Empirical Modelling of Power Requirements in Olive Pruning Residue Shredding: Effects of Varying Moisture Content and Rotary Speeds

Abstract

1. Introduction

2. Materials and Methods

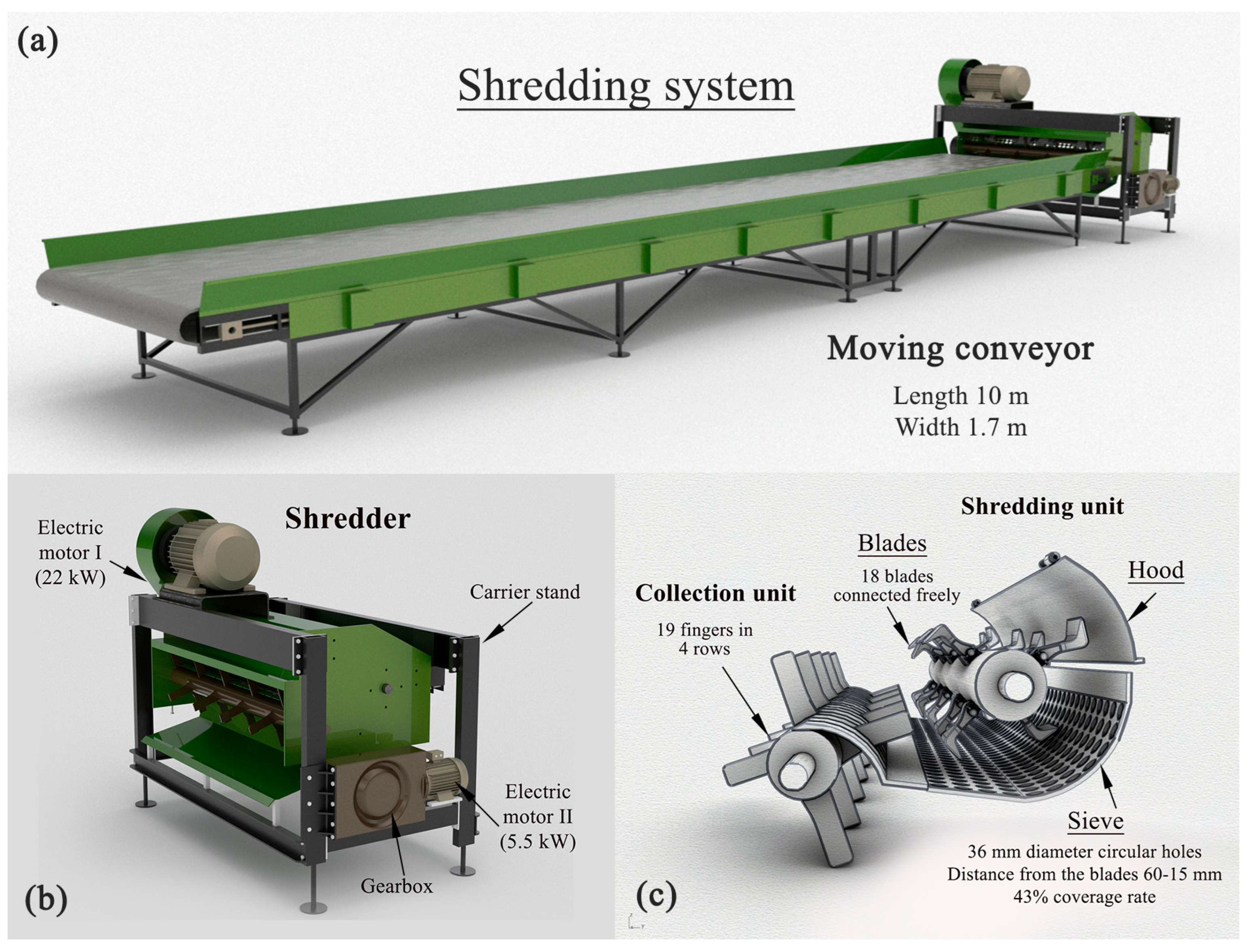

2.1. Shredding System

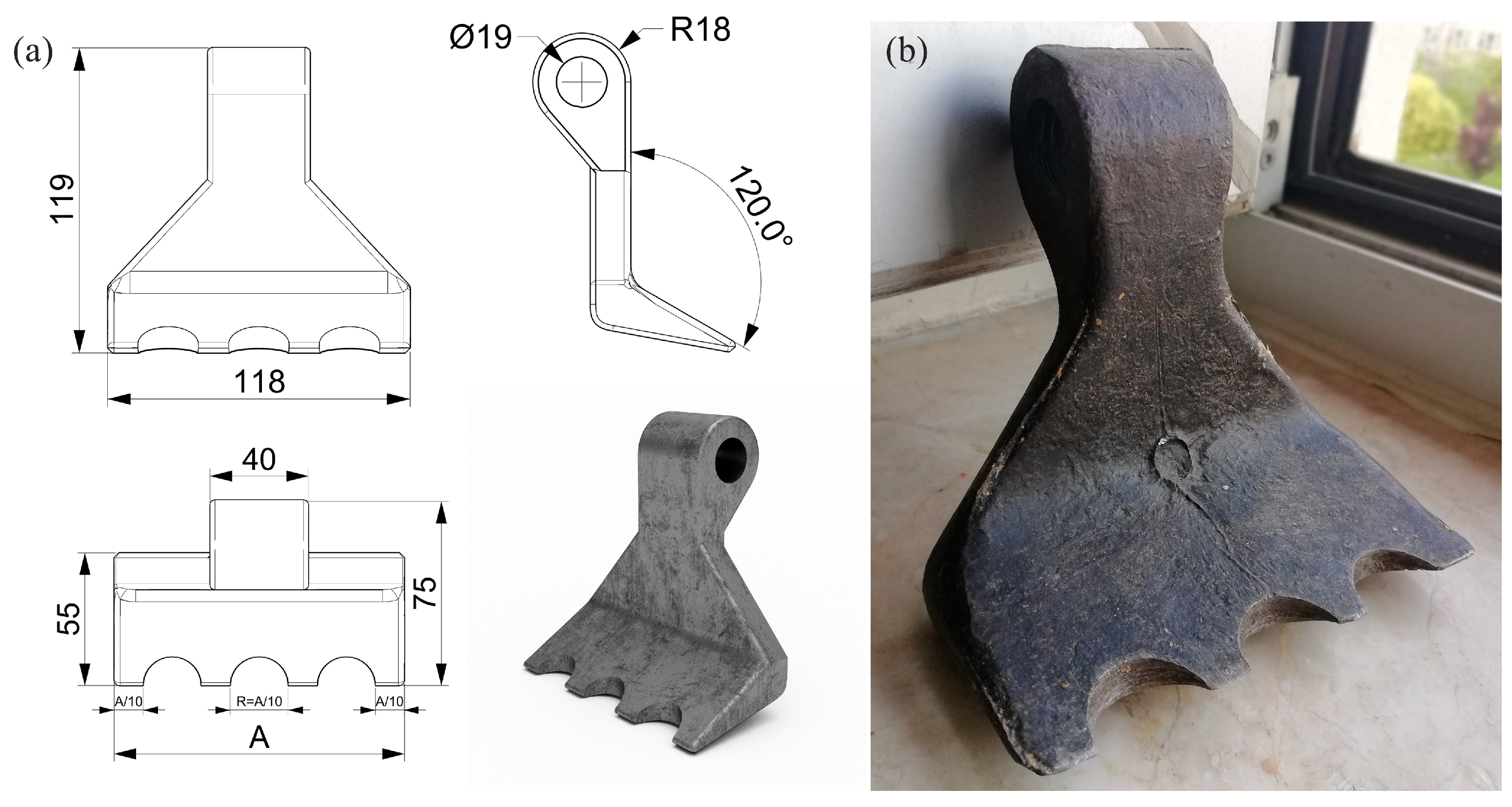

2.2. Shredder Blade

2.3. Pruning Residues

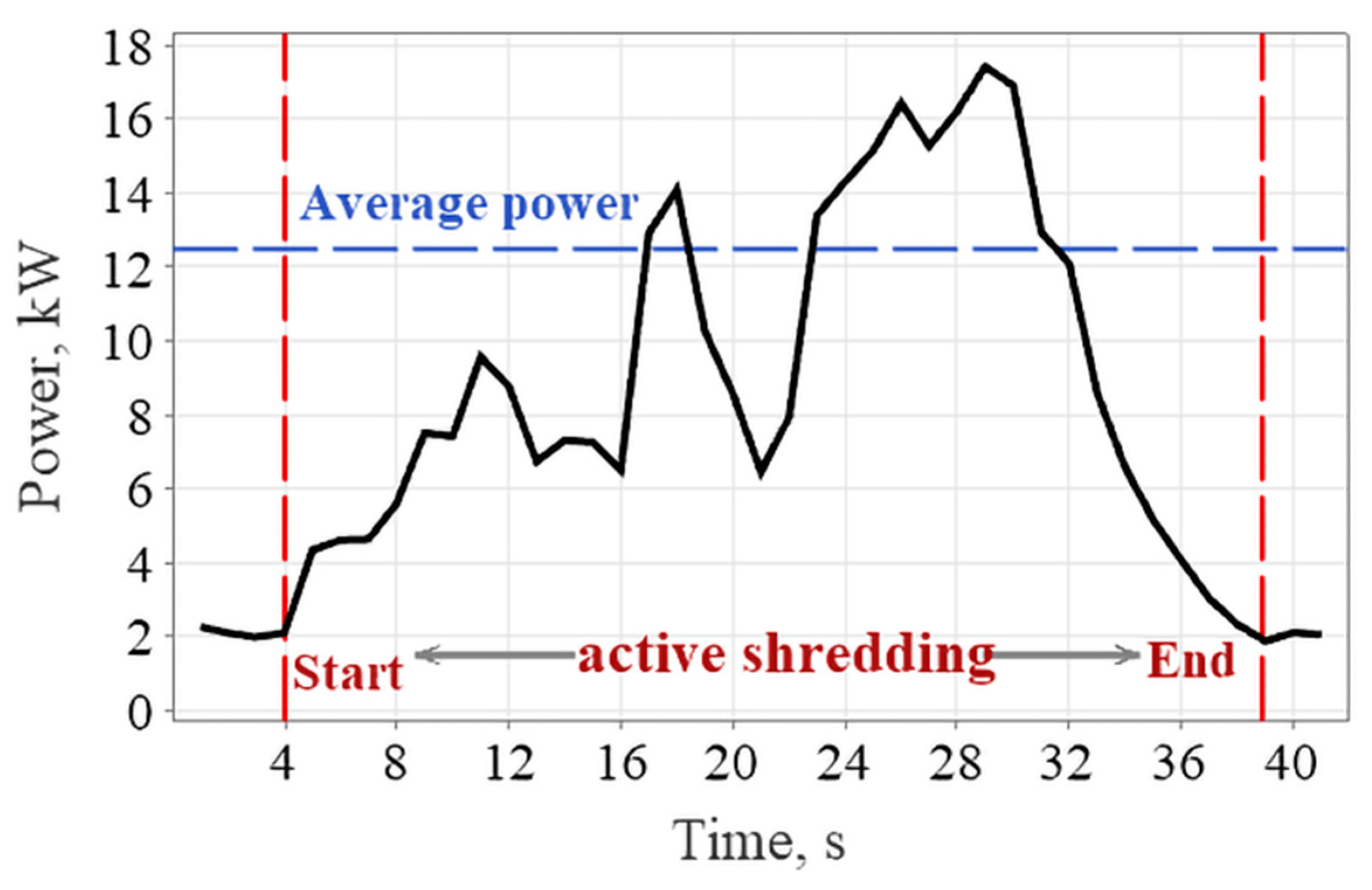

2.4. Determination of Power Values

2.5. Experiment Conditions

2.6. Model Development and Statical Analysis

- i.

- Effect of moisture content variation for each rotor speed;

- ii.

- Effect of rotor speed variation for each moisture content;

- iii.

- Combined effect of rotor speed and moisture content variation.

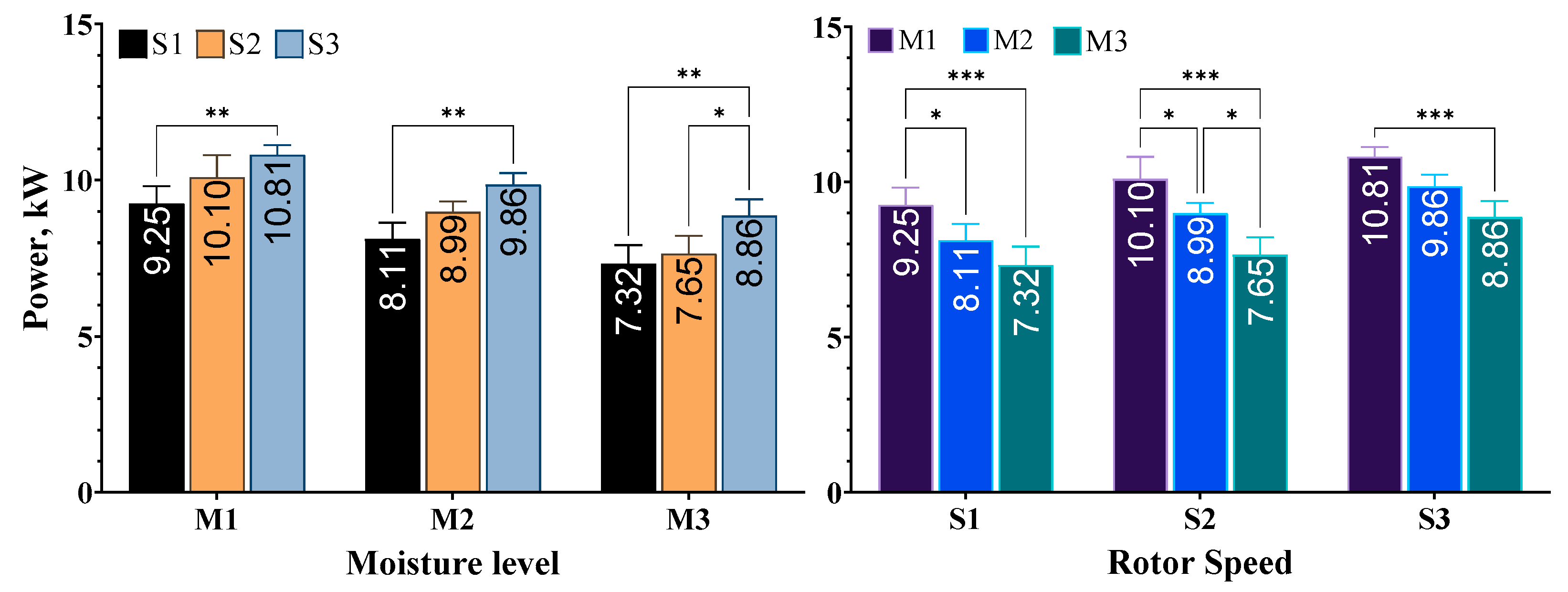

3. Results and Discussion

4. Conclusions

5. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- FAOSTAT. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 14 February 2024).

- García, J.M.; Nino, L.; Martínez-Patiño, C.; Álvarez, C.; Castro, E.; Negro, M.J. Biorefinery based on olive biomass. State of the art and future trends. Bioresour. Technol. 2014, 159, 421–432. [Google Scholar] [CrossRef]

- Ntalos, G.A.; Grigoriou, A.H. Characterization and utilisation of vine pruning as a wood substitute for particleboard production. Ind. Crops Prod. 2002, 16, 59–68. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Nati, C. Harvesting Vineyard Pruning Residues for Energy Use. Biosyst. Eng. 2010, 105, 316–322. [Google Scholar] [CrossRef]

- Velazquez-Marti, B.; Fernandez-Gonzalez, E. Analysis of the process of biomass harvesting with collecting chippers fed by pick up headers in plantations of olive trees. Biosyst. Eng. 2009, 104, 184–190. [Google Scholar] [CrossRef]

- Fedrizzi, M.; Sperandio, G.; Pagano, M.; Pochi, D.; Fanigliulo, R.; Recchi, P. A prototype machine for harvesting and chipping of pruning residues: First test on hazelnut plantation (Corylus avellana L.). In Proceedings of the International Conference of Agricultural Engineering, CIGR-Ageng, Valencia, Spain, 8–12 July 2012. [Google Scholar]

- Bilandzija, N.; Voca, N.; Kricka, T.; Matin, A.; Jurisic, V. Energy potential of fruit tree pruned biomass in Croatia. SJAR 2012, 10, 292–298. [Google Scholar] [CrossRef]

- Nasser, R.A.; Al-Mefarrej, H.A. Evaluation of using midribs of date palm fronds as a raw material for wood-cement composite panels industry in Saudi Arabia. Acta Hortic 2010, 882, 43–50. [Google Scholar] [CrossRef]

- Dyjakon, K.; Boer, J.D.; Bukowskı, P.; Adamczyk, F.; Frąckowıak, P. Wooden biomass potential from apple orchards in Poland. Drewno 2016, 59, 73–86. [Google Scholar] [CrossRef]

- Giorio, C.; Pizzini, S.; Marchiori, E.; Piazza, R.; Grigolato, S.; Zanetti, M.; Cavalli, R.; Simoncin, M.; Soldà, L.; Badocco, D.; et al. Sustainability of using vineyard pruning residues as an energy source: Combustion performances and environmental impact. Fuel 2019, 243, 371–380. [Google Scholar] [CrossRef]

- Fernandez-Sarria, A.; Lopez-Cortes, I.; Estornell, J.; Velazquez-Marti, B.; Salazar, D. Estimating residual biomass of olive tree crops using terrestrial laser scanning. Int. J. Appl. Earth Obs. Geoinf. 2019, 75, 163170. [Google Scholar] [CrossRef]

- Canakci, M.; Topakci, M.; Karayel, D.; Agsaran, B.; Kabas, O.; Yigit, M. The effect of different blades on the performance values of a pruning chopper used to improve soil properties. BJAS 2019, 25, 1052–1059. Available online: https://www.agrojournal.org/25/05-29.pdf (accessed on 1 March 2024).

- Margaritis, N.; Grammelis, P.; Karampinis, E.; Kanaveli, I. Impact of Torrefaction on Vine Pruning’s Fuel Characteristics. J. Energy Eng. 2020, 146, 04020006. [Google Scholar] [CrossRef]

- Suardi, A.; Saia, S.; Alfano, V.; Rezaei, N.; Cetera, P.; Bergonzoli, S.; Pari, L. Pruning harvesting with modular towed chipper: Little effect of the machine setting and configuration on performance despite strong impact on wood chip quality. PLoS ONE 2021, 16, e0261810. [Google Scholar] [CrossRef] [PubMed]

- Çanakci, M.; Topakci, M.; Karayel, D.; Ağsaran, B. Determination of basic machinery management data for PTO driven pruning residue chopper. JAS 2010, 16, 46–54. (In Turkish) [Google Scholar] [CrossRef]

- Calatrava, J.; Franco, J.A. Using pruning residues as mulch: Analysis of its adoption and process of diffusion in Southern Spain olive orchards. J. Environ. Manag. 2011, 92, 620–629. [Google Scholar] [CrossRef] [PubMed]

- Jimenez-Jimenez, F.; Blanco-Roldan, G.L.; Marquez-Garcia, F.; Castro-Garcia, S.; Aguera-Vega, J. Estimation of soil coverage of chopped pruning residues in olive orchards by image analysis. SJAR 2013, 11, 626. [Google Scholar] [CrossRef]

- Manzanares, P.; Ruiz, E.; Ballesteros, M.; Negro, M.J.; Gallego, F.J.; Lopez-Linares, J.C.; Castro, E. Residual biomass potential in olive tree cultivation and olive oil industry in Spain: Valorisation proposal in a biorefinery context. SJAR 2017, 15, e0206. [Google Scholar] [CrossRef]

- Holtz, B.A.; McKenry, M.V.; Caesar-TonThat, T.C. Wood chipping almond brush and its effect on the almond rhizosphere, soil aggregation and soil nutrients. Acta Hortic 2004, 638, 127–137. [Google Scholar] [CrossRef]

- Repullo, M.A.; Carbonell, R.; Hidalgo, J.; Rodrı’guez-Lizana, A.; Ordóñez, R. Using olive pruning residues to cover soil and improve fertility. Soil Tillage Res. 2012, 124, 36–46. [Google Scholar] [CrossRef]

- Çanakcı, M. Chopping and mechanization of the pruning residues. Hasad (Harvest) J.—Plant Prod. 2014, 29, 70–78. (In Turkish) [Google Scholar]

- Martinez-Valencia, L.; Camenzind, D.; Wigmosta, M.; Garcia-Perez, M.; Wolcott, M. Biomass supply chain equipment for renewable fuels production: A review. Biomass Bioenergy 2021, 148, 106054. [Google Scholar] [CrossRef]

- Chen, M.; Chen, Z.; Luo, L.; Tang, Y.; Cheng, J.; Wei, H.; Wang, J. Dynamic visual servo control methods for continuous operation of a fruit harvesting robot working throughout an orchard. Comput. Electron. Agric. 2024, 219, 108774. [Google Scholar] [CrossRef]

- Wang, C.; Li, C.; Han, Q.; Wu, F.; Zou, X. A Performance Analysis of a Litchi Picking Robot System for Actively Removing Obstructions, Using an Artificial Intelligence Algorithm. Agronomy 2023, 13, 2795. [Google Scholar] [CrossRef]

- Wang, H.; Lin, Y.; Xu, X.; Chen, Z.; Wu, Z.; Tang, Y. A Study on Long-Close Distance Coordination Control Strategy for Litchi Picking. Agronomy 2022, 12, 1520. [Google Scholar] [CrossRef]

- Witney, B. Choosing and Using Farm Machines; Land Technology Ltd.: Edinburgh, Scotland, 1996; p. 412. [Google Scholar]

- Rotz, C.A.; Muhtar, H.A. Rotary power requirements for harvesting and handling equipment. Appl. Eng. Agric. 1992, 8, 751–757. [Google Scholar] [CrossRef]

- Yiğit, M.; Çanakcı, M. Pruning Machine Blade. Design Registration; Turkish Patent and Trademark Office: Ankara, Turkey, 25 October 2021; No: 2021 010165. [Google Scholar]

- ASABE S358.2; Moisture Measurement—Forages. ASABE Standards: St. Joseph, MI, USA, 2006.

- Spinelli, R.; Magagnotti, N.; Paletto, G.; Preti, C. Determining the impact of some wood characteristics on the performance of a mobile chipper. Silva Fenn. 2011, 45, 85–95. [Google Scholar] [CrossRef]

- Savoie, P.; Gagnon-Bouchard, M. High-speed processing of woody stems with a flail hammer shredder. Appl. Eng. Agric. 2012, 27, 5–12. [Google Scholar] [CrossRef]

- Pecenka, R.; Lenz, H.; Jekayinfa, S.O.; Hoffmann, T. Influence of Tree Species, Harvesting Method and Storage on Energy Demand and Wood Chip Quality When Chipping Poplar, Willow and Black Locust. Agriculture 2020, 10, 116. [Google Scholar] [CrossRef]

- Asuero, A.G.; Sayago, A.; González, A.G. The Correlation Coefficient: An Overview. Crit. Rev. Anal. Chem. 2006, 36, 41–59. [Google Scholar] [CrossRef]

- Flizikowski, J.; Kruszelnicka, W.; Macko, M. The Development of Efficient Contaminated Polymer Materials Shredding in Recycling Processes. Polymers 2021, 13, 713. [Google Scholar] [CrossRef]

- Johnson, P.C.; Clementson, C.L.; Mathanker, S.K.; Grift, T.E.; Hansen, A.C. Cutting energy characteristics of Miscanthus × giganteus stems with varying oblique angle and cutting speed. Biosyst. Eng. 2012, 112, 42–48. [Google Scholar] [CrossRef]

- Xue, Z.; Fu, J.; Chen, Z.; Wang, F.; Han, S.; Ren, L. Optimization experiment on parameters of chopping device of forage maize harvester. J. Jilin Univ. 2020, 50, 739–748. [Google Scholar]

- Liang, R.; Zhang, B.; Zhou, P.; Li, Y.; Meng, H.; Kan, Z. Power consumption analysis of the multi-edge toothed device for shredding the residual film and impurity mixture. Comput. Electron. Agric. 2022, 196, 106898. [Google Scholar] [CrossRef]

- Igboayaka, E.C.; Ndukwu, M.C.; Ernest, I.C. A Modelling approach for determining the throughput capacity and energy consumption of a cassava tuber shredder. JCAMS 2018, 6, 801–816. [Google Scholar] [CrossRef]

| Olive Pruning Residues | Shredding System | |||||

|---|---|---|---|---|---|---|

| Moisture Content | Material Density | Frequency | Collector Rotary Speed | Feed Rate (Conveyor Speed) | Shredder Rotary Speeds | |

| % | kg/m | Hz | rpm | km/h | rpm | |

| wb. | db. | 23.50 | 45 | 1.5 | - | |

| 45 (M1) | 1.83 | 1 | 27.00 | - | - | 1200 (S1) |

| 35 (M2) | 1.54 | 33.70 | - | - | 1500 (S2) | |

| 25 (M3) | 1.34 | 40.53 | - | - | 1800 (S3) | |

| Moisture Level | Models | MAE | RMSE | R² |

|---|---|---|---|---|

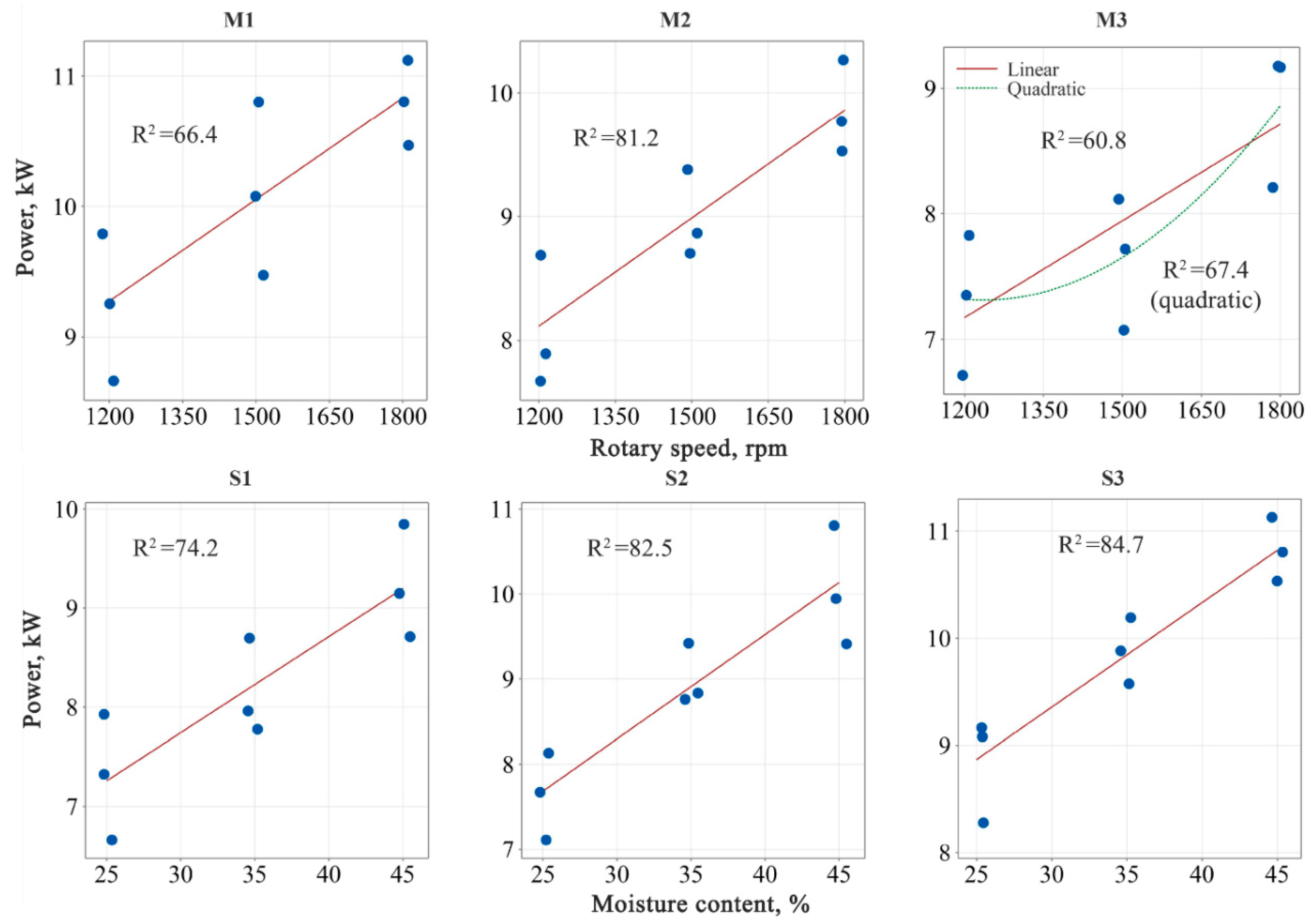

| M1 | y = 6.162 + 0.002594 s * | 0.362 | 0.452 | 0.664 |

| M2 | y = 4.617 + 0.002913 s | 0.307 | 0.343 | 0.812 |

| M3 | y = 4.084 + 0.002572 s | 0.453 | 0.506 | 0.608 |

| yq = 14.774 − 0.0121 s + 5 × 10−6 s2 | 0.413 | 0.461 | 0.674 | |

| Rotary Speed | ||||

| S1 | y = 4.839 + 0.09682 m ** | 0.419 | 0.467 | 0.742 |

| S2 | y = 4.626 + 0.12240 m | 0.381 | 0.460 | 0.825 |

| S3 | y = 6.431 + 0.09749 m | 0.290 | 0.338 | 0.847 |

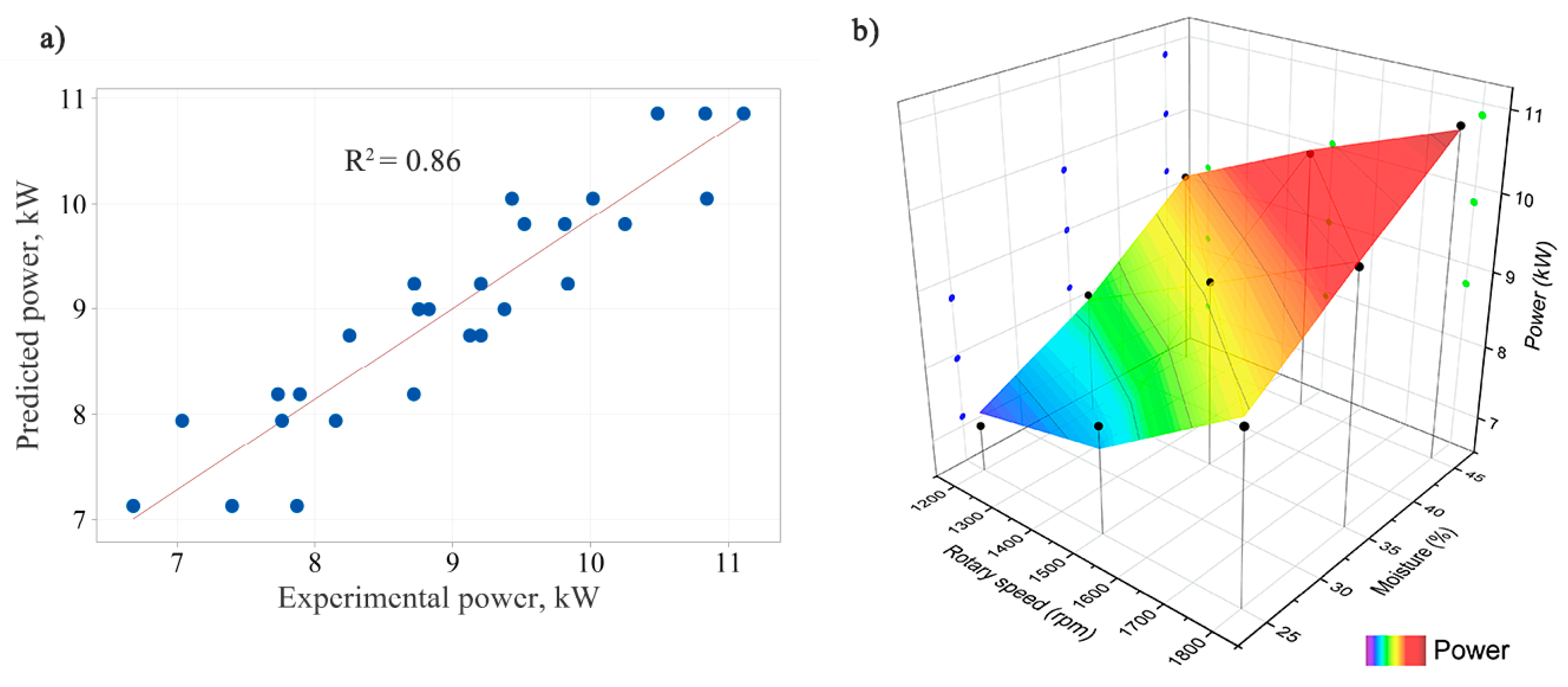

| Rotary Speed and Moisture Level | Final Model | |||

| S, M | y = 1.259 + 0.002693 s + 0.10557 m | 0.376 | 0.441 | 0.859 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yiğit, M.; Çanakcı, M.; Karayel, D. Empirical Modelling of Power Requirements in Olive Pruning Residue Shredding: Effects of Varying Moisture Content and Rotary Speeds. Agronomy 2024, 14, 1455. https://doi.org/10.3390/agronomy14071455

Yiğit M, Çanakcı M, Karayel D. Empirical Modelling of Power Requirements in Olive Pruning Residue Shredding: Effects of Varying Moisture Content and Rotary Speeds. Agronomy. 2024; 14(7):1455. https://doi.org/10.3390/agronomy14071455

Chicago/Turabian StyleYiğit, Mete, Murad Çanakcı, and Davut Karayel. 2024. "Empirical Modelling of Power Requirements in Olive Pruning Residue Shredding: Effects of Varying Moisture Content and Rotary Speeds" Agronomy 14, no. 7: 1455. https://doi.org/10.3390/agronomy14071455

APA StyleYiğit, M., Çanakcı, M., & Karayel, D. (2024). Empirical Modelling of Power Requirements in Olive Pruning Residue Shredding: Effects of Varying Moisture Content and Rotary Speeds. Agronomy, 14(7), 1455. https://doi.org/10.3390/agronomy14071455