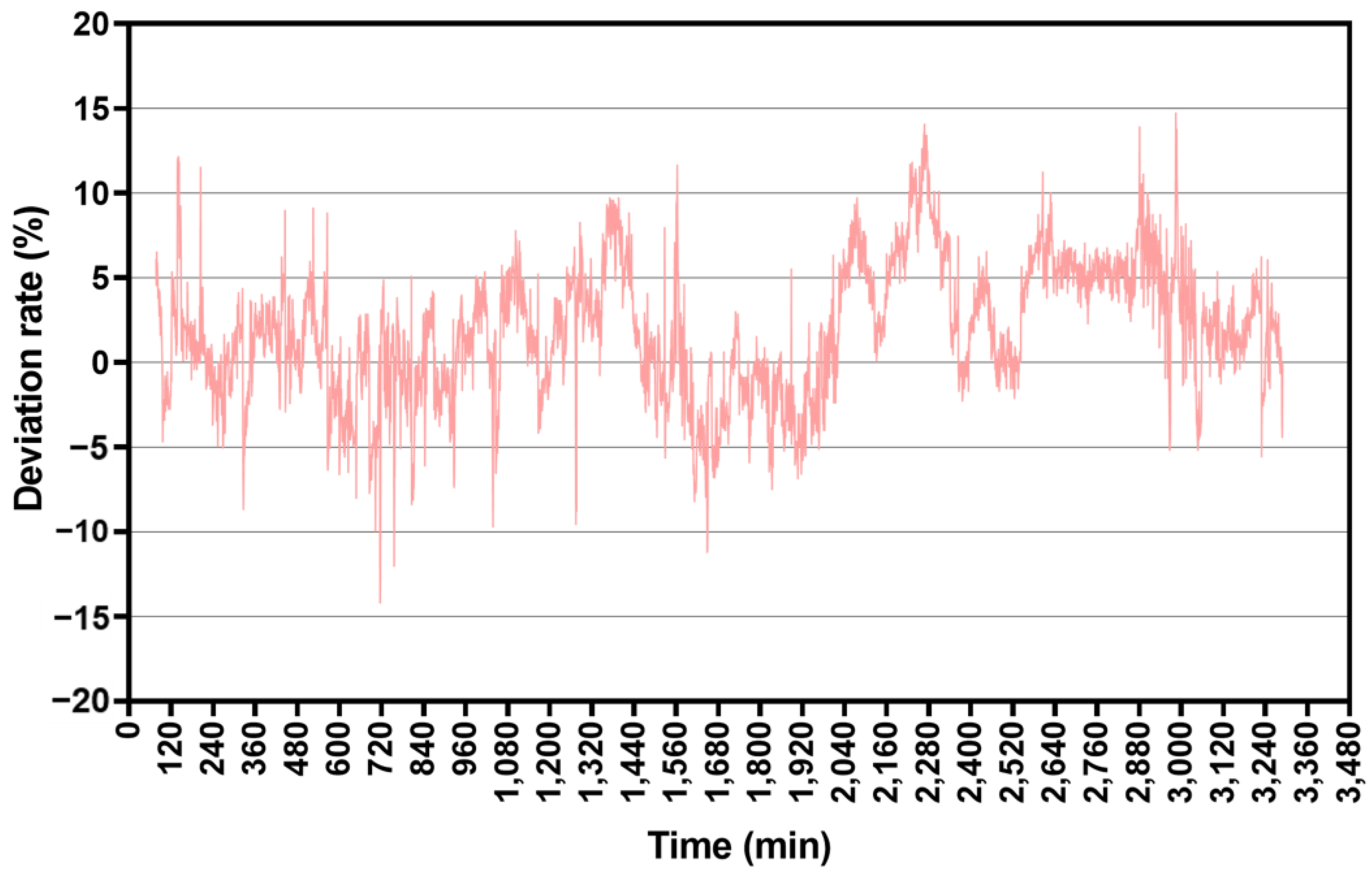

3.1. The Online Measurements for Voyaging Ships

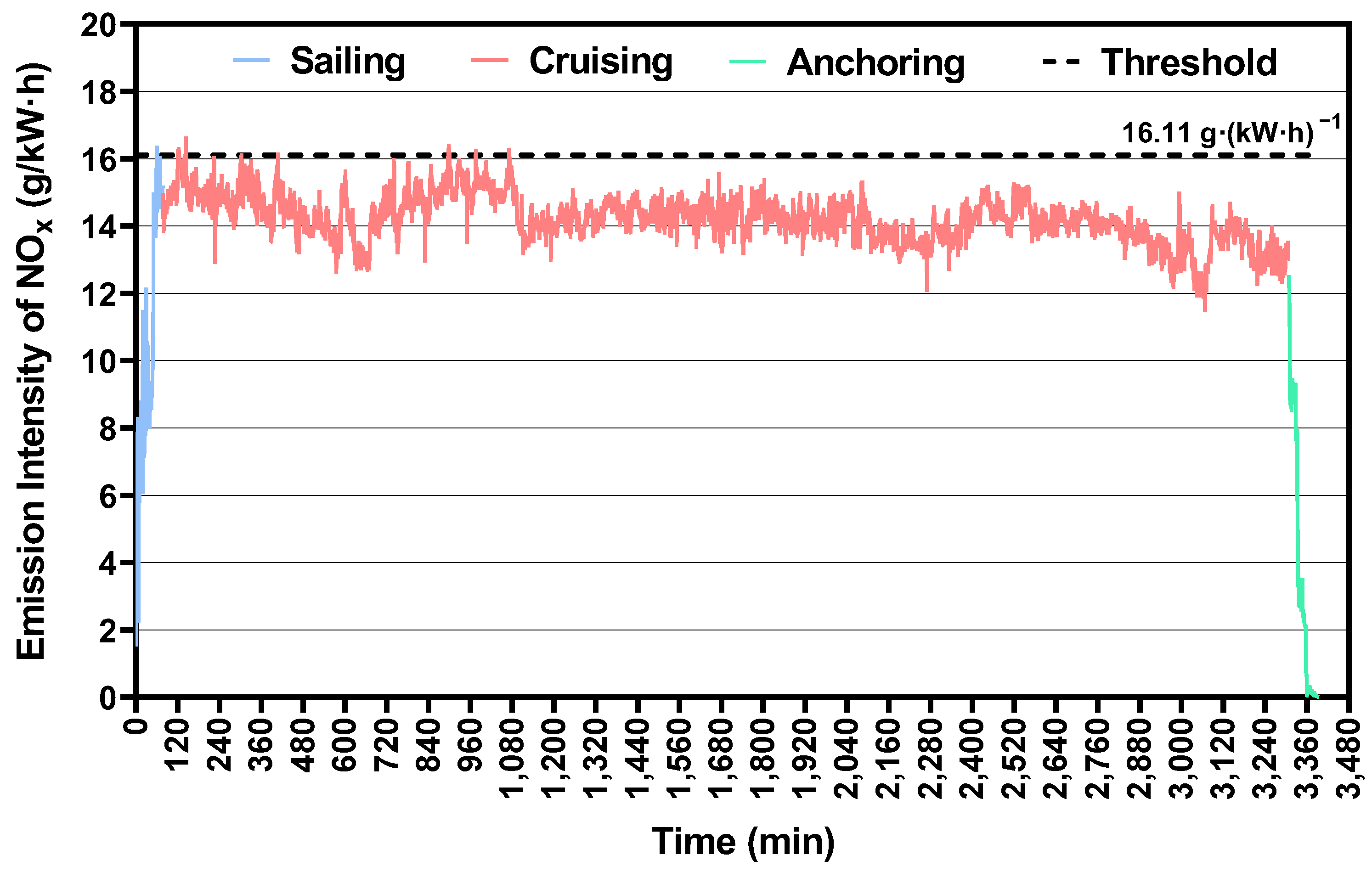

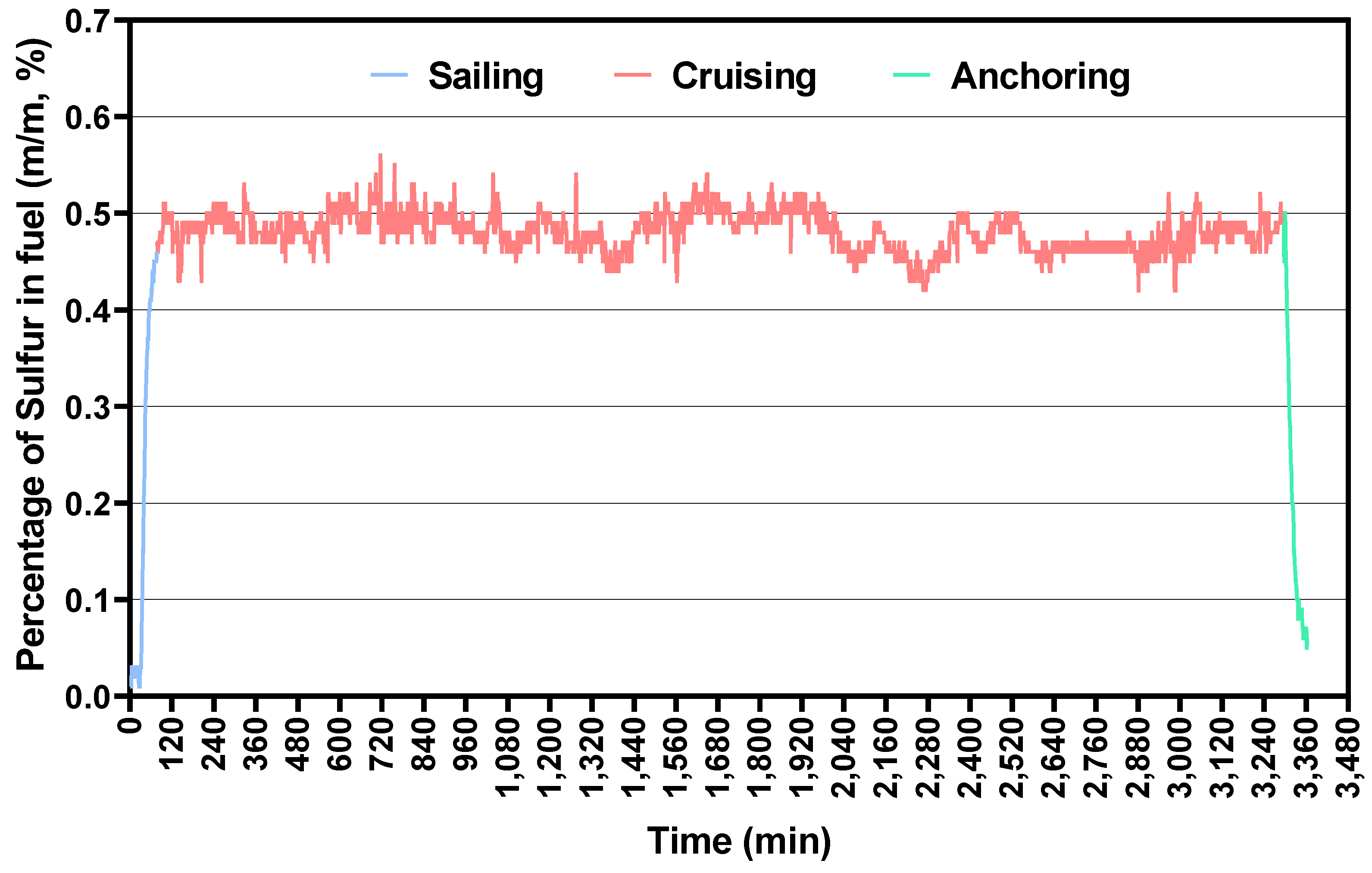

3.2. NOx-Emission Intensity and Sulfur Content of Ship Fuel

3.3. Compliance Determination

4. Conclusions and Countermeasures

4.1. Conclusions

4.2. Countermeasures and Suggestions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lin, B.; Lin, C.Y. Compliance with international emission regulations: Reducing the air pollution from merchant vessels. Mar. Policy 2006, 30, 220–225. [Google Scholar] [CrossRef]

- Liu, Z.M.; Lu, X.H.; Feng, J.L.; Fan, Q.Z.; Zhang, Y.; Yang, X. Influence of ship emissions on urban air quality: A comprehensive study using highly time-resolved online measurements and numerical simulation in Shanghai. Environ. Sci. Technol. 2016, 51, 202–211. [Google Scholar] [CrossRef] [PubMed]

- Eyring, V.; Isaksen, I.S.A.; Berntsen, T.; Collins, W.J.; Corbett, J.J.; Endresen, O.; Grainger, R.G.; Moldanova, J.; Schlager, H.; Stevenson, D.S. Transport impacts on atmosphere and climate: Shipping. Atmos. Environ. 2010, 44, 4735–4771. [Google Scholar] [CrossRef]

- Marine Environment Protection Committee 78th Session of Agenda Item 11: Identification and Protection of Special Areas, ECAs and PSSAs—Proposal to Designate the Mediterranean Sea, As a Whole, As an Emission Control Area for Sulphur Oxides; International Maritime Organization (IMO): London, UK, 2022.

- Pyć, D. ECA compliance and enforcement—legal regime for ships. SHS Web Conf. 2018, 58, 01026. [Google Scholar] [CrossRef]

- Liu, H.; Fu, M.L.; Jin, X.X.; Shang, Y.; Shindell, D.; Faluvegi, G.; Shindell, C.; He, K.B. Health and climate impacts of ocean-going vessels in East Asia. Nat. Clim. Chang. 2016, 6, 1037. [Google Scholar] [CrossRef]

- IMO. Emission Control Areas (ECAs) Designated under MARPOL Annex VI. Available online: https://www.imo.org/en/OurWork/Environment/Pages/Emission-Control-Areas-(ECAs)-designated-under-regulation-13-of-MARPOL-Annex-VI-(NOx-emission-control).aspx (accessed on 5 December 2022).

- IMO. Mediterranean Sea Emission Control Area for Sulphur Oxides Approved. Available online: https://www.imo.org/en/MediaCentre/MeetingSummaries/Pages/MEPC-78th-session.aspx (accessed on 5 December 2022).

- Bergqvist, R.; Turesson, M.; Weddmark, A. Sulphur emission control areas and transport strategies-the case of Sweden and the forest industry. Eur. Transp. Res. Rev. 2015, 7, 10. [Google Scholar] [CrossRef]

- IMO. Nitrogen Oxides (NOx)—Regulation 13. Available online: https://www.imo.org/en/OurWork/Environment/Pages/Nitrogen-oxides-(NOx)-%E2%80%93-Regulation-13.aspx (accessed on 5 December 2022).

- 2021 Statistical Bulletin on the Development of Transportation Industry (in Chinese); Ministry of Transport of the People’s Republic of China: Beijing, China, 2022. Available online: http://www.gov.cn/shuju/2022-05/25/content_5692174.htm (accessed on 21 November 2022).

- Kotchenruther, R.A. The effects of marine vessel fuel sulfur regulations on ambient PM2.5 at coastal and near coastal monitoring sites in the US. Atmos. Environ. 2017, 151, 52–61. [Google Scholar] [CrossRef]

- Zhang, Q.; Zheng, Z.Q.; Wan, Z.; Zheng, S.Y. Does emission control area policy reduce sulfur dioxides concentration in Shanghai? Transport. Res. Part D-Transport. Environ. 2020, 81, 11. [Google Scholar] [CrossRef]

- Clean Shipping Project Platform. Best Practice Report on Compliance Monitoring of Ships with Respect to Current and Future IMO Regulation; Chalmers University of Technology: Göteborg, Sweden, 2021. [Google Scholar]

- IMO MARPOL Annex VI. Regulations for the prevention of air pollution from ships. Resolut. MEPC 2005, 176, 58, Adopted by the Protocol of 1997, 15–26 September 1997. [Google Scholar]

- Kattner, L.; Mathieu-Uffing, B.; Burrows, J.P.; Richter, A.; Schmolke, S.; Seyler, A.; Wittrock, F. Monitoring compliance with sulfur content regulations of shipping fuel by in situ measurements of ship emissions. Atmos. Chem. Phys. 2015, 15, 10087–10092. [Google Scholar] [CrossRef]

- Celik, S.; Drewnick, F.; Fachinger, F.; Brooks, J.; Darbyshire, E.; Coe, H.; Paris, J.D.; Eger, P.G.; Schuladen, J.; Tadic, I.; et al. Influence of vessel characteristics and atmospheric processes on the gas and particle phase of ship emission plumes: In situ measurements in the Mediterranean Sea and around the Arabian Peninsula. Atmos. Chem. Phys. 2020, 20, 4713–4734. [Google Scholar] [CrossRef]

- Loov, J.M.B.; Alfoldy, B.; Gast, L.F.L.; Hjorth, J.; Lagler, F.; Mellqvist, J.; Beecken, J.; Berg, N.; Duyzer, J.; Westrate, H.; et al. Field test of available methods to measure remotely SOx and NOx emissions from ships. Atmos. Meas. Tech. 2014, 7, 2597–2613. [Google Scholar] [CrossRef]

- Krause, K.; Wittrock, F.; Richter, A.; Schmitt, S.; Pohler, D.; Weigelt, A.; Burrows, J.P. Estimation of ship emission rates at a major shipping lane by long-path DOAS measurements. Atmos. Meas. Tech. 2021, 14, 5791–5807. [Google Scholar] [CrossRef]

- Seyler, A.; Meier, A.C.; Wittrock, F.; Kattner, L.; Mathieu-Uffing, B.; Peters, E.; Richter, A.; Ruhtz, T.; Schonhardt, A.; Schmolke, S.; et al. Studies of the horizontal inhomogeneities in NO2 concentrations above a shipping lane using ground-based multi-axis differential optical absorption spectroscopy (MAX-DOAS) measurements and validation with airborne imaging DOAS measurements. Atmos. Meas. Tech. 2019, 12, 5959–5977. [Google Scholar] [CrossRef]

- Zhou, F.; Hou, L.W.; Zhong, R.; Chen, W.; Ni, X.P.; Pan, S.D.; Zhao, M.; An, B.W. Monitoring the compliance of sailing ships with fuel sulfur content regulations using unmanned aerial vehicle (UAV) measurements of ship emissions in open water. Atmos. Meas. Tech. 2020, 13, 4899–4909. [Google Scholar] [CrossRef]

- Zhou, F.; Pan, S.D.; Chen, W.; Ni, X.P.; An, B.W. Monitoring of compliance with fuel sulfur content regulations through unmanned aerial vehicle (UAV) measurements of ship emissions. Atmos. Meas. Tech. 2019, 12, 6113–6124. [Google Scholar] [CrossRef]

- Berg, N.; Mellqvist, J.; Jalkanen, J.P.; Balzani, J. Ship emissions of SO2 and NO2: DOAS measurements from airborne platforms. Atmos. Meas. Tech. 2012, 5, 1085–1098. [Google Scholar] [CrossRef]

- Cooper, D.A. Exhaust emissions from ships at berth. Atmos. Environ. 2003, 37, 3817–3830. [Google Scholar] [CrossRef]

- Wang, Z.; Qin, C.H.; Liu, C.L.; Peng, C.S.; Zhu, L.; Zhang, W.; Chen, J.F. A Method for Compliance Judgment and Violation Identification of Ship Fuel Oil (in Chinese); CN201910141501.4; China National Intellectual Property Administration: Beijing, China, 2021. [Google Scholar]

| Items | Range | Precision Error |

|---|---|---|

| CO2 | 0~20 Vol. % | <2% |

| SO2 | 0~1000 ppm | <2% |

| NOx | 0~2000 ppm | <2% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Ma, Q.; Zhang, Z.; Li, Z.; Qin, C.; Chen, J.; Peng, C. A Study on Monitoring and Supervision of Ship Nitrogen-Oxide Emissions and Fuel-Sulfur-Content Compliance. Atmosphere 2023, 14, 175. https://doi.org/10.3390/atmos14010175

Wang Z, Ma Q, Zhang Z, Li Z, Qin C, Chen J, Peng C. A Study on Monitoring and Supervision of Ship Nitrogen-Oxide Emissions and Fuel-Sulfur-Content Compliance. Atmosphere. 2023; 14(1):175. https://doi.org/10.3390/atmos14010175

Chicago/Turabian StyleWang, Zheng, Qianchi Ma, Zhida Zhang, Zichao Li, Cuihong Qin, Junfeng Chen, and Chuansheng Peng. 2023. "A Study on Monitoring and Supervision of Ship Nitrogen-Oxide Emissions and Fuel-Sulfur-Content Compliance" Atmosphere 14, no. 1: 175. https://doi.org/10.3390/atmos14010175

APA StyleWang, Z., Ma, Q., Zhang, Z., Li, Z., Qin, C., Chen, J., & Peng, C. (2023). A Study on Monitoring and Supervision of Ship Nitrogen-Oxide Emissions and Fuel-Sulfur-Content Compliance. Atmosphere, 14(1), 175. https://doi.org/10.3390/atmos14010175