Study on the Influence of Fresh Air System of Range Hood on Kitchen Air Quality

Abstract

:1. Introduction

1.1. Research Background

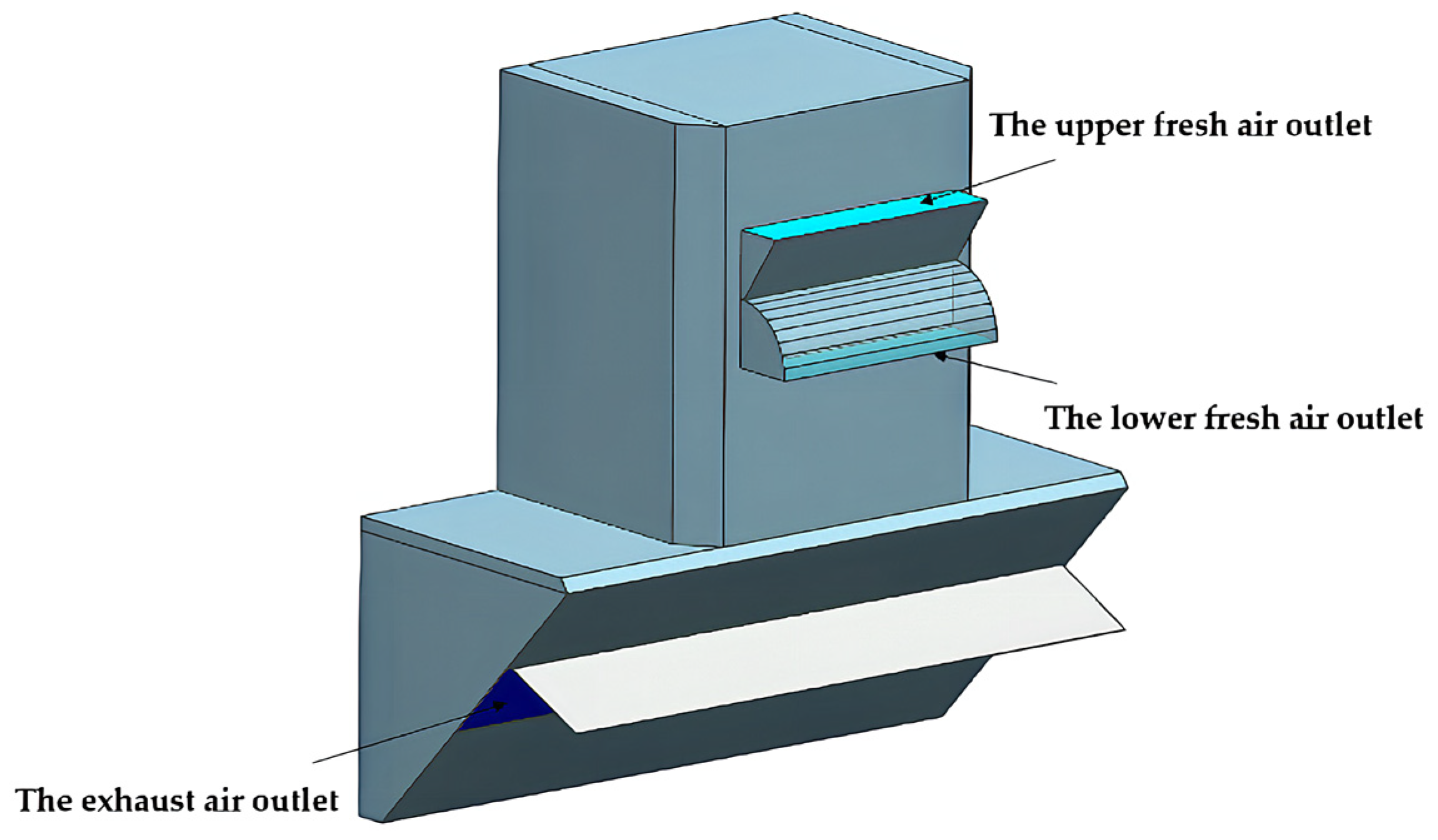

1.2. Fresh Air System for Cooker Hoods

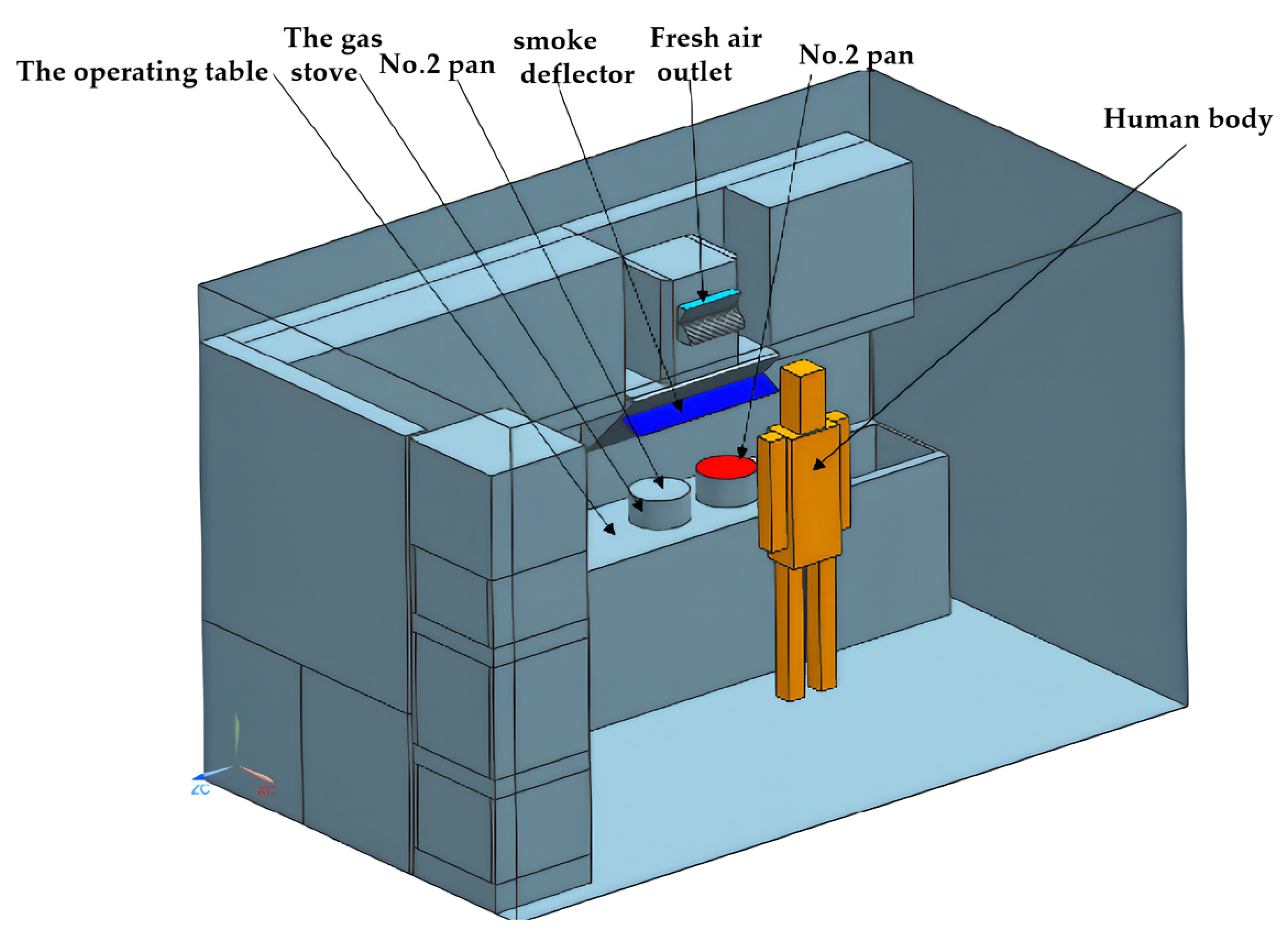

2. Calculation Model for the Internal Environment of the Kitchen

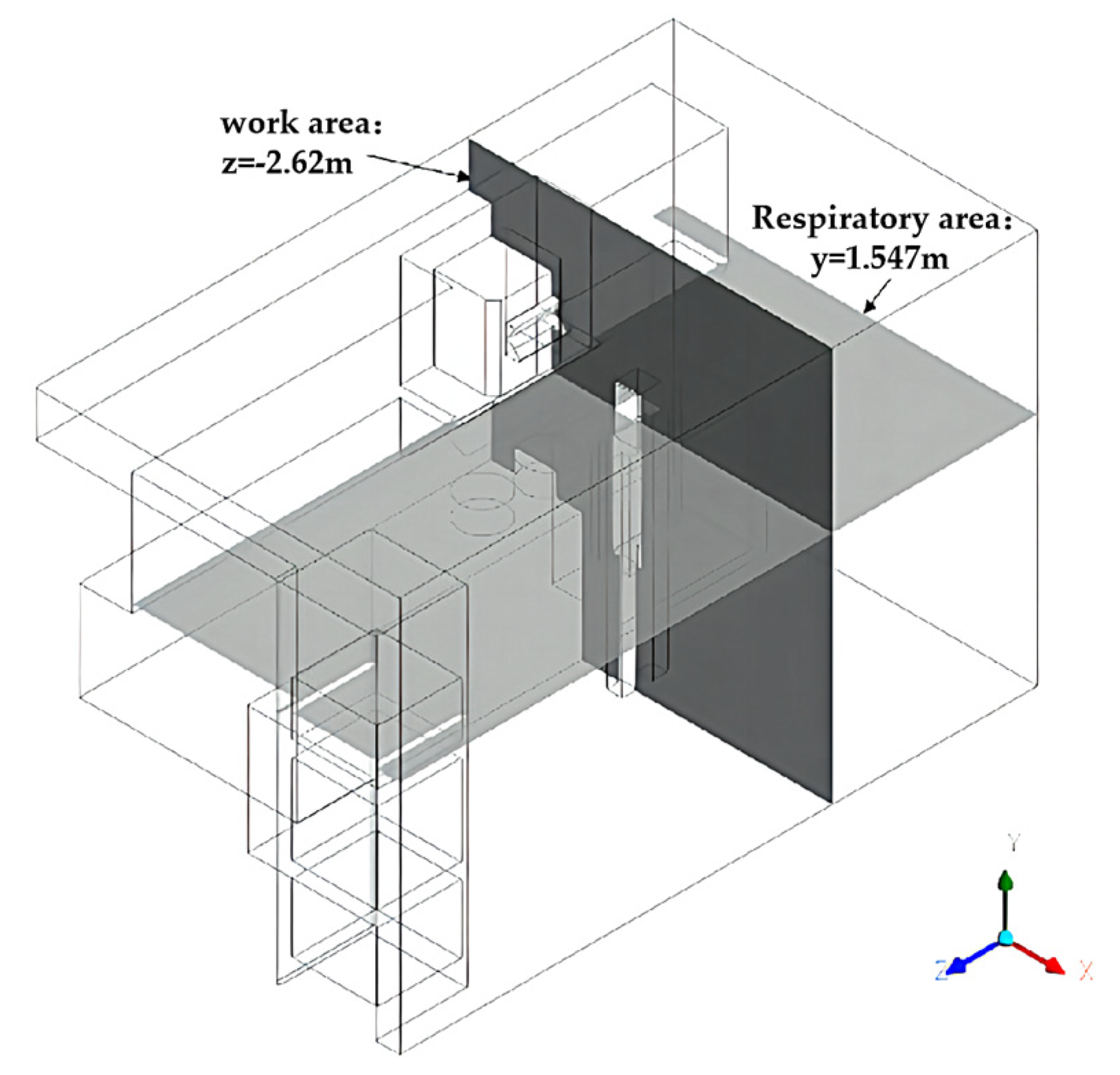

2.1. Geometric Model of a Kitchen Containing a Fresh Air System

2.2. Grid Model

2.3. Mathematical Models

2.3.1. Flow Control Equations

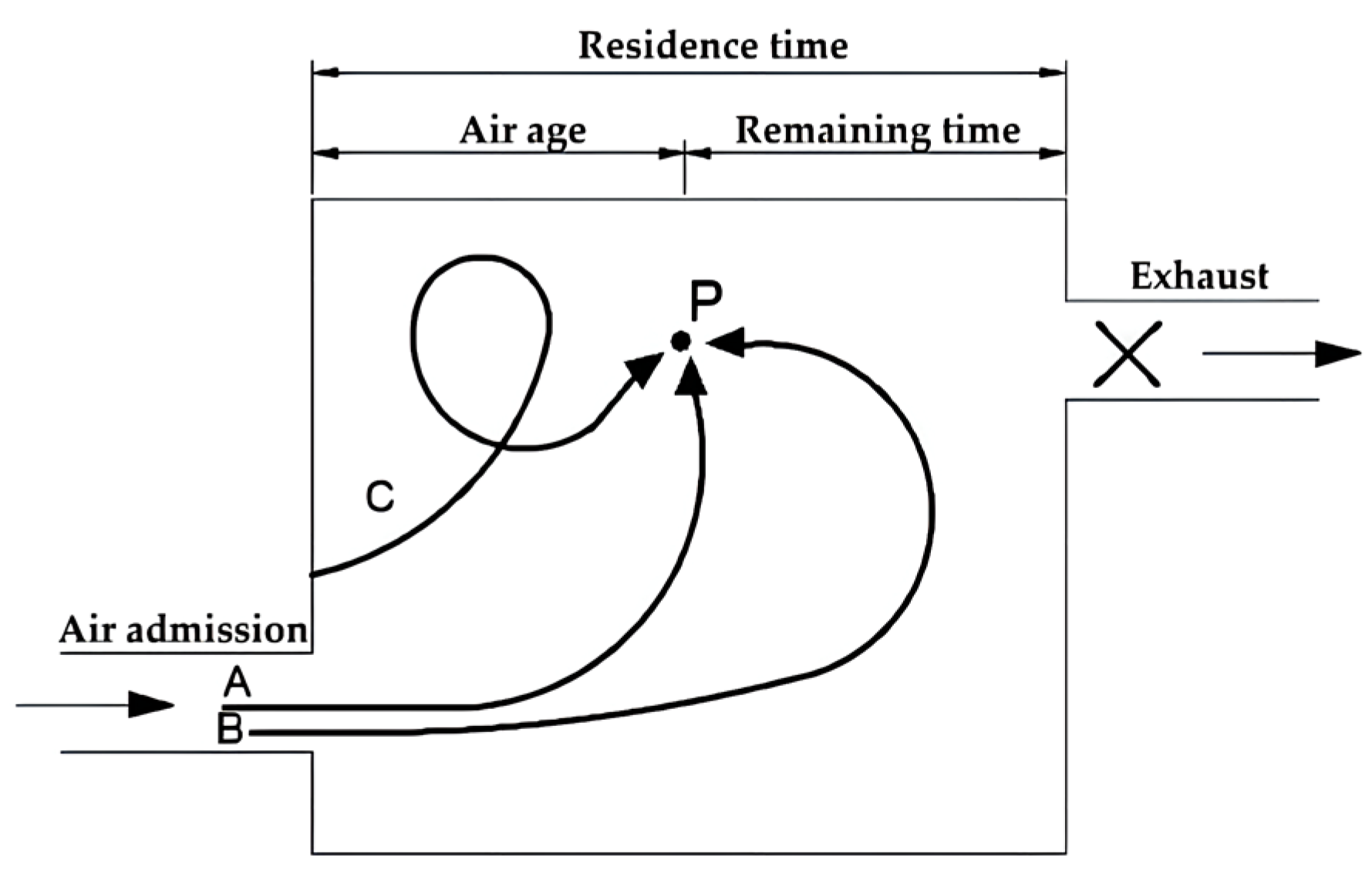

2.3.2. Air Age Transport Equation

2.3.3. Turbulence Model

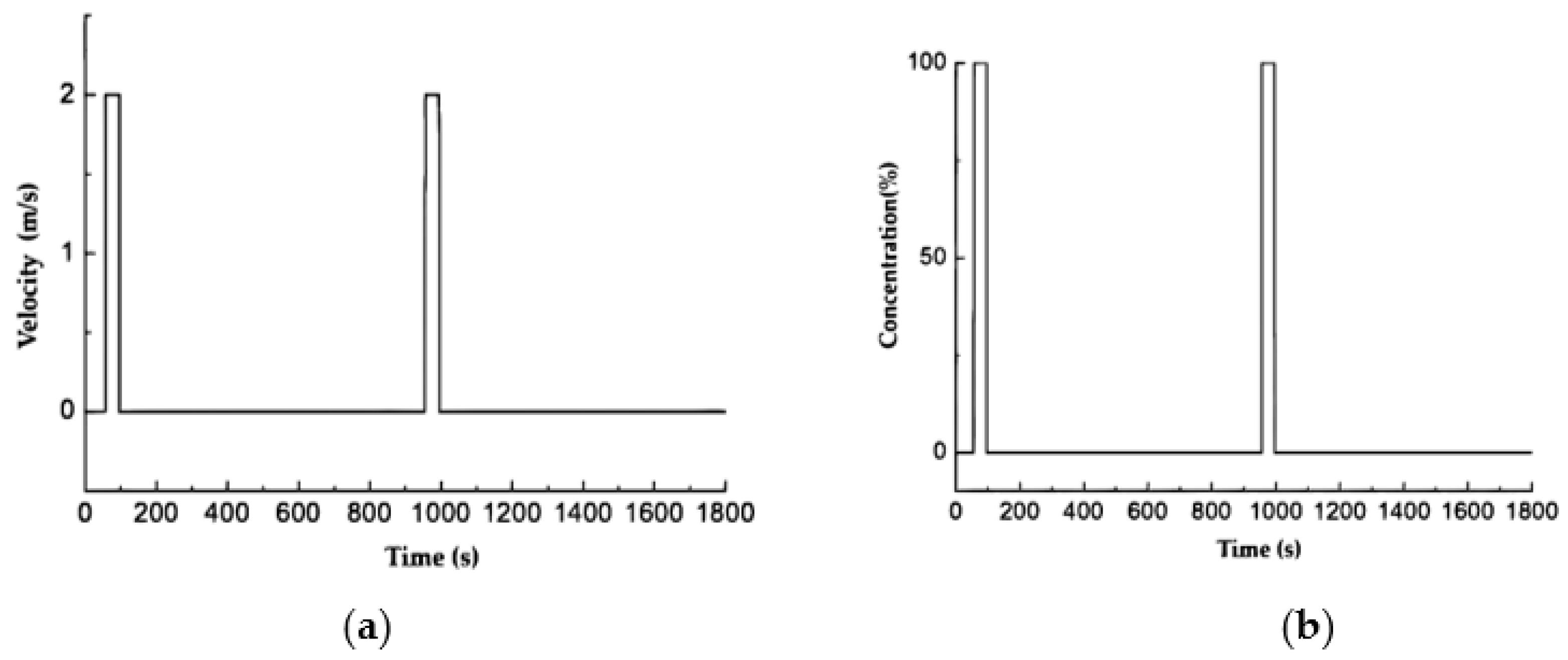

2.4. Measurement of the Oil Smoke Concentration

2.5. Boundary Condition Setting

3. Methods for Evaluating the Internal Air Quality of Kitchens

4. Discussion

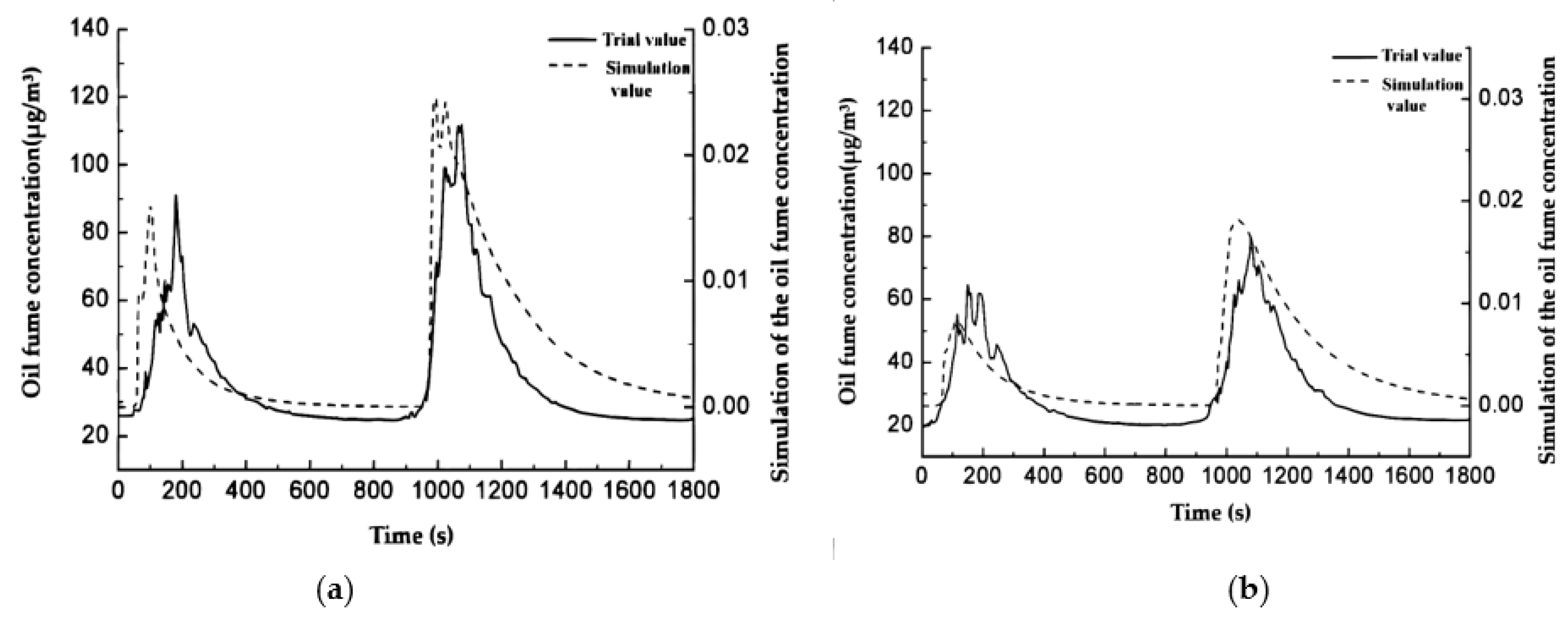

4.1. Calibration Analysis of the Kitchen Environment Computational Model

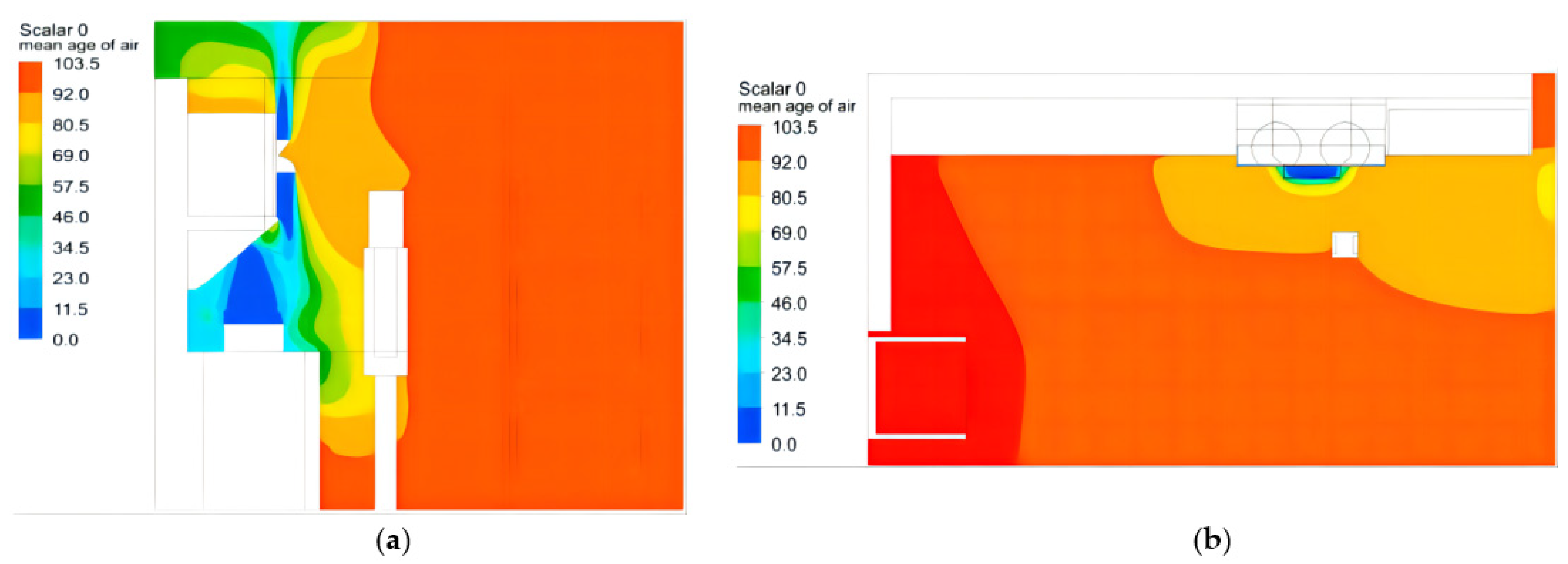

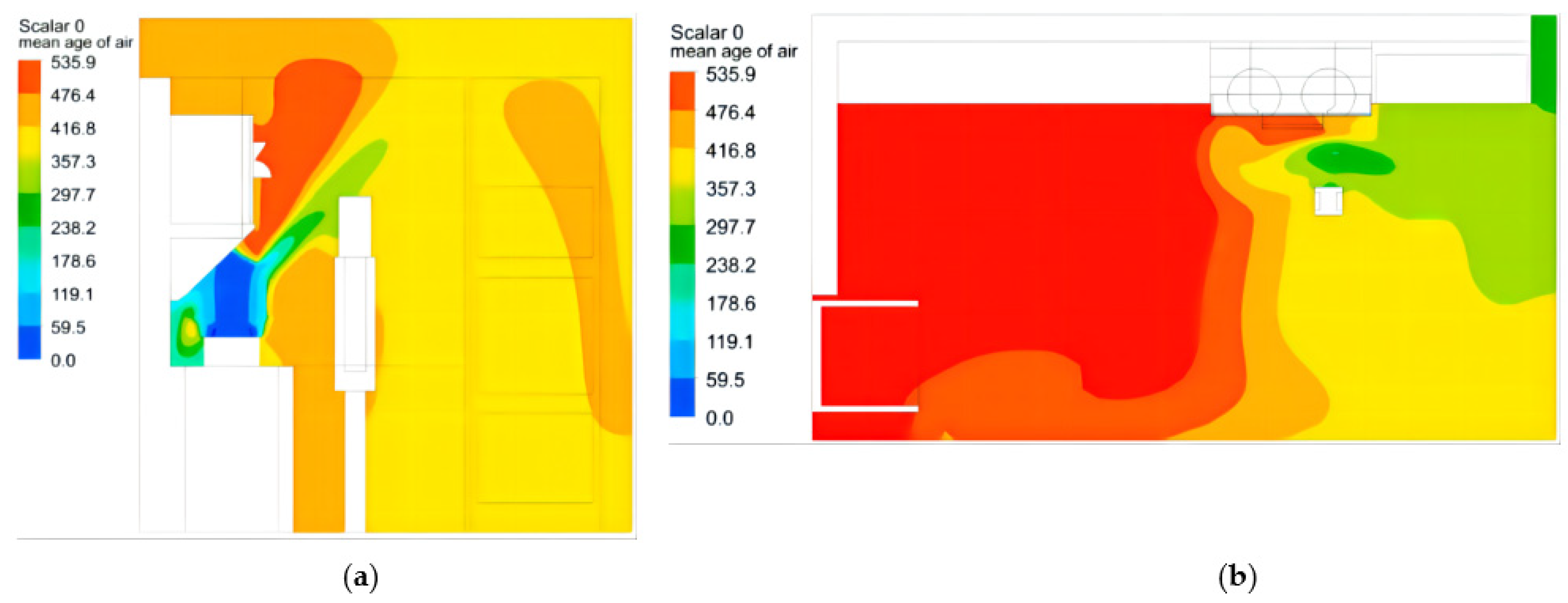

4.2. Quantitative Analysis of Fresh Air System on Kitchen Air Quality

5. Conclusions

- The air age and air exchange efficiency are the reasonable indexes for the use of evaluation criteria for kitchen air quality control.

- The effect of this test kitchen fresh air system on indoor air quality is quantitatively analyzed. The average air age at the human face is improved to 88.4 s from 333.9 s and the air exchange efficiency is improved to 82.4% from 16.7% after the fresh air system is switched on. It shows that the fresh air system can effectively improve the air quality of the human face area.

- The presented approach can accurately assess the ambient air quality of kitchens and provide directions for the optimization of different kitchen designs to improve the indoor air quality.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- LKakoulli, C.; Kyriacou, A.; Michaelides, M.P. A Review of Field Measurement Studies on Thermal Comfort, Indoor Air Quality and Virus Risk. Atmosphere 2022, 13, 191. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, Y.; Zhao, B. Emission rates of multiple air pollutants generated from Chinese residential cooking. Environ. Sci. Technol. 2018, 52, 1081–1087. [Google Scholar] [CrossRef]

- Parrott, K.; Emmel, J.; Beamish, J. Use of kitchen ventilation: Impact on indoor air quality. Forum Fam. Consum. Issues 2003, 8, 1. [Google Scholar]

- Singeri, B.C.; Delp, W.W.; Apte, M.G. Experimental Evaluation of Installed Cooking Exhaust Fan Performance; LBNL-4183E; Lawrence Berkeley National Laborobotory: Berkeley, CA, USA, 2011. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Cao, Q.; Zhao, X.; Lu, Z.; Deng, Z.; Dong, J.; Lin, X.; Qing, K.; Zhang, W.; Chen, Q. Improving indoor air quality and thermal comfort in residential kitchens with a new ventilation system. Build. Environ. 2020, 180, 107016. [Google Scholar] [CrossRef]

- Liu, S.; Dong, J.; Ca, Q.; Zhou, X.; Li, J.; Lin, X.; Qing, K.; Zhang, W.; Chen, Q. Indoor thermal environment and air quality in Chinese-style residential kitchens. Indoor Air 2020, 30, 198–212. [Google Scholar] [CrossRef] [PubMed]

- Cao, C.; Gao, J.; Wu, L.; Ding, X.; Zhang, X. Ventilation improvement for reducing individual exposure to cooking-generated particles in Chinese residential kitchen. Indoor Built Environ. 2017, 26, 226–237. [Google Scholar] [CrossRef]

- Zhang, H.; Cheng, X.; Pan, W.; Liu, S.; Zhang, M.; Long, Z.; Zhang, T.; Chen, Q. Experimental study of relative exposure to particles transmitted from kitchen in an apartment. Procedia Eng. 2017, 205, 3830–3837. [Google Scholar] [CrossRef]

- Suriano, D.; Penza, M. Assessment of the Performance of a Low-Cost Air Quality Monitor in an Indoor Environment through Different Calibration Models. Atmosphere 2022, 13, 567. [Google Scholar] [CrossRef]

- Zhou, B.; Chen, F.; Dong, Z.; Nielsen, P.V. Study on pollution control in residential kitchen based on the push-pull ventilation system. Build. Environ. 2016, 107, 99–112. [Google Scholar] [CrossRef]

- Dobbin, N.A.; Liu, S.; Wallace, L.; Kulka, R.; You, H.; Shin, T.; Aubin, D.; St-Jean, M.; Singer, B.C. The benefit of kitchen exhaust fan use after cooking-An experimental assessment. Build. Environ. 2018, 135, 286–296. [Google Scholar] [CrossRef]

- Peng, M.; Ji, N.; Shama, W.; Huang, D.; Zhong, L. Comprehensive evaluation of indoor air quality classification. Green Tech. 2021, 23, 91–93. [Google Scholar] [CrossRef]

- Díaz-Calderón, S.F.; Castillo, J.A.; Huelsz, G. Indoor air quality evaluation in naturally cross-ventilated buildings for education using age of air. J. Phys. Conf. Ser. 2021, 2069, 012182. [Google Scholar] [CrossRef]

- Debnath, R.; Bardhan, R.; Banerjee, R. Investigating the age of air in rural Indian kitchens for sustainable built-environment design. J. Build. Eng. 2016, 7, 320–333. [Google Scholar] [CrossRef]

- Mao, N.; Song, M.; Chan, M.; Pan, D.; Deng, S. Computational fluid dynamics (CFD) modelling of air flow field, mean age of air and CO2 distributions inside a bedroom with different heights of conditioned air supply outlet. Appl. Energy 2016, 164, 906–915, ISSN 0306-2619. [Google Scholar] [CrossRef]

- Wang, F.; Chen, Z.L.; Shi, F. Kitchen environment analysis of range hood with air curtain based on CFD technology. J. Ningbo Univ. 2019, 32, 42–47. [Google Scholar]

- Liu, J. Research and application status of replacement ventilation. Constr. Eng. Technol. Des. 2018, 12, 365. [Google Scholar]

- Li, A.; Risto, K.; Kim, H. Chapter 3-In decay of turbulent kinetic energy in shear flow. In Industrial Ventilation Design Guidebook, 2nd ed.; Goodfellow, H.D., Kosonen, R., Eds.; Journal of Huazhong University of Science and Technology (Naturndustrial Ventilation Design Method); Academic Press: Cambridge, MA, USA, 2020; pp. 19–37. [Google Scholar] [CrossRef]

- Liu, X.F.; Yuan, S.Q.; He, Z.X.; He, H.Q. Application of Ventilation to Improve Catering Kitchen Environment. Environ. Sci. Technol. 2009, 32, 152–155. [Google Scholar]

- Chen, F.; Li, C.; Lu, Y.; Dong, Z.; Zhao, X. The influence of the smoke collection cover on the smoke exhaust efficiency of the side suction lampblack hood. Energy-Sav. Technol. 2019, 37, 275–279. [Google Scholar]

- Liu, Z.; Han, J.; Zhou, J.; Zhang, C.; Zhang, G. Research on residential wind environment evaluation based on wind speed ratio and air age. Build. Technol. 2015, 46, 996–1001. [Google Scholar] [CrossRef]

- Li, D.; Ma, G.; Guo, T.; Li, M. Research on decay of turbulent kinetic energy in shear flow. J. Huazhong Univ. of Sci. Tech. (Nat. Sci. Ed.) 2021, 49, 83–87. [Google Scholar] [CrossRef]

- Wang, G. Numerical simulation and experiment research on indoor air distribution of the energy-saving. In Environment Protective and Comfortable Domestic Kitchen; Hunan University of Technology: Zhuzhou, China, 2009. [Google Scholar]

- Ma, R.M. Ventilation effectiveness and IAQ. HVAC 2000, 30, 20–23. [Google Scholar]

- Tang, Z.; Zhan, J. Numerical simulation of indoor air environment and evaluation of ventilation modes. Hydrodyn. Res. Prog. (Ser. A) 2004, 19, 904–911. [Google Scholar]

- Wang, H.; Fan, C. Evaluation index of indoor ventilation and sewage discharge effect. HVAC 1997, 27, 29–34. [Google Scholar]

- Lu, Y.Q. Practical Heating and Air Conditioning Design Manual; China Construction Industry Press: Beijing, China, 2008. [Google Scholar]

- Ministry of Construction of the People’s Republic of China. Energy-Saving Design Standard for Residential Buildings in Hot Summer and Cold Winter Areas JGJ 134-2010; China Construction Industry Press: Beijing, China, 2010. [Google Scholar]

| 1.00 | 1.30 | 1.44 | 1.92 |

| Air Age (s) | Air Freshness | Air Exchange Efficiency |

|---|---|---|

| 78 (ideal state) | Pure (non-polluting) | 100% |

| 116.42 | Freshness | 67% |

| 156.00 | Moderate | 50% |

| 598.16 | Moderate pollution | 13.04% |

| 1793.1 | foul | 4.35% |

| Working Conditions | Average Air Age of the Human Face | Air Exchange Efficiency of the Human Face | Average Indoor Air Age | Indoor Air Exchange Efficiency | Indoor Air Exchange Efficiency | Air Freshness |

|---|---|---|---|---|---|---|

| New breeze on | 88.4 s | 88.2% | 94.7 s | 82.4% | 82.4% | Freshness |

| Fresh air off | 333.9 s | 23.4% | 468.6 s | 16.7% | 16.7% | Moderate pollution |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Peng, L.; Yu, B.; Chen, Z.; Shi, F.; He, H. Study on the Influence of Fresh Air System of Range Hood on Kitchen Air Quality. Atmosphere 2022, 13, 920. https://doi.org/10.3390/atmos13060920

Xu X, Peng L, Yu B, Chen Z, Shi F, He H. Study on the Influence of Fresh Air System of Range Hood on Kitchen Air Quality. Atmosphere. 2022; 13(6):920. https://doi.org/10.3390/atmos13060920

Chicago/Turabian StyleXu, Xuefeng, Liang Peng, Bingsong Yu, Zhenlei Chen, Fan Shi, and Haitao He. 2022. "Study on the Influence of Fresh Air System of Range Hood on Kitchen Air Quality" Atmosphere 13, no. 6: 920. https://doi.org/10.3390/atmos13060920

APA StyleXu, X., Peng, L., Yu, B., Chen, Z., Shi, F., & He, H. (2022). Study on the Influence of Fresh Air System of Range Hood on Kitchen Air Quality. Atmosphere, 13(6), 920. https://doi.org/10.3390/atmos13060920