Study on Preparation and Performance of Biomass–Polyurethane Light Planting Substrate

Abstract

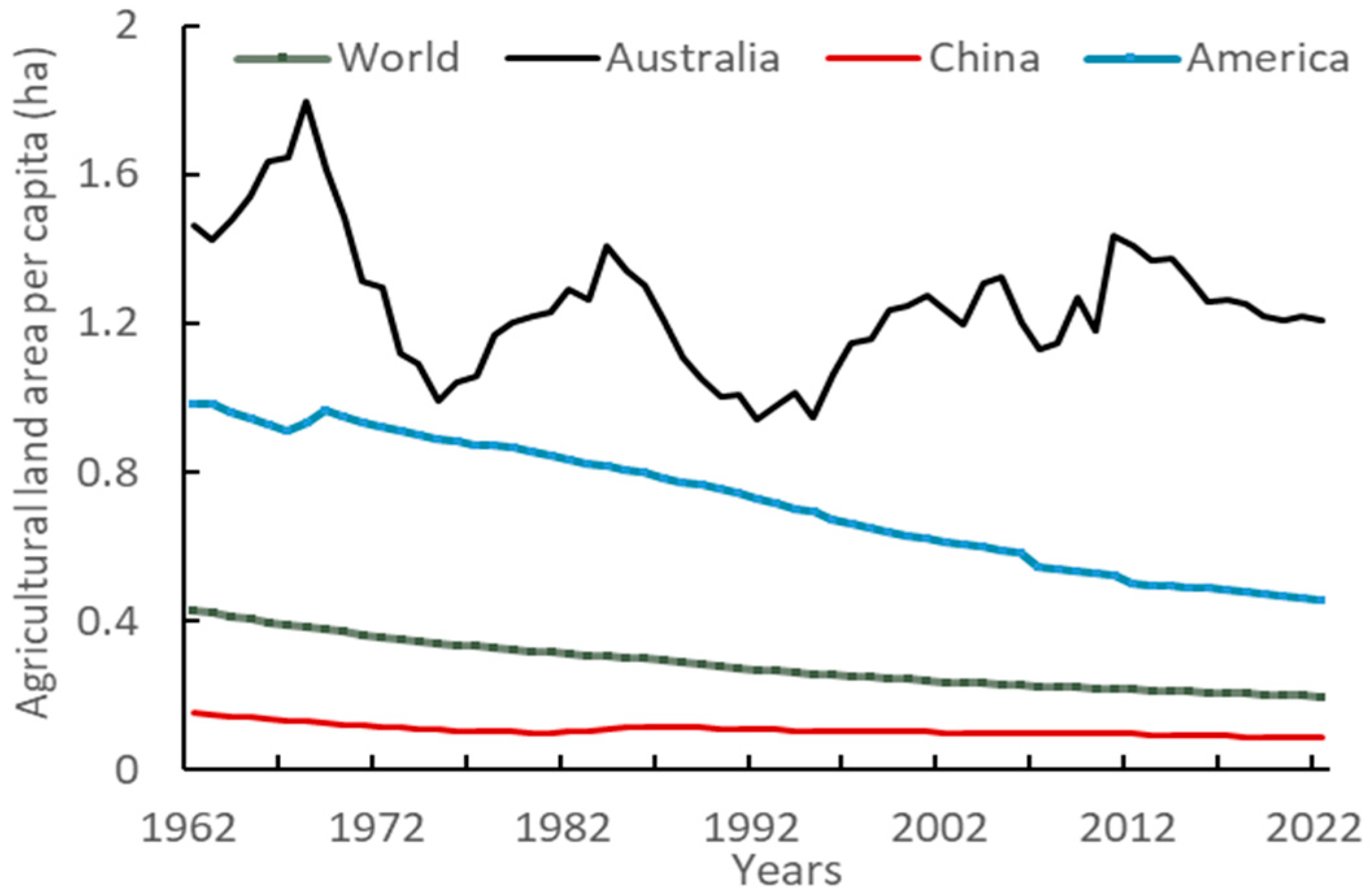

1. Introduction:

2. Materials and Methods

2.1. Experimental Materials

2.2. Test Instruments

2.3. Methods

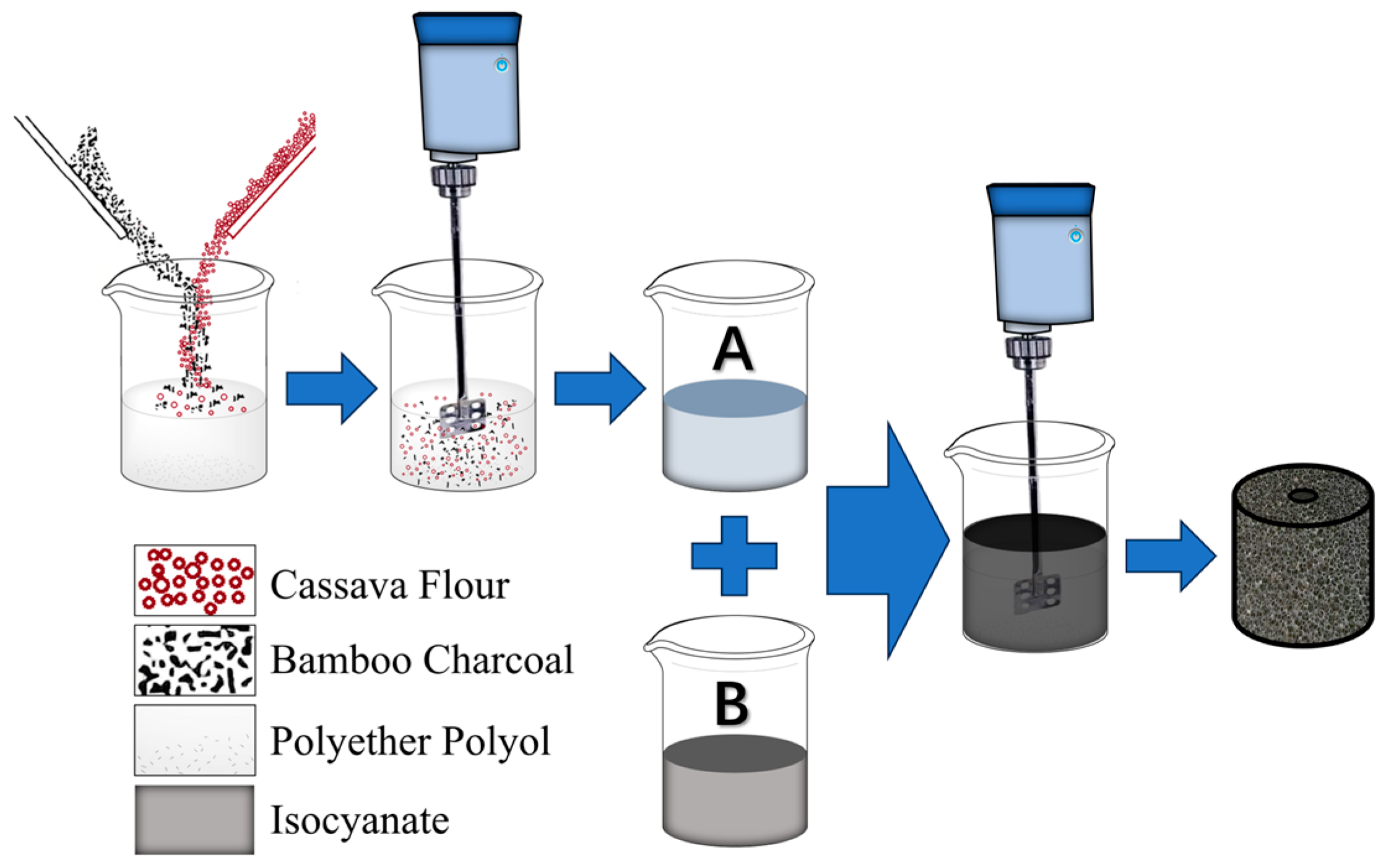

2.3.1. Preparation of Bio-Polyurethane Light Foam Matrix

2.3.2. Effects of Biomass Composition Ratio on the Performance of Lightweight Foam Substrate (LWFS)

2.3.3. Effects of Polyol/Isocyanate Ratio on the Performance of LWFS

2.3.4. Effects of Biomass/Polyol–Isocyanate Ratio on the Performance of LWFS

3. Results and Discussion

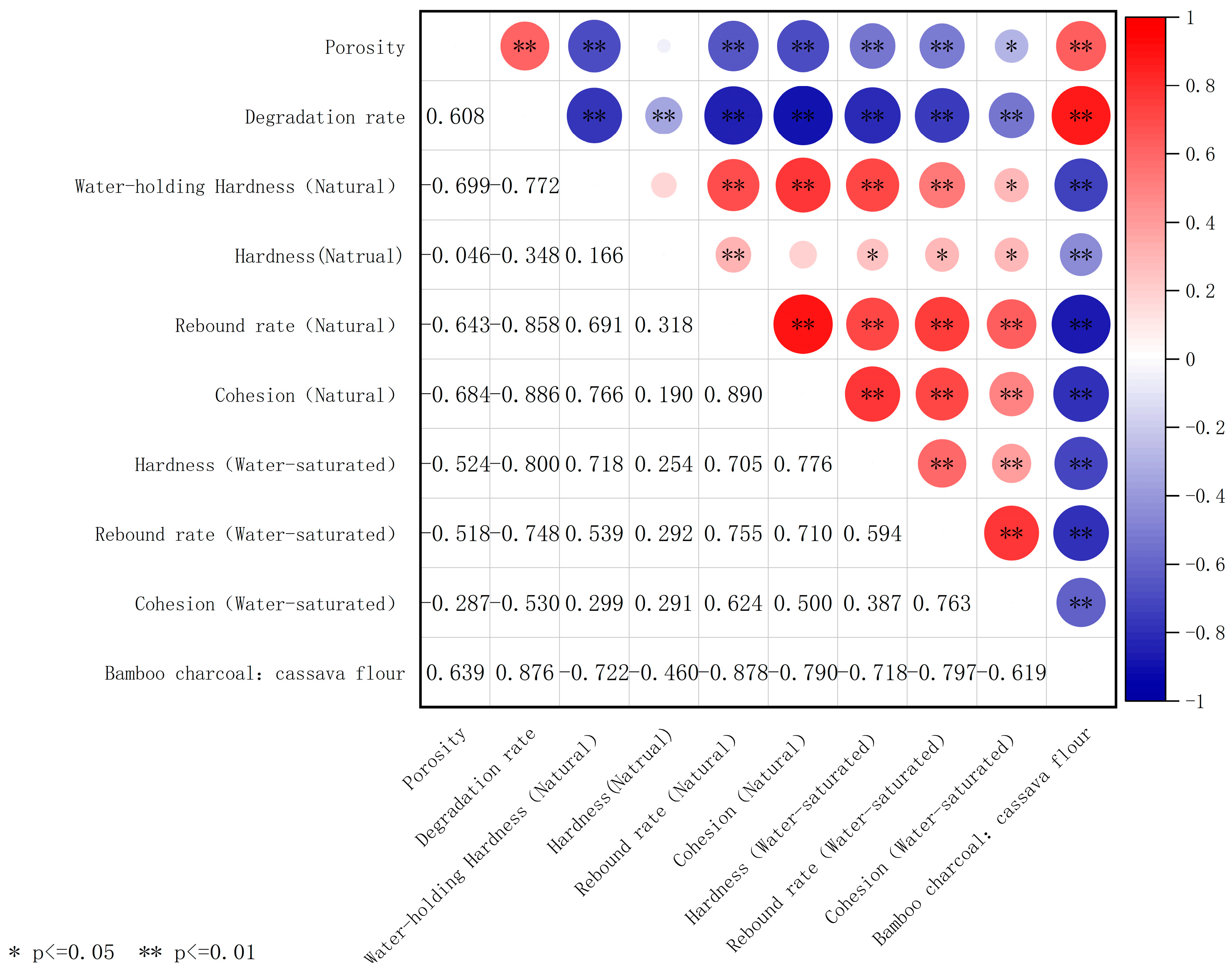

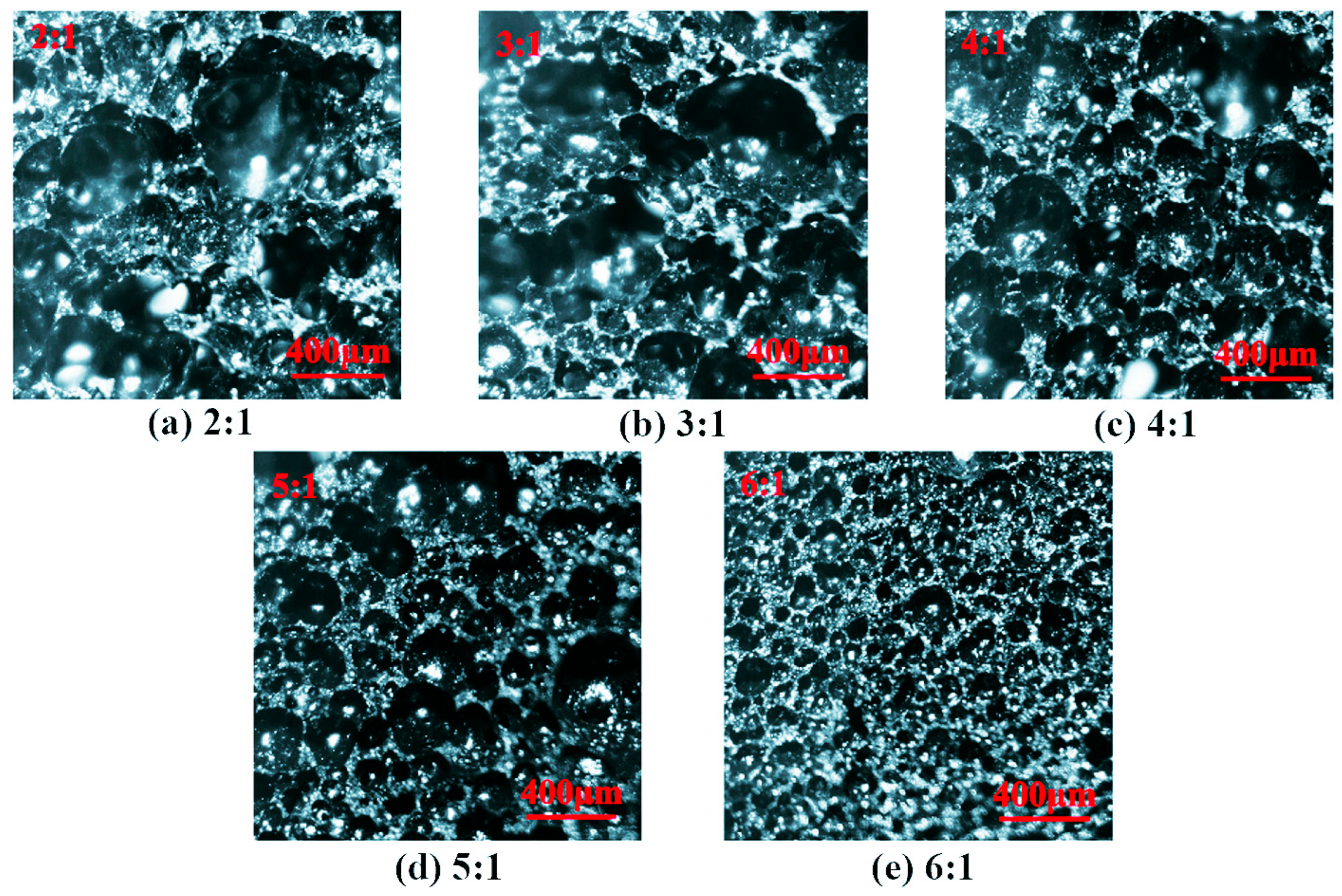

3.1. Effects of Biomass Composition Ratio on the Performance of LWFS

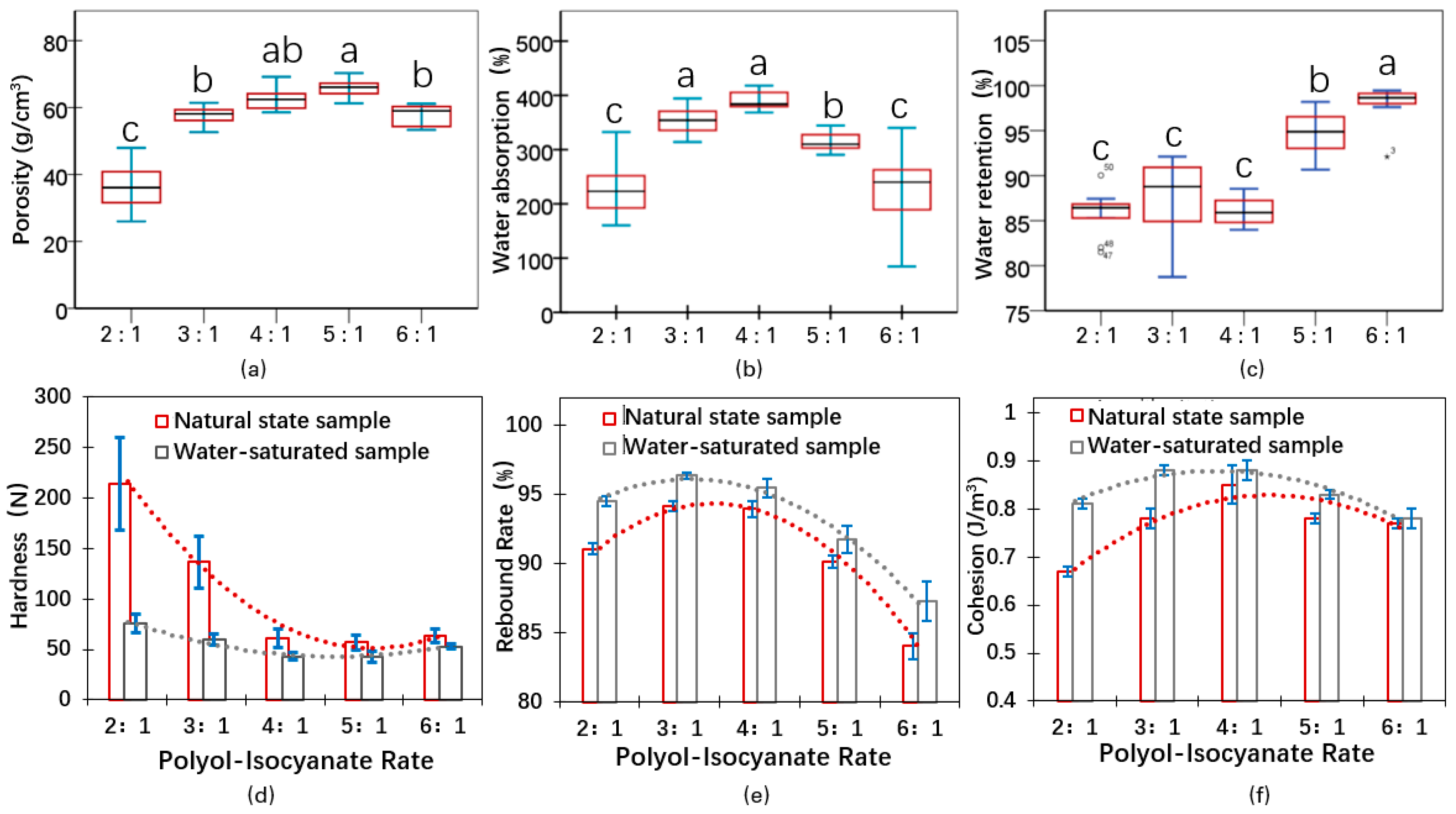

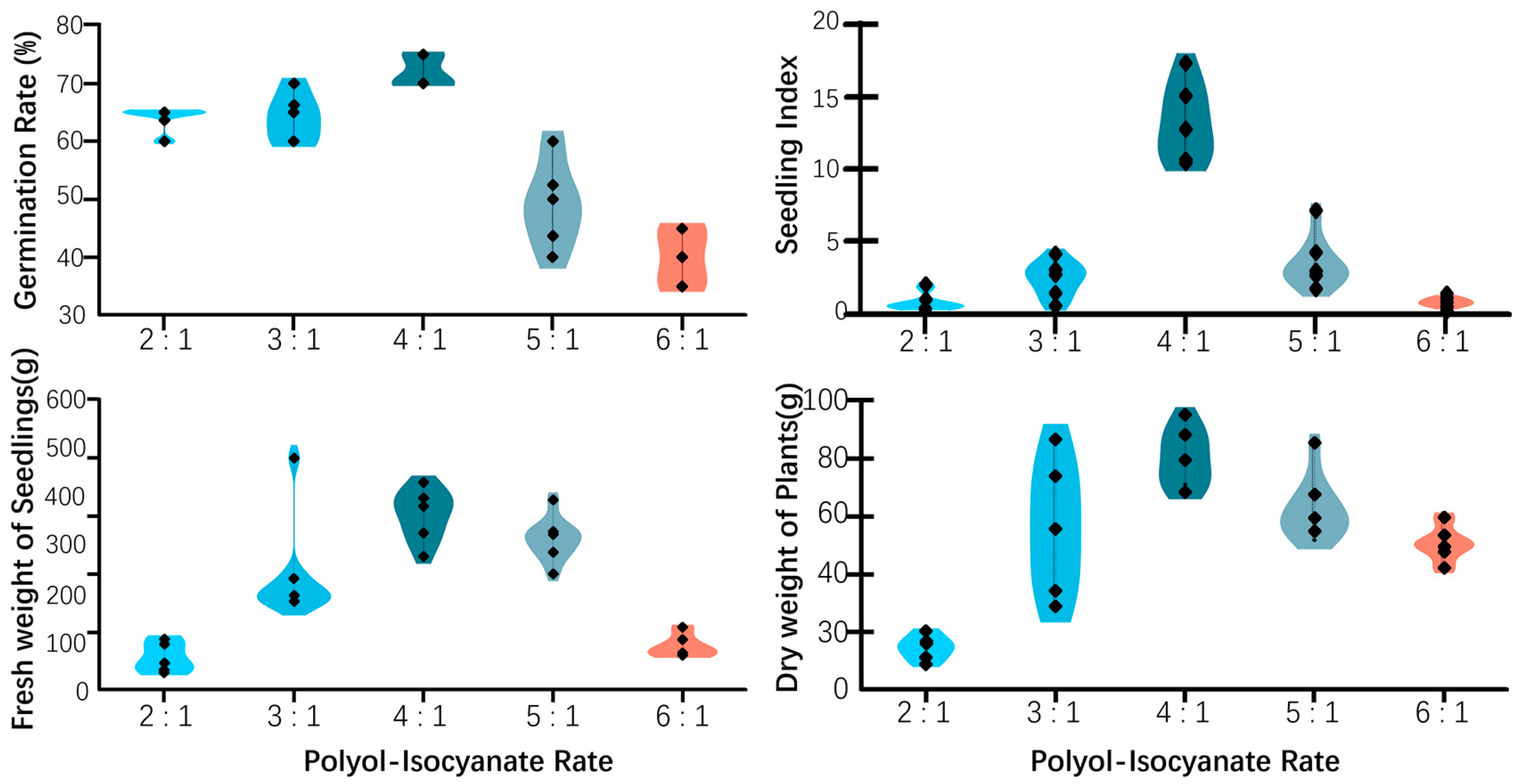

3.2. Effects of Polyol/Isocyanate Ratio on the Performance of LWFS

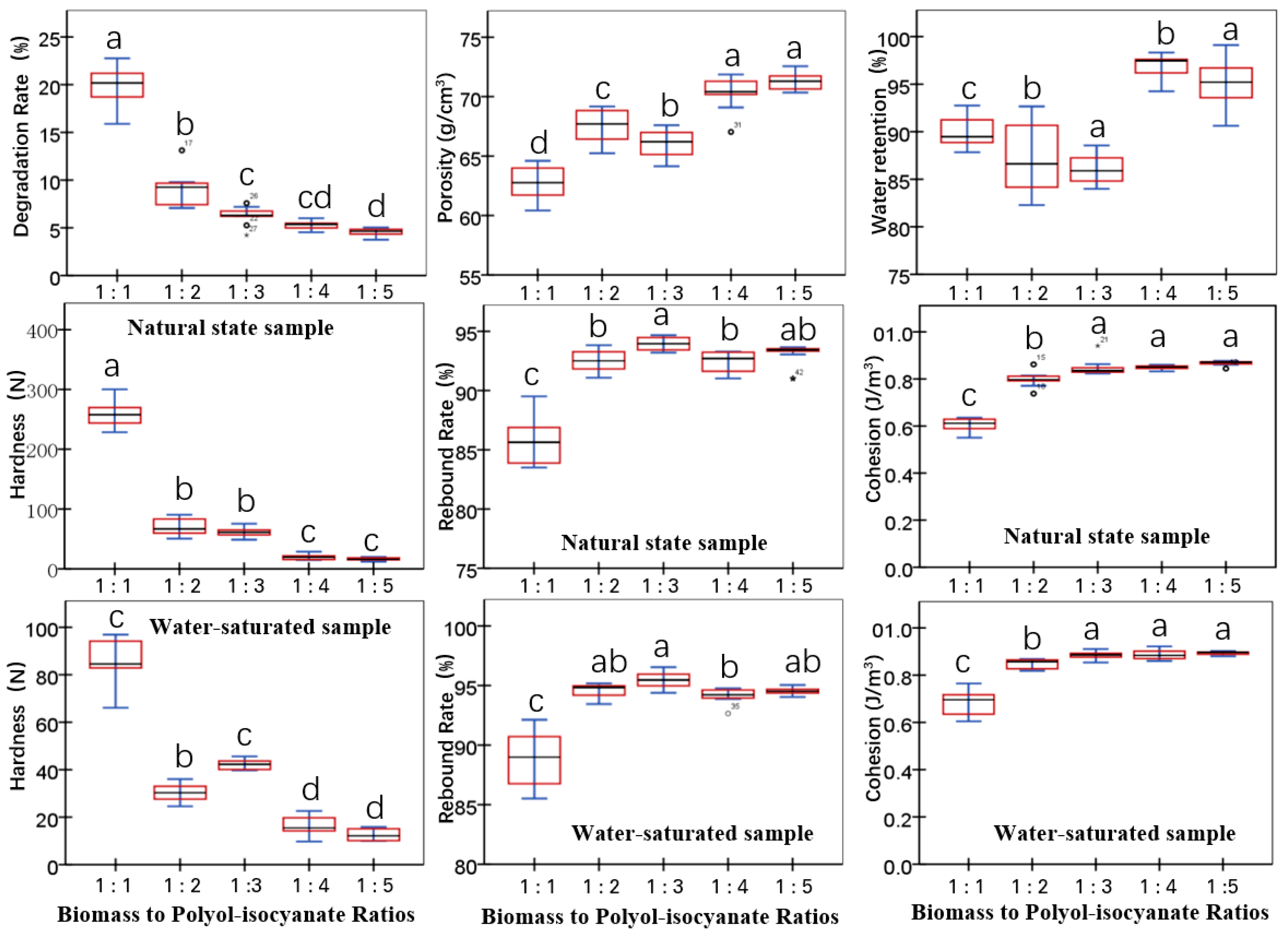

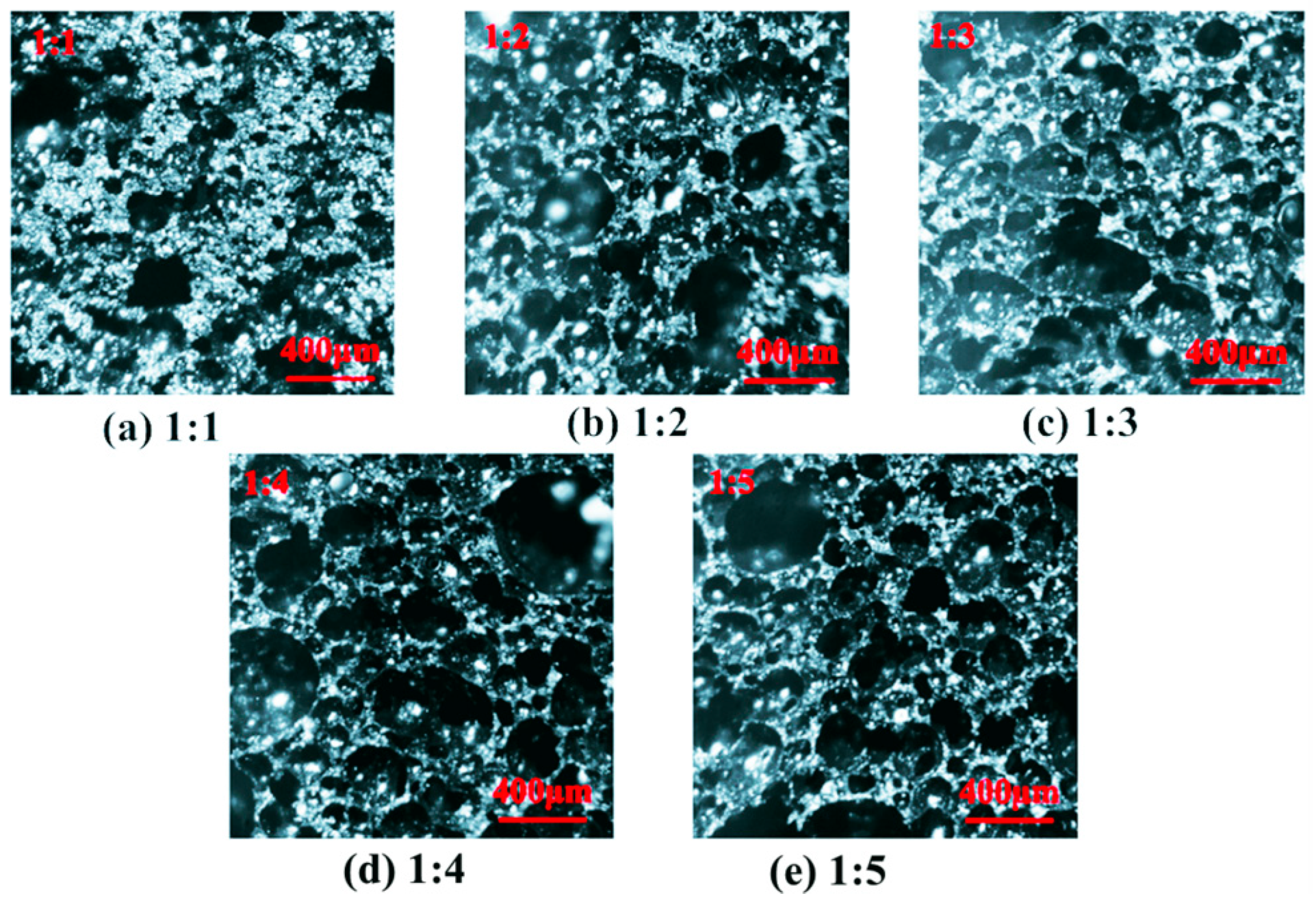

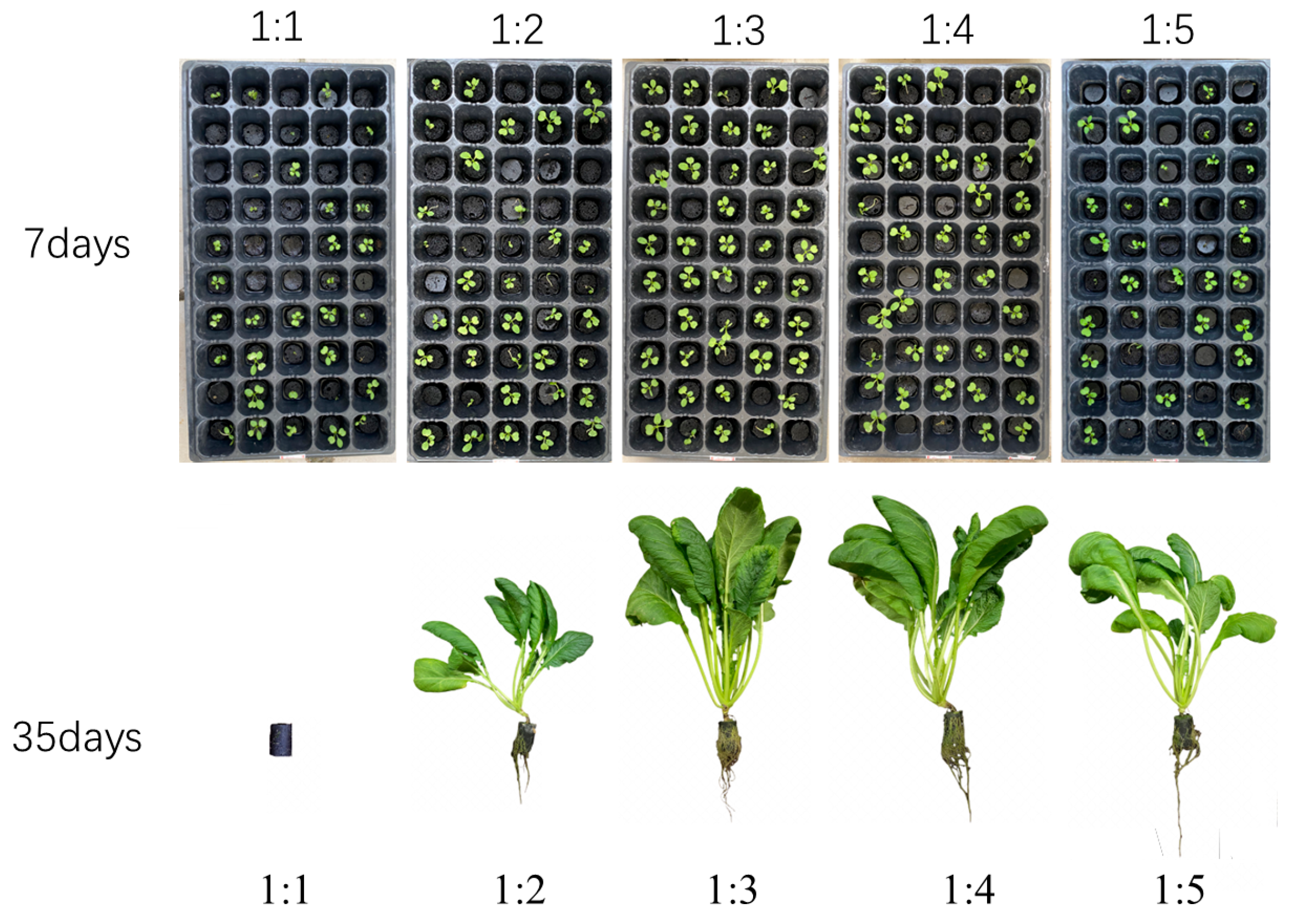

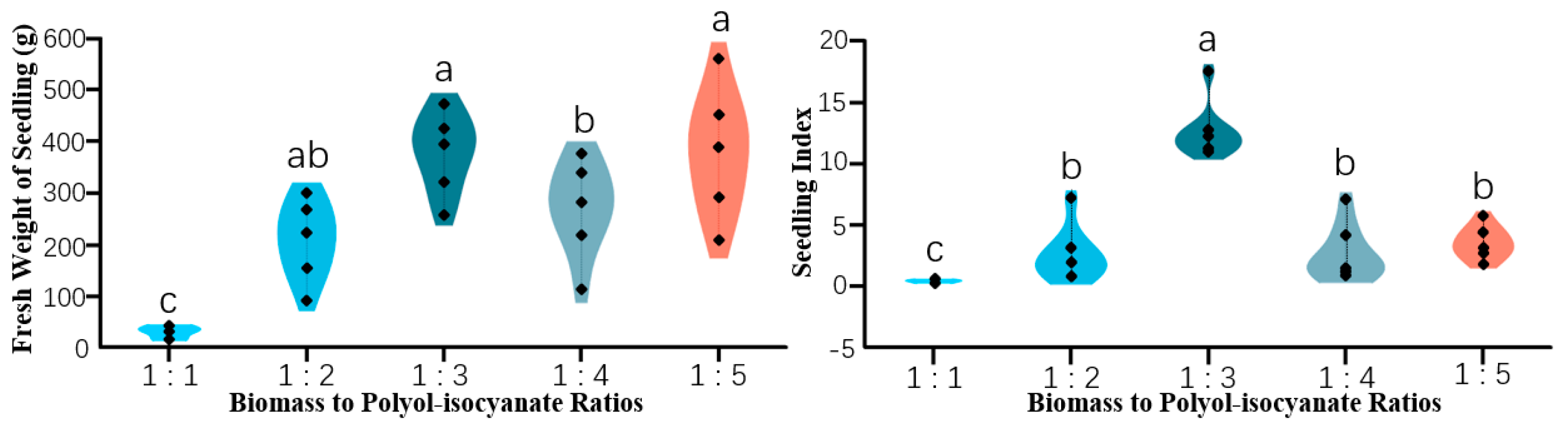

3.3. Effects of Biomass/Polyol–Isocyanate Ratio on the Performance of LWFS

4. Conclusions

- i.

- The proportion of bamboo charcoal to cassava flour within the biomass blend significantly influences the LWFS characteristics. Increasing the bamboo charcoal content effectively enhances porosity and degradation rate. Concurrently, cassava flour, upon absorbing water and expanding, contributes to improving substrate resilience and cohesion. Based on these effects, the optimal formulation was determined to be a 1:2 ratio of bamboo charcoal/cassava flour.

- ii.

- An increase in the polyol content enhanced LWFS’s water retention capacity. The optimal polyol/isocyanate ratio was identified as 4:1, combined with a 1:2 bamboo charcoal/cassava flour ratio. At this specific formulation, the substrate demonstrated significantly superior overall performance, including key metrics such as water retention capacity, germination rate, seedling index, and plant biomass.

- iii.

- The LWFS exhibited optimal overall performance at a biomass/polyol–isocyanate ratio of 1:3, with a 4:1 ratio of polyol/isocyanate and a 1:2 ratio of bamboo charcoal/cassava flour. At this ratio, the degradation rate was 6.24 ± 0.94%, while porosity, water absorption, and water retention capacity reached 66.07 ± 1.10%, 389.18 ± 16.42%, and 86.03 ± 1.59%, respectively. Critically, the germination rate (84 ± 5.16%), seedling index (12.49 ± 1.94), and plant dry weight (4 ± 0.51 g) all reached their maximum values. The resulting structure is stable and resistant to collapse, highlighting its significant potential for applications in controlled-environment agriculture and three-dimensional cultivation systems within plant factories.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. Available online: https://www.fao.org (accessed on 10 June 2024).

- Eigenbrod, C.; Gruda, N. Urban vegetable for food security in cities. A review. Agron. Sustain. Dev. 2015, 35, 483–498. [Google Scholar] [CrossRef]

- Savvas, D.; Gruda, N. Application of soilless culture technologies in the modern greenhouse industry—A review. Eur. J. Hort. Sci. 2018, 83, 280–293. [Google Scholar] [CrossRef]

- Yang, T.; Li, F.; Zhou, X.; Xu, C.; Feng, J.; Fang, F. Impact of nitrogen fertilizer, greenhouse, and crop species on yield-scaled nitrous oxide emission from vegetable crops: A meta-analysis. Ecol. Indic. 2019, 105, 717–726. [Google Scholar] [CrossRef]

- Blok, C.; Urrestarazu, M. Substrate growing developments in Europe 2010–2027. Horticom Plataforma 2010, 1, 95–105. [Google Scholar]

- Basso, M.; Pizzi, A.; Al-Marzouki, F.; Abdalla, S. Horticultural/hydroponics and floral natural foams from tannins. Ind. Crops Prod. 2016, 87, 177–181. [Google Scholar] [CrossRef]

- Gaffney, P.P.J.; Hancock, M.H.; Taggart, M.A.; Andersen, R. Restoration of afforested peatland: Immediate effects on aquatic carbon loss. Sci. Total Environ. 2020, 742, 140594. [Google Scholar] [CrossRef]

- Liu, H. Research and Application of Environmentally Friendly Green Growing Porous Concrete. Master’s Thesis, Southeast University, Nanjing, China, 2004. [Google Scholar]

- Weissert, L.F.; Disney, M. Carbon storage in peatlands: A case study on the Isle of Man. Geoderma 2013, 204–205, 111–119. [Google Scholar] [CrossRef]

- Urák, I.; Hartel, T.; Gallé, R.; Balog, A. Worldwide peatland degradations and the related carbon dioxide emissions: The importance of policy regulations. Environ. Sci. Policy 2017, 69, 57–64. [Google Scholar] [CrossRef]

- Lees, K.J.; Quaife, T.; Artz, R.R.E.; Khomik, M.; Sottocornola, M.; Kiely, G.; Hambley, G.; Hill, T.; Saunders, M.; Cowie, N.R.; et al. A model of gross primary productivity based on satellite data suggests formerly afforested peatlands undergoing restoration regain full photosynthesis capacity after five to ten years. J. Environ. Manag. 2019, 246, 594–604. [Google Scholar] [CrossRef]

- Sabatino, L. Increasing Sustainability of Growing Media Constituents and Stand-Alone Substrates in Soilless Culture Systems. Agronomy 2020, 10, 1384. [Google Scholar] [CrossRef]

- Jia, J. Effects of Construction and Demolition Waste on the Growth and Physiology of Container-Grown Duranta Repens. Master’s Thesis, Shanghai Institute of Technology, Shanghai, China, 2023. [Google Scholar]

- Mariotti, B.; Oliet, J.A.; Andivia, E.; Tsakaldimi, M.; Villar-Salvador, P.; Ivetić, V.; Montagnoli, A.; Janković, I.K.; Bilir, N.; Bohlenius, H.; et al. A Global Review on Innovative, Sustainable, and Effective Materials Composing Growing Media for Forest Seedling Production. Curr. For. Rep. 2023, 9, 413–428. [Google Scholar] [CrossRef]

- Yang, Y. Research and Analysis on the Development of Solid Matrix Soilless Cultivation in China. Mod. Hortic. 2023, 46, 51–53. [Google Scholar]

- Barrett, G.E.; Alexander, P.D.; Robinson, J.S.; Bragg, N.C. Achieving environmentally sustainable growing media for soilless plant cultivation systems—A review. Sci. Hortic-Amst. 2016, 212, 220–234. [Google Scholar] [CrossRef]

- Ivdre, A.; Soto, G.D.; Cabulis, U. Polyols Based on Poly(ethylene terephthalate) and Tall Oil: Perspectives for Synthesis and Production of Rigid Polyurethane Foams. J. Renew. Mater. 2016, 4, 285–293. [Google Scholar] [CrossRef]

- Silva, V.R.; Mosiewicki, M.; Yoshida, M.; da Silva, M.C.; Stefani, P.M.; Marcovich, N.E. Polyurethane foams based on modified tung oil and reinforced with rice husk ash I: Synthesis and physical chemical characterization. Polym. Test. 2013, 32, 438–445. [Google Scholar] [CrossRef]

- Wichmann, S. Commercial viability of paludiculture: A comparison of harvesting reeds for biogas production, direct combustion, and thatching. Ecol. Eng. 2017, 103, 497–505. [Google Scholar] [CrossRef]

- Liu, Z. Preparation and Properties of Waste Biomass-Based Polyurethane. Master’s Thesis, Beijing University of Chemical Technology, Beijing, China, 2021. [Google Scholar]

- Silva, V.; Mosiewicki, M.; Yoshida, M.; da Silva, M.C.; Stefani, P.M.; Marcovich, N.E. Polyurethane foams based on modified tung oil and reinforced with rice husk ash II: Mechanical characterization. Polym. Test. 2013, 32, 665–672. [Google Scholar] [CrossRef]

- Qi, X.; Zhang, M.; Wu, S.; Zhou, J.; Wu, M.; Rao, J. Preparation and properties of polyurethane-peat soil lightweight foaming material. J. For. Environ. 2021, 3, 325–330. [Google Scholar]

- Du, X.; Lei, W.; Zhong, P.; Wang, J. Structure and Properties of Polyurethane-Based Plant Culture Substrate. Plastic 2024, 53, 52–58. [Google Scholar]

- Ma, J.; Wang, T. Effect of conjugative polyalcohol on polyurethane foam for soilless cultivation. Polym. Mater. Sci. Eng. 2018, 34, 74–78. [Google Scholar]

- Gruda, N. Current and Future Perspective of Growing Media in Europe. Acta Hortic. 2012, 960, 37–43. [Google Scholar] [CrossRef]

- Lian, Z. Theories and Techniques of Soilless Culture, 1st ed.; China Agriculture Press: Beijing, China, 1994; pp. 102–106. [Google Scholar]

- Chen, L.; Cheng, H.; Wang, Y.; Zhi, Z.; Jin, Z. Starch-based Biodegradable Materials and It’s Applications in Food Industry. J. Chin. Inst. Food Sci. Technol. 2022, 22, 364–375. [Google Scholar]

- He, J.; Sun, J.; Zhai, W.; Chen, Q.; Zhen, J.; Wang, X.; Li, J. Preparation and Study of Soil-Free Polyurethane Foam Cultivation Substrate for Afforestation of Barren Hills. China Plast. Ind. 2019, 47, 145–147+151. [Google Scholar]

- Hu, Q.; Liao, X.; Wang, Y. Mechanical and biological characteristics analysis of mechanically transplanted rapeseed substrate block seedlings. Trans. Chin. Soc. Agric. Eng. 2019, 35, 58–65. [Google Scholar]

- Zhang, D.; Jiang, Z.; Deng, C.; Zhou, D.; Liu, H.; Yang, L. Influence of the carbonization temperature on microwave absorption properties of bamboo charcoal powder. Mater. Introd. 2010, 24, 5–8. [Google Scholar]

- Mu, Y.; Wan, X.; Han, Z.; Peng, Y.; Zhong, S. Rigid polyurethane foams based on activated soybean meal. J. Appl. Polym. Sci. 2012, 124, 4331–4338. [Google Scholar] [CrossRef]

- Glaser, B.; Asomah, A.A.A. Plant Growth and Chemical Properties of Commercial Biochar-versus Peat-Based Growing Media. Horticulturae 2022, 8, 339. [Google Scholar] [CrossRef]

- Li, H.; Wang, B.; Shui, H.; Wei, Q.; Xu, C.C. Preparation of bio-based polyurethane hydroponic foams using 100% bio-polyol derived from Miscanthus through organosolv fractionation. Ind. Crops Prod. 2022, 181, 114774. [Google Scholar] [CrossRef]

- Li, H.; Ali, Z.; Yuan, Z.; Hu, Y.; Wei, Q.; Xu, C.C. Wheat straw-derived bio-based hydroponic polyurethane foams for plant growth. Biofuels Bioprod. Biorefining 2023, 17, 549–563. [Google Scholar] [CrossRef]

| Rock Wool | Rock Wool | Rock Wool | Rock Wool | Peat Substrate Blocks | Peat Substrate Blocks | Peat Substrate Blocks | Foam Sponge | |

|---|---|---|---|---|---|---|---|---|

| Units | Blocks | Blocks | Blocks | Blocks | Blocks | Blocks | Blocks | Blocks |

| Model (cm) | 7.5 × 7.5 × 6.5 | 3.6 × 3.6 × 4 | 2.5 × 2.5 × 4 | 7.5 × 7.5 × 6.5 | 10.5 × 6.5 × 10 | 3.3 × 3.6 × 2.8 | 2 × 6.2 × 1 | Φ32 × 30 |

| Price (CNY) | 28.99 | 0.73 | 0.6 | 4.1 | 7.49 | 1.32 | 0.7 | 0.14 |

| Manufacturer | The Netherlands (Grodan) | The Netherlands (Grodan) | The Netherlands (Grodan) | China (Le Pao) | Germany (OIMG) | Germany (OIMG) | Germany (OIMG) | China (QWC) |

| Treatments | Biomass Charcoal (g) | Cassava Flour (g) | Polyacid Polyol (g) | Isocyanate (g) |

|---|---|---|---|---|

| 6:1 | 14.57 | 2.43 | 40 | 10 |

| 4:1 | 13.60 | 3.40 | ||

| 2:1 | 11.33 | 5.67 | ||

| 1:1 | 8.50 | 8.50 | ||

| 1:2 | 5.67 | 11.33 | ||

| 1:4 | 3.40 | 13.60 | ||

| 1:6 | 2.43 | 14.57 |

| Bamboo Charcoal/Cassava Flour | Porosity (g/cm3) | Degradation Rate DW (%) | Water-Holding (%) | Natural State Sample | Water-Saturated Sample | ||||

|---|---|---|---|---|---|---|---|---|---|

| Hardness (N) | Rebound Rate (%) | Cohesion (J/m3) | Hardness (N) | Rebound Rate (%) | Cohesion (J/m3) | ||||

| 1:6 | 51.73 ± 6.25 e | 5.06 ± 0.81 d | 90.13 ± 0.83 a | 48.06 ± 4.80 de | 94.78 ± 0.53 a | 0.87 ± 0.01 a | 47.95 ± 5.87 a | 95.64 ± 0.82 abc | 0.87 ± 0.05 a |

| 1:4 | 64.58 ± 3.72 d | 4.73 ± 0.26 d | 87.33 ± 0.54 b | 56.98 ± 11.16 abc | 94.99 ± 0.66 a | 0.87 ± 0.01 a | 48.43 ± 6.18 a | 95.67 ± 0.63 a | 0.89 ± 0.01 a |

| 1:2 | 66.07 ± 3.24 cd | 4.84 ± 3.13 d | 86.03 ± 0.50 bc | 61.13 ± 8.66 ab | 93.96 ± 0.58 a | 0.84 ± 0.01 b | 42.96 ± 3.74 a | 95.48 ± 0.65 ab | 0.88 ± 0.02 b |

| 1:1 | 67.95 ± 2.79 cd | 7.64 ± 3.24 c | 84.52 ± 0.43 cd | 63.79 ± 6.84 a | 92.66 ± 0.62 b | 0.81 ± 0.01 c | 40.39 ± 3.95 b | 94.45 ± 0.57 abc | 0.88 ± 0.01 b |

| 2:1 | 66.48 ± 3.52 bc | 10.75 ± 3.14 b | 83.78 ± 0.76 d | 53.49 ± 10.76 bcd | 91.02 ± 1.65 c | 0.79 ± 0.01 d | 32.44 ± 5.59 bc | 93.77 ± 1.14 bc | 0.87 ± 0.02 c |

| 4:1 | 70.72 ± 3.55 bc | 11.06 ± 1.83 b | 81.36 ± 0.47 e | 48.91 ± 7.12 cde | 90.28 ± 1.34 c | 0.78 ± 0.01 de | 30.61 ± 4.71 c | 93.04 ± 0.84 c | 0.87 ± 0.01 c |

| 6:1 | 73.14 ± 2.82 a | 12.08 ± 0.69 a | 81.19 ± 0.86 e | 42.11 ± 10.08 e | 88.01 ± 2.35 d | 0.78 ± 0.01 e | 31.38 ± 4.98 d | 91.89 ± 1.76 d | 0.85 ± 0.01 c |

| F | 31.63 | 21.154 | 24.612 | 7.74 | 41.019 | 88.319 | 23.133 | 21.418 | 2.708 |

| p | 0.000 *** | 0.000 *** | 0.000 *** | 0.000 *** | 0.000 *** | 0.000 *** | 0.000 *** | 0.000 *** | 0.021 * |

| Evaluation Indicators | Correlation Coefficient | Gray Relational Grade | Ranking | |

|---|---|---|---|---|

| Porosity (%) | 0.662 ** | 0.848 | 1 | |

| Water absorption (%) | −0.095 | 0.784 | 9 | |

| Water-holding (%) | 0.792 ** | 0.829 | 2 | |

| Natural state sample | Hardness (N) | −0.821 ** | 0.664 | 13 |

| Rebound rate (%) | −0.689 ** | 0.806 | 6 | |

| Cohesion (J/m3) | 0.443 ** | 0.815 | 4 | |

| Water-saturated sample | Hardness (N) | −0.663 ** | 0.75 | 10 |

| Rebound rate (%) | −0.798 ** | 0.807 | 5 | |

| Cohesion (J/m3) | −0.328 * | 0.806 | 7 | |

| Germination rate (%) | −0.722 ** | 0.691 | 12 | |

| Fresh weight (mg) | 0.144 | 0.788 | 8 | |

| Seedling rate (%) | 0.029 | 0.7 | 11 | |

| Dry weight of plant (g) | 0.458 ** | 0.826 | 3 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Z.; Song, J.; Chu, X.; Liu, H.; Mu, Y.; Gu, S.; Wei, H.; Chen, X. Study on Preparation and Performance of Biomass–Polyurethane Light Planting Substrate. Agronomy 2025, 15, 2720. https://doi.org/10.3390/agronomy15122720

Ma Z, Song J, Chu X, Liu H, Mu Y, Gu S, Wei H, Chen X. Study on Preparation and Performance of Biomass–Polyurethane Light Planting Substrate. Agronomy. 2025; 15(12):2720. https://doi.org/10.3390/agronomy15122720

Chicago/Turabian StyleMa, Zhiyu, Jinqiu Song, Xuan Chu, Hongli Liu, Yinghui Mu, Song Gu, Hongyu Wei, and Xingping Chen. 2025. "Study on Preparation and Performance of Biomass–Polyurethane Light Planting Substrate" Agronomy 15, no. 12: 2720. https://doi.org/10.3390/agronomy15122720

APA StyleMa, Z., Song, J., Chu, X., Liu, H., Mu, Y., Gu, S., Wei, H., & Chen, X. (2025). Study on Preparation and Performance of Biomass–Polyurethane Light Planting Substrate. Agronomy, 15(12), 2720. https://doi.org/10.3390/agronomy15122720