Abstract

The application of organic manure is a crucial agronomic practice for enhancing crop quality. This study aimed to elucidate the effects of organic manure and nitrogen fertilizers on the physicochemical properties of waxy maize starch. A field experiment was conducted with two cultivars (JKN768 and SYN2) and six fertilization treatments: no nitrogen fertilizer application (T1); constant nitrogen fertilizer application (T2); and the replacement of 20% (T3), 40% (T4), 60% (T5), and 100% (T6) of nitrogen fertilizer with organic manure. The combined application of organic manure and nitrogen fertilizer improved the morphology and volume-weighted mean diameter of starch granules and reduced the relative crystallinity and enthalpy gelatinization of the starch. Compared with T2, the treatment in which 40% of the nitrogen fertilizer was replaced with organic manure (T4) significantly increased the volume-weighted mean diameter of starch granules in JKN768 and decreased it in SYN2, while it increased the content of rapidly digestible starch in JKN768 and SYN2 by 7.85% and 4.96%, respectively. Additionally, T4 decreased the relative crystallinity of starch in JKN768 and SYN2 by 7.12% and 3.72%, respectively, while it decreased the content of slowly digestible starch in JKN768 and SYN2 by 20% and 13.45%, respectively. The results of this study highlight that replacing 40% of nitrogen fertilizer with organic manure can significantly enhance the multi-scale structural characteristics of waxy maize starch, and they provide theoretical support for the improvement of waxy maize starch quality.

1. Introduction

With the progression of society and improvements in living standards, shifts have been observed in human dietary patterns. Waxy maize is a prominent variety of fresh produce characterized by mutations in the waxy gene, which result in unique grain properties [1,2]. The starch derived from waxy maize predominantly consists of 100% amylopectin, which confers superior digestibility and advantageous qualities that enable the starch to be used in the production of stabilizers, thickeners, and adhesives [3,4]. In China, waxy maize is a key raw material for branched-chain starch production, which plays a major role in the fresh waxy maize market [4].

Starch is the main component of maize grains, accounting for about 75% of the weight of maize. Starch exhibits a hierarchical structure characterized by multi-scale structural features, including the chain length of amylopectin, particle morphology, layered arrangement, crystalline organization, and molecular conformation [5,6,7]. Key characteristics evaluated in waxy maize starch include its amylopectin content, particle size distribution, crystallinity, and gelatinization temperature. Starch also plays a crucial role in human digestion and nutrient absorption. According to its digestibility rate, starch may be classified as rapidly digestible, slowly digestible, or resistant [8]. By modulating the digestibility rate during processing, it is possible to improve the proportion of slowly digestible and resistant starch in the final product, and thus to enhance the nutritional profile of grains [9]. Furthermore, there exists a complex relationship between the digestibility rate and the particle characteristics of starch, as well as its crystalline and molecular structures [10]. Understanding the multi-scale structural and functional traits of starch is crucial for assessing the quality of waxy maize grains [11,12], and optimizing the starch characteristics of waxy maize can enhance its suitability for cooking and eating.

Genetic traits and agronomic practices have a profound influence on the physicochemical characteristics of starch. The use of nitrogen fertilizer plays a crucial role in determining crop yield and quality, and proper nitrogen fertilizer management is essential for enhancing starch yield while minimizing nitrogen costs [13]. Balanced fertilizer application is crucial for achieving high-yield, high-quality, and efficient maize cultivation. Nitrogen fertilizer is an indispensable nutrient in crop production, having the potential to significantly enhance crop productivity and quality. Nitrogen fertilizers stimulate cellular processes that optimize starch accumulation, promote amyloplast formation, and support the synthesis of smaller starch granules [14,15,16]. However, excessive application of nitrogen fertilizers may lower the grain yield and quality of cereal crops [17,18], impair the activity of soluble starch synthase and branching enzymes, and lead to a decline in the content of short-chain branched amylopectin [19,20,21]. Organic fertilizers are of significant importance in traditional agriculture, as they not only supply essential nutrients for plant growth and sustenance, but also offer prolonged high-fertility benefits [22]. To enhance crop quality and promote sustainable agricultural practices, the integrated application of organic and nitrogen fertilizers has received extensive endorsement [23]. In rice, the application of organic fertilizer can improve the structure and physicochemical properties of the starch, increase the contents of high-value protein and amino acids, increase the contents of microelements, and enhance the cooking and eating quality of the rice [16]. In colored wheat, replacing 30% of chemical fertilizer with organic fertilizer can significantly enhance the starch structure [24]. In summer maize, the combined application of 15–30% organic fertilizer and 70–85% chemical fertilizer was found to alleviate the kernel position effect by improving post-silking N uptake and dry-matter accumulation [25]. The integration of organic manure with nitrogen fertilizer is a crucial fertilizer strategy in waxy maize production. In our previous study, we investigated the effects of the application of different ratios of sheep manure organic fertilizer and nitrogen fertilizer on the dry-matter accumulation, fresh ear yield, and grain quality of waxy maize; the results showed that replacing 40% of the chemical nitrogen fertilizer with organic manure improved the maize’s appearance and eating texture, while increasing the amylopectin content in the grains [26]. Thus, it is essential to study the changes in the physicochemical properties of waxy maize starch under different fertilizer application conditions. The impact of the application of organic manure in combination with nitrogen fertilizer on the physicochemical properties of waxy maize starch remains poorly understood.

In this study, the effects of the combined application of organic and inorganic fertilizers on waxy maize starch were analyzed by X-ray diffraction, infrared spectroscopy, and in vitro digestibility. The purpose of this study was twofold: (1) to investigate how the application of organic manure in combination with nitrogen fertilizer influences the multi-scale structure and in vitro digestibility of waxy maize starch; (2) to implement agricultural techniques to optimize waxy maize starch for specialized industrial applications while enabling it to meet modern consumer demands.

2. Materials and Methods

2.1. Experimental Site and Materials

This study was carried out at Hebei Normal University of Science and Technology’s experimental station in Changli County, Hebei Province, China (39°07′ N, 119°17′ E). The total precipitation in the experimental area from May to August in 2023 was 348.26 mm. The soil at the site is classified as sandy loam, containing the following nutrients: 12.40 g kg−1 of organic matter content, 64.08 mg kg−1 of alkali-hydrolyzable nitrogen, 11.69 mg kg−1 of Olsen phosphorus, and 54.50 mg kg−1 of exchangeable potassium. Two waxy maize varieties, namely Jingkenuo 768 (JKN768) and Suyunuo 2 (SYN2), representing sweet waxy and common waxy maize genotypes, respectively, were used in the study. The fertilizers applied as basal modes included compound fertilizer (22% N, 8% P2O5, 14% K2O), superphosphate (P2O5, 52%), potassium sulfate (51% K2O), and commercial organic sheep manure (50% organic matter, 2.14% N, 1.24% P2O5, 2.18% K2O).

2.2. Experimental Design

A split-plot design was implemented, assigning waxy maize cultivars to main plots and fertilization treatments to subplots. The cultivars used, Jingkenuo 768 (JKN768) and Suyunuo 2 (SYN2), were subjected to the following treatments: no nitrogen application (T1), constant nitrogen fertilizer application (T2), and the replacement of 20% (T3), 40% (T4), 60% (T5), and 100% (T6) of nitrogen fertilizer with organic manure. The nitrogen nutrient composition for T3, T4, T5, and T6 was similar to that for T2, with equal amounts of nitrogen applied at a rate of 180 kg hm−2. The experimental plot for each treatment was set up in three replications. Each plot had a length of 15 m and width of 6 m. All the phosphorus and potassium nutrient inputs were consistent with application rates for P2O5 of 75 kg hm−2 and K2O of 108 kg hm−2. All the fertilizer treatments were applied to the soil immediately before sowing. The planting density for both of the two tested varieties was 52,500 hm−2; the sowing date was 11 May 2023, and the harvest date was 8 August 2023. During the plant growth stage, irrigation, weeds, pests, and diseases were all well controlled.

2.3. Total Starch and Amylopectin Contents

Twenty-three days after silking, kernels were collected from three fresh ears for each treatment, which were then dried until they reached a stable weight and subjected to fine milling through a 100-mesh screen to ensure a uniform particle size for starch and protein analysis. The total starch and sugar contents in the prepared samples were quantified via the anthrone–sulfuric acid method. The contents of amylose and amylopectin in the samples were measured using commercial kits obtained from Solaibao. The total N content was determined based on the standard Kjeldahl method. The total protein content was calculated as the total N content × 6.25. Each treatment was conducted with three replicates.

2.4. Starch Isolation

Twenty-three days after silking, the kernels were collected for each treatment. The method used for starch isolation was similar to that used in the assays for determining the total starch and amylopectin contents. The grain starch was separated according to a previously reported method [27]. A 100 g mass of fresh grains was immersed in water for 48 h before being subjected to homogenization and filtration, after which it was centrifuged at 4000 rpm for 30 min to isolate the starch component. The obtained high-purity starch was dried at 40 °C prior to structural characterization and functional property analysis. Each treatment was conducted in three replicates.

2.5. Starch Morphology and Granule Size Distribution

The morphological characteristics of the starch were examined using a High-Resolution Scanning Electron Microscope (Hitachi SU8010, Rili, Japan) at 1000× and 5000× magnifications. The particle size distribution of the starch was assessed by following a previously described method [28] using a Mastersizer 3500 Laser Diffraction Analyzer (Malvern, UK), after applying ultrasonic treatment for 60 s in 100% anhydrous ethanol, used as a dispersing medium. All the analyses were conducted in three replicates.

2.6. Starch Crystalline Structure

The crystalline structure of the starch was examined using an x-ray diffractometer (Bruker-AXS D8 Advance, Karlsruhe, Germany) operated at 40 kV and 200 mA [29]. The conditions for the measurements were a 2θ angular span from 5° to 40°, with a 0.04° step and a scanning rate of 4° min−1. Quantitative analysis of the crystalline patterns was performed using the MDI Jade 6.5 software. All the analyses were conducted in three replicates.

2.7. Starch Ordered Degree

The molecular order of the starch was evaluated using Fourier-Transform Infrared Spectroscopy (Bruker 27, Karlsruhe, Germany). Data analysis was performed using the OMNIC 8.2 software, focusing on the spectral region between 800 and 1200 cm−1. Specific absorbance peaks situated at 1045, 1022, and 995 cm−1 indicating the degree of starch ordering were both identified and quantified via examination of the deconvoluted spectra [18,19]. All the analyses were conducted in three replicates.

2.8. Starch Swelling Potential and Solubility

The swelling potential and solubility of the starch were evaluated according to previously described methods, with minor modifications [30]. Briefly, to assess their starch–water ratio, kernels were heated in a 95 °C water bath for 40 min, after which the swelling potential and solubility of the starch were determined according to a previously reported method [30]. Each sample was analyzed in three replicates.

2.9. Iodine-Binding Strength, Blue Value, and λmax of Starch

The iodine-binding strength, blue value, and λmax index in the kernels were assessed according to previously described methods, with slight modifications [31]. Absorption spectra of the samples were acquired using a UV-Vis spectrophotometer (UV 2600, Shimadzu, Kyot, Japan) across the 500~650 nm wavelength range. The iodine-binding strength values of the samples are expressed as the ratio between the value at 635 nm and that at 520 nm (A635/A520). Each sample was analyzed in three replicates.

2.10. Starch Pasting Properties

The pasting properties of the starch in the maize kernels were analyzed using a Rapid Visco Analyzer 4500 (Perten, Sydney, Australia), following a previously described method [27]. Slurries containing a mixture of 1.96 g of starch and 26.04 mL of distilled water were prepared in an aluminum crucible. They were then subjected to a heating process whereby the temperature was ramped up from 50 °C to 95 °C at a steady rate of 12 °C·min−1, before being subjected to cooling phase, whereby the temperature was brought back down to 50 °C. Critical viscometric parameters were calculated using the Thermocline for Windows (TCW) software. Each sample was analyzed in three replicates.

2.11. Starch Thermal Properties

The thermal properties of the starch were analyzed using a DSC 3000 analyzer (Netzsch, Selb, Germany), following a previously described method [27]. For this purpose, a 5 mg sample of starch was homogenized with 10 μL of water in a hermetically sealed aluminum crucible, stored at 4 °C for 24 h, and then heated from 20 °C to 100 °C at a constant heating rate of 10 °C·min−1. Each sample was stored at 4 °C for seven days, before being subjected to retrogradation analysis. The thermodynamic parameters of each sample were determined using thermal analysis software (Proteus®). Each sample was analyzed in three replicates.

2.12. In Vitro Digestibility of Starch

The in vitro digestibility of the starch was evaluated according to a previously reported method [32]. Briefly, a 5 mg sample of starch and 2.5 mL of distilled water were added to a 25 mL centrifuge tube, then thermally processed at 95 °C for 5 min. Afterwards, 4 mL of an enzymatic mixture (1 mg porcine pancreatic α—amylase, 0.05 mL amyloglucosidase) was added to the tube and mixed well. The mixture was incubated at 37 °C, and then at 0, 20, and 120 min post incubation, 1 mL aliquots were collected and mixed with 9 mL of absolute ethanol to halt enzymatic activity. The glucose content in the starch samples was measured using the D-glucose (GOPOD) assay kit( Suolaibao, Beijing, China). The proportions of rapidly digestible, slowly digestible, and resistant starch were calculated according to a previously reported method [32]. Each sample was analyzed in three replicates.

2.13. Statistical Analysis

The data shown in the subsequent tables and figures represent the means calculated from three independent replicates. Statistical analyses were performed using the SPSS 22 software, and graphical representations were generated using the Origin 2021 software. Significant differences were determined using the least significant difference test, and are shown at the alpha level of p < 0.05. Pearson correlation analysis was used to assess the relationships between variables.

3. Results

3.1. Starch and Sugar Contents

The effects of the application of organic manure on the starch and sugar contents in the two different cultivars are shown in Table 1. JKN768 exhibited higher total protein and sugar contents but lower total starch and amylopectin starch contents, compared to SYN2. As the amount of organic manure applied increased, the total protein, total starch, and amylopectin contents initially increased and then declined. The highest total starch and amylopectin contents were observed for T3 and T4. The total sugar content followed a similar trend, peaking for T2 in JKN768, and for T4 and T5 in SYN2. These results indicate that replacing 40% of the nitrogen fertilizer with organic manure effectively balanced the sugar and starch contents, promoting starch synthesis.

Table 1.

The effects of organic manure and nitrogen fertilizer application on the total starch, amylopectin, and amylose contents in waxy maize.

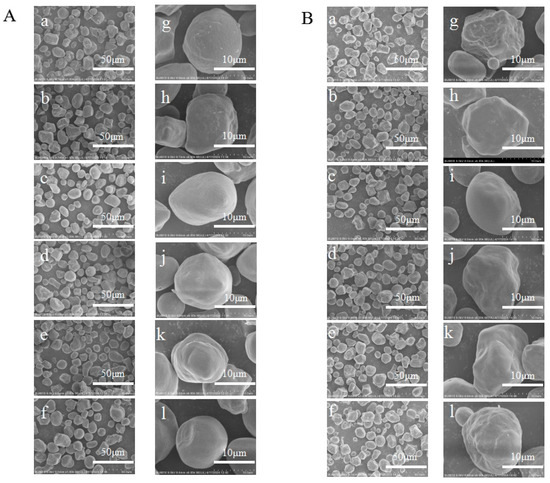

3.2. Starch Granule Morphology and Size Distribution

Scanning electron microscopy analysis revealed that across the various treatments and cultivars, the starch granules shared similar morphological characteristics, including round, polygonal, and oval shapes (Figure 1). Two waxy varieties showed smooth starch granules on the surface under T1, but the surface was uneven, with pits. Under T2, the starch granules of the waxy maize exhibited an uneven surface and irregular shape. As the proportion of organic manure application increased, the morphology of the starch granules improved, gradually becoming regular and round. Compared to those under T2, the starch granules under T3 and T4 became larger, whilst the surface of the starch granules was uneven and pitted. This demonstrates that the combination of organic manure and nitrogen fertilizer can improve the shape of starch particles in waxy maize.

Figure 1.

The effects of organic manure and nitrogen fertilizer application on the morphology of waxy maize starch, illustrated using scanning electron micrographs. Micrographs were taken at 1000 and 5000 magnification. (A,B) represent JKN768 and SYN2, respectively. (a–f) represent the results for T1, T2, T3, T4, T5, and T6 at 1000 magnification, respectively. (g–l) represent the results for T1, T2, T3, T4, T5, and T6 at 5000 magnification, respectively.

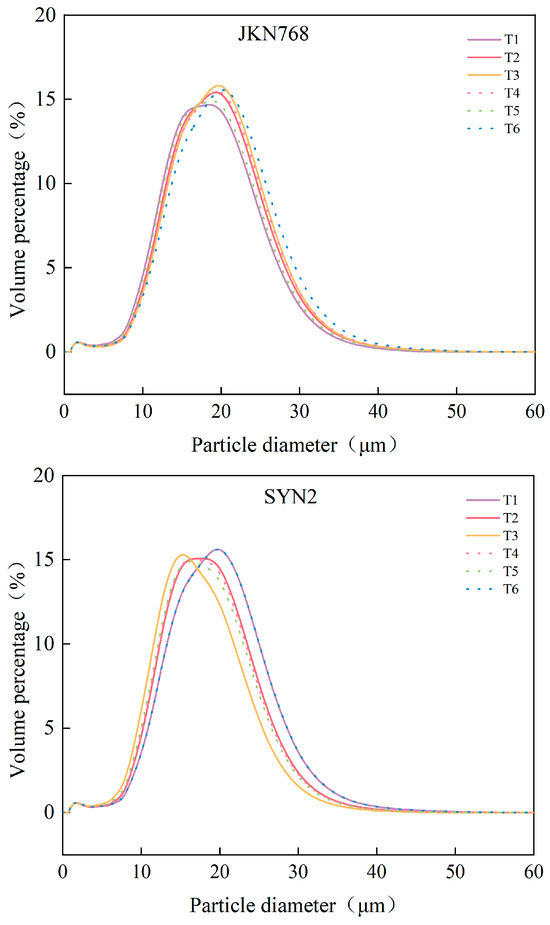

The effects of organic manure application on the volume and particle size of the starch are shown in Table 2. Compared to that under T2, the D(4, 3) value of starch in JKN768 increased by 1.70%, 3.97%, and 2.20% under T3–T5, respectively, and decreased by 0.92% under T6. On the contrary, the D(4, 3) value of starch in SYN2 decreased by 0.79%, 2.58%, 1.07%, and 3.08% under T3-T6, respectively. The starch granules were classified into three distinct categories, designated as “a,” “b,” and “c,” based on their diameter measurements (Figure 2). Replacing 40% of the nitrogen fertilizer with organic manure increased the average starch granule diameter in JKN768, but decreased it in SYN2. Notably, JKN768 contained a higher proportion of large granules (“a”), whereas SYN2 contained a greater proportion of medium-sized granules (“b”).

Table 2.

The effects of organic manure and nitrogen fertilizer application on the D(4, 3), D(3, 2), d (0.1), d (0.5), and d (0.9) values of waxy maize starch.

Figure 2.

The effects of organic manure and nitrogen fertilizer application on the volume distribution of waxy maize starch.

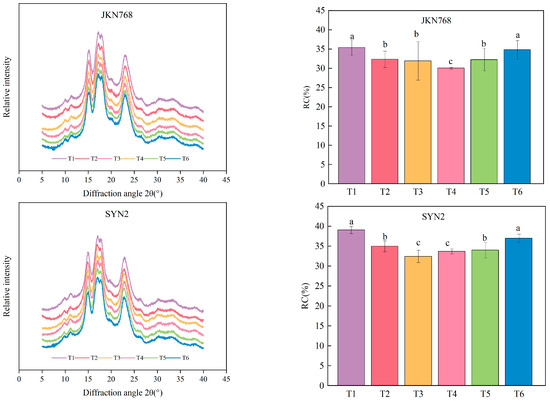

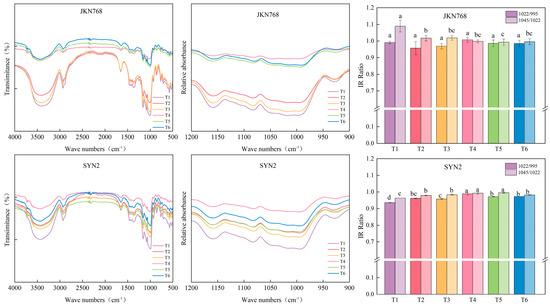

3.3. Crystalline Structure and Degree of Ordering

Organic manure and nitrogen fertilizers did not alter the type of starch crystals (Figure 3). The RC values for both varieties under T3–T5 decreased compared to those under T1 and T6 (Figure 3); this decline was consistent across both varieties. Relative to that under T2, the RC of the starch in JKN768 decreased by 1.27%, 7.12%, 9.73%, and 0.32% under T3–T5, respectively, while the RC of the starch in SYN2 decreased by 7.31%, 3.71%, 14.42%, and 2.85% under the same treatments. Similarly, the R1045/1022 ratio of the starch of JKN768 was higher than that of the starch in SYN2. The combined application of organic manure and nitrogen fertilizer did not alter the FTIR results for the starch (Figure 4). The combined application slightly decreased the R1045/1022 ratio of the starch in JKN768, but slightly increased that of the starch in SYN2 (Figure 4). It can be concluded that T3–T5 reduced the crystallinity of the starch and improved the orderliness of its structure.

Figure 3.

The effects of organic manure and nitrogen fertilizer application on the X-ray diffraction patterns and relative crystallinity (RC) of waxy maize starch. Mean values labeled with different letters are significantly different (p < 0.05).

Figure 4.

The effects of organic manure and nitrogen fertilizer application on the FTIR diffraction patterns and short-range ordered structure (1024/1022 and 1022/995) of waxy maize starch. Mean values labeled with different letters are significantly different (p < 0.05).

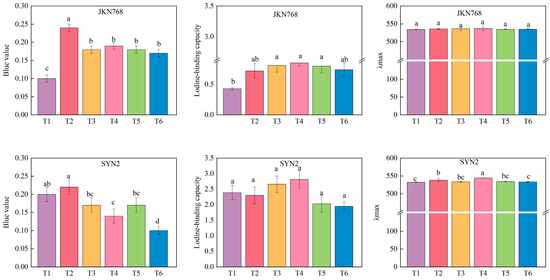

3.4. Blue Value, Swelling Power, and Solubility

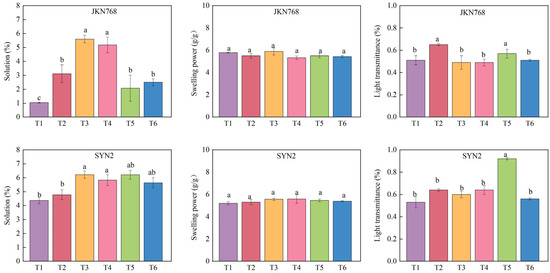

The λmax ranges for the two maize varieties were 534.57~537.23 nm and 532.30~544.30 nm, respectively (Figure 5). No notable differences were seen across the different fertilizer treatments. As the proportion of nitrogen fertilizer replaced with organic manure increased, the iodine-binding capacity of the starch in JKN768 initially increased and then declined, while that of the starch in SYN2 consistently decreased. The blue value of the starch significantly declined in both varieties, peaking under T2. As the proportion of nitrogen fertilizer replaced with organic manure rose, the swelling power and solubility of the starch in JKN768 increased (Figure 6). Relative to those under T2, the swelling power and solubility of the starch under T4 rose by 5.27% and 23.31%, respectively. In SYN2, these values initially rose, and then declined, with the swelling power increasing by 39.96% under T4.

Figure 5.

The effects of organic manure and nitrogen fertilizer application on the blue value, iodine-binding capacity, and λmax of waxy maize starch. Mean values labeled with different letters are significantly different (p < 0.05).

Figure 6.

The effects of organic manure and nitrogen fertilizer application on the solution, swelling power, and light transmittance of waxy maize starch. Mean values labeled with different letters are significantly different (p < 0.05).

3.5. Pasting Properties and Thermal Properties

The starch exhibited distinct gelatinization properties according to the treatment used. Compared to the starch in SYN2, that in JKN768 exhibited higher PV, TV, FV, and SB values. The application of organic manure and nitrogen fertilizer altered the gelatinization properties of the starch in both varieties (Table 3). Compared to T2, T3–T6 decreased the PV, TV, FV, and SB values of the starch, while increasing the BD. In JKN76, the highest PV and BD values were observed under T3, while the highest TV, FV, BD, and SB values occurred under T2. Conversely, in SYN2, the PV, TV, FV, and SB values of the starch showed reduction under T2, whereas the BD increased under T4 and T5.

Table 3.

The effects of organic manure and nitrogen fertilizer application on the pasting properties of waxy maize starch.

The starch also exhibited different thermal properties according to the treatment used (Table 4). Compared to the starch in SYN2, that in JNY768 exhibited a lower To and % R, and higher Tp, Tc, ΔHgel, and ΔHret values. Organic manure application affected the thermal characteristics of the starch. Compared to those under T2, the To, Tp, ΔHgel, and % R values of the starch decreased as the proportion of organic manure application increased. The To, Tp, and ΔHgel values showed the smallest decrease under T3, while under T4, the R values of the starch in JKN768 and SYN2 exhibited significant decreases of 12.76% and 19.52%. The To and ΔHgel of the waxy maize starch decreased under the T3 and T4 treatments of organic manure combined with nitrogen fertilizer, and the R value significantly decreased.

Table 4.

The effects of organic manure and nitrogen fertilizer application on the thermal properties of waxy maize starch.

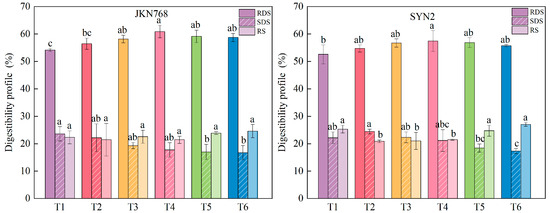

3.6. In Vitro Starch Digestibility

The starch exhibited distinct properties under the different treatments. JNK768 had a higher content of SDS and RS, but a lower content of RDS, whereas SYN2 displayed the opposite trend (Figure 7). The SDS and RS contents of JKN768 were consistently higher than those of SYN2, suggesting the superior capacity for producing slowly digestible and resistant starch. As the proportion of organic manure applied increased, the RDS content in JKN768 and SYN2 initially rose before declining, peaking under T4 and T5. Compared to that under T2, the RDS content of JKN768 increased by 7.85% and 4.81% under T4 and T5, respectively, while for SYN2, it increased by 4.96% and 3.92% under the same treatments. Compared to that under T2, the SDS content of JKN768 decreased by 20% and 23.23% under T4 and T5, respectively, while the SDS content of SYN2 declined by 13.45% and 24.56%. The combined application of organic manure and nitrogen fertilizer significantly reduced the SDS content and increased the RDS and RS contents in the waxy maize.

Figure 7.

The effects of organic manure and nitrogen fertilizer application on the in vitro digestibility of waxy maize starch. Mean values labeled with different letters are significantly different (p < 0.05).Different colors represent different treatments, purple, red, orange, pink, green and blue represents T1, T2, T3, T4, T5 and T6 treatment, respectively. Under the same treatment, the left filling, middle slash and right grid patterns represents RDS, SDS and RS, respectively.

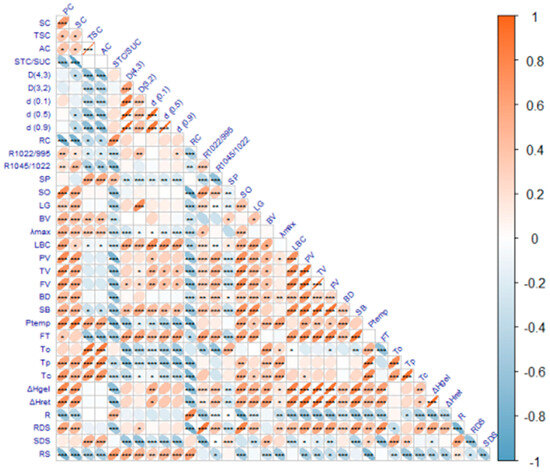

3.7. Correlation Analysis

A Pearson correlation analysis was performed to evaluate the associations between the physicochemical characteristics and in vitro digestibility of the waxy maize starch (Figure 8). TSC and AC were negatively correlated with D(4, 3), D(3, 2), d (0.1), d (0.5), d (0.9), RC, R1022/995, R1045/1022, ΔHgel, ΔHret, R, PV, TV, FV, BD, SB, RDS, and RS. In contrast, TSC and AC were positively correlated with SP, SO, LG, BV, To, Tp, Tc, and SDS. RDS was positively correlated with PC, SC, D(3, 2), solubility, R1022/995, R1045/1022, LBC, PV, TV, FV, BD, SB, LG, BV, To, Tc, ΔHgel, and ΔHret. SDS was positively correlated with TSC, AC, SC, To, Tp, and R. Conversely, the RS content exhibited a strong positive correlation with D(4, 3), D(3, 2), d(0.1), d(0.5), and d(0.9).

Figure 8.

Pearson correlation analysis of the associations between the physicochemical properties and in vitro digestibility of the waxy maize starch. Positive and negative correlations are denoted in red and blue, respectively. The strength of the correlation is indicated by the width of the ellipsis and the color gradient; the bar indicates the coefficients and their related colors. PC: protein content; SC: sugar content; TSC: total starch content; AC: amylopectin content; STC/SUC: starch/sugar; AAC: apparent amylose content; d (0.1), d (0.5), and d (0.9) are the maximum sizes (μm) at 10%, 50%, and 90% of the total volume, respectively; D(3,2) is the surface-weighted mean diameter of starch particles; D(4,3) is the volume-weighted mean diameter of starch particles; RC: relative crystallinity; R1045/1022: the ratio of absorbance of 1047/1022 cm−1; R1022/995: the ratio of absorbance of 1022/995 cm−1; LG: light transmittance; SO: solubility; SP: swelling power; BV: blue value; λmax: maximum absorption wavelength; LBC: iodine-binding capacity; PV: peak viscosity; TV: trough viscosity; BV: breakdown viscosity; FV: final viscosity; SV: setback viscosity; Ptemp: pasting temperature; To: onset temperature; Tp: peak temperature; Tc: completion temperature; ΔHgel: phase transition enthalpy of original starch; ΔHret: phase transition enthalpy of regeneration starch; R: regeneration rate; RDS: rapidly digestible starch; SDS: slowly digestible starch; RS: resistant starch. *,** and *** represents significant at the 0.05, 0.01 and 0.001 probability level.

4. Discussion

The use of nitrogen fertilizer is a crucial agronomic practice to increase crop yield and quality. Optimizing the physicochemical properties of starch, which is a major constituent of cereal grains, could help to improve the suitability of cereal products for cooking and consumption [33]. Maize grains are primarily composed of starch, proteins, and soluble sugars, which influence the physicochemical properties of waxy maize. In this study, JKN768 exhibited higher contents of total protein and sugar, but lower total starch and amylopectin starch contents, compared to SYN2. These differences are attributed to the fact that JKN768 is a sweet glutinous variety with an average sugar content exceeding 12, which causes it to exhibit the distinctly enhanced sweetness and unique taste profile that are characteristic of glutinous maize [34]. As the proportion of organic manure applied increased, the contents of total protein, total starch, and amylopectin initially increased, and then declined (Table 1); the highest total starch and amylopectin contents were observed under T3 and T4. The total sugar content followed a similar trend, peaking under T2 for JKN768 and under T4 and T5 for SYN2 (Table 1). These changes may be a result of the organic manure modulating the supply of nutrients by adjusting the nutrient retention and release processes. Compared with the rapid release of nutrients by chemical fertilizer (T2), which exceeds the uptake ability of waxy maize, organic manure can modulate the nitrogen supply by adjusting the nitrogen retention and release processes. This promotes plant growth and grain development by ensuring consistent provision of nutrients, as well as improving the physicochemical properties of the soil and the composition and abundance of soil microorganisms [16,35,36], which may be the main reason for the improved grain quality observed as a result of additional application of organic fertilizer.

While genetic diversity has a primary influence on starch granule morphology, cultivation practices have a minimal impact [37]. The scanning electron microscopy analysis revealed that across the various treatments and cultivars, the starch granules shared similar morphological characteristics, including round, polygonal, and oval shapes (Figure 1). Despite the differences in treatment and cultivar, the granules retained their irregular polygonal or spherical forms, suggesting that fertilization does not alter the fundamental morphology of waxy maize starch. The size of starch granules was affected by N fertilization [5]. The D(4, 3) value of starch corresponds to its volume-weighted mean diameter. In this study, the D(4,3) value of the starch in JKN768 increased under T3–T5 compared with that under T2. Conversely, the D(4,3) value of the starch in SYN2 decreased under T3 and T6. These variations were likely due to differences in starch synthesis pathways between the two cultivars. Compared with the rapid release of nutrients from chemical fertilizers (T2), applying organic manure can potentially facilitate the mineralization of nitrogen and promote its absorption by plants, ensuring a sufficient nutrient supply during the blooming and grain-filling stages of waxy maize [38]. Interestingly, T6 reduced the volume-weighted and surface-weighted mean diameters of the starch particles, which may have been due to the fact that organic manure alone cannot provide a sufficient level of nutrients required by plants for plant growth and development, resulting in nitrogen deficiency during the growth and development of crops [39], and insufficient energy required for the growth and development of starch particles. The growth and development of starch granules were hindered. In this study, the starch content was negatively correlated with D(4, 3). Correlation analysis showed that the RS content exhibited a strong positive correlation with D(4, 3) and D(3, 2), which indicated that D(4, 3) and D(3, 2) had the most substantial impact on the RS content. In accordance with existing classifications [40], starch granules were classified into three distinct categories, designated as “a,” “b,” and “c,” based on their diameter measurements (Figure 2). In this study, the increase in the granule size of the starch in JKN768 under T3–T5 was attributed to a higher proportion of both small (c) and large (a) granules. The increased particle size of the starch in SYN2 under T3 and T4 was primarily due to a greater proportion of small- and medium-sized granules (b and c), while the reduction in particle size under T5 and T6 resulted from a lower proportion of large granules (a); this phenomenon explains why SYN2 exhibited smaller starch granules with increasing organic fertilizer levels. Evidence was found of starch granule appearance being correlated with nitrogen fertilization. This may have been a result of the organic manure modulating the supply of nutrients by adjusting the nutrient retention and release processes. Appropriate use of nitrogen fertilizer can promote grain-filling and starch synthesis, and result in smoother starch granules [19]. However, excessive N application resulted in more small- and medium-sized granules. This pattern aligns with the findings reported in [16] that organic manure application reduced the quantity, volume, and area of small starch granules in rice, while increasing those of larger granules. In potato, a decrease in starch granule size was attributed to an increased proportion of small granules [41].

Generally, native starches are divided into types A, B, and C in line with their X-ray diffraction (XRD) spectra [42]. The branched double-helical structure of amylopectin contributes to the semi-crystalline nature of starch. The crystal structure of starch is significantly affected by rainfall, temperature, humidity, and plant density. Importantly, the crystallization type of the waxy maize starch remained unaffected by the cultivar or fertilizer treatment. Previous studies have highlighted the impacts of plant density and nitrogen application on starch crystallization and amylopectin branching patterns [43]. In this study, our findings indicated that organic manure and nitrogen fertilizer did not alter the type of starch crystals. The RC values for both varieties under T3–T5 decreased compared to those under T1 and T6; this decline was consistent across both varieties. The RC of the starch in JKN768 and SYN2 decreased under T3–T5 relative to that under T2. These results suggest that the combined application of organic manure and nitrogen fertilizers reduced the starch stability in the waxy maize, potentially due to a lower gelatinization enthalpy. Furthermore, the application of organic manure and nitrogen fertilizer effectively modulated the starch crystalline stability, aligning with findings in rice starch [13]. Attenuated total reflectance–FTIR is a valuable tool for assessing the short-range ordering starch molecules. The absorbance ratio at 1045–1022 cm−1 (R1045/1022) is a key indicator of structural-order organization [14]. The application of organic manure in combination with nitrogen fertilizer slightly decreased the R1045/1022 ratio in JKN768, but slightly increased it in SYN2. These results indicate that integrating organic manure with nitrogen fertilizer had an impact on the stability of the starch’s double-helical architecture, enhanced the ordered arrangement of starch granules, and curbed the formation of less-ordered structures.

Starch’s ability to bind iodine is closely linked to its structural characteristics, and the measurement of this parameter can be an effective way to evaluate the ratio of extended chains in branched starches [31]. The λmax ranges for the two waxy maize varieties were 534.57~537.23 nm and 532.30~544.30 nm, respectively (Figure 5), which are typical of glutinous varieties [44].The structural configuration of amylopectin, especially its distribution in the crystalline and amorphous regions of starch granules, plays a crucial role in determining the functional properties of starch, such as its swelling power and solubility [45]. As the proportion of nitrogen fertilizer replaced with organic manure rose, the swelling power and solubility of the starch in JKN768 increased. In SYN2, these values initially rose, and then declined, with the swelling power increasing under T4, consistently with previous studies [46,47].

The pasting and thermal properties of the starch served as crucial indicators for assessing the quality of the waxy maize. RVA properties are key indicators of starch gelatinization, retrogradation, swelling, and gelling behavior [13,14]. The pasting properties of the starch varied across treatments and were influenced by amylopectin branching and granule size [48]. Compared to SYN2, JKN768 exhibited larger starch granules and enhanced starch pasting properties. Starches with larger granules generally have higher pasting temperatures than those with a similar amylose content but smaller granules, as more amylose is released from intact granules [47,49]. N fertilization changed the pasting and thermal properties of the starch [5]. Appropriate nitrogen application promotes starch accumulation, leading to higher viscosity and a lower retrogradation tendency [5]. The application of organic manure in combination with nitrogen fertilizer decreased the PV, TV, FV, and SB values, while increasing BD. These changes may have been the result of the organic manure modulating the supply of nutrients by adjusting the nutrient retention and release processes. With an increase in the proportion of nitrogen fertilizer replaced by organic manure, the amount of organic manure applied increased, while the amount of chemical nitrogen fertilizer applied decreased, leading to a reduced peak viscosity, final viscosity, and trough viscosity of the waxy maize starch. This is consistent with previous research findings in rice [16,48], where reduced nitrogen fertilizer application was found to decrease the starch viscosity. Variations in gelatinization temperatures are associated with differences in amylose content and amylopectin structure at different nitrogen levels [50]. Organic manure application affected the thermal characteristics of the starch, with T3–T6 reducing the To and Tp values, consistently with particle size trends. With an increase in the proportion of nitrogen fertilizer replaced by organic manure, the amount of organic manure applied increased, while the amount of chemical nitrogen fertilizer applied decreased, leading to a reduction in To and Tp in the waxy maize grains. This is consistent with previous research findings in rice [16,48] which showed that reducing the amount of nitrogen fertilizer applied decreased the To and Tp of the starch. ΔHgel, which reflects starch crystallinity and the extent of double-helix disruption during gelatinization, significantly increased under T3–T6 compared to under T2, aligning with previous rice starch studies [16,48]. These results suggest that the application of organic manure in combination with nitrogen fertilizer significantly influences amylose and amylopectin synthesis, thereby affecting the gelatinization and thermal properties in waxy maize starch.

The digestibility of starch can be influenced by its granular, crystalline, and molecular structures [10,11]. According to the in vitro digestion analysis, starch can typically be classified into three major types: rapidly digestible starch (RDS), slowly digestible starch (SDS), and resistant starch (RS) [8]. Previous research has indicated that a higher RDS may elevate the risk of cardiovascular diseases, diabetes, and oral health issues [51]. Both RS and SDS have been found to provide health-related benefits [52,53]. In this study, the SDS and RS contents in JKN768 were consistently higher than those in SYN2, suggesting that JKN768 has a superior capacity for producing slowly digestible and resistant starch. Resistant starch (RS) can improve the lipid and cholesterol metabolism, exert prebiotic effects on colon microorganisms, and reduce the risk of ulcerative colitis and colon cancer [54]. Slowly digestible starch (SDS) can promote a lower glycemic response, higher glucose tolerance, and lower blood lipid levels [55] The application of organic manure affected the digestibility of the starch; as the amount of organic manure applied increased, the content of RDS in both JKN768 and SYN2 initially rose, and then declined, exhibiting its highest values under T4 and T5. Correlation analysis showed that RDS was positively correlated with PC, SC, D(3, 2), solubility, R1022/995, R1045/1022, LBC, PV, TV, FV, BD, SB, LG, BV, To, Tc, ΔHgel, and ΔHret. Compared to that under T2, the SDS content in JKN768 and SYN2 decreased under T4 and T5. These changes may have been a result of the organic manure modulating the supply of nutrients by adjusting the nutrient retention and release processes. SDS was positively correlated with TSC, AC, SC, To, Tp, and R, which indicates that To, Tp, and R had the most important influence on the SDS content. Conversely, the RS content exhibited a strong positive correlation with D(4, 3), D(3, 2), d(0.1), d(0.5), and d(0.9), which indicates that D(4, 3) and D(3, 2) had the most substantial impact on the RS content. Overall, the combined application of organic manure with nitrogen fertilizers significantly reduced the SDS content, while increasing the RDS and RS contents, in the waxy maize.

5. Conclusions

The results of this study indicate that the combined application of organic manure and nitrogen fertilizers could constitute a comprehensive and sustainable fertilization strategy. This combined application modulated the multi-scale structure, physicochemical properties, and in vitro digestibility of waxy maize starch. Replacing 40% of the nitrogen fertilizer with organic manure resulted in an increase in the average granule size, solubility, swelling power, peak viscosity, breakdown viscosity, and content of rapidly digestible and resistant starch, while reducing the relative crystallinity, final viscosity, gelatinization enthalpy, and content of slowly digestible starch. Therefore, the combined application of organic manure and nitrogen fertilizers can enhance the quality of waxy maize starch.

Author Contributions

F.L.: investigation, data curation, writing—original draft. L.L.: investigation, methodology. W.Z.: software, investigation. P.J.: methodology, visualization. X.L.: writing—review and editing, funding acquisition. P.T.: resources, supervision, writing—review and editing. Y.Z.: resources, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Hebei Province Central Guidance Fund for Local Scientific and Technological Development Projects (246Z6401G), and the National Key Research and Development Program of China (No. 2023YFD2301505).

Data Availability Statement

The original contributions presented in the study are included in this article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Zheng, H.J.; Wang, H.; Yang, J.H.; Wu, J.; Shi, B.; Cai, R.; Xu, Y.B.; Wu, A.Z.; Luo, L.J. Genetic diversity and molecular evolution of Chinese waxy maize germplasm. PLoS ONE 2013, 8, e66606. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.Y.; Long, W.J.; Chen, D.; Zhou, G.Y.; Du, J.; Wu, S.Y.; Cai, Q. Waxy allele diversity in waxy maize landraces of Yunnan Province, China. J. Integr. Agric. 2022, 21, 578–585. [Google Scholar]

- Hsieh, C.F.; Liu, W.C.; Whaley, J.K.; Shi, Y.C. Structure and functional properties of waxy starches. Food Hydrocoll. 2019, 94, 238–254. [Google Scholar] [CrossRef]

- Luo, J.Y.; He, C.M.; Yan, S.J.; Jiang, C.L.; Chen, A.; Li, K.; Zhu, Y.L.; Gui, S.T.; Yang, N.; Xiao, Y.J.; et al. A metabolic roadmap of waxy corn flavor. Mol. Plant 2024, 12, 1883–1898. [Google Scholar] [CrossRef]

- Wang, J.; Wen, Z.R.; Fu, P.X.; Lu, W.P.; Lu, D.L. Effects of nitrogen rates on the physicochemical properties of waxy maize starch. Starch-Stärke 2019, 71, 1900146. [Google Scholar] [CrossRef]

- Huang, S.J.; Zha, F.C.; Zhu, Z.; Zhou, L.H.; Zheng, Q.H.; Wang, C.L. Characterization of eating quality and starch properties of two Wx alleles japonica rice cultivars under different nitrogen treatments. J. Integr. Agric. 2020, 19, 988–998. [Google Scholar] [CrossRef]

- Tao, K.Y.; Yu, W.W.; Prakash, S.; Gilbert, R.G. High-amylose rice: Starch molecular structural features controlling cooked rice texture and preference. Carbohydr. Polym. 2019, 219, 251–260. [Google Scholar] [CrossRef]

- Englys, H.N.; Kingman, S.; Cummings, J. Classification and measurement of nutritionally important starch fractions. Eur. J. Clin. Nutr. 1992, 46, S33–S50. [Google Scholar]

- Guo, K.; Liang, W.X.; Wang, S.J.; Guo, D.W.; Liu, F.L.; Persson, S.; Herburger, K.; Petersen, B.L.; Liu, X.X.; Blennow, A.; et al. Strategies for starch customization: Agricultural modification. Carbohydr. Polym. 2023, 321, 121336. [Google Scholar] [CrossRef]

- Kaplan, M.; Karaman, K.; Kardes, Y.M.; Kale, H. Phyticacid content and starch properties of maize (Zea mays L.): Effects of irrigation process and nitrogen fertilizer. Food Chem. 2019, 283, 375–380. [Google Scholar] [CrossRef]

- Wu, X.R.; Guo, K.; Liang, W.X.; Wang, Q.; Zhai, M.M.; Li, J.Y.; Herburger, K.; Wang, Z.H.; Zhong, Y.Y.; Han, Q.F. Optimizing planting density enhances the multi-scale structural characteristics and in vitro digestibility of maize starch via modulating the size distribution of granules. Int. J. Biol. Macromol. 2024, 280, 136004. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.C.; Chen, L.; Guo, X.B.; Liang, Y.; Xie, F.W. Understanding the multi-scale structure and digestibility of different waxy maize starches. Int. J. Biol. Macromol. 2020, 144, 252–258. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.; Pal, N.; Mahajan, G.; Singh, S.; Shevkani, K. Rice grain and starch properties: Effects of nitrogen fertilizer application. Carbohydr. Polym. 2011, 86, 219–225. [Google Scholar] [CrossRef]

- Nowotnaa, A.; Gambus, H.; Kratsch, G.; Krawontka, J.; Gambus, F.; Sabat, R.; Ziobro, R. Effect of nitrogen fertilization on the physico-chemical properties of starch isolated from German triticale varieties. Starch-Stärke 2007, 59, 397–399. [Google Scholar] [CrossRef]

- Yang, X.Y.; Bi, J.; Gilbert, R.G.; Li, G.H.; Liu, Z.H.; Wang, S.H.; Ding, Y.F. Amylopection chain length distribution in grains of japonica rice as affected by nitrogen fertilizer and genotype. J. Cereal Sci. 2016, 71, 230–238. [Google Scholar] [CrossRef]

- Zhou, T.Y.; Chen, L.; Wang, W.L.; Xu, W.J.; Zhang, W.Y.; Zhang, H.; Liu, L.J.; Wang, Z.Q.; Gu, J.F.; Yang, J.C. Effects of application of rapeseed cake as organic fertilizer on rice quality at high yield level. J. Sci. Food Agric. 2020, 102, 1832–1841. [Google Scholar] [CrossRef]

- Dupont, M.; Altenbach, S.B. Molecular and biochemical impacts of environmental factors on wheat grain development and protein synthesis. J. Cereal Sci. 2003, 38, 133–146. [Google Scholar] [CrossRef]

- Li, G.H.; Hu, Q.Q.; Shi, Y.G.; Cui, K.H.; Nie, L.X.; Huang, J.L.; Peng, S.B. Low nitrogen application enhances starch-metabolizing enzyme activity and improves accumulation and translocation of non-structural carbohydrates in rice stems. Front. Plant Sci. 2018, 9, 1128. [Google Scholar] [CrossRef] [PubMed]

- Zhou, T.Y.; Zhou, Q.; Li, E.P.; Yuan, L.M.; Wang, W.L.; Zhang, H.; Liu, L.J.; Wang, Z.Q.; Yang, J.C.; Gu, J.F. Effects of nitrogen fertilizer on structure and physicochemical properties of ‘super’rice starch. Carbohydr. Polym. 2020, 239, e116237. [Google Scholar] [CrossRef]

- Zhou, T.Y.; Li, Z.K.; Li, E.P.; Wang, W.L.; Yuan, L.M.; Zhang, H.; Liu, L.G.; Wang, Z.Q.; Gu, G.F.; Yang, J.C. Optimization of nitrogen fertilization improves rice quality by affecting the structure and physicochemical properties of starch at high yield levels. J. Integr. Agric. 2021, 21, 1576–1592. [Google Scholar]

- Zhao, T.C.; He, A.B.; Khan, M.N.; Yin, Q.; Song, S.K.; Nie, L.X. Coupling of reduced inorganic fertilizer with plant-based organic fertilizer as a promising fertilizer management strategy for colored rice in tropical regions. J. Integr. Agric. 2024, 23, 93–107. [Google Scholar] [CrossRef]

- Custodio, M.C.; Cuevas, R.P.; Ynion, J.; Laborte, A.G.; Velasco, M.L.; Demont, M. Rice quality: How is it defined by consumers, industry, food scientists, and geneticists? Trends Food Sci. Technol. 2019, 92, 122–137. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.T.; Xiong, Y.X.; Li, Y.P.; Qiu, Y.C.; Huang, G.H. Effects of organic amendment incorporation on maize (Zea mays L.) growth, yield and water-fertilizer productivity under arid conditions. Agric. Water Manag. 2022, 269, 107663. [Google Scholar] [CrossRef]

- Wen, J.L.; Li, Z.Y.; Yao, J.F.; Wang, S.; Liu, Y.; Liu, Y. The combined application of organic and inorganic fertilizers improved the quality of colored wheat by physicochemical properties and rheological characteristics of starch. Int. J. Biol. Macromol. 2024, 282, 137175. [Google Scholar] [CrossRef]

- Zhai, L.C.; Zhang, L.H.; Cui, Y.Z.; Zhai, L.F.; Zheng, M.J.; Yao, Y.R.; Zhang, J.T.; Hou, W.B.; Wu, L.Y.; Jia, X.L. Combined application of organic fertilizer and chemical fertilizer alleviates the kernel position effect in summer maize by promoting post-silking nitrogen uptake and dry matter accumulation. J. Integr. Agric. 2024, 23, 1179–1194. [Google Scholar] [CrossRef]

- Lou, F.; Zuo, Y.P.; Li, M.; Dai, X.M.; Wang, J.; Han, J.L.; Wu, S.; Li, X.L.; Duan, H.J. Effects of organic fertilizer substitution of partial chemical fertilizer nitrogen on yield, quality and nitrogen utilization of waxy maize. Acta Agron. Sin. 2024, 50, 1053–1064. [Google Scholar]

- Lu, D.L.; Lu, W.P. Effects of protein removal on the physicochemical properties of waxy maize flours. Starch-Stärke 2012, 64, 874–881. [Google Scholar] [CrossRef]

- Liang, W.X.; Blennow, A.; Herburger, K.; Zhong, Y.Y.; Wen, X.X.; Liu, Y.; Liao, Y.C. Effects of supplemental irrigation on winter wheat starch structure and properties under ridge-furrow tillage and flat tillage. Carbohydr. Polym. 2021, 270, 118310. [Google Scholar] [CrossRef]

- Xu, A.H.; Lin, L.S.; Guo, K.; Liu, T.X.; Yin, Z.T.; Wei, C.X. Physicochemical properties of starches from vitreous and floury endosperms from the same maize kernels. Food Chem. 2019, 291, 149–156. [Google Scholar] [CrossRef]

- Zou, J.; Xu, M.J.; Tang, W.; Wen, L.R.; Yang, B. Modification of structural, physicochemical and digestive properties of normal maize starch by thermal treatment. Food Chem. 2020, 309, 125733. [Google Scholar] [CrossRef]

- Fiedorowicz, M.; Rebilas, K. Physicochemical properties of waxy corn starch and corn amylopection illuminated with lin-early polarised visible light. Carbohydr. Polym. 2002, 50, 315–319. [Google Scholar] [CrossRef]

- Wang, Z.T.; Qu, L.L.; Li, J.; Niu, S.D.; Guo, J.; Lu, D.L. Effects of exogenous salicylic acid on starch physicochemical properties and in vitro digestion under heat stress during the grain-filling stage in waxy maize. Int. J. Biol. Macromol. 2024, 254, 127765. [Google Scholar] [CrossRef] [PubMed]

- Xiong, R.Y.; Tan, X.M.; Yang, T.Y.; Pan, X.H.; Zeng, Y.J.; Huang, S.; Shang, Q.Y.; Zhang, J.; Zeng, Y.H. Relation of cooked rice texture to starch structure and physicochemical properties under different nitrogen managements. Carbohydr. Polym. 2022, 295, 119882. [Google Scholar] [CrossRef]

- Xu, L.; Shi, Y.X.; Xi, S.L.; Yu, A.H.; Lu, B.S.; Zhao, J.R. Breeding of a new type of fresh maize and its representative variety JKN 768. Plant Genet. Resour. 2023, 24, 317–324. [Google Scholar]

- Chen, L.; Xie, H.; Wang, G.L.; Yuan, L.M.; Qian, X.Q.; Wang, W.L.; Xu, Y.J.; Zhang, W.Z.; Zhang, H.; Liu, L.J.; et al. Reducing environmental risk by improving crop management practices at high crop yield levels. Field Crop Res. 2021, 265, 10812. [Google Scholar] [CrossRef]

- Zhang, M.; Yao, Y.L.; Tian, Y.H.; Ceng, K.; Zhao, M.; Zhao, M.; Yin, B. Increasing yield and N use efficiency with organic fertilizer in Chinese intensive rice cropping systems. Field Crop Res. 2018, 227, 102–109. [Google Scholar] [CrossRef]

- Tao, J.C.; Wan, C.X.; Leng, J.J.; Dai, S.R.; Wu, Y.X.; Lei, X.H.; Wang, J.L.; Yang, Q.H.; Wang, P.K.; Gao, J.F. Effects of biochar coupled with chemical and organic fertilizer application on physicochemical properties and in vitro digestibility of common buckwheat (Fagopyrum esculentum Moench) starch. Int. J. Biol. Macromol. 2023, 246, 125591. [Google Scholar] [CrossRef]

- Nitika; Punia, D.; Khetarpaul, N. Physico-chemical characteristics, nutrient composition and consumer acceptability of wheat varieties grown under organic and inorganic farming conditions. Int. J. Food Sci. Nutr. 2008, 59, 224–245. [Google Scholar] [CrossRef]

- Gelaye, Y. Effect of combined application of organic manure and nitrogen fertilizer rates on yield and yield components of potato: A review. Cogent Food Agric. 2023, 9, 2217603. [Google Scholar] [CrossRef]

- Chen, J.W.; Chen, Y.; Watson-Lazowski, A.; Hawkins, E.; Barclay, J.E.; Fahy, B.; Bowers, R.D.; Corbin, K.; Warren, F.J.; Blennow, A.; et al. Wheat myosinresembling chiloroplast protein controls B-type starch granule initiation timing during endosperm development. Plant Physiol. 2024, 196, 1980–1996. [Google Scholar] [CrossRef]

- Guo, K.; Lin, L.S.; Li, E.; Zhong, Y.Y.; Petersen, B.L.; Blennow, A.; Bian, X.F.; Wei, C.X. Effects of growth temperature on multi-scale structure of root tuber starch in sweet potato. Carbohydr. Polym. 2022, 298, 120136. [Google Scholar] [CrossRef]

- Duan, W.X.; Zhang, H.Y.; Xie, B.T.; Wang, B.Q.; Zhang, L.M. Impacts of nitrogen fertilization rate on the root yield, starch yield and starch physicochemical properties of the sweet potato cultivar Jishu 25. PLoS ONE 2019, 14, e0221351. [Google Scholar] [CrossRef]

- Warren, F.J.; Gidley, M.J.; Flanagan, B.M. Infrared spectroscopy as a tool to characterise starch ordered structure-A joint FTIR-ATR, NMR, XRD and DSC study. Carbohydr. Polym. 2016, 139, 35–42. [Google Scholar] [CrossRef]

- Wang, M.; Sun, M.Q.; Zhang, Y.Y.; Chen, Y.; Wu, Y.W.; Yang, J. Effect of microwave irradiation-retrogradation treatment on the digestive and physicochemical properties of starches with different crystallinity. Food Chem. 2019, 298, 125015. [Google Scholar] [CrossRef] [PubMed]

- Kaur, L.; Singh, J.; McCarthy, O.J.; Singh, H. Physico-chemical, rheological and structural properties of fractionated potato starches. J. Food Eng. 2007, 82, 383–394. [Google Scholar] [CrossRef]

- Zhu, D.W.; Zhang, H.C.; Guo, B.W.; Xu, K.; Dai, Q.G.; Wei, C.X.; Zhou, G.S.; Huo, Z.Y. Effects of nitrogen level on structure and physicochemical properties of rice starch. Food Hydrocoll. 2017, 63, 525–532. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Shen, Q.; Yang, Y.; Zhang, F.; Wang, C.; Liu, Z.Y.; Zhao, Q.Y.; Wang, X.R.; Diao, X.M.; Cheng, R.H. Structural, functional and mechanistic insights uncover the role of starch in foxtail millet cultivars with different congee-making quality. Int. J. Biol. Macromol. 2023, 242, 125107. [Google Scholar] [CrossRef] [PubMed]

- Zhu, D.W.; Zhang, H.C.; Guo, B.W.; Xu, K.; Dai, Q.G.; Wei, C.X.; Wei, H.Y.; Gao, H.; Hu, Y.J.; Cui, P.Y.; et al. Effect of nitrogen management on the structure and physicochemical properties of rice starch. J. Agric. Food Chem. 2016, 64, 8019–8025. [Google Scholar] [CrossRef]

- Zhang, W.L.; Yang, Q.H.; Xia, M.J.; Bai, W.M.; Wang, P.K.; Gao, X.L.; Li, J.; Feng, B.L.; Gao, J.F. Effects of nitrogen level on the physicochemical properties of Tartary buckwheat (Fagopyrum tataricum (L.) Gaertn.) starch. Int. J. Biol. Macromol. 2019, 129, 799–808. [Google Scholar] [CrossRef]

- Singh, S.; Singh, N.; Isono, N.; Noda, T. Relationship of granule size distribution and amylopection structure with pasting, thermal, and retrogradation properties in wheat starch. J. Agric. Food Chem. 2010, 58, 1180–1188. [Google Scholar] [CrossRef]

- Miao, M.; Hamake, B.R. Food matrix effects for modulating starch bioavailability. Annu. Rev. Food Sci. Technol. 2021, 12, 169–191. [Google Scholar] [CrossRef] [PubMed]

- Qiao, D.L.; Tu, W.Y.; Zhang, B.J.; Wang, R.; Li, N.N.; Nishinari, K.; Riffat, S.; Jiang, F.T. Understanding the multi-scale structure and digestion rate of water chestnut starch. Food Hydrocoll. 2019, 91, 311–318. [Google Scholar] [CrossRef]

- Li, N.N.; Cai, Z.X.; Guo, Y.; Xu, T.; Qiao, D.L.; Zhang, B.J.; Zhao, S.M.; Huang, Q.L.; Niu, M.; Jia, C.H.; et al. Hierarchical structure and slowly digestible features of rice starch following microwave cooking with storage. Food Chem. 2019, 295, 475–483. [Google Scholar] [CrossRef] [PubMed]

- Fuentes-Zaragoza, E.; Riquelme-Navarrete, M.J.; Sánchez-Zapata, E.; Pérez-Álvarez, J.A. Resistant starch as functional ingredient: A review. Food Res. Int. 2010, 43, 931–942. [Google Scholar] [CrossRef]

- Miao, M.; Zhang, T.; Mu, W.M.; Jiang, B. Effect of controlled gelatinization in excess water on digestibility of waxy maize starch. Food Chem. 2010, 119, 41–48. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).