Octahedral Paclobutrazol–Zinc Complex for Enhanced Chemical Topping Efficacy in Mechanized Cotton Production: A Two-Year Field Evaluation in Xinjiang

Abstract

1. Introduction

2. Materials and Methods

2.1. Synthesis of Paclobutrazol–Zinc Complexes

2.2. Characterization of Paclobutrazol–Zinc Complexes

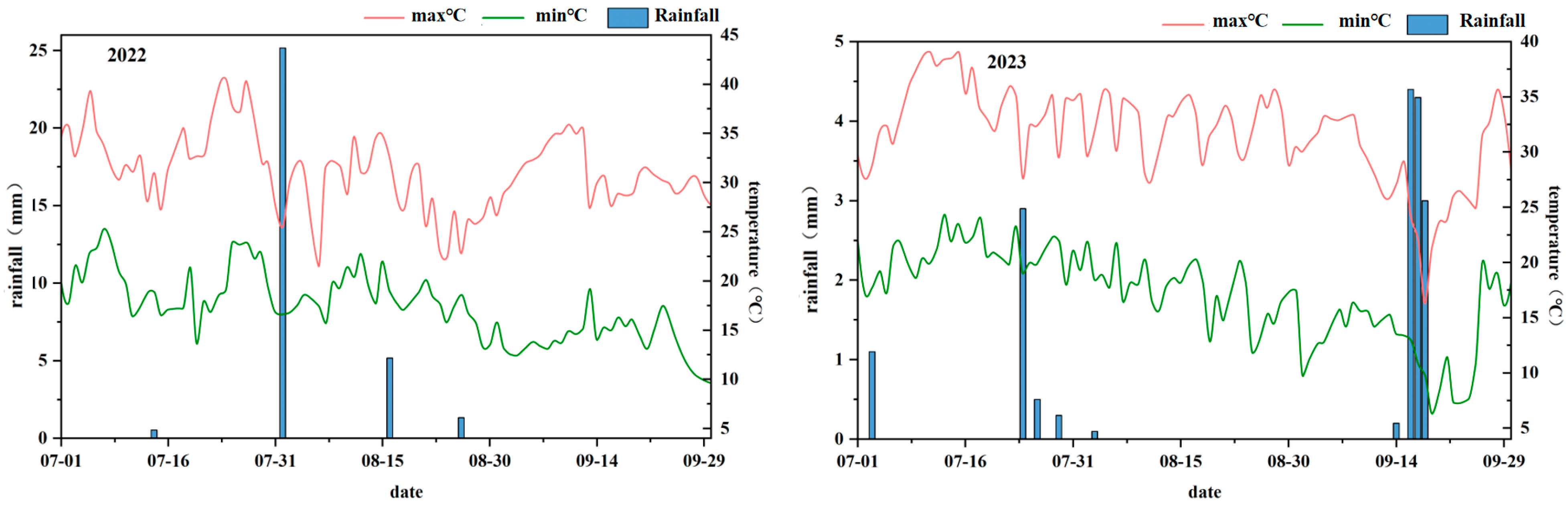

2.3. General Situation of the Test Site

2.4. Experimental Design

2.5. Measurement Items and Methods

2.5.1. Determination of Agronomic Traits

2.5.2. Determination of Cotton Yield and Cotton Fiber Quality

2.6. Data Analysis

3. Results

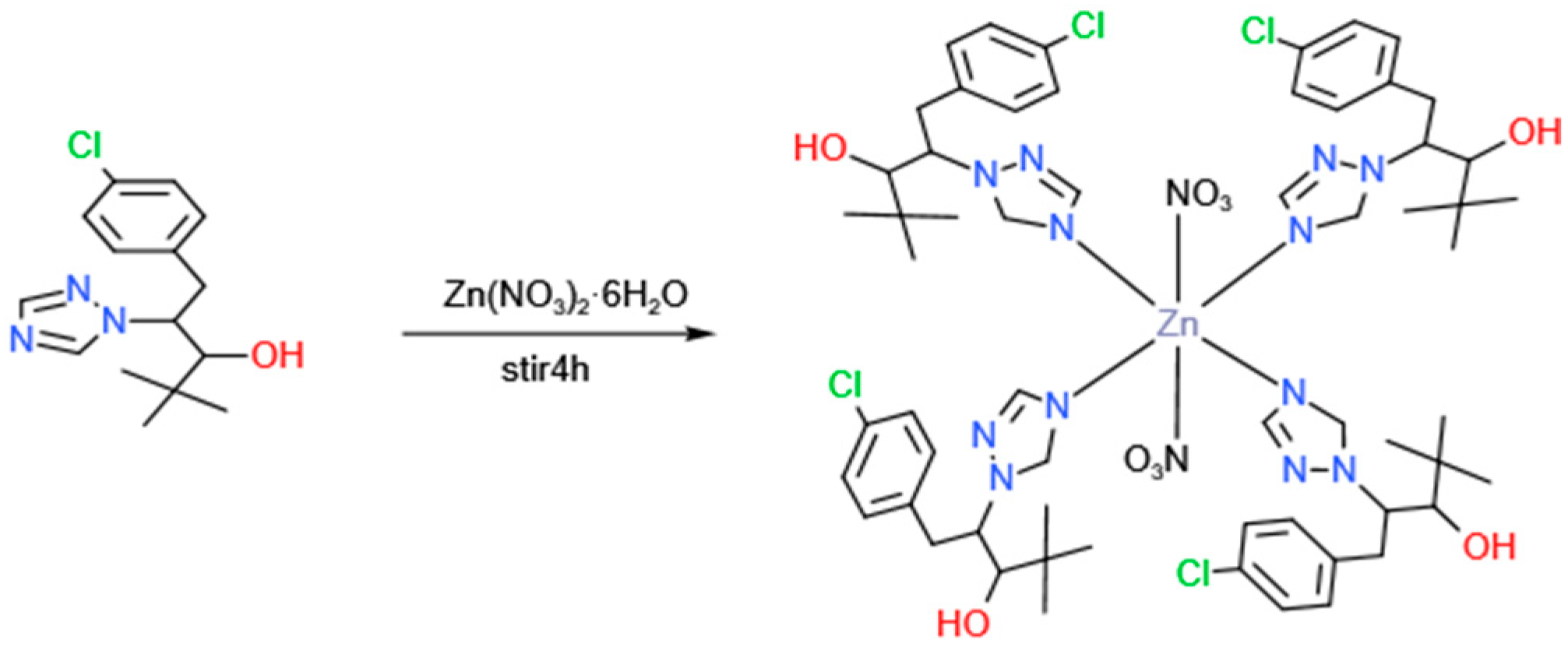

3.1. Preparation of the Paclobutrazol–Zinc Complex

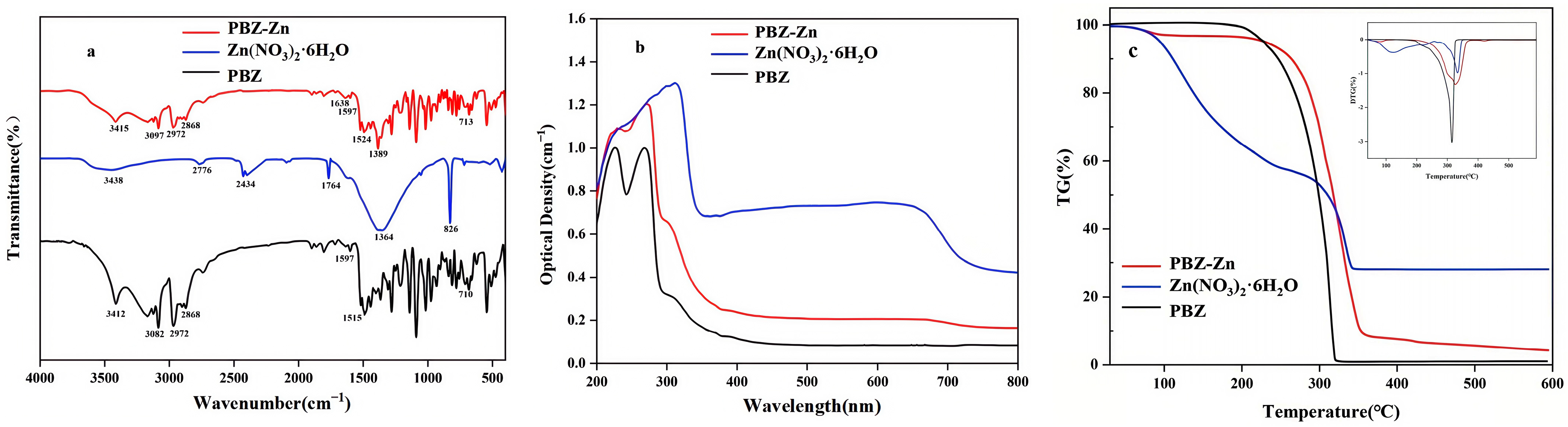

3.2. Characterization of Paclobutrazol–Zinc Complexes

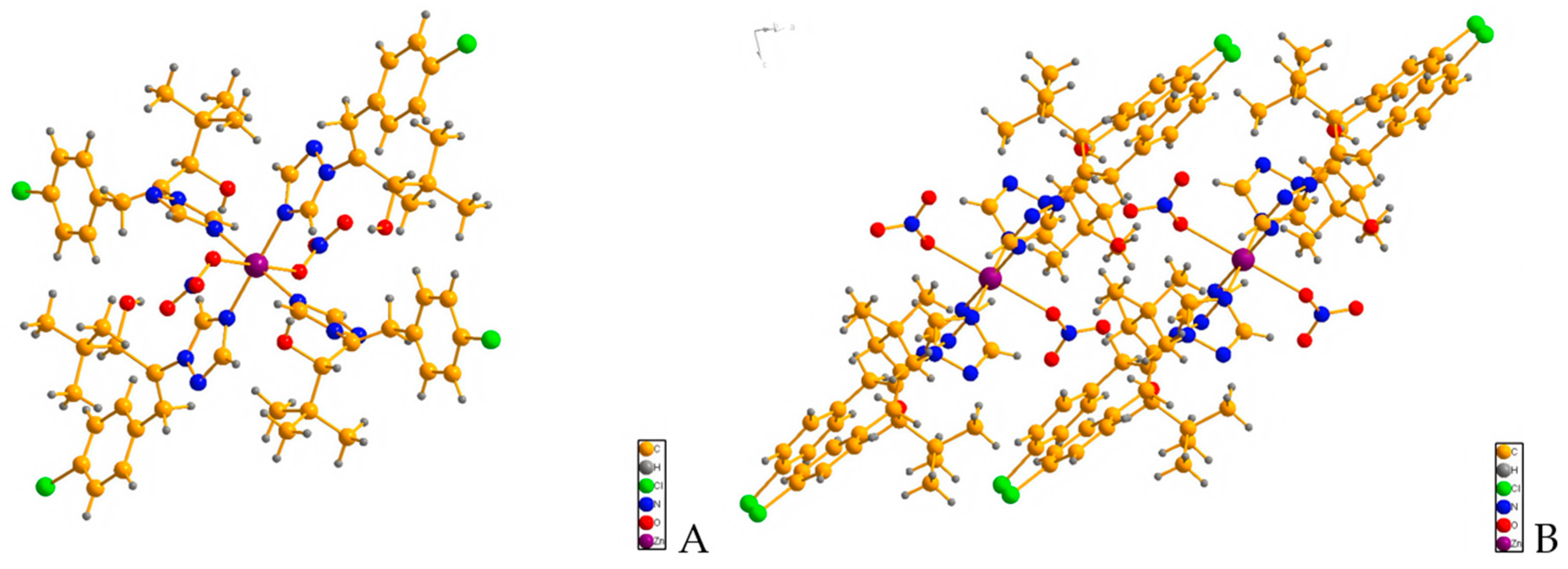

3.3. Single-Crystal Structure Analysis of the Paclobutrazol–Zinc Complex

3.4. Analysis of the Surface Tension of the Paclobutrazol–Zinc Complexe

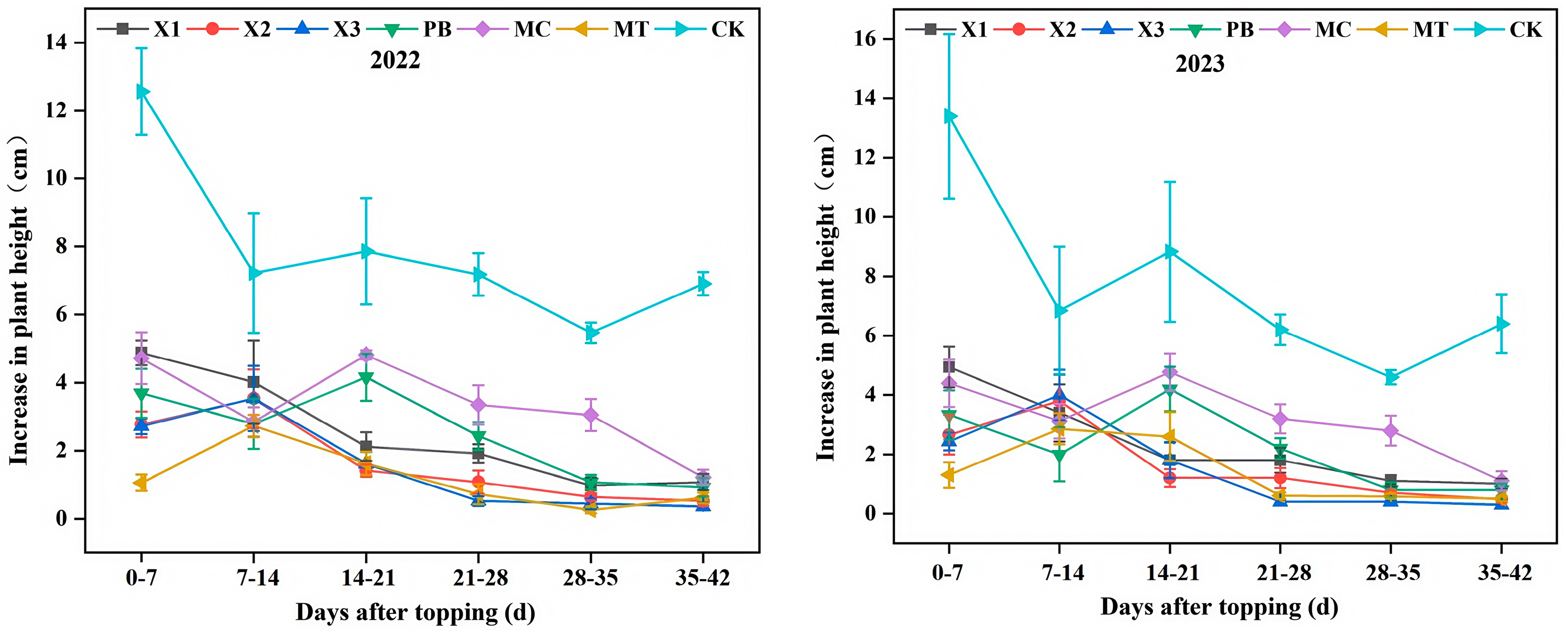

3.5. Effects of the Paclobutrazol–Zinc Complex on Cotton Plant Height

3.6. Effects of Paclobutrazol–Zinc Complexes on Cotton Fruit Branch Length

3.7. Effects of the Paclobutrazol–Zinc Complex on Main Agronomic Traits of Cotton

3.8. Effects of the Paclobutrazol–Zinc Complex on Cotton Yield

3.9. Effects of the Paclobutrazol–Zinc Complex on Cotton Fiber Quality

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| X1 | complex 75 g·hm−2 |

| X2 | complex 120 g·hm−2 |

| X3 | complex 165 g·hm−2 |

| PB | paclobutrazol 120 g·hm−2 |

| MC | mepiquat chloride 180 g·hm−2 |

| MT | artificial topping |

| CK | clear water |

References

- Bednarz, C.W.; Shurley, W.D.; Anthony, W.S.; Nichols, R.L. Yield, quality, and profitability of cotton produced at varying plant densities. Agron. J. 2005, 97, 235–240. [Google Scholar] [CrossRef]

- Mao, L.; Zhang, L.; Evers, J.B.; Werf, W.; Liu, S.D.; Zhang, S.P.; Wang, B.M.; Li, Z.H. Yield components and quality of intercropped cotton in response to mepiquat chloride and plant density. Field Crops Res. 2015, 179, 63–71. [Google Scholar] [CrossRef]

- Dai, J.L.; Luo, Z.; Li, W.J.; Tang, W.; Zhang, D.M.; Lu, H.Q.; Li, Z.H.; Xin, C.S.; Kong, H.Q.; Eneji, A.; et al. A simplified pruning method for profitable cotton production in the Yellow River valley of China. Field Crops Res. 2014, 164, 22–29. [Google Scholar] [CrossRef]

- Yang, Y.M.; Ouyang, Z.; Yang, Y.H.; Liu, X.J. Simulation of the effect of pruning and topping on cotton growth using COTTON2k model. Field Crops Res. 2008, 106, 126–137. [Google Scholar] [CrossRef]

- Lu, X.R.; Jia, X.Y.; Niu, J.H. Development status and prospect of cotton industry in China. Sci. Agric. Sin. 2018, 51, 26–36. [Google Scholar]

- Si, Z.; Liu, H.; Zhu, J.; Chen, J.D.; Wang, Q.; Fang, L.; Gao, F.K.; Tian, Y.; Chen, Y.L.; Chang, L.J.; et al. Mutation of SELF-PRUNING homologs in cotton promotes short-branching plant architecture. J. Exp. Bot. 2018, 69, 2543–2553. [Google Scholar] [CrossRef]

- Rademacher, W. Plant growth regulators: Backgrounds and uses in plant production. Plant Growth Regul. 2015, 34, 845–872. [Google Scholar] [CrossRef]

- Bons, H.K.; Kaur, M. Role of plant growth regulators in improving fruit set, quality an yield of fruit crops:A review. Hortic. Sci. Biotechnol. 2019, 95, 137–146. [Google Scholar] [CrossRef]

- Liang, F.B.; Yang, C.X.; Sui, L.L.; Xu, S.Z.; Yao, H.S.; Zhang, W.F. Flumetralin and dimethyl piperidinium chloride alter light distribution in cotton canopies by optimizing the spatial configuration of leaves and bolls. Integr. Agric. 2020, 19, 1777–1788. [Google Scholar] [CrossRef]

- Wang, D.; Ma, Y.J.; Song, X.P.; Shan, Y.P.; Ma, X.Y.; Ren, X.L.; Hu, H.Y.; Ma, Y. Chemical topping effect of pentazolol, dimethylene and flutenamide on cotton. China Cotton 2021, 48, 23–28. [Google Scholar]

- You, Y.; Wang, T. Research Progress on the Function and Application of Paclobutrazol (Review). Subtrop. Plant Sci. 2013, 42, 361–366. [Google Scholar]

- Park, H.S.; Sun, R.; Lee, E.J.; Kim, J.; Hur, N.H. Triazole-bridged zinc dinuclear complexes: Mechanochemical synthesis, crystal structure, and biological activity. ACS Omega 2022, 7, 40860–40868. [Google Scholar] [CrossRef]

- Khedr, A.M.; Gaber, M.; Abd El-Zaher, E.H. Synthesis, structural characterization, and antimicrobial activities of Mn (II), Co (II), Ni (II), Cu (II) and Zn (II) complexes of triazole-based azodyes. Chin. J. Chem. 2011, 29, 1124–1132. [Google Scholar] [CrossRef]

- Chohan, Z.H.; Hanif, M. Design, synthesis, and biological properties of triazole derived compounds and their transition metal complexes. J. Enzym. Inhib. Med. Chem. 2010, 25, 737–749. [Google Scholar] [CrossRef] [PubMed]

- Raj, D.; Padhi, S.K. The sporadic μ-pyridine bridge in transition metal complexes: A real bond or an interaction? Coord. Chem. Rev. 2022, 450, 214238. [Google Scholar] [CrossRef]

- Datta, S.; Saha, M.L.; Stang, P.J. Hierarchical assemblies of supramolecular coordination complexes. Acc. Chem. Res. 2018, 51, 2047. [Google Scholar] [CrossRef]

- Zhai, Q.G.; Wu, X.Y.; Chen, S.M. Construction of Cd/Zn(II)-I, 2, 4-triazolate coordination complexes via changing substituents and anions. Cryst. Growth Des. 2006, 6, 2126. [Google Scholar] [CrossRef]

- Hui, S.; Liu, Q.; Huang, Z.; Yang, J.; Liu, Y.M.; Jiang, S. Gold nanoclusters-decorated zeolitic imidazolate frameworks with reactive oxygen species generation for photoenhanced antibacterial study. Bioconjug. Chem. 2020, 31, 2439–2445. [Google Scholar] [CrossRef]

- Kim, K.C. Design strategies for metal-organic frameworks selectively capturing harmful gases. J. Organomet. Chem. 2018, 854, 94–105. [Google Scholar] [CrossRef]

- Ren, G.Y. Crystal Structure, Biological Activity and Structure-Activity Relationship of Paclobutrazol and Uniconazole Transition Metal Complexes; Northwest University: Xi’an, China, 2018. [Google Scholar]

- Banerjee, P.; Pandey, O.P.; Sengupta, S.K. Microwave assisted synthesis, spectroscopi and antibacterial studies of titanocene chelates of Schiff bases derived from 3-substituted-4-amino-5-hydrazino-1, 2, 4-triazoles. Transit. Met. Chem. 2008, 33, 1047–1052. [Google Scholar] [CrossRef]

- Ren, G.Y.; Li, J.; Wei, X.Z.; Zhou, J.H.; Yan, B.; Guo, Z.Q.; Ren, Y.H.; Sun, X.H.; Ma, H.X. The enhanced biological activities of three Zn (II) complexes based on different 1, 2, 4-triazole fungicides. Appl. Organomet. Chem. 2018, 32, 4474. [Google Scholar] [CrossRef]

- Bi, Y.B. Study on the Antibacterial Activity and Plant Growth Regulatory Efficiency of Copper Complexes of Hexazolol; Northwest University: Xi’an, China, 2012. [Google Scholar]

- Yuan, D.; Li, X.; Yao, H.; Li, Y.; Zhu, X.; Zhao, J.; Zhang, H.; Zhang, Y.; Jie, E.; Srinivasan, M.; et al. A Liquid Crystal Ionomer-Type Electrolyte toward Ordering-Induced Regulation for Highly Reversible Zinc Ion Battery. Adv. Sci. 2023, 10, 2206469. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Wang, X.; Wang, X.R. Chemical topping technology of mepiquat chloride for cotton in the northern cotton-growing area of the Yellow River Basin. Sci. Agric. Sin. 2016, 49, 2497–2510. [Google Scholar]

- Wu, Y.Q.; Tang, J.Y.; Tian, J.S.; Du, M.W.; Gou, L.; Zhang, Y.; Zhang, W.F. Different concentrations of chemical topping agents affect cotton yield and quality by regulating plant architecture. Agronomy 2023, 13, 1741. [Google Scholar] [CrossRef]

- Lou, S.; Du, M.W.; Gao, F.; Tian, X.L.; Zhang, P.Z.; Li, J.; Duan, L.S. The Effect of New Nano-Released 1, 1-Dimethyl-Piperidinium Chloride (DPC) Drip Application on Cotton Agronomic Traits. Agronomy 2023, 13, 1543. [Google Scholar] [CrossRef]

- Kaggwa-Asiimwe, R.; Andrade-Sanchez, P.; Wang, G.Y. Plant architecture influences growth and yield response of upland cotton to population density. Field Crops Res. 2013, 145, 52–59. [Google Scholar] [CrossRef]

- Chen, M.Z.; Yang, Y.L.; Wang, Y.X.; Tian, J.S.; Xu, S.Z.; Liu, N.N.; Zhang, W.F. Evolution of plant architecture and main economic traits during the replacement process of early-maturing upland cotton varieties in Xinjiang. Sci. Agric. Sin. 2019, 52, 3279–3290. [Google Scholar]

- Wang, F.Y.; Han, H.Y.; Lin, H.; Chen, B.; Kong, X.H.; Ning, X.Z.; Wang, X.W.; Yu, Y.; Liu, J.D. Effects of planting patterns on yield, quality, and defoliation in machine-harvested cotton. J. Integr. Agric. 2019, 18, 2019–2028. [Google Scholar] [CrossRef]

- Sultana, F.; Dev, W.; Zhang, Z.G.; Wang, Y.R.; Chen, J.L.; Wang, J.; Li, Y.B. The consequences of plant architecture and spatial distribution of light interception on cotton growth and yield. Int. J. Agric. Biosci. 2023, 12, 153–158. [Google Scholar]

- Zhao, Q.; Zhou, C.J.; Zhang, J.S.; Li, S.L.; Hui, Y.L.; Tian, X.L. Effects of Chemical Defoliation on Agronomic and Economic Traits of Cotton in Southern Xinjiang. J. Cotton Sci. 2011, 23, 329–333. [Google Scholar]

- Fagerström, A.; Kocherbitov, V.; Ruzgas, T.; Westbye, P.; Bergström, K.; Engblom, J. Effects of surfactants and thermodynamic activity of model active ingredient on transport over plant leaf cuticle. Colloids Surf. B Biointerfaces 2013, 103, 572–579. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Sun, X.; Yin, M.; Shen, J.; Yan, S. Recent advances in nanoparticle-mediated co-delivery system: A promising strategy in medical and Agricultural Field. Int. J. Mol. Sci. 2023, 24, 5121. [Google Scholar] [CrossRef]

- Wang, D.; Jiang, W.L.; Ma, Y.J. Effects of mepiquat chloride and paclobutrazol on growth regulation of cotton under different application methods. China Cotton 2018, 45, 37–40+46. [Google Scholar]

- Wang, X.; Hu, Y.; Ji, C.; Chen, Y.F.; Sun, S.; Zhang, Z.S.; Zhang, Y.T.; Wang, S.; Yang, M.F.; Ji, F. Yields, growth and water use under chemical topping in relations to row configuration and plant density in drip-irrigated cotton. J. Cotton Res. 2024, 7, 13. [Google Scholar] [CrossRef]

- Qi, H.; Du, M.W.; Lu, M.; Xie, L.W.; Eneji, A.E.; Xu, D.Y.; Tian, X.L.; Li, Z.H. Cotton maturity and responses to harvest aids following chemical topping with mepiquat chloride during bloom period. J. Integr. Agric. 2022, 21, 2577–2587. [Google Scholar] [CrossRef]

- Feng, G.; Luo, H.; Zhang, Y.; Gou, L.; Yao, Y.; Lin, Y.; Zhang, W. Relationship between plant canopy characteristics and photosynthetic productivity in diverse cultivars of cotton (Gossypium hirsutum L.). Crop J. 2016, 4, 499–508. [Google Scholar] [CrossRef]

- Zhi, X.; Han, Y.; Li, Y.; Wang, G.P.; Du, W.L.; Li, X.X.; Mao, S.C.; Feng, L. Effects of plant density on cotton yield components and quality. J. Integr. Agric. 2016, 15, 1469–1479. [Google Scholar] [CrossRef]

- Tuerxun, J.; Li, X.Y.; Tian, C.Y.; Guo, J.P.; Khan, S.; Wang, J.D.; Ai, X.T. Super high yield performance of lint cotton cultivars in upstream Tarim river, Xinjiang, China. Res. Crops 2014, 15, 487–497. [Google Scholar] [CrossRef]

- Dai, J.; Li, W.; Zhang, D.; Tang, W.; Li, Z.H.; Lu, H.Q.; Kong, X.Q.; Luo, Z.; Xu, S.Z.; Xin, C.S.; et al. Competitive yield and economic benefits of cotton achieved through a combination of extensive pruning and a reduced nitrogen rate at high plant density. Field Crops Res. 2017, 209, 65–72. [Google Scholar] [CrossRef]

- Feng, G.Y.; Yao, Y.D.; Luo, H.H.; Zhang, Y.L.; Du, M.W.; Zhang, W.F.; Xia, D.L.; Dong, H.Y. Characteristics of light distribution in ultra-high yield cotton canopy and its relationship with population photosynthetic production in Xinjiang. Chin. J. Appl. Ecol. 2012, 23, 1286–1294. [Google Scholar]

- Zhu, L.X.; Liu, L.T.; Sun, H.; Zhang, Y.J.; Zhang, K.; Bai, Z.Y.; Li, A.C.; Dong, H.Z.; Li, C.D. Effects of chemical topping on cotton development, yield and quality in the Yellow River Valley of China. J. Integr. Agric. 2022, 21, 78–90. [Google Scholar] [CrossRef]

- Arekhi, E.; Ghasemi Bezdi, K.; Ajam Norozei, H.; Faghani, E. The effect of growth regulators on biochemical properties, yield, and fiber quality of different cultivars of cotton (Gossypium hirsutum) under different irrigation intervals. J. Plant Growth Regul. 2023, 42, 5574–5586. [Google Scholar] [CrossRef]

| Empirical formula | C60H80Cl4N14O10Zn |

| Formula weight | 1364.55 |

| Temperature/K | 293(2) |

| Crystal system | triclinic |

| Space group | P-1 |

| a/Å | 8.7372(2) |

| b/Å | 13.4110(4) |

| c/Å | 15.4425(4) |

| α/° | 87.873(2) |

| β/° | 80.689(2) |

| γ/° | 71.387(2) |

| Volume/Å3 | 1692.03(8) |

| Z | 1 |

| ρcalcg/cm3 | 1.339 |

| μ/mm−1 | 2.492 |

| F(000) | 716.0 |

| Crystal size/mm3 | 0.2 × 0.12 × 0.1 |

| Radiation | Cu Kα (λ = 1.54184) |

| Index ranges | −7 ≤ h ≤ 10, −15 ≤ k ≤ 15, −18 ≤ l ≤ 18 |

| Reflections collected | 19267 |

| Data/restraints/parameters | 5929/65/411 |

| Goodness-of-fit on F2 | 1.083 |

| Final R indexes [I >= 2σ (I)] | R1 = 0.0638, wR2 = 0.1820 |

| Final R indexes [all data] | R1 = 0.0775, wR2 = 0.1954 |

| Largest diff. peak/hole/e Å−3 | 0.62/−0.55 |

| Treatment | Surface Tension (mN/m) |

|---|---|

| Paclobutrazol | 70.08 ± 0.02 |

| Paclobutrazol–zinc complex | 57.33 ± 0.01 |

| Year | Treatment | Dose (g·hm−2) | Length of the Inverted First Fruit Branch (cm) | Length of the Inverted Second Fruit Branch (cm) | Length of the Inverted Third Fruit Branch (cm) | Length of the Inverted Fourth Fruit Branch (cm) |

|---|---|---|---|---|---|---|

| 2022 | Paclobutrazol–zinc complex | 75 | 4.87 ± 0.96 b | 7.31 ± 0.73 b | 9.34 ± 0.65 b | 11.69 ± 0.59 a |

| 120 | 3.17 ± 0.99 bc | 4.56 ± 0.48 e | 7.32 ± 0.69 d | 9.64 ± 0.53 b | ||

| 165 | 3.04 ± 0.79 c | 4.79 ± 0.67 de | 8.68 ± 0.37 bc | 10.09 ± 0.93 b | ||

| Paclobutrazol | 120 | 4.03 ± 1.03 bc | 6.54 ± 0.75 bc | 8.29 ± 0.55 c | 10.09 ± 0.69 b | |

| Mepiquat chloride | 180 | 4.01 ± 1.12 bc | 5.60 ± 0.79 cd | 9.01 ± 0.72 bc | 11.46 ± 0.82 a | |

| Artificial topping | / | 8.79 ± 1.86 a | 9.90 ± 1.07 a | 12.40 ± 0.84 a | 12.50 ± 0.74 a | |

| Water | / | 4.12 ± 0.64 bc | 5.29 ± 0.30 de | 8.91 ± 0.38 bc | 11.69 ± 0.97 a | |

| 2023 | Paclobutrazol–zinc complex | 75 | 4.94 ± 1.07 b | 6.90 ± 0.62 b | 8.68 ± 0.66 b | 11.12 ± 0.75 ab |

| 120 | 3.08 ± 0.79 c | 4.34 ± 0.51 e | 7.17 ± 0.65 c | 9.30 ± 1.05 c | ||

| 165 | 3.22 ± 0.94 bc | 4.72 ± 0.65 de | 8.26 ± 0.75 bc | 9.90 ± 0.85 bc | ||

| Paclobutrazol | 120 | 4.10 ± 0.96 bc | 6.30 ± 0.73 bc | 8.14 ± 0.69 bc | 9.83 ± 0.58 c | |

| Mepiquat chloride | 180 | 4.08 ± 1.01 bc | 5.50 ± 0.56 cd | 8.84 ± 0.65 b | 11.40 ± 0.62 ab | |

| Artificial topping | / | 8.91 ± 1.78 a | 9.43 ± 1.19 a | 11.86 ± 1.10 a | 12.34 ± 0.95 a | |

| Water | / | 4.18 ± 0.66 bc | 5.20 ± 0.42 cde | 8.92 ± 0.79 b | 11.26 ± 0.35 a |

| Year | Treatment | Dose (g·hm−2) | The Height of the First Fruit (cm) | Length Between Main Stem Nodes (cm) | Number of Fruit Branches (number) | Stem Diameter (mm) |

|---|---|---|---|---|---|---|

| 2022 | Paclobutrazol–zinc complex | 75 | 23.83 ± 1.29 b | 7.09 ± 1.07 a | 10.20 ± 0.84 b | 11.62 ± 1.69 b |

| 120 | 21.20 ± 1.22 c | 5.98 ± 0.64 b | 11.60 ± 0.55 a | 12.68 ± 1.16 ab | ||

| 165 | 23.74 ± 1.55 b | 5.98 ± 0.65 b | 11.00 ± 0.89 ab | 12.89 ± 1.54 ab | ||

| Paclobutrazol | 120 | 26.65 ± 1.42 a | 6.36 ± 0.57 ab | 11.20 ± 0.45 ab | 12.72 ± 1.19 ab | |

| Mepiquat chloride | 180 | 26.17 ± 1.61 a | 6.22 ± 0.91 ab | 11.20 ± 0.45 ab | 12.00 ± 1.00 b | |

| Artificial topping | / | 27.26 ± 1.42 a | 6.71 ± 0.61 ab | 10.14 ± 0.76 b | 14.21 ± 1.12 a | |

| Water | / | 27.95 ± 1.19 a | 7.20 ± 0.66 a | 11.20 ± 0.84 ab | 11.60 ± 1.35 b | |

| 2023 | Paclobutrazol–zinc complex | 75 | 24.10 ± 1.34 c | 6.80 ± 0.71 a | 10.40 ± 0.14 ab | 11.58 ± 0.55 b |

| 120 | 21.66 ± 1.48 d | 5.73 ± 0.58 b | 11.40 ± 0.55 a | 12.69 ± 1.00 ab | ||

| 165 | 24.08 ± 1.07 c | 5.79 ± 0.59 b | 11.12 ± 1.47 a | 13.09 ± 1.12 ab | ||

| Paclobutrazol | 120 | 27.20 ± 1.04 ab | 6.41 ± 0.37 ab | 11.40 ± 1.14 a | 12.93 ± 1.75 ab | |

| Mepiquat chloride | 180 | 26.50 ± 1.41 b | 6.38 ± 0.55 ab | 11.40 ± 0.55 a | 12.14 ± 1.12 b | |

| Artificial topping | / | 27.71 ± 1.58 ab | 6.40 ± 0.58 ab | 9.71 ± 0.65 b | 14.51 ± 1.69 a | |

| Water | / | 28.34 ± 1.18 a | 7.15 ± 0.77 a | 11.60 ± 0.89 a | 11.80 ± 0.84 b |

| Year | Treatment | Dose (g·hm−2) | Number of Bolls Per Plant (number) | Boll Weight (g) | Seed Cotton Yield (kg·hm−2) | Ginning Outturn (%) | Lint Cotton Yield (kg·hm−2) |

|---|---|---|---|---|---|---|---|

| 2022 | Paclobutrazol–zinc complex | 75 | 6.46 ± 0.23 c | 6.23 ± 0.53 a | 7244.24 ± 171.14 c | 41.86 ± 0.63 ab | 3032.44 ± 71.64 cd |

| 120 | 7.61 ± 0.17 a | 6.53 ± 0.17 a | 8944.79 ± 109.69 a | 43.15 ± 0.36 a | 3859.68 ± 47.33 a | ||

| 165 | 6.23 ± 0.18 c | 6.43 ± 0.49 a | 7210.60 ± 148.51 c | 41.56 ± 0.9 ab | 2996.72 ± 61.72 c | ||

| Paclobutrazol | 120 | 6.40 ± 0.17 c | 6.18 ± 0.85 a | 7119.36 ± 122.94 c | 41.83 ± 1.17 ab | 2978.03 ± 51.42 cd | |

| Mepiquat chloride | 180 | 6.56 ± 0.21 bc | 6.25 ± 0.19 a | 7380.00 ± 107.85 c | 41.92 ± 1.06 ab | 3093.70 ± 45.21 c | |

| Artificial topping | / | 6.98 ± 0.20 b | 6.73 ± 0.45 a | 8455.57 ± 183.36 b | 43.68 ± 0.89 a | 3693.39 ± 80.09 b | |

| Water | / | 5.24 ± 0.24 d | 6.11 ± 0.29 a | 5762.95 ± 89.49 d | 40.86 ± 1.17 b | 2354.74 ± 36.57 e | |

| 2023 | Paclobutrazol–zinc complex | 75 | 6.95 ± 0.38 bc | 6.07 ± 0.60 a | 7592.32 ± 129.97 c | 42.08 ± 0.49 a | 3194.60 ± 54.69 c |

| 120 | 7.96 ± 0.42 a | 6.47 ± 0.54 a | 9098.28 ± 127.25 a | 42.15 ± 0.43 a | 3834.63 ± 53.63 a | ||

| 165 | 6.56 ± 0.32 c | 6.35 ± 0.45 a | 7634.60 ± 152.44 c | 41.23 ± 1.04 a | 3147.75 ± 57.85 c | ||

| Paclobutrazol | 120 | 6.67 ± 0.33 c | 5.94 ± 0.26 a | 7124.04 ± 153.27 d | 41.09 ± 1.33 a | 2927.50 ± 62.98 d | |

| Mepiquat chloride | 180 | 6.97 ± 0.20 bc | 6.13 ± 0.23 a | 7685.35 ± 161.65 c | 40.97 ± 1.29 a | 3148.94 ± 66.23 c | |

| Artificial topping | / | 7.32 ± 0.23 b | 6.52 ± 0.58 a | 8596.02 ± 132.99 b | 42.59 ± 0.60 a | 3660.76 ± 56.64 b | |

| Water | / | 5.57 ± 0.35 d | 5.99 ± 0.29 a | 6006.88 ± 159.94 e | 41.58 ± 1.07 a | 2497.66 ± 66.50 e |

| Year | Treatment | Dose (g·hm−2) | Upper Half Mean Length (mm) | Uniformity Index (%) | Fiber Strength (cN/tex) | Micronaire |

|---|---|---|---|---|---|---|

| 2022 | Paclobutrazol–zinc complex | 75 | 31.38 ± 1.27 a | 84.67 ± 0.64 a | 28.31 ± 1.83 ab | 4.53 ± 0.27 ab |

| 120 | 31.98 ± 1.45 a | 85.67 ± 0.40 a | 29.24 ± 1.24 a | 4.60 ± 0.41 a | ||

| 165 | 31.65 ± 1.31 a | 85.67 ± 0.60 a | 28.83 ± 1.28 ab | 4.30 ± 0.25 ab | ||

| paclobutrazol | 120 | 31.41 ± 0.79 a | 85.13 ± 0.80 a | 28.66 ± 1.55 ab | 4.59 ± 0.32 a | |

| mepiquat chloride | 180 | 31.13 ± 1.47 a | 84.57 ± 0.65 a | 26.90 ± 1.19 b | 4.41 ± 0.57 ab | |

| artificial topping | / | 31.44 ± 0.57 a | 85.13 ± 0.93 a | 27.25 ± 1.12 ab | 4.19 ± 0.28 ab | |

| clear water | / | 31.32 ± 1.14 a | 84.83 ± 0.40 a | 28.16 ± 0.90 ab | 3.97 ± 0.24 b | |

| 2023 | Paclobutrazol–zinc complex | 75 | 30.70 ± 0.79 a | 84.87 ± 0.23 a | 30.66 ± 1.58 ab | 4.90 ± 0.29 ab |

| 120 | 31.28 ± 0.23 a | 86.10 ± 0.56 a | 31.49 ± 1.45 a | 4.99 ± 0.44 a | ||

| 165 | 30.97 ± 0.56 a | 85.90 ± 0.79 a | 31.22 ± 1.45 ab | 4.65 ± 0.27 ab | ||

| paclobutrazol | 120 | 30.74 ± 0.92 a | 85.27 ± 1.04 a | 31.04 ± 0.97 ab | 4.97 ± 0.35 a | |

| mepiquat chloride | 180 | 30.41 ± 0.90 a | 84.70 ± 1.05 a | 29.20 ± 0.31 b | 4.78 ± 0.61 ab | |

| artificial topping | / | 30.78 ± 1.04 a | 84.60 ± 1.25 a | 29.51 ± 1.21 ab | 4.54 ± 0.30 ab | |

| clear water | / | 31.25 ± 0.15 a | 85.33 ± 1.51 a | 30.50 ± 0.62 ab | 4.30 ± 0.26 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, J.; Wan, S.; Chen, G.; Zhang, J.; Liu, C.; Wu, J.; Li, Y.; Liu, J.; Liu, S.; Zhang, B.; et al. Octahedral Paclobutrazol–Zinc Complex for Enhanced Chemical Topping Efficacy in Mechanized Cotton Production: A Two-Year Field Evaluation in Xinjiang. Agronomy 2025, 15, 1659. https://doi.org/10.3390/agronomy15071659

Shen J, Wan S, Chen G, Zhang J, Liu C, Wu J, Li Y, Liu J, Liu S, Zhang B, et al. Octahedral Paclobutrazol–Zinc Complex for Enhanced Chemical Topping Efficacy in Mechanized Cotton Production: A Two-Year Field Evaluation in Xinjiang. Agronomy. 2025; 15(7):1659. https://doi.org/10.3390/agronomy15071659

Chicago/Turabian StyleShen, Jincheng, Sumei Wan, Guodong Chen, Jianwei Zhang, Chen Liu, Junke Wu, Yong Li, Jie Liu, Shuren Liu, Baojiu Zhang, and et al. 2025. "Octahedral Paclobutrazol–Zinc Complex for Enhanced Chemical Topping Efficacy in Mechanized Cotton Production: A Two-Year Field Evaluation in Xinjiang" Agronomy 15, no. 7: 1659. https://doi.org/10.3390/agronomy15071659

APA StyleShen, J., Wan, S., Chen, G., Zhang, J., Liu, C., Wu, J., Li, Y., Liu, J., Liu, S., Zhang, B., Lu, M., & Dong, H. (2025). Octahedral Paclobutrazol–Zinc Complex for Enhanced Chemical Topping Efficacy in Mechanized Cotton Production: A Two-Year Field Evaluation in Xinjiang. Agronomy, 15(7), 1659. https://doi.org/10.3390/agronomy15071659