A Two-Factor Thermal Screen Control Strategy for Chinese Solar Greenhouses in High-Latitude Areas

Abstract

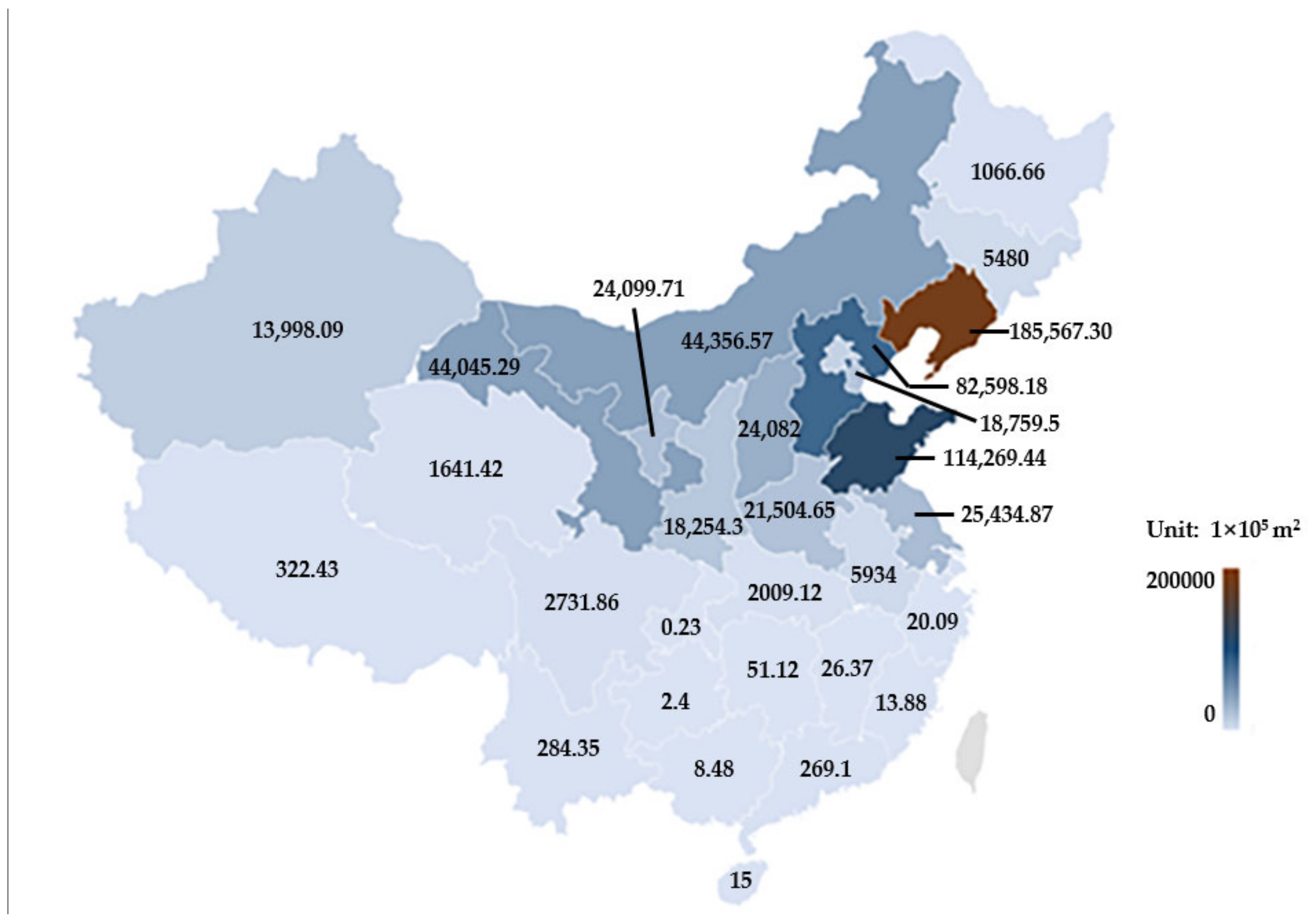

1. Introduction

2. Materials and Methods

2.1. Energy Balance Calculation

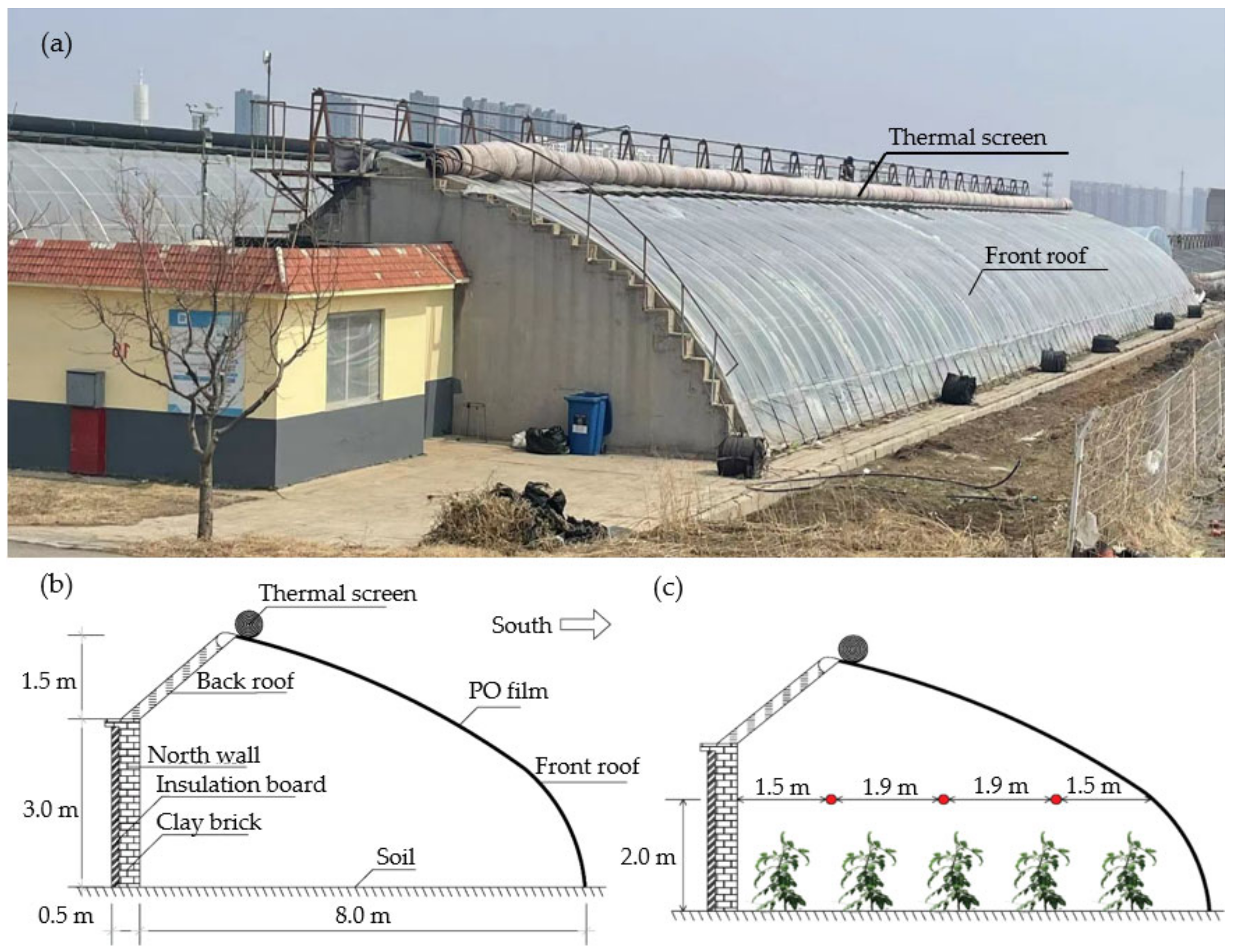

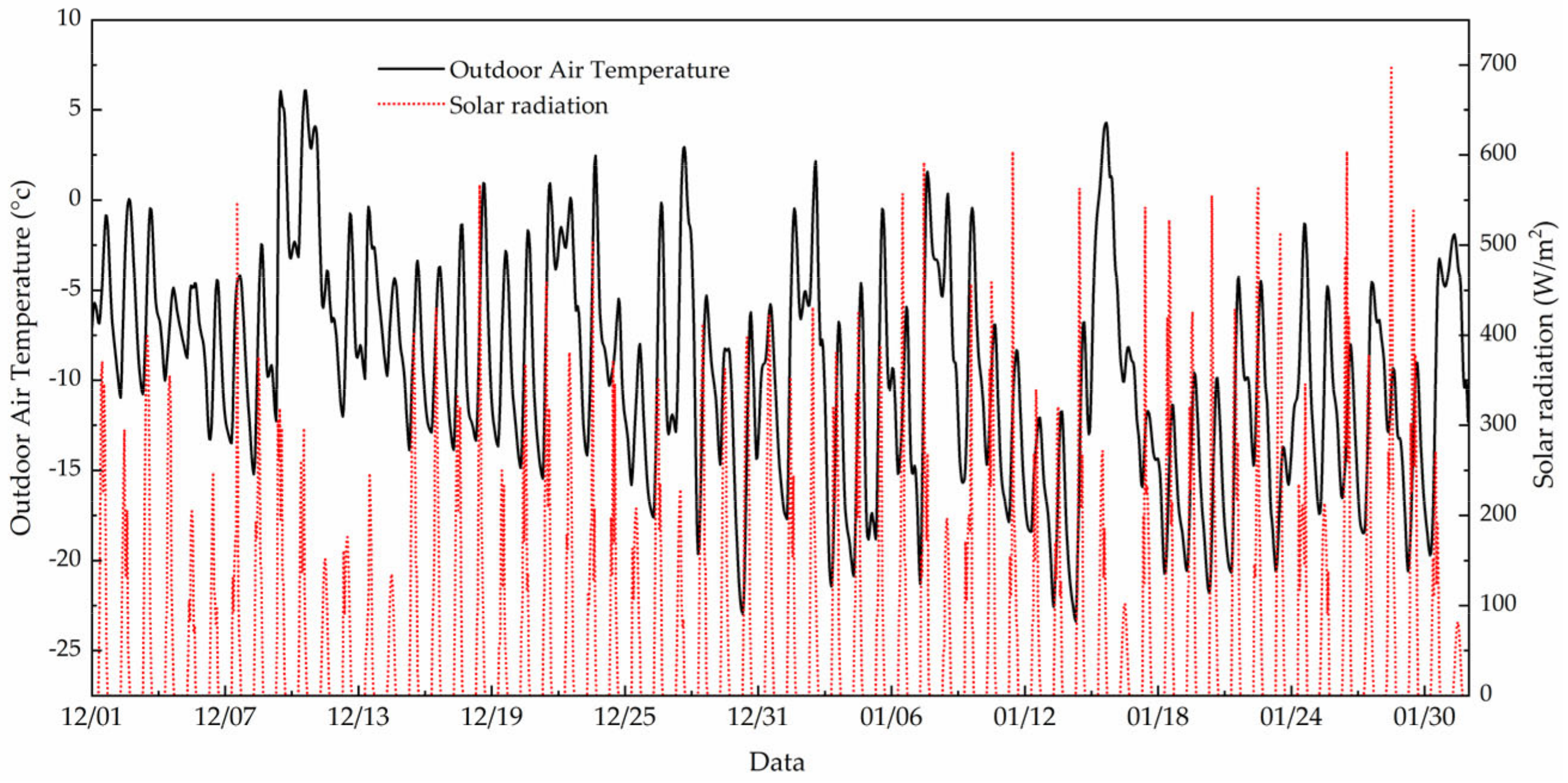

2.2. Reference Greenhouse

2.3. Experimental Arrangement

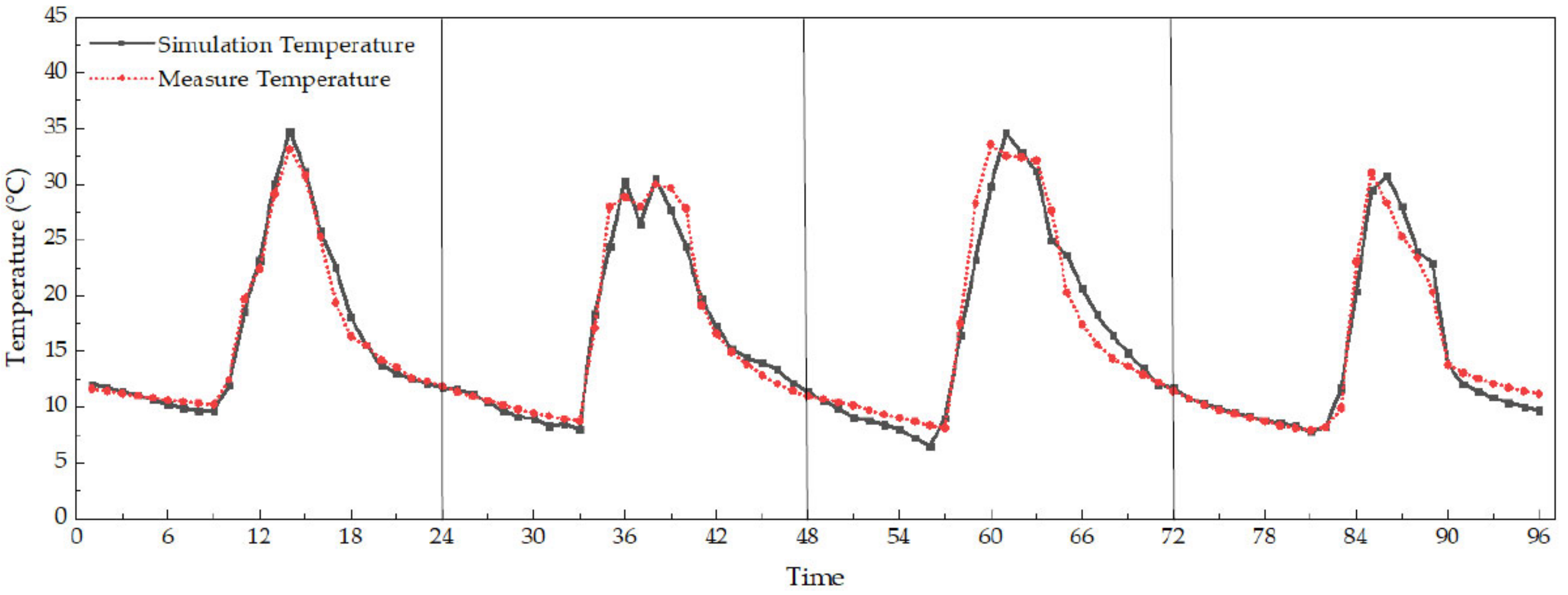

2.4. Calculation Model

3. Results

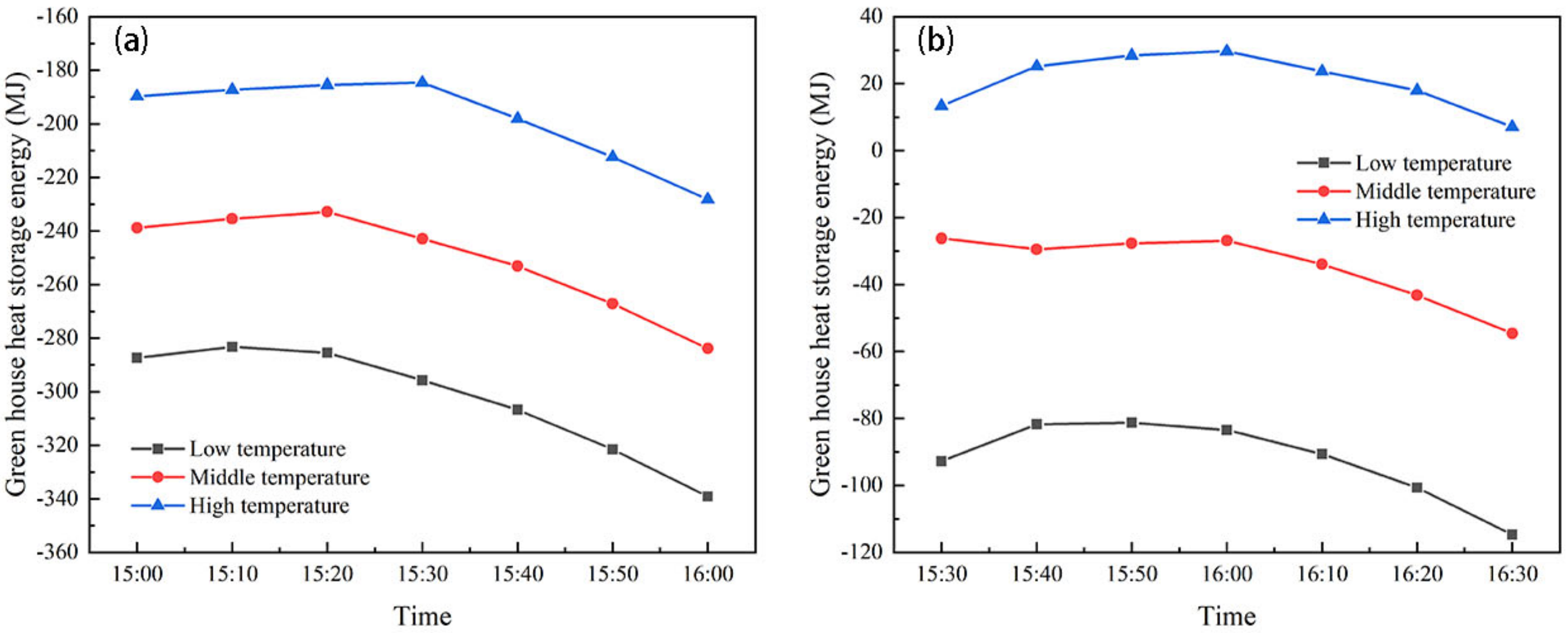

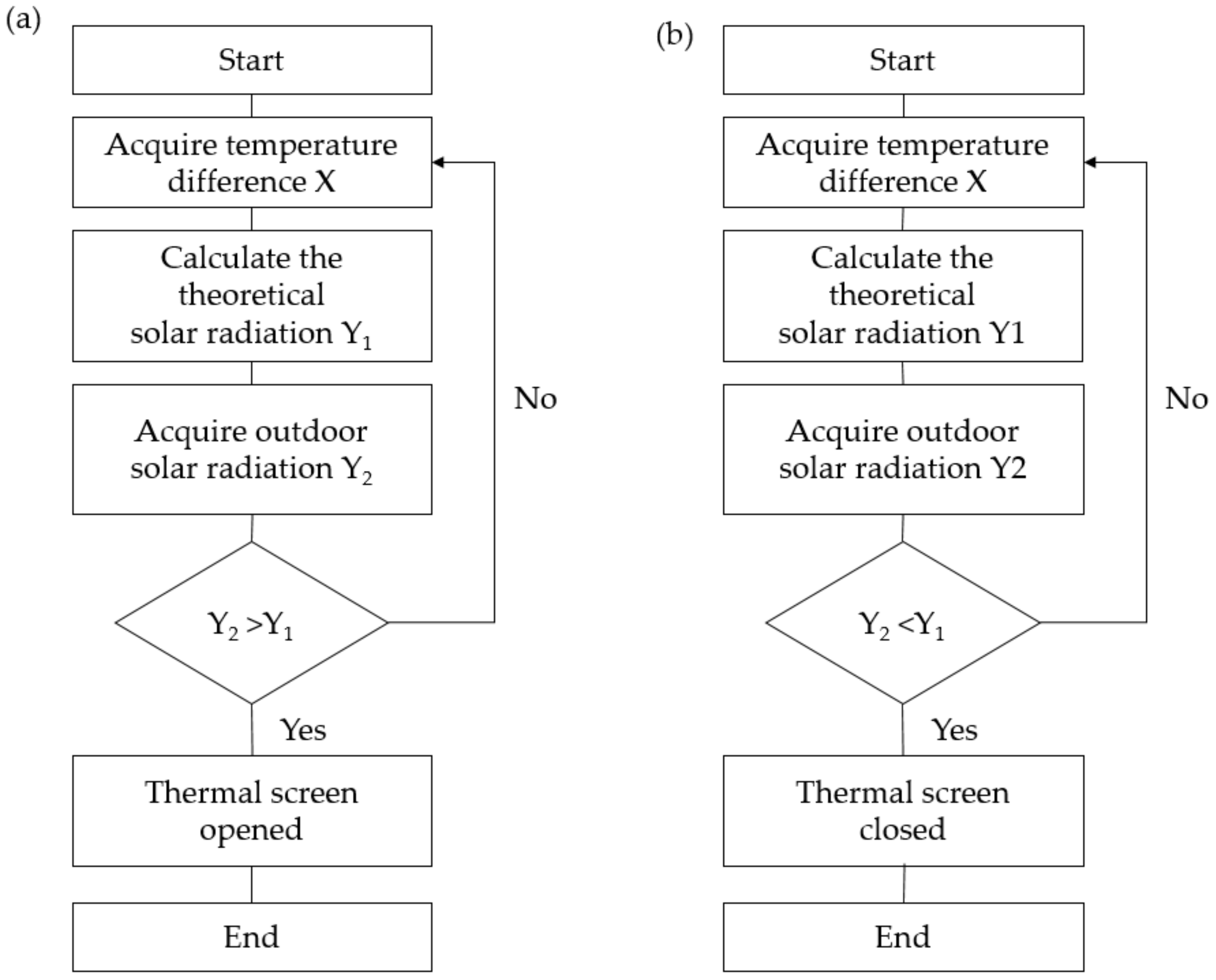

3.1. Calculation of Opening Time

3.2. Calculation of Closing Time

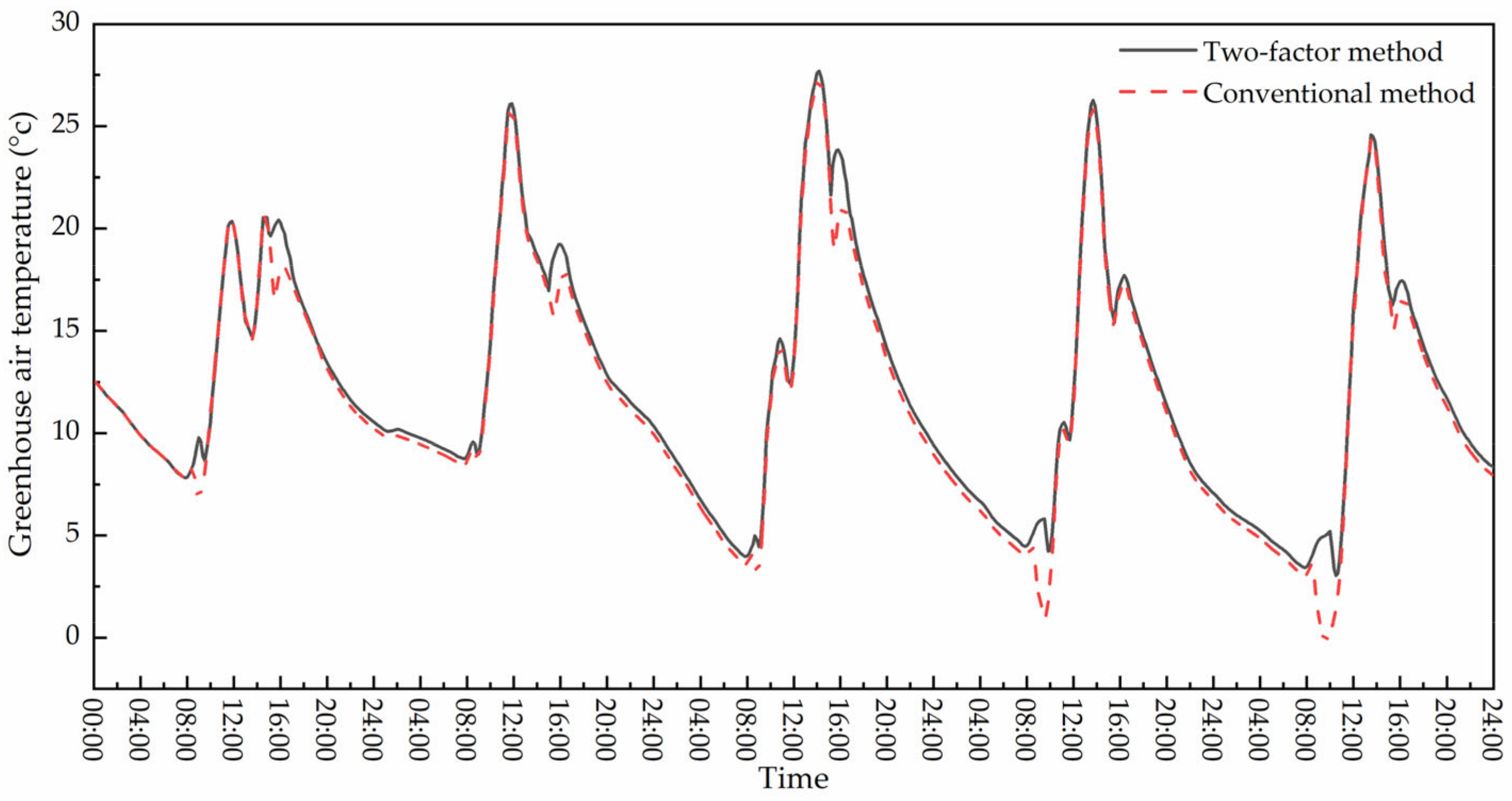

3.3. Performance Evaluation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| c | specific heat at constant pressure (kJ/kg·°C) |

| h | solar altitude (°) |

| IA | accuracy rate |

| J | solar radiation rate (W/m2) |

| K | heat transfer coefficient (W/m2·°C) |

| L | infiltrate air volume (m3) |

| N | air change coefficient (/h) |

| P | coefficient of atmospheric transparency |

| Q | the energy flow of greenhouse (J) |

| r | Earth–sun distance (km) |

| S | heat stored by greenhouse structure (J) |

| t | temperature (°C) |

| U | heat loss of the greenhouse (J) |

| V | volume of the greenhouse (m3) |

| Greek symbols | |

| δ | solar declination (°) |

| η | solar-hour angle (°) |

| θ | solar-azimuth angle (°) |

| ρ | density (kg/m3) |

| τ | front roof solar radiation transmittance |

| φ | local latitude (°) |

| Subscripts | |

| act | human activities and lighting |

| evn | envelope |

| f | front roof |

| inf | infiltration |

| out | external air temperature |

| pla | plant |

| s | soil |

| set | setting air temperature |

| ven | ventilation |

| w | wall |

References

- Iddio, E.; Wang, L.; Thomas, Y.; McMorrow, G.; Denzer, A. Energy Efficient Operation and Modeling for Greenhouses: A Literature Review. Renew. Sustain. Energy Rev. 2020, 117, 109480. [Google Scholar] [CrossRef]

- Fabrizio, E. Energy Reduction Measures in Agricultural Greenhouses Heating: Envelope, Systems and Solar Energy Collection. Energy Build. 2012, 53, 57–63. [Google Scholar] [CrossRef]

- Fan, Z.; Liu, X.; Yue, X.; Xu, H.; Li, T.; Li, Y. Effect of External Thermal Insulation Layer on the Chinese Solar Greenhouse Microclimate. R. Soc. Open Sci. 2021, 8, 211217. [Google Scholar] [CrossRef] [PubMed]

- Xu, D.; Li, Y.; Zhang, Y.; Xu, H.; Li, T.; Liu, X. Effects of Orientation and Structure on Solar Radiation Interception in Chinese Solar Greenhouse. PLoS ONE 2020, 15, e0242002. [Google Scholar] [CrossRef]

- Ling, H.; Chen, C.; Wei, S.; Guan, Y.; Ma, C.; Xie, G.; Li, N.; Chen, Z. Effect of Phase Change Materials on Indoor Thermal Environment under Different Weather Conditions and over a Long Time. Appl. Energy 2015, 140, 329–337. [Google Scholar] [CrossRef]

- Chen, R. Advance of the Research on the Architecture and Environment of the Chinese Energy-Saving Sunlight Greenhouse. Trans. CSAE 1994, 10, 123–129. [Google Scholar]

- Li, T. Theory and Practice of Vegetable Cultivation in Solar Greenhouse; China Agriculture Press: Beijing, China, 2013. [Google Scholar]

- Kim, H.K.; Ryou, Y.S.; Kim, Y.H.; Lee, T.S.; Oh, S.S.; Kim, Y.H. Estimating the Thermal Properties of the Cover and the Floor in a Plastic Greenhouse. Energies 2021, 14, 1970. [Google Scholar] [CrossRef]

- Geoola, F.; Kashti, Y.; Levi, A.; Brickman, R. A Study of the Overall Heat Transfer Coefficient of Greenhouse Cladding Materials with Thermal Screens Using the Hot Box Method. Polym. Test. 2009, 28, 470–474. [Google Scholar] [CrossRef]

- Xue, F.; Zhang, Y.; Fu, Y.; Li, P.; Guo, S. Effect of Four Kinds of Thermal Insulation Quilts on the Thermal Insulaation of Ningxia Winter Solar Greenhouse. North. Hortic. 2019, 14, 66–72. [Google Scholar]

- Rasheed, A.; Kwak, C.S.; Na, W.H.; Lee, J.W.; Kim, H.T.; Lee, H.W. Development of a Building Energy Simulation Model for Control of Multi-Span Greenhouse Microclimate. Agronomy 2020, 10, 1236. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, J.; Chen, Y. Relationship between the Time of Taking off and Covering the Curtain and Temperature Change in Sunlight Greenhouse. Hubei Agric. Sci. 2014, 53, 1524–1527. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y.; Ren, J.; Fu, Y.; Guo, S.; Li, P. Study on Uncovering and Covering Time of Thermal Blankets in Solar Greenhouse and Its Automatic Control Realization. J. Anhui Agric. Univ. 2020, 47, 480–487. [Google Scholar]

- Gilli, C.; Camps, C. Influence of Two Different Thermal Screen Managements on Yield, Quality and Energy Consumption of a Soilless Tomato Culture. Acta Hortic. 2012, 952, 97–102. [Google Scholar] [CrossRef]

- Choab, N.; Allouhi, A.; El Maakoul, A.; Kousksou, T.; Saadeddine, S.; Jamil, A. Review on Greenhouse Microclimate and Application: Design Parameters, Thermal Modeling and Simulation, Climate Controlling Technologies. Sol. Energy 2019, 191, 109–137. [Google Scholar] [CrossRef]

- Chen, C.; Li, Y.; Li, N.; Wei, S.; Yang, F.; Ling, H.; Yu, N.; Han, F. A Computational Model to Determine the Optimal Orientation for Solar Greenhouses Located at Different Latitudes in China. Sol. Energy 2018, 165, 19–26. [Google Scholar] [CrossRef]

- Du, H.; Shi, M.; Zhang, Y.; Le, Z.; Zhou, P.; Li, J. Infiuence of Uncovered/Covered Insulation Time of the Heat Preservation Quilt on Temperature in Solar Greenhouse. Guizhou Agric. Sci. 2019, 47, 112–118. [Google Scholar]

- Rasheed, A.; Na, W.H.; Lee, J.W.; Kim, H.T.; Lee, H.W. Optimization of Greenhouse Thermal Screens for Maximized Energy Conservation. Energies 2019, 12, 3592. [Google Scholar] [CrossRef]

- Gao, M. Rural Population Ageing in China: Key Impacts, Coping Strategies and Policy Construction. J. Nanjing Agric. Univ. Soc. Sci. Ed. 2022, 22, 8–21. [Google Scholar] [CrossRef]

- Liu, X.; Wu, X.; Xia, T.; Fan, Z.; Shi, W.; Li, Y.; Li, T. New Insights of Designing Thermal Insulation and Heat Storage of Chinese Solar Greenhouse in High Latitudes and Cold Regions. Energy 2022, 242, 122953. [Google Scholar] [CrossRef]

- Sethi, V.P. On the Selection of Shape and Orientation of a Greenhouse: Thermal Modeling and Experimental Validation. Sol. Energy 2009, 83, 21–38. [Google Scholar] [CrossRef]

- Duan, R.; Jiang, H. Agricultural Microclimatology; China Meteorological Press: Beijing, China, 2009. [Google Scholar]

- Chen, C.; Yu, N.; Yang, F.; Mahkamov, K.; Han, F.; Li, Y.; Ling, H. Theoretical and Experimental Study on Selection of Physical Dimensions of Passive Solar Greenhouses for Enhanced Energy Performance. Sol. Energy 2019, 191, 46–56. [Google Scholar] [CrossRef]

- Molina, J.O.; Ponce, M.; Horn, M.; Gómez, M.M. Towards a Sustainable Bioclimatic Approach for the Peruvian High Andean Rural Area: Evaluation of the Thermal Contribution of a Greenhouse Attached to a Dwelling. In Proceedings of the Conference: ISES Solar World Congress 2019/IEA SHC International Conference on Solar Heating and Cooling for Buildings and Industry 2019, Santiago, Chile, 4–7 November 2019; Volume 2020, pp. 355–364. [Google Scholar] [CrossRef]

- Ouazzani Chahidi, L.; Fossa, M.; Priarone, A.; Mechaqrane, A. Energy Saving Strategies in Sustainable Greenhouse Cultivation in the Mediterranean Climate–A Case Study. Appl. Energy 2021, 282, 116156. [Google Scholar] [CrossRef]

- Cort, J. Willmott On the Validation of Models. Phys. Geogr. 1981, 2, 184–194. [Google Scholar]

- Sun, Z.; Cao, X.; Liu, Z.; Lei, Y.; Liu, Y. Determination of Agricultural Weather Forecast Index in Time for Curtain-Rolling for Solar Greenhouse. Chin. Agric. Sci. Bull. 2013, 29, 129–134. [Google Scholar]

- Tong, G.; Chen, Q.; Xu, H. Passive Solar Energy Utilization: A Review of Envelope Material Selection for Chinese Solar Greenhouses. Sustain. Energy Technol. Assess. 2022, 50, 101833. [Google Scholar] [CrossRef]

| Material | Block Brick | PO Films | Soil | Insulation Board (XPS) | Thermal Screen |

|---|---|---|---|---|---|

| Thickness (mm) | 370 | 0.2 | 500 | 130 | 50 |

| Conductivity (w/m·k) | 0.81 | 0.64 | 0.45 | 0.03 | 0.1 |

| Density (kg/m3) | 1800 | -- | 1100 | 50 | -- |

| Specific heat(J/kg·K) | 1050 | -- | 600 | 1380 | -- |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Lu, L.; Sun, D.; Liu, P.; Li, Y.; Li, T.; Liu, X. A Two-Factor Thermal Screen Control Strategy for Chinese Solar Greenhouses in High-Latitude Areas. Agronomy 2023, 13, 821. https://doi.org/10.3390/agronomy13030821

Liu H, Lu L, Sun D, Liu P, Li Y, Li T, Liu X. A Two-Factor Thermal Screen Control Strategy for Chinese Solar Greenhouses in High-Latitude Areas. Agronomy. 2023; 13(3):821. https://doi.org/10.3390/agronomy13030821

Chicago/Turabian StyleLiu, Hanlin, Liangchen Lu, Dapeng Sun, Peng Liu, Yiming Li, Tianlai Li, and Xingan Liu. 2023. "A Two-Factor Thermal Screen Control Strategy for Chinese Solar Greenhouses in High-Latitude Areas" Agronomy 13, no. 3: 821. https://doi.org/10.3390/agronomy13030821

APA StyleLiu, H., Lu, L., Sun, D., Liu, P., Li, Y., Li, T., & Liu, X. (2023). A Two-Factor Thermal Screen Control Strategy for Chinese Solar Greenhouses in High-Latitude Areas. Agronomy, 13(3), 821. https://doi.org/10.3390/agronomy13030821