1. Introduction

Button mushroom (

Agaricus bisporus) is the most abundant cultivated mushroom, which is well known for its considerable economic benefits and plentiful medicinal and nutritional properties [

1]. According to the FAO annual report in 2016, about 11 million tons (t) of mushrooms were produced in the world; Asian countries accounted for a significant share of this production [

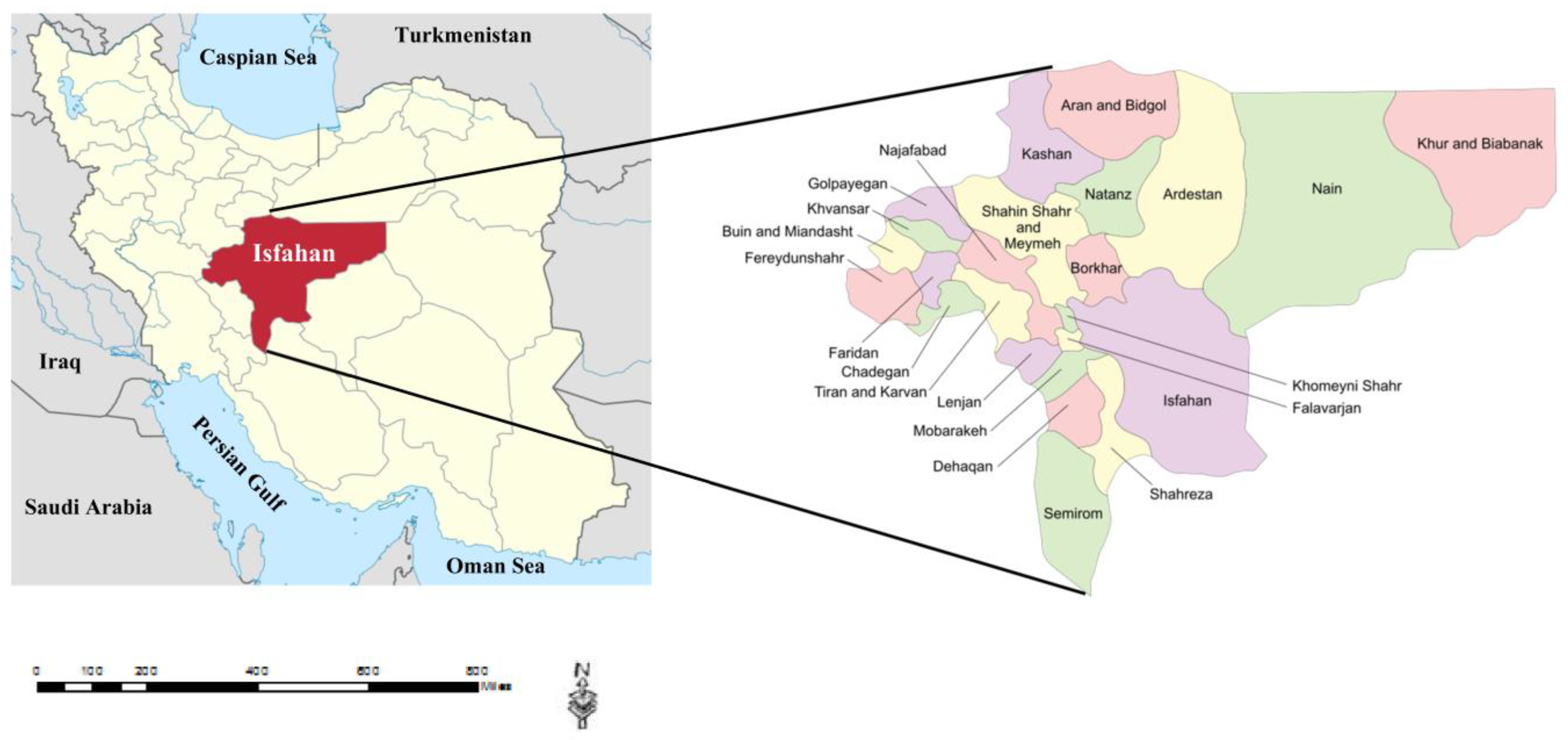

2]. Button mushroom production in Iran increased from 6997 to 152,378 t from 2001 to 2017, and approximately 10% of this was produced in Isfahan province [

3].

Global warming, which is defined as consecutive increases in the earth’s atmospheric mean temperature, is one of the momentous topics in recent decades. It results from increased GHG concentration in the atmosphere, caused by human activities such as fossil fuels burning and deforestation [

4]. GHG emissions from the agriculture sector are a direct result of food supply chains. Optimum and efficient use of energy and sources is the main condition for sustainable agriculture [

5]. Life cycle assessment (LCA) is a known and powerful tool to assess environmental sustainability of technologies and products [

6] and provide a systematic way to evaluate the advancements in source productivity [

7]. Input production, storage, and distribution as well as usage with engine-based equipment lead to combustion of fossil fuels and the release of GHGs such as CO

2, N

2O and CH

4 into the atmosphere and result in global warming [

8].

Cumulative exergy demand (CExD) index is defined as the total exergy sum of all inputs needed to produce a crop [

9]. In other words, the aim of CExD analysis is to make an efficient system or process to reduce loss or deterioration of exergy [

10]. ESC is a fundamental tool, presenting useful information to help assess policies. ESC is defined as the marginal impact costs caused by emitting one extra t of greenhouse gas (CO

2 eq) at any point in time, including ‘non-market’ impacts on human and environmental health [

11]. The computation of carbon social cost, which is defined as the marginal damage cost of climate change, is a key strategy for the evaluation of climate policy [

12].

For sustainable agricultural development, energy use, environmental effects, and cost efficiency are three important aspects at the center of attention [

13]. The relationship between energy use and GHG emissions is intimate; therefore, there is a need to manage energy use in agriculture sector to decrease environmental footprints associated with input utilization. The energy consumption pattern varies according to management and agricultural systems, climate, and other conditions. Determining the relationship between environmental impacts and energy use is one of the most important steps in sustainable agriculture.

In recent years, linear methods have been used to model various agricultural and sometimes environmental phenomena. Their main disadvantage is that some real-world phenomena simply do not conform to the linear model assumptions. Hence, the need to use modern technologies, such as artificial intelligence and ML, increases significantly [

14]. ML, within artificial intelligence, has been introduced as a useful tool to develop intelligent predictive algorithms in different applications. ML approaches have the ability to handle multivariate and multi-dimensional data and to discover hidden relationships within data in dynamic and complex conditions [

15]. The applicability of various ML methods is generally quite different in various fields, problems, and types of data sets [

16]. With respect to the mentioned methods, ANN is one of basic models of ML that includes competent soft computing techniques with effort simulating the human biological nervous system via linking different artificial elements, termed neurons [

17].

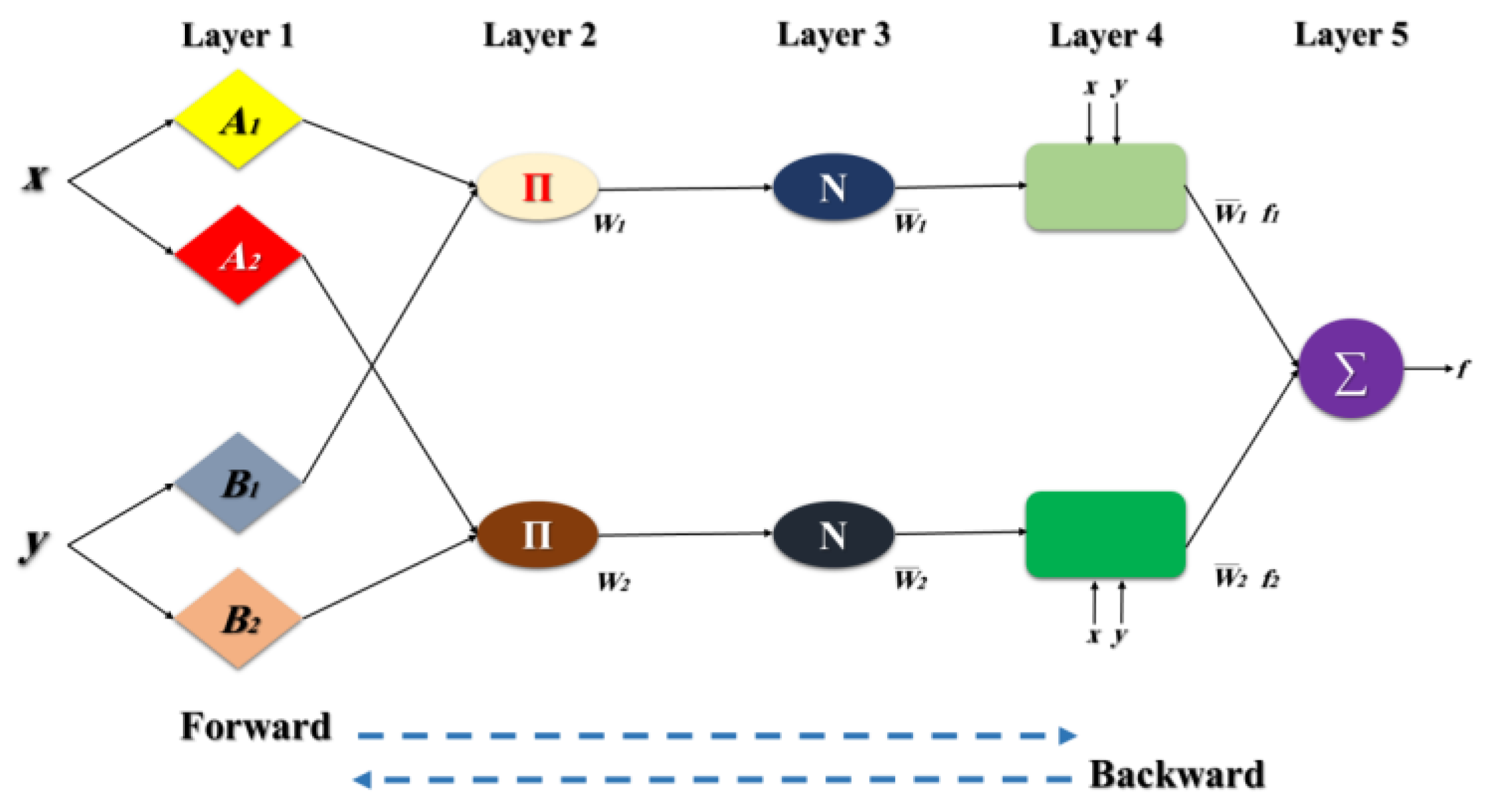

Another intelligent system for modeling and forecasting is ANFIS [

18]. It is a suitable method for the interpretation of non-linear systems [

18]. Because ANFIS is the combination of fuzzy and ANN systems, it has the benefits of both models. In engineering issues where classical methods are too complicated to be used, this technique can be useful [

19]. As the next model, SVM, based on Vapnik’s statistical learning theory, is widely used in some practical problems. Its main idea is to detect a separating hyperplane in between two parallel hyperplanes, where these two parallel hyperplanes are built according to the maximum margin principle [

20]. The SVR algorithm is a small sample learning machine based on statistical learning theory [

21]. It is founded on the structural risk minimization principle and has unique benefits for small data collection and can keep a good development and generalization ability.

Modeling of energy, environmental, and economic indices in agricultural production has been conducted by different methods from several years ago, and each of them investigated a sector as illustrated in

Table 1. Although all studies listed in

Table 1 are valuable, but a comprehensive intelligent model that includes all environmental, exergy, and economic parameters is not presented in any of them, and only one or two perspectives have been examined.

Accordingly, the present study covers all mentioned parameters comprehensively for modeling with ML methods as a novelty, and the aims are considered in the current study: (i) evaluation of damage categories of button mushroom by LCA; (ii) computation of energy forms by CExD analysis in button mushroom production; (iii) determination of emissions costs of button mushroom; (iv) development of comprehensive model by ML models including ANN, ANFIS, and SVR; and (v) offering the best method and model for predicting environmental damages, energy forms of CExD, and ESC of button mushroom production.

3. Results and Discussion

3.1. Environmental Analysis of Mushroom Production

The consumed inputs and resulting direct emissions for mushroom production in the studied region are illustrated in

Table 3. It can be observed that the total CO

2 emission discharged to the atmosphere due to utilization of diesel fuel in different mushroom production operations is 224.02 kg ha

−1. The reason for this is excessive and inefficient use of diesel fuel to heat greenhouses in the region. Moreover, different stages of compost production and consumption lead to the release of 945.091 t ha

−1 of CO

2. Inefficient usage of diesel fuel in mushroom production has different reasons including old systems of heating equipment, high heat losses of greenhouses, and old methods of compost production.

In the production process of compost, diesel fuel is used to supply heating required by microorganisms. It is also used in the mushroom production process to maintain the greenhouse temperature in optimal conditions. Low diesel fuel price in Iran, which leads to its inefficient use in various industries, is one of the reasons of high diesel fuel consumption. Heating systems used in mushroom greenhouses have low efficiency and consume large amounts of fossil fuels due to the lack of intelligent heating system.

Thus, to reduce diesel fuel consumption and mitigate its negative effects, it is recommended that high efficiency heating systems with less pollution are to be applied. Insulation of greenhouse walls and the use of materials with low heat transfer coefficient in the construction of greenhouse walls and roofs can also be useful in preventing heat loss. These strategies also reduce the energy consumption required for fuel transportation. Natural gas is less polluting than diesel fuel, and given that Iran is rich in natural gas resources, the use of natural gas to provide heating in mushroom production is recommended as an early return strategy.

Dorr et al. [

87] studied the environmental effects of an urban mushroom farm in France. They reported that in terms of climate change impact, the product system emitted about 3 kg CO

2-eq. kg

−1 mushroom, and On-Farm energy consumption was the top contributor to all impact categories.

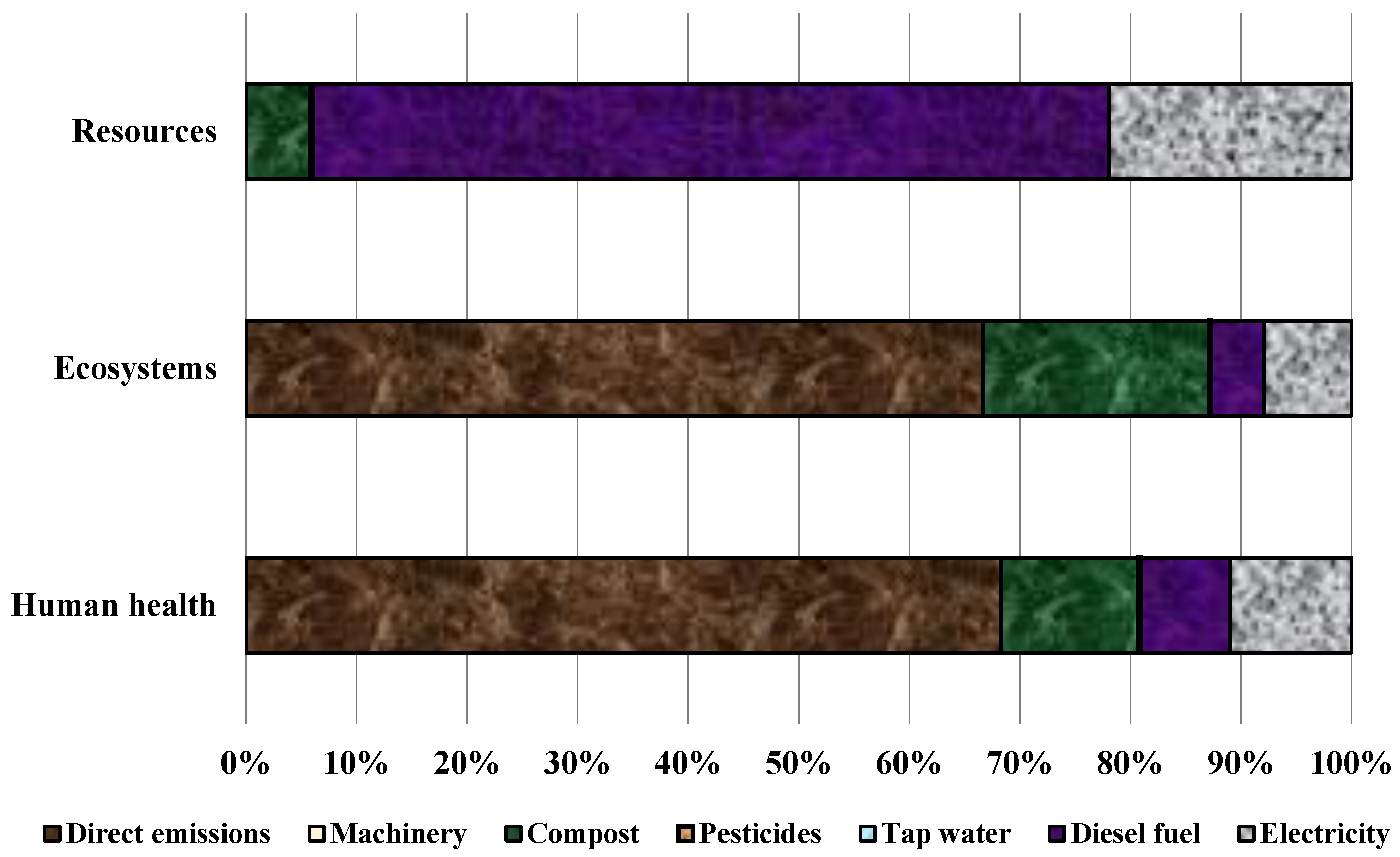

Endpoint results by applying LCA method for 100TMP are illustrated in

Table 4. Human health damage category is 0.91 DALY per 100TMP. DALY is an overall measure of disease burden, defined as the number of years lost because of disability, early death, or ill-health. It is introduced as a method to compare the life expectancy and overall health (

Table 4).

Hosseini-Fashami et al. [

40] investigated environmental effects of strawberry production and reported that human health per 100 t of greenhouse strawberry production was 0.097 DALY. Mostashari-Rad et al. [

46] studied environmental indicators for horticultural crops and reported these indicators as 0.5 and 0.1 for 100 t of hazelnut and citrus production, respectively.

Resources and ecosystems are other damage categories, which are determined by the ReCiPe2016 method. As can be seen in

Table 4, ecosystem damage category is 2.84 × 10

−3 species.yr per 100TMP. Moreover, resources damage category is computed as 35,850.42 USD2013 based on FU.

Figure 5 shows the pattern of environmental impacts and contribution of various inputs to mushroom production endpoints. The highest effect in ecosystems and human health damage categories is direct emissions. Direct emissions are related to input consumption in the production process of mushroom. Irregular diesel fuel use in compost production is one of the most important factors on direct emissions. Based on these results, the greatest effects in resources damage category is from diesel fuel. This shows that in mushroom production, diesel fuel consumption brings great loss on environment, and its usage must be decreased to diminish environmental risk. Electricity is another input that has significant effect on resources damage categories. In greenhouses, electricity is used for lighting, electric equipment, and sometimes for heating. Low efficiency of production and transmission network of electricity as well as use of time-worn electrical equipment are reasons for high electricity consumption in the studied greenhouses.

Comparison between the greenhouses and farms indicated that the greenhouses have more severe detrimental effects on environmental impacts. Fossil fuels are one of the most important items for this result. With respect to the geographical position of studied area, replacing renewable technologies especially solar systems can be an appropriate solution to improve the environmental damage. Moreover, ground air collectors using phase change materials are the cheapest and most popular methods during application of solar systems.

In several studies similar results were reported that direct emissions had the greatest effect in ecosystem and human health damage categories [

44,

46,

88,

89].

Because of different units of investigated damage categories, it is not possible to compare them with one another. Thus, to overcome this problem, a weighting method is applied. The weighting results demonstrated that, among three damage categories, human health with about 15 kPt, is significantly category from the emission viewpoint. Direct emissions (more due to diesel fuel consumption) have the greatest contribution in this category, followed by compost. Ecosystems index is at the next place, and the share of direct emissions is a major part of this impact.

Hosseini-Fashami et al. [

40] used weighting analysis to compare damage categories in greenhouse strawberry production and reported that from the emission viewpoint, ecosystem quality is the major category.

3.2. Energy Form Assessment of CExD

The energy assessment results according to CExD in mushroom greenhouses are shown in

Table 5. The results demonstrate that TCD of mushroom production is about 3974 GJ 100 TMP

−1. The category of non-renewable, fossil is the highest form of energy consumption in mushroom production (about 98% of TCD). The non-renewable fossil value is computed as 7088.05 GJ 100 TMP

−1 (

Table 5). In the mushroom production system, fossil fuel usage is for heating propose, and because its utilization is high, this results in high non-renewable, fossil form utilization in this system.

In a study carried out in northwest of Iran, Nabavi-Pelesaraei et al. [

90] employed CexD for energy assessment of oil production from sunflowers. Their results demonstrated that the category non-renewable fossil was about 173,499 MJ per one t of sunflower oil production.

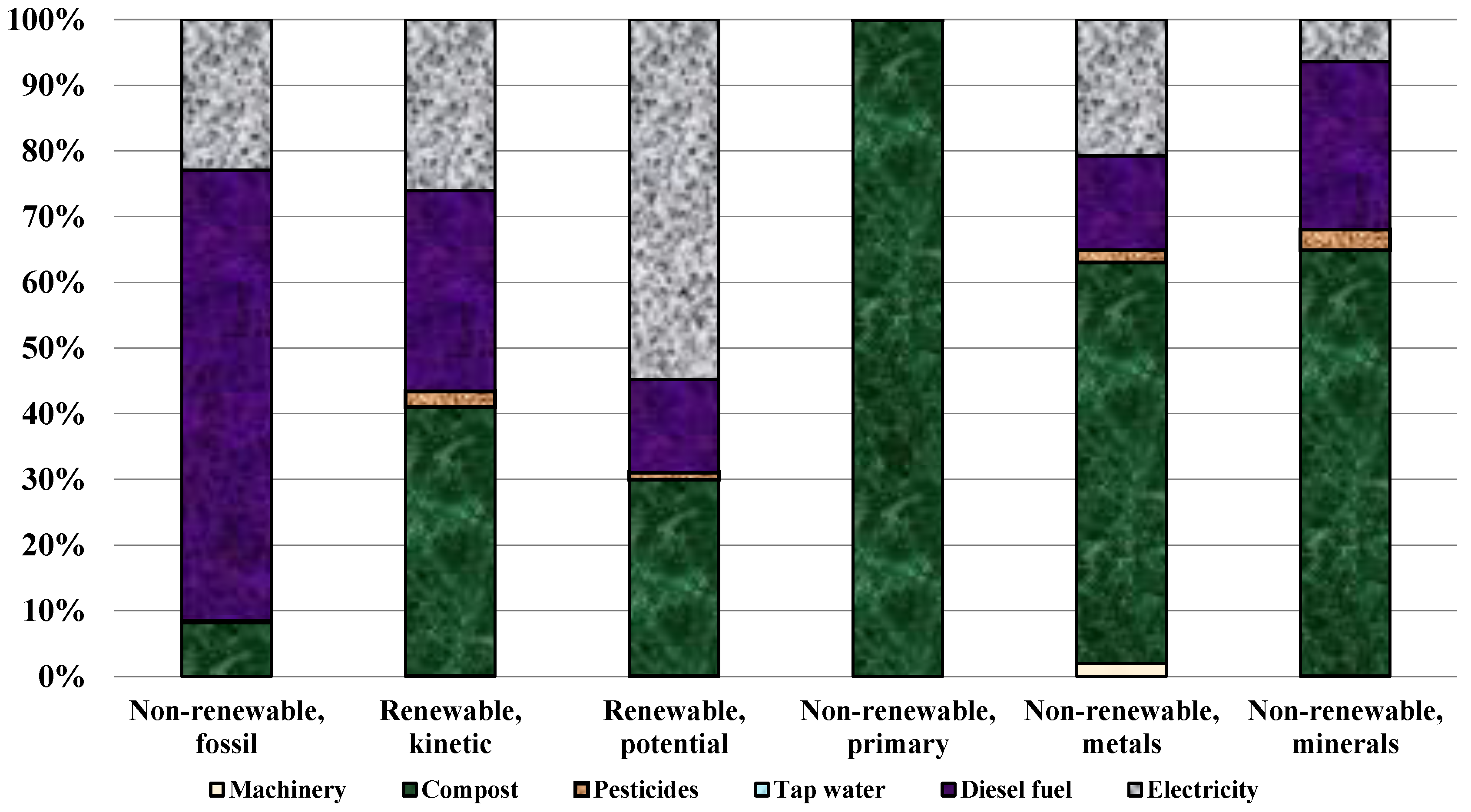

The percentages of different input energy forms of CExD for mushroom greenhouses are illustrated in

Figure 6. The results show that, in mushroom production, diesel fuel has the largest percentage of share in the category non-renewable, fossil (around 70%) and is followed by electricity (about 23%). Similar results have been reported in many studies conducted in Iran where diesel fuel is the main factor in the category non-renewable, fossil [

17,

44]. The results also indicate that, in non-renewable, potential, electricity has the greatest energy usage among different inputs. Furthermore, in non-renewable, primary, non-renewable, minerals, non-renewable, meals, and renewable, kinetic, compost has the highest energy usage among different inputs. This displays that a large amount of inputs are used inefficiently in compost production. Thus, a proper usage of inputs, especially diesel fuel in compost production, can result in great energies reduction for mushroom production.

3.3. Evaluation of ESC

The results of ESC for 100 TMP are shown in

Table 6. The results indicate that TESC per 100 TMP in Isfahan province is equal to 1035.10

$, in which a large part is related to ESC of CO

2, SO

2, and NO

X. In other words, the shares of CO

2, SO

2, and NO

X are equal to 47.1, 37.3 and 11% of TESC, respectively. In another study about ESC of agricultural systems, Nabavi-Pelesaraei et al. [

42] estimated TESC for rice milling factories was about 31

$ per t of white rice in the Guilan province of Iran. Their results also showed that a large part of this cost is related to CO

2 emission.

The high consumption of diesel fuel in mushroom production can also be considered in terms of TSC. Compared to other emissions, the unit cost of CO2 is small; nevertheless, due to high utilization of diesel fuel in mushroom production which leads to high emission of CO2, it will be one of the major portions of the whole cost. Therefore, saving diesel fuel consumption can reduce TESC in mushroom production. Besides, a change in fuel type used in compost production process and the application of renewable energy are strongly recommended.

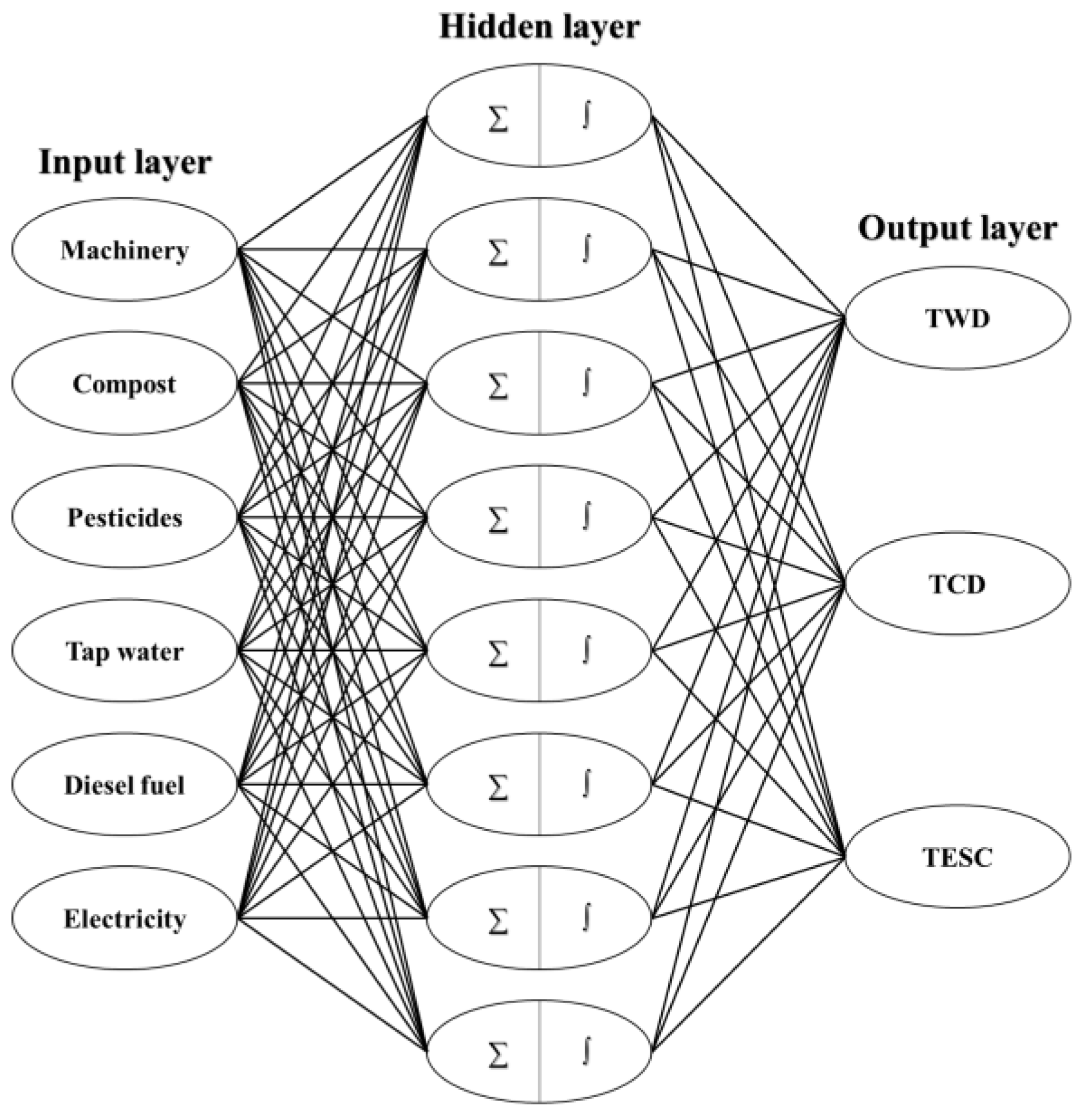

3.4. ANN Model Assessment

In the current study, a back-propagation feed-forward ANN was used for estimating TWD, TCD, and TESC of button mushroom production. For all models, statistical metrics including R

2, AARE, and RMSE were computed. The schematic diagram of the best structure of ANN model by the maximum R

2 and lowest AARE and RMSE values is presented in

Figure 7. As shown in

Figure 7, the structure with one hidden layer is the best ANN structure in all models (6-8-3).

The statistical indicators of the ANN models in TWD, TCD, and TESC of mushroom production are listed in

Table 7. The results indicate that, for mushroom production, R

2 ranges from 0.889 to 0.915 for the training stage, 0.886 to 0.912 for the testing stage, and 0.893 to 0.927 overall. The results also demonstrate that

R2 ranges from 0.881 to 0.911 in the validation stage. This indicate that the introduced model is able to forecast TWD, TCD, and TESC in mushroom production.

High accuracy of ANN models was recognized in some previous researches such as Bai et al. [

91] for forecasting air pollutants concentrations, Gao et al. [

92] for estimation of ozone concentration, Acheampong and Boateng [

93] for modeling carbon emission intensity, and Gonçalves Neto et al. [

94] for modeling of biogas production from food.

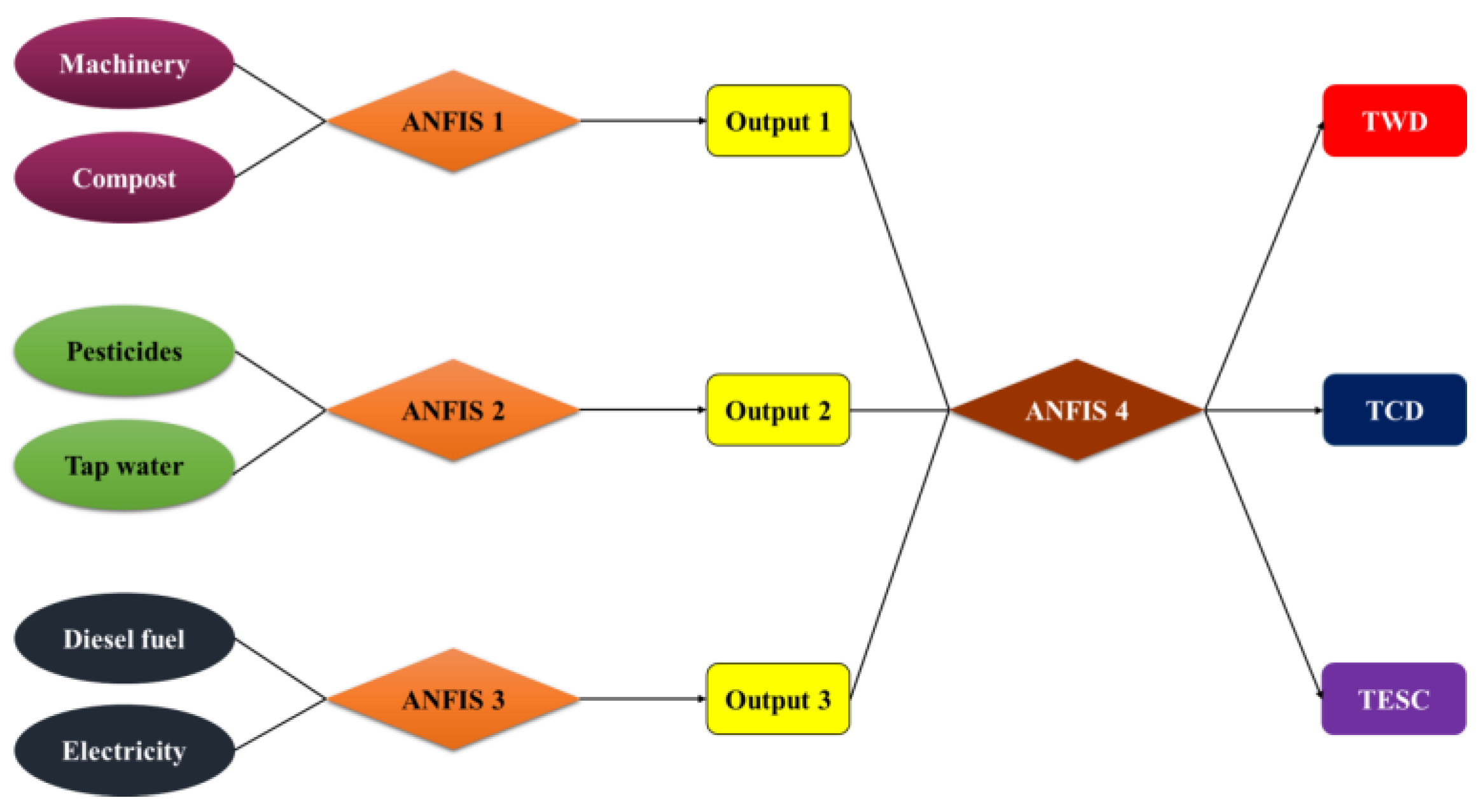

3.5. ANFIS Model Assessment

Statistical components of the two-level ANFIS structure in predicting TWD, TCD, and TESC of mushroom production are shown in

Table 8. According to results, ANFIS with Gbell MFs for input layer and linear MF for output layer offers the best performance. In other words, this hybrid learning method can simulate the communication among inputs and outputs, specify the optimized MF contribution, and provide great precision.

The two-level ANFIS model (ANFIS 4) is shown in the results, with the highest

R2 found for TESC (0.872). In this model, the RMSE is computed as 0.219. The results also show that, in the two-level ANFIS model (ANFIS 4),

R2 for TCD is 0.870, and AARE is 6.57. Results of the current study agree with Kaab et al. [

18], which applied ANFIS to forecast output energy and environmental effects of sugarcane cultivation. Naderloo et al. [

19] used ANFIS model for forecasting of wheat grain yield in Iran. They clustered the inputs for ANFIS into two categories and trained two networks. Electricity, diesel fuel, and chemical fertilizer energies were inputs for ANFIS 1, and machinery, labor, chemicals, water, and seed energies were considered for ANFIS 2. Their RMSE values were 0.013 and 0.018 for ANFIS1 and ANFIS 2, respectively. Besides,

R2 values were 0.996 and 0.992 for ANFIS 1 and ANFIS 2, respectively. Finally, they used these predicted values as the inputs of the third ANFIS and found that RMSE and

R2 were 0.013 and 0.996, respectively.

3.6. SVR Model Assessment

The performance parameters including AARE, RMSE,

Q2LOO, and

Q2EXT are tabulated in

Table 9. The ranges of RMSE,

Q2LOO, and

Q2EXT AARE are between 0.85 and 1.03, between 0.003 and 0.011, between 0.161 and 0.179, and between 0.233 and 0.252 for TWD, TCD, and TESC, respectively. The results of performance parameters reveal that the accuracy of SVR model is very high. Other studies on application of SVR in agri-industrial modeling confirmed the results in attaining high accuracy for predicting different parameters [

95,

96,

97].

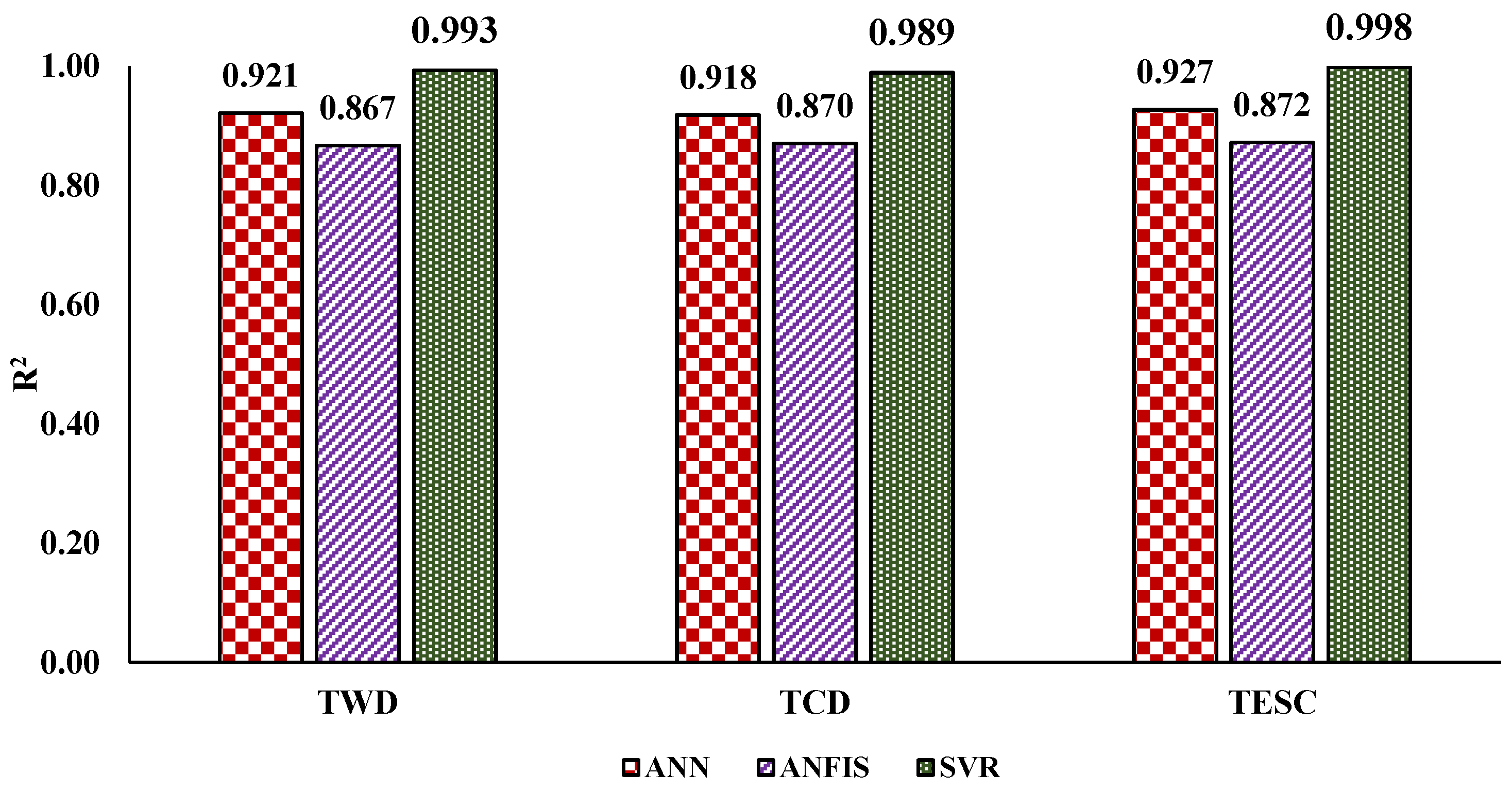

3.7. Comparison between Evaluated ML Models

In the last section, the accuracies of different ML models are evaluated using coefficients of determination.

Figure 8 shows

R2 in different ML models, which indicates that the

R2 of the SVR model for predicting dependent variables including TWD, TCD, and TESC are higher than the

R2 of other models. In other words, SVR model outperforms other models. Taheri et al. [

98] applied ANN and SVR to model the drying of lentil in a microwave fluidized bed. The results indicated that moisture ratio and temperature of lentil could be predicted accurately using ANN and SVR. Performance evaluation of the models with statistical parameters indicated that ANN provided relatively better accuracy for prediction of lentil temperature.

Comparison of results between ANN and ANFIS shows that the ANN model outperforms the ANFIS model. In studies that used ANN and ANFIS for prediction, different results have been reported. Depending on the type of data and the model case, one of these two methods had better performance. In research performed by Kaab et al. [

18], ANFIS and ANN models were used to forecast energy output and environmental issue of sugarcane farms. The results showed that in the plant farms, ANN was better than ANFIS in all dimensions, but in the case of ratoon farms, the results were different, and ANFIS achieved better prediction results than ANN.

Modeling results indicated that SVR had the highest performance for prediction environmental damages, exegetic categories, and ESC with respect to statistical indicators. In this sense, SVR models are more user-friendly, need less computation, and can use multiple classifiers trained on various types of data. On the other hand, ANN can develop better models in comparison. A low uncertainty rate in greenhouses production is the main reason for this result. Finally, it is advised that more research such as optimization with multi-objective approach (environmental, energy and economical) of mushroom production will be used for improving environmental condition.

4. Conclusions

The current study investigates the applications of different ML methods including ANN, ANFIS, and SVR for modeling environmental impacts, exergy categories, and emissions social cost (ESC) of mushroom production. According to results of the current study, the following conclusions can be drawn:

In general, in human health and ecosystem damage categories, direct emissions have the highest portion. Furthermore, in resources damage category, diesel has the most significant impact.

Diesel fuel and electricity have the highest and second highest portions in the categories of Non-renewable, fossil, respectively. In Non-renewable, primary, Non-renewable, metals, Non-renewable, minerals, and Renewable, kinetic, compost has a high share among energy consumption of inputs.

ESC results indicate that TESC per 100TMP is 1035.10$, in which a large part is related to ESC of CO2, SO2, and NOX.

Results of ANN model show that 6-8-3 topology is the best structure for predicting TWD, TCD, and TESC.

The best model of ANFIS that attains the highest accuracy is obtained by a two-level structure with Gbell MFs for input layer and linear MF for output layer.

SVR modeling reveals that statistical indices including AARE (%), RMSE, and R2 vary in ranges of 0.85–1.03, 0.003–0.011, and 0.989–0.993 for TWD, TCD, and TESC, respectively.

Comparison between the investigated ML models indicates that the SVR model outperforms others models in predicting TWD, TCD, and TESC. Moreover, the accuracy of ANN model is better than ANFIS. The reason of this result is the certainty of data in mushroom production in the studied area.

Finally, it should be noted that, although the prediction of exergoenvironmental index and ESC can be useful to save time and costs by ML methods, it is recommended to focus on optimization methods for enhancement of input consumption efficiency and reduction of negative exergoenvironmental effects of mushroom production for future studies.