1. Introduction

Cyclone separators are an important class of separation equipment in chemical processes. In the literature, several studies, such as application of computational fluid dynamics (CFD) to analyze the gas–solid flow behavior of cyclones [

1], performance evaluation of a wellhead multistage bundle gas–liquid separator [

2], numerical study of the gas–solid two-phase flow in the tangential inlet cyclone separator [

3], gas–solid simulations of a small cyclone separator [

4], numerical assessment of the performance of pre-existing cyclone separators [

5], and numerical characterization of the performance of new cyclone separators [

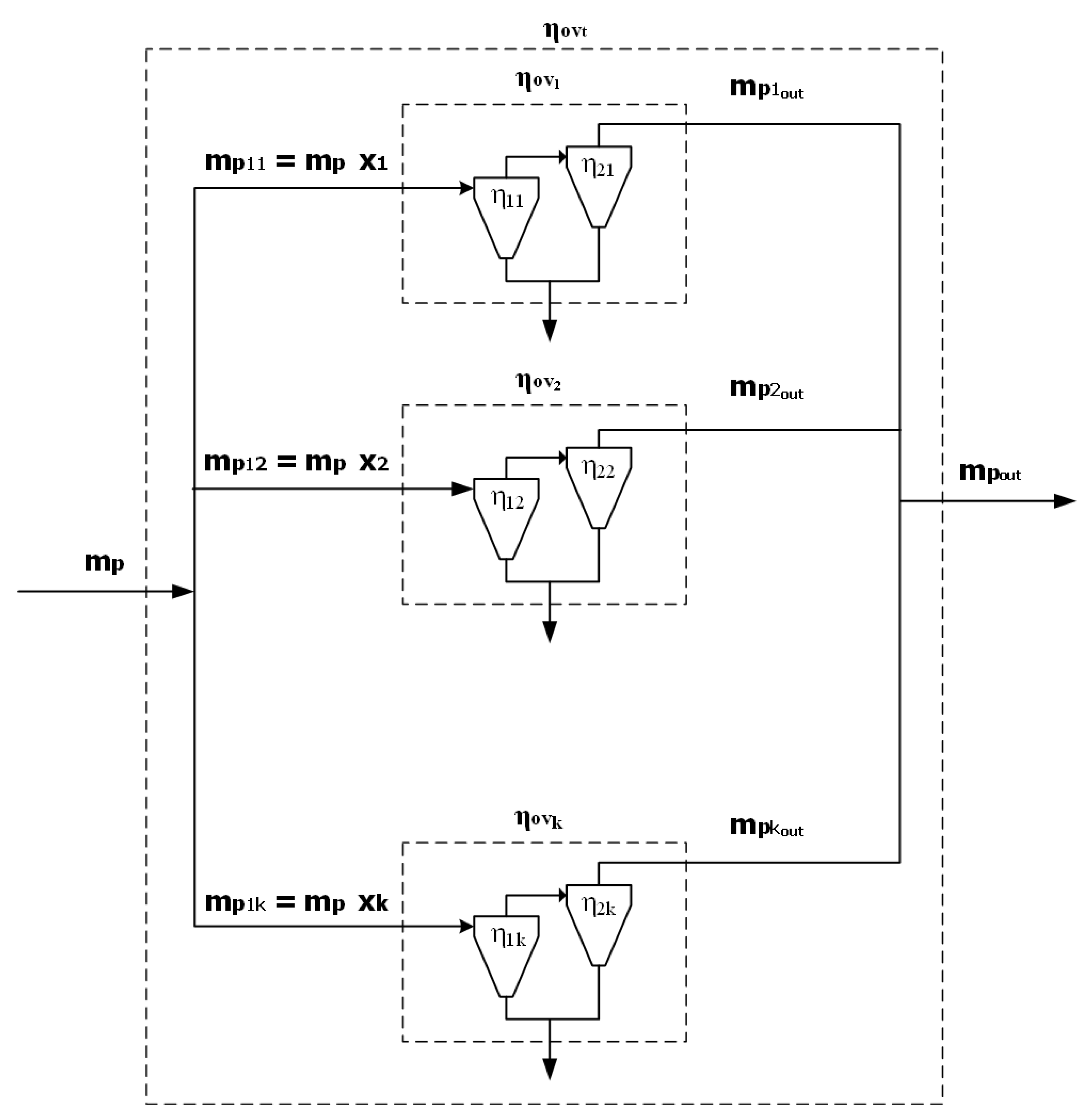

6], have been reported on different types of cyclone separators depending on the type of feed utilized. Cyclone separators are primarily used to separate particles of a specific size, such as granular applications or in the removal of pollutant particles. The driving force for the gas-solid separation consists of the centrifugal force caused by the stream passing through the cyclone. Due to this centrifugal force, heavier particles move towards the wall of the cyclone while the lighter particles concentrate towards the center and then move upwards through an inner cylindrical section. Compared to other gas-solid separation technology such as membranes or filters, cyclones are more advantageous with respect to efficiency, operational flexibility and also capital cost. Efficiency and pressure drop are two important parameters used to quantify the performance and design of a cyclone when used stand-alone or in series/parallel configuration. In general, a higher efficiency is achieved at the cost of higher pressure drop which in turn increases the operating costs. An optimal design of the cyclone or configuration of cyclones would yield higher efficiency with lower pressure drop. To achieve this, more than one cyclone is used in series and parallel configuration where the number and size of the different cyclones used can be obtained by performing optimization studies. This requires an accurate description of the behavior of the cyclone which can be achieved from experiments and/or mathematical modeling. Many studies have been conducted and reported based on experimental, theoretical, and computational research on cyclones. The majority of these studies have focused on the development of single cyclones. By using cyclones in series, a higher efficiency can be achieved at the cost of higher pressure drop, but the literature related to this configuration is very scarce [

7]. Additionally, few research groups have conducted studies (e.g., implementation of mathematical programming models for optimizing the configuration of series and parallel cyclone arrangement in a fertilizer plant [

8], optimization of gas cyclones operating in parallel mode [

9], iterative computation approach for optimizing the number and size of parallel cyclones [

10], nondominated sorting genetic algorithm (NSGA)-based multiobjective optimization of a set of identical reverse-flow cyclone separators in parallel arrangement [

11], and application of geometric programming for the optimal design of cyclone separators [

12]) for parallel arrangement of cyclones. Several advances in the structural optimization and also modern optimization tools have led to obtaining optimal solutions for very tedious cyclone optimization problems [

13,

14]. General Algebraic Modeling System (GAMS) is robust software for solving complex optimization problems which is used for the research described in this article [

15]. Cyclones used in a paper mill industry [

11,

16] are considered for the modeling and optimal configuration. The geometric parameters used to describe a cyclone are shown in

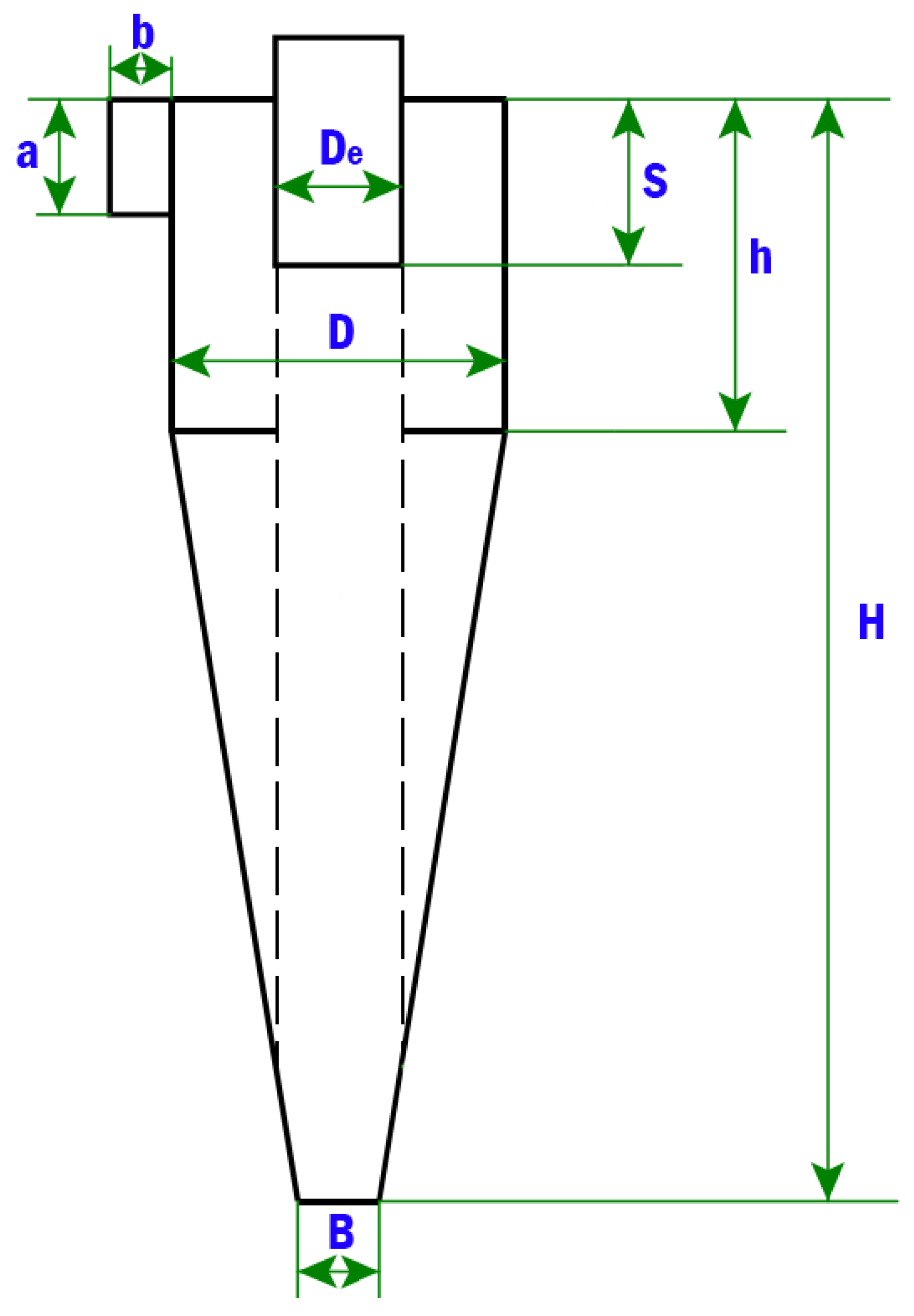

Figure 1.

In

Figure 1,

a is the inlet height,

b is the inlet width,

B is the dust outlet diameter,

D is the diameter of the cyclone,

De is the gas outlet or vortex finder diameter,

S is the gas outlet length,

h is the cylindrical height of the cyclone and

H is the overall height of the cyclone. Cyclones are also designed by using nDmD, where n and m are numbers used as multiples of the diameter to obtain the cylindrical height (

h) and the conical height (

H-

h). For example, a cyclone represented by 1D3D means the cylindrical height is equal to the diameter while the conical height is equal to three times the diameter. By knowing these three parameters, the values of other unknown parameters (such as

B,

S,

De, etc.) of the cyclone are fixed. In this article, 1D3D and 2D2D cyclones are used for optimization. Wang et al. [

17,

18] reported that 1D3D and 2D2D cyclones are more efficient in capturing particle diameters less than 100 nm compared to other cyclone designs. There are other experimental studies performed using these cyclones to evaluate their performance when used in series. An existing 2D2D cyclone was connected to other 2D2D cyclone for the first test and to a 1D3D cyclone for the second test by Gillum et al. [

19]. The results showed that the overall efficiency of 2D2D–1D3D in series (99.82%) was greater than 2D2D–2D2D (99.78%) where the pressure drop across the secondary 1D3D cyclone (1115 Pa) was greater than the 2D2D secondary cyclone (1010 Pa). Columbus [

20] also studied a 2D2D primary cyclone in series with a 1D3D secondary cyclone in capturing particulate matters (PM) emitted from a seed cotton separator. The results showed that the overall efficiency of the arrangement was 97% in the first study and 96.4% in the second followed by a very high pressure drop in all treatments. Whitelock and Buser [

21] evaluated the effectiveness of up to four 1D3D cyclones in series on heavy loading of particulate air streams (236 g/m

3). Their study showed that the series arrangement had a significant improvement in cyclone overall efficiency (97%) compared to a single cyclone (91%). However, having the two cyclones in series appeared to be the best choice because use of three or four 1D3D cyclones in series only slightly increased the overall efficiency along with a significant increase in the pressure drop across all cyclones. The experimental studies exploring different number of cyclones and different arrangement have paved a way to develop a mathematical model which in turn is used to solve an industrial emission problem.

3. Results and Discussion

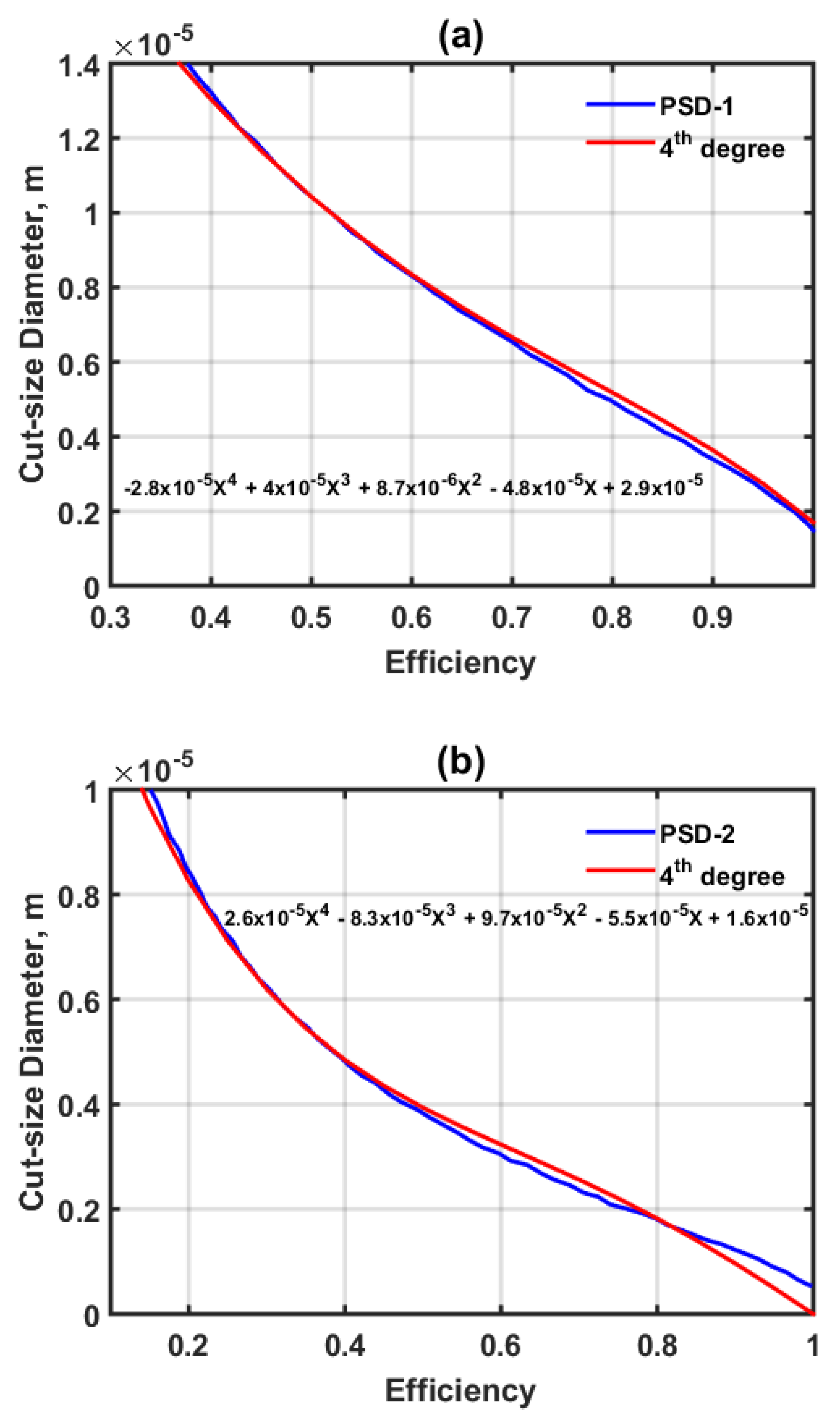

Optimization is performed for different scenarios where the bounds for the decision variables are varied between the values specified in

Table 4. The results show that the optimal value of cyclone diameter (

Dp) lies at its upper bound (

). The value of

is found to be the most important decision variable that will lead the model to obtain the optimal solution to the problem. The search is stopped purposely at the value of 2.5 m of the upper bound of

Dp since the resultant value of the overall efficiency (

) becomes less than 30% which is an unacceptable value in the industry.

Table 5 shows some of the results obtained from optimization simulations for different values of bounds used for the decision variables. The effects of varying the upper bound value of decision variables

and

. in order to find the optimal value of the cyclone diameter and number of parallel lines can also be seen in

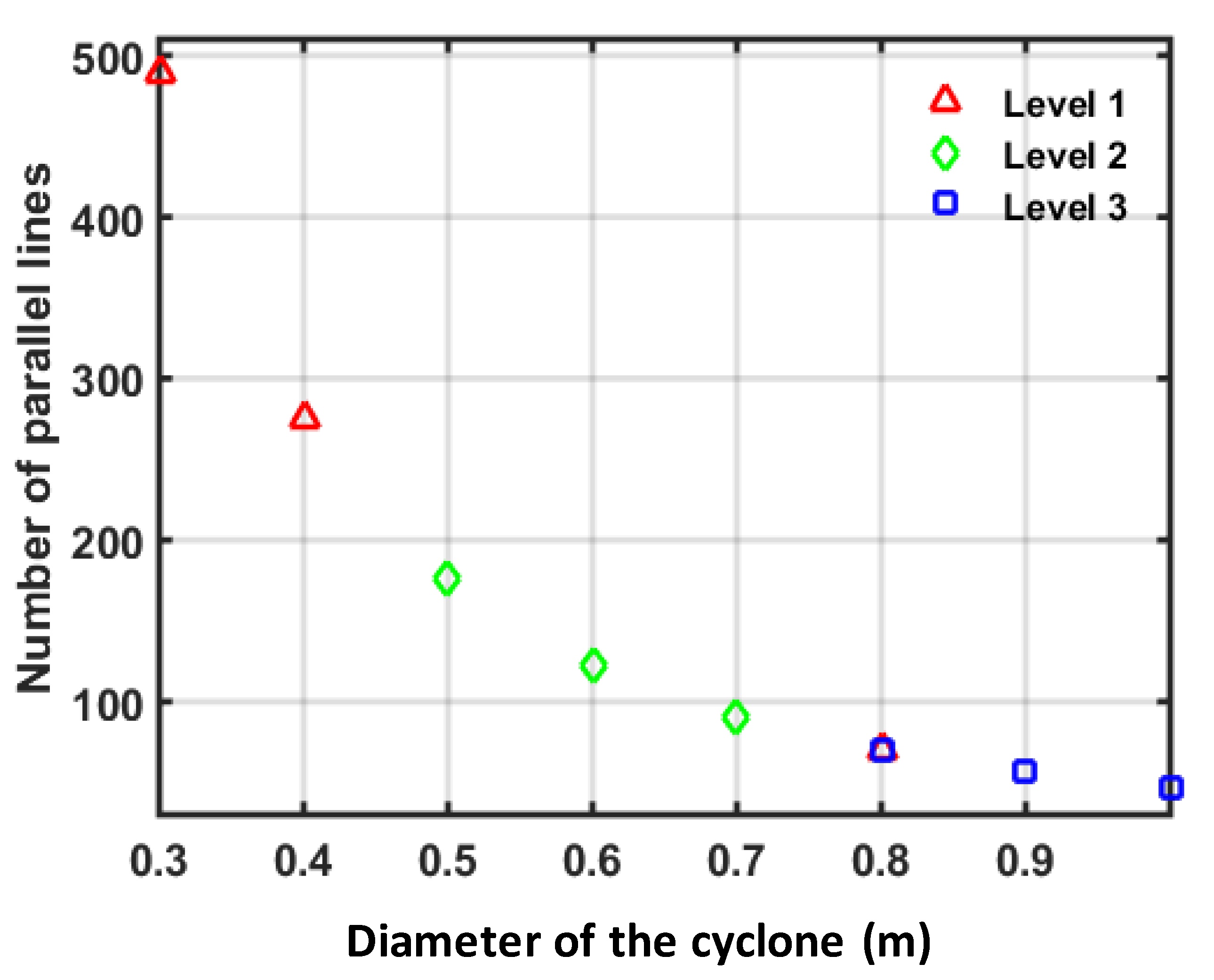

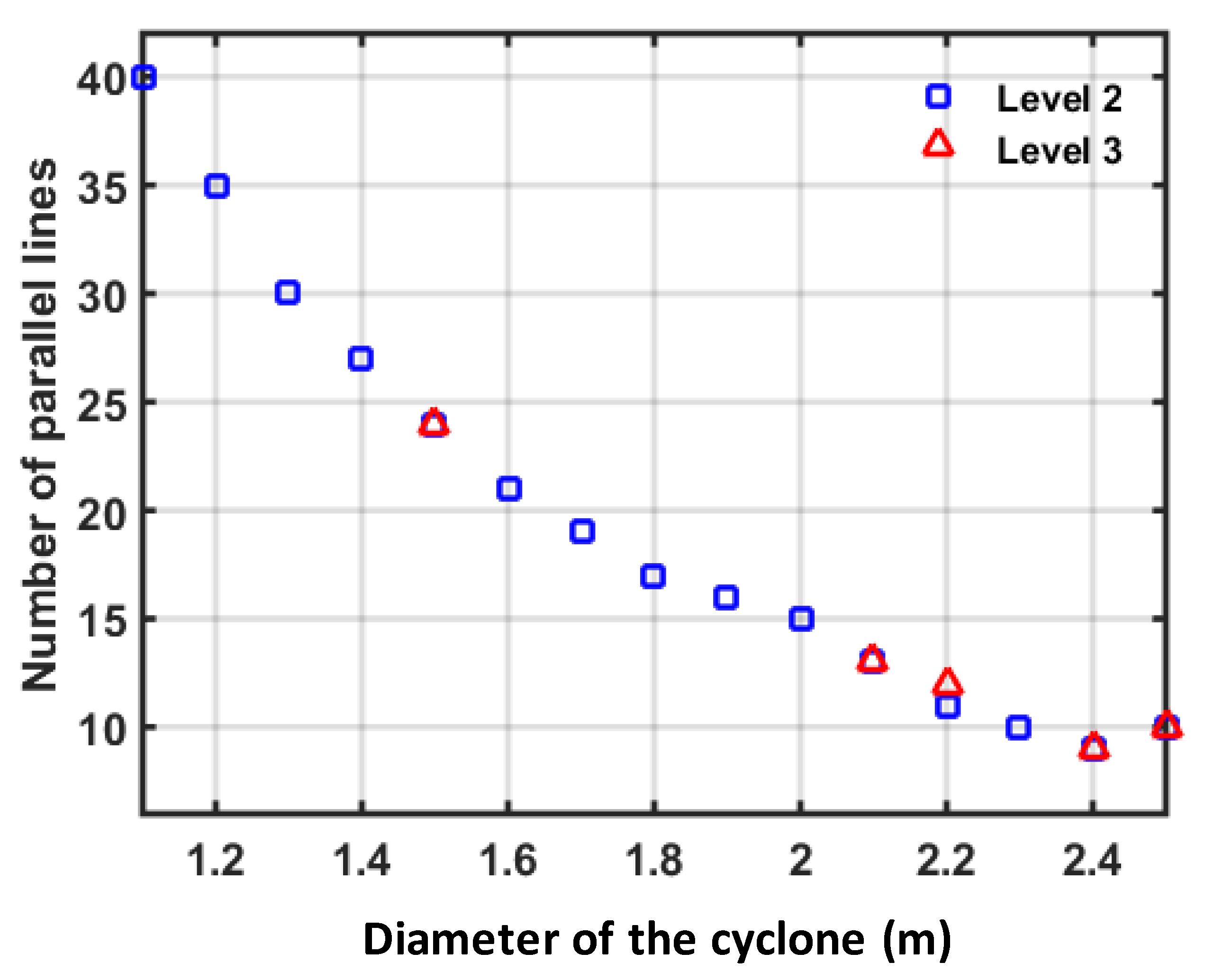

Figure 5 and

Figure 6.

From these figures, while the optimal value of cyclone diameter lies at its upper bound, the optimal solution for the number of parallel lines lies within a wide range of values. These optimal values of

Dp and

Np will be used by the optimization process to compute the optimal value of the pressure drop, inlet velocity, and total cost. It should be noted that a certain value of the upper bound of N

p cannot be used in obtaining the feasible solutions for all relaxed NLP sub-problems. For example, the optimal solution is only obtained by GAMS/DICOPT when using

along with the value of 0.3 m as the upper bound of cyclone diameter. As a result, the arrangement of 1D3D–2D2D in series (level 3) is found as the best arrangement with

Np = 489 and of 30 m/s being achieved by the inlet velocity. The resultant value of the total cost for this case is high (

$0.057/s) because of the large number of the cyclones (i.e., 489 parallel lines × 2 series cyclone = 978 cyclones) with

Dp = 0.3 m.

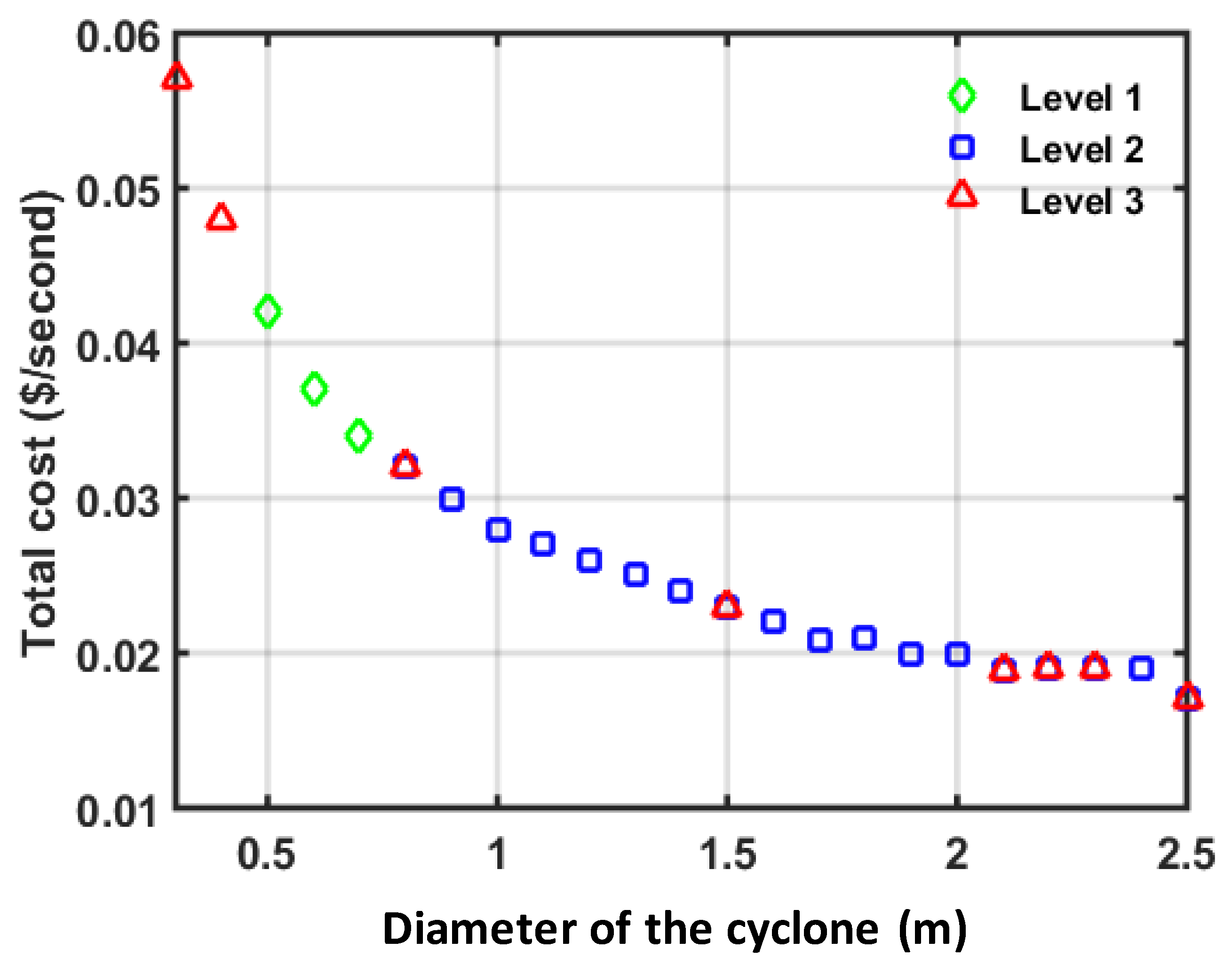

Figure 7 shows the relationship between the optimal value of the cyclone diameter and the minimum total cost achieved from the optimization.

From

Figure 7, an increase in the optimal value of

Dp will result in a decrease in the total cost

ctot. This is because the operating cost is proportional to

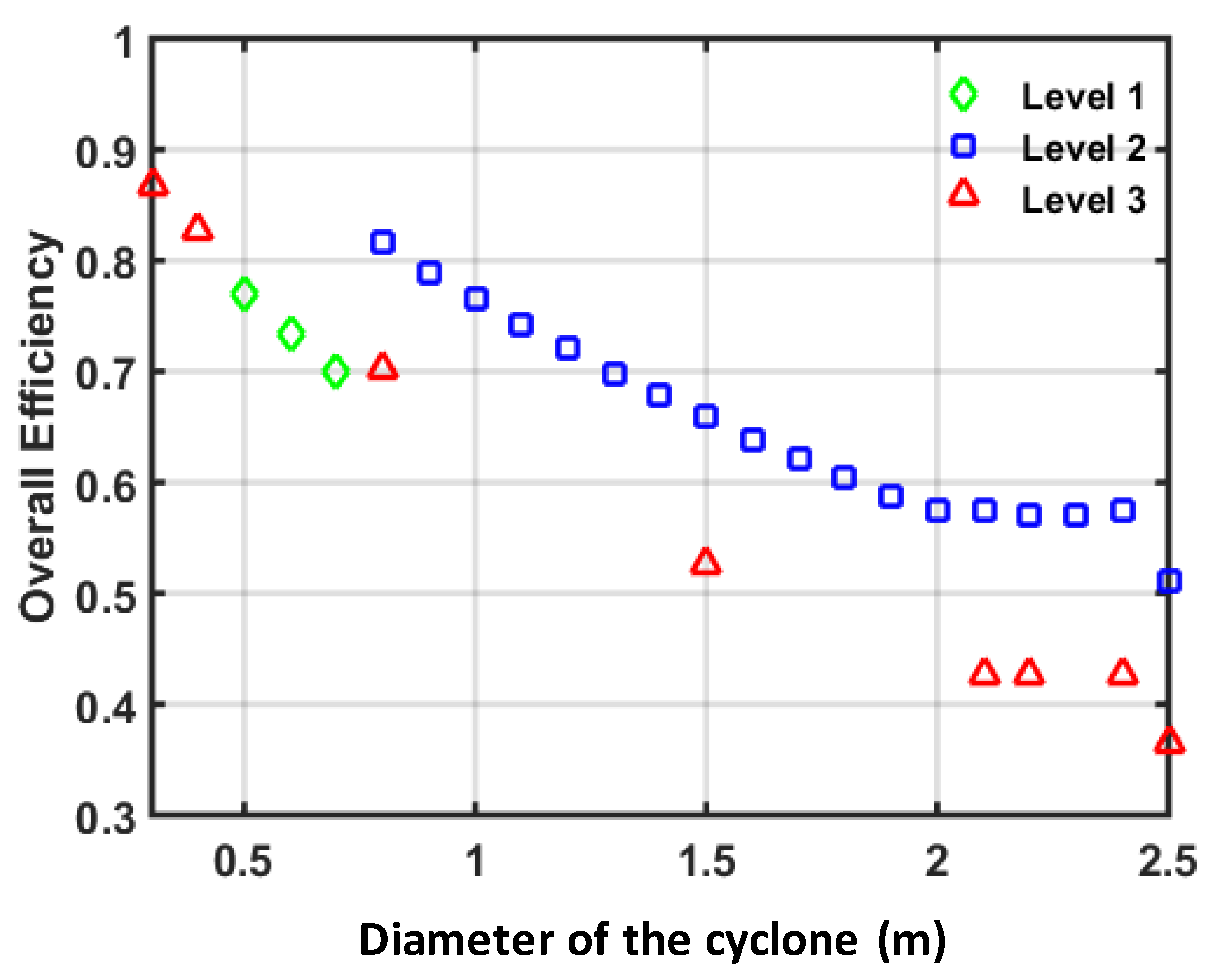

and even though the capital cost is proportional to diameter of the cyclone, a decreased value of the operating cost tends to be more dominant than the capital cost in obtaining the optimum total cost. The maximum value of the overall efficiency of the cyclone arrangement that can be attained for a certain upper bound of the cyclone diameter is shown in

Figure 8. The overall efficiency decreased nonlinearly as cyclone diameter increased with different slope of each level (cyclone arrangement) being chosen. The relationship between the overall efficiency and cyclone diameter in this optimization confirms the same relationship obtained by Faulkner et al. [

30], who studied the effects of cyclone diameter on the collection efficiency of 1D3D cyclones.

Moreover, higher collection efficiency is accompanied by an increase in value of the inlet velocity and pressure drop across the cyclone, resulting in a higher total cost. Similar results were also reported by Gimbun et al., 2005. The optimal value of the cyclone pressure drop remains constant for some range of

Dp (i.e.,

Dp = 0.3–0.8 m) since the optimal value of the inlet velocity lies in its upper bound. Thereafter, the trend of cyclone pressure drop will follow a decreasing trend of the inlet velocity as the number of parallel lines (number of cyclones) decreases. The optimum efficiency of the second cyclones would have a lower value than the first cyclone though the dimensions of the second cyclone are the same as the first cyclone. This is due to the fact that the cut size diameter of the second cyclone will increase (due to an increase in the overall efficiency of the first cyclone) to retain the same diameter second cyclone (as given in Equations (16) and (17)). These results are found to be in line with the results reported by Whitelock and Buser [

21], who studied the performance of multiple (up to four) 1D3D cyclones arranged in series. It is interesting to observe from

Figure 8 that there are only three from four levels available that have been chosen by the model as the best arrangement for a certain value of the decision variables

Dp and

Np. For instance, with the resultant value of the efficiency more than 75 %, level 3 (1D3D + 2D2D) is selected as the best cyclone arrangement for

Dp = 0.3–0.4 m, level 1 (1D3D + 1D3D) for

Dp = 0.5 m, and level 2 (2D2D + 2D2D) for

Dp = 0.8–1.0 m. From the whole range, level 1 is available only when the value of

Dp is in the range between 0.5 and 0.7 m. Meanwhile, level 2 is found as being more dominant than the others in which it is selected as the best arrangement for a wide range value of the optimum diameter of the cyclone (

Dp = 0.8 m to 2.5 m). At a certain point, there are two levels selected as the best arrangement with the same

Dp and

Np. For example, the upper bound value of 0.8, 1.5, 2.1, 2.4, and 2.5 m would result in two levels selected (i.e., level 2 and level 3) as the best arrangement with the same optimum number of parallel lines at each

Dp. Another result shows that the same two levels are selected as the best arrangement with the same

Dp = 2.2 m, but with different value of

Np. The total costs associated with each level (

Figure 7) is found to have the same value. Based on these results, two different types of cyclone arrangement can be selected at the same cost but with different efficiencies (

Figure 8) where the overall efficiency of cyclone arrangement on level 2 (2D2D + 2D2D) is found to be higher than level 3 (1D3D + 2D2D). To further check the sensitivity of the decision variables to the optimal solutions, an additional optimization was also performed by using all the three decision variables (

N,

Dp, and

ηov). This optimization is also intended to computationally investigate the effect of

ηov if the bound is changed. In this case, the lower bound for the overall cyclone efficiency (

) is set to have the initial value of 80% and then is increased in increments of 5%. Meanwhile, prior bounds of

and

are also selected. The optimal value of cyclone diameter and number of parallel lines for a given constraint of decision variable

ηov should lie within the bounds. Otherwise, a higher value of the upper bound (

and

) should be applied. The computational results of this optimization are presented in

Table 6.

The method selects the lower bound of

ηov as the optimal value. The sensitivity of

ηov to the optimal solutions obtained from this optimization is found to be in accordance with the numerical findings given in

Table 5. For instance, as the cyclone diameter decreased along with the optimal value of inlet cyclone remains constant at its upper bound, the overall efficiency will increase. The optimal value of

ηov = 90% obtained in this optimization is higher than the value of the previous optimization (

ηov = 86.8%). It indicates that a higher

ηov is attainable by changing its lower bound until the optimal solution could be reached. From

Table 6, the model shows its consistency in selecting the cyclone arrangement of 1D3D + 2D2D (level 3) as the best arrangement to obtain the optimal value of overall efficiency in the range of 80–90%. If these results are combined with the results given in

Table 5 (for

ηov > 80%), it will complete the search for the optimal solution of level 3 to attain the maximum value of overall efficiency as presented in

Table 7.

However, the optimal solution for

ηov = 90% (

Table 6) provides two levels as the best arrangement, i.e., level 2 and 3. The cyclone arrangement of 2D2D + 2D2D (level 2) will have a lower optimum number of parallel lines even though its dimensions are bigger than the cyclone arrangement of 1D3D + 2D2D (level 3). Consequently, the total cost of the cyclone arrangement of 2D2D + 2D2D is lower than the 1D3D + 2D2D, or in other words, the cyclone arrangement of 2D2D + 2D2D is more efficient in the total cost. The optimization results obtained from the present mathematical programming models were also compared with the results from Ravi et al. [

11], who studied a multi-objective optimization of a set of

N identical reverse-flow cyclone separators in parallel by using the non-dominated sorting genetic algorithm (NSGA). Since they used nine decision variables in the optimization, compared to three decision variables in the present study, not all results would be presented. In particular, only the optimum solution of the number of parallel cyclones, cyclone diameter, and the efficiency of the cyclone are used for comparison.

Table 8 shows the comparison of the optimal solution of decision variables, i.e., the number the of cyclone, diameter of the cyclone, and efficiency of the cyclone, where the results were evaluated using the same input feed given in

Table 3 and the same range of dimensions ratio of the cyclones (i.e.,

a0,

b0, and

De0). It should be noted that there is no table provided by Ravi et al. [

11], all the results are presented in scatter charts instead. Hence, the values listed in

Table 8 are rough estimated numbers from those charts provided.

The comparisons illustrated that the present study gave the lower number of parallel cyclones for the same value of the efficiency of the cyclone. In addition, the optimum efficiency of the cyclone that can be achieved from the present study (90%) is slightly higher than Ravi et al. [

11]. Based on the above comparisons, it can be concluded that the optimization of the cyclone arrangement in parallel-series using 1D3D and/or 2D2D cyclones found to be a novel solution among other pollution control strategies to reduce the pollution to the minimum level.