Design and Analysis of a Sowing Depth Detection and Control Device for a Wheat Row Planter Based on Fuzzy PID and Multi-Sensor Fusion

Abstract

1. Introduction

2. Material and Methods

2.1. Materials and Test Equipment

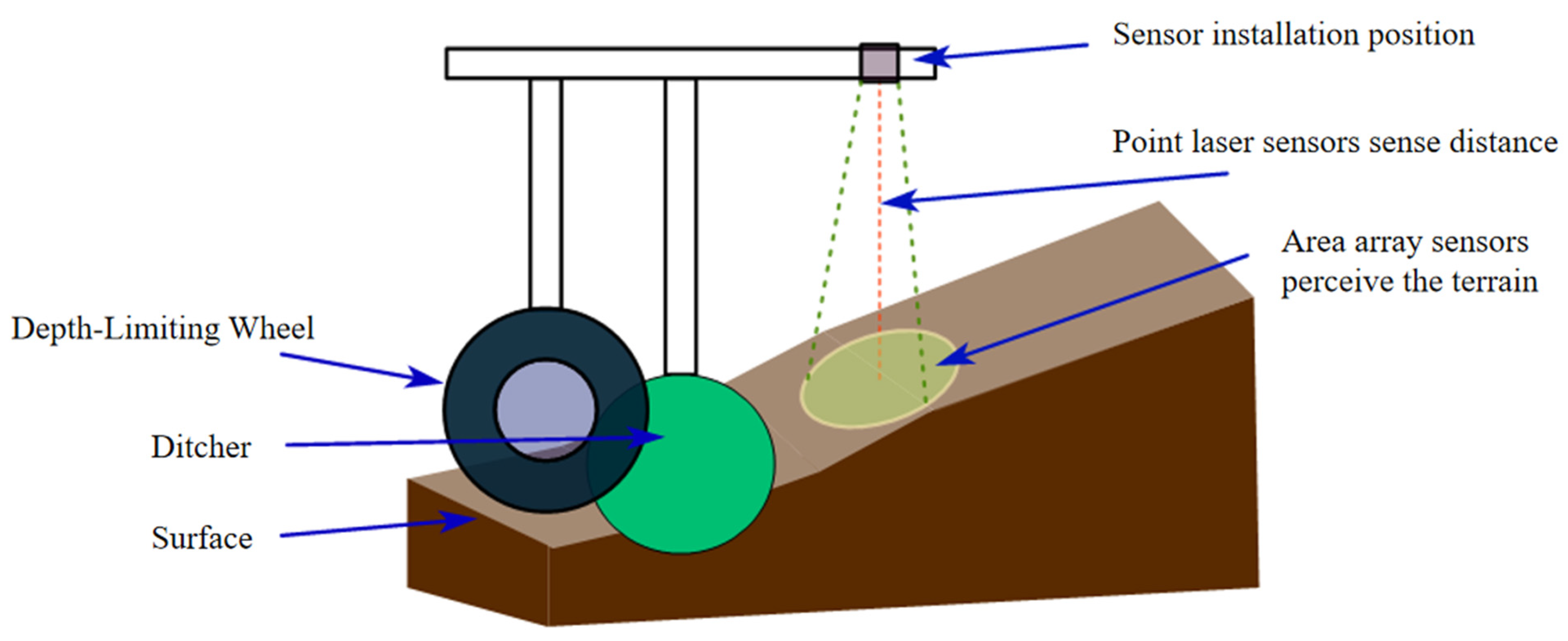

2.1.1. Principle of Sowing Depth Detection

2.1.2. Analysis of the Principle of Traditional PID Control and Its Applicability

2.1.3. PID Controller Parameter Tuning Methods

2.1.4. Fundamentals of Fuzzy Control Theory

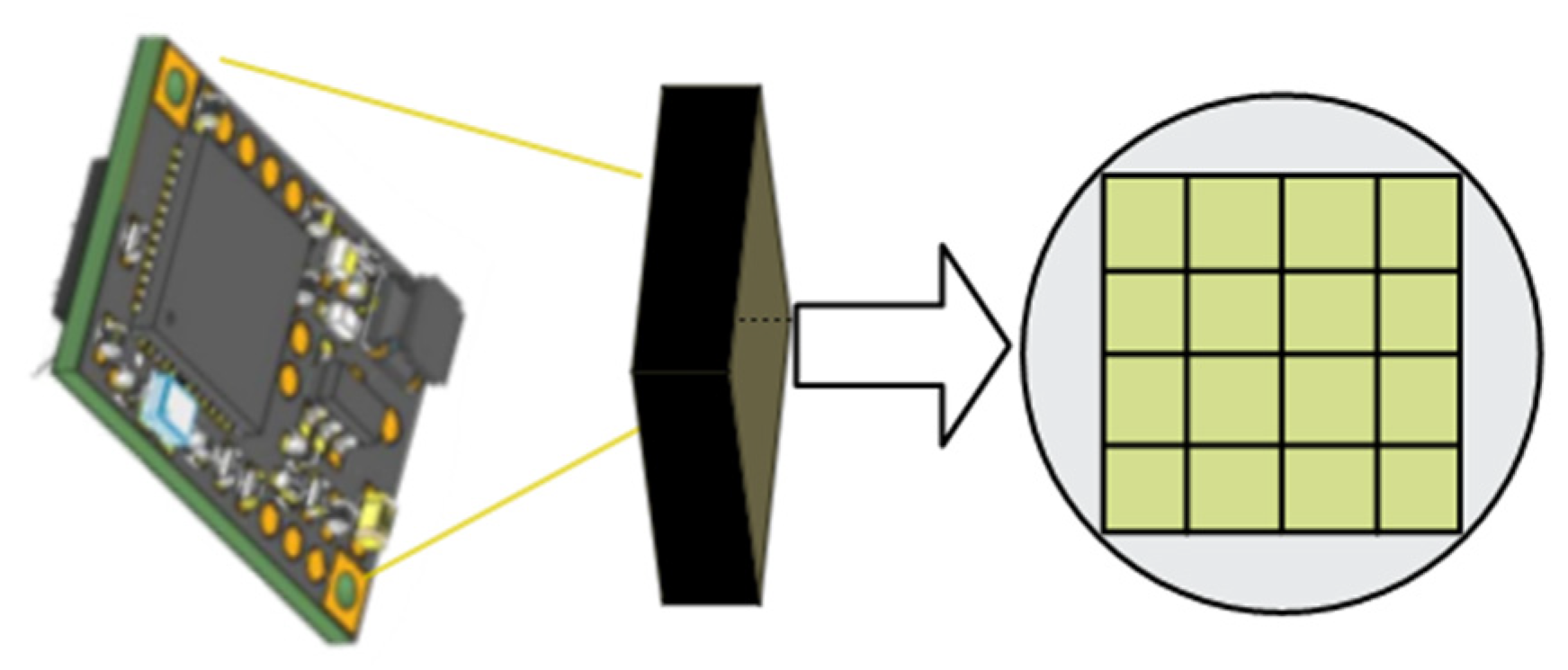

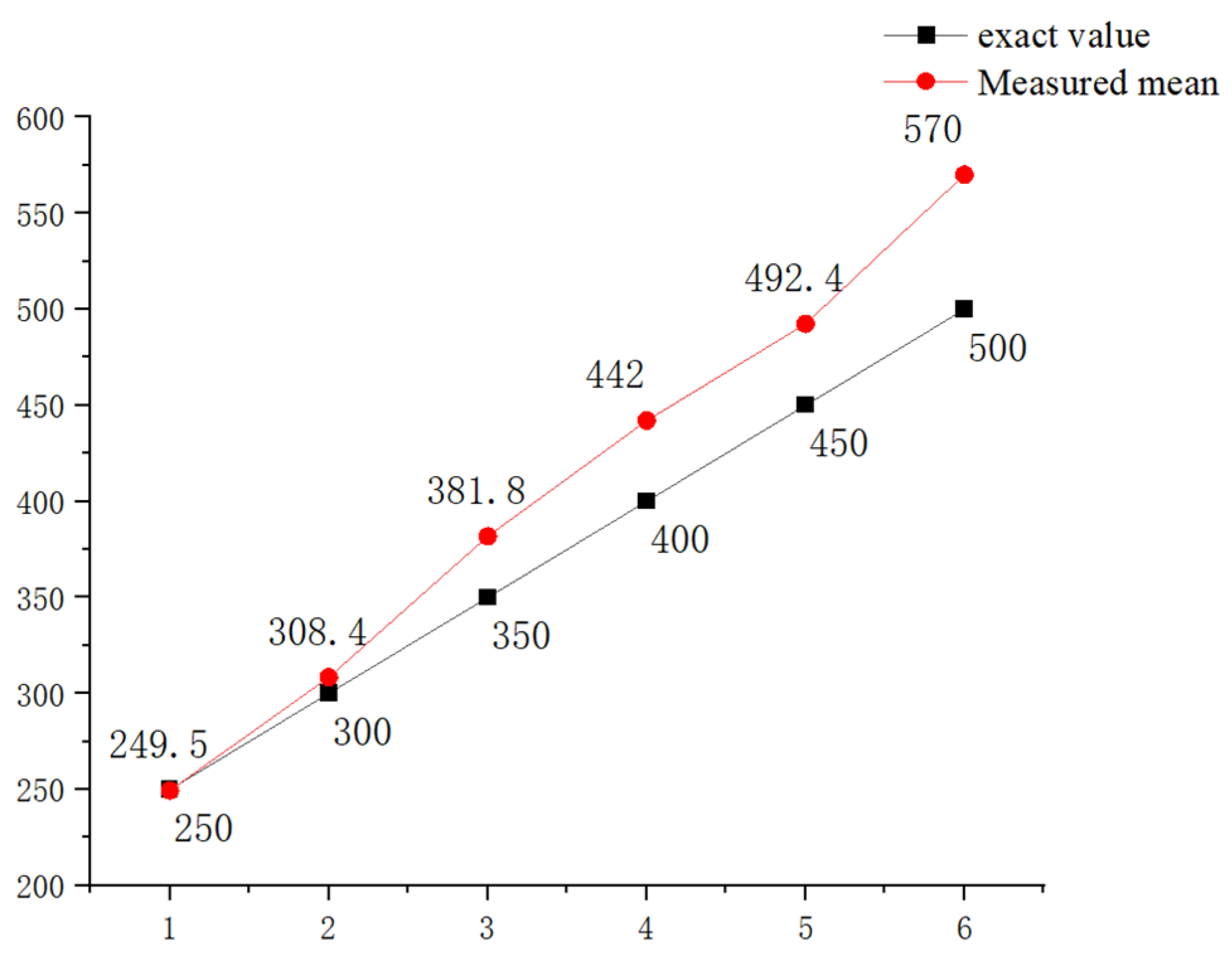

2.1.5. Design, Implementation and Calibration of Sensor Module

2.1.6. Depth-Limiting Mechanism and Stepper Motor Control System

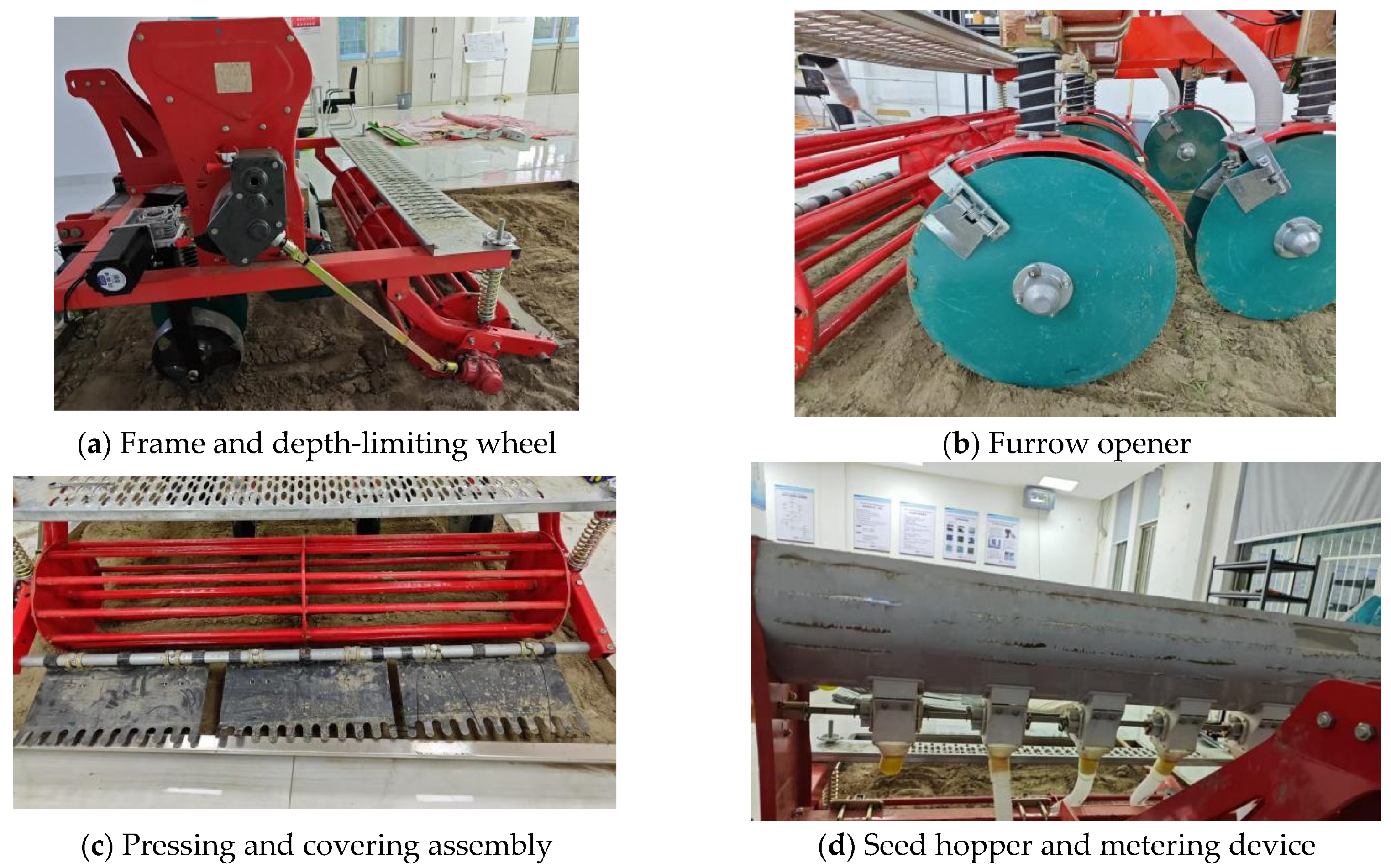

2.1.7. Overall Structure and Integration of the Sowing Machine

2.2. Test Method

2.2.1. Software Architecture of the System

2.2.2. Data Acquisition and Preprocessing

2.2.3. Sowing Depth Error Calculation and Data Fusion

2.2.4. Design of the Fuzzy PID Control Algorithm

- (1)

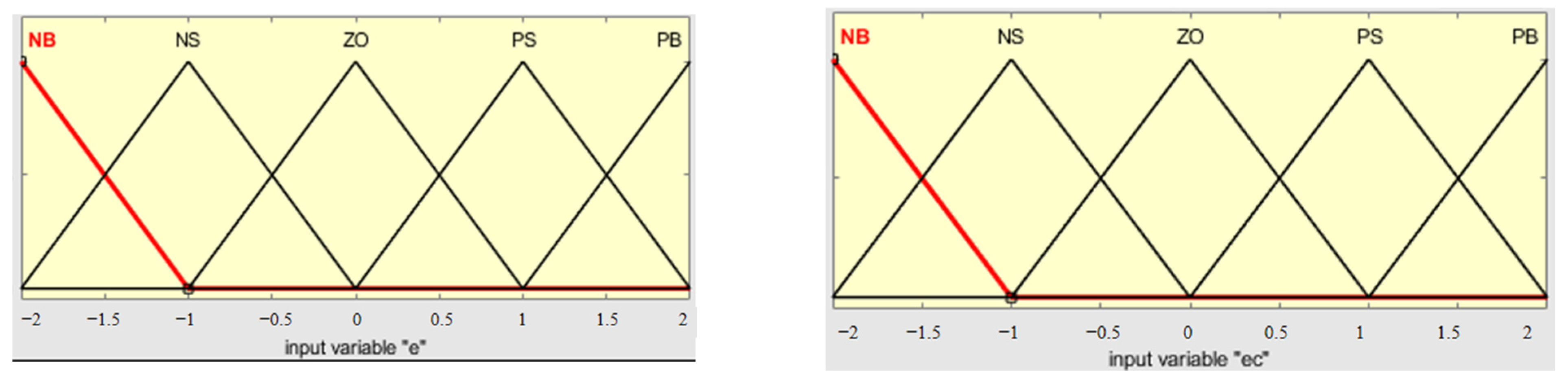

- In the design of the fuzzy controller, the quantization range for the error e and the error rate ec is set within [−2,2], and this continuous interval is discretized to obtain a discrete set [42,43]. The input linguistic variables include e and ec, while the output variables are the PID parameter adjustment quantities ΔKp, ΔKi, and ΔKd. Their basic universes of discourse and quantized domains are shown in Table 4 [44,45].

- (2)

- This design adopts triangular membership functions. By adjusting the parameters of the triangular membership functions, different input quantities can be precisely classified into corresponding fuzzy subsets. The triangular function is widely used in engineering applications. The shape of the membership functions is shown in the corresponding Figure 10.

- (3)

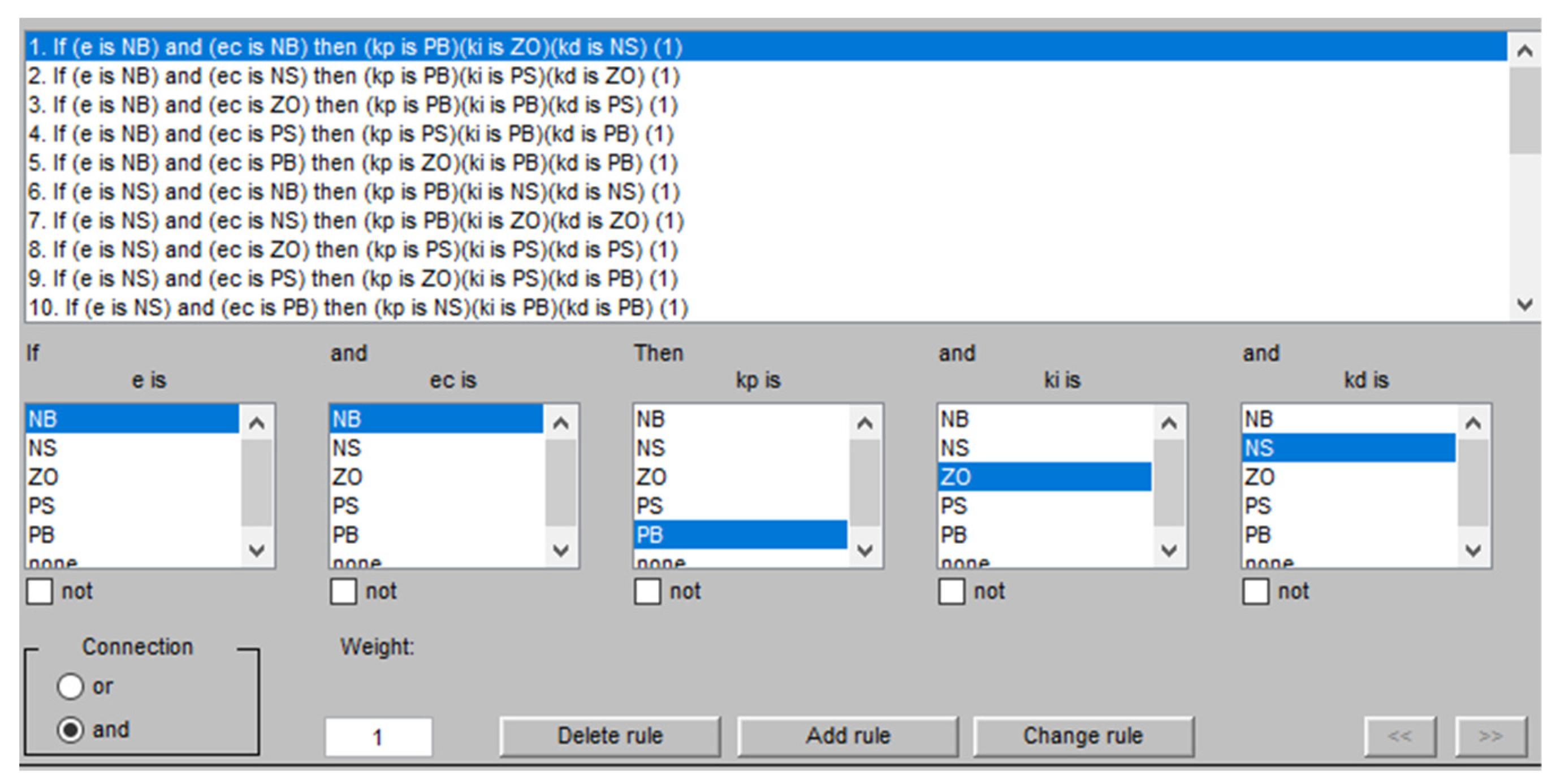

- This study adopts the Mamdani-type fuzzy inference system and constructs a fuzzy controller with two inputs and one output. The input variables are sowing depth error e and error rate ec, and the output variable U corresponds to the online adjustment increments of the PID controller parameters. All three variables are divided into seven membership subsets: NB (negative big), NM (negative medium), NS (negative small), ZO (zero), PS (positive small), PM (positive medium), and PB (positive big). During each control cycle, the system continuously acquires real-time error e and error rate ec, and based on the pre-defined rule base in the form of “IF e is A AND ec is B THEN U is C”; fuzzy inference is applied to generate the corresponding control adjustment output. Although the rules are summarized from observations and empirical experience of sowing depth control effects, their core still follows the classic PID tuning principles, with modifications based on actual control needs.

- (4)

- In the sowing depth PID controller, the parameter self-tuning formulas are given as follows:

3. Results and Discussion

3.1. MATLAB/Simulink Simulation and System Verification

3.1.1. Simulation Model Construction and Parameter Settings

- (1)

- Reference Input Module: This defines the target value of the sowing depth to simulate the actual sowing depth setpoint.

- (2)

- Disturbance Module: This uses a combination of constant and sine wave signals to simulate different terrain conditions, such as flat ground, gentle slopes, and wavy undulations.

- (3)

- Error Calculation Module: This calculates the real-time error e between the setpoint and detected sowing depth and computes the error rate ec using a difference method.

- (4)

- Controller Module:

- (5)

- Controlled Object Module: The model of depth-limiting wheel height variation is represented using a transfer function or state-space form, reflecting the dynamic characteristics of the sowing machine.

- (6)

- Output Module: This captures simulation outputs such as sowing depth response curves and error curves for evaluating system performance [49].

3.1.2. Simulation Testing Under Different Terrain Conditions

3.1.3. Comparative Analysis of Simulation Results

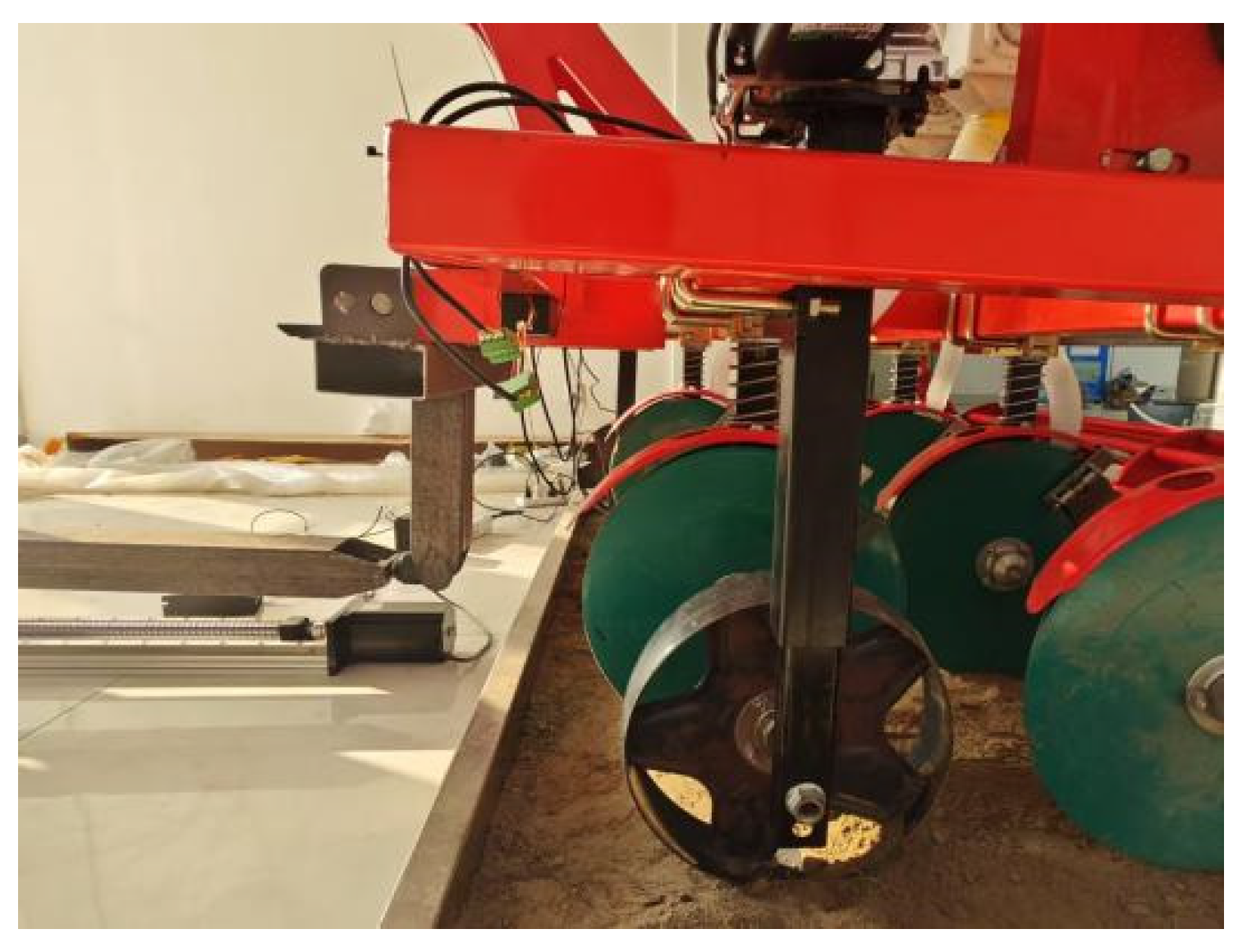

3.2. Construction Verification of the Test Platform and Data Analysis

3.2.1. Experimental Platform Overview

- (1)

- Multi-Row Sowing Machine Body:

- (2)

- Replaceable Terrain Soil Trough:

- (3)

- Horizontal Drive Unit:

- (4)

- Connection Structure Between Frame and Slide:

- (5)

- Depth-Limiting Adjustment Module:

- (6)

- Sensor System:

- (7)

- Control System:

3.2.2. Experimental Plan and Terrain Conditions

- (1)

- Flat terrain: The test bed surface is kept level to verify the system’s steady-state response and sowing depth control accuracy in the absence of external disturbances.

- (2)

- Gentle slope: A linear inclined surface is set on one side of the platform to simulate a gradual ascent or descent, assessing the controller’s ability to track continuous slope changes during operation.

- (3)

- Localized undulation: Uneven terrain modules of varying height are randomly placed on the platform to simulate irregular soil clumps or straw residue, testing the system’s response to sudden terrain disturbances.

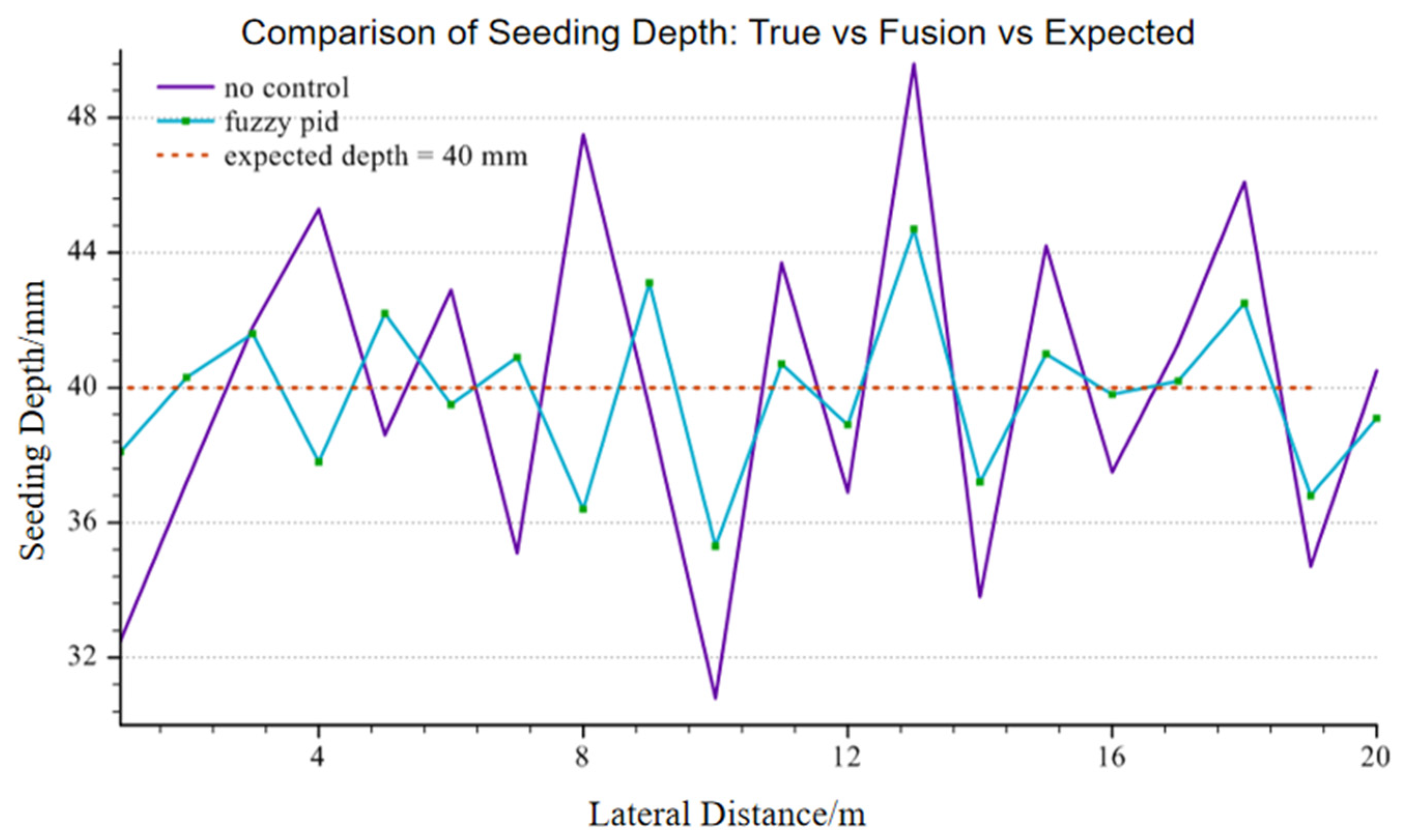

3.2.3. Data Acquisition and Analysis

3.3. Discussion

4. Conclusions

- (1)

- Multi-Sensor Fusion Model Construction

- (2)

- Fuzzy PID-Based Online Adjustment Control Strategy Design

- (3)

- Dual-Level Experimental Verification Platform Establishment and Application

- (4)

- Future Research and Engineering Expansion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nielsen, S.K.; Munkholm, L.J.; Lamande, M.; Norremark, M.; Skou-Nielsen, N.; Edwards, G.T.C.; Green, O. Seed Drill Instrumentation for Spatial Coulter Depth Measurements. Comput. Electron. Agric. 2017, 141, 207–214. [Google Scholar] [CrossRef]

- Romaneckas, K.; Steponavicius, D.; Jasinskas, A.; Kazlauskas, M.; Naujokiene, V.; Bruciene, I.; Svereikaite, A.; Sarauskis, E. How to Analyze, Detect and Adjust Variable Seedbed Depth in Site-Specific Sowing Systems: A Case Study. Agronomy 2022, 12, 1092. [Google Scholar] [CrossRef]

- Studhalter, M.; Janovicek, K.; Kim, J.; Byker, H.; Mountain, N.; Nasielski, J. Row Spacing, Seeding Depth, Seeding Rate, and Trinexapac-Ethyl Effects on Oat Yield and Lodging. Crop Sci. 2023, 63, 2509–2523. [Google Scholar] [CrossRef]

- Kong, L.; Sun, M.; Wang, F. Effects of Seeding Depth on Subcrown Internode Elongation and Grain Yield in Wheat. Pakistan J. Agric. Sci. 2016, 53, 625–632. [Google Scholar]

- Wang, Q.; Xu, Q.; Lu, C.; Li, H.; He, J.; Wang, Q. Research Status and Development of Key Technologies for No-Tillage Seeding Intellectualization. J. S. China Agric. Univ. 2021, 42, 27–35. [Google Scholar]

- Bai, H.; Fang, X.; Wang, D.; Yuan, Y.; Zhou, L.; Niu, K. Design and Test of Control System for Seeding Depth and Compaction of Corn Precision Planter. Trans. Chin. Soc. Agric. Mach. 2020, 51, 61–72. [Google Scholar]

- Mapoka, K.O.M.; Birrell, S.J.; Tekeste, M. A Comprehensive Survey of Nondestructive Sensing Technologies for the Detection of Corn Seeds in a Closed Trench and Measuring Planting Depth to Augment the Conventional Method. Comput. Electron. Agric. 2019, 158, 249–257. [Google Scholar] [CrossRef]

- Lee, J.; Yamazaki, M.; Oida, O.; Nakashima, H.; Shimizu, H. Electro-Hydraulic Tillage Depth Control System for Rotary Implements Mounted on Agricultural Tractor Design and Response Experiments of Control System. Terramechanics 1998, 35, 229–238. [Google Scholar] [CrossRef]

- Suomi, P.; Oksanen, T. Automatic Working Depth Control for Seed Drill Using Iso 11783 Remote Control Messages. Comput. Electron. Agric. 2015, 116, 30–35. [Google Scholar] [CrossRef]

- Nielsen, S.K.; Nørremark, M.; Green, O. Sensor and Control for Consistent Seed Drill Coulter Depth. Comput. Electron. Agric. 2016, 127, 690–698. [Google Scholar] [CrossRef]

- Zhao, J.L.; Zhu, L.T.; Jia, H.L.; Huang, D.Y.; Guo, M.Z.; Cong, Y.J. Automatic Depth Control System for a No-Till Seeder. Int. J. Agric. Biol. Eng. 2018, 11, 115–121. [Google Scholar] [CrossRef]

- Morales, Y.; Tsubouchi, T.; Yuta, S. Vehicle Localization in Outdoor Mountainous Forested Paths and Extension of Two-Dimensional Road Centerline Maps to Three-Dimensional Maps. Adv. Robot. 2010, 24, 489–513. [Google Scholar] [CrossRef]

- Zhang, S. Application of Fuzzy Pid Control in Motor Test. In Proceedings of the 2nd International Conference on Computer Engineering, Information Science and Application Technology (Iccia), Wuhan, China, 8–9 July 2017. [Google Scholar]

- Phu Nguyen, D.; Hung Nguyen, N.; Ahmadian, A.; Senu, N. A New Fuzzy Pid Control System Based on Fuzzy Pid Controller and Fuzzy Control Process. Int. J. Fuzzy Syst. 2020, 22, 2163–2187. [Google Scholar]

- Ma, F. An Improved Fuzzy Pid Control Algorithm Applied in Liquid Mixing System. In Proceedings of the IEEE International Conference on Information and Automation (Icia), Hailar, China, 28–30 July 2014. [Google Scholar]

- Simon, J. Fuzzy Control of Self-Balancing, Two-Wheel-Driven, SLAM-Based, Unmanned System for Agriculture 4.0 Applications. Machines 2023, 11, 467. [Google Scholar] [CrossRef]

- Wrat, G.; Bhola, M.; Ranjan, P.; Mishra, S.K.; Das, J. Energy saving and Fuzzy-PID position control of electro-hydraulic system by leakage compensation through proportional flow control valve. ISA Trans. 2020, 101, 269–280. [Google Scholar] [CrossRef]

- Liu, W.; Ma, B.; Chen, X.; Yu, C.; Jing, T.; Huang, L. Design of a Single Sowing Depth Measurement System for an Air Suction Corn Planter. Eng. Agric. 2022, 42, e20210173. [Google Scholar]

- Valente, M.; Joly, C.; De La Fortelle, A. Deep Sensor Fusion for Real-Time Odometry Estimation. In Proceedings of the 2019 Ieee/Rsj International Conference on Intelligent Robots and Systems (Iros), Macau, China, 3–8 November 2019; pp. 6679–6685. [Google Scholar]

- Zhao, S.; Zhang, Y. Design and Field Test of Corn Seeding System Base on Fuzzy Pid Control Method Combine with Pso. Eng. Agric. 2024, 44, e20230123. [Google Scholar] [CrossRef]

- Liu, W.; Ma, B.; Ma, L.; Chen, X.; Yu, C.; Huang, L.; Li, H. Application of Kalman Filter Combined with Genetic Pid Control Algorithm in Improving Seeding Accuracy. J. Anhui Agric. Univ. 2021, 48, 674–679. [Google Scholar]

- Liu, C.; Zhao, J.; Gu, J.; Du, Y.; Li, Z.; Zhu, Z.; Mao, E. Pressure Control Algorithm Based on Adaptive Fuzzy Pid with Compensation Correction for the Tractor Electronic Hydraulic Hitch. Appl. Sci. 2020, 10, e20230123. [Google Scholar] [CrossRef]

- Tang, B.Y.; Da, X.L.; Wang, W.J. An Adaptive Control Method for Time-Varying Systems. Eur. J. Oper. Res. 2000, 124, 342–352. [Google Scholar] [CrossRef]

- Chen, J.; Ning, X.; Li, Y.; Yang, G.; Wu, P.; Chen, S. A Fuzzy Control Strategy for the Forward Speed of a Combine Harvester Based on Kdd. Appl. Eng. Agric. 2017, 33, 15–22. [Google Scholar]

- Liu, H.; Yan, S.; Shen, Y.; Li, C.; Zhang, Y.; Hussain, F. Model Predictive Control System Based on Direct Yaw Moment Control for 4Wid Self-Steering Agriculture Vehicle. Int. J. Agric. Biol. Eng. 2021, 14, 175–181. [Google Scholar] [CrossRef]

- Song, X.; Li, H.; Chen, C.; Xia, H.; Zhang, Z.; Tang, P. Design and Experimental Testing of a Control System for a Solid-Fertilizer-Dissolving Device Based on Fuzzy Pid. Agriculture 2022, 12, 1382. [Google Scholar] [CrossRef]

- Ahmad, F.; Adeel, M.; Qiu, B.; Ma, J.; Shoaib, M.; Shakoor, A.; Chandio, F.A. Sowing Uniformity of Bed-Type Pneumatic Maize Planter at Various Seedbed Preparation Levels and Machine Travel Speeds. Int. J. Agric. Biol. Eng. 2021, 14, 165–171. [Google Scholar] [CrossRef]

- Yan, T.; Zhu, H.; Sun, L.; Wang, X.; Ling, P. Investigation of an Experimental Laser Sensor-Guided Spray Control System for Greenhouse Variable-Rate Applications. Trans. Asabe 2019, 62, 899–911. [Google Scholar] [CrossRef]

- Zhu, X.; Chikangaise, P.; Shi, W.; Chen, W.-H.; Yuan, S. Review of Intelligent Sprinkler Irrigation Technologies for Remote Autonomous System. Int. J. Agric. Biol. Eng. 2018, 11, 23–30. [Google Scholar] [CrossRef]

- Li, Y.; Qi, B.; Bao, E.; Tang, Z.; Lian, Y.; Sun, M. Design and Analysis of Sowing Depth Detection and Control Device for Multi-Row Wheat Seeders Adapted to Different Terrain Variations. Agriculture 2025, 15, 290. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, Z.; Li, Y.; Guan, Z.; Tang, X. Research on Following Suction and Discharging Motion Control Method of Vacuum-Vibration Precision Seeding Manipulator. Appl. Eng. Agric. 2022, 38, 873–883. [Google Scholar] [CrossRef]

- Hu, J.; Zhao, X.; Liu, W.; Yao, M.; Zhao, J. Development of a Seeding Control Method Based on Seed Height in the Hopper of a Precision Wheat Drill. Appl. Eng. Agric. 2021, 37, 1131–1138. [Google Scholar] [CrossRef]

- Yang, S.; Zhai, C.; Gao, Y.; Dou, H.; Zhao, X.; He, Y.; Wang, X. Planting Uniformity Performance of Motor-Driven Maize Precision Seeding Systems. Int. J. Agric. Biol. Eng. 2022, 15, 101–108. [Google Scholar] [CrossRef]

- Cheema, M.J.M.; Nauman, M.; Ghafoor, A.; Farooque, A.A.; Haydar, Z.; Ashraf, M.U.; Awais, M. Direct Seeding of Basmati Rice Through Improved Drills: Potential and Constraints in Pakistani Farm Settings. Appl. Eng. Agric. 2021, 37, 53–63. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, C.; Li, H.; Xia, H. Design and Evaluation of a Control System for the Fertigation Device. J. Asabe 2022, 65, 1293–1302. [Google Scholar] [CrossRef]

- Huang, X.-Y.; Pan, S.-H.; Sun, Z.-Y.; Ye, W.-T.; Aheto, J.H. Evaluating Quality of tomato During Storage Using Fusion Information of Computer Vision and Electronic Nose. J. Food Process Eng. 2018, 41, e12832. [Google Scholar] [CrossRef]

- Khulal, U.; Zhao, J.; Hu, W.; Chen, Q. Nondestructive Quantifying total Volatile Basic Nitrogen (Tvb-N) Content in Chicken Using Hyperspectral Imaging (Hsi) Technique Combined with Different Data Dimension Reduction Algorithms. Food Chem. 2016, 197, 1191–1199. [Google Scholar] [CrossRef]

- Huang, X.; Wang, W.; Li, Z.; Wang, Q.; Zhu, C.; Chen, L. Design Method and Experiment of Machinery for Combination of Seed Fertilizer and Herbicide. Int. J. Agric. Biol. Eng. 2019, 12, 63–71. [Google Scholar]

- Yao, K.; Sun, J.; Tang, N.; Xu, M.; Cao, Y.; Fu, L.; Zhou, X.; Wu, X. Nondestructive Detection for Panax Notoginseng Powder Grades Based on Hyperspectral Imaging Technology Combined with Cars-Pca and Mpa-Lssvm. J. Food Process Eng. 2021, 44, e13718. [Google Scholar] [CrossRef]

- Zhang, T.; Wu, X.; Wu, B.; Dai, C.; Fu, H. Rapid Authentication of the Geographical Origin of Milk Using Portable Near-Infrared Spectrometer and Fuzzy Uncorrelated Discriminant Transformation. J. Food Process Eng. 2022, 45, e1404. [Google Scholar] [CrossRef]

- Li, Y.; Cao, Q.; Liu, F. Research on Fuzzy Pid Control of Electronically Controlled Hydraulic Power Steering System for Unmanned Agricultural Vehicle. In Proceedings of the International Conference on High Performance Big Data and Intelligent Systems (Hpbd&Is), Shenzhen, China, 9–11 May 2019. [Google Scholar]

- Li, M.; Wang, L.; Liu, J.; Ye, J. Method Study on Fuzzy-Pid Adaptive Control of Electric-Hydraulic Hitch System. In Proceedings of the International Conference on Advances In Materials, Machinery, Electronics (Amme), Wuhan, China, 25–26 February 2017. [Google Scholar]

- Wang, Q.; Zhou, J.; Hou, J. Irrigation and Fertilizer Control Strategy Based on Variable Domain Fuzzy Pid. J. Northwest A F Univ. Nat. Sci. Ed. 2023, 51, 144–154. [Google Scholar]

- Wang, Y.; Liu, J.; Li, J.; Chen, B.; Li, Q. Using the Smith Pso-Fuzzy Pid Model to Control Electrical Conductivity of Nutrient Solution of Precision Fertilization. J. Irrig. Drain. 2022, 41, 37–44. [Google Scholar]

- Xue, J.; Zhou, L. Design of Fuzzy Pid Control Algorithm Facing to Greenhouse. In Proceedings of the 9th International Conference on Intelligent Human-Machine Systems and Cybernetics (Ihmsc), Hangzhou, China, 26–27 August 2017. [Google Scholar]

- Yu, Y.; Hao, S.; Guo, S.; Tang, Z.; Chen, S. Motor torque Distribution Strategy for Different Tillage Modes of Agricultural Electric Tractors. Agriculture 2022, 12, 1373. [Google Scholar] [CrossRef]

- Tang, Z.; Wang, H.; Jing, T.; Liu, S.; Shen, C. Centroid Swinging Property of a Machine Body Undergoing Longitudinal Excitation in a Straw Compression Baler. Eng. Agric. 2024, 44, e20230109. [Google Scholar] [CrossRef]

- Chen, S.; Qi, J.; Gao, J.; Chen, W.; Fei, J.; Meng, H.; Ma, Z. Research on the Control System for the Conveying and Separation Experimental Platform of Tiger Nut Harvester Based on Sensing Technology and Control Algorithms. Agriculture 2025, 15, 115. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, K.; Ding, R.; Jiang, Y.; Jiang, Y. A Novel Hydraulic Interconnection Design and Sliding Mode Synchronization Control of Leveling System for Crawler Work Machine. Agriculture 2025, 15, 137. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, Z.; Lin, Q.; Zhang, L.; Xu, J. Mbd of Grey Prediction Fuzzy-Pid Irrigation Control Technology. Desalination Water Treat. 2018, 110, 328–336. [Google Scholar] [CrossRef]

- Liu, L.; Wang, X.; Zhang, X.; Cheng, X.; Wei, Z.; Ji, J.; Li, H.; Zhang, H.; Wang, M. Sowing Depth Control Strategy Based on the Downforce Measurement and Control System of ’T’-Shaped Furrow Opener. Biosyst. Eng. 2024, 247, 97–108. [Google Scholar] [CrossRef]

- Zhai, J.; Xia, J.; Zhou, Y.; Zhang, S. Design and Experimental Study of the Control System for Precision Seed-Metering Device. Int. J. Agric. Biol. Eng. 2014, 7, 13–18. [Google Scholar]

| Parameter | Parameter Range | Parameter | Parameter Range |

|---|---|---|---|

| Visual angle FOV | 16° | Weight | 9 g |

| Indoor measuring range | 60 | Accuracy rating | ±10 mm |

| Service voltage | +5 V |

| Parameter | Parameter Range | Parameter | Parameter Range |

|---|---|---|---|

| Service voltage | 4.5–5.5 v | Measuring ranging | 0.07–7.5 m |

| Accuracy rating | ±15 mm | Machine size | 46 × 18 × 20 mm |

| Ranging frequency | 120 Hz |

| Project | Design Value | Project | Design Value |

|---|---|---|---|

| Structual form | Mechanical | Operating speed range | 1.0~1.6 m/s |

| Furrow opener form | Double disc type | Sowing part transmission mode | Shaft drive |

| Machine size | 1820 × 1210 × 1550 mm | Line spacing | 21 cm |

| Working lines | 6 rows | Seed feeder form | Outer grooved wheel type |

| Variable | Physical Domain | Quantized Domain |

|---|---|---|

| e | [−100,100] | [−2,2] |

| ec | [−20,20] | [−2,2] |

| ΔKp | [−20,20] | [−6,6] |

| ΔKi | [−0.4,0.4] | [−6,6] |

| ΔKd | [−0.05,0.05] | [−6,6] |

| ec e | NB | NS | ZO | PS | PB |

|---|---|---|---|---|---|

| NB | PB | PB | PB | PS | ZO |

| NS | PB | PB | PS | ZO | NS |

| ZO | PS | ZO | ZO | ZO | NS |

| PS | NS | ZO | PS | PB | PB |

| PB | NS | NS | ZO | PB | PB |

| ec e | NB | NS | ZO | PS | PB |

|---|---|---|---|---|---|

| NB | ZO | NS | NS | NS | NS |

| NS | PS | ZO | ZO | ZO | ZO |

| ZO | PB | PS | ZO | PS | PS |

| PS | PB | PS | ZO | PB | PB |

| PB | PB | PB | PS | PB | PB |

| ec e | NB | NS | ZO | PS | PB |

|---|---|---|---|---|---|

| NB | NS | NS | NS | NS | NS |

| NS | ZO | ZO | ZO | ZO | ZO |

| ZO | PS | PS | ZO | PS | PS |

| PS | PB | PB | ZO | PB | PB |

| PB | PB | PB | PS | PB | PB |

| Control Strategy | Rise Time Tr (s) | Overshoot Mp (%) | Settling Time Ts (s) | Disturbance Rejection |

|---|---|---|---|---|

| Traditional PID | 0.290 | 44.7 | 3.119 | Weak |

| Fuzzy PID | 0.262 | 32.3 | 1.652 | Strong |

| Terrain Condition | Control Strategy | Average Error (mm) | Standard Deviation (mm) | t-Value | Range of p-Values |

|---|---|---|---|---|---|

| Flat Terrain | None | 5.033 | 2.413 | 2.439 | p < 0.05 |

| Fuzzy PID | 4.496 | 1.607 | |||

| Gentle Slope | None | 6.815 | 2.319 | 3.718 | p < 0.05 |

| Fuzzy PID | 5.255 | 2.201 | |||

| Undulating Terrain | None | 7.110 | 3.099 | 2.023 | p < 0.05 |

| Fuzzy PID | 6.434 | 2.910 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Qi, B.; Bao, E.; Tang, Z.; Lian, Y.; Sun, M. Design and Analysis of a Sowing Depth Detection and Control Device for a Wheat Row Planter Based on Fuzzy PID and Multi-Sensor Fusion. Agronomy 2025, 15, 1490. https://doi.org/10.3390/agronomy15061490

Li Y, Qi B, Bao E, Tang Z, Lian Y, Sun M. Design and Analysis of a Sowing Depth Detection and Control Device for a Wheat Row Planter Based on Fuzzy PID and Multi-Sensor Fusion. Agronomy. 2025; 15(6):1490. https://doi.org/10.3390/agronomy15061490

Chicago/Turabian StyleLi, Yueyue, Bing Qi, Encai Bao, Zhong Tang, Yi Lian, and Meiyan Sun. 2025. "Design and Analysis of a Sowing Depth Detection and Control Device for a Wheat Row Planter Based on Fuzzy PID and Multi-Sensor Fusion" Agronomy 15, no. 6: 1490. https://doi.org/10.3390/agronomy15061490

APA StyleLi, Y., Qi, B., Bao, E., Tang, Z., Lian, Y., & Sun, M. (2025). Design and Analysis of a Sowing Depth Detection and Control Device for a Wheat Row Planter Based on Fuzzy PID and Multi-Sensor Fusion. Agronomy, 15(6), 1490. https://doi.org/10.3390/agronomy15061490