Life Cycle Assessment for Soybean Supply Chain: A Case Study of State of Pará, Brazil

Abstract

1. Introduction

Aim of this Study

2. Materials and Methods

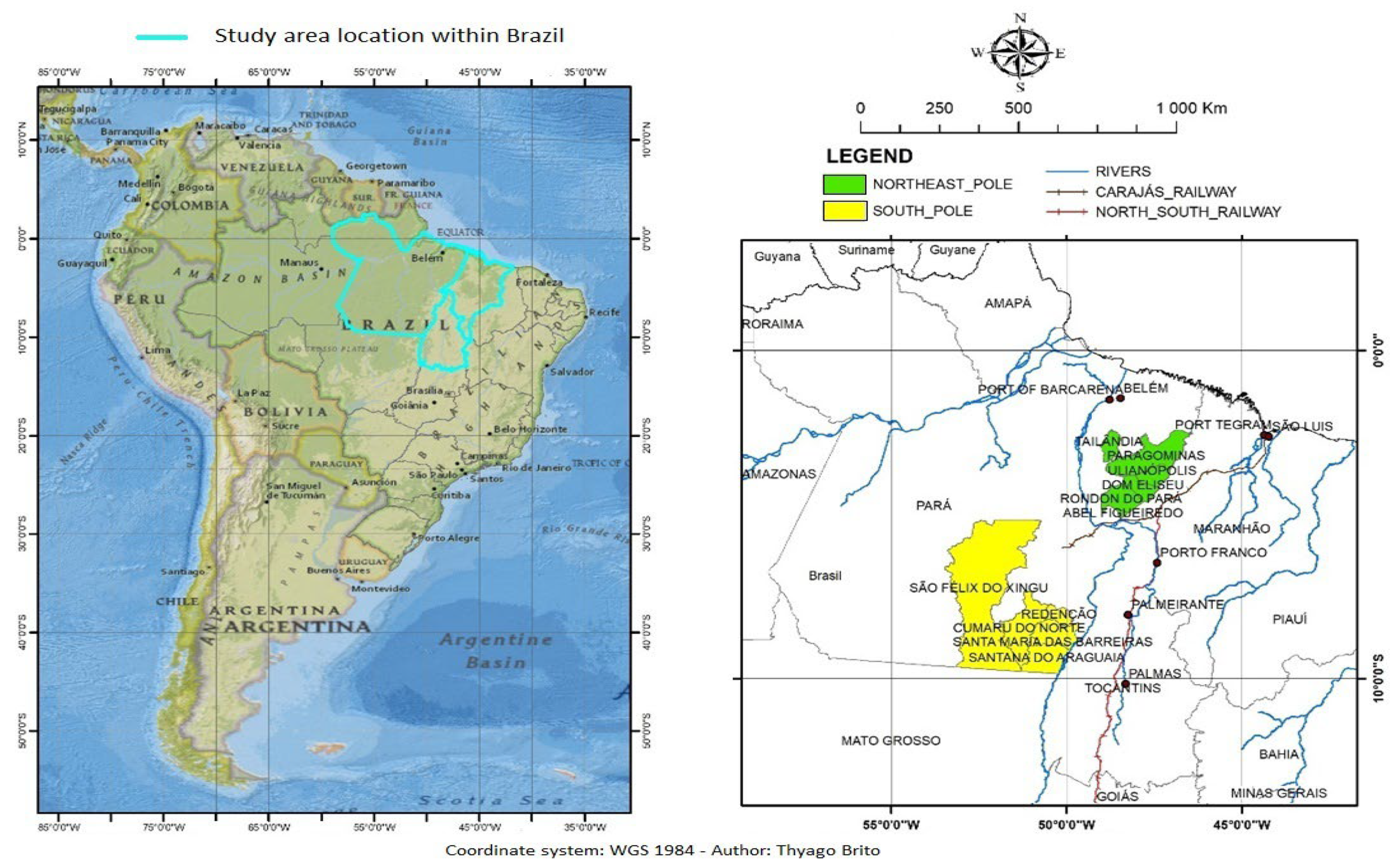

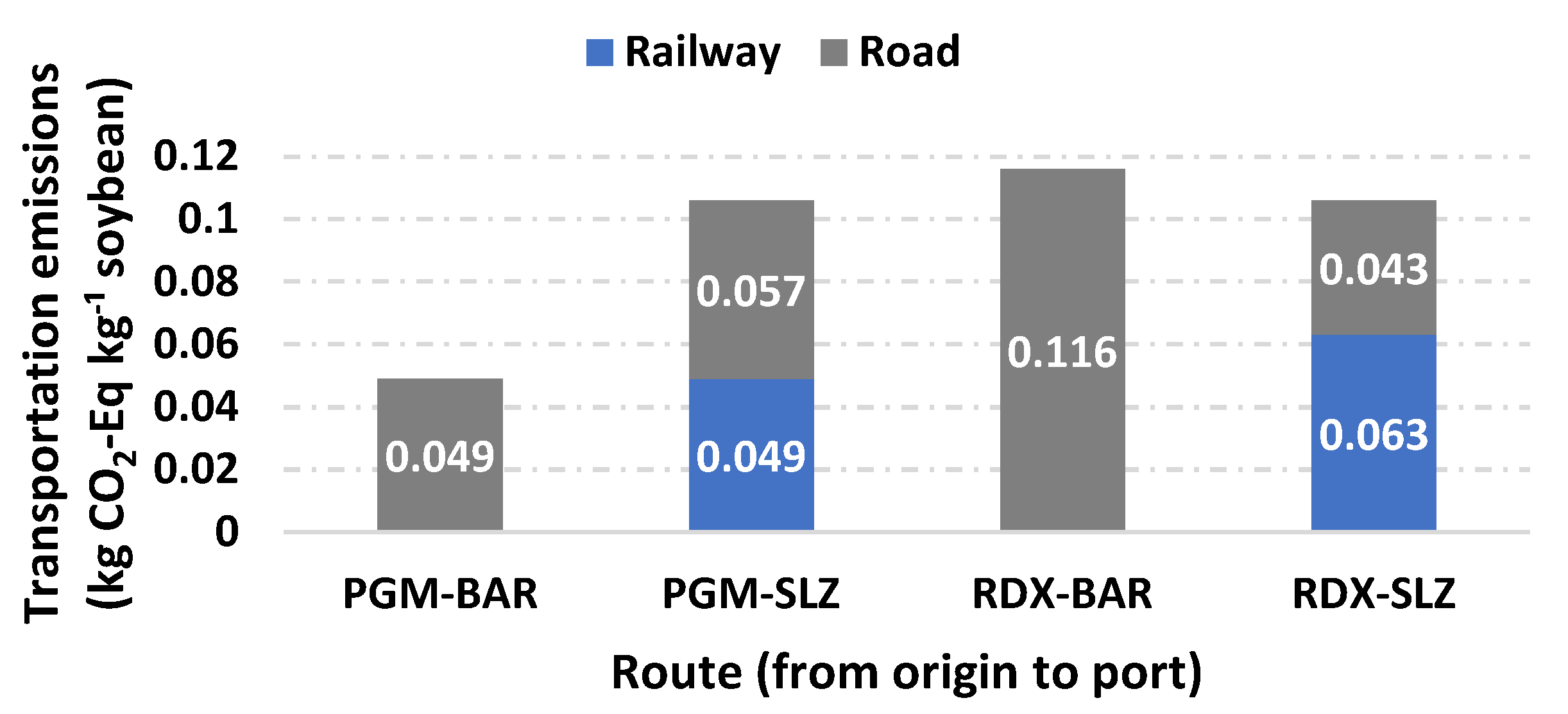

2.1. Description of Study Area, Transport and Crop

2.2. Life Cycle Assessment

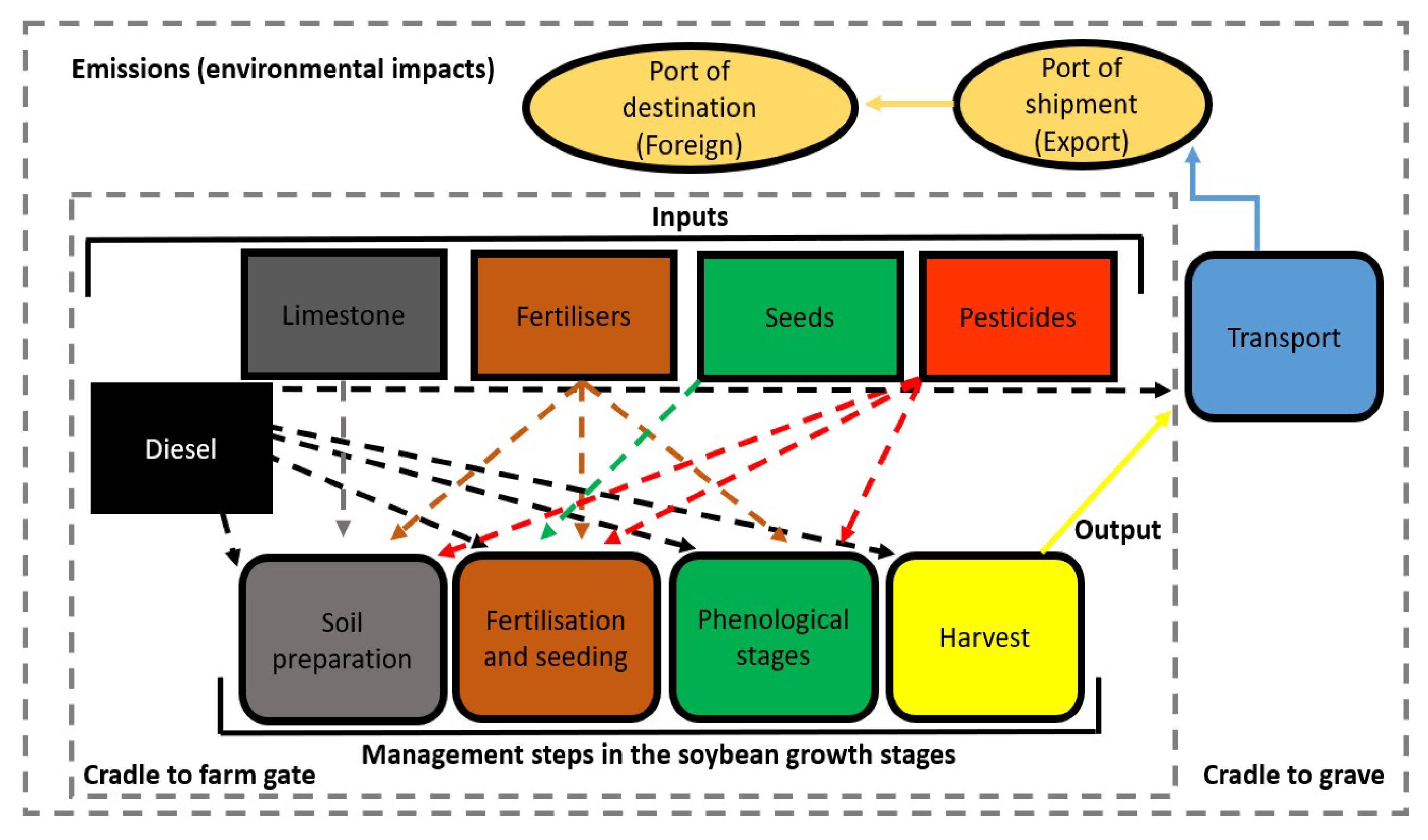

2.2.1. Scope of the Study and Crop Management

2.2.2. Software, Database and LCIA Method Used

2.2.3. Land Use Change (LUC)

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Z.; Ying, H.; Chen, M.; Bai, J.; Xue, Y.; Yin, Y.; Batchelor, W.; Yang, Y.; Bai, Z.; Du, M.; et al. Optimization of China’s maize and soy production can ensure feed sufficiency at lower nitrogen and carbon footprints. Nat. Food 2021, 2, 426–433. [Google Scholar] [CrossRef]

- Castanheira, E.G.; Freire, F. Greenhouse gas assessment of soybean production: Implications of land use change and different cultivation systems. J. Clean. Prod. 2013, 54, 49–60. [Google Scholar] [CrossRef]

- USDA—United States Department of Agriculture; Foreign Agricultural Service. World Agricultural Production, Circular Series, WAP 4-21. 2021. Available online: http://apps.fas.usda.gov/psdonline/circulars/production.pdf (accessed on 15 April 2021).

- Trademap—Trade Statistics for International Business Development. Imports and Exports. 2022. Available online: https://www.trademap.org/Index.aspx (accessed on 21 March 2022).

- ANTAQ—Agência Nacional de Transportes Aquaviários. 2022. Available online: http://ea.antaq.gov.br/ (accessed on 15 November 2022).

- CONAB—Companhia Nacional de Abastecimento. Acompanhamento da Safra Brasileira de Grãos, v. 7—Safra 2019/20—Nono Levantamento; CONAB—Companhia Nacional de Abastecimento: Brasília, Brazil, 2020; pp. 1–66. Available online: http://www.conab.gov.br (accessed on 29 March 2021)ISSN 2318-6852.

- CONAB—Companhia Nacional de Abastecimento. Séries Históricas das Safras—Soja. Available online: https://www.conab.gov.br/info-agro/safras/serie-historica-das-safras?start=30 (accessed on 29 March 2021).

- Gibbs, H.K.; Rausch, L.; Munger, J.; Schelly, I.; Morton, D.C.; Noojipady, P.; Soares-Filho, B.; Barreto, P.; Micol, L.; Walker, N.F. Brazil’s Soy Moratorium. Science 2015, 347, 377–378. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, P.; Xiong, X.; Wang, Y.; Zhou, R.; Tao, H.; Grace, U.; Wang, N.; Xiong, Y. Environmental risk of multi-year polythene film mulching and its green solution in arid irrigation region. J. Hazard. Mater. 2022, 435, 128981. [Google Scholar] [CrossRef]

- Maciel, V.G.; Zortea, R.B.; Grillo, I.B.; Lie Ugaya, C.M.; Einloft, S.; Seferin, M. Greenhouse gases assessment of soybean cultivation steps in southern Brazil. J. Clean. Prod. 2016, 131, 747–753. [Google Scholar] [CrossRef]

- Matsuura, M.I.S.F.; Dias, F.R.T.; Picoli, J.F.; Lucas, K.R.G.; de Castro, C.; Hirakuri, M.H. Life-cycle assessment of the soybean-sunflower production system in the Brazilian Cerrado. Int. J. Life Cycle Assess. 2017, 22, 492–501. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework (ISO 14040). ISO: Geneva, Switzerland, 2006.

- Raucci, G.S.; Moreira, C.S.; Alves, P.A.; Mello, F.F.C.; Frazão, L.D.A.; Cerri, C.E.P.; Cerri, C.C. Greenhouse gas assessment of Brazilian soybean production: A case study of Mato Grosso State. J. Clean. Prod. 2015, 96, 418–425. [Google Scholar] [CrossRef]

- Cavalett, O.; Ortega, E. Integrated environmental assessment of biodiesel production from soybean in Brazil. J. Clean. Prod. 2010, 18, 55–70. [Google Scholar] [CrossRef]

- Lehuger, S.; Gabrielle, B.; Gagnaire, N. Environmental impact of the substitution of imported soybean meal with locally-produced rapeseed meal in dairy cow feed. J. Clean. Prod. 2009, 17, 616–624. [Google Scholar] [CrossRef]

- Silva, V.P.; van der Werf, H.M.G.; Spies, A.; Soares, S.R. Variability in environmental impacts of Brazilian soybean according to crop production and transport scenarios. J. Environ. Manag. 2010, 91, 1831–1839. [Google Scholar] [CrossRef]

- Knoope, M.M.J.; Balzer, C.H.; Worrell, E. Analysing the water and greenhouse gas effects of soya bean-based biodiesel in five different regions. GCB Bioenergy 2019, 11, 381–399. [Google Scholar] [CrossRef]

- Selvaraj, A.; Gautam, J.; Verma, S.; Verma, G.; Jain, S. Life cycle sustainability assessment of crops in India. Curr. Res. Environ. Sustain. 2021, 3, 10074. [Google Scholar] [CrossRef]

- Brito, T.R.C.; Aranha, J.T.M.; Fernandes-Silva, A.A.; Santos, L.A.C.; Fragoso, R.M.S. A review and analysis of life cycle assessment tendencies in the Brazilian soybean supply chain. Biol. Environ. Proc. R. Ir. Acad. 2022, 122, 53–65. [Google Scholar] [CrossRef]

- SEARATES. Online Freight Shipping & Transit Time Calculator. 2023. Available online: https://www.searates.com/es/services/distances-time/ (accessed on 30 May 2023).

- INMET—Instituto Nacional de Meteorologia. Meteorological Database of INMET. Available online: https://bdmep.inmet.gov.br/ (accessed on 29 March 2021).

- ISO 14044:2006/Amd 1:2017; Environmental Management—Life Cycle Assessment—Requirements and Guidelines (ISO 14044). ISO: Geneva, Switzerland, 2006.

- Yan, Y.; Jarvie, S.; Liu, Q.; Zhang, Q. Effects of fragmentation on grassland plant diversity depend on the habitat specialization of species. Biol. Conserv. 2022, 275, 109773. [Google Scholar] [CrossRef]

- Yang, Y.; Li, T.; Pokharel, P.; Liu, L.; Qiao, J.; Wang, Y.; An, S.; Chang, S. Global effects on soil respiration and its temperature sensitivity depend on nitrogen addition rate. Soil Biol. Biochem. 2022, 174, 108814. [Google Scholar] [CrossRef]

- Zilli, E.; Campo, R.J.; Hungria, M. Eficácia da inoculação de Bradyrhizobium em pré-semeadura da soja. Pesqui. Agropecuária Bras. 2010, 45, 335–338. [Google Scholar] [CrossRef]

- Novaes, R.M.L.; Pazianotto, R.A.A.; Brandão, M.; Alves, B.J.R.; May, A.; Folegatti-Matsuura, M.I.S. Estimating 20-year land use change and derived CO2 emissions associated with crops, pasture and forestry in Brazil and each of its 27 states. Glob. Chang. Biol. 2017, 23, 3716–3728. [Google Scholar] [CrossRef]

- Faist Emmenegger, M.; Reinhard, J.; Zah, R. Sustainability Quick Check for Biofuels—Intermediate Background Report; Agroscope Reckenholz-Tänikon: Dübendorf, Switzerland, 2009. [Google Scholar]

- Nemecek, T.; Schnetzer, J. Methods of Assessment of Direct Field Emissions for LCIs of Agricultural Production Systems, Data v3.0; Agroscope Recknholz-Tänikon Research Station ART: Zurich, Switzerland, 2012. [Google Scholar]

- Biaggioni, M.A.M.; Bovolenta, F.C. Comparative energy analysis for soybean journey transport. Eng. Agrícola 2010, 30, 587–599. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, S.; Sun, B.; Wang, F.; Huang, J.; Wang, X.; Bao, Q. Effects of thermal properties and behavior of wheat starch and gluten on their interaction: A review. Int. J. Biol. Macromol. 2021, 177, 474–484. [Google Scholar] [CrossRef]

- Silva, G.F.; Calonego, J.C.; Luperini, B.C.O.; Chamma, L.; Alves, E.R.; Rodrigues, S.A.; Putti, F.F.; Silva, V.M.; Silva, M.A. Soil-plant relationships in soybean cultivated under conventional tillage and long-term no-tillage. Agronomy 2022, 12, 697. [Google Scholar] [CrossRef]

- Zhang, L.; Buatois, L.; Mángano, M. Potential and problems in evaluating secular changes in the diversity of animal-substrate interactions at ichnospecies rank. Terra Nova 2022, 34, 433–440. [Google Scholar] [CrossRef]

- Sun, J.; Jia, Q.; Li, Y.; Zhang, T.; Chen, J.; Ren, Y.; Dong, K.; Xu, S.; Shi, N.; Fu, S. Effects of Arbuscular Mycorrhizal Fungi and Biochar on Growth, Nutrient Absorption, and Physiological Properties of Maize (Zea mays L.). J. Fungi 2022, 8, 1275. [Google Scholar] [CrossRef] [PubMed]

- SEDEME—Secretaria de Estado de Desenvolvimento Econômico, Mineração e Energia. Relatório de Impacto Ambiental, Ferrovia Paraense S.A. 2017. Available online: https://www.semas.pa.gov.br/wp-content/uploads/2017/06/rima/RIMA_FerroviaParaenseSA.pdf (accessed on 2 December 2022).

- CARGILL. Relatório de Impacto Ambiental, Terminal de Uso Privado—TUP Abaetetuba. 2018. Available online: https://www.semas.pa.gov.br/wp-content/uploads/2019/07/RIMA_TUP_Abaetetuba.pdf (accessed on 2 October 2022).

- LDC—Louis Dreyfus Company. Relatório de Impacto Ambiental, Terminal de Uso Privado—TUP Rio Pará. Available online: https://www.semas.pa.gov.br/wp-content/uploads/2012/12/RIMA-TUP-LDC-PONTA-DE-PEDRAS.pdf (accessed on 2 October 2022).

- Brito, T.C.B.; Lima, J.R.S.; Oliveira, C.L.; Souza, R.M.S.; Antonino, A.C.D.; Medeiros, E.V.; Souza, E.S.; Alves, E.M. Mudanças no uso da terra e efeito nos componentes do balanço hídrico no agreste pernambucano. Rev. Bras. Geogr. Física 2020, 13, 870–886. [Google Scholar] [CrossRef]

- Cederberg, C.; Henriksson, M.; Berglund, M. An LCA researcher’s wish list—Data and emission models need to improve LCA studies of animal production. Animal 2013, 7, 212–219. [Google Scholar] [CrossRef] [PubMed]

- ABIOVE—Associação Brasileira das Indústrias de Óleos Vegetais. Soy Moratorium—12th Year Report, Cropping 2018/19. 2020. Available online: https://www.abiove.org.br/relatorios/moratoria-da-soja-relatorio-12o-ano/ (accessed on 15 April 2021).

| Pole Origin | Road Distance (km) | Multimodal Platform | Railway Distance (km) | Total Distance Travelled (km) | Port of Shipment |

|---|---|---|---|---|---|

| Paragominas (PGM) | 351 | 351 | BAR-PA 3 | ||

| Paragominas (PGM) | 406 | Porto Franco-MA 1 | 783 | 1189 | SLZ-MA 4 |

| Redenção (RDX) | 827 | 827 | BAR-PA 3 | ||

| Redenção (RDX) | 305 | Palmeirante-TO 2 | 1001 | 1306 | SLZ-MA 4 |

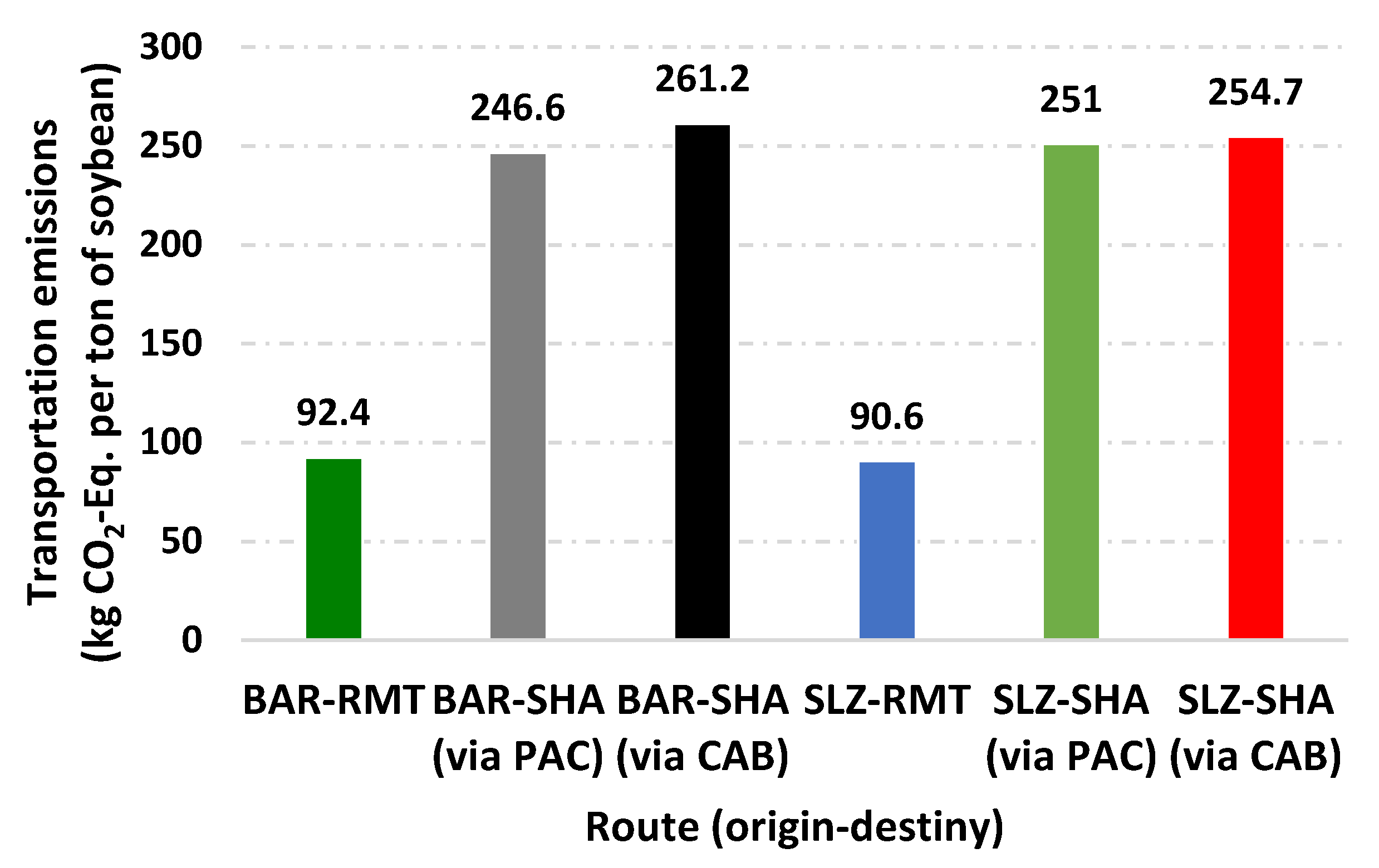

| Port of Origin (Export) | Port of Destination (Foreign) | Route | Sea Transport Distance (km) |

|---|---|---|---|

| BAR-PA, BR 1 | RTM, NL 3 | 7808 | |

| BAR-PA, BR 1 | SHA, CN 4 | Via PAC 5 | 20,848 |

| BAR-PA, BR 1 | SHA, CN 4 | Via CAB 6 | 22,083 |

| SLZ-MA, BR 2 | RTM, NL 3 | 7658 | |

| SLZ-MA, BR 2 | SHA, CN 4 | Via PAC 5 | 21,221 |

| SLZ-MA, BR 2 | SHA, CN 4 | Via CAB 6 | 21,531 |

| Input | Amount | Output | Amount |

|---|---|---|---|

| Application of plant protection product by field sprayer | 0.00258 ha | Ammonia (NH3) | 0.00028 kg |

| Combine harvesting | 0.00030 ha | Dinitrogen monoxide (N2O) | 0.00063 kg |

| Fertilising, by broadcaster | 0.00030 ha | Nitrate | 0.02804 kg |

| Sowing | 0.00030 ha | Nitrogen oxides | 0.00013 kg |

| Tillage, harrowing, by spring tine harrow | 0.00028 ha | Carbon dioxide, fossil | 0.02502 kg |

| Tillage, ploughing | 0.00010 ha | 2,4-D | 0.00045 kg |

| Transport, tractor and trailer, agricultural | 0.01570 t km | Acetamiprid | 2.65000 × 10−5 kg |

| Soybean seed, for sowing | 0.01280 kg | Fenpropathrin | 1.70000 × 10−5 kg |

| Lime | 0.04929 kg | Fluazinam | 0.00011 kg |

| Urea, as N | 0.00212 kg | Glyphosate | 0.00061 kg |

| Phosphate fertiliser, as P2O5 | 0.03576 kg | Mancozeb | 0.00034 kg |

| Phosphate Rock, as P2O5, beneficiated, dry | 0.00212 kg | Prothioconazol | 2.65000 × 10−5 kg |

| Potassium chloride, as K2O | 0.03030 kg | Pyraclostrobin (prop) | 2.52300 × 10−5 kg |

| Occupation, annual crop, non-irrigated, intensive | 3.25298 m2 year | Pyriproxyfen | 7.60000 × 10−6 kg |

| Transformation, from annual crop, non-irrigated | 3.03030 m2 | Phosphorus | 0.00128 kg |

| Transformation, to annual crop, non-irrigated, intensive | 3.03030 m2 | Thiophanate-methyl | 0.00011 kg |

| Energy, gross calorific value, in biomass | 20.5000 MJ | Trifloxystrobin | 2.27000 × 10−5 kg |

| Carbon dioxide, in air | 1.37808 kg | Soybean production | 1 kg |

| 2,4-dichlorophenol | 0.00045 kg | ||

| Pesticide, unspecified | 7.44300 × 10−5 kg | ||

| Pyrethroid-compound | 1.70000 × 10−5 kg | ||

| Pyridine-compound | 0.00012 kg | ||

| Glyphosate | 0.00061 kg | ||

| Mancozeb | 0.00034 kg | ||

| Triazine-compound | 2.65000 × 10−5 kg | ||

| [Sulfonyl] urea-compound | 0.00011 kg |

| Impact Category | Unit | Total Emissions | Main Hotspot |

|---|---|---|---|

| Agricultural land occupation (ALOP) | m2 year | 3.25298 × 100 | PS = 3.25298 × 100 (100%) |

| Climate change (GWP100) | kg CO2-Eq | 4.83120 × 10−1 | PS = 2.11540 × 10−1 (43.8%) |

| Freshwater ecotoxicity (FETPinf) | kg 1,4-DCB-Eq | 1.99383 × 10−2 | PS = 1.946 × 10−2 (95.4%) |

| Freshwater eutrophication (FEP) | kg P-Eq | 1.89967 × 10−4 | PS = 1.011 × 10−4 (53.2%) |

| Human toxicity (HTPinf) | kg 1,4-DCB-Eq | 1.09150 × 10−1 | MFPF = 4.81 × 10−2 (44.1%) |

| Ionising radiation (IRP_HE) | kg U235-Eq | 1.97907 × 10−2 | MFPF = 8.14 × 10−3 (41.1%) |

| Marine ecotoxicity (METPinf) | kg 1,4-DCB-Eq | 2.42444 × 10−3 | PS = 1.429 × 10−3 (58.9%) |

| Marine eutrophication (MEP) | kg N-Eq | 7.10465 × 10−3 | PS = 6.413 × 10−3 (90.2%) |

| Ozone depletion (ODPinf) | kg CFC-11-Eq | 2.82500 × 108 | MFCH = 7.59 × 10−9 (26.9%) |

| Particulate matter formation (PMFP) | kg PM10-Eq | 9.67280 × 10−3 | MFPF = 3.24 × 10−4 (29.6%) |

| Photochemical oxidant formation (POFP) | kg NMVOC-Eq | 2.03110 × 10−3 | MFCH = 6.67 × 10−3 (32.8%) |

| Terrestrial acidification (TAP100) | kg SO2-Eq | 2.57782 × 10−3 | PS = 7.623 × 10−4 (29.6%) |

| Terrestrial ecotoxicity (TETPinf) | kg 1,4-DCB-Eq | 1.32600 × 10−2 | PS = 1.243 × 10−2 (93.7%) |

| Soybean Crop Expansion (%) | Scenarios | Emissions (tCO2 Eq·ha−1·yr−1) | T0 Soy (ha), Pre-Existent 1999 | T1 Soy (ha), 1st Season 2018 | Arable | Permanent Crops | Unspecified, Natural |

|---|---|---|---|---|---|---|---|

| Min. | 3.8 | 1238 | 545,227 | 455,187 (84%) | 38,523 (7%) | 50,279 (9%) | |

| 100 | Pro. | 30.35 | 1238 | 545,227 | 36,811 (7%) | 3115 (1%) | 504,063 (92%) |

| Max. | 32.69 | 1238 | 545,227 | − | − | 543,989 (100%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brito, T.; Fragoso, R.; Santos, L.; Martins, J.A.; Fernandes Silva, A.A.; Aranha, J. Life Cycle Assessment for Soybean Supply Chain: A Case Study of State of Pará, Brazil. Agronomy 2023, 13, 1648. https://doi.org/10.3390/agronomy13061648

Brito T, Fragoso R, Santos L, Martins JA, Fernandes Silva AA, Aranha J. Life Cycle Assessment for Soybean Supply Chain: A Case Study of State of Pará, Brazil. Agronomy. 2023; 13(6):1648. https://doi.org/10.3390/agronomy13061648

Chicago/Turabian StyleBrito, Thyago, Rui Fragoso, Leovigildo Santos, José António Martins, Anabela Afonso Fernandes Silva, and José Aranha. 2023. "Life Cycle Assessment for Soybean Supply Chain: A Case Study of State of Pará, Brazil" Agronomy 13, no. 6: 1648. https://doi.org/10.3390/agronomy13061648

APA StyleBrito, T., Fragoso, R., Santos, L., Martins, J. A., Fernandes Silva, A. A., & Aranha, J. (2023). Life Cycle Assessment for Soybean Supply Chain: A Case Study of State of Pará, Brazil. Agronomy, 13(6), 1648. https://doi.org/10.3390/agronomy13061648