Predicting Minimum Temperatures of Plastic Greenhouse During Strawberry Growing in Changfeng, China: A Comparison of Machine Learning Algorithms and Multiple Linear Regression

Abstract

1. Introduction

2. Materials and Methods

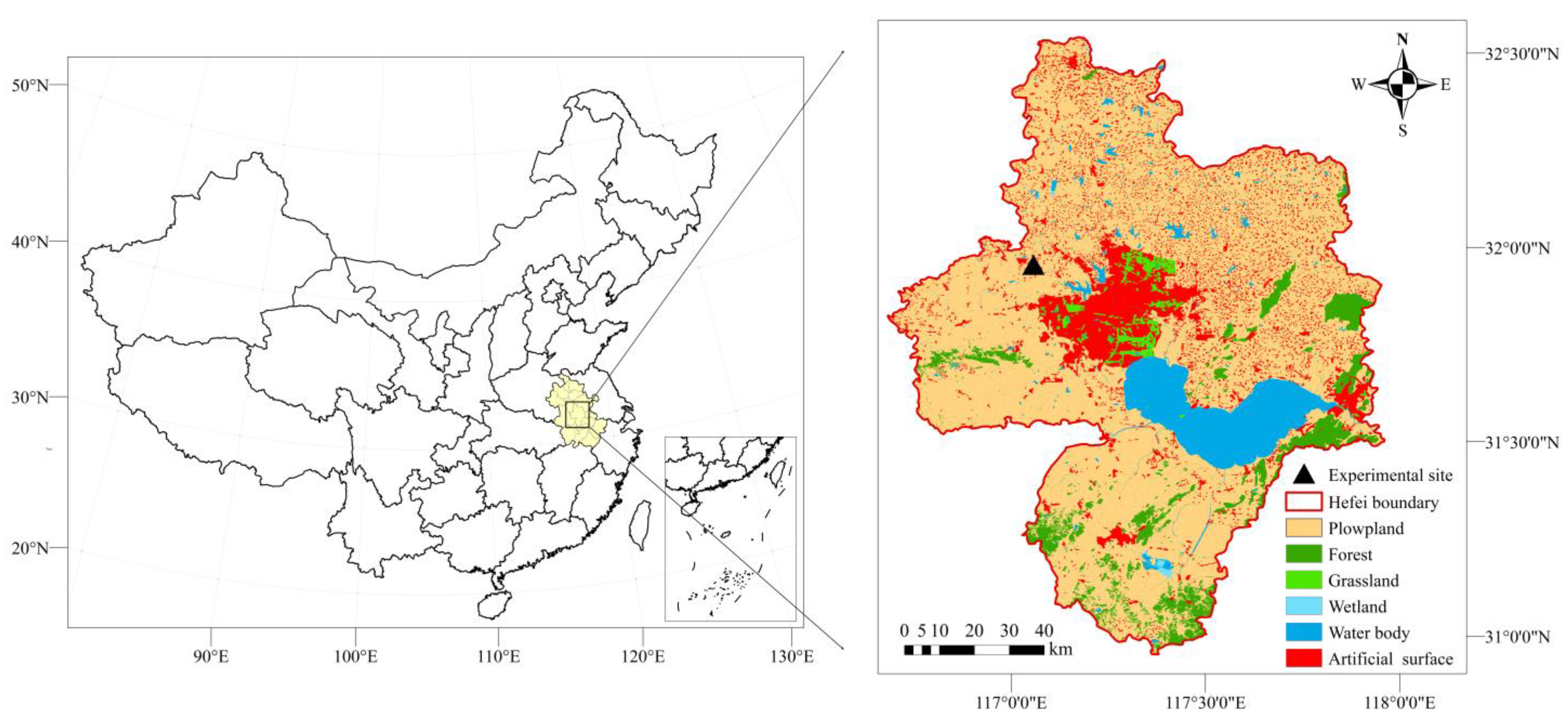

2.1. Study Area

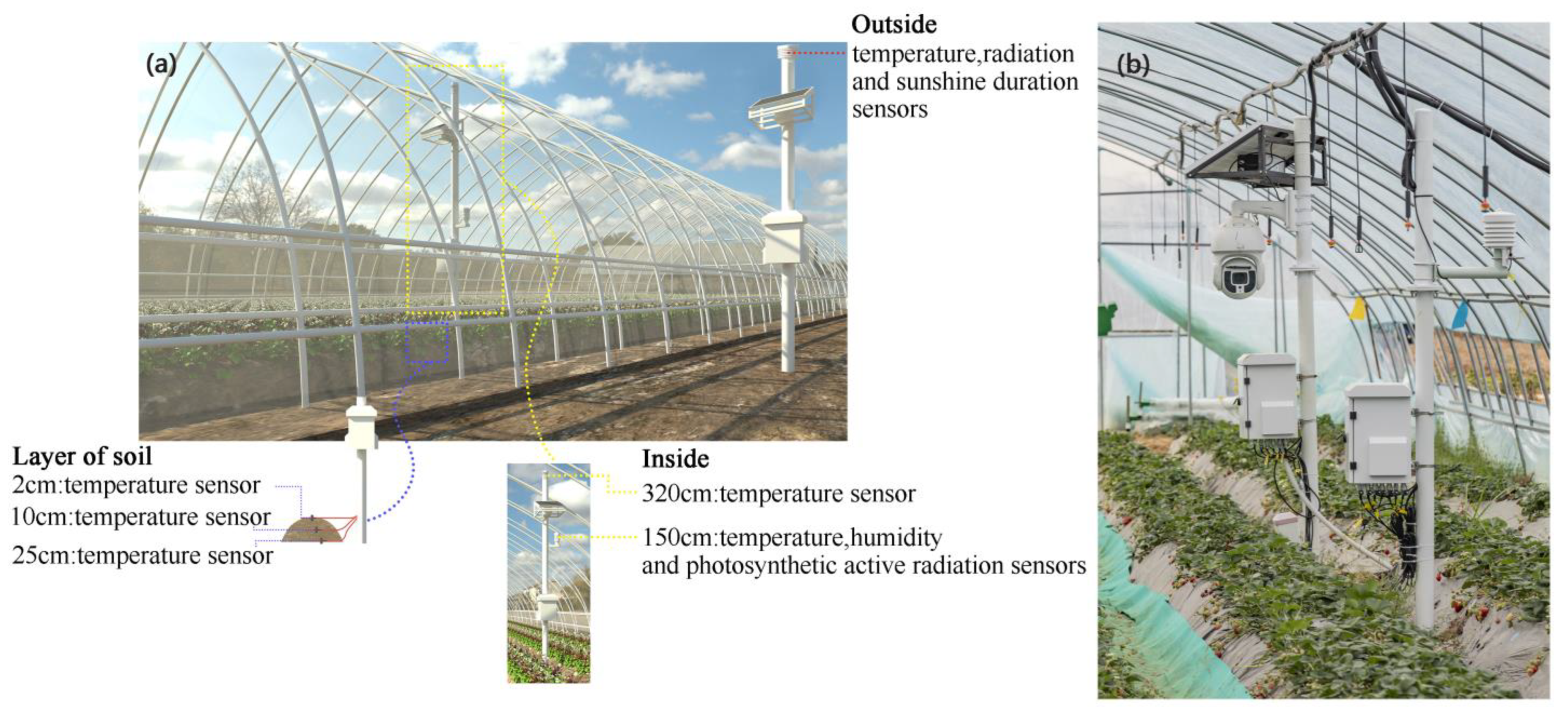

2.2. Data Collection Inside and Outside the Plastic Greenhouse

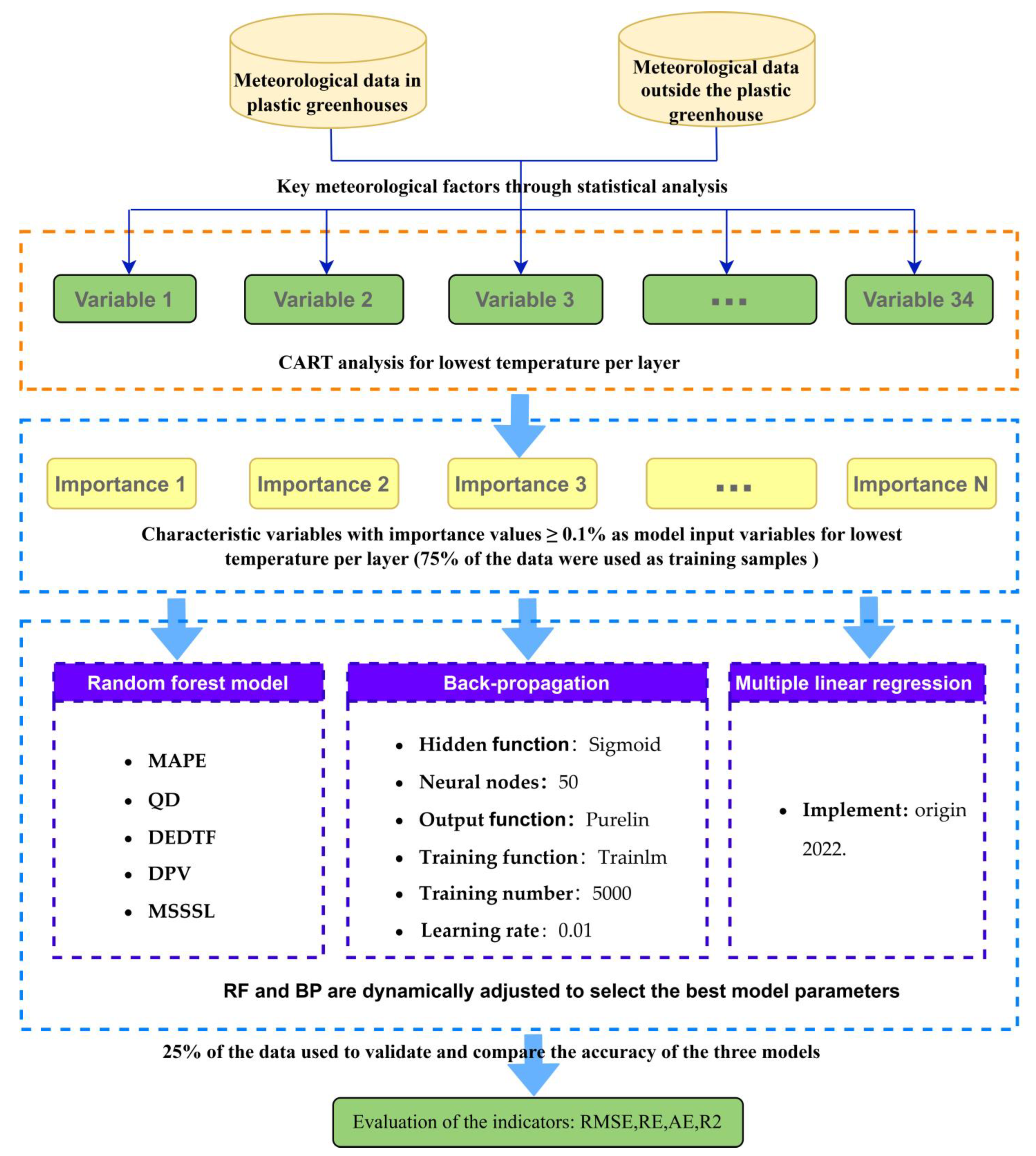

2.3. Predication Models

2.4. Model Accuracy Evaluation Methods

3. Results

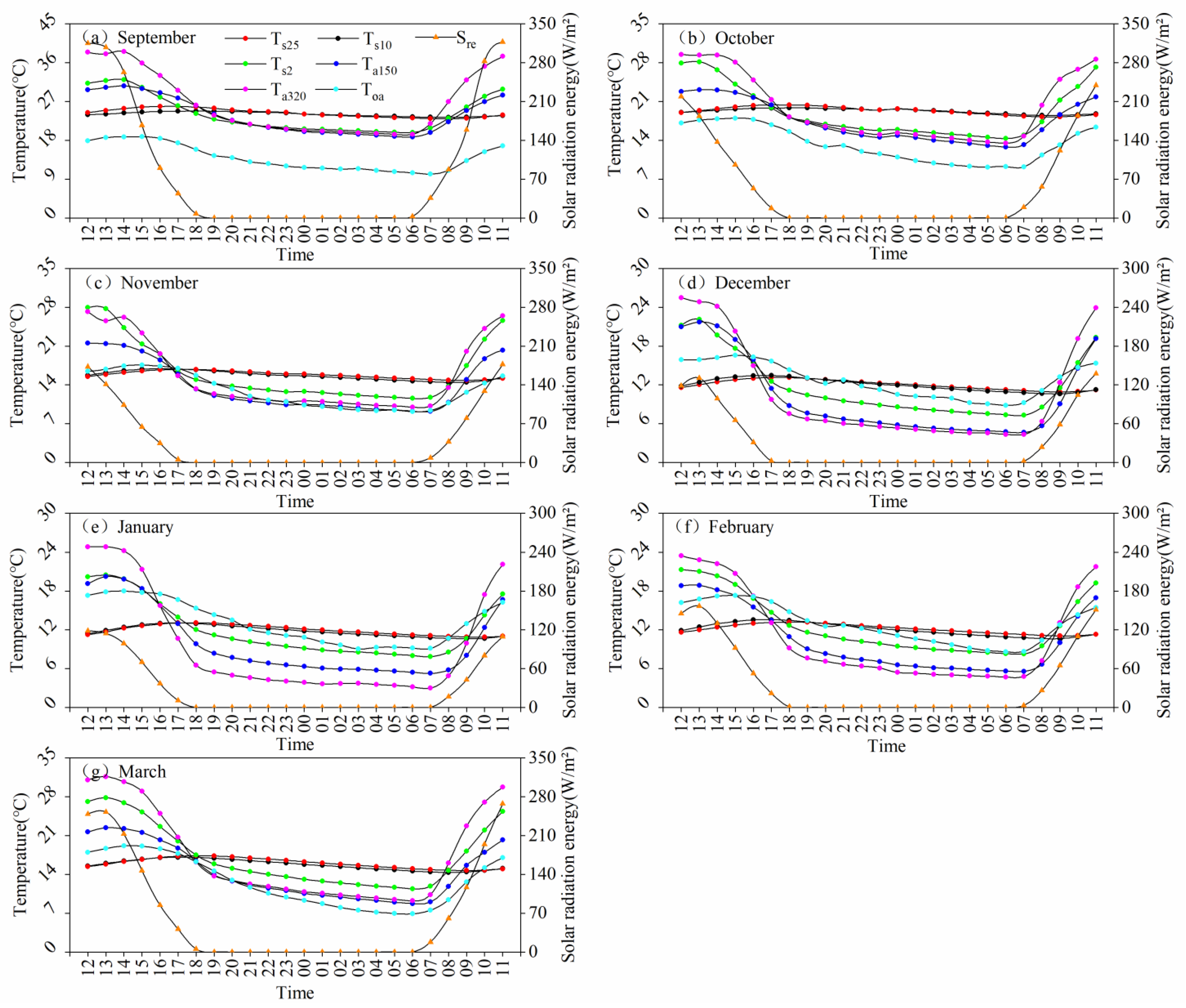

3.1. Characteristics of Monthly and Hourly Mean Temperature and Mean Solar Energy Variations in Different Depths and Heights at Plastic Greenhouses for Strawberry Cultivation

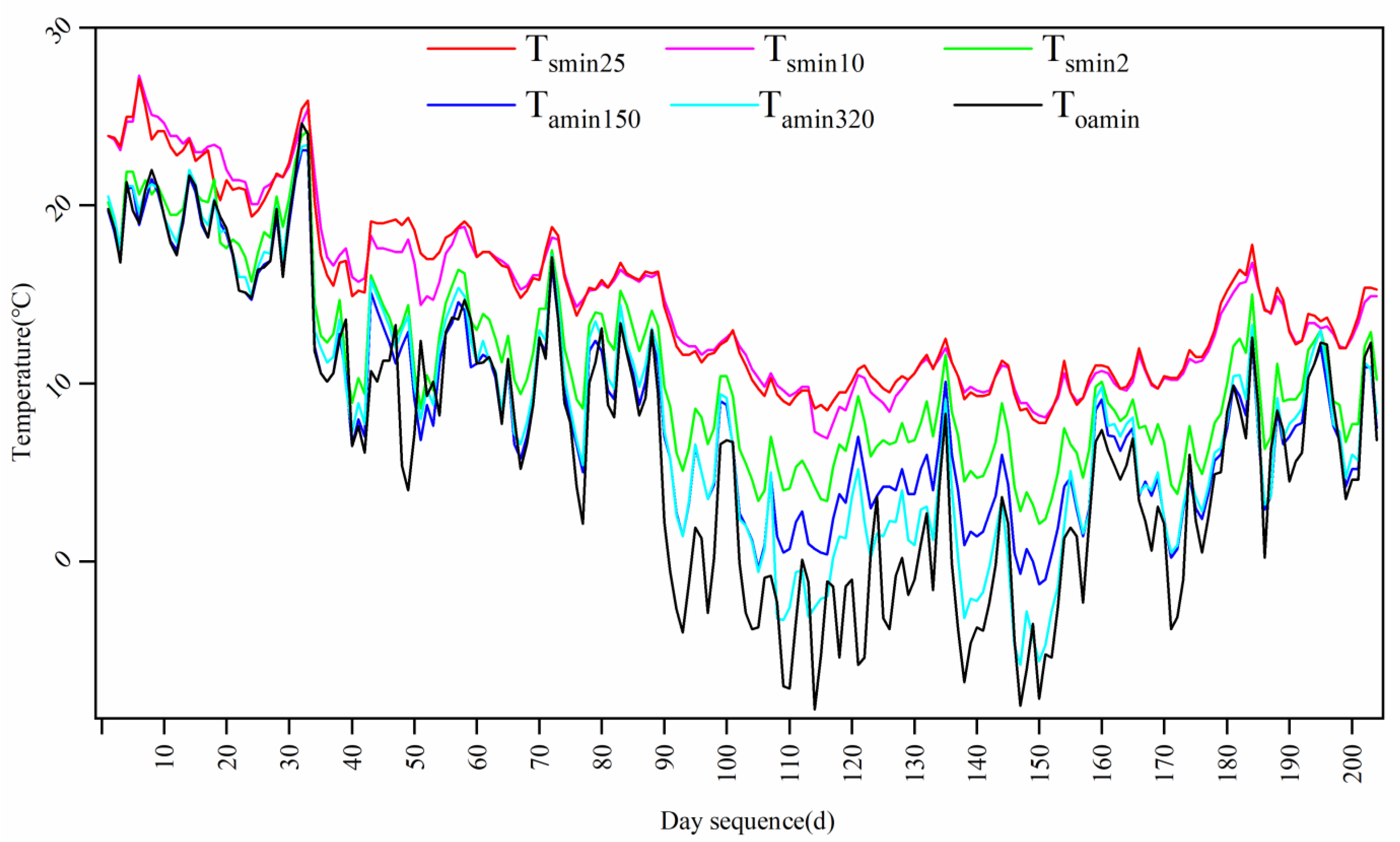

3.2. Characteristics of Daily Variation in Minimum Temperature in Different Depths and Heights of Plastic Greenhouse for Strawberry Cultivation

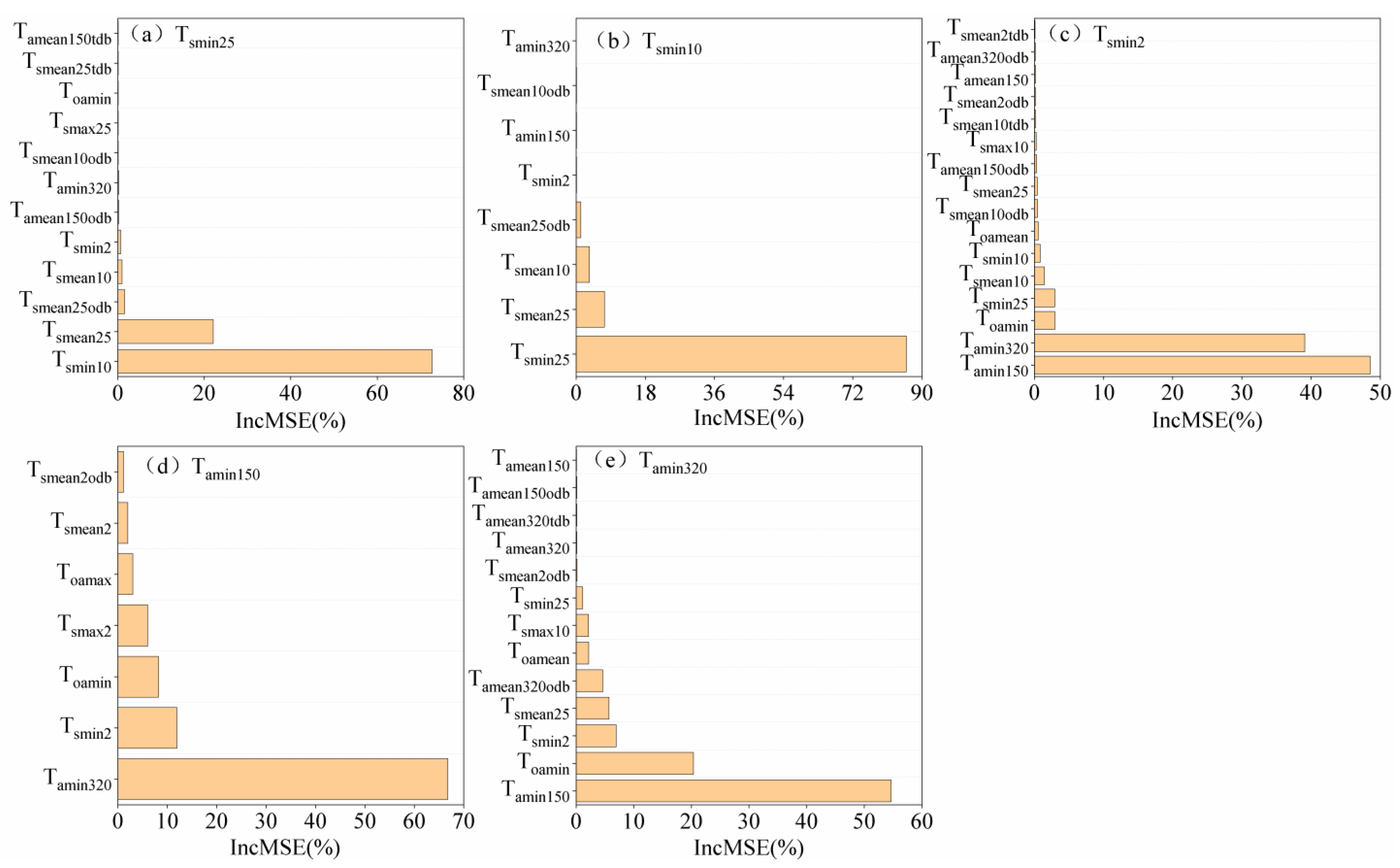

3.3. Analysis of the Importance of Variables Characterising Different Meteorological Elements in Plastic Greenhouse for Strawberry Cultivation

3.4. Construction of the Minimum Temperature Forecast Model in Different Depths and Heights of Plastic Greenhouse for Strawberry Cultivation

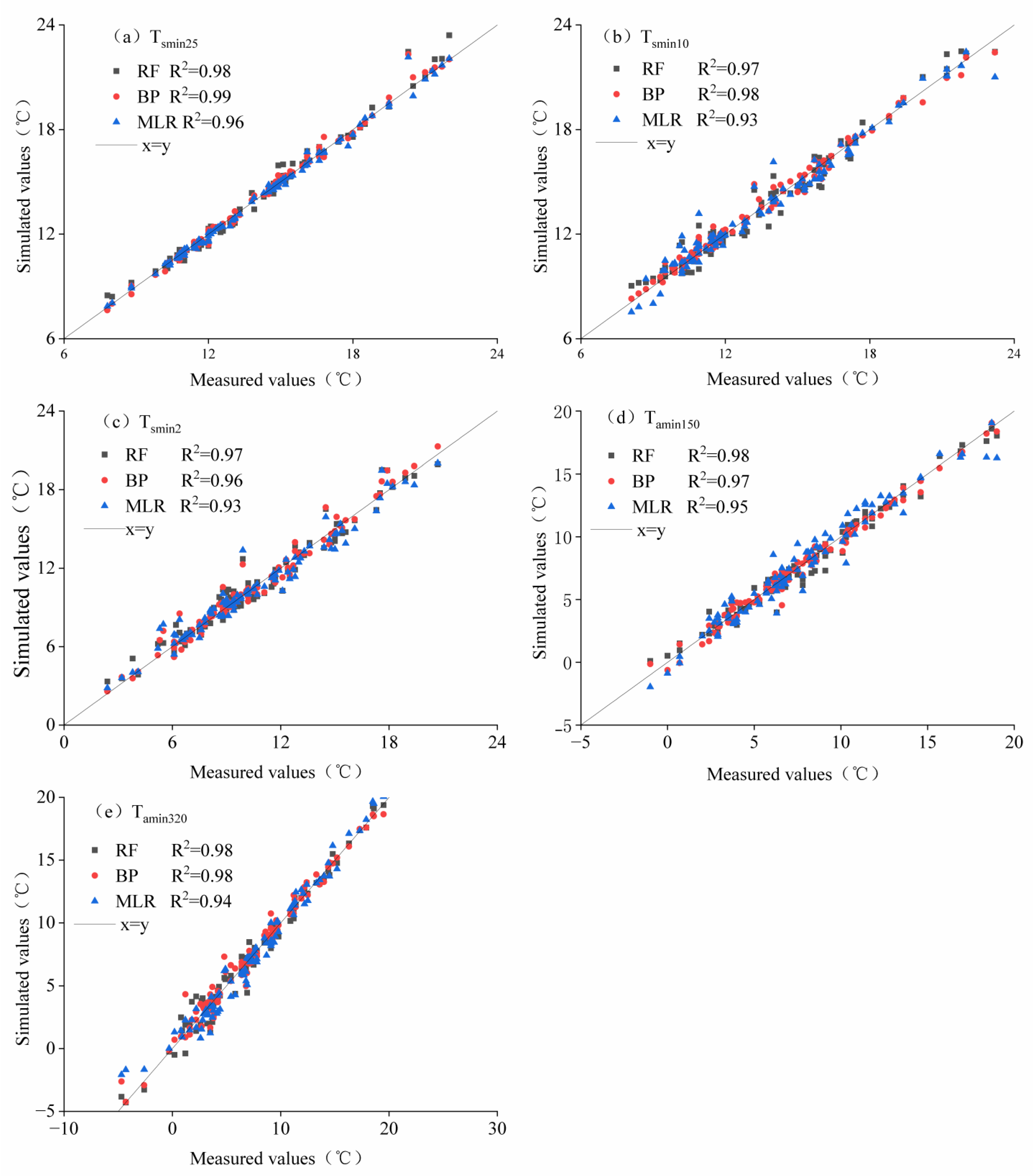

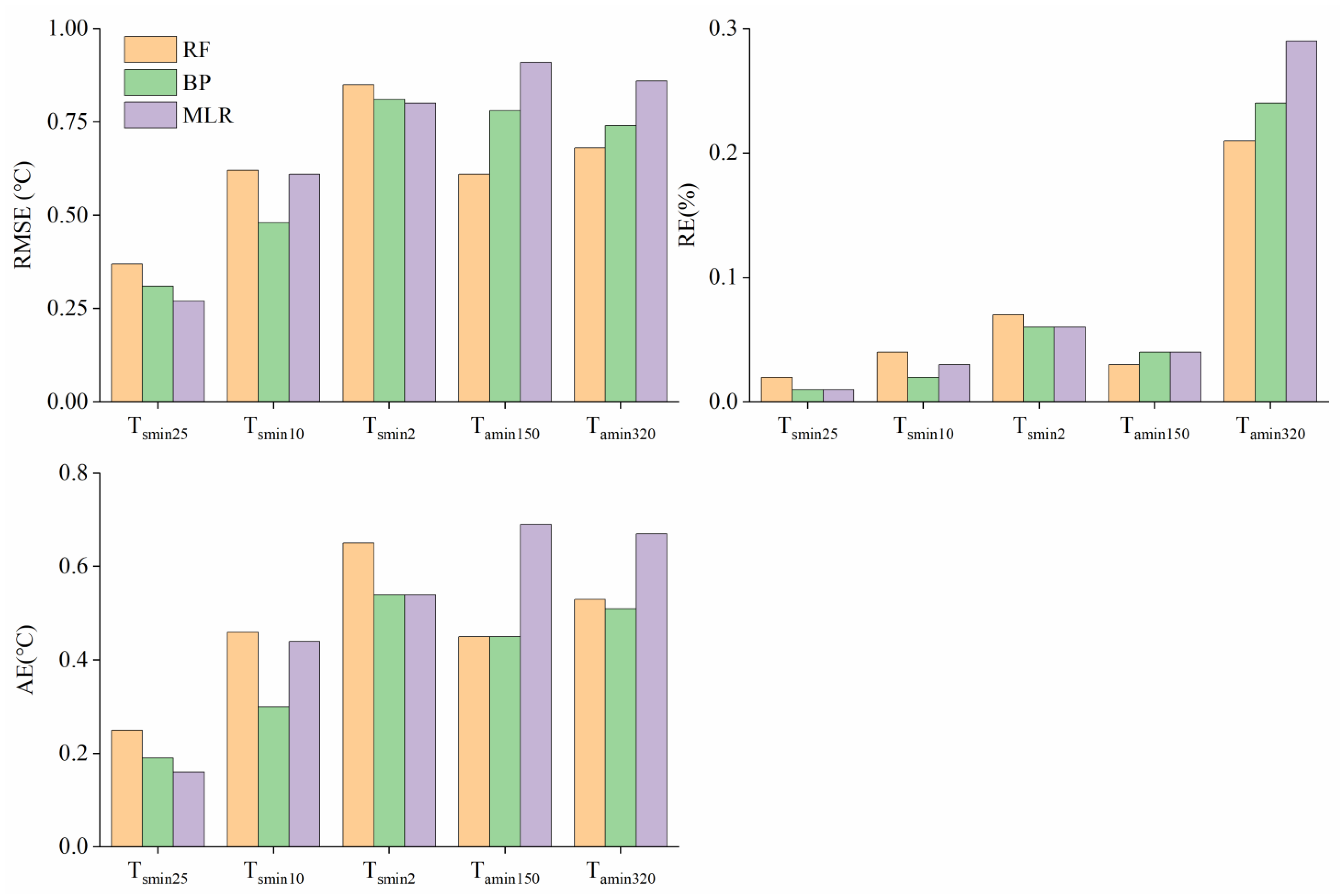

3.5. Model Validation for Predicting Minimum Temperatures in Different Depths and Heights of Plastic Greenhouses for Strawberry Cultivation

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Song, C. Quality Strawberry Greenhouse Pollution-free Cultivation Technology. Agric. Eng. Technol. 2021, 41, 79–81. [Google Scholar]

- Carbone, F.; Preuss, A.; DeVos, R.C.H.; D’Amico, E.; Perrotta, G.; Bovy, A.G.; Martens, S.; Rosati, C. Developmental, genetic and environmental factors affect the expression of flavonoid genes, enzymes and metabolites in strawberry fruits. Plant Cell Environ. 2009, 32, 1117–1131. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y. Strawberry High-yield Cultivation Technology. Rural. Sci. Technol. 2021, 12, 70–71. [Google Scholar]

- Wang, S.Y.; Camp, M.J. Temperatures after bloom affect plant growth and fruit quality of strawberry. Sci. Hortic. 2000, 85, 183–199. [Google Scholar] [CrossRef]

- Li, Q.; Shen, S.; Cao, W.; Zou, X. Neural Network Simulation on Air Temperature and Relative Humidity inside Plastic Greenhouse during Winter and Spring in Southern China. Chin. J. Agrometeorol. 2012, 33, 190–196. [Google Scholar]

- Businger, J.A. The Glasshouse Climate Physics of Plant Environment; North-Holland Publishing Company: Amsterdam, The Netherlands, 1963; pp. 277–318. [Google Scholar]

- Yang, D.; Ding, H.; Sun, J.; Li, Q.; Wei, S.; Huang, H. Characteristics and Forecasting Technology of Greenhouse Temperature Deficit in Southern Plastic Greenhouse. Chin. J. Agrometeorol. 2019, 40, 240–249. [Google Scholar]

- Li, Q.; Shen, H.; Tao, S.; Zou, X. Simulation of Daily Air Temperature Inside Plastic Greenhouse Based on Harmonic Method. Chin. J. Agrometeorol. 2014, 35, 33–41. [Google Scholar]

- Li, D.; Zhang, X.; Qi, H.; Zhang, B. Forecast Model of the Highest and Lowest Temperature in the Sunlight Greenhouse in Suzhou. Chin. J. Agrometeorol. 2013, 34, 170–178. [Google Scholar]

- Abdel-Ghany, A.M.; Kozai, T. Dynamic modeling of the environment in a naturally ventilated, fog-cooled greenhouse. Renew. Energy 2006, 31, 1521–1539. [Google Scholar] [CrossRef]

- Kumar, A.; Tiwari, G.N. Thermal modeling of a natural convection greenhouse drying system for jaggery: An experimental validation. Sol. Energy 2006, 80, 1135–1144. [Google Scholar] [CrossRef]

- Fidaros, D.K.; Baxevanou, C.A.; Bartzanas, T. Numerical simulation of thermal behavior of a ventilated arc greenhouse during a solar day. Renew. Energy 2010, 35, 1380–1386. [Google Scholar] [CrossRef]

- Okushima, L.; Sase, S.; Nara, M.A. support system for natural ventilation design of greenhouses based on computational aerodynamics. Acta Hortic. 1989, 284, 129–136. [Google Scholar] [CrossRef]

- Kacira, M.; Sase, S.; Okushima, L. Effects of side vents and span numbers on wind-induced natural ventilation of agothic multi-span greenhouse. Jpn. Agric. Res. Q. 2004, 38, 227–233. [Google Scholar] [CrossRef]

- Su, W.; Xue, X.; Xiong, Y.; Cao, J. Modeling the effect of natural ventilation on temperature inside solar greenhouse. Chin. J. Ecol. 2016, 35, 1635–1642. [Google Scholar]

- Frausto, H.U.; Pieters, J.G.; Deltour, J.M. Modelling greenhouse temperature by means of auto regressive models. Biosyst. Eng. 2003, 84, 147–157. [Google Scholar] [CrossRef]

- Herrero, J.M.; Blasco, X.; Martínez, M.; Ramos, C.; Sanchis, J. Non-linear robust identification of a greenhouse model using multi-objective evolutionary algorithms. Biosyst. Eng. 2007, 98, 335–346. [Google Scholar] [CrossRef]

- Morteza, T.; Yahya, A.; Seyed, F.R. Modeling and experimental validation of heat transfer and energy consumption in an innovative greenhouse structure. Inf. Process. Agric. 2016, 3, 57–174. [Google Scholar]

- Du, S.; Li, Y.; Chen, L.; Li, J. Modelling Greenhouse Environment with Artifical Neural Networks. Comput. Meas. Control 2006, 14, 887–889. [Google Scholar]

- Wang, D. SVM Regression Modeling for Greenhouse Environment. J. Agric. Mach. 2004, 35, 106–109. [Google Scholar]

- Bai, L.; Xu, Y.; He, M.; Li, N. Remote Sensing Inversion of Near Surface Air Temperature Based on Random Forest. J. Geo-Inf. Sci. 2017, 19, 390–397. [Google Scholar]

- Zhang, H.; Wu, P.; Yin, A.; Yang, X.; Zhang, M.; Gao, C. Prediction of soil organic carbon in an intensively managed reclamation zone of eastern China: A comparison of multiple linear regressions and the random forest model. Sci. Total Environ. 2017, 592, 704–713. [Google Scholar] [CrossRef] [PubMed]

- Iverson, L.R.; Prasad, A.M.; Matthews, S.N.; Peters, M. Estimating potential habitat for 134 eastern US tree species under six climate scenarios. For. Ecol. Manag. 2008, 254, 390–406. [Google Scholar] [CrossRef]

- Xu, M.; Zhao, Y.; Zhang, G.; Gao, P.; Yang, R. Method for forecasting winter wheat first flowering stage based on machine learning algorithm. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2021, 37, 162–171. [Google Scholar]

- Li, D.; Chen, W.; Le, Z.; Fan, X.; Sun, Y.; Meng, Y.; Yang, J. Forecast method for the first flowering date of Dangshansu pear based on random forest algorithm and meteorological factors. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2020, 36, 143–151. [Google Scholar]

- Xu, M.; Xu, J.; Xie, Z.; Gao, P.; Li, Y.; Miao, J. Application of the random forest machine algorithm in forecasting diseased panicle rate of wheat scab in Jiangsu province. Acta Meteorol. Sin. 2020, 78, 43–153. [Google Scholar]

- Liu, J.; He, X.; Wang, P.; Huang, J. Early prediction of winter wheat yield with long time series meteorological data and random forest method. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2019, 35, 158–166. [Google Scholar]

- Myles, A.J.; Feudale, R.N.; Liu, Y.; Woody, N.A.; Brown, S.D. An introduction to decision tree modeling. J. Chemom. A J. Chemom. Soc. 2004, 18, 275–285. [Google Scholar] [CrossRef]

- De’Ath, G.; Fabricius, K.E. Classification and regression trees: A poweful yet simple technique for ecological data analysis. Ecology 2008, 81, 3178–3192. [Google Scholar] [CrossRef]

- Teixeira, A. Analyse discrimante par arbre de décision binaire (CART: Classification And Regression Tree). Revue des Maladies Respiratoires. 2004, 21, 1174–1176. [Google Scholar] [CrossRef]

- Wiesmeier, M.; Barthold, F.; Blank, B.; Kögelknabner, I. Digital mapping of soil organic matter stocks using random forest modeling in a semi-arid steppe ecosystem. Plant Soil 2011, 340, 7–24. [Google Scholar] [CrossRef]

- Wiesmeier, M.; Munro, S.; Barthold, F.; Steffens, M.; Schad, P.; Kögel-Knabner, I. Carbon storage capacity of semi-arid grassland soils and sequestration potentials in northern China. Glob. Change Biol. 2015, 21, 3836–3845. [Google Scholar] [CrossRef]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Prasad, A.M.; Iverson, L.R.; Liaw, A. Newer classification and regression tree techniques: Bagging and Random forests for ecological rediction. Ecosystems 2006, 9, 181–199. [Google Scholar] [CrossRef]

- Cybenko, G. Approximation by superpositions of a sigmoidal function. Math. Control. Signals Syst. 1989, 2, 303–314. [Google Scholar] [CrossRef]

- He, R.; Guan, Z.Y.; Jin, L.A. Short-term cloud forecast model by neural networks. Trans. Atmos. Sci. 2010, 33, 725–730. [Google Scholar]

- Xu, C.; Wang, M.; Yang, Z.; Han, W.; Zheng, S. Effect of High Temperature in Seedling Stage on Phenological Stage of Strawberry and its Simulation. Chin. J. Agrometeorol. 2020, 41, 644–654. [Google Scholar]

- Xu, R.; Yang, Z.; Sheng, M.; Wang, M. Effects of Low Temperature Stress at Seedling Stage on Chlorophyll Content and Canopy Hyperspectral of “Hongyan” Strawberry. Chin. J. Agrometeorol. 2022, 43, 148–158. [Google Scholar]

- Xu, J.; Yang, Z.; Yuan, C.; Luo, J.; Wang, C.; Zhang, H.; Jiang, N. Effect of Low Temperature at Anthesis on the Fluorescence Properties of Photosystem and Protective Enzyme Activity of Strawberry Leaves. Chin. J. Agrometeorol. 2024, 45, 178. [Google Scholar]

- Khammayom, N.; Maruyama, N.; Chaichana, C. The Effect of Climatic Parameters on Strawberry Production in a Small Walk-In Greenhouse. AgriEngineering 2022, 4, 104–121. [Google Scholar] [CrossRef]

- Koehler, G.; Wilson, R.C.; Goodpaster, J.V.; Sønsteby, A.; Lai, X.; Witzmann, F.A.; You, J.S.; Rohloff, J.; Randall, S.K.; Alsheikh, M. Proteomic Study of Low-Temperature Responses in Strawberry Cultivars (Fragaria × ananassa) That Differ in Cold Tolerance. Plant Physiol. 2012, 159, 1787–1805. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, H.; Li, S. Research on Cold Damage and Cold Resistance in Horticultural Plants-A Review of Literature. Acta Hortic. Sin. 1994, 21, 239–244. [Google Scholar]

- Hu, M.; Jin, C.; Pan, H. Impact of persistent rainy and sunny weather on strawberry production in early spring. Zhejiang Agric. Sci. 2012, 10, 1407–1409. [Google Scholar]

- Jiang, N.; Yang, Z.; Zhang, H.; Xu, J.; Li, C. Effect of Low Temperature on Photosynthetic Physiological Activity of Different Photoperiod Types of Strawberry Seedlings and Stress Diagnosis. Agronomy 2023, 13, 1321. [Google Scholar] [CrossRef]

| No. | Variable | Abbreviation | Unit |

|---|---|---|---|

| 1 | Soil temperature at a depth of 25 cm | Ts25 | °C |

| 2 | Maximum soil temperature at a depth of 25 cm | Tsmax25 | °C |

| 3 | Minimum soil temperature at a depth of 25 cm | Tsmin25 | °C |

| 4 | Mean soil temperature at a depth of 25 cm | Tsmean25 | °C |

| 5 | Mean soil temperature of one day before at a depth of 25 cm | Tsmean25odb | °C |

| 6 | Mean soil temperature of two days before at a depth of 25 cm | Tsmean25tdb | °C |

| 7 | Soil temperature at a depth of 10 cm | Ts10 | °C |

| 8 | Maximum soil temperature at a depth of 10 cm | Tsmax10 | °C |

| 9 | Minimum soil temperature at a depth of 10 cm | Tsmin10 | °C |

| 10 | Mean soil temperature at a depth of 10 cm | Tsmean10 | °C |

| 11 | Mean soil temperature of one day before at a depth of 10 cm | Tsmean10odb | °C |

| 12 | Mean soil temperature of two days before at a depth of 10 cm | Tsmean10tdb | °C |

| 13 | Soil temperature at a depth of 2 cm | Ts2 | °C |

| 14 | Maximum soil temperature at a depth of 2 cm | Tsmax2 | °C |

| 15 | Minimum soil temperature at a depth of 2 cm | Tsmin2 | °C |

| 16 | Mean soil temperature at a depth of 2 cm | Tsmean2 | °C |

| 17 | Mean soil temperature of one day before at a depth of 2 cm | Tsmean2odb | °C |

| 18 | Mean soil temperature of two days before at a depth of 2 cm | Tsmean2tdb | °C |

| 19 | Air temperature at a height of 150 cm | Ta150 | °C |

| 20 | Maximum air temperature at a height of 150 cm | Tamax150 | °C |

| 21 | Minimum air temperature at a height of 150 cm | Tamin150 | °C |

| 22 | Mean air temperature at a height of 150 cm | Tamean150 | °C |

| 23 | Mean air temperature of one day before at a height of 150 cm | Tamean150odb | °C |

| 24 | Mean air temperature of two days before at a height of 150 cm | Tamean150tdb | °C |

| 25 | Relative humidity at a height of 150 cm | RH150 | % |

| 26 | Maximum relative humidity at a height of 150 cm | RHmax150 | % |

| 27 | Minimum relative humidity at a height of 150 cm | RHmin150 | % |

| 28 | Photosynthetic active radiation at a height of 150 cm | PAR150 | μmol m−2 day−1 |

| 29 | Air temperature at a height of 320 cm | Ta320 | °C |

| 30 | Maximum air temperature at a height of 320 cm | Tamax320 | °C |

| 31 | Minimum air temperature at a height of 320 cm | Tamin320 | °C |

| 32 | Mean air temperature at a height of 320 cm | Tamean320 | °C |

| 33 | Mean air temperature of one day before at a height of 320 cm | Tamean320odb | °C |

| 34 | Mean air temperature of two days before at a height of 320 cm | Tamean320tdb | °C |

| 35 | Relative humidity at a height of 320 cm | RH320 | % |

| 36 | Maximum relative humidity at a height of 320 cm | RHmax320 | % |

| 37 | Minimum relative humidity at a height of 320 cm | RHmin320 | % |

| 38 | Outdoor maximum air temperature | Toamax | °C |

| 39 | Outdoor minimum air temperature | Toamin | °C |

| 40 | Outdoor mean air temperature | Tamean | °C |

| 41 | Outdoor sunshine duration | SD | hour |

| 42 | Outdoor solar radiation energy | Sre | W/m2 |

| Tmin | QD | MAPE | DEDTF | DPV | MSSSL | DNDT |

|---|---|---|---|---|---|---|

| Tsmin25 | AE | 1.87 | 13 | 0.7 | 4 | 17 |

| Tsmin10 | RMSE | 3.56 | 9 | 0.5 | 4 | 19 |

| Tsmin2 | AE | 6.93 | 7 | 0.7 | 4 | 17 |

| Tamin150 | RMSE | 4.25 | 12 | 0.7 | 4 | 19 |

| Tamin320 | RMSE | 16.51 | 13 | 0.6 | 4 | 17 |

| Variables | Multiple Regression Equation | R2 |

|---|---|---|

| Tsmin25 | y = 0.172 × Tsmin10 − 0.096 × Tsmean10 + 0.033 × Tsmean10odb − 0.417 × Tsmax25 + 1.166 × Tsmean25 + 0.012 × Tsmean25odb + 0.004 × Tsmean25tdb + 0.108 × Tsmin2 + 0.003 × Tamin320 − 0.026 × Tamean150 + 0.012 × Tamean150tdb + 0.005 × Toamin + 0.433 | 0.994 ** |

| Tsmin10 | y = 0.167 × Tsmean10 + 0.134 × Tsmean10odb + 1.237 × Tsmin25 − 0.231 × Tsmean25 − 0.106 × Tsmean25odb − 0.429 × Tsmin2 − 0.045 × Tamin320 + 0.302 × Tamin150 − 0.518 | 0.969 ** |

| Tsmin2 | y = − 0.294 × Tsmax10 − 0.752 × Tsmin10 + 0.894 × Tsmean10 − 0.028 × Tsmean10odb + 0.056 × Tsmean10tdb + 0.822 × Tsmin25 − 0.480 × Tsmean25 − 0.025 × Tsmean2 + 0.185 × Tsmean2odb − 0.07 × Tamin320 − 0.145 × Tamean320odb + 0.630 × Tamin150 + 0.079 × Tamean150 + 0.002 × Tamean150 + 0.033 × Toamin + 0.050 × Toamean + 1.116 | 0.957 ** |

| Tamin150 | y = 0.005 × Tsmax2 + 0.836 × Tsmin2 − 0.027 × Tsmean2 − 0.099 × Tsmean2odb + 0.284 × Tamin320 − 0.025 × Toamax + 0.047 × Toamin − 1.137 | 0.955 ** |

| Tamin320 | y = 0.129 × Tsmax10 + 0.056 × Tsmin25 − 0.281 × Tsmean25 − 0.186 × Tsmin2 − 0.086 × Tsmean2odb + 0.256 × Tamean320 + 0.205 × Tamean320odb + 0.034 × Tamean320tdb + 1.148 × Tamin150 − 0.494 × Tamean150 − 0.180 × Tamean150 + 0.097 × Toamin + 0.171 × Toamean + 1.753 | 0.971 ** |

| Forecasting Methods | RMSE (°C) | RE (%) | AE (°C) | R2 | |

|---|---|---|---|---|---|

| Tsmin25 | RF | 0.37 | 0.02 | 0.25 | 0.98 |

| BP | 0.31 | 0.01 | 0.19 | 0.99 | |

| MLR | 0.27 | 0.01 | 0.16 | 0.96 | |

| Tsmin10 | RF | 0.62 | 0.04 | 0.46 | 0.97 |

| BP | 0.48 | 0.02 | 0.30 | 0.98 | |

| MLR | 0.61 | 0.03 | 0.44 | 0.93 | |

| Tsmin2 | RF | 0.85 | 0.07 | 0.65 | 0.97 |

| BP | 0.81 | 0.06 | 0.54 | 0.96 | |

| MLR | 0.80 | 0.06 | 0.54 | 0.93 | |

| Tamin150 | RF | 0.61 | 0.03 | 0.45 | 0.98 |

| BP | 0.78 | 0.04 | 0.45 | 0.97 | |

| MLR | 0.91 | 0.04 | 0.69 | 0.95 | |

| Tamin320 | RF | 0.68 | 0.21 | 0.53 | 0.98 |

| BP | 0.74 | 0.24 | 0.51 | 0.98 | |

| MLR | 0.86 | 0.29 | 0.67 | 0.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Huang, Q.; Wu, D.; Xie, J.; Cao, M.; Liu, J. Predicting Minimum Temperatures of Plastic Greenhouse During Strawberry Growing in Changfeng, China: A Comparison of Machine Learning Algorithms and Multiple Linear Regression. Agronomy 2025, 15, 709. https://doi.org/10.3390/agronomy15030709

Wang X, Huang Q, Wu D, Xie J, Cao M, Liu J. Predicting Minimum Temperatures of Plastic Greenhouse During Strawberry Growing in Changfeng, China: A Comparison of Machine Learning Algorithms and Multiple Linear Regression. Agronomy. 2025; 15(3):709. https://doi.org/10.3390/agronomy15030709

Chicago/Turabian StyleWang, Xuelin, Qinqin Huang, Dong Wu, Jinhua Xie, Ming Cao, and Jun Liu. 2025. "Predicting Minimum Temperatures of Plastic Greenhouse During Strawberry Growing in Changfeng, China: A Comparison of Machine Learning Algorithms and Multiple Linear Regression" Agronomy 15, no. 3: 709. https://doi.org/10.3390/agronomy15030709

APA StyleWang, X., Huang, Q., Wu, D., Xie, J., Cao, M., & Liu, J. (2025). Predicting Minimum Temperatures of Plastic Greenhouse During Strawberry Growing in Changfeng, China: A Comparison of Machine Learning Algorithms and Multiple Linear Regression. Agronomy, 15(3), 709. https://doi.org/10.3390/agronomy15030709