Master–Slave Agricultural Machinery Cooperative Harvesting Control Based on VMD-Transformer-LSTM and Dual-Layer MPC

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Platforms

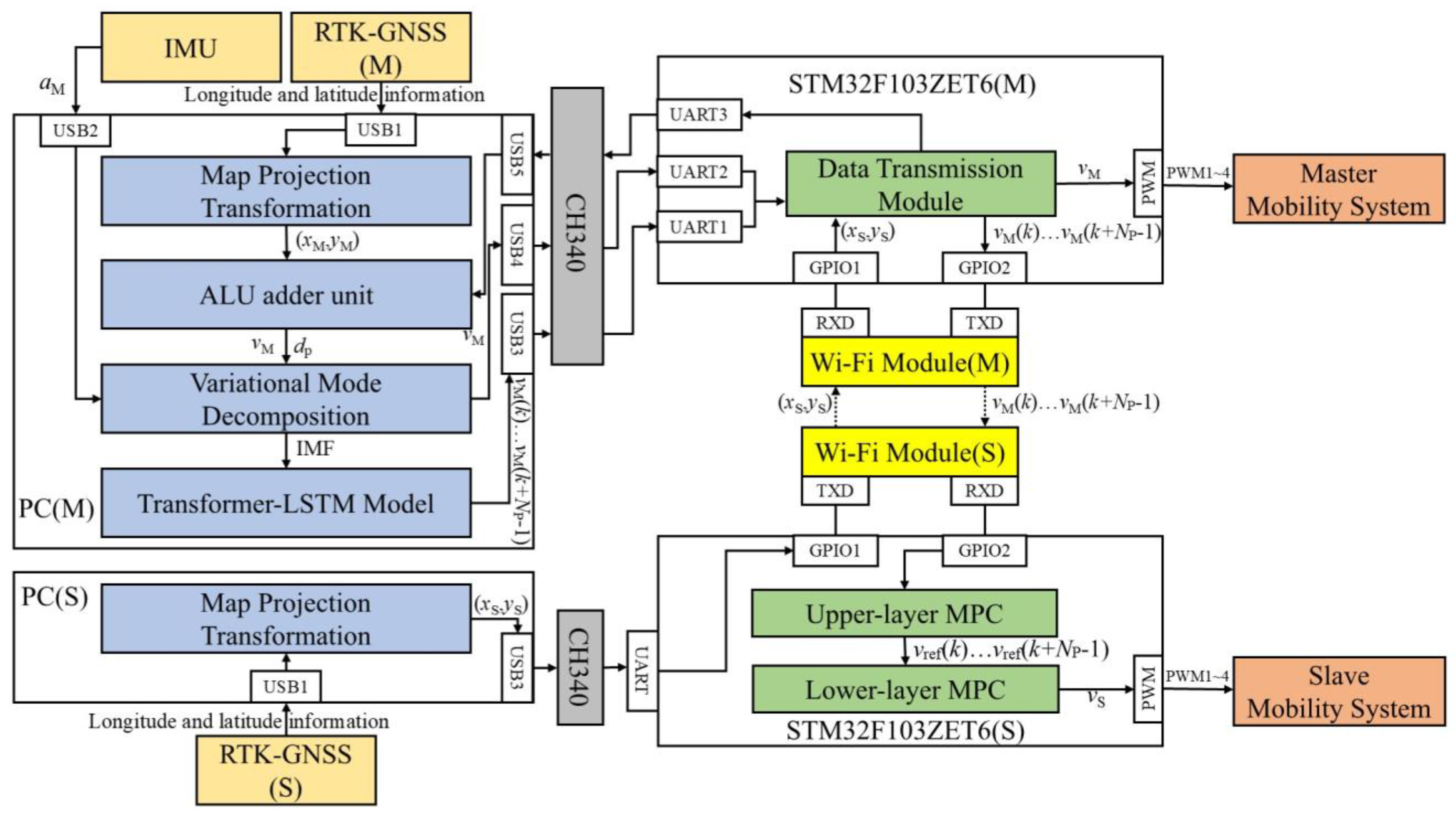

2.2. Control System

2.3. Algorithm Overview

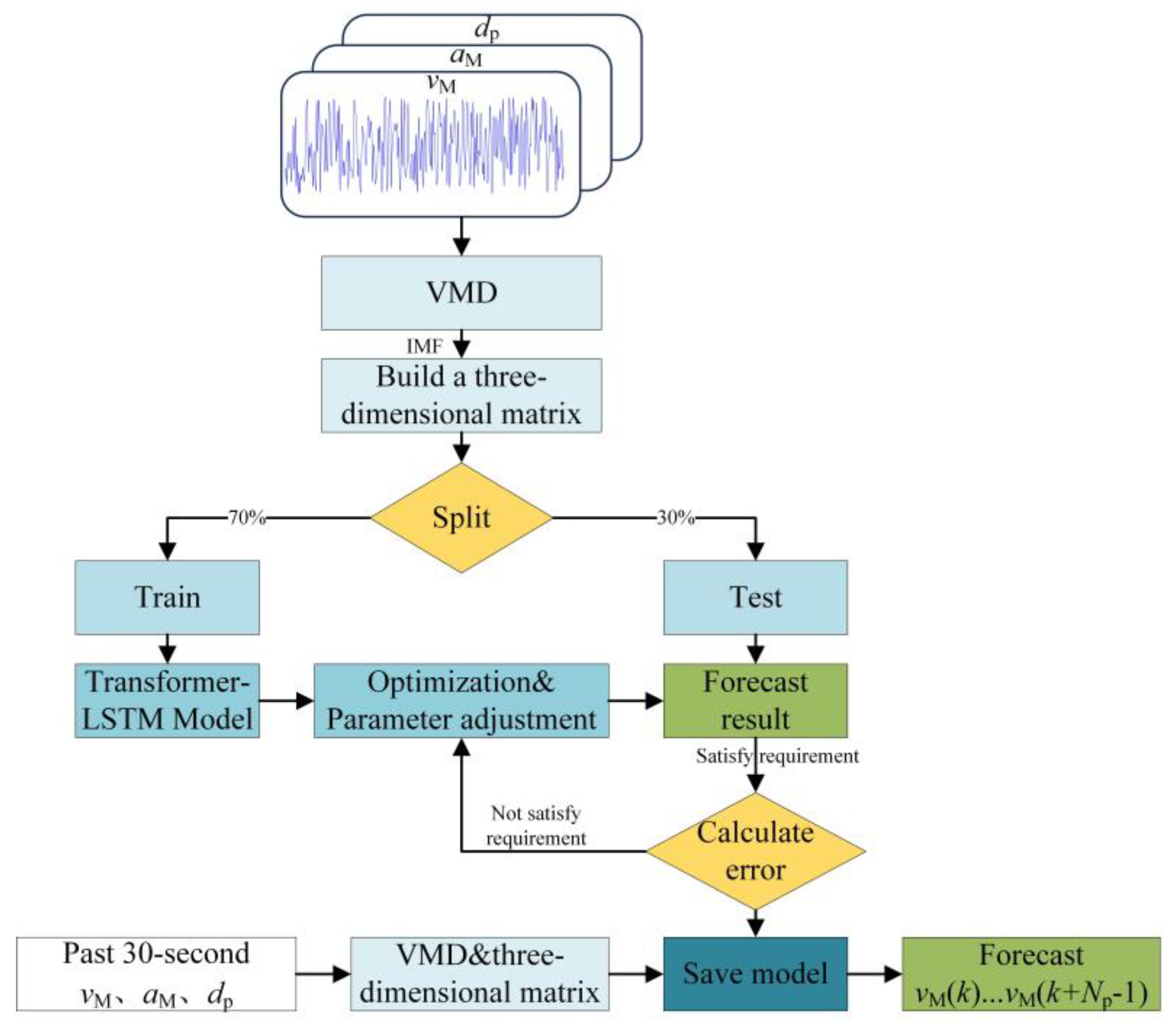

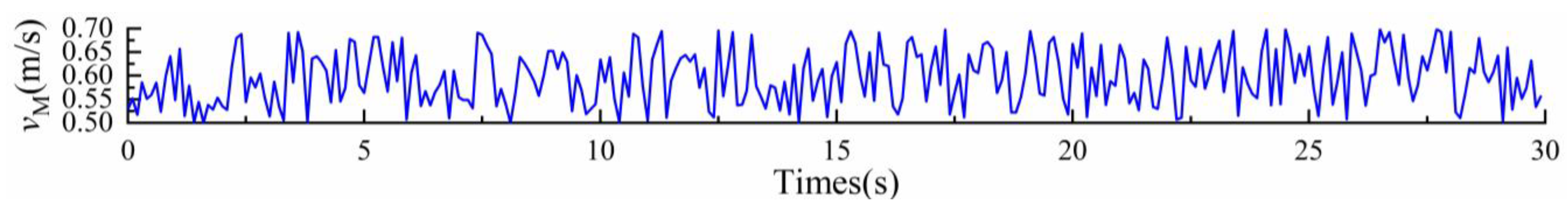

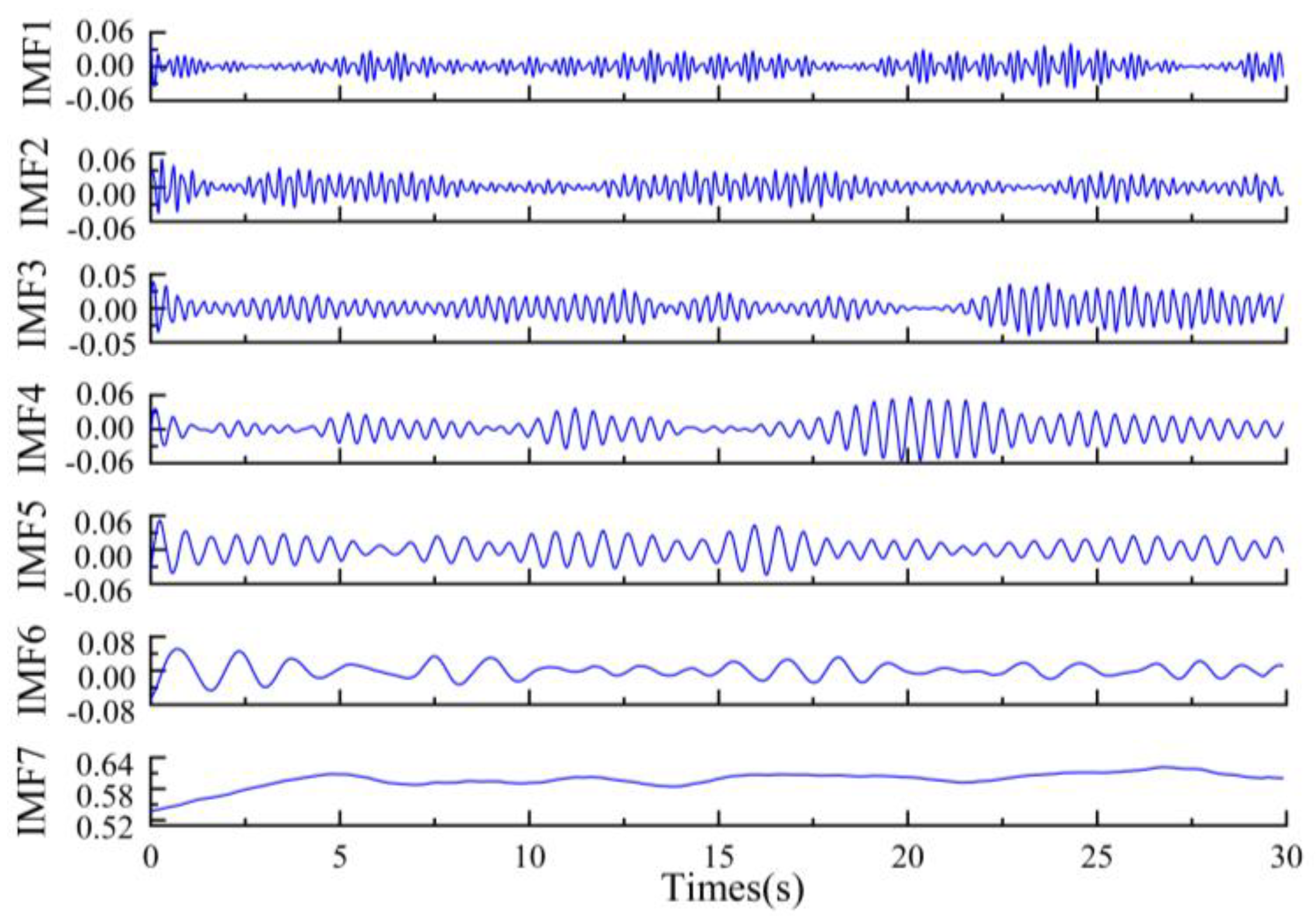

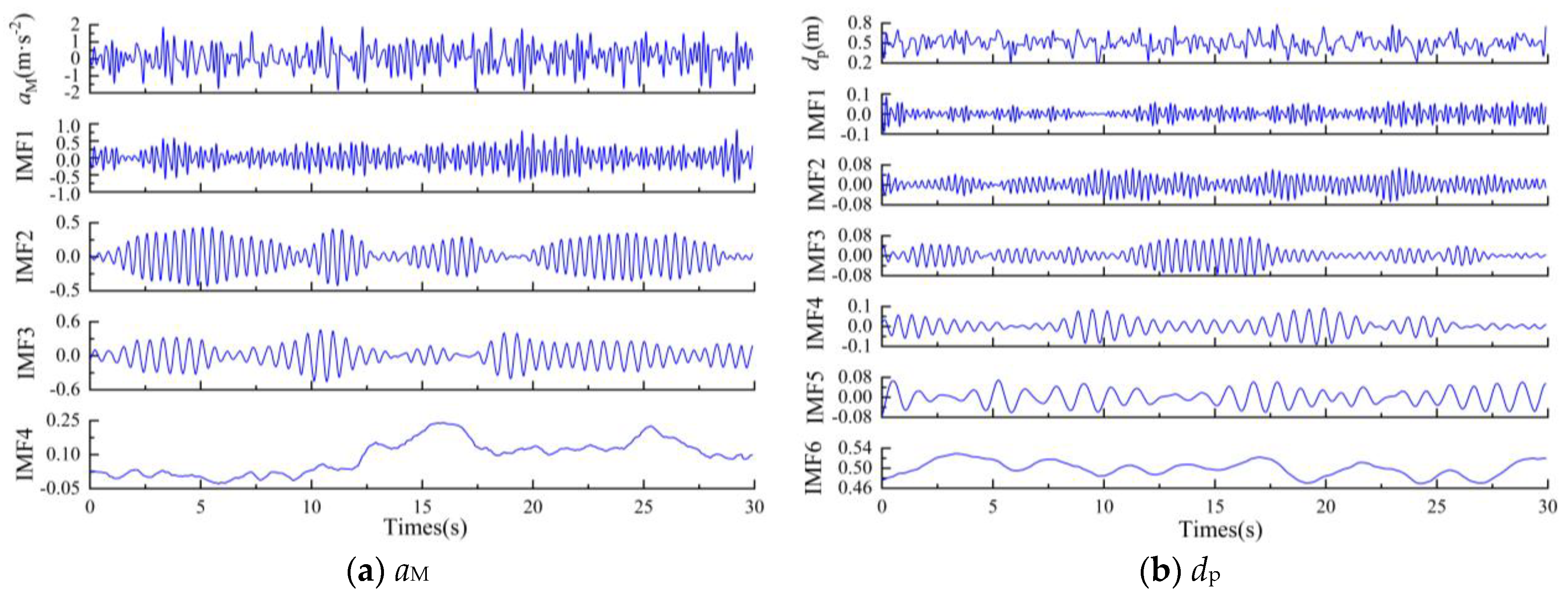

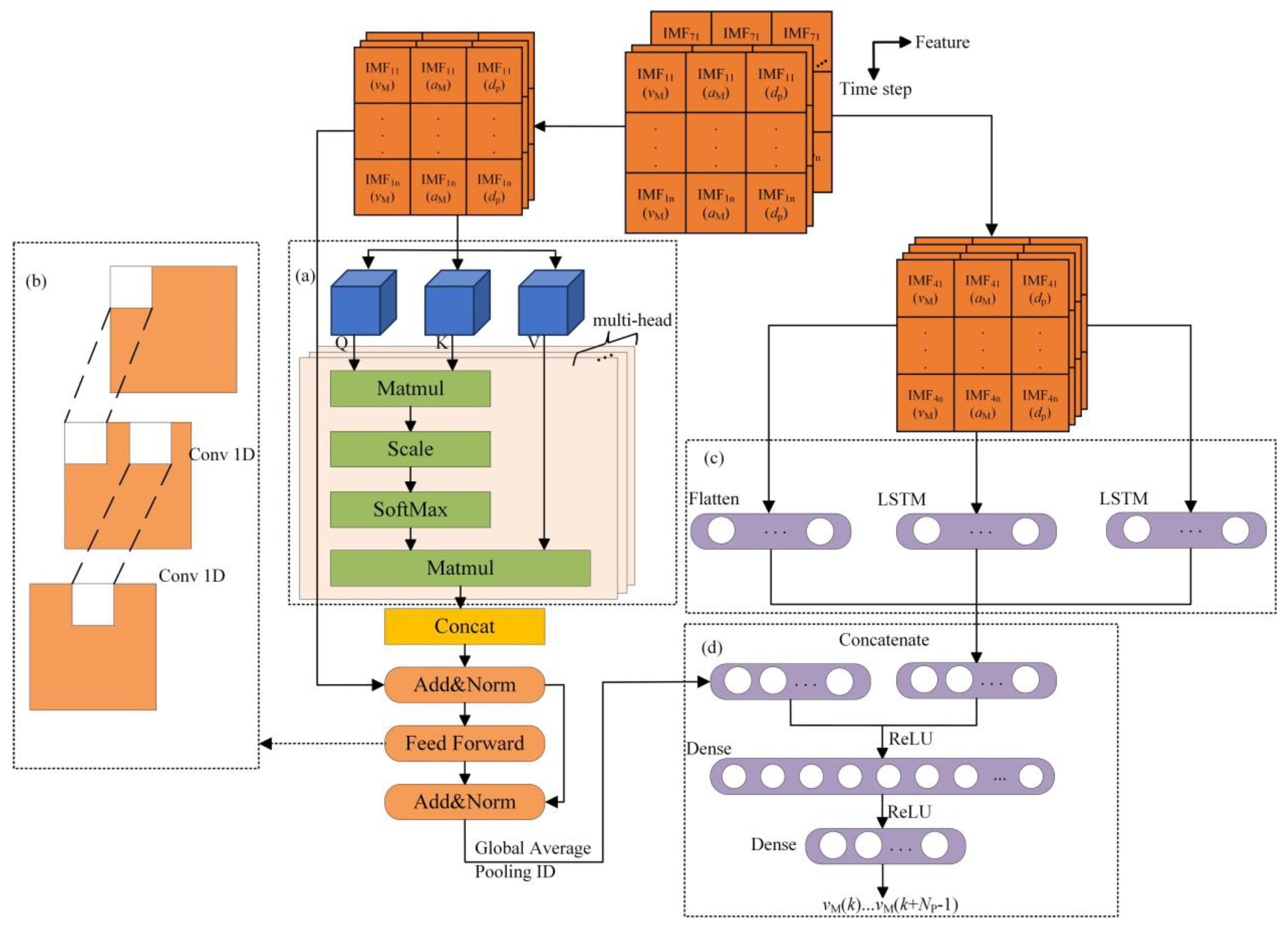

2.4. Master Speed Prediction

2.4.1. Master Speed Prediction Process

2.4.2. Variational Mode Decomposition

- (a)

- Decomposition Principle

- (b)

- Selection of the Number h of Components

2.4.3. Transformer-LSTM Prediction Model

2.4.4. Evaluation Metrics

2.5. Slave Speed Control

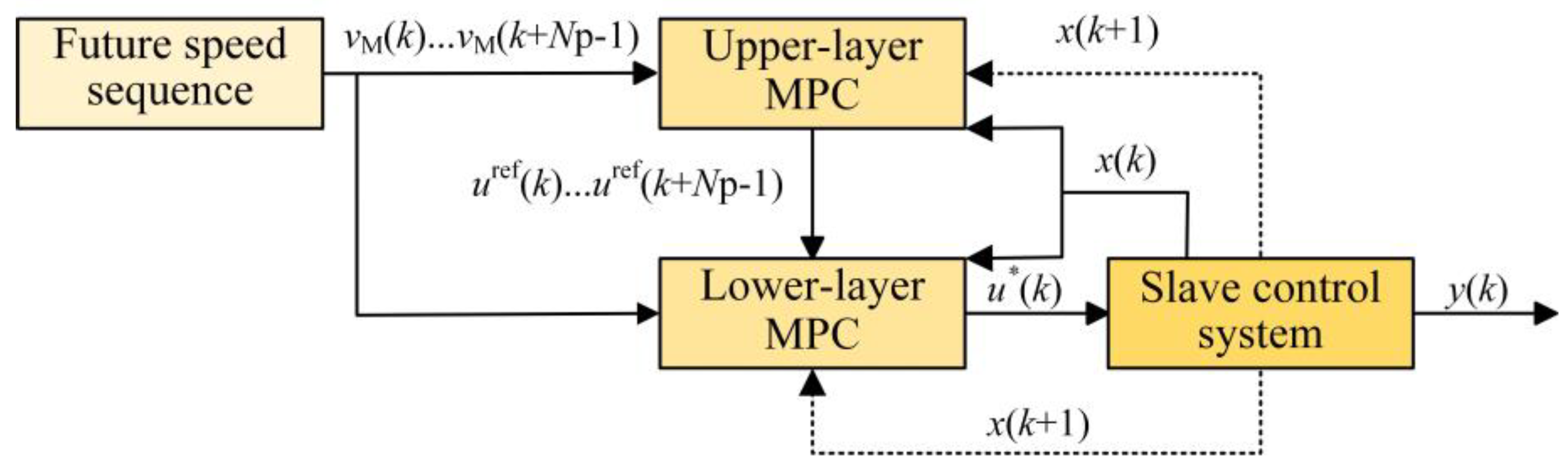

2.5.1. Dual-Layer MPC

2.5.2. Upper-Layer MPC Constraints

2.5.3. Lower-Layer MPC Constraints

3. Results and Discussion

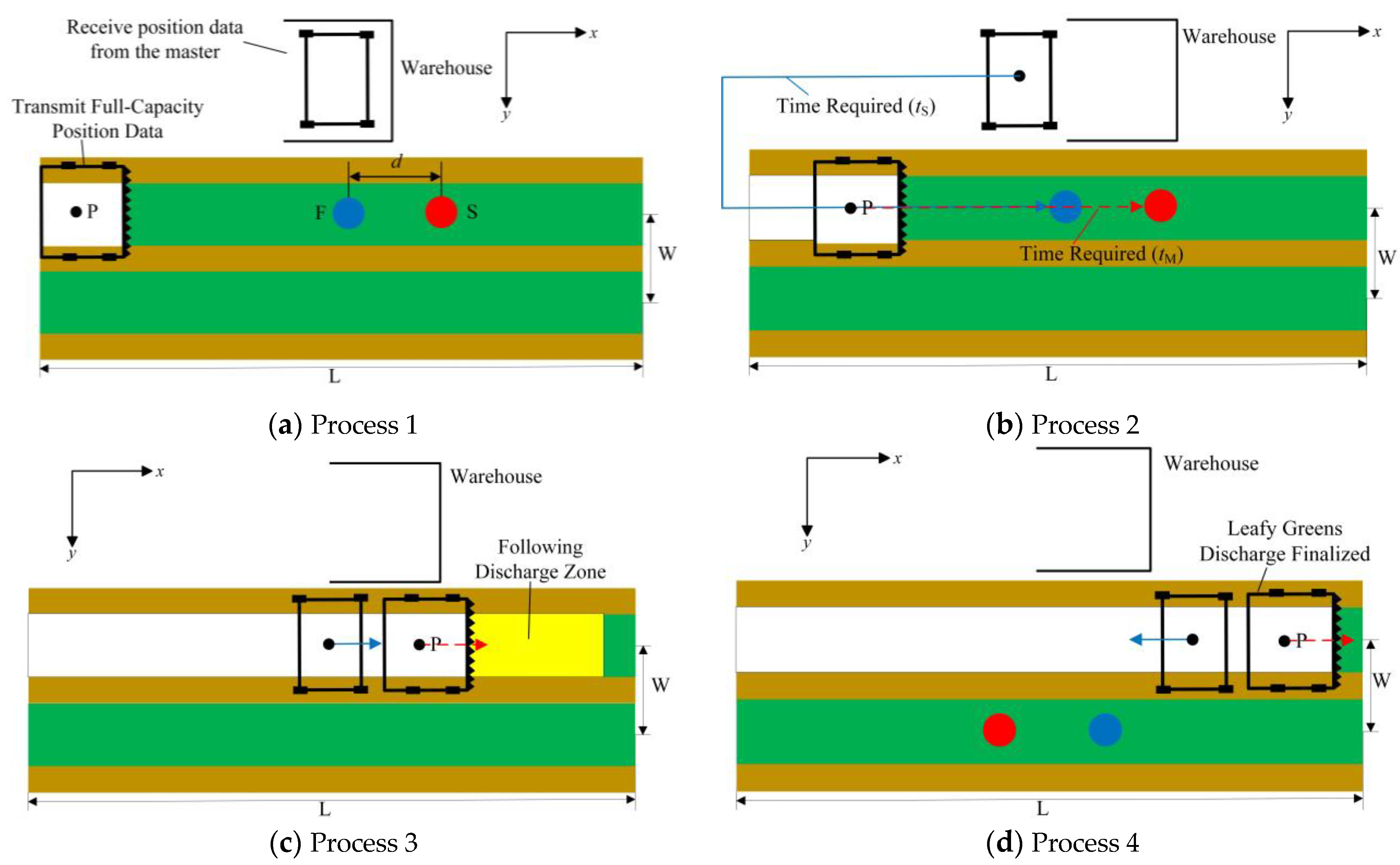

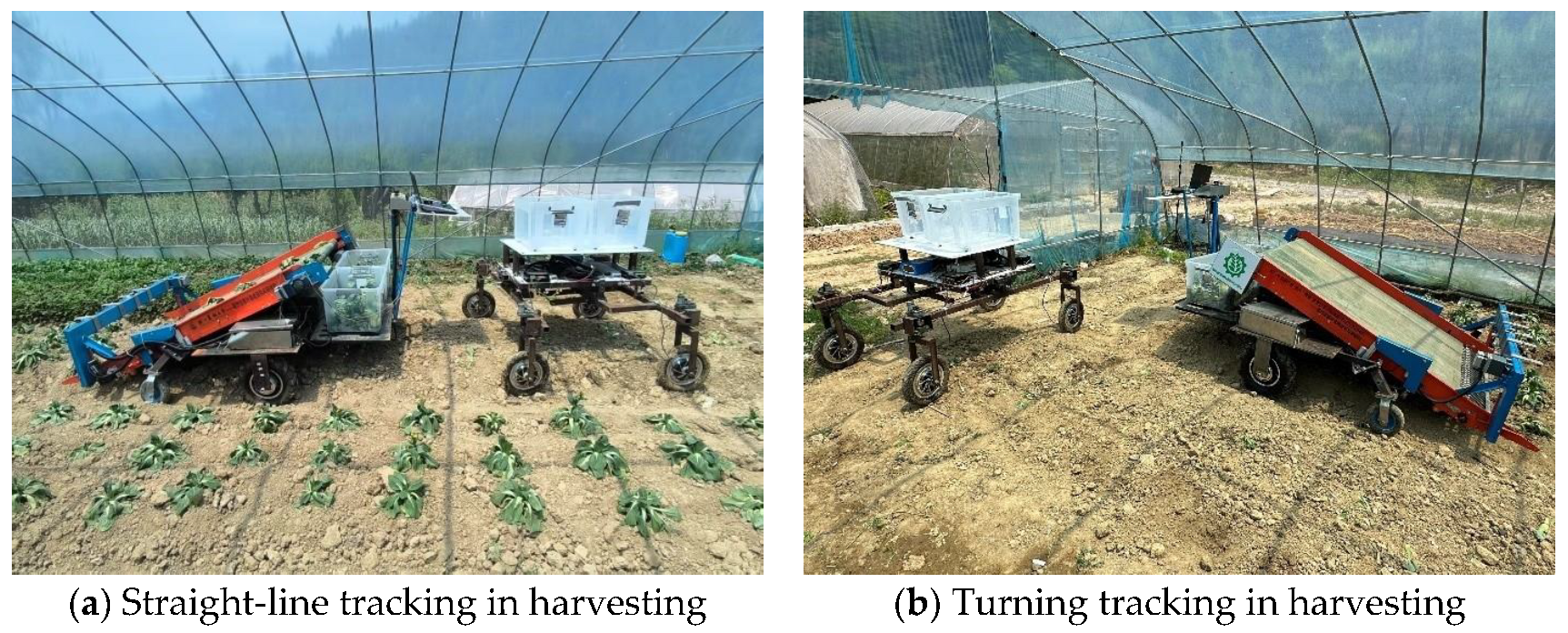

3.1. Experimental Scenario

3.2. Master Speed Prediction Experiment

3.2.1. Experimental Design

3.2.2. Experimental Results

3.2.3. Data Analysis

3.3. Slave Following Experiment

3.3.1. Experimental Design

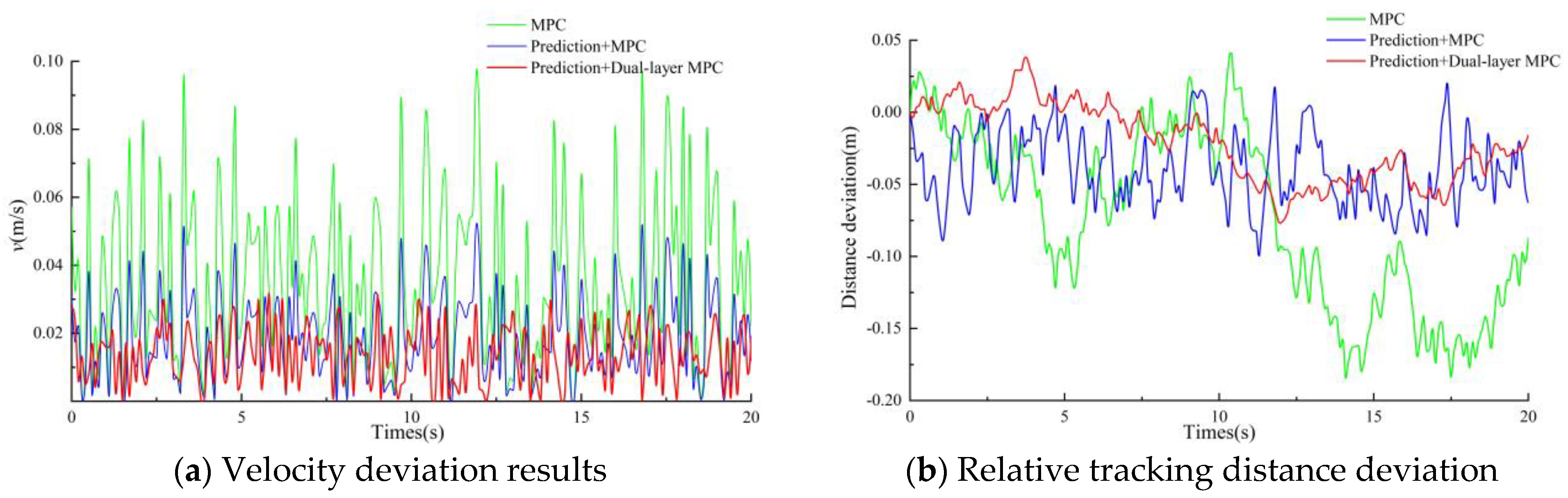

3.3.2. Data Analysis

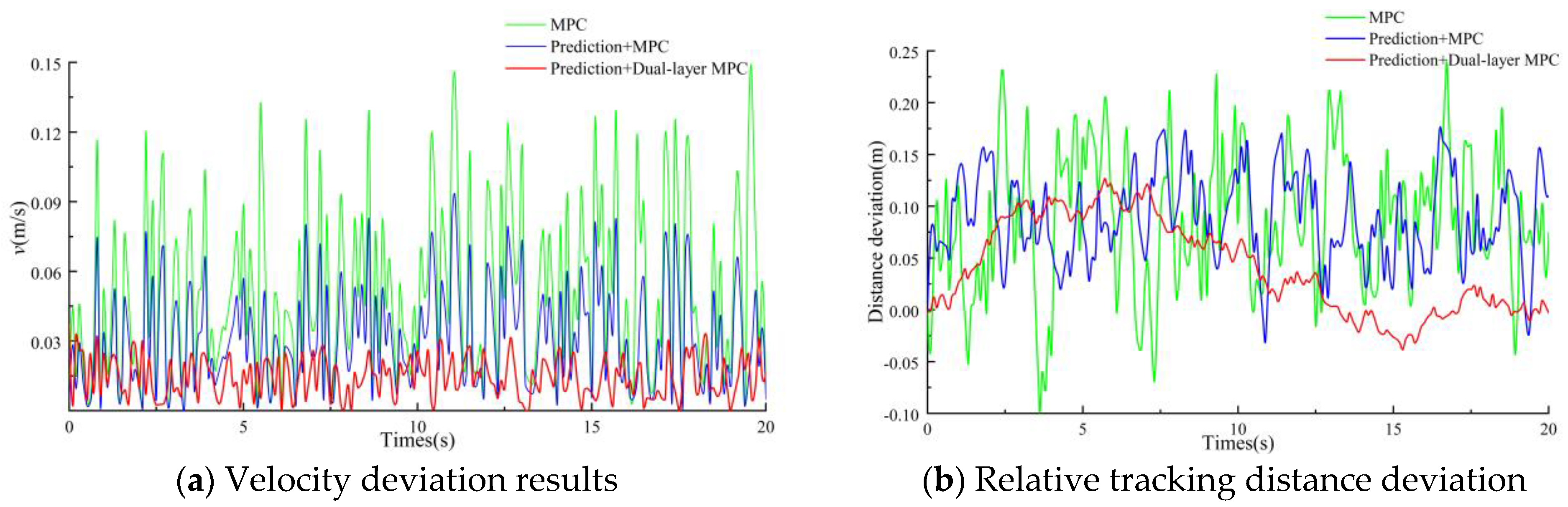

- (a)

- Straight-line Tracking

- (b)

- Turning tracking

| Evaluation Metrics | MPC | Prediction + MPC | Prediction + Dual-Layer MPC |

|---|---|---|---|

| average speed deviation (m/s) | 0.052 | 0.032 | 0.014 |

| Maximum distance deviation (m) | 0.234 | 0.176 | 0.126 |

| average distance deviation (m) | 0.092 | 0.078 | 0.047 |

| average speed deviation (m/s) | 0.050 | 0.037 | 0.015 |

| Maximum distance deviation (m) | 0.249 | 0.179 | 0.137 |

| average distance deviation (m) | 0.097 | 0.083 | 0.049 |

| average speed deviation (m/s) | 0.054 | 0.030 | 0.014 |

| Maximum distance deviation (m) | 0.202 | 0.174 | 0.118 |

| average distance deviation (m) | 0.091 | 0.076 | 0.045 |

| Paired Variables | Pairing Value 1 | Pairing Value 2 | p | Cohen’s d | |

|---|---|---|---|---|---|

| speed deviation | MPC vs. Prediction + dual-layer MPC | 0.0520 ± 0.0020 | 0.0143 ± 0.0006 | <0.001 | 1.167 |

| Prediction + MPC vs. Prediction + dual-layer MPC | 0.0330 ± 0.0036 | 0.0143 ± 0.0006 | <0.001 | 0.891 | |

| distance deviation | MPC vs. Prediction + dual-layer MPC | 0.0933 ± 0.0031 | 0.0470 ± 0.0020 | <0.001 | 0.898 |

| Prediction + MPC vs. Prediction + dual-layer MPC | 0.0790 ± 0.0036 | 0.0470 ± 0.0020 | 0.003 | 0.485 |

3.3.3. Data Analysis

- (a)

- Straight-line Tracking

- (b)

- Turning Tracking

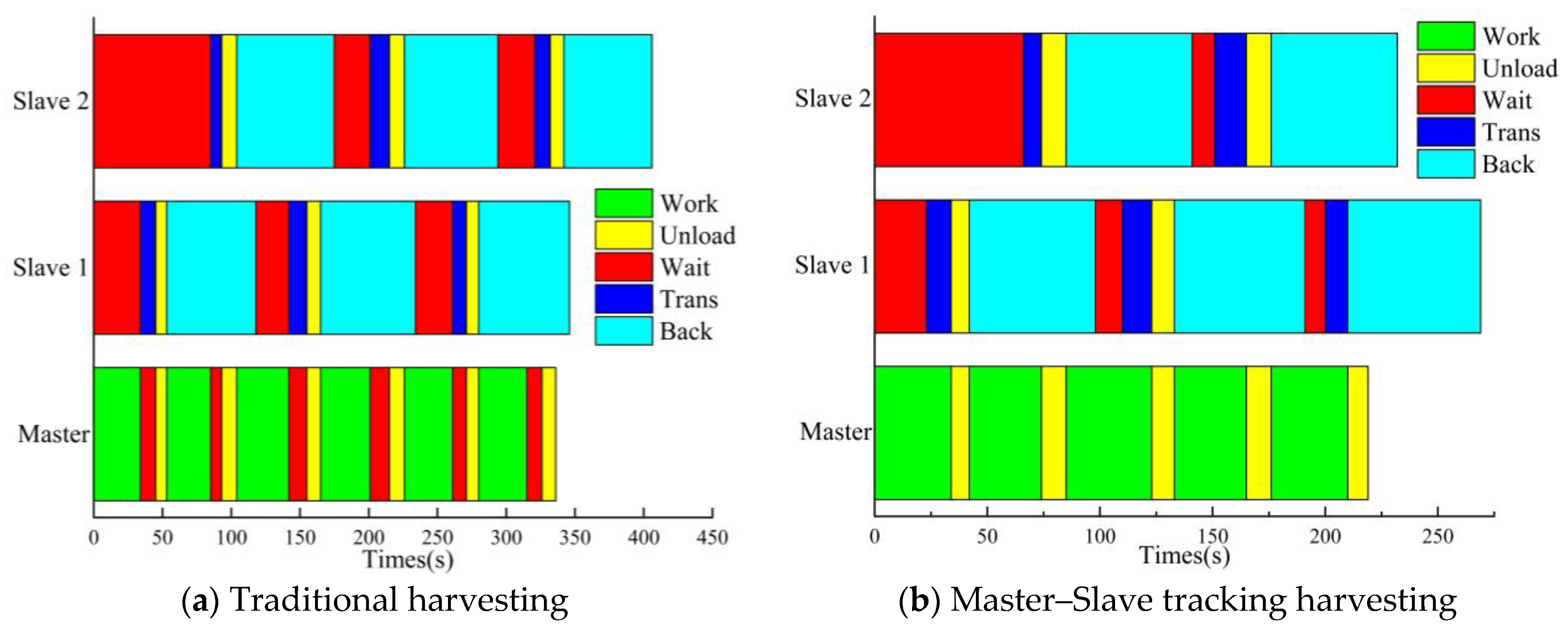

3.4. Collaborative Harvesting Operation Experiment

3.4.1. Experimental Design

3.4.2. Experimental Results

3.4.3. Data Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, H.; Zhong, T.; Zhang, K.; Wang, Y.; Zhang, M. Design of Agricultural Machinery Multi-machine Cooperative Navigation Service Platform Based on WebGIS. Trans. Chin. Soc. Agric. Mach. 2022, 53 (Suppl. S1), 28–35. [Google Scholar]

- Zhang, C.; Jia, L.; Liu, S.; Dou, G.; Liu, Y.; Kong, B. Dynamic job allocation method of multiple agricultural machinery cooperation based on improved ant colony algorithm. Sci. Rep. 2024, 14, 22414. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, F.; Chang, S.; Li, Z.; Li, Z. Research on a multiobjective cooperative operation scheduling method for agricultural machinery across regions with time windows. Comput. Electron. Agric. 2024, 224, 109121. [Google Scholar] [CrossRef]

- Yao, Z.; Zhao, C.; Zhang, T. Agricultural machinery automatic navigation technology. Iscience 2024, 27, 108714. [Google Scholar] [CrossRef]

- Zhang, M.; Li, X.; Wang, L.; Jin, L.; Wang, S. A Path Planning System for Orchard Mower Based on Improved A* Algorithm. Agronomy 2024, 14, 391. [Google Scholar] [CrossRef]

- Goodall, N.; Lan, C. Car-following characteristics of adaptive cruise control from empirical data. J. Transp. Eng. Part A Syst. 2020, 146, 04020097. [Google Scholar]

- Melson, C.; Levin, M.; Hammit, B.; Boyles, S. Dynamic traffic assignment of cooperative adaptive cruise control. Transp. Res. Part C Emerg. Technol. 2018, 90, 114–133. [Google Scholar]

- Wang, C.; Gong, S.; Zhou, A.; Li, T.; Peeta, S. Cooperative adaptive cruise control for connected autonomous vehicles by factoring communication-related constraints. Transp. Res. Part C Emerg. Technol. 2020, 113, 124–145. [Google Scholar] [CrossRef]

- Wu, X.; Yuan, C.; Shen, J.; Chen, L.; Cai, Y.; He, Y. Cooperative Control Research on Emergency Collision Avoidance of Human–Machine Cooperative Driving Vehicles. IEEE Trans. Veh. Technol. 2024, 73, 9632–9644. [Google Scholar] [CrossRef]

- Xu, G.; Chen, M.; Miao, H.; Yao, W.; Diao, P.; Wang, W. Following operation control method of farmer machinery based on model predictive control. Trans. Chin. Soc. Agric. Mach. 2020, 51 (Suppl. S2), 11–20. [Google Scholar]

- Ding, F.; Zhang, W.; Luo, X.; Hu, L.; Zhang, Z.; Wang, M.; Li, H.; Peng, M.; Wu, X.; Hu, L.; et al. Gain self-adjusting single neuron PID control method and experiments for longitudinal relative position of harvester and transport vehicle. Comput. Electron. Agric. 2023, 213, 108215. [Google Scholar] [CrossRef]

- Zhang, W.; Hu, L.; Ding, F.; Luo, X.; Zhang, Z.; Hu, L.; Huang, P.; Peng, M. Parking precise alignment control and cotransporter system for rice harvester and transporter. Comput. Electron. Agric. 2023, 215, 108443. [Google Scholar] [CrossRef]

- Roshanianfard, A.; Noguchi, N.; Okamoto, H.; Ishii, K. A review of autonomous agricultural vehicles (The experience of Hokkaido University). J. Terramech. 2023, 91, 155–183. [Google Scholar] [CrossRef]

- Mao, W.; Liu, H.; Hao, W.; Yang, F.; Liu, Z. Development of a combined orchard harvesting robot navigation system. Remote Sens. 2022, 14, 675. [Google Scholar] [CrossRef]

- Ma, Z.; Chong, K.; Ma, S.; Fu, W.; Yin, Y.; Yu, H.; Zhao, C. Control Strategy of Grain Truck Following Operation Considering Variable Loads and Control Delay. Agriculture 2022, 12, 1545. [Google Scholar] [CrossRef]

- Li, Y.; Yu, H.; Xiao, L.; Yuan, Y. Inspection robot GPS outages localization based on error Kalman filter and deep learning. Robot. Auton. Syst. 2025, 183, 104824. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, Z.; Wu, J.; Jin, Y.; Jeng, D.; Li, S.; Li, G.; Ding, D. Solving the temporal lags in local significant wave height prediction with a new VMD-LSTM model. Ocean. Eng. 2024, 313, 119385. [Google Scholar] [CrossRef]

- Zhang, X.; Hou, D.; Mao, Q.; Wang, Z. Predicting microseismic sensitive feature data using variational mode decomposition and transformer. J. Seismol. 2024, 28, 229–250. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, L.; Li, Y.; Li, D. Model predictive control and its application in agriculture: A review. Comput. Electron. Agric. 2018, 151, 104–117. [Google Scholar] [CrossRef]

- Cáceres, G.; Millán, P.; Pereira, M.; Lozano, D. Smart farm irrigation: Model predictive control for economic optimal irrigation in agriculture. Agronomy 2021, 11, 1810. [Google Scholar] [CrossRef]

- Soitinaho, R.; Oksanen, T.; Pereira, M.; Lozano, D. Local Navigation and Obstacle Avoidance for an Agricultural Tractor With Nonlinear Model Predictive Control. IEEE Trans. Control Syst. Technol. 2023, 31, 2043–2054. [Google Scholar] [CrossRef]

- Lee, C.; Chung, D.; Kim, J.; Kim, J. Nonlinear model predictive control with obstacle avoidance constraints for autonomous navigation in a canal environment. IEEE/ASME Trans. Mechatron. 2023, 29, 1985–1996. [Google Scholar] [CrossRef]

- Nag, A.; Yamamoto, K. Distributed control for flock navigation using nonlinear model predictive control. Adv. Robot. 2024, 38, 619–631. [Google Scholar] [CrossRef]

- Knudsen, B.; Alessandretti, A.; Jones, C.; Foss, B. A nonlinear model predictive control scheme for sensor fault tolerance in observation processes. Int. J. Robust Nonlinear Control. 2020, 30, 5657–5677. [Google Scholar] [CrossRef]

- Xiao, H.; Li, Z.; Chen, C. Formation control of leader–follower mobile robots’ systems using model predictive control based on neural-dynamic optimization. IEEE Trans. Ind. Electron. 2016, 63, 5752–5762. [Google Scholar] [CrossRef]

- Xu, T.; Liu, J.; Zhang, Z.; Chen, G.; Cui, D.; Li, H. Distributed MPC for trajectory tracking and formation control of multi-UAVs with leader-follower structure. IEEE Access 2023, 11, 128762–128773. [Google Scholar] [CrossRef]

- Noguchi, N.; Will, J.; Reid, J.; Zhang, Q. Development of a master–slave robot system for farm operations. Comput. Electron. Agric. 2004, 44, 1–19. [Google Scholar] [CrossRef]

- Dragomiretskiy, K.; Zosso, D. Variational mode decomposition. IEEE Trans. Signal Process. 2013, 62, 531–544. [Google Scholar] [CrossRef]

- Liu, S.; Zhao, R.; Yu, K.; Zheng, B.; Liao, B. Output-only modal identification based on the variational mode decomposition (VMD) framework. J. Sound Vib. 2022, 522, 116668. [Google Scholar] [CrossRef]

- Parmar, N.; Vaswani, A.; Uszkoreit, J.; Kaiser, L.; Shazeer, N.; Ku, A.; Tran, D. Image transformer. In Proceedings of the International Conference on Machine Learning, Orlando, FL, USA, 17–20 December 2018; pp. 4055–4064. [Google Scholar]

- Han, K.; Xiao, A.; Wu, E.; Guo, J.; Xu, C.; Wang, Y. Transformer in transformer. Adv. Neural Inf. Process. Syst. 2021, 34, 15908–15919. [Google Scholar]

- Han, K.; Wang, Y.; Chen, H.; Chen, X.; Guo, J.; Liu, Z. A survey on vision transformer. IEEE Trans. Pattern Anal. Mach. Intell. 2022, 45, 87–110. [Google Scholar] [CrossRef] [PubMed]

- Greff, K.; Srivastava, R.; Koutník, J.; Steunebrink, B.; Schmidhuber, B. LSTM: A search space odyssey. IEEE Trans. Neural Netw. Learn. Syst. 2016, 28, 2222–2232. [Google Scholar] [CrossRef] [PubMed]

| h | IMF1/Hz | IMF2/Hz | IMF3/Hz | IMF4/Hz | IMF5/Hz | IMF6/Hz | IMF7/Hz | IMF8/Hz |

|---|---|---|---|---|---|---|---|---|

| 3 | 0.3729 | 0.1525 | 0 | |||||

| 4 | 0.3729 | 0.2034 | 0.1186 | 0 | ||||

| 5 | 0.3831 | 0.3051 | 0.2034 | 0.1186 | 0 | |||

| 6 | 0.4407 | 0.3729 | 0.2034 | 0.1525 | 0.0746 | 0 | ||

| 7 | 0.4407 | 0.3729 | 0.3051 | 0.2034 | 0.1525 | 0.0746 | 0 | |

| 8 | 0.4407 | 0.3729 | 0.3051 | 0.2373 | 0.2034 | 0.1525 | 0.0746 | 0 |

| Model | LSTM | Transformer | Transformer-LSTM | VMD-Transformer-LSTM |

|---|---|---|---|---|

| MAE | 0.0193 | 0.0267 | 0.0128 | 0.0107 |

| MAPE | 3.24% | 4.51% | 2.16% | 1.79% |

| RMSE | 0.0241 | 0.0333 | 0.0163 | 0.0136 |

| R2 | 87.84% | 76.89% | 92.57% | 94.81% |

| Paired Variables | Mean Difference | p | Cohen’s d | Lower Bound of the 95%CI | Upper Bound of the 95%CI |

|---|---|---|---|---|---|

| LSTM vs. VMD-Transformer-LSTM | 0.022 | <0.001 | 1.67 | 0.0193 | 0.0248 |

| Transformer vs. VMD-Transformer-LSTM | 0.024 | <0.001 | 1.45 | 0.0208 | 0.0277 |

| Transformer-LSTM vs. VMD-Transformer-LSTM | 0.007 | <0.001 | 0.70 | 0.0046 | 0.0085 |

| Evaluation Metrics | MPC | Prediction + MPC | Prediction + Dual-Layer MPC |

|---|---|---|---|

| average speed deviation (m/s) | 0.036 | 0.019 | 0.007 |

| Maximum distance deviation (m) | 0.185 | 0.101 | 0.068 |

| average distance deviation (m) | 0.077 | 0.041 | 0.028 |

| average speed deviation (m/s) | 0.032 | 0.017 | 0.008 |

| Maximum distance deviation (m) | 0.179 | 0.099 | 0.071 |

| average distance deviation (m) | 0.074 | 0.038 | 0.029 |

| average speed deviation (m/s) | 0.039 | 0.022 | 0.006 |

| Maximum distance deviation (m) | 0.192 | 0.124 | 0.063 |

| average distance deviation (m) | 0.081 | 0.049 | 0.025 |

| Paired Variables | Pairing Value 1 | Pairing Value 2 | p | Cohen’s d | |

|---|---|---|---|---|---|

| speed deviation | MPC vs. Prediction + dual-layer MPC | 0.0357 ± 0.0035 | 0.0070 ± 0.0010 | <0.001 | 1.463 |

| Prediction + MPC vs. Prediction + dual-layer MPC | 0.0193 ± 0.0025 | 0.0070 ± 0.0010 | <0.001 | 0.891 | |

| distance deviation | MPC vs. Prediction + dual-layer MPC | 0.0773 ± 0.0035 | 0.0273 ± 0.0021 | <0.001 | 1.335 |

| Prediction + MPC vs. Prediction + dual-layer MPC | 0.0427 ± 0.0055 | 0.0273 ± 0.0021 | <0.001 | 0.885 |

| Harvesting Model | Agricultural Machinery Categories | Average Non-Operating Time(s) | Average Total Time Consumption(s) |

|---|---|---|---|

| Traditional harvesting | Master | 67 | 336 |

| Slave 1 | 85 | 346 | |

| Slave 2 | 138 | 406 | |

| Master–slave tracking harvesting | Master | 0 | 210 |

| Slave 1 | 44 | 269 | |

| Slave 2 | 76 | 232 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, J.; Yao, L.; Chen, Y.; Bian, C.; Xu, L.; Yao, L. Master–Slave Agricultural Machinery Cooperative Harvesting Control Based on VMD-Transformer-LSTM and Dual-Layer MPC. Agronomy 2025, 15, 2308. https://doi.org/10.3390/agronomy15102308

Wen J, Yao L, Chen Y, Bian C, Xu L, Yao L. Master–Slave Agricultural Machinery Cooperative Harvesting Control Based on VMD-Transformer-LSTM and Dual-Layer MPC. Agronomy. 2025; 15(10):2308. https://doi.org/10.3390/agronomy15102308

Chicago/Turabian StyleWen, Junhao, Liwen Yao, Yuhong Chen, Ce Bian, Lijun Xu, and Lijian Yao. 2025. "Master–Slave Agricultural Machinery Cooperative Harvesting Control Based on VMD-Transformer-LSTM and Dual-Layer MPC" Agronomy 15, no. 10: 2308. https://doi.org/10.3390/agronomy15102308

APA StyleWen, J., Yao, L., Chen, Y., Bian, C., Xu, L., & Yao, L. (2025). Master–Slave Agricultural Machinery Cooperative Harvesting Control Based on VMD-Transformer-LSTM and Dual-Layer MPC. Agronomy, 15(10), 2308. https://doi.org/10.3390/agronomy15102308