Abstract

Over the past decades, China has suffered from negative environmental impacts from distempered dust-laden airflow-purification activities. After a decade of effort, dust-laden airflow purification and powder particle recycling have been realized in specialized companies in China, and law enforcement for illegal activities of dust-laden airflow discharge has also been made increasingly strict. Thus, up to now, dust-laden airflow purification in China should be developed toward being more in-depth and refined to promote industrial applications of dust-laden airflow purification. This article reviews the status of existing technologies for dust-laden airflow purification. A novel and environmentally friendly technology for purifying the dust-laden airflow is proposed which uses a metal bag filter to collect dust particles. The bottlenecks in the dust-laden airflow-purification system are analyzed. Some preliminary experiments of pinch technologies are also conducted. Finally, in order to provide directional guidance for the future development of metal bag filters, some key points regarding the metal bag filter purification system are proposed to point towards a future trend in dust-laden airflow purification.

1. Introduction

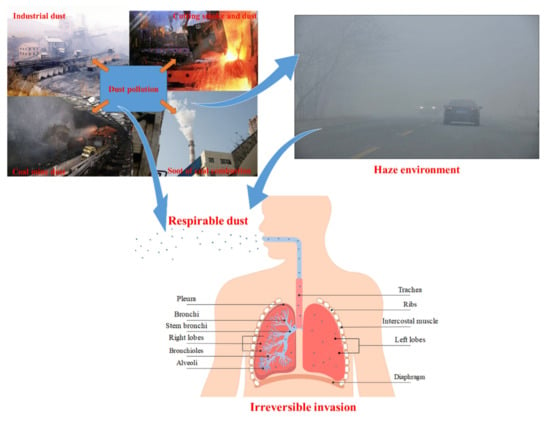

Humans have suffered from negative environmental impacts caused by airborne particles in modern industrial society [1,2,3,4]. Figure 1 shows that small airborne particles from industry can produce detrimental effects on the environment and human health. Research shows that when the concentration of pollutants in the air exceeds the standard, harmful substances will enter the human body via inhalation and reach various organs of the body through the blood, resulting in the gradual failure of various organs. In September 2014, the “Action plan of energy saving, emission reduction, upgrading, and retrofitting of coal-fired power plants” was announced, which demands that the emission of dust in eastern China does not exceed 10 mg/m3. The emission standard for dust from coal-fired power plants that meet 10 mg/m3 is also called the ultra-clean emission standard. Such stringent pollutant emission standards pose great challenges for dust-laden airflow-treatment systems in power plants. The ultra-clean emission standard has been paid great attention by researchers and governments all over the world, especially in China. Because of the adverse effects of air pollutants on health, many governments have formulated guidelines to regulate industry emissions [5,6,7]. Meanwhile, numerous studies have been conducted on the filtration and removal of small airborne particles from dust-laden airflow [8,9,10].

Figure 1.

Influence of the improper small airborne particles from industrial activities on the environment and human health.

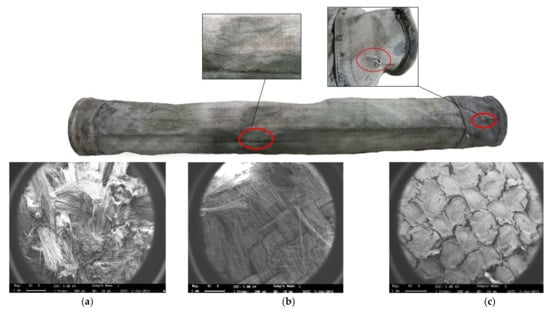

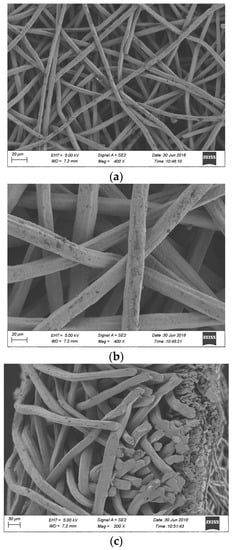

Fiber filtration is a cost-effective scavenger method for fine particulates, and may help to prevent their emissions from escaping into the ambient environment [11,12,13]. Among all types of fabric filters, the bag filter is an effective way of collecting dust emissions [14,15,16]. This is because the bag filter has the advantages of high collection efficiency, high filtration airflow, and easy maintenance [17,18]. However, the filter bags are easily destroyed in use and need to be replaced regularly [19], with the main damage often located 0–500-mm above the bag entrance, which was caused by condensed air working on local filter [20]. In engineering applications, due to the influence of factors such as the layout of the injection pipe, the nozzle, and the injection pressure, the uneven distribution of airflow leads to the uneven distribution of the filter bag load, resulting in damage to the dust collector. In China, according to the filter bag yield of 20%, the amount of discarded waste filter bags was 18 million m2 in 2010 [21,22]. Figure 2 shows the wasted filter bags used in our previous experiment. The bottom location was easily destroyed in industry applications. The wasted filter bags will be burned or landfilled. These treatment methods will lead to environmental problems [23,24].

Figure 2.

The wasted filter bags in our previous experiment. (a) SEM of bottom area. (b) SEM of middle area. (c) SEM of top area.

Therefore, it is anticipated that China has great potential for developing environmentally friendly dust-laden airflow treatment systems. In this paper, taking the metal bag filter as an example, a prospective solution is used to filter dust-laden airflow. This article reviews the status of treatment technologies of dust-laden airflow, then optimizes and integrates the existing proper approaches. The bottlenecks in the dust-laden airflow purification system are analyzed, and some preliminary experiments of pinch technologies are also conducted. A reproducible and sustainable industrial ecological protocol using metal bag filters to filter dust-laden airflow is proposed, providing an efficient, promising, and green method for treating airborne particles in modern industrial society.

2. Environmentally Friendly Metal Bag Filter System

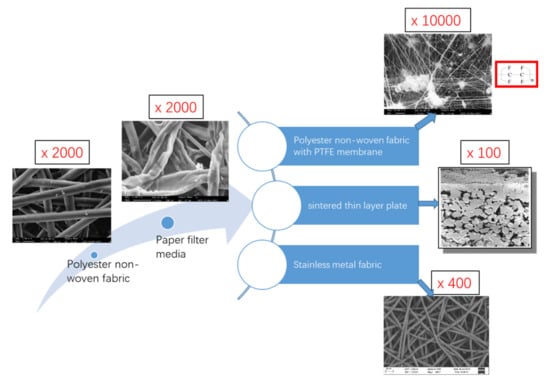

2.1. Evolution of Filter Medium

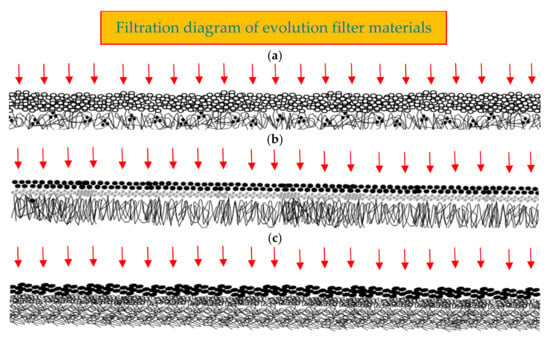

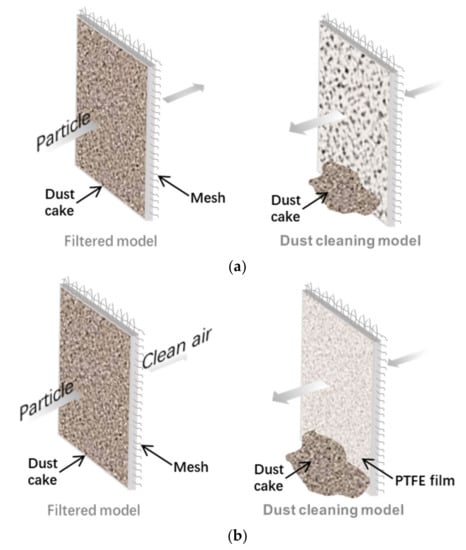

In recent years, with the emergence of new filter materials and the rapid development of preparation technology for filter materials, the new filter materials have greatly increased filtration efficiencies. Figure 3 shows the evolution of filter materials. The microstructures and characteristics of the filter materials are the dominant factors for controlling cake formation and detachment. The processes of cake formation and detachment of different fabrics are quite different [25,26]. Figure 4 shows the filtration and dust-cake removal differences of the evolved filter medium. The fibers in the needle felt filter material are arranged in a three-dimensional staggered manner, which is conducive to the formation of a dust layer. There is no direct gap, and the dust collection rate is higher than that of general woven filter materials. Needle felt filter materials have no or only a small amount of base cloth, so the porosity is, generally, 70–80%, with good air permeability and low resistance. In the filtration process of membrane-coated filter materials, the base cloth and needle felt only play supporting roles. They does not need to rely on the initial dust layer that is formed on the surface of the filter material for filtration, and the PTFE film itself can play the role of the primary dust layer. Regarding the filtering mechanism of metal fiber filter materials: in the design of filter materials, using ultra-fine fibers as the windward surface of metal fiber felt-filter material, combined with using fibers with coarse wire diameters as the support layer, a structure with a gradient structure and pore diameter can be formed on the surface of the filter material from small to large, and most of the dust can be prevented from remaining on the surface of the filter material by a fine-fiber layer, so as to play the role of surface filtration. Some researchers have focused on the microstructures of the filter materials and on the performances of bag filters. Humphries and Madden (1983) tested nine different fabric filters to demonstrate the influence of the fabric structure on the pulse cleaning efficiency [27]. Woo et al. (2001) showed that the filter pores have great influences on the dust-cake detachment [28]. Binnig et al. (2009) showed that the cleaning intensities were related to permeability of filter media [29]. Meanwhile, the surface treatment of filter media has great influences on the cake formation and detachment [30]. Rodrigues et al. (2005) showed that surface treatment of filter media afforded an increased particle collection efficiency and a reduced residual pressure during the filtration [31]. According to Mauschitz et al. (2005), the surface treatment of filter media prolonged the filtration period and reduced the pressure drop after pulse cleaning [32]. The above results show that the microstructures of the filter media have a profound effect on cake formation and detachment, even in apparently similar fabrics [33,34].

Figure 3.

Microstructures of novel filter materials.

Figure 4.

Filtration differences of the evolution filter medium. (a) Conventional fiber needled felt and ash layer. (b) Surface treatment with polytetrafluoroethylene fibers and ash layer. (c) Metal fiber and ash layer.

Therefore, the micro morphology of the filter materials can regulate and control the macroscopic properties of the filter. From Figure 3, Figure 4 and Figure 5, the microstructures and characteristics of the filter materials are the dominant factors for controlling cake formation and detachment. The filtration materials develop towards surface-filtration and gradient-filtration structures, as shown in Figure 5. The metal fiber filter materials, especially, have potential to filter dust-laden airflow. Figure 6 shows the microstructures of stainless metal fiber filter materials. Metal fiber filter materials are a new novelty filtration medium. The metal fibers are sintered after the non-woven laying. Gradient fiber layer structures were designed. The porous metal fiber materials are horn gradient structures and have through-holes. Meanwhile, metal fiber filter materials are resistant to high temperatures. Therefore, metal fiber filter materials have great potential for use in high-temperature dust-laden airflow filtration.

Figure 5.

Dust cake detachment differences of the different evolutions of filter media. (a) Dust cake detachment for conventional fiber needled felt and ash layer (deep filtration). (b) Dust cake detachment for surface treatment and metal filter materials (apparent filtration).

Figure 6.

Microstructures of metal filter materials. (a) Surface of stainless metal fabric. (b) Supporting surface of stainless metal fabric. (c) Cross-section of stainless metal fabric.

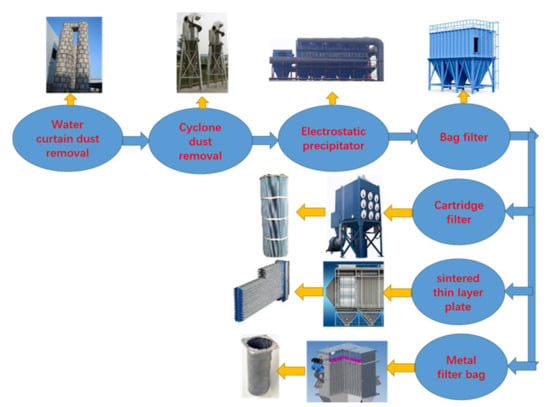

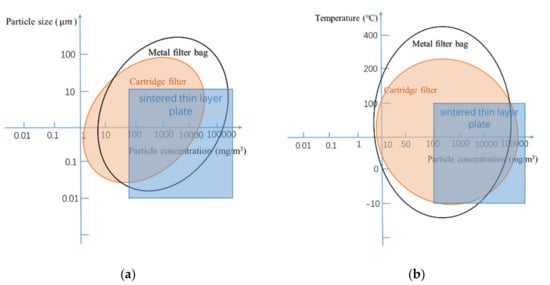

2.2. Evolution of Dust Collector

In China, the government has made great effort to protect the environment. Dust emissions, especially, have been given tremendous limitations. Therefore, dust-laden airflow purification in China should be developed toward being more in-depth and refined to obtain clean airflow discharge. Although the Chinese government and a number of researchers have made great efforts to improve dust-laden airflow purification, there are still some obstacles that limit the industrial application of dust collectors. Specifically, dust collectors have been used to collect high-temperature airflow, ultrafine particles, absorbent particles, and high dust concentrations, etc. Figure 7 shows the evolution of dust collectors. Up to now, cartridge filters and bag filters have been used to collect high dust concentrations and ultrafine particles. The sinter-plate filter can be used to collect high dust concentrations, high-humidity dust-laden airflow, and ultrafine particles. The metal bag filter can be used to collect high-temperature dust-laden airflow and ultrafine particles. Figure 8 shows the area map of dry-type dust collectors in terms of particle size, filtration temperature, and dust concentration space. The conventional bag filter can be used to collect dust-laden airflow at temperatures <280 °C. The metal fiber bag filter can be used to collect dust-laden airflow at high temperatures (>280 °C). The metal fiber filter bag made of stainless can resist temperatures as high as 400 °C. If the FeCrAL medium is used, the metal fiber filter bag can resist temperatures as high as 1000 °C. Therefore, using the metal fiber bag filter to filter dust-laden airflow is environmentally friendly.

Figure 7.

The evolution of dust collectors.

Figure 8.

Area map of dry-type dust collectors in terms of particle size, filtration temperature, and concentration space. (a) Area map of dry-type dust collectors in terms of particle size and concentration space. (b) Area map of dry-type dust collectors in terms of filtration temperature and concentration space.

Some researchers have directed some focus toward the filtration performances of the metal bag filters. Su et al. (2016) showed that metal fiber bags have the characteristics of high-temperature resistance, good air permeability, low pressure loss, corrosion resistance, and easy processing [35]. Choi J H et al. (2004) have shown that the metal filter element has higher air permeability than conventional filter elements [36]. According to Sun et al. (2015), the metal fiber-sintered felt has good air permeability. The metal-sintered felt with the fiber diameter of 15 μm has pressure loss of only 49 Pa, and its filtration efficiency can be as high as 99.99%. Meanwhile, the dust discharge concentration was lower than 3.6 mg/m3 [37]. Yang et al. (2018) used the metal bag filters and evaluated the performances of metal bag filters in a cement plant. The results showed that the dust discharge concentration was as low as 5.62 mg/m3 [38]. This dust emission concentration meets the most stringent national emission standards in China. Therefore, the metal bag filters will be widely used to remove the dust fields from coal-fired boilers of power plants, oil and gas separation, gas purification, cement manufacturing, chemical catalyst recovery, waste incineration, and EAF steelmaking, etc.

2.3. Environmentally Friendly Metal Bag Filter System for High-Filtration Velocity Dust-Laden Airflow

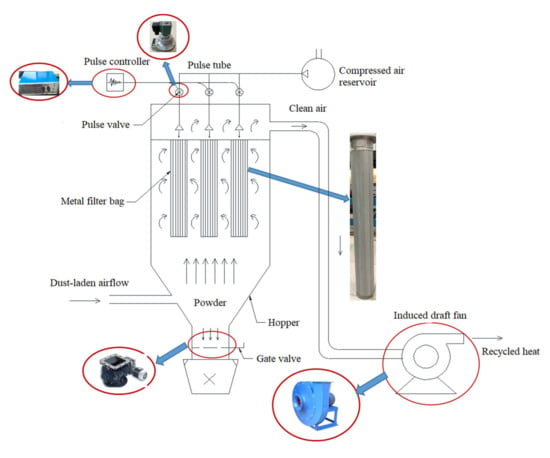

In summing up experiences of the existing techniques, a process which is suitable and has potential for industrial applications, as presented in Figure 9, developed by our team from the Southwest University of Science and Technology, China, satisfies the requirements of a high-filtration velocity system for dust-laden airflow purification, namely: (1) widespread applicability for dust-laden airflow purification, due to the collection of high dust concentrations and high-filtration velocity; (2) high efficiency—the metal fibers are sintered after the non-woven laying. Gradient fiber-layer structures were designed. The porous metal fiber materials are the horn gradient structures and have through-holes. Meanwhile, the metal fiber materials have the resistance to high temperatures; (3) low cost and low energy consumption, for the simple construction of equipment and industrial waste heat reutilization; (4) environmentally friendly, for no pollution to environment.

Figure 9.

The metal filter bag system for purification of the high-velocity dust-laden airflow.

2.4. Environmentally Friendly Metal Bag Filter System for High-Temperature Dust-Laden Airflow

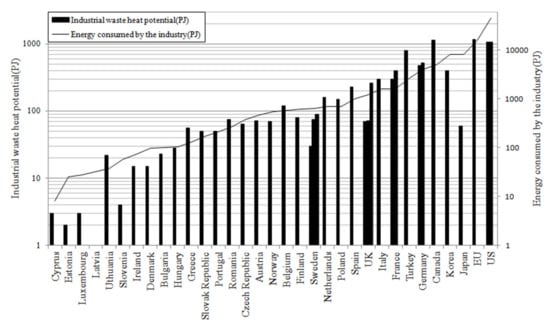

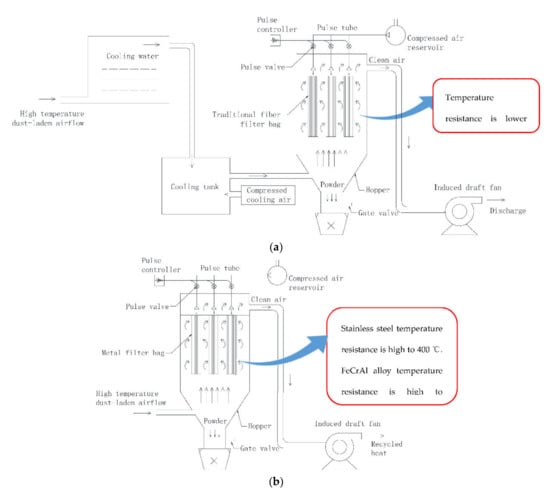

Industrial exhaust heat is a potential energy source. Moreover, the industrial sector is one of the top three energy-consuming sectors worldwide [39,40]. Figure 10 shows the relation of the industrial waste heat potential (left axis) and the energy consumed by the industry (right axis) [41]. The utilization amounts of industrial waste heat found are lower than expected. In China, based on investigation, the exhaust heat is 17–67% of the total fuel consumption. The recyclable exhaust heat is 60% of the total exhaust heat. Currently, the industrial exhaust heat was used mainly to generate electricity and as a heat source. However, the efficiency is about 20% to generate electricity. Moreover, much of the exhaust heat has not been used. The 30% exhaust steam (temperature is lower than 400 °C) discharges into the atmosphere directly. Some places (especially cold areas) use industrial exhaust heat to stay dry and warm. Among all the industrial sectors, the main waste-heat producers are usually the metal industry, chemical industry, food and drinks industry, pulp and paper industry, and non-metal minerals (including cement, glass, ceramic, and lime) industries [42,43,44,45,46,47]. The mostly industrial waste heat is the dust-laden airflow. The conventional bag filter can be only used to collect dust-laden airflow that is cooler than 280 °C. Therefore, the industrial waste heat is cooled to lower than 280 °C, and the industrial waste heat is discarded, as shown in Figure 11. From Figure 11, a metal bag filter can be used directly to filter high-temperature dust-laden airflow. This novel filter material is the dominant factor for controlling wasted heat utilization.

Figure 10.

The relation of the industrial waste heat potential (left axis) and the energy consumed by the industry (right axis).

Figure 11.

The traditional fiber filter bag and metal filter bag system for purifying the high-temperature dust-laden airflow. (a) The traditional fiber bag filter system for purifying the high-temperature dust-laden airflow. (b) The metal bag filter system for purifying the high-temperature dust-laden airflow.

A novel environmentally friendly way is proposed for filtering high-temperature dust-laden airflow. The high-temperature airflow, after treatment, can be used to generate electricity, cold, or another type of heat. This can have an importance influence on the reutilized industrial waste heat. The novel metal filter bag can be used in this experiment. The novel metal filter bag has a high resistance to destruction. Meanwhile, the metal bag filter can be used to filter high-temperature dust-laden airflow directly. The high-temperature airflow, after treatment, has more selectivity and can possibly be reused. Meanwhile, the abrasion of dust particles on the heat exchanger will be drastically reduced. Sometimes, the environmental problem can be resolved.

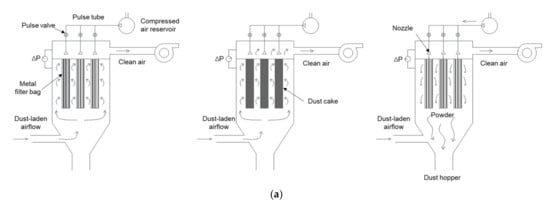

3. Environmentally Friendly Metal Bag Filter System for Filtration

3.1. An Idea for Environmentally Friendly Metal Bag Filter System

In our preliminary experiment, the bottleneck of the environmentally friendly metal bag filter is the cleaning performance of the metal filter bag. The microstructures of the metal filter and the gradient structures make the macro filtration and cleaning performance differ from the other filters, as shown in Figure 4 and Figure 5. In order to investigate the cleaning performance of metal filter bag, the experiment was designed to obtain the relationship between residual dust and pressure drops vs. the filtration velocity.

3.1.1. Experimental Setup and Experimental Design

The diagram of the metal filter bag system for purification of the dust-laden airflow was shown in Figure 9. Six metal filter bags were used in the dust collector. The metal filter bag (φ 130 × 1000 mm) was made of 316 L stainless materials. The microstructures were shown in Figure 6. The filter thickness is 0.52 mm, the porosity is 78%, and the air permeability is 120 L (min·dm2)−1 at 200 Pa. The experimental setup consists of a compressed-air supply system. The cleaning pulse of the compressed air is kept at a constant by a pressurized air reservoir (volume, 40 L) and is controlled by a pulse valve.

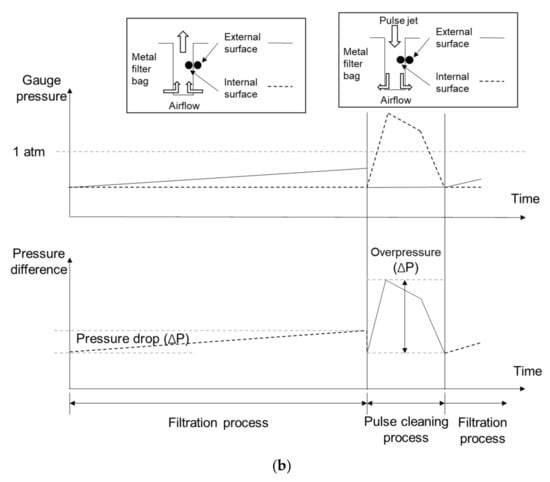

The experimental design: systematic pressure drops (systematic resistance) at various filtration velocities were observed and recorded during the experiment. In the experimental process, the dust collector dislodged the dust cakes automatically. The pulse width (opening time of electromagnetic valve (DMF-Z-20 type) controlled by a pulse controller) was 0.08 s and the pulse interval was 10 s. After 60 min, the dust feed was stopped and each cartridge was carried out manually for only one pulse-jetting; then, the machine was shut down and six metal filter bags were taken out and weighed, respectively. After weighing, six metal filter bags were put back into the filter and jet pulsed continuously several times, until their surfaces resembled the new ones. Then, the operation conditions were reset for the next experiment. The residual dust cakes are defined as the weight difference between the cleaned filter cartridge and a new one. In our preliminary experiment, the dust concentration was set at 0.08 kg/m3 (fly ash dust, particle size is d10 = 2.352 μm, d50 = 10.361 μm, d90 = 36.24 μm). The pulse pressure was set at 0.5 MPa and the filtration velocity was set at 2.0–2.8 m/min. The jet nozzle was set to 7 mm; the jet distance was set to 150 mm. These cleaning parameters were obtained in our previous experiment [48]. Figure 12 shows that the pressure drop varies with time during the filtration and cleaning process for the purification of the dust-laden airflow.

Figure 12.

The pressure drop varies as the time during the filtration and cleaning process for purification the dust-laden airflow. (a) The filtration and cleaning process. (b) The pressure drop varies with time during the filtration and cleaning process.

3.1.2. Experimental Results and Discussions

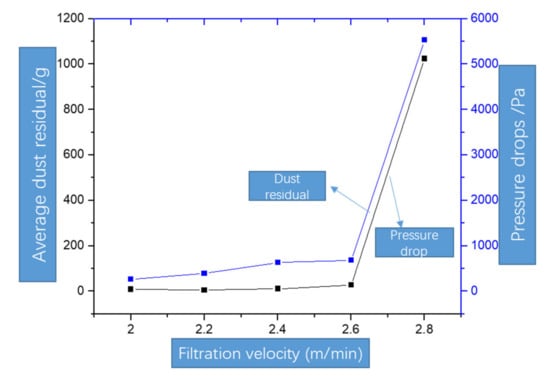

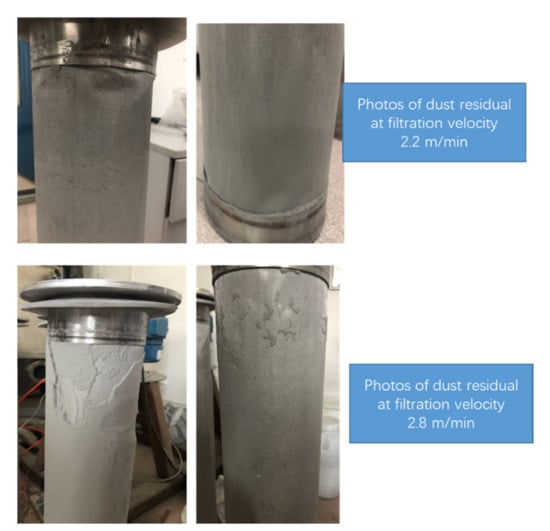

Figure 13 shows that the residual dust and pressure drops varies with the filtration velocity during the filtration and cleaning process for the purification of the dust-laden airflow. When the filtration velocity is 2.0, 2.2, and 2.4 m/min, the residual dust and systematic pressure drops appear to be positively correlated to the filtration velocity, and the curves increase in a relatively stable manner. When the filtration velocity increases to 2.6 m/min, the residual dust and systematic pressure drops increase further at the top area of the metal filter bag, especially at 5 cm from the opening of the metal filter bag. When the filtration velocity increases to 2.8 m/min, the dust layer on the filter material will be compacted, resulting in a sharp increase in residual dust and systematic pressure drops. Figure 14 shows the photos of the residual dust at filtration velocities of 2.2 and 2.8 m/min. Therefore, under our experimentally designed parameters, the filtration velocity of the metal filter bag should be lower than 2.8 m/min. In our next study, the relationship between the residual dust and the systematic pressure drops vs. the filtration and cleaning parameters will be investigated. Moreover, there is one problem that should be considered in more attempts in further studies.

Figure 13.

The residual dust and pressure drops vary with filtration velocity during the filtration and cleaning process for the purification of the dust-laden airflow.

Figure 14.

The photos of residual dust at filtration velocities of 2.2 and 2.8 m/min.

4. Future Points of Environmentally Friendly Metal Bag Filter System

After a decade of effort, China has a relatively developed legislative system, formal filtration systems, and advanced controlling techniques. The future development direction of the filtration system, which ought to be more in-depth and refined, should be focused on both higher filtration efficiencies and ultra-clean emissions, and should be more environmentally friendly.

There are four considerations that ought to be noticed and ensured: (1) ultra-clean emissions should be obtained, especially for the PM2.5, and the superfine fiber surface layer or gradient filter structure should be used; (2) breakage-resistant materials should be used, such as metal filter materials or sintered thin layer plates; (3) for systematic stability, the rational pulse jet cleaning parameters for the filtration system should be used; (4) the intelligent management of the filtration system and cleaning filtration should be ensured. In addition, in future studies, sufficient attention should also be on developing alternative technologies which are more environmentally friendly.

Author Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by M.Z., X.M., A.L., C.Y., W.Q., P.L., M.H. and C.H. The first draft of the manuscript was written by M.Z. and all authors commented on previous versions of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by the Opening Project of the State Key Laboratory of Advanced Technology for Float Glass (2018KF04), the National Natural Science Foundation of China (No. 51508481), the Longshan Fund of the Southwest University of Science and Technology (No. 18LZX659, 17LZX661), and was also supported by Xi’an Filter Metal Materials Co., Ltd. (18zh0200).

Institutional Review Board Statement

The participant has consented to the submission of the case report to the journal.

Informed Consent Statement

Informed consent was obtained from all individual participants included in the study.

Data Availability Statement

The data and materials used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Conflicts of Interest

The author(s) of this study declared no potential conflict of interest with reference to the research, authorship, and/or publication of this study.

References

- Park, S.; Joe, Y.H.; Shim, J.; Park, H.; Shin, W.G. Non-uniform filtration velocity of process gas passing through a long bag filter. J. Hazard. Mater. 2019, 365, 440–447. [Google Scholar] [CrossRef]

- Mo, J.; Tian, E.; Pan, J. New electrostatic precipitator with dielectric coatings to efficiently and safely remove sub-micro particles in the building environment. Sustain. Cities Soc. 2020, 55, 102063. [Google Scholar] [CrossRef]

- Johnson, R.; Rieuwerts, J.; Comber, S.D.W. How does a country’s developmental status affect ambient air quality with respect to particulate matter? Int. J. Environ. Sci. Technol. 2021, 18, 3395–3406. [Google Scholar] [CrossRef]

- Wang, Y.; Tapia-Brito, E.; Riffat, J.; Chen, Z.; Jiang, F.; Riffat, S. Investigation on the Efficient Removal of Particulate Matter (PM) with Biomass-Based Aerogel. Future Cities Environ. 2021, 7, 12. [Google Scholar] [CrossRef]

- Gong, G.; Yao, L.; Ren, L. Study on air pollution control under the influence of energy policy in Shanxi Province. In IOP Conference Series: Earth and Environmental Science, Proceedings of the 3rd International Conference on Environmental Prevention and Pollution Control Technologies, Zhuhai, China, 15–17 January 2021; IOP Publishing: Bristol, UK, 2021; Volume 687, p. 012127. [Google Scholar]

- Cui, L.; Li, Y.; Tang, Y.; Shi, Y.; Wang, Q.; Yuan, X.; Kellett, J. Integrated assessment of the environmental and economic effects of an ultra-clean flue gas treatment process in coal-fired power plant. J. Clean. Prod. 2018, 199, 359–368. [Google Scholar] [CrossRef]

- Conibear, L.; Reddington, C.L.; Silver, B.J.; Knote, C.; Arnold, S.R.; Spracklen, D.V. Regional policies targeting residential solid fuel and agricultural emissions can improve air quality and public health in the Greater Bay Area and across China. GeoHealth 2021, 5, e2020GH000341. [Google Scholar] [CrossRef]

- Andenana, N.; Rashida, M.; Hajara, S.; Jamian, N.R.; Pa’ad, K.M.; Rashid, A.M. Effect of Filter Aids on Two Different Filter Media Under High Filtering Velocities. Chem. Eng. Trans. 2019, 72, 37–42. [Google Scholar]

- Boudhan, R.; Joubert, A.; Durecu, S.; Gueraoui, K.; LE Coq, L. Influence of air humidity on particle filtration performance of a pulse-jet bag filter. J. Aerosol Sci. 2019, 130, 1–9. [Google Scholar] [CrossRef]

- Kim, H.B.; Lee, W.J.; Choi, S.C.; Lee, K.B.; Lee, M.-H. Dependence of the fiber diameter on quality factor of filters fabricated with meta-aramid nanofibers. Sep. Purif. Technol. 2019, 222, 332–341. [Google Scholar] [CrossRef]

- Cuiping, Y.; Mingxing, Z.; Longyuan, L.; Haiyan, C. An analysis of a reverse pulse cleaning process using high-flow pleated fabric filter cartridges. Process Saf. Environ. Prot. 2018, 113, 264–274. [Google Scholar] [CrossRef]

- Tao, R.; Yang, M.; Li, S. Effect of adhesion on clogging of microparticles in fiber filtration by DEM-CFD simulation. Powder Technol. 2020, 360, 289–300. [Google Scholar] [CrossRef]

- Li, R.; Wang, B.; Owete, O.; Dertien, J.; Lin, C.; Ahmad, H.; Chen, G. Landfill Leachate Treatment by Electrocoagulation and Fiber Filtration. Water Environ. Res. 2017, 89, 2015–2020. [Google Scholar] [CrossRef]

- Musa, S.; Sidik, N.A.C.; Yusof, S.N.A.; Erdiwansyah, E. Analysis of Internal Flow in Bag Filter by Different Inlet Angle. J. Adv. Res. Numer. Heat Transf. 2020, 3, 12–24. [Google Scholar]

- Heo, K.J.; Oh, H.J.; Eom, H.; Kim, Y.; Jung, J.H. High-performance bag filter with a super-hydrophobic microporous polytetrafluoroethylene layer fabricated by air-assisted electrospraying. Sci. Total Environ. 2021, 783, 147043. [Google Scholar] [CrossRef]

- Boudhan, R.; Joubert, A.; Gueraoui, K.; Durécu, S.; Venditti, D.; Tran, D.T.; LE Coq, L. Pulse-jet bag filter performances for treatment of submicronic and nanosized particles from waste incineration. Waste Biomass Valorization 2018, 9, 731–737. [Google Scholar] [CrossRef]

- Kim, C.S.; Bao, L.; Okuyama, K.; Shimada, M.; Niinuma, H. Filtration efficiency of a fibrous filter for nanoparticles. J. Nanopart. Res. 2006, 8, 215–221. [Google Scholar] [CrossRef]

- Lv, Y.R.; He, H.W.; Chen, F.X.; Yu, J.; Ning, X.; Zhou, R. Polyphenylene sulfide (PPS) fibrous felt coated with conductive polyaniline via in situ polymerization for smart high temperature bag-filter. Mater. Res. Express 2019, 6, 075706. [Google Scholar] [CrossRef]

- Fukui, K.; Ichiba, G.; Rozy, M.I.F.; Ito, K.; Fukasawa, T.; Ishigami, T. Effects of NO2 gas concentration on the degradation of polyphenylene sulfide non-woven bag filter at high temperature. Adv. Powder Technol. 2021, 32, 3278–3287. [Google Scholar] [CrossRef]

- Choudhary, A.K.; Mukhopadhyay, A. Particulates: Selection of cleaning pulse pressure for pulse jet fabric filtration. Filtr. Sep. 2013, 50, 28–30. [Google Scholar] [CrossRef]

- Bo, W. Simple explanation on disposal of scrap filter bag of bag-hose precipitator. China Environ. Prot. Ind. 2011, 6, 63–66. [Google Scholar]

- Zhou, Y.; Ning, X.; Liao, X.; Lin, M.; Liu, J.; Wang, J. Characterization and environmental risk assessment of heavy metals found in fly ashes from waste filter bags obtained from a Chinese steel plant. Ecotoxicol. Environ. Saf. 2013, 95, 130–136. [Google Scholar] [CrossRef] [PubMed]

- Zhou, R.; Shen, H.; Zhao, M. Simulation Studies on Protector of Pulse-jet Cleaning Filter Bag. Energy Procedia 2012, 16, 426–431. [Google Scholar] [CrossRef][Green Version]

- Li, S.; Wang, F.; Xin, J.; Xie, B.; Hu, S.; Jin, H.; Zhou, F. Study on effects of particle size and maximum pressure drop on the filtration and pulse-jet cleaning performance of pleated cartridge filter. Process Saf. Environ. Prot. 2019, 123, 99–104. [Google Scholar] [CrossRef]

- Hasolli, N.; Park, Y.O.; Rhee, Y.W. Filtration performance evaluation of depth filter media cartridges as function of layer structure and pleat count. Powder Technol. 2013, 237, 24–31. [Google Scholar] [CrossRef]

- Ma, D.; Zheng, Q.; Lin, W.; Guo, M. Improvements to dust filtration through acoustic agglomeration and atomization. Aerosol Sci. Technol. 2017, 51, 824–832. [Google Scholar] [CrossRef]

- Humphries, W.; Maddencoal-fi, J.J. Fabric filtration for red boilers: Dust dislodgement in pulse jet filters. Filtr Sep. 1983, 20, 40–44. [Google Scholar]

- Woo, S.K.; Lee, K.S.; Han, I.S.; Seo, D.W.; Park, Y.O. Role of porosity in dust cleaning of silicon carbide ceramic filters. J. Ceram. Soc. Jpn. 2001, 109, 742–747. [Google Scholar] [CrossRef][Green Version]

- Binnig, J.; Meyer, J.; Kasper, G. Origin and mechanisms of dust emission from pulse-jet cleaned filter media. Powder Technol. 2009, 189, 108–114. [Google Scholar] [CrossRef]

- Cuiping, Y.; Guijian, L.; Haiyan, C. Variety Behaviors of Depth and Surface Filter Media with the Ages for Pleated Filter Cartridges. Environ. Eng. Manag. J. 2018, 17, 2577–2586. [Google Scholar] [CrossRef]

- Rodrigues, K.B.; Tieni, E.F.; Gonçalves, J.A.S. Filter media and powder materials influence in the performance of filtration cycles. In Proceedings of the Filtech Europa, Wiesbaden, Germany, 11–13 October 2005. [Google Scholar]

- Mauschitz, G.; Koschutnig, W.; Hoeflinger, W. Analysis of the clogging behaviour of thermally finished nonwoven dust filter media by optically detected porosity parameters. In Proceedings of the Filtech Europa, Wiesbaden, Germany, 11–13 October 2005; pp. II20–II28. [Google Scholar]

- Panov, S.Y.; Belykh, O.M.; Zinkovskii, A.V.; Momotov, V.S. Features of the regeneration process of the filter. Vestn. VGUIT Proc. Voronezh State Univ. Eng. Technol. 2015, 175–179. [Google Scholar]

- Tanabe, E.H.; Barros, P.M.; Rodrigues, K.B.; Aguiar, M. Experimental investigation of deposition and removal of particles during gas filtration with various fabric filters. Sep. Purif. Technol. 2011, 80, 187–195. [Google Scholar] [CrossRef]

- Su, N.; Yang, Y.; Zuo, C. Advantage of metal fiber felt filter bag in high temperature flue gas dust removal. China Environ. Prot. Ind. 2016, 2, 35–36. (In Chinese) [Google Scholar]

- Choi, J.H.; Ahn, I.S.; Bak, Y.C.; Bae, S.-Y.; Ha, S.-J.; Jang, H.-J. Preparation of high porous metal filter element for the fail-safety function. Powder Technol. 2004, 140, 98–105. [Google Scholar] [CrossRef]

- Sun, P.; Meng, W.; Bai, W. Study on the Filtration Performance of Metal Fiber Sintered Felt for Dust Removal. Filtr. Sep. 2015, 25, 30–32. (In Chinese) [Google Scholar]

- Yang, Q.; Hou, L.; Lu, X.; Zhang, X.; Su, N.; Li, M.; Wang, L. Application analysis for metal fiber filter material in cement dust extraction domanial. J. Cem. 2018, 12, 39–41. (In Chinese) [Google Scholar]

- European Environment Agency. Final Energy Consumption by Sector. 2013. Available online: http://www.eea.europa.eu/data-and-maps/indicators/finalenergy-consumption-by-sector-5/assessment (accessed on 15 February 2017).

- Eurostat. 2017. Available online: http://ec.europa.eu/eurostat/ (accessed on 15 February 2017).

- Miró, L.; Brückner, S.; Cabeza, L.F. Mapping and discussing Industrial Waste Heat (IWH) potentials for different countries. Renew. Sustain. Energy Rev. 2015, 51, 847–855. [Google Scholar] [CrossRef]

- Blesl, M.; Ohl, M.; Fahl, U. Ganzheitliche Bewertung Innovativer Mobiler Thermischer Energiespeicherkonzepte für Baden-Württemberg auf Basis Branchen-Und Betriebsspezifischer Wärmebedarfsstrukturen: Endbericht. 2011. Available online: http://dx.doi.org/10.18419/opus-1988 (accessed on 24 February 2022).

- Berthou, M.; Bory, D. Overview of waste heat in the industry in France. In Proceedings of the ECEEE 2012 Summer Study on Energy Efficiency in Industry, Arnhem, The Netherlands, 11–14 September 2012; pp. 453–459. [Google Scholar]

- McKenna, R.C.; Norman, J.B. Spatial modelling of industrial heat loads and recovery potentials in the UK. Energy Policy 2010, 38, 5878–5891. [Google Scholar] [CrossRef]

- Hammond, G.P.; Norman, J.B. Heat recovery opportunities in UK manufacturing. In Proceedings of the International Conference on Applied Energy (ICAE2012), Suzhou, China, 5–8 July 2012. [Google Scholar]

- Werschy, M. Technologierecherche Abwärmenutzung; DBI Gasund Umwelt-Technik GmbH für die Sächsische Energieagentur–SAENA GmbH: Freiburg, Germany, 2012. [Google Scholar]

- Chung, M.; Im, Y.H.; Park, B.S. Distribution of industrial waste heat and characteristics of heat trading among district heating companies in Korea. In Proceedings of the International Conference on Applied Energy (ICAE), Pretoria, South Africa, 1–4 July 2013. [Google Scholar]

- Qin, W.; Zhang, M.; Kang, Y.; Fu, H.; Hou, L.; Zhang, X.; Chen, H. Analysis of factors affecting pressure distribution of pulse jet metal filter bag. Chin. J. Environ. Eng. 2020, 14, 465–472. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).