Variations in Solar Radiation and Their Effects on Rice Growth in Agro-Photovoltaics System

Abstract

1. Introduction

2. Materials and Methods

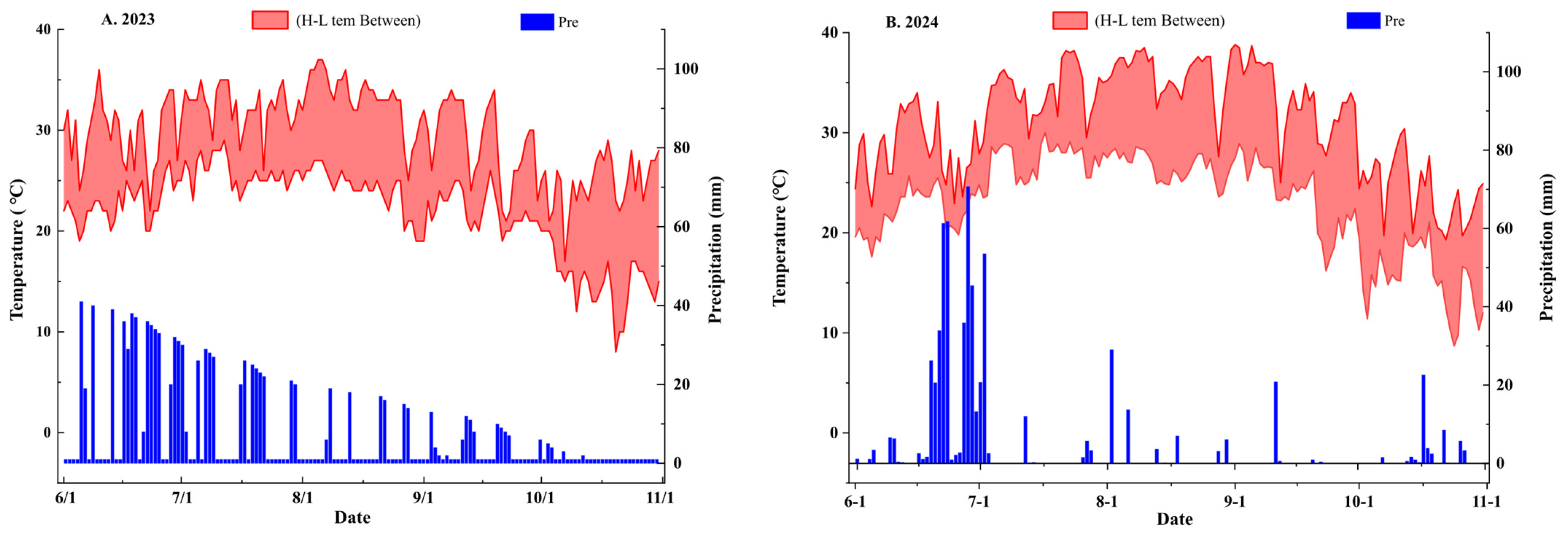

2.1. Study Area and Site Conditions

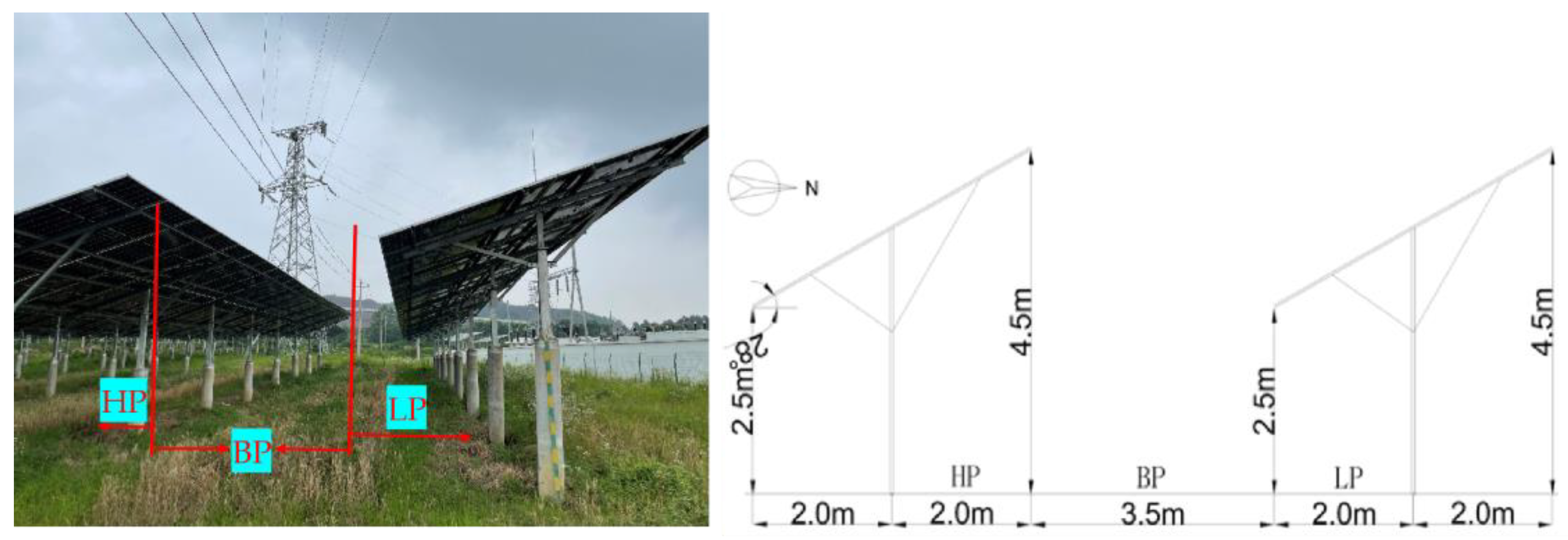

2.2. APV Array and Experiment Design

2.3. Evaluation of PV Panel Layout on Crop Sunlight Exposure

2.3.1. Calculation of Solar Declination, Altitude Angle, and Azimuth Angle

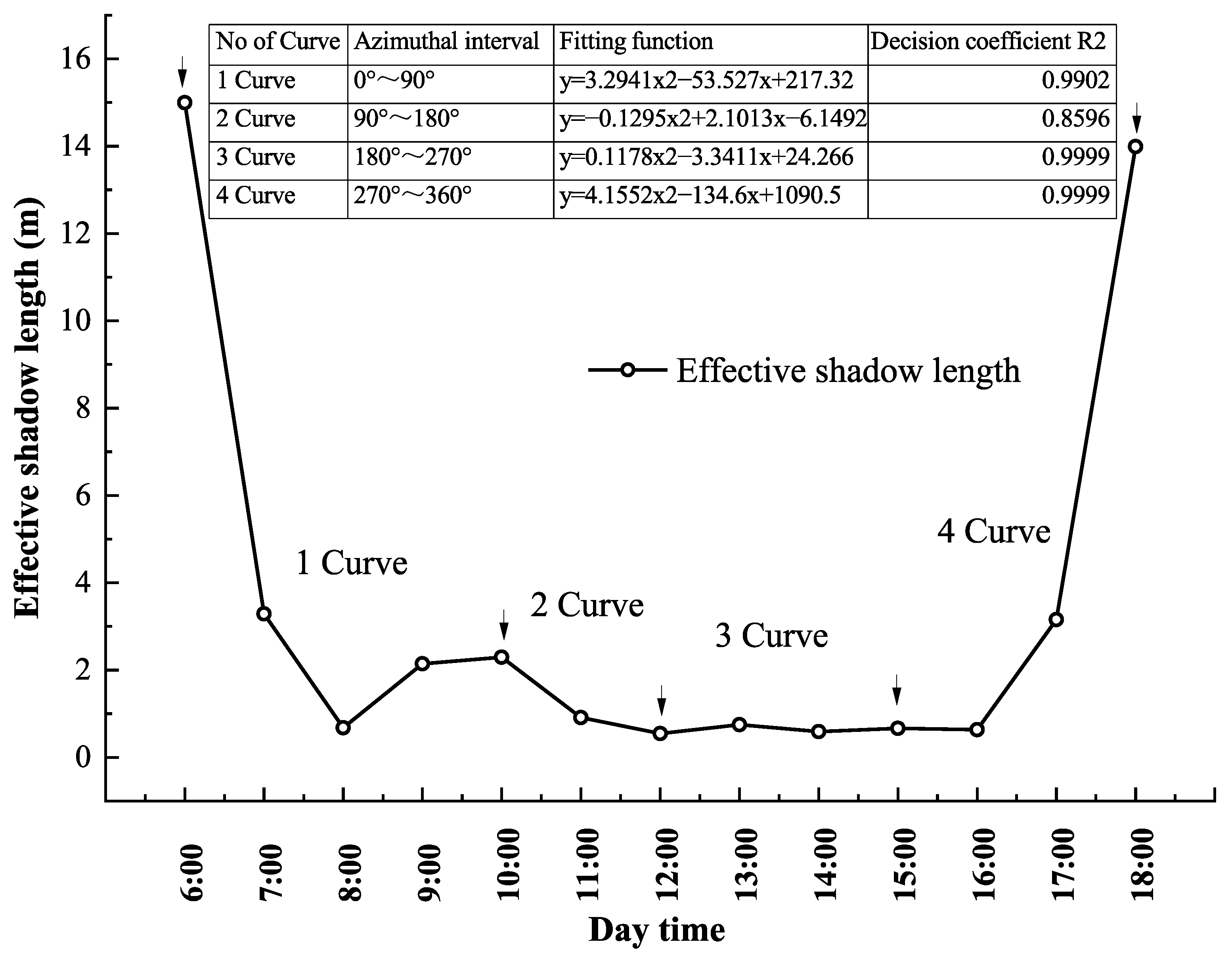

2.3.2. Calculation of Shadow Length of PV Panel and Effective Shadow Length

2.3.3. Measurement of Light Intensity in Agrivoltaic System

2.4. Rice Growth, Photosynthetics, and Yield

2.5. Land Equivalent Ratio

2.6. Statistical Analysis

3. Results

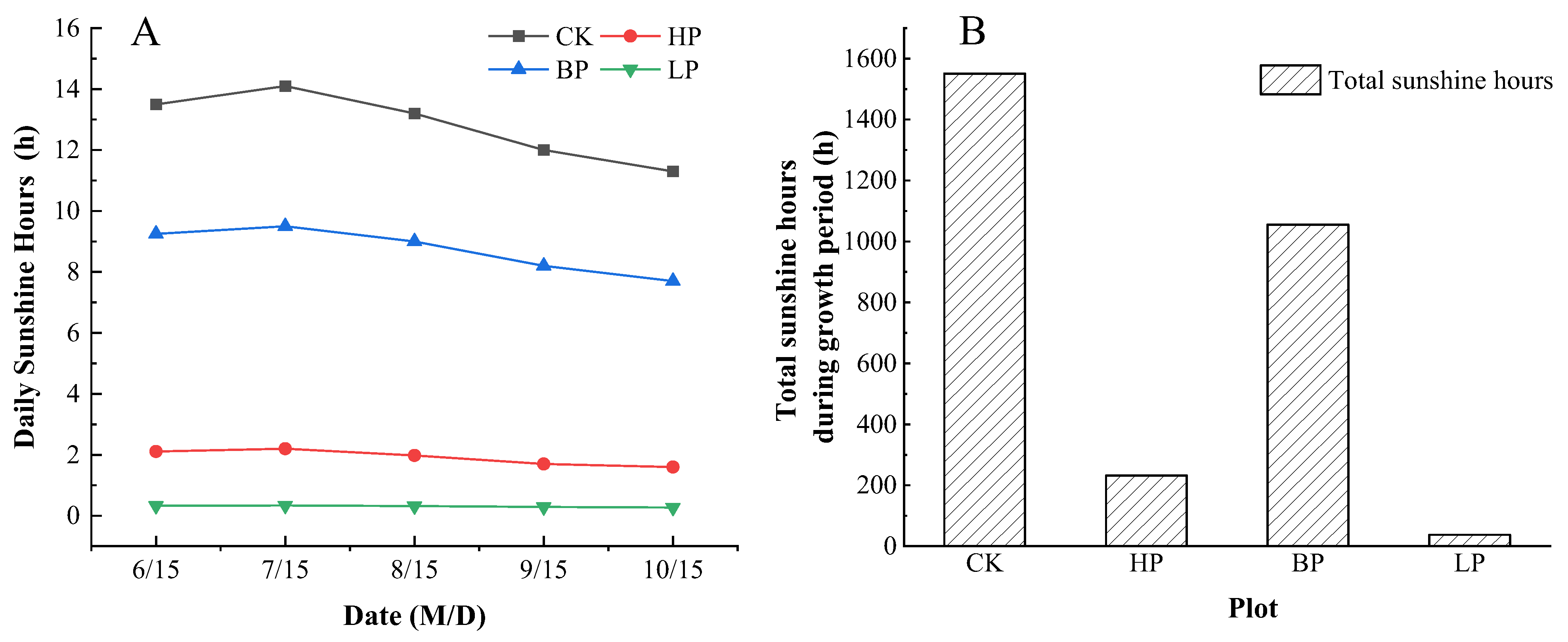

3.1. Effect of APV Array Shading on Daily Variations in Direct Sunlight Exposure Duration

3.2. Changes in Daylight Duration and PPFD Under APV Array During Rice Growth Period

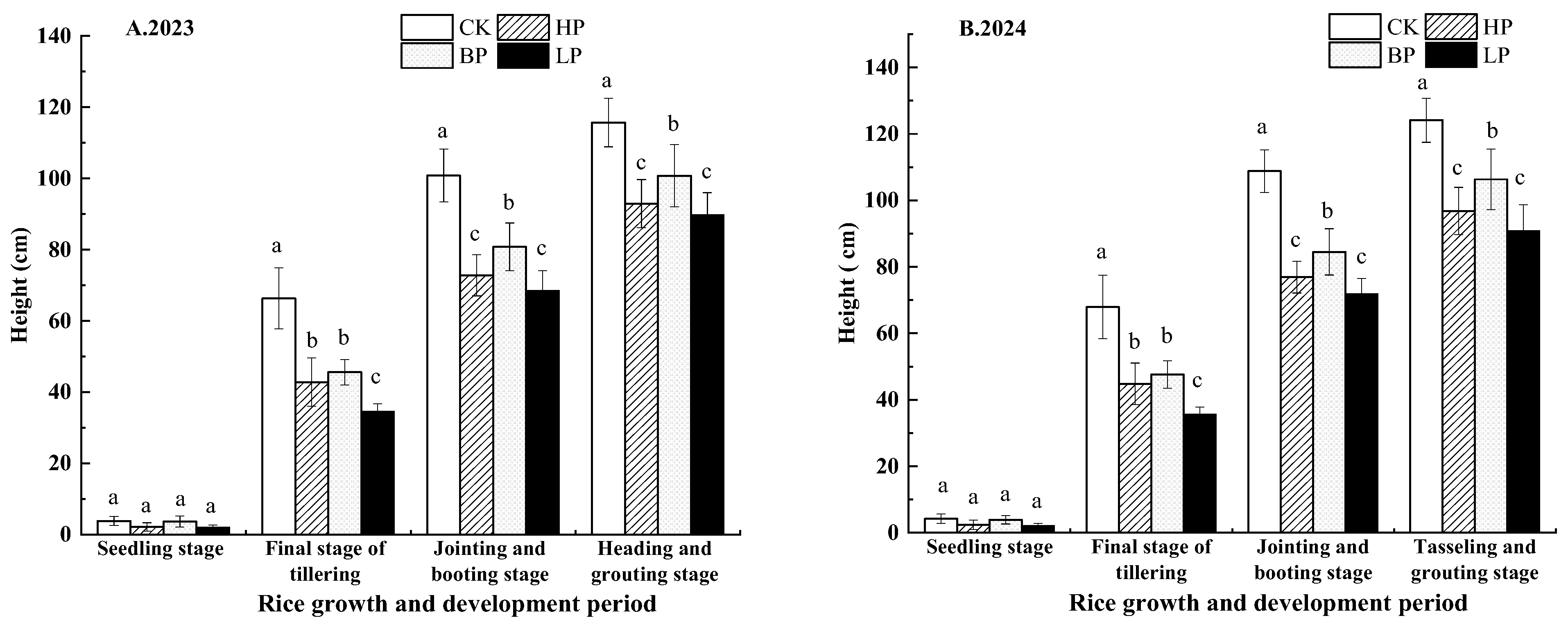

3.3. Rice Growth in the APV System

3.4. The Photosynthesis Parameters of the Expanded Rice Leaf in the APV System

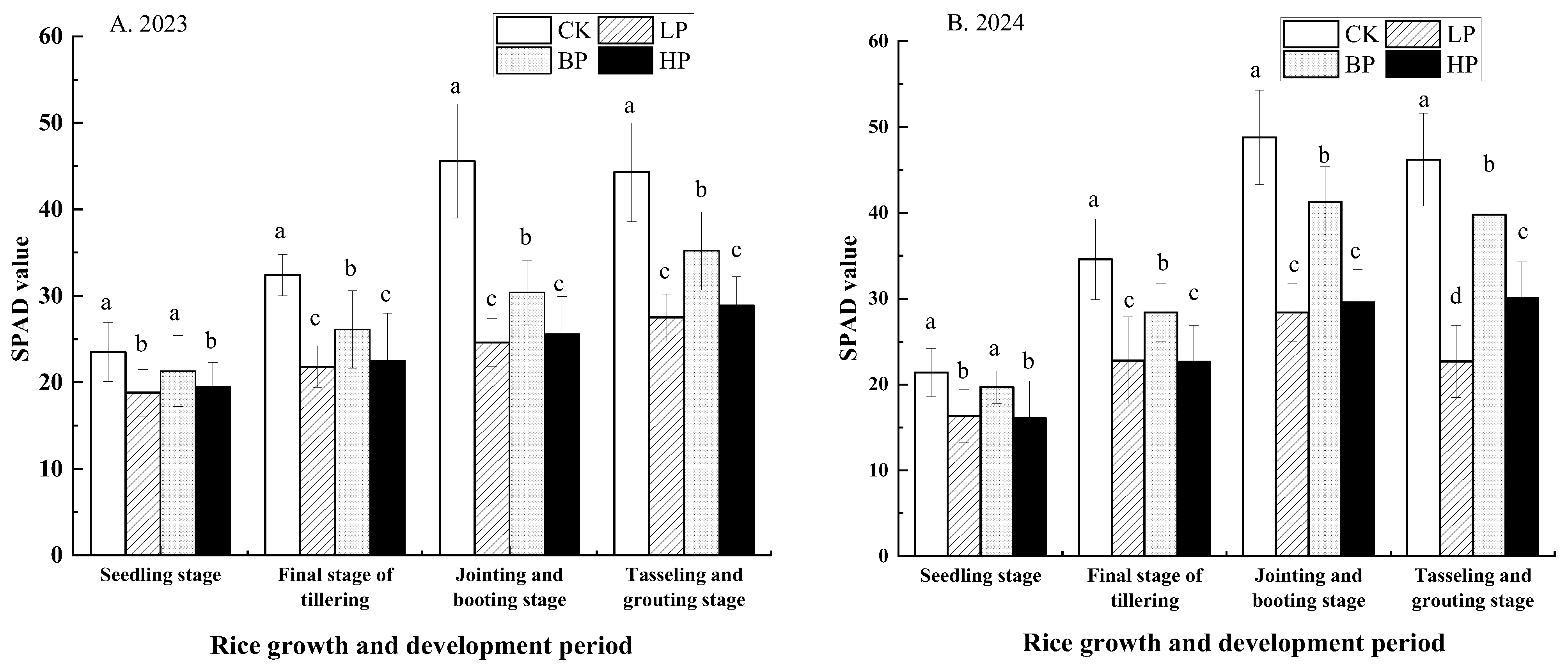

3.4.1. Changes in SPAD Values in Rice

3.4.2. Daily Variations in Photosynthetic Parameters in Penultimate Rice Leaves

3.5. Changes in Dry Matter Accumulation and Rice Yield in Different Planting Plots of APV Arrays

3.6. Analysis of Land Use Efficiency in APV Array Area

4. Discussion

4.1. Effects of APV Arrays on Sunlight Duration

4.2. Effects of Agrivoltaic Arrays on Photosynthetic Properties of Crops

4.3. Effects of AV Arrays on Growth and Yield of Crops

4.4. LER of AV System

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dupraz, C.; Marrou, H.; Talbot, G.; Dufour, L.; Nogier, A.; Ferard, Y. Combining solar photovoltaic panels and food crops for optimising land use: Towards new agrivoltaic schemes. Renew. Energy 2011, 36, 2725–2732. [Google Scholar] [CrossRef]

- Adeh, E.H.; Selker, J.S.; Higgins, C.W. Remarkable agrivoltaic influence on soil moisture, micrometeorology and water-use efficiency. PLoS ONE 2018, 13, e0203256. [Google Scholar] [CrossRef]

- Hernandez, R.R.; Armstrong, A.; Burney, J.; Ryan, G.; Moore-O’Leary, K.; Diedhiou, I.; Grodsky, S.M.; Saul-Gershenz, L.; Davis, R.; Macknick, J.; et al. Techno-ecological synergies of solar energy for global sustainability. Nat. Sustain. 2019, 2, 560–568. [Google Scholar] [CrossRef]

- Mamun, M.A.A.; Dargusch, P.; Wadley, D.; Zulkarnain, N.A.; Aziz, A.A. A review of research on agrivoltaic systems. Renew. Sustain. Energy Rev. 2022, 161, 112351. [Google Scholar] [CrossRef]

- Adeh, E.H.; Good, S.P.; Calaf, M.; Higgins, C.W. Solar PV Power Potential is Greatest Over Croplands. Sci. Rep. 2019, 9, 11442. [Google Scholar] [CrossRef]

- Kumpanalaisatit, M.; Setthapun, W.; Sintuya, H.; Pattiya, A.; Jansri, S.N. Current status of agrivoltaic systems and their benefits to energy, food, environment, economy, and society. Sustain. Prod. Consum. 2022, 33, 952–963. [Google Scholar] [CrossRef]

- Barron-Gafford, G.A.; Pavao-Zuckerman, M.A.; Minor, R.L.; Sutter, L.F.; Barnett-Moreno, I.; Blackett, D.T.; Thompson, M.; Dimond, K.; Gerlak, A.K.; Nabhan, G.P.; et al. Agrivoltaics provide mutual benefits across the food-energy-water nexus in drylands. Nat. Sustain. 2019, 2, 848–855. [Google Scholar] [CrossRef]

- Walston, L.J.; Li, Y.; Hartmann, H.M.; Macknick, J.; Hanson, A.; Nootenboom, C.; Lonsdorf, E.; Hellmann, J. Modeling the ecosystem services of native vegetation management practices at solar energy facilities in the Midwestern United States. Ecosyst. Serv. 2021, 47, 101227. [Google Scholar] [CrossRef]

- Weselek, A.; Ehmann, A.; Zikeli, S.; Lewandowski, I.; Schindele, S.; Hoegy, P. Agrophotovoltaic systems: Applications, challenges, and opportunities. A review. Agron. Sustain. Dev. 2019, 39, 35. [Google Scholar] [CrossRef]

- Marrou, H.; Guilioni, L.; Dufour, L.; Dupraza, C.; Wery, J. Microclimate under agrivoltaic systems: Is crop growth rate affected in the partial shade of solar panels? Agric. For. Meteorol. 2013, 177, 117–132. [Google Scholar] [CrossRef]

- Ko, J.; Cho, J.; Choi, J.; Yoon, C.; An, K.; Ban, J.; Kim, D. Simulation of Crop Yields Grown under Agro-Photovoltaic Panels: A Case Study in Chonnam Province, South Korea. Energies 2021, 14, 8463. [Google Scholar] [CrossRef]

- Yajima, D.; Toyoda, T.; Kirimura, M.; Araki, K.; Ota, Y.; Nishioka, K. Estimation Model of Agrivoltaic Systems Maximizing for Both Photovoltaic Electricity Generation and Agricultural Production. Energies 2023, 16, 3261. [Google Scholar] [CrossRef]

- Lee, H.J.; Park, H.H.; Kim, Y.O.; Kuk, Y.I. Crop Cultivation Underneath Agro-Photovoltaic Systems and Its Effects on Crop Growth, Yield, and Photosynthetic Efficiency. Agronomy 2022, 12, 1842. [Google Scholar] [CrossRef]

- Wei, W.; Luo, J.; Yang, L.; Sang, Y.; Luo, X.; Sui, X. Research on Agricultural Photovoltaic Complementary Development and Profit Model. Acta Energ. Solaris Sin. 2023, 44, 457–464, (In Chinese with English Abstract). [Google Scholar]

- Shan, C.; Wang, X.; Zhang, J.; Ma, B.; Li, G.; Ni, D.; Zhu, Y.; Wang, Z. Light variation under photovoltaic-Salvia miltiorrhiza production system and its effects on Salvia growth. Shandong Agric. Sci. 2018, 50, 73–79. [Google Scholar]

- Trommsdorff, M.; Kang, J.; Reise, C.; Schindele, S.; Bopp, G.; Ehmann, A.; Weselek, A.; Hoegy, P.; Obergfell, T. Combining food and energy production: Design of an agrivoltaic system applied in arable and vegetable farming in Germany. Renew. Sustain. Energy Rev. 2021, 140, 110694. [Google Scholar] [CrossRef]

- Agostini, A.; Colauzzi, M.; Amaducci, S. Innovative agrivoltaic systems to produce sustainable energy: An economic and environmental assessment. Appl. Energy 2021, 281, 116102. [Google Scholar] [CrossRef]

- Dinesh, H.; Pearce, J.M. The potential of agrivoltaic systems. Renew. Sustain. Energy Rev. 2016, 54, 299–308. [Google Scholar] [CrossRef]

- Amaducci, S.; Yin, X.; Colauzzi, M. Agrivoltaic systems to optimise land use for electric energy production. Appl. Energy 2018, 220, 545–561. [Google Scholar] [CrossRef]

- Nasukawa, H.; Kuwabara, Y.; Tatsumi, K.; Tajima, R. Rice yield and energy balance in an agrivoltaic system established in Shonai plain, northern Japan. Sci. Total Environ. 2025, 959, 178315. [Google Scholar] [CrossRef]

- Widmer, J.; Christ, B.; Grenz, J.; Norgrove, L. Agrivoltaics, a promising new tool for electricity and food production: A systematic review. Renew. Sustain. Energy Rev. 2024, 192, 114277. [Google Scholar] [CrossRef]

- Wagner, M.; Lask, J.; Kiesel, A.; Lewandowski, I.; Weselek, A.; Hoegy, P.; Trommsdorff, M.; Schnaiker, M.; Bauerle, A. Agrivoltaics: The Environmental Impacts of Combining Food Crop Cultivation and Solar Energy Generation. Agronomy 2023, 13, 299. [Google Scholar] [CrossRef]

- Gorjian, S.; Bousi, E.; Oezdemir, O.E.; Trommsdorff, M.; Kumar, N.M.; Anand, A.; Kant, K.; Chopra, S.S. Progress and challenges of crop production and electricity generation in agrivoltaic systems using semi-transparent photovoltaic technology. Renew. Sustain. Energy Rev. 2022, 158, 112126. [Google Scholar] [CrossRef]

- Chatterjee, S.; Shimohara, N.; Seo, T.; Jinnai, S.; Moriyama, T.; Saida, M.; Omote, K.; Hama, K.; Iimuro, Y.; Watanabe, Y.; et al. Green-light wavelength-selective organic solar cells: Module fabrication and crop evaluation towards agrivoltaics. Mater. Today Energy 2024, 45, 101673. [Google Scholar] [CrossRef]

- Reher, T.; Lavaert, C.; Willockx, B.; Huyghe, Y.; Bisschop, J.; Martens, J.A.; Diels, J.; Cappelle, J.; Van de Poel, B. Potential of sugar beet (Beta vulgaris) and wheat (Triticum aestivum) production in vertical bifacial, tracked, or elevated agrivoltaic systems in Belgium. Appl. Energy 2024, 359, 122679. [Google Scholar] [CrossRef]

- Gonocruz, R.A.; Nakamura, R.; Yoshino, K.; Homma, M.; Doi, T.; Yoshida, Y.; Tani, A. Analysis of the Rice Yield under an Agrivoltaic System: A Case Study in Japan. Environments 2021, 8, 65. [Google Scholar] [CrossRef]

- Weselek, A.; Bauerle, A.; Hartung, J.; Zikeli, S.; Lewandowski, I.; Hogy, P. Agrivoltaic system impacts on microclimate and yield of different crops within an organic crop rotation in a temperate climate. Agron. Sustain. Dev. 2021, 41, 59. [Google Scholar] [CrossRef]

- Wei, L.; Yu, M.; Qin, N.; Huang, C.; Xie, Y.; Sun, W.; Wu, L.; Wang, W.; Wang, G. Effects of agrophotovoltaic system on field light conditions and sweet potato growth. J. Zhejiang Univ. Agric. Life Sci. 2019, 45, 288–295. [Google Scholar]

- Choi, C.S.; Ravi, S.; Siregar, I.Z.; Dwiyanti, F.G.; Macknick, J.; Elchinger, M.; Davatzes, N.C. Combined land use of solar infrastructure and agriculture for socioeconomic and environmental co-benefits in the tropics. Renew. Sustain. Energy Rev. 2021, 151, 111610. [Google Scholar] [CrossRef]

- Jo, H.; Asekova, S.; Bayat, M.A.; Ali, L.; Song, J.T.; Ha, Y.; Hong, D.; Lee, J. Comparison of Yield and Yield Components of Several Crops Grown under Agro-Photovoltaic System in Korea. Agriculture 2022, 12, 619. [Google Scholar] [CrossRef]

- Dal Pra, A.; Miglietta, F.; Genesio, L.; Lanini, G.M.; Bozzi, R.; More, N.; Greco, A.; Fabbri, M.C. Determination of feed yield and quality parameters of whole crop durum wheat (Triticum durum Desf.) biomass under agrivoltaic system. Agrofor. Syst. 2024, 98, 2861–2873. [Google Scholar] [CrossRef]

- Ko, D.; Chae, S.; Moon, H.; Kim, H.J.; Seong, J.; Lee, M.; Ku, K. Agrivoltaic Farming Insights: A Case Study on the Cultivation and Quality of Kimchi Cabbage and Garlic. Agronomy 2023, 13, 2625. [Google Scholar] [CrossRef]

- Thum, C.H.; Okada, K.; Yamasaki, Y.; Kato, Y. Impacts of agrivoltaic systems on microclimate, grain yield, and quality of lowland rice under a temperate climate. Field Crops Res. 2025, 326, 109877. [Google Scholar] [CrossRef]

- Hasan, A.S.; Ahmed, T.; Mahjabin, M.; Abdullah, F.B.; Rejwana, Z.; Rahman, M.M.; Islam, M. Impact of Shading on Paddy Field: A Case Study in Bangladesh Towards Agrivoltaic. In Proceedings of the 2024 IEEE Region 10 Symposium (TENSYMP), New Delhi, India, 1 January 2024; Volume 1, pp. 1–5. [Google Scholar]

| Time | Solar Declination (°) | Longitude (°) | Solar Altitude Angle (°) | Solar Azimuth Angle (°) | Effective Shadow Length (m) |

|---|---|---|---|---|---|

| 6:00 | 23.33 | 30.15 | 8.2 | 61.3 | 15.00 |

| 7:00 | 23.33 | 30.15 | 20.1 | 74.5 | 3.29 |

| 8:00 | 23.33 | 30.15 | 33.8 | 84.2 | 0.68 |

| 9:00 | 23.33 | 30.15 | 48.3 | 90.1 | 2.15 |

| 10:00 | 23.33 | 30.15 | 62.7 | 109.8 | 2.29 |

| 11:00 | 23.33 | 30.15 | 75.2 | 129.5 | 0.91 |

| 12:00 | 23.33 | 30.15 | 83.1 | 180.5 | 0.54 |

| 13:00 | 23.33 | 30.15 | 75.4 | 230.3 | 0.75 |

| 14:00 | 23.33 | 30.15 | 63.0 | 255.1 | 0.59 |

| 15:00 | 23.33 | 30.15 | 48.7 | 260.3 | 0.67 |

| 16:00 | 23.33 | 30.15 | 34.2 | 275.5 | 0.63 |

| 17:00 | 23.33 | 30.15 | 20.5 | 285.2 | 3.16 |

| 18:00 | 23.33 | 30.15 | 8.7 | 298.4 | 13.99 |

| Plot | Azimuth: 0–90° | Azimuth: 90–180° | Azimuth: 180–360° | Total Sunshine Hours | |||

|---|---|---|---|---|---|---|---|

| Boundary Light Onset Moment | Boundary Light End Moment | Boundary Light Onset Moment | Boundary Light End Moment | Boundary Light Onset Moment | Boundary Light End Moment | ||

| CK | 6.00 | 9.00 | 9.00 | 12.00 | 12.00 | 19.30 | 13.50 |

| LP | 7.96 | 8.29 | - | - | - | - | 0.33 |

| BP | 7.07 | 9.17 | 9.20 | 15.37 | 17.02 | 19.16 | 9.25 |

| HP | - | - | - | - | 15.14 | 17.25 | 2.11 |

| Year | Treatments | |||

|---|---|---|---|---|

| CK | LP | BP | HP | |

| 2023 | 9.11 ± 0.99 a | 5.73 ± 0.95 c | 7.83 ± 1.32 b | 7.22 ± 1.14 b |

| 2024 | 9.42 ± 1.12 a | 5.49 ± 0.88 c | 8.97 ± 1.28 b | 7.34 ± 2.15 b |

| Year | Time | Pn (μmol·m−2·s−1) | Tr (μmol·m−2·s−1) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| CK | LP | BP | HP | CK | LP | BP | HP | ||

| 2023 | 10:00 | 18.51 ± 2.12 a | 8.82 ± 1.53 c | 11.62 ± 0.81 b | 8.93 ± 0.71 c | 4.81 ± 0.54 a | 2.04 ± 0.24 d | 4.01 ± 0.41 b | 3.24 ± 0.31 c |

| 12:00 | 22.29 ± 1.83 a | 7.43 ± 2.02 c | 17.21 ± 1.42 b | 7.24 ± 0.52 c | 6.23± 0.62 a | 2.41 ± 0.31 d | 5.03 ± 0.52 b | 3.81 ± 0.42 c | |

| 14:00 | 16.74 ± 2.01 a | 6.61 ± 1.21 c | 14.83 ± 1.23 b | 6.91 ± 0.73 c | 5.54 ± 0.71 a | 2.23 ± 0.23 d | 4.64 ± 0.61 b | 3.52 ± 0.31 c | |

| 16:00 | 12.43 ± 1.52 a | 5.14 ± 1.80 d | 10.34 ± 1.31 b | 6.52 ± 0.93 c | 3.93 ± 0.44 a | 1.83 ± 0.24 c | 3.52 ± 0.34 a | 2.83± 0.21 b | |

| 2024 | 10:00 | 22.47 ± 2.05 a | 10.33 ± 1.62 c | 14.28 ± 0.92 b | 9.75 ± 0.68 c | 4.92 ± 0.56 a | 2.11 ± 0.25 d | 4.17 ± 0.43 b | 3.35 ± 0.32 c |

| 12:00 | 24.17 ± 1.75 a | 6.89 ± 1.98 c | 18.36 ± 1.38 b | 6.75 ± 0.49 c | 6.47 ± 0.65 a | 2.28 ± 0.29 d | 5.24 ± 0.54 b | 3.95 ± 0.43 c | |

| 14:00 | 17.82 ± 2.10 a | 6.79 ± 1.22 c | 13.45 ± 1.20 b | 7.05 ± 0.75 c | 5.43 ± 0.69 a | 2.31 ± 0.24 d | 4.52 ± 0.59 b | 3.45 ± 0.30 c | |

| 16:00 | 13.27 ± 1.58 a | 4.87 ± 1.76 d | 11.05 ± 1.35 b | 6.93 ± 0.95 c | 4.02 ± 0.45 a | 1.89 ± 0.25 c | 3.48 ± 0.33 a | 2.75 ± 0.20 b | |

| Year | Time | Gs mmol·m−2·s−1 | Ci μmol·m−2·s−1 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| CK | LP | BP | HP | CK | LP | BP | HP | ||

| 2023 | 10:00 | 0.34 ± 0.05 ab | 0.19 ± 0.03 c | 0.39 ± 0.06 a | 0.29 ± 0.04 b | 245.33 ± 20.22 c | 325.81 ± 41.02 a | 252.74 ± 25.41 c | 275.39 ± 29.84 b |

| 12:00 | 0.33 ± 0.05 a | 0.15 ± 0.03 c | 0.27 ± 0.04 b | 0.23 ± 0.03 b | 269.48 ± 20.34 c | 349.15 ± 45.18 a | 263.25 ± 24.92 c | 307.92 ± 34.87 b | |

| 14:00 | 0.32 ± 0.06 b | 0.15 ± 0.02 c | 0.36 ± 0.04 a | 0.29 ± 0.05 b | 263.17 ± 24.34 c | 328.45 ± 39.85 a | 255.33 ± 29.15 c | 288.72 ± 29.12 b | |

| 16:00 | 0.25 ± 0.03 b | 0.23 ± 0.02 b | 0.31 ± 0.04 a | 0.24 ± 0.03 b | 235.33 ± 15.22 c | 295.81 ± 36.02 a | 242.74 ± 20.41 c | 265.39 ± 26.87 b | |

| 2024 | 10:00 | 0.35 ± 0.05 a | 0.18 ± 0.03 c | 0.40 ± 0.06 a | 0.30 ± 0.04 b | 240.15 ± 20.27 c | 320.34 ± 40.14 a | 250.34 ± 25.22 c | 280.51 ± 30.87 b |

| 12:00 | 0.28 ± 0.04 b | 0.15 ± 0.03 c | 0.35 ± 0.05 a | 0.25 ± 0.03 b | 260.67 ± 25.15 c | 350.64 ± 45.54 a | 270.85 ± 20.28 c | 310.62 ± 35.33 b | |

| 14:00 | 0.32 ± 0.06 b | 0.17 ± 0.02 c | 0.38 ± 0.04 a | 0.28 ± 0.05 b | 250.19 ± 30.34 c | 33028 ± 40.37 a | 260.64 ± 25.57 c | 290.91 ± 30.18 b | |

| 16:00 | 0.25 ± 0.03 b | 0.22 ± 0.02 b | 0.30 ± 0.04 a | 0.22 ± 0.03 b | 230.22 ± 15.17 c | 300.22 ± 35.19 a | 240.61 ± 20.75 c | 270.34 ± 25.28 b | |

| Year | Plot | Effective Spikes (No/m2) | Fruit Rate (%) | Thousand Kernel Weight (g) | Grain Weight per Spike (g) | Yield (kg/m2) | Yield Reduction Rate (%) |

|---|---|---|---|---|---|---|---|

| 2023 | CK | 241.19 ± 4.27 a | 84.36 | 26.44 ± 1.54 a | 4.13 ± 0.21a | 0.98 ± 0.19 a | --- |

| LP | 155.78 ± 4.34 c | 49.34 | 24.85 ± 0.88 c | 2.26 ± 0.19a | 0.46 ± 0.18 b | 53.06 | |

| BP | 188.24 ± 4.71 b | 78.15 | 26.13 ± 1.37 a | 3.93 ± 0.20a | 0.81 ± 0.16a b | 17.34 | |

| HP | 163.85 ± 4.67 c | 61.43 | 25.37 ± 1.42 b | 2.97 ± 0.22a | 0.57 ± 0.15a b | 41.18 | |

| 2024 | CK | 249.36 ± 4.36 a | 86.78 | 27.11 ± 1.51 a | 4.18 ± 0.15a | 1.01 ± 0.17 a | --- |

| LP | 157.34 ± 5.10 c | 50.12 | 24.91 ± 1.22 a | 2.33 ± 0.17c | 0.47 ± 0.14 b | 53.47 | |

| BP | 192.16 ± 4.18 b | 78.34 | 27.06 ± 0.97 a | 3.98 ± 0.14a | 0.82 ± 0.11 ab | 18.81 | |

| HP | 165.65 ± 5.24 c | 62.28 | 25.41 ± 1.07 a | 3.01 ± 0.12b | 0.58 ± 0.15 b | 42.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, Y.; Gao, X.; He, J.; Luo, J.; Sui, X.; Su, P. Variations in Solar Radiation and Their Effects on Rice Growth in Agro-Photovoltaics System. Agronomy 2025, 15, 1975. https://doi.org/10.3390/agronomy15081975

Jia Y, Gao X, He J, Luo J, Sui X, Su P. Variations in Solar Radiation and Their Effects on Rice Growth in Agro-Photovoltaics System. Agronomy. 2025; 15(8):1975. https://doi.org/10.3390/agronomy15081975

Chicago/Turabian StyleJia, Yamin, Xiaoli Gao, Junkang He, Jiufu Luo, Xin Sui, and Peilan Su. 2025. "Variations in Solar Radiation and Their Effects on Rice Growth in Agro-Photovoltaics System" Agronomy 15, no. 8: 1975. https://doi.org/10.3390/agronomy15081975

APA StyleJia, Y., Gao, X., He, J., Luo, J., Sui, X., & Su, P. (2025). Variations in Solar Radiation and Their Effects on Rice Growth in Agro-Photovoltaics System. Agronomy, 15(8), 1975. https://doi.org/10.3390/agronomy15081975