Postharvest Preservation of the New Hybrid Seedless Grape, ‘BRS Isis’, Grown Under the Double-Cropping a Year System in a Subtropical Area

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Location

2.2. Treatments and Storage

2.3. Evaluation of Gray Mold Incidence

2.4. Physicochemical Analysis

2.5. Statistical Analysis

3. Results

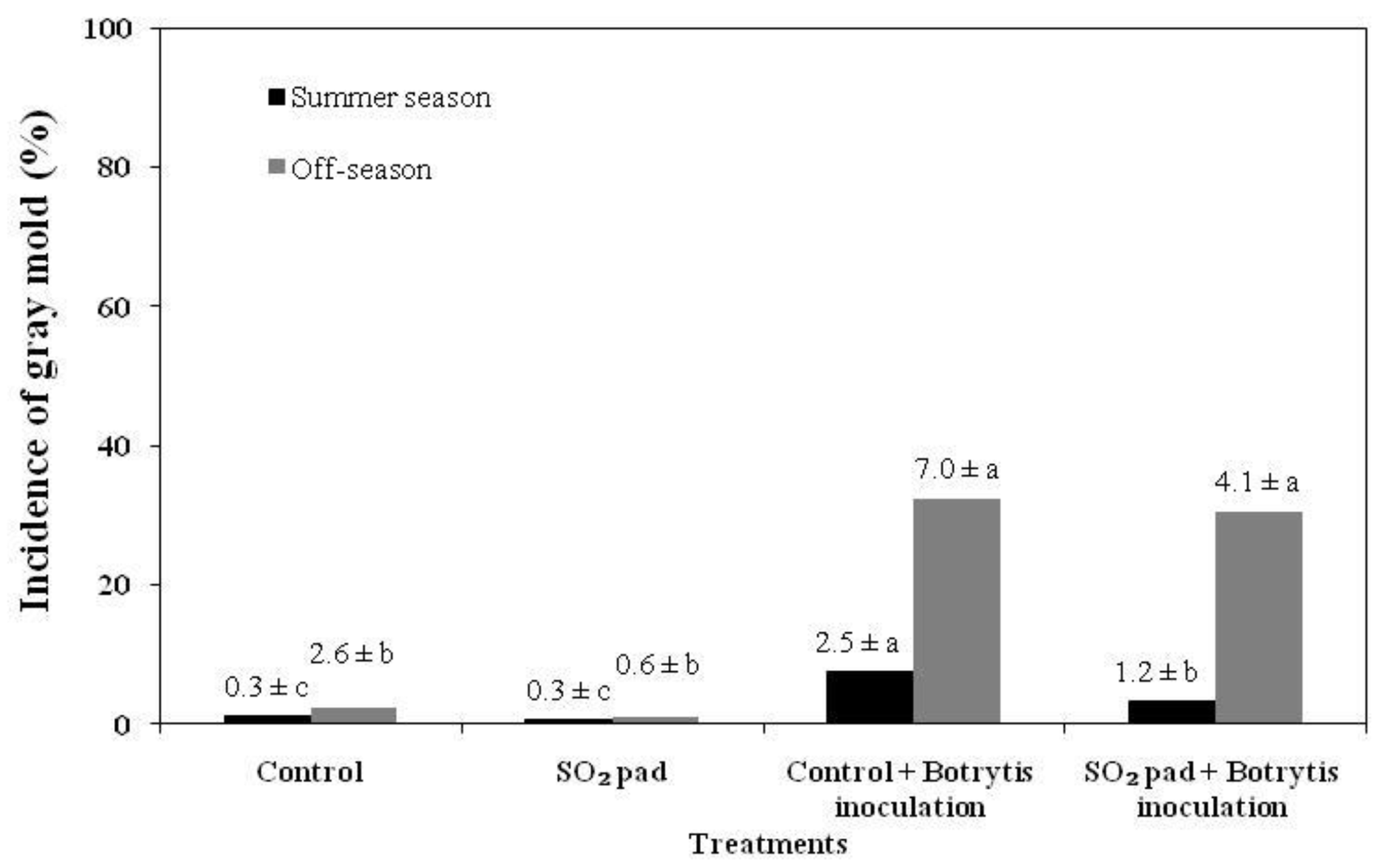

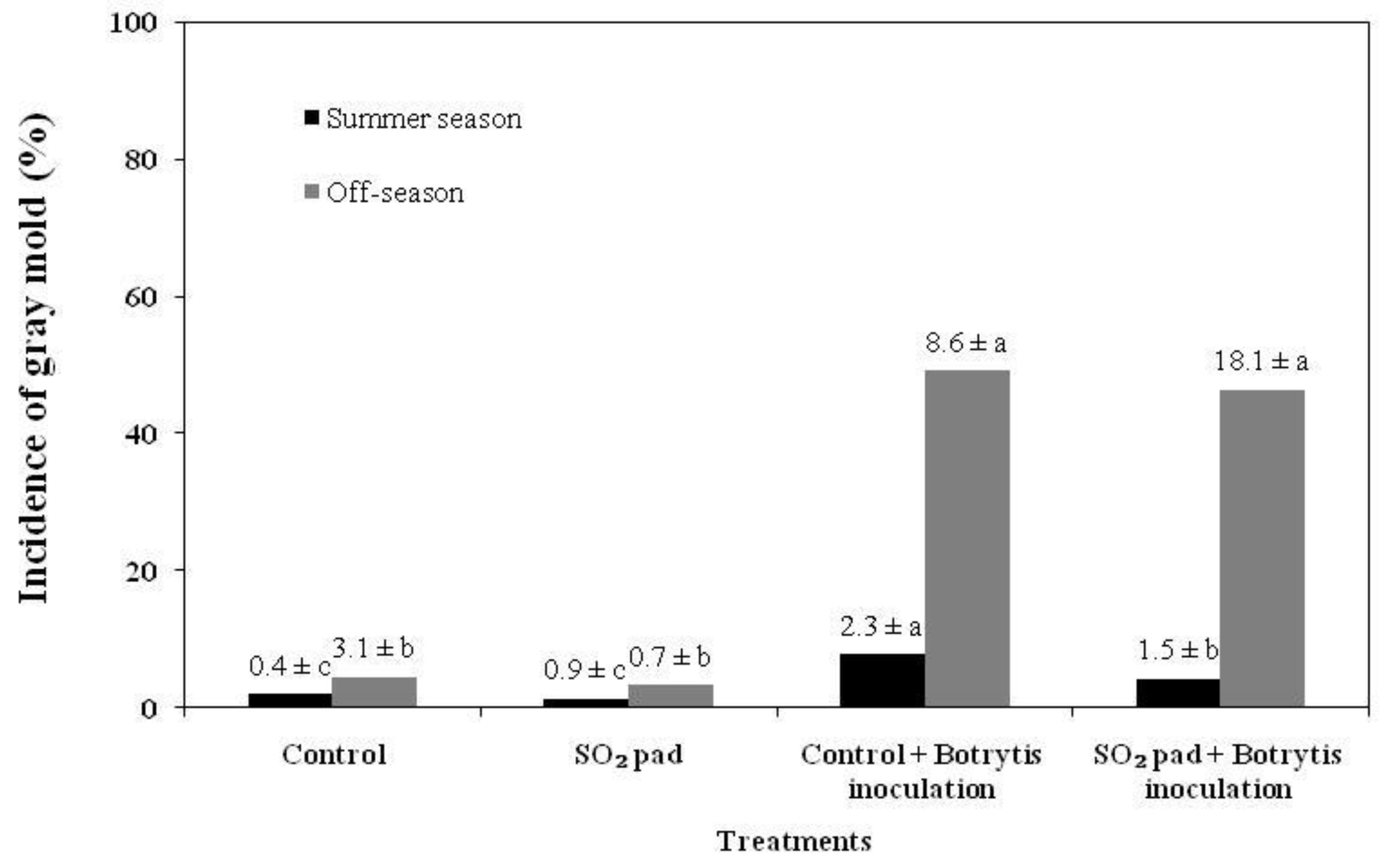

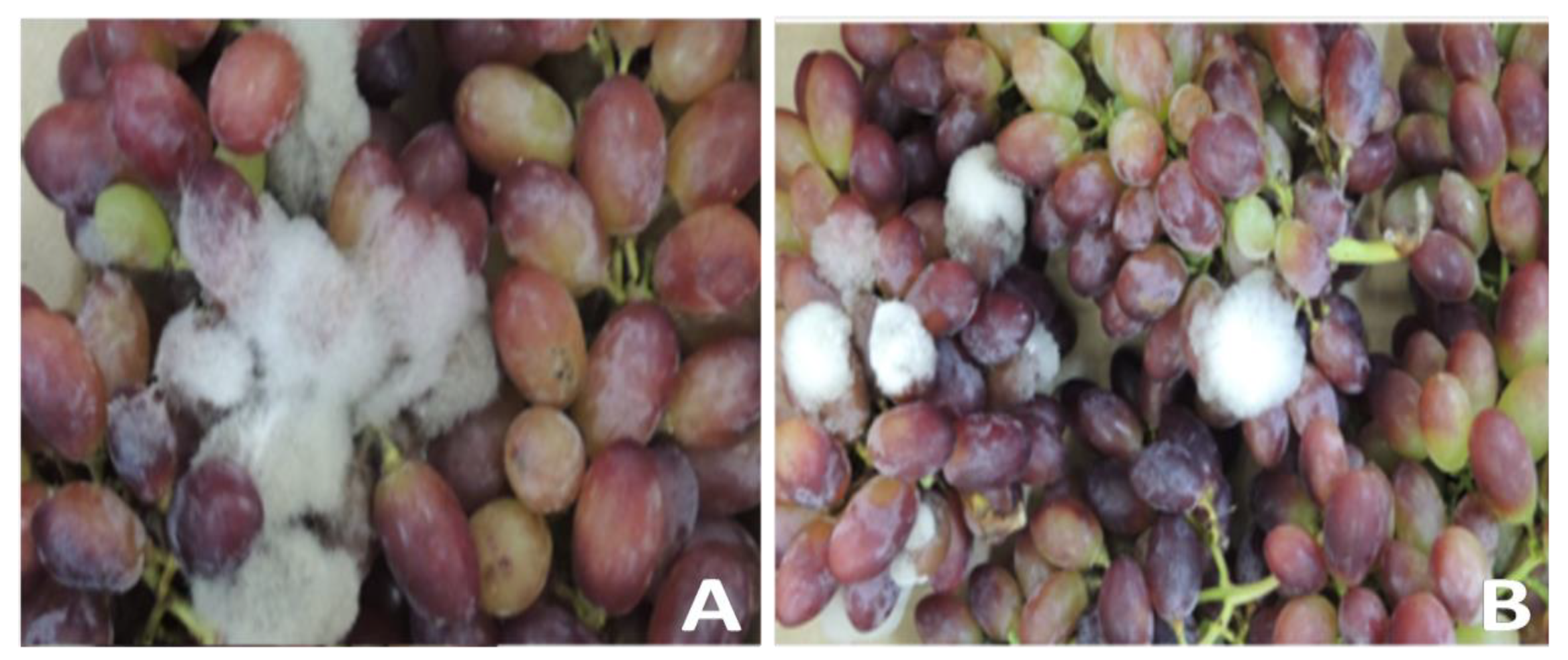

3.1. Incidence of Gray Mold

3.2. Physical Characteristics of Grapes

3.3. Chemical Characteristics of Grapes

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ritschel, P.S.; Maia, J.D.G.; Camargo, U.A.; de Souza, R.T.; Fajardo, T.V.M.; de Naves, R.L.; Girardi, C.L. BRS Isis Nova Cultivar de Uva de Mesa Vermelha, Sem Sementes e Tolerante ao Míldio; Comunicado Técnico 143; Embrapa: Brasilia, Brazil, 2013; pp. 6–11. [Google Scholar]

- Daudt, C.E.; Fogaca, A.O. Phenolic compounds in Merlot wines from two wine regions of Rio Grande do Sul, Brazil. Food Sci. Technol. 2013, 33, 355–361. [Google Scholar] [CrossRef]

- Silva-Sanzanaa, C.; Balica, I.; Sepúlvedaa, P.; Olmedoa, P.; Leóna, G.; Defilippi, B.G.; Blanco-Herreraa, F.; Campos-Vargasa, R. Effect of modified atmosphere packaging (MAP) on rachis quality of ‘Red Globe’ table grape variety. Postharvest Biol. Technol. 2016, 119, 33–40. [Google Scholar] [CrossRef]

- Sen, F.; Oksar, R.; Kesgin, M. Effects of shading and covering on ‘Sultana Seedless’ grape quality and storability. J. Agric. Sci. Technol. 2016, 18, 245–254. [Google Scholar]

- Hashim, A.F.; Youssef, K.; Abd-Elsalam, K.A. Ecofriendly nanomaterials for controlling gray mold of table grapes and maintaining postharvest quality. Eur. J. Plant Pathol. 2019, 154, 377–388. [Google Scholar] [CrossRef]

- Youssef, K.; de Oliveira, A.G.; Tischer, C.A.; Hussain, I.; Roberto, S.R. Synergistic effect of a novel chitosan/silica nanocomposites-based formulation against gray mold of table grapes and its possible mode of action. Int. J. Biol. Macromol. 2019, 141, 247–258. [Google Scholar] [CrossRef] [PubMed]

- Carisse, O.; Van Der Heyden, H. Relationship of airborne Botrytis cinerea conidium concentration to tomato flower and stem infections: A threshold for de-leafing operations. Plant Dis. 2015, 99, 137–142. [Google Scholar] [CrossRef] [PubMed]

- Feliziani, E.; Romanazzi, G. Postharvest decay of strawberry fruit: Etiology, epidemiology, and disease management. J. Berry Res. 2016, 6, 47–63. [Google Scholar] [CrossRef]

- Crisosto, C.H.; Garner, D.; Crisosto, G. Carbon dioxide-enriched atmosphere during cold storage limit losses from Botrytis but accelerate Rachis browning of ‘Red globe’ table grapes. Postharvest Biol. Technol. 2002, 26, 181–189. [Google Scholar] [CrossRef]

- Celik, M.; Kalpulov, T.; Zutahy, Y.; Ish-Shalom, B.; Lurie, S.; Litcher, A. Quantitative and qualitative analysis of Botrytis inoculated on table grapes by qPCR and antibodies. Postharvest Biol. Technol. 2009, 52, 235–239. [Google Scholar] [CrossRef]

- Romanazzi, G.; Joseph, L.S.; Erica, F.; Droby, S. Integrated management of postharvest gray mold on fruit crops. Postharvest Biol. Technol. 2016, 113, 69–76. [Google Scholar] [CrossRef]

- Sen, F.; Altun, A.; Kesgin, M.; Inan, M.S. Effect of different shading practices used in the pre-harvest stage on quality and storage life of sultana seedless grapes. J. Agric. Sci. Technol. 2012, 2, 1234–1240. [Google Scholar]

- Brackmann, A.; Ceretta, M.; Pinto, J.A.V.; Venturini, T.L.; Lucio, A.D.L. Tolerância de maçãs ‘Gala’ a baixas temperaturas durante o armazenamento. Ciência Rural 2010, 40, 1909–1915. [Google Scholar] [CrossRef]

- Liguori, G.; Sortino, G.; De Pasquale, C.; Inglese, P. Effects of modified atmosphere packaging on quality parameters of minimally processed table grapes during cold storage. Adv. Hortic. Sci. 2015, 29, 152–154. [Google Scholar]

- Lichter, A.; Zutahy, Y.; Kaplunov, T.; Lurie, S. Evaluation of table grape storage in boxes with sulfur dioxide releasing pads with either an internal plastic liner or external wrap. HortTechnology 2008, 18, 206–214. [Google Scholar] [CrossRef]

- Melgarejo-Flores, B.G.; Ortega-Ramírez, L.A.; Silva-Espinoza, B.A.; González-Aguilar, G.A.; Miranda, M.R.A.; Ayala-Zavala, J.F. Antifungal protection and antioxidant enhancement of table grapes treated with emulsions, vapors, and coatings of cinnamon leaf oil. Postharvest Biol. Technol. 2013, 86, 321–328. [Google Scholar] [CrossRef]

- Domingues, A.R.; Roberto, S.R.; Ahmed, S.; Shahab, M.; Junior, O.J.C.; Sumida, C.H.; Souza, R.T. Postharvest Techniques to Prevent the Incidence of Botrytis Mold of ‘BRS Vitoria’ Seedless Grape under Cold Storage. Horticulturae 2018, 4, 17. [Google Scholar] [CrossRef]

- Lurie, S.; Pesis, E.; Gadiyeva, O.; Feygenberg, O.; Ben-Arie, R.; Kaplunov, T.; Zutachi, Y.; Lichter, A. Modified ethanol atmosphere to control decay of table grapes during storage. Postharvest Biol. Pathol. 2006, 42, 222–227. [Google Scholar] [CrossRef]

- Zutahy, Y.; Lichter, A.; Kaplunov, T.; Lurie, S. Extended storage of ‘Red Globe’ grapes in modified SO2 generating pads. Postharvest Biol. Technol. 2008, 50, 12–17. [Google Scholar] [CrossRef]

- Ricce, W.S.; Caramori, P.H.; Roberto, S.R. Potencial climático para a produc¸ ãode uvas em sistema de dupla poda anual no estado do Paraná. Bragantia 2013, 72, 408–415. [Google Scholar] [CrossRef][Green Version]

- Youssef, K.; Roberto, S.R.; Chiarotti, F.; Koyama, R.; Hussain, I.; De Souza, R.T. Control of Botrytis mold of the new seedless grape ‘BRS Vitoria’ during cold storage. Sci. Hortic. 2015, 193, 316–321. [Google Scholar] [CrossRef]

- Ahmed, S.; Roberto, S.R.; Domingues, A.R.; Shahab, M.; Junior, O.J.C.; Sumida, C.H.; Souza, R.T. Effects of Different Sulfur Dioxide Pads on Botrytis Mold in ‘Italia’ Table Grapes under Cold Storage. Horticulturae 2018, 4, 29. [Google Scholar] [CrossRef]

- Youssef, K.; Roberto, S.R. Applications of salt solutions before and after harvest affect the quality and incidence of postharvest gray mold of ‘Italia’ table grapes. Postharvest Biol. Technol. 2014, 87, 95–102. [Google Scholar] [CrossRef]

- Mattiuz, B.; Miguel, A.C.A.; Galati, V.C.; Nachtigal, J.C. Efeito da temperaturano armazenamento de uvas apirênicas minimamente processadas. Rev. Bras. Frutic. 2009, 31, 44–52. [Google Scholar] [CrossRef]

- Carreño, J.; Martínez, A.; Almela, L.; Fernández-López, J.A. Proposal of an index for the objective evaluation of the color of red table grapes. Food Res. Int. 1995, 28, 373–377. [Google Scholar] [CrossRef]

- Mcguire, R.G. Reporting of objective color measurements. HortScience 1992, 27, 1254–1255. [Google Scholar] [CrossRef]

- Lancaster, J.E.; Lister, C.; Reay, P.F.; Triggs, C.M. Influence of pigment composition on skin color in a wide range of fruits and vegetables. Am. Soc. Hortic. Sci. 1997, 122, 594–598. [Google Scholar] [CrossRef]

- Peppi, M.C.; Fidelibus, M.W.; Dokoozlian, N. Abscisic acid application timing and concentration affect firmness, pigmentation and color of ‘Flame Seedless’ grapes. HortScience 2006, 41, 1440–1445. [Google Scholar] [CrossRef]

- Youssef, K.; Roberto, S.R. Salt strategies to control Botrytis mold of ‘Benitaka’ table grapes and to maintain fruit quality during storage. Postharvest Biol. Technol. 2014, 95, 95–102. [Google Scholar] [CrossRef]

- Carreño, J.; Martinez, A.; Almela, L.; Fernández-López, J.A. Measuring the color of table grapes. Color Res. Appl. 1998, 21, 50–54. [Google Scholar] [CrossRef]

- UNECE—United Nations Economic Commission for Europe. Standard FFV-19 Concerning the Marketing and Commercial Quality Control of Table Grapes; United Nations: New York, NY, USA; Geneva, Switzerland, 2010; p. 8. [Google Scholar]

- Tessmann, D.J.; Vida, J.B.; Genta, W.; Roberto, S.R.; Kishino, A.Y. Doenças e Seu Manejo. In Viticultura Tropical: O sistema de produção de uvas de mesa do Paraná; Kishino, A.Y., Carvalho, S.L.C., Roberto, S.R., Eds.; IAPAR: Londrina, Brazil, 2018; pp. 453–548. [Google Scholar]

- Valverde, J.M.; Guillén, F.; Martínez-Romero, D.; Castillo, S.; Serrano, M.; Valero, D. Improvement of table grapes quality and safety by the combination of modified atmosphere packaging (MAP) and eugenol, menthol, or thymol. J. Agric. Food Chem. 2005, 53, 7458–7464. [Google Scholar] [CrossRef]

- Nelson, K.E. Retarding deterioration of table grapes with in–package sulfur dioxide generators with and without refrigeration. Acta Hortic. 1983, 138, 121–130. [Google Scholar] [CrossRef]

- Wright, H.; Delong, J.; Lada, R.; Prange, R. The relationship between water status and chlorophyll a fluorescence in grapes (Vitis spp.). Postharvest Biol. Technol. 2009, 51, 193–199. [Google Scholar] [CrossRef]

- Artés-HernándeZ, F.; Tomàs-Barberán, F.A.; Artés, F. Modified atmosphere packaging preserves quality of SO2-free ‘Superior seedless’ table grapes. Postharvest Biol. Technol. 2006, 39, 146–154. [Google Scholar] [CrossRef]

- Rosales, R.; Romero, I.; Fernandez-Caballero, C.; Escribano, M.I.; Merodio, C.; Sanchez-Ballesta, M.T. Low Temperature and Short-Term High CO2 treatment in postharvest storage of table grapes at two maturity stages: Effects on Transcriptome Profiling. Front. Plant Sci. 2016, 7, 1020. [Google Scholar] [CrossRef] [PubMed]

| Treatments | Mass loss (%) | Shattered berries (%) | CIRG | |||

| At 50 days of cold storage | ||||||

| Summer season | Off-season | Summer season | Off-season | Summer season | Off-season | |

| Control | 6.3 ± 2.4 | 3.1 ± 0.4 b | 0.0 ± 0.0 | 1.2 ± 2.5 | 3.8 ± 0.4 | 5.1 ± 0.3 |

| SO2 pad | 5.6 ± 1.4 | 3.0 ± 0.2 b | 0.3 ± 0.3 | 0.7 ± 0.5 | 4.4 ± 0.2 | 5.4 ± 0.3 |

| Control + Bot | 5.4 ± 0.9 | 3.7 ± 0.3 a | 0.7 ± 0.6 | 3.1 ± 1.0 | 4.5 ± 0.5 | 5.4 ± 0.4 |

| SO2 pad + Bot | 7.0 ± 2.6 | 3.6 ± 0.3 a | 0.2 ± 0.4 | 2.1 ± 1.1 | 4.6 ± 0.5 | 5.5 ± 0.2 |

| F value | 0.7 NS | 5.4 * | 2.5 NS | 2.6 NS | 3.4 NS | 1.5 NS |

| At seven days at22 ± 2 °C | ||||||

| Summer season | Off-season | Summer season | Off-season | Summer season | Off-season | |

| Control | 5.8 ± 0.3c | 1.2 ± 0.1c | 0.1 ± 0.3b | 1.8 ± 2.2b | 4.0 ± 0.6 | 4.8 ± 0.4 |

| SO2 pad | 7.2 ± 0.8ab | 1.6 ± 0.4ab | 0.7 ± 0.6b | 1.5 ± 1.3b | 3.8 ± 0.3 | 4.6 ± 0.3 |

| Control + Bot | 7.6 ± 0.5a | 1.3 ± 0.2bc | 1.5 ± 0.5a | 12.1 ± 9.3a | 4.4 ± 0.2 | 4.8 ± 0.3 |

| SO2 pad + Bot | 6.8 ± 0.5b | 1.8 ± 0.2a | 0.6 ± 0.6b | 11.9 ± 4.3a | 4.2 ± 0.5 | 4.8 ± 0.2 |

| F value | 10.1 * | 3.8 * | 6.3 * | 6.4 * | 2.0 NS | 0.3 NS |

| Treatments | SS (°Brix) | TA (%) | SS/TA | |||

| At 50 days of cold storage | ||||||

| Summer season | Off-season | Summer season | Off-season | Summer season | Off-season | |

| Control | 14.5 ± 0.4a | 14.3 ± 0.2 | 0.6 ± 0.1 | 0.9 ± 0.1 | 23.1 ± 3.4 | 16.8 ± 1.2 |

| SO2 pad | 13.9 ± 0.5b | 14.2 ± 0.5 | 0.6 ± 0.03 | 0.8 ± 0.1 | 23.2 ± 1.4 | 17.7 ± 1.0 |

| Control + Bot | 13.6 ± 0.4b | 14.1 ± 0.2 | 0.6 ± 0.1 | 0.9 ± 0.1 | 23.5 ± 2.0 | 16.6 ± 1.7 |

| SO2 pad + Bot | 14.0 ± 0.3ab | 14.1 ± 0.4 | 0.6 ± 0.03 | 0.8 ± 0.03 | 23.3 ± 0.9 | 18.3 ± 0.6 |

| F value | 3.8 * | 0.3 NS | 0.8 NS | 1.8 NS | 0.04 NS | 2.1 NS |

| At seven days at22 ± 2 °C | ||||||

| Summer season | Off-season | Summer season | Off-season | Summer season | Off-season | |

| Control | 15.0 ± 0.4 | 13.9 ± 0.2 | 0.7 ± 0.1 | 0.9 ± 0.1 | 22.9 ± 1.9 | 15.9 ± 1.9 |

| SO2 pad | 14.4 ± 0.6 | 14.1 ± 0.5 | 0.7 ± 0.01 | 0.7 ± 0.03 | 22.1 ± 1.2 | 19.1 ± 0.6 |

| Control + Bot | 14.3 ± 0.5 | 13.8 ± 0.4 | 0.6 ± 0.03 | 0.7 ± 0.03 | 22.2 ± 1.3 | 19.0 ± 1.1 |

| SO2 pad + Bot | 14.6 ± 0.4 | 14.0 ± 1.1 | 0.7 ± 0.03 | 0.8 ± 0.1 | 21.8 ± 0.6 | 18.8 ± 3.4 |

| F value | 2.1 NS | 0.1 NS | 1.1 NS | 2.6 NS | 0.7 NS | 2.8 NS |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, S.; Ruffo Roberto, S.; Youssef, K.; Carlos Colombo, R.; Shahab, M.; José Chaves Junior, O.; Hideki Sumida, C.; Teodoro de Souza, R. Postharvest Preservation of the New Hybrid Seedless Grape, ‘BRS Isis’, Grown Under the Double-Cropping a Year System in a Subtropical Area. Agronomy 2019, 9, 603. https://doi.org/10.3390/agronomy9100603

Ahmed S, Ruffo Roberto S, Youssef K, Carlos Colombo R, Shahab M, José Chaves Junior O, Hideki Sumida C, Teodoro de Souza R. Postharvest Preservation of the New Hybrid Seedless Grape, ‘BRS Isis’, Grown Under the Double-Cropping a Year System in a Subtropical Area. Agronomy. 2019; 9(10):603. https://doi.org/10.3390/agronomy9100603

Chicago/Turabian StyleAhmed, Saeed, Sergio Ruffo Roberto, Khamis Youssef, Ronan Carlos Colombo, Muhammad Shahab, Osmar José Chaves Junior, Ciro Hideki Sumida, and Reginaldo Teodoro de Souza. 2019. "Postharvest Preservation of the New Hybrid Seedless Grape, ‘BRS Isis’, Grown Under the Double-Cropping a Year System in a Subtropical Area" Agronomy 9, no. 10: 603. https://doi.org/10.3390/agronomy9100603

APA StyleAhmed, S., Ruffo Roberto, S., Youssef, K., Carlos Colombo, R., Shahab, M., José Chaves Junior, O., Hideki Sumida, C., & Teodoro de Souza, R. (2019). Postharvest Preservation of the New Hybrid Seedless Grape, ‘BRS Isis’, Grown Under the Double-Cropping a Year System in a Subtropical Area. Agronomy, 9(10), 603. https://doi.org/10.3390/agronomy9100603