Effect of the Installation Angle of Nozzle on the Atomizing Performance of Air-Assisted Spraying Dust Suppression Device

Abstract

:1. Introduction

2. Establishment of the Physical Model and Mathematical Model

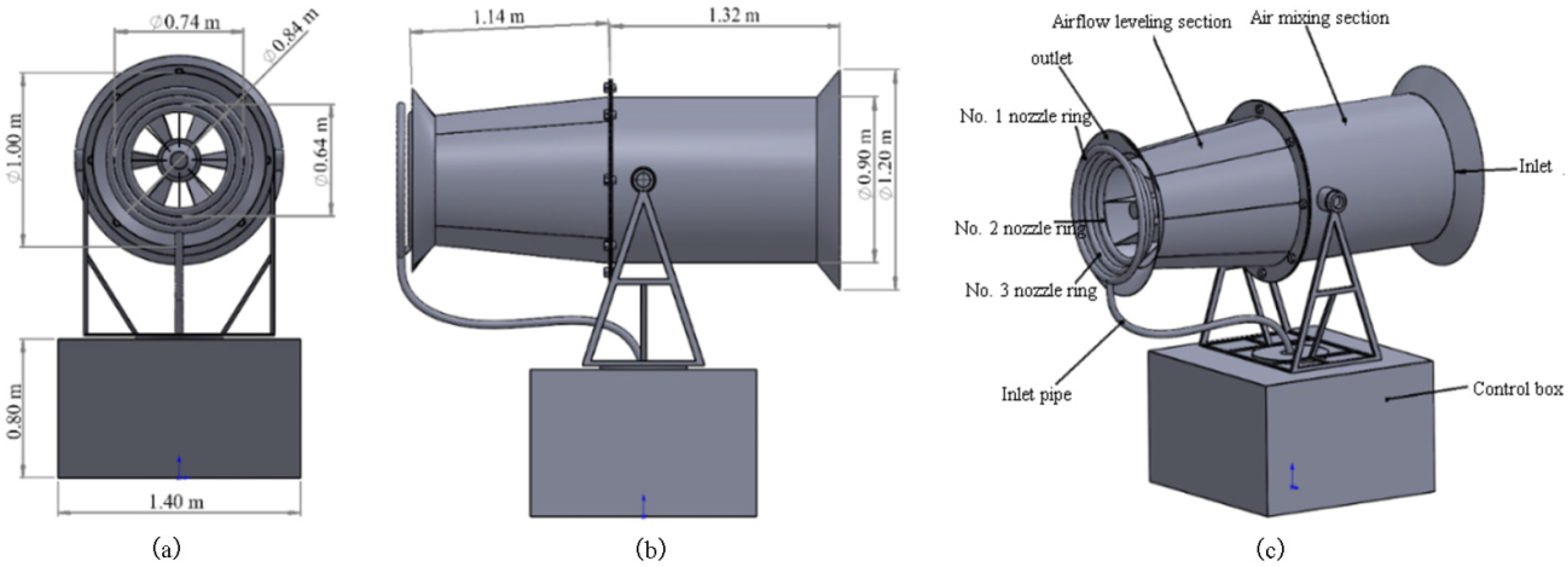

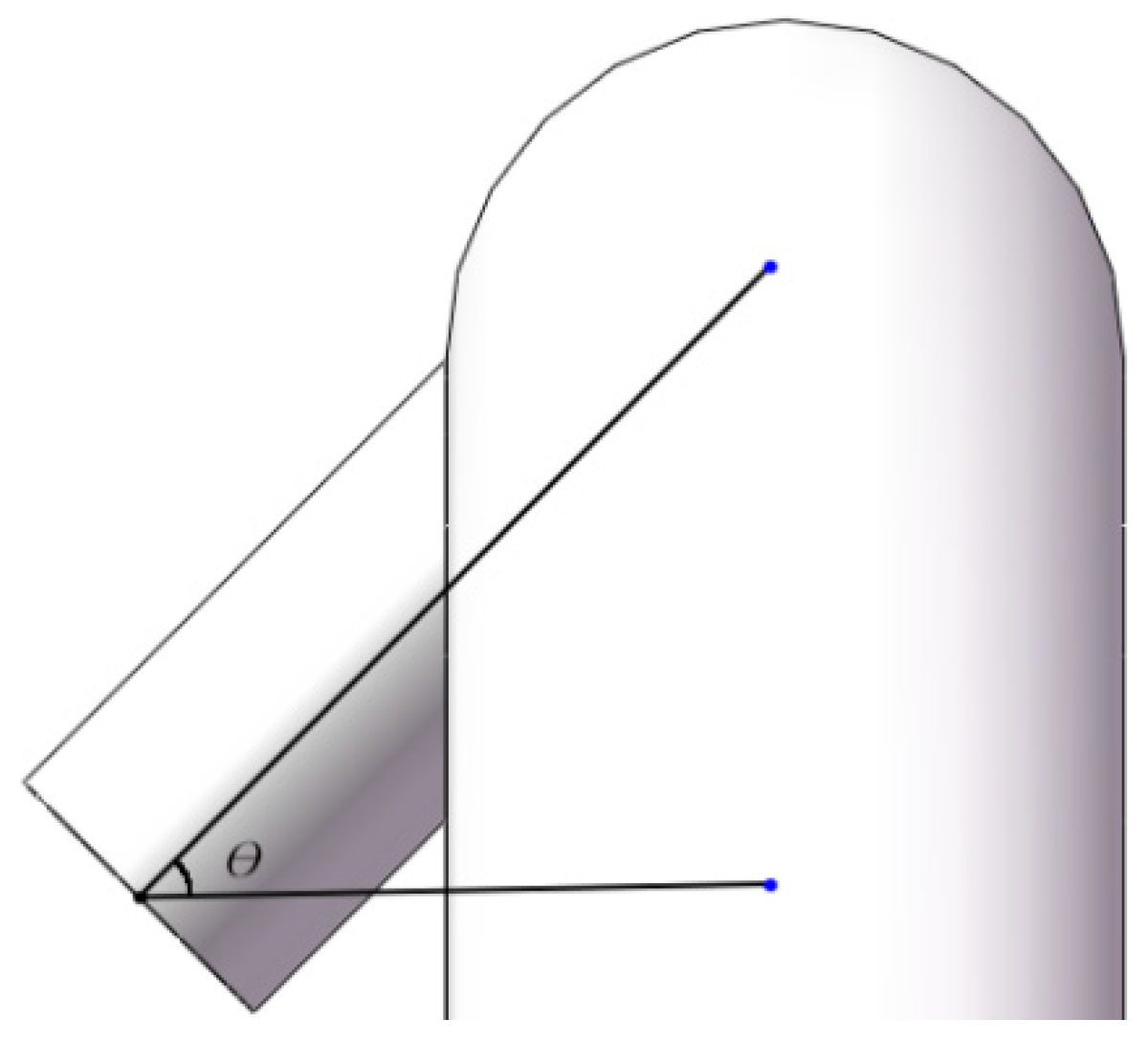

2.1. Physical Model

2.2. Boundary Condition

2.3. Mathematical Model

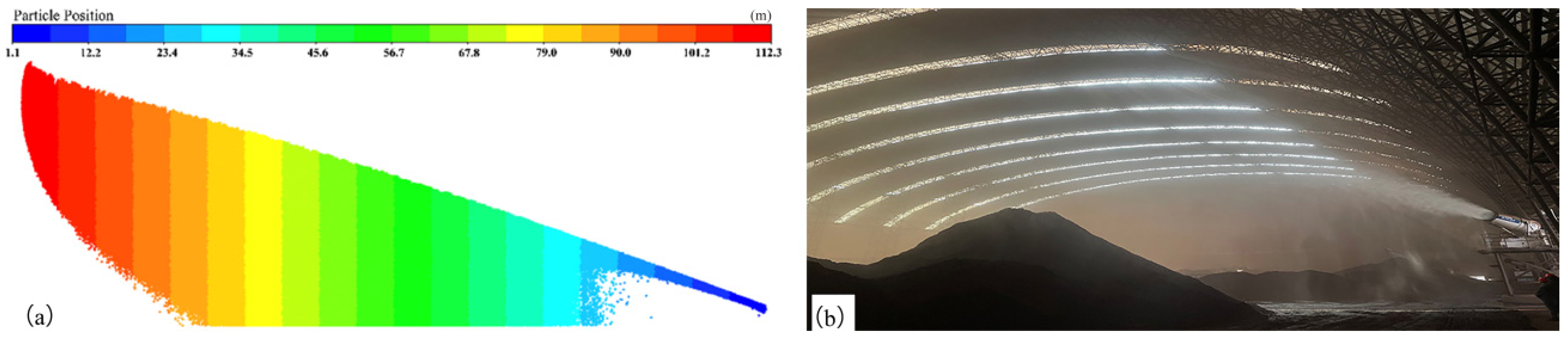

3. Validation of the Effectiveness of the Air-Assisted Spraying Dust Suppression Device Model

4. Establishment of the Physical Model and Mathematical Model

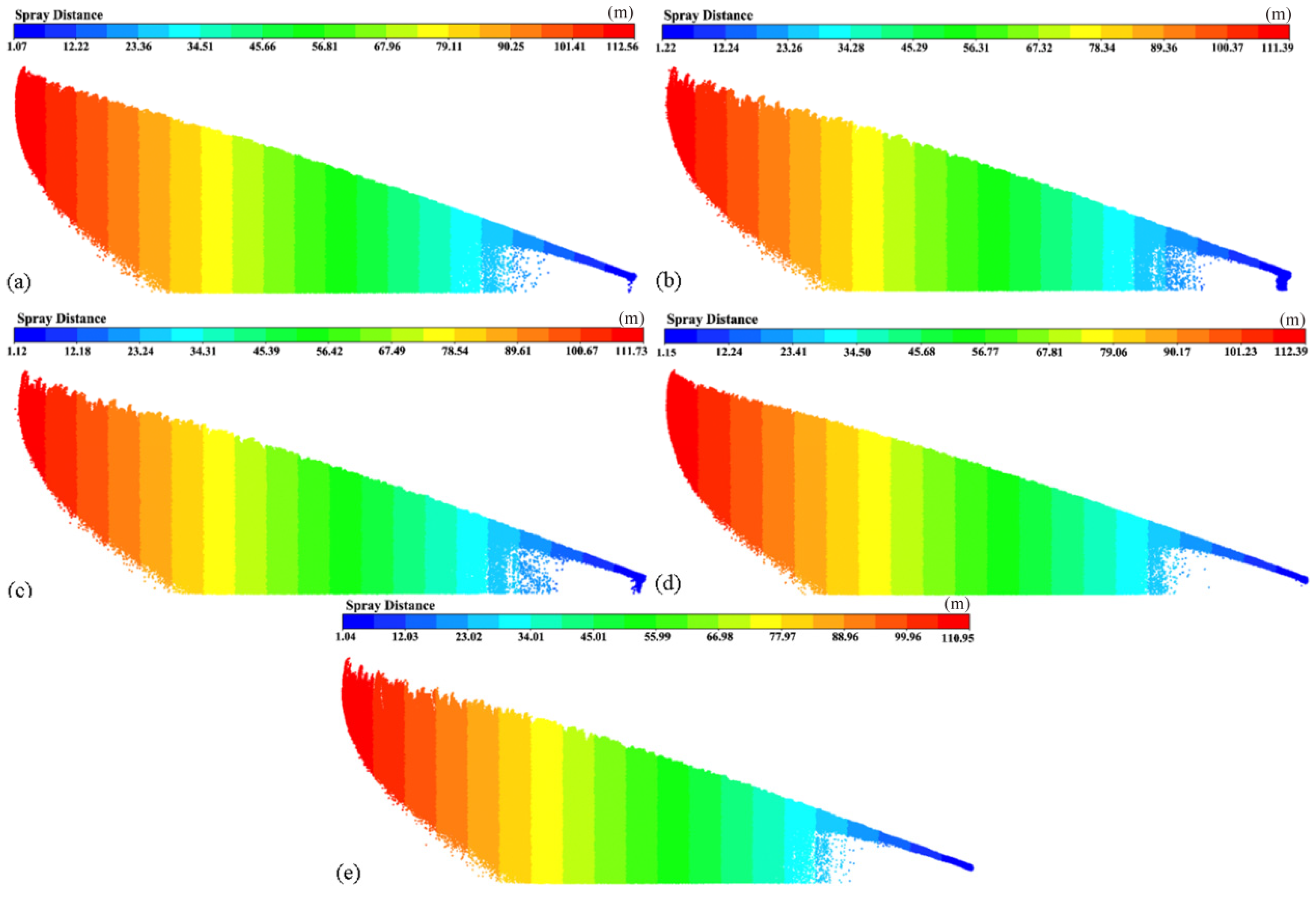

4.1. Effect of the Spraying Range of the Air-Assisted Spraying Dust Suppression Device

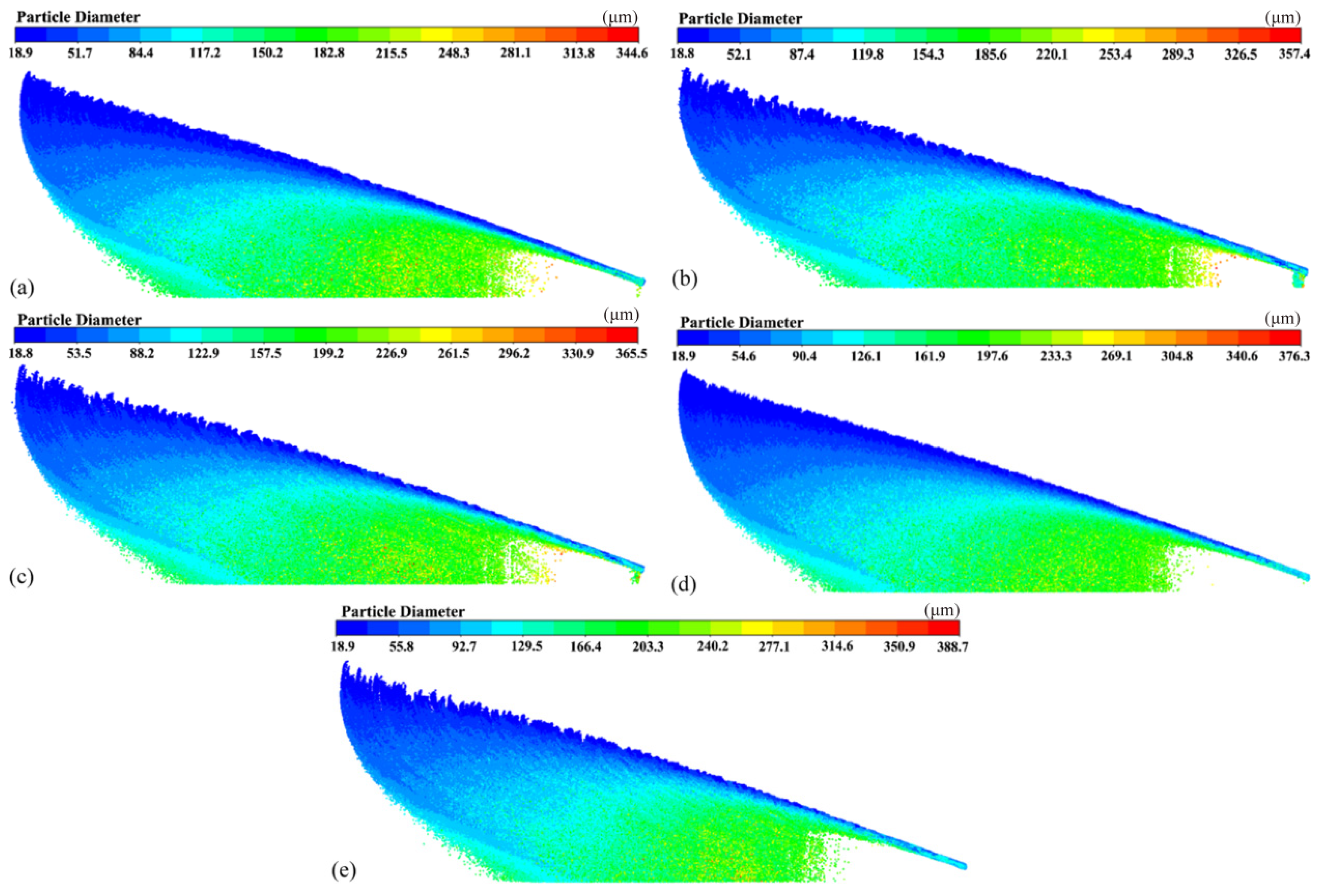

4.2. Effect of the Droplet Size of the Air-Assisted Spraying Dust Suppression Device

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Editorial Department of China Occupational Medicine. National Occupational Diseases report in 2020. China Occup. Med. 2021, 48, 396. [Google Scholar]

- Jiang, Z.A.; Zeng, F.B.; Wang, Y.P. Research Status and Prospect of Dust Pollution Control in Typical Working Places During Mining and Transportation of Metal Mines in China. Met. Mine 2021, 50, 135–153. [Google Scholar]

- Yang, W.T.; Qiao, P.; Liu, X.Z.; Lei, Y.L. Analysis of Multi-scale Spatio-temporal Differentiation Characteristics of PM 2.5 in China from 2011 to 2017. Environ. Sci. 2020, 41, 5236–5244. [Google Scholar]

- Wang, H.; An, D.F.; Zhang, L.L. Analysis on major smoke and dust emission sources in iron and steel enterprise. Environ. Eng. 2016, 34, 62–64. [Google Scholar]

- Diao, Y.F.; Lu, Y.; Zhuang, J.W. Special microscopic features of the metallic dust in the welding and cutting areas of the casting and forging workshop. J. Saf. Environ. 2021, 125, 1971–1977. [Google Scholar]

- Jia, L.; Wang, D.X.; Zhou, D.; Sun, Y.W.; Liang, B. Experimental test and examination on dust dissipation regularity of chutes in the open pit mine. J. Saf. Environ. 2018, 104, 751–754. [Google Scholar]

- Zhou, G.; Zhang, L.C.; Liu, R.L.; Sun, B.; Kong, Y.; Huang, Z.A. Numerical simulation investigation for the pollution characteristics of dust particles in the fully mechanized mining face under different air humidity conditions. J. Environ. Chem. Eng. 2021, 9, 106861. [Google Scholar] [CrossRef]

- Xie, Z.W.; Xiao, Y.M.; Jiang, C.X.; Ren, Z.L.; Li, X.Q.; Yu, K.C. Numerical study on fine dust pollution characteristics under various ventilation time in metro tunnel after blasting. Build. Environ. 2021, 204, 108111. [Google Scholar] [CrossRef]

- Cai, P.; NIe, W.; Chen, D.W.; Yang, S.B.; Liu, Z.Q. Effect of airflow rate on pollutant dispersion pattern of coal dust particles at fully mechanized mining face based on numerical simulation. Fuel 2019, 239, 623–635. [Google Scholar] [CrossRef]

- Zhang, H.H.; Nie, W.L.; Wang, H.K.; Bao, Q.; Jin, H.; Liu, Y.H. Preparation and experimental dust suppression performance characterization of a novel guar gum-modification-based environmentally-friendly degradable dust suppressant. Powder Technol. 2018, 339, 314–325. [Google Scholar] [CrossRef]

- Wang, P.F.; Chang, T.; Liu, R.H.; Wang, J. Mathematical model for multivariate nonlinear prediction of SMD of X-type swirl pressure nozzles. Process Saf. Environ. Prot. 2019, 125, 228–237. [Google Scholar] [CrossRef]

- Xu, G.; Chen, Y.P.; Eksteen, J.; Xu, J.L. Surfactant-aided coal dust suppression: A review of evaluation methods and influencing factors. Sci. Total Environ. 2018, 639, 1060–1076. [Google Scholar] [CrossRef] [PubMed]

- Yin, W.J.; Zhou, G.; Gao, D.H. Simulation analysis and engineering application of distribution characteristics about multi-stage atomization field for cutting dust in fully mechanized mining face. Adv. Powder Technol. 2019, 30, 2600–2615. [Google Scholar] [CrossRef]

- Wang, H.T.; Wei, X.B.; Du, Y.H.; Wang, D.M. Experimental investigation on the dilatational interfacial rheology of dust-suppressing foam and its effect on foam performance. Process Saf. Environ. Prot. 2019, 123, 351–357. [Google Scholar] [CrossRef]

- Zhou, W.J.; Nie, W.; Liu, C.Q.; Liu, Q.; Wang, H.T.; Wei, C.H.; Yan, J.Y.; Yin, S.; Xiu, Z.H.; Xu, C.W. Modelling of ventilation and dust control effects during tunnel construction. Int. J. Mech. Sci. 2019, 160, 358–371. [Google Scholar] [CrossRef]

- Liu, Q.; Nie, W.; Hua, Y.; Jia, L.B.; Li, C.S.; Ma, H.; Wei, C.H.; Liu, C.Q.; Zhou, W.J.; Peng, H.T. A study on the dust control effect of the dust extraction system in TBM construction tunnels based on CFD computer simulation technology. Adv. Powder Technol. 2019, 30, 2059–2075. [Google Scholar] [CrossRef]

- Zhang, X.T. Test study on distribution of space flow field of air-assisted long range sprayer. Min. Processing Equip. 2015, 43, 122–125. [Google Scholar]

- Zhang, X.T. Study on the distribution law of droplet diffusion and deposition of Long range air-assisted sprayer. Min. Saf. Environ. Prot. 2019, 46, 5–9. [Google Scholar]

- Jiang, H.; Guo, R.L.; Zhu, J.T. Two-phase jet flow field of remote spray dust removal. J. Xi’an Univ. Sci. Technol. 2019, 39, 249–255. [Google Scholar]

- Wang, L.L.; Wang, Y.L.; Xing, G.P.; Yan, C.M. A dust suppression hydraulic drive car fan structure optimization design. Spec. Purp. Veh. 2017, 4, 87–89. [Google Scholar]

- Zhou, H.W.; Zhang, P.; Li, B.; Zhao, Z.Y. Design and analysis of spraying pipeline system in mist cannon truck. Spec. Purp. Veh. 2019, 99–101. [Google Scholar]

- Chai, S.J.; Wang, H.Q.; Zhang, Y.Y.; Fan, C.J. Experimental method on static and dynamic balance of fog gun impeller. Spec. Purp. Veh. 2019, 84–86. [Google Scholar]

- Wang, Y.Z. Development of a dust suppression fog system and its application in driving face. China Energy Environ. Prot. 2019, 41, 54–57. [Google Scholar]

- Tao, T.; Wei, X.H. Numerical Simulation and Analysis of Flow Field in Five—Finger Sprayer of Orchard Sprayer. J. Agric. Mech. Res. 2020, 42, 40–45. [Google Scholar]

- Wen, Y.H.; Zhang, E.H.; Huang, J.H.; Li, H.Q. Research on the Suppression Effect of the Mist Cannon Truck on PM10. Automob. Appl. Technol. 2020, 10, 184–186. [Google Scholar]

- Cheng, X.J.; Yang, P.Y.; Yang, Z. Finite Element Analysis for Air Cannon Blade of a Dust Suppression Vehicle. Automob. Parts 2018, 2, 62–64. [Google Scholar]

- Xu, H.P.; Xing, F.T.; Mei, D.; Yang, Y.L. Research on Spray Parameters of Dust Suppression Vehicle Based on Numerical Simulation. Comput. Simul. 2019, 36, 142–145. [Google Scholar]

- Wang, P.F.; Zhang, K.; Liu, R.H. Influence of air supply pressure on atomization characteristics and dust-suppression efficiency of internal-mixing air-assisted atomizing nozzle. Powder Technol. 2019, 355, 393–407. [Google Scholar] [CrossRef]

- Li, H.X.; Liu, Q.Z.; Liu, Y.P.; Zhang, J.L. Numerical simulation on atomization characteristics of ultrasonic vibration nozzle based on CFD. Chin. J. Vac. Sci. Technol. 2017, 37, 113–117. [Google Scholar]

- Liu, X.J.; Ru, Y. Numerical Simulation and Experiment for Air-assisted Spraying Fan. For. Mach. Woodwork. Equip. 2019, 47, 9–13. [Google Scholar]

- Kim, K.D.; Jin, D.H.; Choi, Y.C. Numerical simulation on the generation of ultrasound and formation of water fog in the ultrasonic gas atomizer. Ultrasonics 2020, 102, 105851. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.; Yin, W.J.; Feng, B. Numerical simulation on the distribution characteristics of dust-droplet field dur-ing support movement in a fully-mechanized mining face and related engi-neering applications. J. China Coal Soc. 2018, 43, 3425–3435. [Google Scholar]

- Wang, P.F.; Li, Y.J.; Liu, R.H.; Shi, Y.J. Effect of forced-to-exhaust ratio of air volume on dust control of wall-attached swirling ventilation for mechanized excavation face. Tunn. Undergr. Space Technol. 2019, 90, 194–207. [Google Scholar] [CrossRef]

- Li, Y.J.; Wang, P.F.; Liu, R.H.; Jiang, Y.D.; Han, H. Determination of the optimal axial-to-radial flow ratio of the wall-mounted swirling ventilation in fully mechanized excavation face. Powder Technol. 2020, 360, 890–910. [Google Scholar] [CrossRef]

- Wang, P.F.; Shi, Y.J.; Zhang, L.Y.; Li, Y.J. Effect of structural parameters on atomization characteristics and dust reduction performance of internal-mixing air-assisted atomizer nozzle. Process Saf. Environ. Prot. 2019, 128, 316–328. [Google Scholar] [CrossRef]

- Li, Y.J.; Wang, P.F.; Liu, R.H.; Gao, R.Z. Optimization of structural parameters and installation position of the wall-mounted air cylinder in the fully mechanized excavation face based on CFD and orthogonal design. Process Saf. Environ. Prot. 2019, 130, 344–358. [Google Scholar] [CrossRef]

- Han, H.; Wang, P.F.; Li, Y.J.; Liu, R.H.; Tian, C. Effect of water supply pressure on atomization characteristics and dust-reduction efficiency of internal mixing air atomizing nozzle. Adv. Powder Technol. 2020, 31, 252–268. [Google Scholar] [CrossRef]

- Han, H.; Wang, P.F.; Liu, R.H.; Tian, C. Experimental study on atomization characteristics and dust-reduction performance of four common types of pressure nozzles in underground coal mines. Int. J. Coal. Sci. Technol. 2020, 3, 581–596. [Google Scholar] [CrossRef]

| Spraying Range S/m | Measured Data | Simulation Data | Relative Error/% | |||

|---|---|---|---|---|---|---|

| Wind Velocity/(m/s) | D50/μm | Wind Velocity/(m/s) | D50/μm | Wind Velocity | D50 | |

| 46 | 2.11 | 153.65 | 1.86 | 138.75 | 11.8 | 9.7 |

| 56 | 1.89 | 124.00 | 1.65 | 111.48 | 12.7 | 10.1 |

| 66 | 1.57 | 109.29 | 1.36 | 100.33 | 13.4 | 8.2 |

| 76 | 1.03 | 101.45 | 1.12 | 89.58 | 8.1 | 11.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Wang, J.; Wang, P.; Liu, J.; Yuan, X.; Han, H. Effect of the Installation Angle of Nozzle on the Atomizing Performance of Air-Assisted Spraying Dust Suppression Device. Atmosphere 2022, 13, 520. https://doi.org/10.3390/atmos13040520

Li H, Wang J, Wang P, Liu J, Yuan X, Han H. Effect of the Installation Angle of Nozzle on the Atomizing Performance of Air-Assisted Spraying Dust Suppression Device. Atmosphere. 2022; 13(4):520. https://doi.org/10.3390/atmos13040520

Chicago/Turabian StyleLi, Huijun, Jinxuan Wang, Pengfei Wang, Jiajia Liu, Xinhu Yuan, and Han Han. 2022. "Effect of the Installation Angle of Nozzle on the Atomizing Performance of Air-Assisted Spraying Dust Suppression Device" Atmosphere 13, no. 4: 520. https://doi.org/10.3390/atmos13040520

APA StyleLi, H., Wang, J., Wang, P., Liu, J., Yuan, X., & Han, H. (2022). Effect of the Installation Angle of Nozzle on the Atomizing Performance of Air-Assisted Spraying Dust Suppression Device. Atmosphere, 13(4), 520. https://doi.org/10.3390/atmos13040520