Abstract

In order to improve the adaptability of sweet cherry sorters to sweet cherries, a full-view-type grading cup for automated sweet cherry sorters was developed based on the physical characteristics of three species of sweet cherries: Tieton, Huang Mi, and Lapins. The structure and working principle of the full-view-type grading cup are described in this paper. The main factors affecting the operating stability of the grading cup were identified in this study by analyzing the mechanical properties of sweet cherries during the conveying and rotating process. According to the Box-Behnken test design method, we took the operating speed, the Young’s modulus, and the friction coefficient of the double-roller supporter as the test factors and we took the success rate as the test index. The operating parameters of the full-view-type grading cup were tested and studied, and the regression model between the test index and the test factors was established. The influence law of each factor on the test index was analyzed, and the test factors were comprehensively optimized according to the regression model. The results showed that when the operating speed was 48 sweet cherries/min; the butadiene rubber (BR) 9000, with a Young’s modulus of 0.012 GPa was selected as the material for making the double-support rollers; and the friction coefficient was designed to be 15, the success rate was 86.0%. The results of this research have provided a theoretical basis for the design and optimization of grading cups for automated sweet cherry sorters.

1. Introduction

Sweet cherries are a valuable variety of fruit for consumers because they are rich in a variety of vitamins and minerals, especially since the iron content is extremely high [1,2]. Sweet cherries ripen in high-temperature seasons. They are highly susceptible to softening, browning, decay, and deterioration after picking, due to their thin skin, soft flesh, and juicy nature. Therefore, these factors greatly limit the sales of these cherries in different places and the market supply period of sweet cherries [3,4,5,6,7]. Nowadays, sweet cherries are sorted by hand on most farms. However, as opposed to the tedious, expensive, and inefficient manual sorting process, the automated sorting device is stable, has consistent standards, and is low cost and efficient, which further improves the marketability of sweet cherries [8,9,10,11,12,13,14,15,16].

Norway’s TOMRA Company developed the TOMRA5B type and Spectrim type sorters to fulfill all the operations, including detecting the fruit’s parameters—such as fruit shape, coloring rate, and size—and identifying cosmetic defects, such as disease and insect damage in fruits and vegetables [17]. Moreover, a new fruit sorter, Inspectra2, based on near-infrared spectroscopy, can detect the internal sugar and acidity, ripeness, and other physical and chemical indicators of fruits without destructive treatment [18]. However, these complicated, giant, and expensive sorters are only suitable for large-scale production by large agribusinesses and are not suitable for small-scale cherry cultivation conditions or lower sorting quantities. Therefore, it was essential to develop a small, low-cost classification device, which meets our national conditions.

The grading cup is the key executing part of the interaction between the sorter and the fruits. At present, suitable grading cups are designed for the conveying and sorting of some fruit. As a single-unit conveyor, the grading cup is not only used to convey fruit smoothly but also to display as much information about the quality of the fruit as possible for the external information collection device. Therefore, it is necessary to design grading cups with superior performance. Ying et al. developed a twin-cone-roller grading cup with chains, which can simultaneously complete the automatic single-row conveying and the uniform rotating of aligned spherical fruit. However, the twin-cone-roller grading cups cannot restrain the fruits properly, which allows the fruit to fall easily [19]. Zhang et al. designed different grading cups with chains, which can be applied to different sizes of fruit. However, the operation stability of these grading cups was poor, as the fruit could easily shake and fall, which would eventually lead to lower transportation efficiency [20,21]. There was a free-pallet-fruit grading cup, which was developed by Zhai et al. to reduce the injury rate of delicate fruit; however, the volume of this grading cup is too large to be turned over, and so the sorting efficiency is low [22]. Chang et al. studied and developed a multi-functional pallet grading cup with a chain to perform the fruit conveying, weighing, and the internal non-destructive detection of the automated sorting device [23]. However, there were also some shortcomings such as its complex structure and high manufacturing costs.

The present study focused on developing a full-view-type grading cup for an automated sweet cherry sorter to perform the following functions: the fruit conveying; weighing; rotating for image detection; and turning over, with reference to the free pallet and the cups with chains. The device has a unique structure and rotating method, which can provide theoretical and technical references for the R&D of similar devices for sweet cherry sorting. The partial performance of the machine’s sorting was tested through a rotating experiment.

2. Materials and Methods

2.1. Physical Characteristic Test

The geometric sizes and mass of three species of sweet cherries were studied to design a full-view-type grading cup. The test was conducted in May 2022, in the laboratory at Shandong Agricultural University, Tai’an City, Shandong Province, China.

2.1.1. Test Conditions and Methods

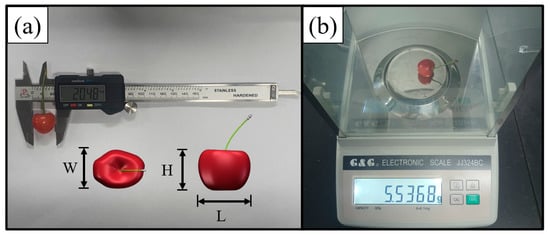

The design of the full-view-type grading cup was affected by the basic size and weight of the sweet cherries. Three species of sweet cherries commonly found in the market (Figure 1) were included, with thirty sweet cherries randomly selected from each species to study. The vertical diameter, H; transverse diameter, L; and width of maximum transverse diameter, W, of sweet cherries were measured with a stainless steel vernier caliper (Jinmai, Shanghai, China). H, L, and W are shown in Figure 2a. The mass, m, of sweet cherries was measured with electronic balance JJ324BC (Shuangjie, Changzhou, China) (Figure 2b).

Figure 1.

Three species of sweet cherries: (a) Tieton; (b) Huang Mi and (c) Lapins.

Figure 2.

The geometric parameters of a sweet cherry: (a) size of sweet cherry and (b) mass of sweet cherry.

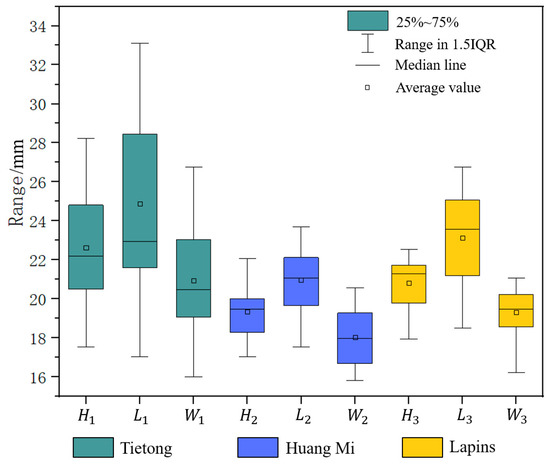

2.1.2. Results Analysis of the Geometric Sizes and Masses

The test results classified by the transverse diameter, L, are shown in Table 1. The original data of geometrical sizes and masses of sweet cherries are shown in Table 1. It was recorded in Figure 3 that the vertical diameter, H, was 17.03–28.22 mm; the transverse diameter, L, was 17.05–33.1 mm; the width of maximum transverse diameter, W, was 15.99–26.75 mm; and the mass, m, was 2.80–13.52 g. The minimum size of the designed full-view-type grading cup was greater than 34 mm.

Table 1.

The size and masses of tested sweet cherries.

Figure 3.

Size of tested sweet cherries.

2.2. Mechanical Structure Design

2.2.1. Structure Overview

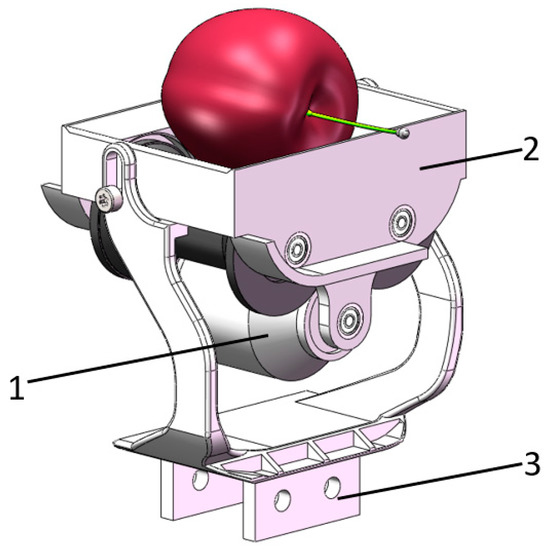

A full-view-type grading cup with chain transportation was developed to meet the needs of image recognition. The functional model of the full-view-type grading cup, using the SolidWorks 2016 SP1.0 (Dassault Systemes S.A, Waltham, MA, USA), is shown in Figure 4. It was designed to involve the following major components: a rotating roller mechanism, a multi-functional frame, and a base plate.

Figure 4.

Functional model of the full-view-type grading cup: 1—rotating roller mechanism; 2—multi-functional frame; and 3—base plate.

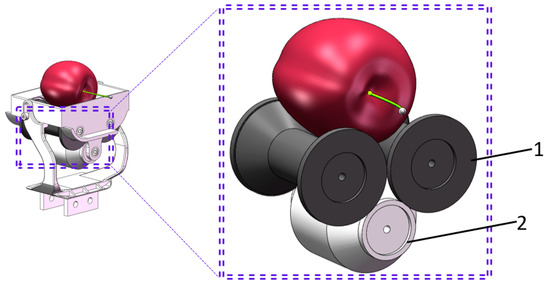

2.2.2. Design of Rotating Roller Mechanism

A key component of the rotating roller mechanism was composed of a double-roller supporter and a driven roller. The double-roller supporter and the driven roller were installed on the micro-gap guardrail through the shafts, as illustrated in Figure 5. The tapered ends and cylindrical midsection of the double-roller supporter were intended as friction surfaces. These unique structures not only improved the adhesion of the grading cups to the sweet cherry, but also cause the sweet cherries to rotate at the appropriate time.

Figure 5.

Structure of rotating roller mechanism: 1—double-roller supporter and 2—driven roller.

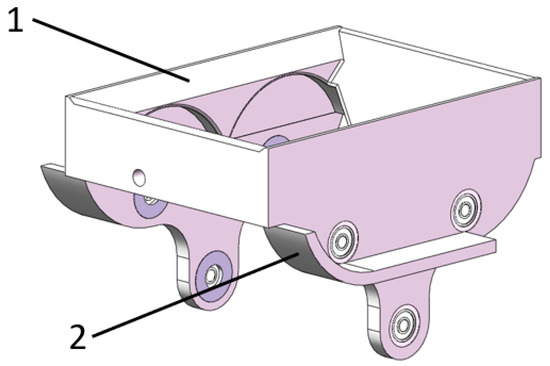

2.2.3. Design of Multi-functional Frame

The multi-functional frame, as shown in Figure 6, was designed with a weigh-in-motion plate and a micro-gap guardrail. As the primary body of the multi-functional frame, the micro-gap guardrail not only supported the rotating roller mechanism, but also kept the sweet cherries from falling. As shown in Figure 6, symmetric weigh-in-motion plates were constructed on both sides of the micro-gap guardrail. With such a simple and compact structure, the weighing operation could be accomplished during the conveying process, significantly improving efficiency.

Figure 6.

Structure of multi-functional frame: 1—micro-gap guardrail and 2—weigh-in-motion plate.

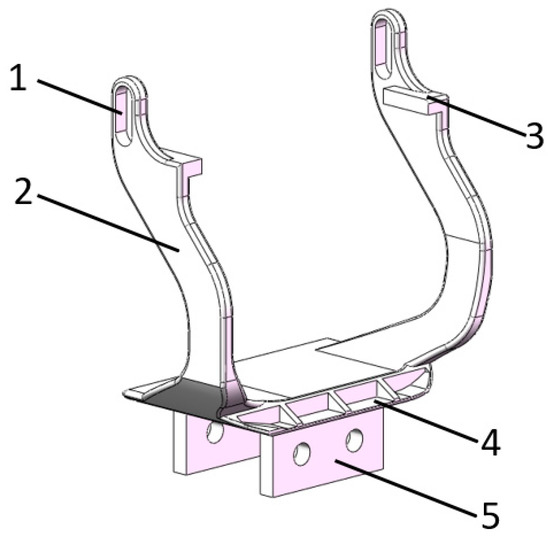

2.2.4. Design of Base Plate

The base plate is a crucial component, since it not only supports the multi-functional frame but also links with the chain to give traction to the grading cup. The base plate was designed with a chain connection, balanced shoulders, S-shaped brackets, balanced supports, and notches, as shown in Figure 7. The chain created traction for the grading cups by using chain connections. The grading cups moved consistently, without tilting, thanks to balanced shoulders that were designed to be securely integrated with the slide chain groove. The base plate was designed with S-shaped brackets. The S-shaped brackets’ unique construction not only met the demands of support but also allowed for the frictional rolling of the driven roller. On the S-shaped bracket there were two pairs of balanced supports and notches. The multi-functional frame, with the assistance of balanced supports and notches, not only maintained balance, but also moved up and down in the notches to meet the demand of weigh-in-motion.

Figure 7.

Structure of base plate: 1—notches; 2—S-shaped brackets; 3—balanced shoulders; 4–balanced supporters; and 5—chain connector.

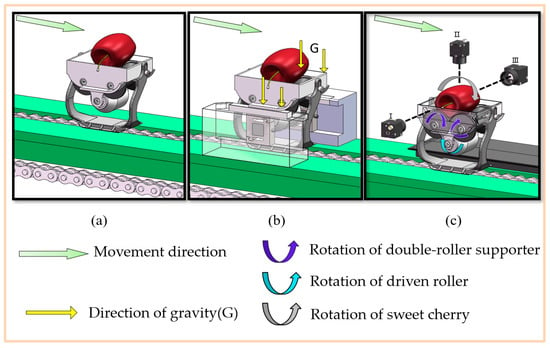

2.3. Operation Programs and Motion Planning

2.3.1. Operation Principle

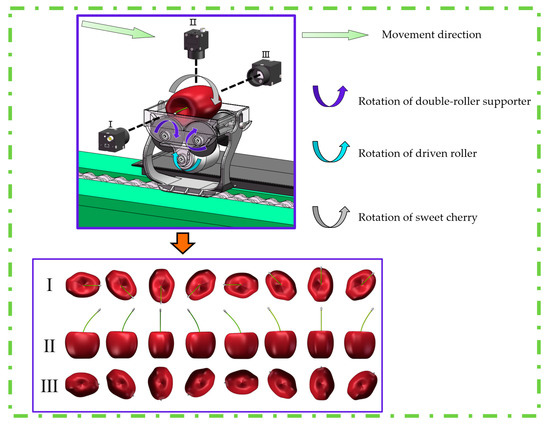

The full-view-type grading cup was designed to make it easier for the equipment to gather image data of sweet cherries, improving sorting efficiency. To convey and test the sweet cherries in groups, a row of full-view grading cups were mounted on the chain. As shown in Figure 8, one sweet cherry was conveyed per full-view-type grading cup to avoid mutual interference among the sweet cherries (Figure 8a). Each grading cup conveyed one sweet cherry for motion weighing (Figure 8b). Each grading cup conveyed one sweet cherry for capturing its full-view images (Figure 8c).

Figure 8.

Operation principle for the full-view-type grading cup: (a) convey sweet cherry; (b) motion weighing; and (c) capture images.

Driven by the chain, the full-view-type grading cups with sweet cherries moved forward in turn (Figure 8a). The operation process, in detail, was as follows:

S1: The full-view-type grading cups loaded with the sweet cherries moved to the weighing frame (Figure 8b). With the help of a weigh-in-motion plate, the multi-functional frame and the sweet cherry were lifted by the weighing frame.

S2: with the help of a weigh-in-motion plate, the gravity of the multi-functional frame and the sweet cherry were applied to the pressure sensors, which were installed on the weighing frame.

S3: the pressure sensors sent data to other equipment to obtain the mass of the sweet cherry.

S4: driven by the chain, the full-view-type grading cups loaded with the sweet cherries moved to the place where their images were captured (Figure 8c).

S5: the double-roller supporter and driven roller are dependent on friction to rotate.

S6: when friction occurred between driven roller and external friction platform (Figure 9d), the driven roller started to rotate, which drove the double-roller supporter to rotate, with the help of friction.

Figure 9.

Operation principle for rotating: I—images captured by left camera; II—images captured by above camera; III—images captured by right camera.

S7: When the sweet cherry rotated under the power of a double-roller supporter, a group of images was captured by the camera (Figure 9). The equipment waited for the next sweet cherry to capture further data.

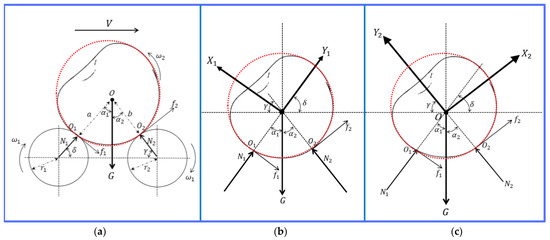

2.3.2. Calculation and Analysis of the Mechanical Model

In this study, a force analysis of the rotating sweet cherry was conducted to identify the corresponding influencing factors. The rightward conveying of the grading cups was taken as an example. Considering the diversity of sweet cherry shapes, the cross-section of sweet cherries was assumed to be circular-like in this study, as shown in Figure 10.

Figure 10.

The force analysis of sweet cherry and double-roller supporter: (a) location diagram; (b) force diagram of ; and (c) force diagram of .

According to the force analysis of the sweet cherries and double-roller supporter shown in Figure 10, , and , are the supporting force and frictional force on the sweet cherry, respectively; is the gravity of the sweet cherry; is the overall conveying speed of the grading cup; is the direction of rotation of the double-roller supporter; is the direction of rotation of the sweet cherry; is the barycenter of the sweet cherry; is the contact point between the sweet cherry and the front-supporting roller; is the contact point between the sweet cherry and the rear-supporting roller; is the horizontal angle of the supporting force ; is the horizontal angle of the supporting force ; is the angle between gravity, , and the normal direction of ; is the angle between gravity, , and the normal direction of ; is the distance between and ; and is the distance between and .

According to the geometric relationships shown in Figure 10, Equations (1)–(4) can be derived as follows:

where , and , are the supporting force and frictional force on the sweet cherry, respectively; and is the friction coefficient between sweet cherry and supporting roller.

During the rotation of the sweet cherry, the sum of the torques of the external forces acting on the sweet cherry at , without considering the effect of centrifugal forces, can be obtained by Equations (1)–(4).

According to Equations (1) and (2), the equations of can be obtained by the above equation.

One of the conditions under which the sweet cherry can keep rotating in this particular position without going over the friction roller is that the sum of the torques at is less than or equal to zero. According to Equations (1)–(4), this can be derived as follows:

The other condition under which the sweet cherry can keep rotating in this particular position without going over the friction roller, is that the combined force in the direction of the tangent to and are both less than or equal to zero, as defined in Equations (8) and (9), as follows:

According to Equations (1)–(4), this can be derived as follows:

From Equations (7) and (9), it can be seen that the sum of the torques at and the combined force in the tangential direction of were mainly related to the friction coefficient, μ, and to the angles δ and γ during the sweet cherries’ rotation. However, the dynamic friction coefficient, μ, was mainly related to the material of the double-roller supporter, and the pinch angles δ and γ were mainly influenced by the size of the sweet cherry itself. Thus, the dynamic friction coefficient was relatively fixed, but the pinch angle was changing all the time.

Through the force analysis of sweet cherries and double-roller supporter, it was found that the friction coefficient affected the success rate of full-view-type grading cups’ operation. Furthermore, the size of Young’s modulus determined the ease of the double- support roller deformation under small loads. Selecting a material with the right Young’s modulus size could play a cushioning role in achieving the effect of stable support and reducing the fall rate [24]. Therefore, based on ADAMS kinematic simulation, the Box-Behnken experimental design method was used to investigate the effects of conveying speed, friction coefficient, and the material of double-roller supporter on the sweet cherries’ conveyance and rotation success rate.

2.4. Design and Analysis of Simulation Experiment

Design of Simulation Experiment

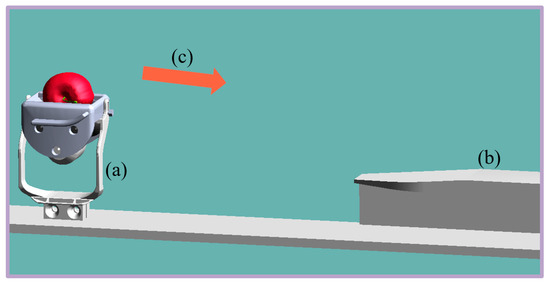

The 3D model of the sweet cherry sorting platform and conveying device was built into SolidWorks 2016 SP1.0 (Dassault Systemes S.A, Waltham, MA, USA) and imported into ADAMS simulation software for kinematic simulation. Firstly, the material properties of each component in the model were defined, the drive and constraints of the model were added, and then the motion parameters were set for the sweet cherry model, and marker points were established at the mass points of the sweet cherry model to obtain the motion trajectory of the marker points during the sweet cherry conveying process.

To simplify the simulation model, sweet cherries in a conventional environment were taken as the simulation objects in this study. The physical properties of sweet cherries after cleaning or pre-cooling were not considered. The conveying and rotating simulation test is shown in Figure 11.

Figure 11.

Simulation model diagram of ADAMS: (a) grading cup and sweet cherry; (b) external friction platform; (c) movement direction.

The success rate of sweet cherries’ conveyance and rotation was used to evaluate the performance of the full-view-type grading cup. “Success” indicated that the sweet cherries were conveyed in the chain grading cups without falling and that they were rotated at proper place, during the sorting process. There were two “failed attempts” in the process of conveying and rotating sweet cherries, i.e., defined as the rate of sweet cherries falling,, and rate of the non-rotation of the sweet cherries, . The total success rate, W, was defined as follows: where was the total number of sweet cherries for conveying and rotating, and , were the number of sweet cherries that fell, and the rotation failure of the sweet cherries, respectively.

According to the results of force analysis of sweet cherry and double-roller supporter, the operating speed, X1; Young’s modulus, X2; and friction coefficient, X3, were selected as the test factors. The success rate of full-view-type grading cup operation was used as the evaluation index. The Box-Behnken composite test design method was adopted. The value range of each factor and the factors and levels in the test are shown in Table 2. The experimental scheme and results of Box-Behnken are shown in Table 3.

Table 2.

Test factors’ level and coding.

Table 3.

Test design scheme and response value.

3. Results and Discussion

3.1. Test Analysis Results

The experimental data in Table 3 were analyzed by polynomial regression, using the statistical analysis software Design Expert 12.0.3. The regression equation for the success rate of the full-view-type grading cup operation was obtained as follows:

The significance tests and ANOVA were performed on the mathematical model and the results are shown in Table 4. The analysis of the significance of the influence showed that, within the range of the selected factors, the order of influence on the success rate of the operation, from high to low, was as follows: X3 (friction coefficient); > X1 (operating speed); and > X2 (Young’s modulus). The data shows that the regression model is significant (p < 0.05), indicating that the model established is meaningful. The lack of fit was not significant (p = 0.4262 > 0.05) and the R2 of the regression coefficient of determination was 0.9740, indicating that the gap between the actual measurements and the mathematical model was small, i.e., that the model fitted the data well, the regression model was significant, the test error was small, and it could better describe the experimental results; therefore, the regression equation was established correctly [25,26].

Table 4.

Significance test for variance analysis and coefficient constants of regression models.

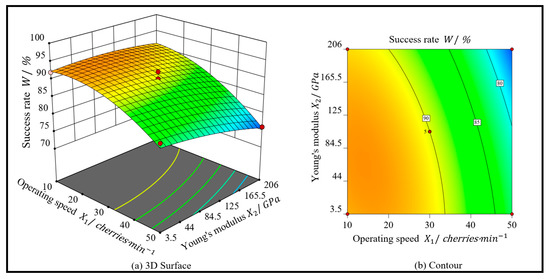

3.2. Response Surface Analysis of Various Factors

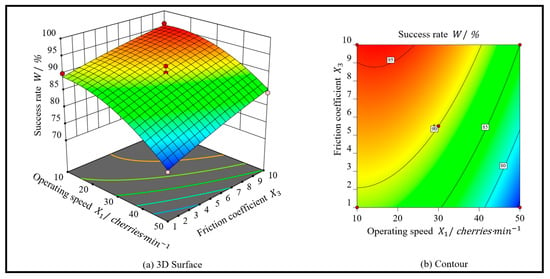

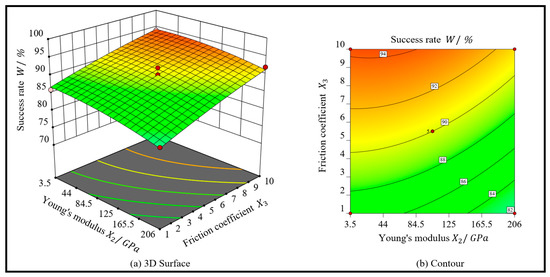

The response surface of the success rate of the full-view-type grading cups’ operation was plotted with Design-Expert 12.0.3. The effect of various factors on the success rate of the full-view-type grading cups’ operation can be seen through this and the relationship between the various variables can be determined and tested. In this case, the operating speed, Young’s modulus, and the friction coefficient were fixed at the middle level, and the influence of the other two factors and their interaction with the success rate of the full-view-type grading cups’ operation were analyzed. The interaction results are shown in Figure 12, Figure 13 and Figure 14.

Figure 12.

Effects of operating speed and Young’s modulus on success rate of sweet cherries.

Figure 13.

Effects of operating speed and friction coefficient on success rate of sweet cherries.

Figure 14.

Effects of Young’s modulus and friction coefficient on success rate of sweet cherries.

Figure 12 shows the interactive influence of the operation speed and the Young’s modulus on the success rate of the full-view-type grading cups’ operation. When the operation speed was controlled at 34 sweet cherries/min and Young’s modulus was 105, the success rate showed a high level. With the decrease in the conveying speed, the initial velocity of the sweet cherries on the grading cups became smaller, the stress between the sweet cherries and the grading cups became smaller, and the success rate became higher. The smaller the Young’s modulus was, the better the damping effect on the sweet cherry was during the conveying process, which resulted in a higher success rate. From the response surface shape and its contour density, it can be seen that the interactive influence of the operation speed and the Young’s modulus had a significant effect on the success rate, and the operation speed had a greater effect on the cherries’ damage rate than Young’s modulus, which was the same as the ANOVA results.

Figure 13 shows the interactive influence of the operation speed and the friction coefficient on the success rate of the full-view-type grading cups’ operation. When the conveying speed was at a low level, the success rate increased with the increase in the friction coefficient, and when the friction coefficient increased to nine, the success rate was greater than 95%. As the friction coefficient between the double support rollers and the sweet cherry increased, the number of sweet cherries operating with sliding friction during the process of the sweet cherry rotation decreased, and the success rate of the full-view-type grading cups’ operation was higher. It can be seen from the contour map that the effect of the friction coefficient on the success rate of the full-view-type grading cups’ operation was more significant than that of the operation speed.

Figure 14 shows the interactive influence of the Young’s modulus and the friction coefficient on the success rate of the full-view-type grading cups’ operation. It can be seen from the contour map, that as Young’s modulus increased, the success rate gradually decreased, and with the increase in the friction coefficient, the success rate increased rapidly. The two factors differed in the weight of their interactive influence on the success rate of the full-view-type grading cups’ operation, and the friction coefficient was more significant than that of the Young’s modulus, which was the same as the ANOVA results.

3.3. Performance Test

According to the analysis of the measured data, it can be seen that the operation speed, the Young’s modulus, and the friction coefficient had a definite effect on the success rate of the full-view-type grading cups’ operation. In order to minimize the failure rate of the grading cups and to improve the operational performance of the sorting device, the regression equation model of the influencing factors and performance indexes was optimally solved by using the optimization function of the Design-Expert 12.0.3 Trial software, and the optimal parameter values were calculated, as follows: the operation speed was 48.388 sweet cherries/min, Young’s modulus was 0.019, and the friction coefficient was 15.0. The success rate was 91.313% under these parameter conditions. Based on the optimization results of the factors, a validation test was conducted on the optimal combination of the operating factors, to test the reliability of the regression model and the optimal combination. To facilitate the practical application, the optimized factors were adjusted appropriately, and the operation speed was set to 48 sweet cherries/min. The butadiene rubber (BR) 9000, with a Young’s modulus of 0.012 GPa was selected as the material for making the double support rollers (GB/T 8659-2018), and the friction coefficient was designed to be 15. A prototype of the full-view grading cup for sorting sweet cherries in groups was built to test its conveying and rotation performance. As shown in Figure 15, the test was conducted in July 2022, in the laboratory at Shandong Agricultural University, Tai’an City, Shandong Province, China. The results are shown in Table 5.

Figure 15.

Performance test for the full-view-type grading cups.

Table 5.

Comparison of optimization results with actual values.

The test results showed that the optimized full-view grading cup operation had a success rate of 86.0%, which indicates that the test results obtained by optimizing the parameters of the device were basically consistent with the actual values analyzed by the response surface. The optimal results will serve as a reference for realistic design work. Our observations and analysis of the actual experimental process revealed the effect of external factors on the stability of the operation, which resulted in a 5.313% reduction in the success rate. A simulation is the analysis of specific factors under ideal conditions, whereas, there are various uncertainties in real situations—such as the vibration of the drive motor, the test table not being fixed in place, and other factors—will have an impact on the actions of the sweet cherries in the device’s operation, as they can cause the rate of falling to increase and the success rate to decrease. In addition, we found that the sweet cherries changed their pose during the rotation process due to various external factors, which resulted in branches affecting the rotation and led to a decrease in the success rate. Due to the limited length of this study, we will investigate the external factors in the next work.

4. Conclusions

(1) The physical characteristics of three common sweet cherries in the market—Tieton, Huangmei, and Lapins—were tested. The vertical diameter, H, was 17.03–28.22 mm; the transverse diameter, L, was 17.05–33.1 mm; the width of the maximum transverse diameter, W, was 15.99–26.75 mm; and the mass, m, was 2.80–13.52 g. Based on the physical characteristics tested, the minimum size of the designed full-view-type grading cup was greater than 34mm. With the help of SolidWorks, the full-view-type grading cup was designed with a rotating roller mechanism, a multi-functional frame, and a base plate for rotating, weighing, and conveying sweet cherries.

(2) Through our analysis of the mechanical properties of sweet cherries in the process of conveying and rotating, the main factors that were seen to affect the operating stability of the grading cups were determined as follows: the operating speed, Young’s modulus, and the friction coefficient of the double-roller supporter. To establish a success rate for the operational model of the full-view-type grading cup, a mathematical model was developed, Using a single-factor and Box-Behnken central composite test. Experimentally, we found that there were optimal values for the technical parameters of the full-view-type grading cup. The structural parameters of the full-view-type grading cup had a significant effect on the success rate of its operation. Under the following conditions: when the conveyer operating speed was 48 sweet cherries/min; when the butadiene rubber (BR) 9000, with a Young’s modulus of 0.012 GPa was selected as the material for making the double support rollers; and when the friction coefficient was 15.0, the success rate was 86.0%.

(3) The full-view-type grading cup designed in this paper could be used to convey and rotate sweet cherries of different sizes and masses, at a low cost. Although the effects of the structural parameters on the operating stability of the grading cups have been completed, the effects of the external factors on the operating stability have not been studied, which, in this study, led to a 5.313% decrease in the success rate. We will carry out further related studies in our next work.

Author Contributions

Methodology, L.R.; software, Y.L.; validation, Y.G.; investigation, Z.S. and B.L.; writing—review and editing, X.H.; writing—review and editing, supervision, and funding acquisition, Y.S. All authors have read and agreed to the published version of the manuscript.

Funding

The study was supported by Innovation Team Fund for the Fruit Industry of Modern Agricultural Technology System in Shandong Province (SDAIT-06-12, SDAIT-06-11), and Shandong Agricultural University’s double first-class award and subsidy funds (SYL2017XTTD07).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare that there is no conflict of interest regarding the publication of this study.

References

- Timm, E.; Guyer, D.; Brown, G.; Schulte, N. Michigan sweet cherry color measurement and prototype color chip development. Appl. Eng. Agric. 1995, 11, 403–407. [Google Scholar] [CrossRef]

- Díaz-Mula, H.M.; Castillo, S.; Martínez-Romero, D.; Valero, D.; Zapata, P.J.; Guillén, F.; Serrano, M. Sensory, nutritive and functional properties of sweet cherry as affected by cultivar and ripening stage. Food Sci. Technol. Int. 2009, 15, 535–543. [Google Scholar] [CrossRef]

- Kirakosyan, A.; Seymour, E.M.; Noon, K.R.; Llanes, D.E.U.; Kaufman, P.B.; Warber, S.L.; Bolling, S.F. Interactions of antioxidants isolated from tart cherry (Prunus cerasus) fruits. Food Chem. 2010, 122, 78–83. [Google Scholar] [CrossRef]

- Esti, M.; Cinquanta, L.; Sinesio, F.; Moneta, E.; Di Matteo, M. Physicochemical and sensory fruit characteristics of two sweet cherry cultivars after cool storage. Food Chem. 2002, 76, 399–405. [Google Scholar] [CrossRef]

- Junfeng, S.; Menglin, X.; Chunsheng, W.; Jianhua, L. Research status and development of post-harvest physiology characteristics and storage techniques of sweet cherry. Storage Process 2009, 9, 7–10. [Google Scholar]

- Li, Z.; Jiang, X.; Shuai, L.; Zhang, B.; Yang, Y.; Mu, J. A Real-Time Detection Algorithm for Sweet Cherry Fruit Maturity Based on YOLOX in the Natural Environment. Agronomy 2022, 12, 2482. [Google Scholar] [CrossRef]

- Matteo, M.; Zoffoli, J.P.; Ayala, M. Calcium Sprays and Crop Load Reduction Increase Fruit Quality and Postharvest Storage in Sweet Cherry (Prunus avium L.). Agronomy 2022, 12, 829. [Google Scholar] [CrossRef]

- Momeny, M.; Jahanbakhshi, A.; Jafarnezhad, K.; Zhang, Y.-D. Accurate classification of cherry fruit using deep CNN based on hybrid pooling approach. Postharvest Biol. Technol. 2020, 166, 111204. [Google Scholar] [CrossRef]

- Rosenberger, C.; Emile, B.; Laurent, H. Calibration and quality control of cherries by artificial vision. J. Electron. Imaging 2004, 13, 539–546. [Google Scholar] [CrossRef]

- Villacrés, J.F.; Auat Cheein, F. Detection and characterization of cherries: A deep learning usability case study in Chile. Agronomy 2020, 10, 835. [Google Scholar] [CrossRef]

- Zhang, Y.; Yin, X.; Xu, T.; Zhao, J. On-line sorting maturity of cherry tomato bymachine vision. In International Conference on Computer and Computing Technologies in Agriculture; Springer: Berlin/Heidelberg, Germany, 2008; pp. 2223–2229. [Google Scholar]

- Pei, Y.; Ye, J.; Jiang, Y.; Lian, M.; Han, X.; Yu, G. Research on cherry shape detection technology based on machine vision. In Proceedings of the 2019 IEEE International Conference on Signal, Information and Data Processing (ICSIDP), Chongqing, China, 11–13 December 2019; pp. 1–5. [Google Scholar]

- Wang, Q.; Wang, H.; Xie, L.; Zhang, Q. Outdoor color rating of sweet cherries using computer vision. Comput. Electron. Agric. 2012, 87, 113–120. [Google Scholar] [CrossRef]

- Kunrui, X.; Xi, L.; Qiaohua, W.; Meihu, M. Online automatic grading of salted eggs based on machine vision. Int. J. Agric. Biol. Eng. 2015, 8, 35–41. [Google Scholar]

- Zhang, H.; Shen, L.; Lan, H.; Li, Y.; Liu, Y.; Tang, Y.; Li, W. Mechanical properties and finite element analysis of walnut under different cracking parts. Int. J. Agric. Biol. Eng. 2018, 11, 81–88. [Google Scholar] [CrossRef]

- Chaschatzis, C.; Karaiskou, C.; Mouratidis, E.G.; Karagiannis, E.; Sarigiannidis, P.G. Detection and Characterization of Stressed Sweet Cherry Tissues Using Machine Learning. Drones 2022, 6, 3. [Google Scholar] [CrossRef]

- Chong, G. Research on Apple Quality Detection Method and Device Based on Hyperspectral Imaging and Deep Learning. Master Dissertation, Shandong Agriculture University, Taian, China, 2021. [Google Scholar]

- TOMRA Systems ASA. Compac’s Inspectra2 NIR Platform. Available online: https://www.tomra.com/en/solutions/food/fruit (accessed on 12 July 2022).

- Xu, H.; Ying, Y.; Ling, G. Research on Fruit Feeding and Rolling Installation with Bicone Rollers. Trans. Chin. Soc. Agric. Mach. 2003, 34, 100–103. [Google Scholar]

- Zhang, Y. Design and Experimental Validation of Fruit Quality Hyperspectral Online Sorting Equipment—Gannan Navel Oranges as an Example. Master’s Thesis, Jiangxi Agricultural University, Nanchang, China, 2021. [Google Scholar]

- Ge, J. Design and Implementation of Fruit Sorting Machine Mechanical Systems and Weighing Module. Master’s Thesis, Northwest A&F University, Xianyang, China, 2012. [Google Scholar]

- Zhai, B. Grading Actuator Simulation and Optimization Analysis for Free Pallet Conveying Fruit. Master’s Thesis, Zhejiang University, Hangzhou, China, 2021. [Google Scholar]

- Han, C. Research and Development of On-Line Non-Destructive Detecting Method and Grading Equipment of Apple Watercore and Soluble Solids Content. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2021. [Google Scholar]

- Xu, C. Study on Nonlinear Mechanical Model and Damping Characteristics of Steel Spring Damping Rubber Pad for Railway Vehicles. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2020. [Google Scholar]

- Qian, Y.; Liu, K. Optimization of soil Cd extraction process using the response surface methodology. Chin. J. Environ. Eng. 2018, 12, 3448–3455. [Google Scholar]

- Yu, Z.; Huai, S.; Wang, W. Leakage rate and optimization of working parameters for cylinder pickup collector based on spring-finger trajectory. Trans. Chin. Soc. Agric. Eng. 2018, 34, 37–43. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).