Optimizing Nutrition Protocols for Improved Rice Yield, Quality, and Nitrogen Use Efficiency in Coastal Saline Soils

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Materials and Growing Conditions

2.2. Experimental Design

2.3. Sampling and Data Collection

2.4. Agronomic Nitrogen Use Efficiency (ANUE)

2.5. Statistical Analysis

3. Results

3.1. Rice Yield and Its Components

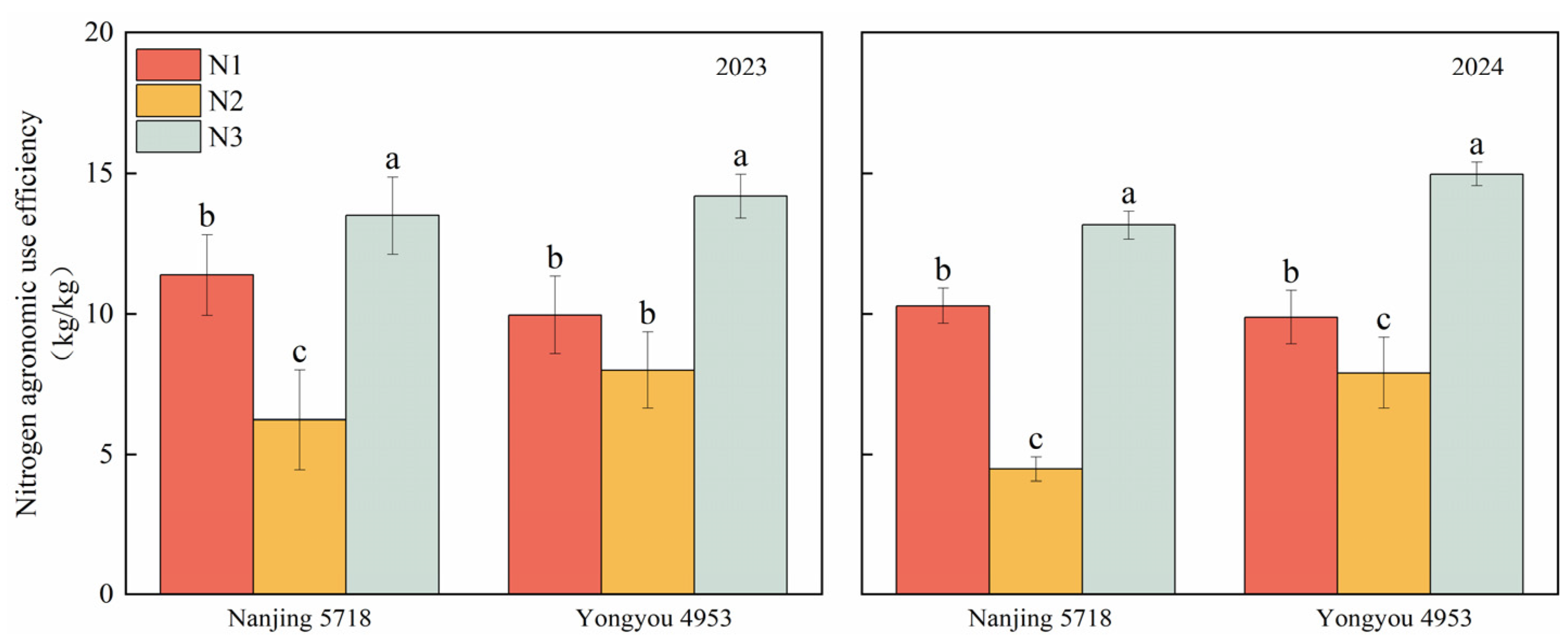

3.2. Agronomic Nitrogen Use Efficiency

3.3. Rice Processing and Appearance Quality

3.4. Rice Taste Quality

3.5. Rice Starch Content

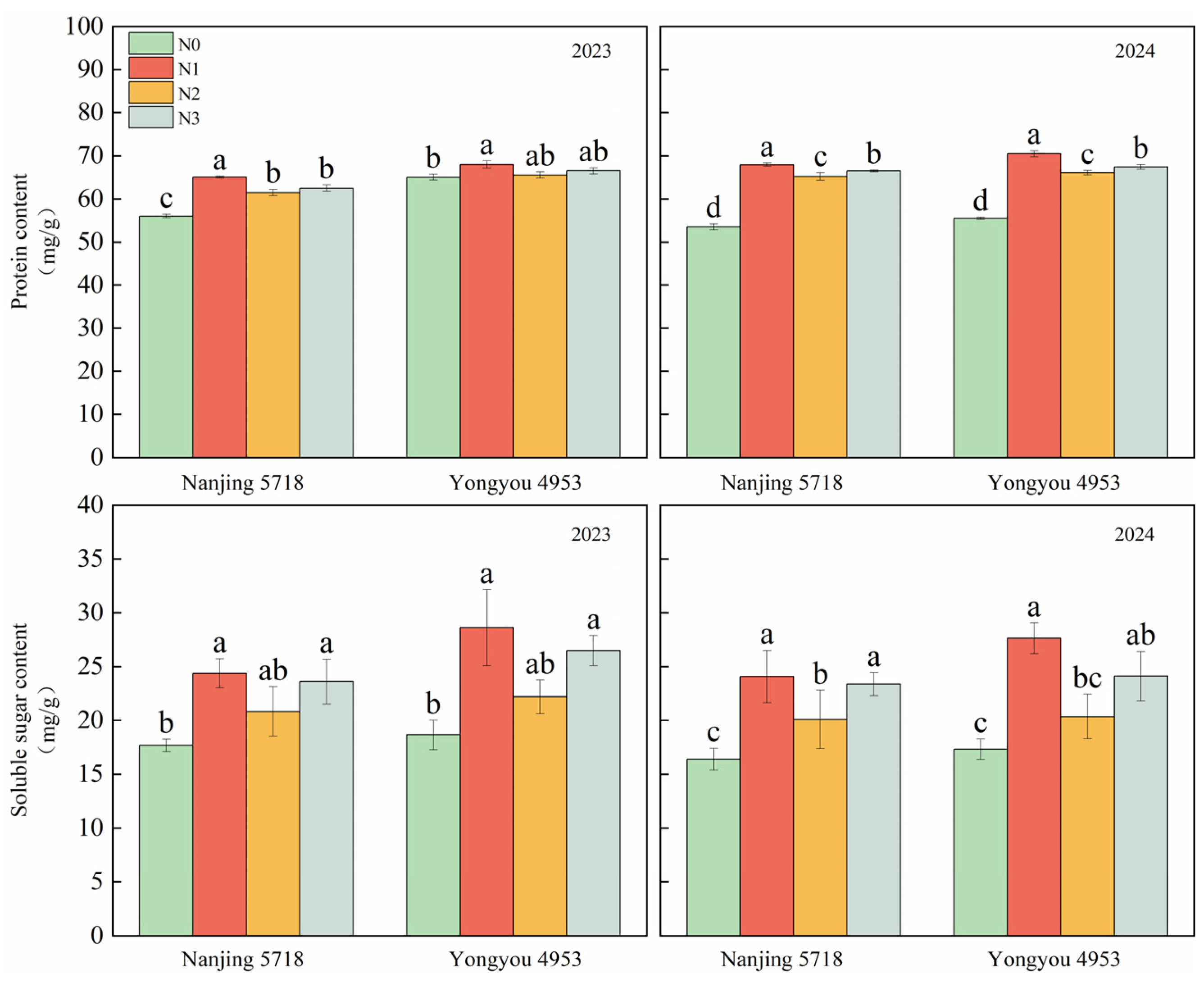

3.6. Rice Protein Content and Soluble Sugar Content

3.7. Rice Viscosity Characteristics (RVA Parameters)

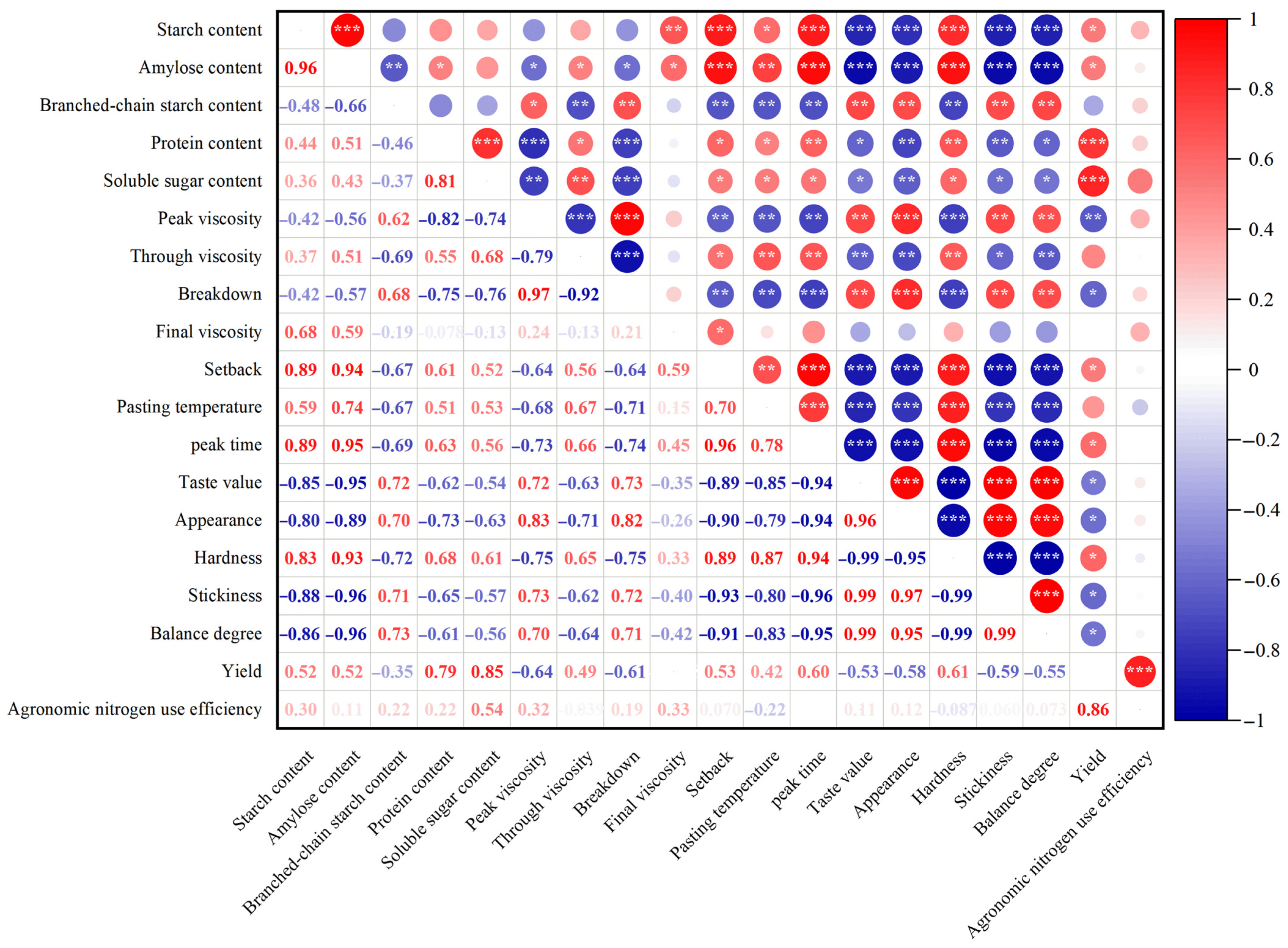

3.8. Correlation Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ANUE | agronomic nitrogen use efficiency |

| CRF | controlled-release fertilizer |

| RVA | Rapid ViscoAnalyser |

References

- Baldos, U.L.C.; Pineda, A.C.; Fuglie, K.O.; Hertel, T.W. Adoption of improved crop varieties limited biodiversity losses, terrestrial carbon emissions, and cropland expansion in the tropics. Proc. Natl. Acad. Sci. USA 2025, 122, e2404839122. [Google Scholar] [PubMed]

- Gomez, C.; Amelin, J.; Coulouma, G.; Gaab, J.; Dharumarajan, S.; Riotte, J.; Sekhar, M.; Ruiz, L. Reuse of bottom sediment from reservoirs to cropland is a promising agroecological practice that must be rationalized. Sci. Rep. 2025, 15, 7523. [Google Scholar]

- Fukagawa, N.K.; Ziska, L.H. Rice: Importance for Global Nutrition. J. Nutr. Sci. Vitaminol. 2019, 65, S2–S3. [Google Scholar] [PubMed]

- Xu, Z.K.; Shao, T.Y.; Lv, Z.X.; Yue, Y.; Liu, A.H.; Long, X.H.; Zhou, Z.S.; Gao, X.M.; Rengel, Z. The mechanisms of improving coastal saline soils by planting rice. Sci. Total Environ. 2020, 703, 135529. [Google Scholar] [PubMed]

- Chu, Q.N.; Xue, L.H.; Cheng, Y.Q.; Liu, Y.; Feng, Y.F.; Yu, S.; Meng, L.; Pan, G.; Hou, P.F.; Duan, J.J.; et al. Microalgae-derived hydrochar application on rice paddy soil: Higher rice yield but increased gaseous nitrogen loss. Sci. Total Environ. 2020, 717, 137127. [Google Scholar]

- Li, Y.; Ai, Z.; Mu, Y.; Zhao, T.; Zhang, Y.; Li, L.; Huang, Z.; Nie, L.; Khan, M.N. Rice yield penalty and quality deterioration is associated with failure of nitrogen uptake from regreening to panicle initiation stage under salinity. Front. Plant Sci. 2023, 14, 1120755. [Google Scholar]

- Lv, B.-S.; Li, X.-W.; Ma, H.-Y.; Sun, Y.; Wei, L.-X.; Jiang, C.-J.; Liang, Z.-W. Differences in Growth and Physiology of Rice in Response to Different Saline-Alkaline Stress Factors. Agron. J. 2013, 105, 1889, Erratum in Crop Ecol. Physiol. 2013, 105, 1119–1128. [Google Scholar]

- Che, W.; Piao, J.; Gao, Q.; Li, X.; Li, X.; Jin, F. Response of soil physicochemical properties, soil nutrients, enzyme activity and rice yield to rice straw returning in highly saline-alkali paddy soils. J. Soil Sci. Plant Nutr. 2023, 23, 4396–4411. [Google Scholar]

- Garcia, G.; Treccarichi, S.; Cali, R.; Arena, D.; Tribulato, A.; Branca, F. Nitrogen Use Efficiency of Microbial and Amino Acid Treatments for Organic Broccoli (Brassica oleracea L. var. italica Plenk) Seed Production. Horticulturae 2025, 11, 253. [Google Scholar] [CrossRef]

- Ma, B.L.; Herath, A.W. Timing and rates of nitrogen fertiliser application on seed yield, quality and nitrogen-use efficiency of canola. Crop Pasture Sci. 2016, 67, 167–180. [Google Scholar]

- Ma, X.; Ding, Z.; Hu, R.; Wang, X.; Hou, J.; Zou, G.; Cao, B. Increasing rice yield with low ammonia volatilization by combined application of controlled-release blended fertilizer and densification. PLoS ONE 2025, 20, e0318177. [Google Scholar]

- Wang, L.; Xue, C.; Pan, X.; Chen, F.; Liu, Y. Application of Controlled-Release Urea Enhances Grain Yield and Nitrogen Use Efficiency in Irrigated Rice in the Yangtze River Basin, China. Front. Plant Sci. 2018, 9, 999. [Google Scholar]

- Ramasamy, S.; ten Berge, H.F.M.; Purushothaman, S. Yield formation in rice in response to drainage and nitrogen application. Field Crops Res. 1997, 51, 65–82. [Google Scholar]

- Sun, Y.; Yuan, X.; Chen, K.; Wang, H.; Luo, Y.; Guo, C.; Wang, Z.; Shu, C.; Yang, Y.; Weng, Y.; et al. Improving the yield and nitrogen use efficiency of hybrid rice through rational use of controlled-release nitrogen fertilizer and urea topdressing. Front. Plant Sci. 2023, 14, 1240238. [Google Scholar]

- Guo, Y.; Zhang, M.; Liu, Z.; Zhao, C.; Lu, H.; Zheng, L.; Li, Y.C. Applying and Optimizing Water-Soluble, Slow-Release Nitrogen Fertilizers for Water-Saving Agriculture. ACS Omega 2020, 5, 11342–11351. [Google Scholar]

- Dong, X.; Ying, Z.; Zhu, H.; Qun, H.; Liu, G.; Wei, H.; Zhang, H. Effects of a one-time application of controlled-release nitrogen fertilizer on quality and yield of rice. Food Energy Secur. 2023, 12, e413. [Google Scholar]

- Mi, K.; Yuan, X.; Wang, Q.; Dun, C.; Wang, R.; Yang, S.; Yang, Y.; Zhang, H.; Zhang, H. Zinc oxide nanoparticles enhanced rice yield, quality, and zinc content of edible grain fraction synergistically. Front. Plant Sci. 2023, 14, 1196201. [Google Scholar]

- Shi, S.; Wang, E.; Li, C.; Cai, M.; Cheng, B.; Cao, C.; Jiang, Y. Use of Protein Content, Amylose Content, and RVA Parameters to Evaluate the Taste Quality of Rice. Front. Nutr. 2022, 8, 758547. [Google Scholar]

- Wang, X.; Wang, K.; Yin, T.; Zhao, Y.; Liu, W.; Shen, Y.; Ding, Y.; Tang, S. Nitrogen Fertilizer Regulated Grain Storage Protein Synthesis and Reduced Chalkiness of Rice Under Actual Field Warming. Front. Plant Sci. 2021, 12, 715436. [Google Scholar]

- Hu, Y.; Cai, Q.; Xu, Y.; Xue, J.; Yu, E.; Wei, H.; Xu, K.; Huo, Z.; Zhang, H. One-time fertilization of controlled-release urea with compound fertilizer and rapeseed cake maintains rice grain yield and improves nitrogen use efficiency under reduced nitrogen conditions. Front. Plant Sci. 2023, 14, 1281309. [Google Scholar]

- Li, J.; Li, Y.e.; Wan, Y.; Wang, B.; Cai, W.; Qin, X.; Zhou, Z.; Wang, X.; Yuan, J.; Deng, Q. Annual greenhouse gas emissions from a rice paddy with different water-nitrogen management strategies in Central China. Soil Tillage Res. 2024, 235, 105906. [Google Scholar]

- Liu, Y.; Ma, C.; Li, G.; Jiang, Y.; Hou, P.; Xue, L.; Yang, L.; Ding, Y. Lower dose of controlled/slow release fertilizer with higher rice yield and N utilization in paddies: Evidence from a meta-analysis. Field Crops Res. 2023, 294, 108879. [Google Scholar]

- Chen, Z.; Wang, Q.; Ma, J.; Zhao, J.; Huai, Y.; Ma, J.; Ye, J.; Yu, Q.; Zou, P.; Sun, W.; et al. Combing mechanical side-deep fertilization and controlled-release nitrogen fertilizer to increase nitrogen use efficiency by reducing ammonia volatilization in a double rice cropping system. Front. Environ. Sci. 2022, 10, 1006606. [Google Scholar]

- Sun, H.; Zhou, S.; Zhang, J.; Zhang, X.; Wang, C. Effects of controlled-release fertilizer on rice grain yield, nitrogen use efficiency, and greenhouse gas emissions in a paddy field with straw incorporation. Field Crops Res. 2020, 253, 107814. [Google Scholar]

- Yang, X.; Geng, J.; Liu, Q.; Zhang, H.; Hao, X.; Sun, Y.; Lu, X. Controlled-release urea improved rice yields by providing nitrogen in synchrony with the nitrogen requirements of plants. J. Sci. Food Agric. 2021, 101, 4183–4192. [Google Scholar]

- Ding, W.-H.; Xie, H.-K.; Xu, C.; Dai, Z.; Zhang, J.; Wang, L.-G.; Li, H. Impacts of one-off fertilization on nitrogen leaching and economic benefits for rice-rape rotation system. J. Appl. Ecol. 2019, 30, 1097–1109. [Google Scholar]

- Lucas, E.R.; Toor, G.S.; McGrath, J.M. Agronomic and environmental phosphorus decline in coastal plain soils after cessation of manure application. Agric. Ecosyst. Environ. 2021, 311, 107337. [Google Scholar]

- Wu, H. Plant salt tolerance and Na+ sensing and transport. Crop J. 2018, 6, 215–225. [Google Scholar]

- Ransom, C.J.; Jolley, V.D.; Blair, T.A.; Sutton, L.E.; Hopkins, B.G. Nitrogen release rates from slow- and controlled-release fertilizers influenced by placement and temperature. PLoS ONE 2020, 15, e0234544. [Google Scholar]

- Zhang, X.; He, P.; Guo, R.; Huang, K.; Huang, X. Effects of salt stress on root morphology, carbon and nitrogen metabolism, and yield of Tartary buckwheat. Sci. Rep. 2023, 13, 12483. [Google Scholar]

- Nazir, F.; Mahajan, M.; Khatoon, S.; Albaqami, M.; Ashfaque, F.; Chhillar, H.; Chopra, P.; Khan, M.I.R. Sustaining nitrogen dynamics: A critical aspect for improving salt tolerance in plants. Front. Plant Sci. 2023, 14, 1087946. [Google Scholar]

- An, L.; Tao, Y.; Chen, H.; He, M.; Xiao, F.; Li, G.; Ding, Y.; Liu, Z. Embryo-Endosperm Interaction and Its Agronomic Relevance to Rice Quality. Front. Plant Sci. 2020, 11, 587641. [Google Scholar]

- Xu, Y.; Guan, X.; Han, Z.; Zhou, L.; Zhang, Y.; Asad, M.A.U.; Wang, Z.; Jin, R.; Pan, G.; Cheng, F. Combined Effect of Nitrogen Fertilizer Application and High Temperature on Grain Quality Properties of Cooked Rice. Front. Plant Sci. 2022, 13, 874033. [Google Scholar]

- Li, Q.; Deng, F.; Zeng, Y.; Li, B.; He, C.; Zhu, Y.; Zhou, X.; Zhang, Z.; Wang, L.; Tao, Y.; et al. Low Light Stress Increases Chalkiness by Disturbing Starch Synthesis and Grain Filling of Rice. Int. J. Mol. Sci. 2022, 23, 9153. [Google Scholar]

- Cheng, S.; Li, S.P.; Tian, J.Y.; Xing, Z.P.; Hu, Y.J.; Guo, B.W.; Wei, H.Y.; Gao, H.; Zhang, H.C. Effects of one-time nitrogen basal application on the yield and quality of different direct-seeding rice crops by machine. Trans. Chin. Soc. Agric. Eng. 2020, 36, 1–10. [Google Scholar]

- Sun, Y.; Wu, Y.; Sun, Y.; Luo, Y.; Guo, C.; Li, B.; Li, F.; Xing, M.; Yang, Z.; Ma, J. Effects of Water and Nitrogen on Grain Filling Characteristics, Canopy Microclimate with Chalkiness of Directly Seeded Rice. Agriculture 2022, 12, 122. [Google Scholar] [CrossRef]

- Xu, D.; Zhu, Y.; Zhu, H.; Hu, Q.; Liu, G.; Wei, H.; Zhang, H. Effects of a One-Time Application of Controlled-Release Nitrogen Fertilizer on Yield and Nitrogen Accumulation and Utilization of Late Japonica Rice in China. Agriculture 2021, 11, 1041. [Google Scholar]

- Wang, L.Y.; He, J.; Hua, K.J.; Zhang, C.J.; Ye, Z.M.; Zhang, L. Combined Effect of Slow-release Fertilizer and Irrigation Method on Growth Yield and Grain Quality of Rice. J. Irrig. Drain. 2023, 42, 44–52. [Google Scholar]

- Zhang, J.; Chen, P.J.; Han, J.J.; Zhai, C.J.; Miao, Y.Q.; Cui, S.Y. Effects of slow-release fertilizer application and nitrogen reduction treatment under saline stress on rice growth, panicle traits, yield and grain quality. J. Triticeae Crops 2023, 39, 1483–1491. [Google Scholar]

- Liu, C.; Zhou, T.; Xue, Z.; Wei, C.; Zhu, K.; Ye, M.; Zhang, W.; Zhang, H.; Liu, L.; Wang, Z.; et al. Combining Controlled-Release and Normal Urea Enhances Rice Grain Quality and Starch Properties by Improving Carbohydrate Supply and Grain Filling. Plants 2025, 14, 107. [Google Scholar] [CrossRef]

- Guo, X.; Wang, L.; Zhu, G.; Xu, Y.; Meng, T.; Zhang, W.; Li, G.; Zhou, G. Impacts of Inherent Components and Nitrogen Fertilizer on Eating and Cooking Quality of Rice: A Review. Foods 2023, 12, 2495. [Google Scholar] [CrossRef]

- Feng, W.; Xue, W.; Zhao, Z.; Shi, Z.; Wang, W.; Bai, Y.; Wang, H.; Qiu, P.; Xue, J.; Chen, B. Nitrogen fertilizer application rate affects the dynamic metabolism of nitrogen and carbohydrates in kernels of waxy maize. Front. Plant Sci. 2024, 15, 1416397. [Google Scholar]

- Diaz, E.O.; Kawamura, S.; Koseki, S. Effect of thickness and maturity on protein content of Japonica brown rice collected during postharvest processing. Biosyst. Eng. 2019, 183, 160–169. [Google Scholar]

- Ni, D.; Chen, Z.; Tian, Y.; Xu, W.; Zhang, W.; Kim, B.-G.; Mu, W. Comprehensive utilization of sucrose resources via chemical and biotechnological processes: A review. Biotechnol. Adv. 2022, 60, 107990. [Google Scholar]

- Honma, Y.; Adhikari, P.B.; Kuwata, K.; Kagenishi, T.; Yokawa, K.; Notaguchi, M.; Kurotani, K.; Toda, E.; Bessho-Uehara, K.; Liu, X.; et al. High-quality sugar production by osgcs1 rice. Commun. Biol. 2020, 3, 617. [Google Scholar]

- Hu, J.; Zhang, S.; Yang, S.; Zhou, J.; Jiang, Z.; Qi, S.; Xu, Y. Effects of Irrigation and Fertilization Management on Yield and Quality of Rice and the Establishment of a Quality Evaluation System. Agronomy 2023, 13, 2034. [Google Scholar] [CrossRef]

- Wang, S.Y.; Li, G.H.; Lu, W.P.; Lu, D.L. Effects of Slow-Release Fertilizer Application Stage on Yield and Quality of Spring-Sown Fresh Waxy Maize. J. Nucl. Agric. Sci. 2021, 35, 2136–2144. [Google Scholar]

| Year | Organic Matter g kg−1 | Alkali-Hydrolyzable Nitrogen mg kg−1 | Available Phosphorus mg kg−1 | Available Potassium mg kg−1 |

|---|---|---|---|---|

| 2023 | 22.1 | 88.5 | 33.2 | 79.3 |

| 2024 | 19.8 | 74.5 | 24.7 | 65.2 |

| Treatment | Nitrogen Fertilizer Type | Nitrogen Application Rate (kg hm−2) | Application Timing and Method |

|---|---|---|---|

| N0 | No nitrogen fertilization | 0 | No nitrogen application |

| N1 | Conventional Urea (46% nitrogen) | 270 | 5:1:2:2 ratio at 1-day before transplanting, 7-day after transplanting, panicle initiation, and penultimate-leaf appearance stage |

| N2 | Controlled-Release Fertilizer (42% nitrogen, 80-day release) + Urea | 270 | 50% CRF applied at 1-day before transplanting, 50% urea applied during planting |

| N3 | Controlled-Release Fertilizer (30% nitrogen, 120-day release) + Urea | 270 | 50% CRF applied at seedling stage, 50% urea applied at 1-day before transplanting |

| Year/ | Treatment | Panicle (×104 hm−2) | Spikelets per Panicle | Seed-Setting Rate (%) | 1000-Grain Weight | Grain Yield |

|---|---|---|---|---|---|---|

| Variety | (g) | (t hm−2) | ||||

| 2023 | ||||||

| Nanjing | N0 | 254.0 ± 3.6 d | 131.0 ± 1.8 d | 79.3 ± 0.4 d | 23.1 ± 0.4 c | 4.7 ± 0.4 d |

| 5718 | N1 | 299.7 ± 4.2 b | 146.9 ± 0.9 b | 86.5 ± 0.4 a | 25.8 ± 0.5 a | 7.8 ± 0.1 b |

| N2 | 290.3 ± 2.0 c | 143.7 ± 1.2 c | 83.8 ± 0.6 c | 24.7 ± 0.4 b | 6.4 ± 0.4 c | |

| N3 | 318.6 ± 4.9 a | 153.1 ± 0.2 a | 85.2 ± 0.9 b | 25.2 ± 0.3 ab | 8.4 ± 0.2 a | |

| Yongyou | N0 | 220.5 ± 5.0 d | 234.7 ± 0.7 d | 73.6 ± 0.4 c | 20.7 ± 0.4 c | 6.1 ± 0.5 c |

| 4953 | N1 | 259.1 ± 1.3 b | 263.8 ± 0.1 b | 78.3 ± 0.9 a | 23.0 ± 0.3 a | 8.8 ± 0.6 b |

| N2 | 246.6 ± 2.7 c | 257.6 ± 0.4 c | 75.5 ± 0.7 b | 22.2 ± 0.3 b | 8.2 ± 0.3 b | |

| N3 | 274.4 ± 2.7 a | 273.0 ± 0.6 a | 77.4 ± 1.3 a | 22.5 ± 0.3 ab | 9.9 ± 0.5 a | |

| Mean | 270.4 | 200.5 | 79.9 | 23.4 | 7.5 | |

| 2024 | ||||||

| Nanjing | N0 | 259.2 ± 4.7 d | 133.3 ± 0.6 c | 80.7 ± 0.8 c | 23.0 ± 0.3 c | 5.1 ± 0.2 d |

| 5718 | N1 | 306.3 ± 2.2 b | 145.5 ± 0.5 b | 89.2 ± 0.8 a | 25.8 ± 0.4 a | 7.9 ± 0.3 b |

| N2 | 295.6 ± 2.1 c | 143.1 ± 0.6 b | 86.8 ± 0.9 b | 24.5 ± 0.6 b | 6.3 ± 0.2 c | |

| N3 | 320.5 ± 2.7 a | 153.7 ± 0.7 a | 88.6 ± 1.1 ab | 25.3 ± 0.2 ab | 8.7 ± 0.3 a | |

| Yongyou | N0 | 228.9 ± 2.4 d | 240.6 ± 0.5 d | 72.4 ± 1.2 c | 20.1 ± 0.3 d | 5.9 ± 0.6 d |

| 4953 | N1 | 255.5 ± 2.6 b | 265.0 ± 0.4 b | 78.5 ± 0.9 a | 23.0 ± 0.1 a | 8.6 ± 0.2 b |

| N2 | 250.4 ± 2.0 c | 261.1 ± 0.5 c | 76.9 ± 0.8 b | 21.8 ± 0.3 c | 8.0 ± 0.4 c | |

| N3 | 274.1 ± 2.9 a | 271.3 ± 0.2 a | 77.3 ± 1.0 b | 22.4 ± 0.2 b | 9.9 ± 0.5 a | |

| Mean | 273.8 | 201.7 | 81.3 | 23.2 | 7.6 | |

| F | Year | ** | ** | ** | - | - |

| Variety | ** | ** | ** | ** | ** | |

| Treatment | ** | ** | ** | ** | ** | |

| Year × Variety | - | ** | ** | - | * | |

| Year × Treatment | - | ** | * | - | - | |

| Variety × Treatment | ** | ** | ** | - | ** | |

| Year × Variety × Treatment | - | ** | - | - | - |

| Year/ | Treatment | Processing Quality | Appearance Quality | |||

|---|---|---|---|---|---|---|

| Variety | Brown Rice Rate | Milled Rice Rate | Head Rice Rate | Chalkiness Degree | Chalky Rice Percentage | |

| 2023 | ||||||

| Nanjing | N0 | 84.0 ± 0.1 a | 68.5 ± 0.2 a | 44.2 ± 0.7 a | 1.6 ± 0.08 d | 8.7 ± 0.2 d |

| 5718 | N1 | 84.2 ± 0.5 a | 62.6 ± 0.8 c | 38.7 ± 0.6 bc | 4.9 ± 0.09 a | 16.9 ± 0.1 a |

| N2 | 84.7 ± 0.1 a | 65.8 ± 0.8 b | 36.0 ± 2.5 c | 3.2 ± 0.08 b | 14.8 ± 0.1 b | |

| N3 | 84.6 ± 0.3 a | 66.4 ± 0.7 ab | 42.6 ± 0.6 ab | 2.9 ± 0.10 c | 11.1 ± 0.1 c | |

| Yongyou | N0 | 84.1 ± 0.7 a | 72.9 ± 1.1 a | 57.6 ± 0.6 a | 1.1 ± 0.05 b | 4.4 ± 0.1 d |

| 4953 | N1 | 84.1 ± 0.2 a | 69.2 ± 0.9 b | 49.9 ± 0.7 c | 2.1 ± 0.18 a | 11.1 ± 0.1 a |

| N2 | 84.2 ± 0.5 a | 71.7 ± 1.4 ab | 47.8 ± 0.3 d | 1.9 ± 0.23 a | 10.0 ± 0.2 b | |

| N3 | 84.8 ± 0.1 a | 72.3 ± 0.4 ab | 54.1 ± 0.3 b | 1.3 ± 0.05 b | 7.6 ± 0.1 c | |

| Mean | 84.5 | 68.5 | 46.4 | 2.4 | 10.6 | |

| 2024 | ||||||

| Nanjing | N0 | 83.9 ± 0.3 a | 68.9 ± 0.6 a | 47.9 ± 0.8 a | 3.4 ± 0.25 d | 7.6 ± 0.2 d |

| 5718 | N1 | 84.1 ± 0.2 a | 64.0 ± 0.9 b | 43.2 ± 1.0 c | 5.7 ± 0.11 a | 16.0 ± 0.1 a |

| N2 | 84.0 ± 0.1 a | 66.7 ± 1.0 a | 41.4 ± 1.8 c | 5.1 ± 0.11 b | 13.1 ± 0.1 b | |

| N3 | 83.9 ± 0.3 a | 68.0 ± 0.3 a | 44.8 ± 1.1 b | 4.3 ± 0.15 c | 10.6 ± 0.1 c | |

| Yongyou | N0 | 83.9 ± 0.9 a | 72.8 ± 1.0 a | 54.2 ± 0.7 a | 1.5 ± 0.11 d | 4.6 ± 0.2 d |

| 4953 | N1 | 83.9 ± 0.3 a | 67.9 ± 0.8 b | 48.9 ± 0.4 b | 2.8 ± 0.09 a | 13.0 ± 0.1 a |

| N2 | 84.0 ± 0.1 a | 71.3 ± 0.4 a | 47.2 ± 0.8 b | 2.5 ± 0.11 b | 11.3 ± 0.2 b | |

| N3 | 84.3 ± 0.6 a | 72.1 ± 0.1 a | 52.8 ± 0.1 a | 2.1 ± 0.08 c | 8.7 ± 0.1 c | |

| Mean | 83.9 | 69 | 47.6 | 3.4 | 10.6 | |

| F | Year | - | - | ** | ** | - |

| Variety | - | ** | ** | ** | ** | |

| Treatment | - | ** | ** | ** | ** | |

| Year × Variety | - | * | ** | ** | ** | |

| Year × Treatment | - | - | - | ** | ** | |

| Variety × Treatment | - | - | - | ** | ** | |

| Year × Variety × Treatment | - | - | - | ** | ** | |

| Year/ | Treatment | Taste Value | Appearance | Hardness | Stickiness | Balance Degree |

|---|---|---|---|---|---|---|

| Variety | ||||||

| 2023 | ||||||

| Nanjing | N0 | 64.9 ± 1.8 a | 6.3 ± 0.2 a | 6.9 ± 0.2 b | 6.3 ± 0.3 a | 5.8 ± 0.3 a |

| 5718 | N1 | 53.9 ± 1.0 b | 4.4 ± 0.3 d | 7.6 ± 0.3 a | 4.4 ± 0.3 c | 4.2 ± 0.4 b |

| N2 | 56.3 ± 0.5 b | 4.9 ± 0.5 c | 7.6 ± 0.1 a | 4.5 ± 0.3 c | 4.3 ± 0.3 b | |

| N3 | 64.3 ± 2.9 a | 5.7 ± 0.2 b | 7.1 ± 0.1 b | 5.6 ± 0.5 b | 5.7 ± 0.5 a | |

| Yongyou | N0 | 50.7 ± 0.8 a | 4.1 ± 0.3 a | 7.8 ± 0.1 c | 3.5 ± 0.3 a | 3.5 ± 0.1 a |

| 4953 | N1 | 34.1 ± 2.0 d | 2.6 ± 0.4 b | 9.1 ± 0.2 a | 1.2 ± 0.4 c | 0.8 ± 0.3 c |

| N2 | 39.5 ± 0.8 c | 3.7 ± 0.1 a | 8.7 ± 0.2 ab | 2.0 ± 0.2 b | 1.7 ± 0.2 b | |

| N3 | 44.7 ± 1.4 b | 4.0 ± 0.2 a | 8.4 ± 0.3 b | 2.3 ± 0.3 b | 2.2 ± 0.4 b | |

| Mean | 51.1 | 4.5 | 7.9 | 3.7 | 3.5 | |

| 2024 | ||||||

| Nanjing | N0 | 63.1 ± 1.6 a | 6.2 ± 0.1 a | 6.8 ± 0.1 c | 6.2 ± 0.2 a | 5.8 ± 0.3 a |

| 5718 | N1 | 51.1 ± 2.8 c | 4.2 ± 0.1 d | 7.6 ± 0.1 a | 4.2 ± 0.2 c | 4.3 ± 0.2 b |

| N2 | 54.9 ± 1.8 b | 4.7 ± 0.2 c | 7.6 ± 0.1 a | 4.2 ± 0.3 c | 4.4 ± 0.1 b | |

| N3 | 62.6 ± 1.9 a | 5.4 ± 0.2 b | 7.2 ± 0.1 b | 5.5 ± 0.4 b | 5.7 ± 0.5 a | |

| Yongyou | N0 | 48.5 ± 2.2 a | 4.3 ± 0.1 a | 7.8 ± 0.1 d | 3.3 ± 0.3 a | 3.5 ± 0.2 a |

| 4953 | N1 | 32.9 ± 1.6 d | 2.8 ± 0.2 c | 9.1 ± 0.1 a | 1.2 ± 0.2 c | 0.8 ± 0.2 d |

| N2 | 37.4 ± 2.1 c | 3.5 ± 0.2 b | 8.8 ± 0.1 b | 2.1 ± 0.1 b | 1.8 ± 0.1 c | |

| N3 | 42.3 ± 2.2 b | 3.8 ± 0.2 b | 8.5 ± 0.1 c | 2.3 ± 0.3 b | 2.2 ± 0.1 b | |

| Mean | 49.1 | 4.4 | 7.9 | 3.6 | 3.6 | |

| F | Year | ** | - | - | - | - |

| Variety | ** | ** | ** | ** | ** | |

| Treatment | ** | ** | ** | ** | ** | |

| Year × Variety | - | - | - | - | - | |

| Year × Treatment | - | - | - | - | - | |

| Variety × Treatment | ** | ** | ** | ** | ** | |

| Year × Variety × Treatment | - | - | - | - | - |

| Year/ | Treatment | Starch Content | Amylose Content | Branched-Chain Starch Content |

|---|---|---|---|---|

| Variety | ||||

| 2023 | ||||

| Nanjing | N0 | 80.2 ± 0.6 a | 11.9 ± 0.2 b | 68.4 ± 0.5 a |

| 5718 | N1 | 80.5 ± 1.0 a | 12.8 ± 0.1 a | 67.7 ± 0.8 a |

| N2 | 80.2 ± 0.2 a | 12.4 ± 0.2 ab | 67.8 ± 0.2 a | |

| N3 | 80.6 ± 0.6 a | 12.2 ± 0.2 b | 68.4 ± 0.5 a | |

| Yongyou | N0 | 82.1 ± 0.1 a | 14.2 ± 0.1 c | 67.9 ± 0.2 a |

| 4953 | N1 | 82.2 ± 0.1 a | 15.0 ± 0.1 a | 67.2 ± 0.1 b |

| N2 | 81.9 ± 0.5 a | 14.8 ± 0.1 ab | 67.1 ± 0.4 b | |

| N3 | 82.3 ± 0.1 a | 14.6 ± 0.1 b | 67.7 ± 0.1 a | |

| Mean | 81.2 | 13.5 | 67.8 | |

| 2024 | ||||

| Nanjing | N0 | 80.0 ± 0.3 a | 12.0 ± 0.1 c | 68.1 ± 0.2 a |

| 5718 | N1 | 80.9 ± 0.5 a | 12.8 ± 0.1 a | 68.1 ± 0.4 a |

| N2 | 80.1 ± 0.1 a | 12.3 ± 0.1 b | 67.8 ± 0.1 a | |

| N3 | 80.3 ± 0.3 a | 12.1 ± 0.1 bc | 68.3 ± 0.3 a | |

| Yongyou | N0 | 82.2 ± 0.1 a | 14.2 ± 0.1 c | 68.0 ± 0.1 a |

| 4953 | N1 | 82.2 ± 0.1 a | 15.1 ± 0.1 a | 67.2 ± 0.1 b |

| N2 | 82.4 ± 0.1 a | 14.9 ± 0.1 ab | 67.5 ± 0.1 b | |

| N3 | 82.6 ± 0.5 a | 14.7 ± 0.1 b | 67.8 ± 0.4 a | |

| Mean | 81.3 | 13.5 | 67.8 | |

| F | Year | - | - | - |

| Variety | ** | ** | ** | |

| Treatment | - | ** | ** | |

| Year × Variety | - | - | - | |

| Year × Treatment | - | - | - | |

| Variety × Treatment | - | - | - | |

| Year × Variety × Treatment | - | - | - |

| Year/ | Treatment | Peak Viscosity | Through Viscosity | Breakdown | Final Viscosity | Setback | Pasting Temperature | Peak Time |

|---|---|---|---|---|---|---|---|---|

| Variety | (cP) | (cP) | (cP) | (cP) | (cP) | (°C) | (min) | |

| 2023 | ||||||||

| Nanjing 5718 | N0 | 3374 ± 7 a | 1325 ± 59 c | 2049 ± 66 a | 2630 ± 81 a | −744 ± 88 c | 74.2 ± 0.3 b | 5.4 ± 0.05 b |

| N1 | 2267 ± 4 d | 2115 ± 136 a | 152 ± 140 d | 1871 ± 57 b | −396 ± 61 a | 76.4 ± 0.6 a | 6.0 ± 0.14 a | |

| N2 | 2572 ± 64 c | 1555 ± 11 b | 1017 ± 75 c | 2011 ± 63 b | −562 ± 11 b | 75.2 ± 0.1 ab | 5.8 ± 0.05 a | |

| N3 | 2737 ± 12 b | 1469 ± 2 bc | 1268 ± 14 b | 2036 ± 51 b | −701 ± 13 c | 74.8 ± 0.5 b | 5.7 ± 0.09 ab | |

| Yongyou 4953 | N0 | 2797 ± 147 a | 1447 ± 48 c | 1350 ± 99 a | 2995 ± 62 a | 198 ± 85 a | 75.5 ± 0.6 c | 6.2 ± 0.01 a |

| N1 | 2180 ± 19 b | 2062 ± 204 a | 118 ± 185 c | 2406 ± 74 d | 327 ± 54 a | 91.4 ± 0.5 a | 6.5 ± 0.09 a | |

| N2 | 2199 ± 92 b | 1736 ± 40 b | 463 ± 52 b | 2484 ± 76 c | 285 ± 16 a | 87.0 ± 0.1 b | 6.5 ± 0.24 a | |

| N3 | 2612 ± 23 a | 1591 ± 187 bc | 1021 ± 209 a | 2854 ± 25 b | 242 ± 47 a | 76.3 ± 0.5 c | 6.3 ± 0.01 a | |

| Mean | 2592 | 1663 | 930 | 2411 | −182 | 78.9 | 6.1 | |

| 2024 | ||||||||

| Nanjing 5718 | N0 | 3270 ± 79 a | 1289 ± 50 c | 1982 ± 129 a | 2163 ± 180 a | −1107 ± 91 c | 74.5 ± 0.1 b | 5.4 ± 0.19 c |

| N1 | 2294 ± 37 d | 1531 ± 35 a | 763 ± 72 d | 1866 ± 32 a | −428 ± 6 a | 76.9 ± 0.9 a | 5.9 ± 0.16 a | |

| N2 | 2561 ± 16 c | 1473 ± 6 ab | 1088 ± 22 c | 1982 ± 157 a | −579 ± 141 ab | 75.2 ± 0.1 b | 5.7 ± 0.12 ab | |

| N3 | 2750 ± 18 b | 1339 ± 57 bc | 1412 ± 39 b | 2098 ± 123 a | −652 ± 81 b | 74.6 ± 0.2 b | 5.6 ± 0.05 b | |

| Yongyou 4953 | N0 | 2813 ± 41 a | 1438 ± 37 c | 1375 ± 4 a | 2686 ± 97 a | −128 ± 56 b | 75.7 ± 0.2 b | 6.1 ± 0.06 c |

| N1 | 2138 ± 60 d | 1771 ± 34 a | 367 ± 94 c | 2383 ± 43 b | 245 ± 43 a | 85.6 ± 3.8 a | 6.4 ± 0.06 a | |

| N2 | 2467 ± 45 c | 1647 ± 8 b | 821 ± 53 b | 2410 ± 25 b | −58 ± 31 b | 84.9 ± 1.6 ab | 6.4 ± 0.08 a | |

| N3 | 2616 ± 5 b | 1612 ± 34 b | 1004 ± 39 b | 2531 ± 66 ab | −85 ± 20 b | 77.9 ± 3.5 ab | 6.2 ± 0.13 b | |

| Mean | 2614 | 1513 | 1101 | 2265 | −349 | 78.2 | 5.9 | |

| F | Year | - | ** | ** | ** | ** | - | ** |

| Variety | ** | ** | ** | ** | ** | ** | ** | |

| Treatment | ** | ** | ** | ** | ** | ** | ** | |

| Year × Variety | * | - | - | - | ** | * | - | |

| Year × Treatment | * | ** | ** | ** | * | * | - | |

| Variety × Treatment | ** | - | ** | - | * | ** | - | |

| Year × Variety × Treatment | - | - | * | * | * | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Geng, X.; Liu, Y.; Wang, L.; Zhu, J.; Ma, W.; Sheng, X.; Shi, L.; Chen, Y.; Gao, P.; et al. Optimizing Nutrition Protocols for Improved Rice Yield, Quality, and Nitrogen Use Efficiency in Coastal Saline Soils. Agronomy 2025, 15, 1662. https://doi.org/10.3390/agronomy15071662

Zhang X, Geng X, Liu Y, Wang L, Zhu J, Ma W, Sheng X, Shi L, Chen Y, Gao P, et al. Optimizing Nutrition Protocols for Improved Rice Yield, Quality, and Nitrogen Use Efficiency in Coastal Saline Soils. Agronomy. 2025; 15(7):1662. https://doi.org/10.3390/agronomy15071662

Chicago/Turabian StyleZhang, Xiang, Xiaoyu Geng, Yang Liu, Lulu Wang, Jizou Zhu, Weiyi Ma, Xiaozhou Sheng, Lei Shi, Yinglong Chen, Pinglei Gao, and et al. 2025. "Optimizing Nutrition Protocols for Improved Rice Yield, Quality, and Nitrogen Use Efficiency in Coastal Saline Soils" Agronomy 15, no. 7: 1662. https://doi.org/10.3390/agronomy15071662

APA StyleZhang, X., Geng, X., Liu, Y., Wang, L., Zhu, J., Ma, W., Sheng, X., Shi, L., Chen, Y., Gao, P., Wei, H., & Dai, Q. (2025). Optimizing Nutrition Protocols for Improved Rice Yield, Quality, and Nitrogen Use Efficiency in Coastal Saline Soils. Agronomy, 15(7), 1662. https://doi.org/10.3390/agronomy15071662